Drone-mounted Remote

Methane Leak Detector

User’s Manual

www.hesaitech.com

100-en-1901B2

HESAI WeChat

Notice

Please read this manual carefully before using the equipment.

CAUTION

To avoid violating the warranty and to minimize the chances of getting electrically shocked, please do not disassemble the device on your

own accord. The device must not be tampered with and must not be changed in any way. There are no user-serviceable parts inside the

device. For repairs and maintenance inquiries, please contact an authorized Hesai Technologies service personnel.

DISCLAIMER

The information contained within this user’s manual and the functions offered is intended to provide information about products. All

reasonable efforts have been made to ensure the accuracy of the information. However, Hesai cannot be held responsible for any errors.

Hesai does not warrant the accuracy and reserves the right to make changes to the catalog and its functions at any time without notice.

Table of Contents

1

2

3

4

5

Safety Notice

Introduction

Specifications

Installation Guide

4.1 Installation Notice

4.2 Mechanical Installation

4.3 Interface Introduction

UART Serial Port Data and

Parameter Configuration

5.1 UART Serial Port Data Output

01

02

03

04

05

06

07-08

Appendix I

Warranty and Maintenance

Appendix II

EC-Declaration of Conformity

Appendix III

FCC Statement

10

11

12

5.2

Parameter Configuration

09

Safety Notice1

Prior to using this product, please read the safety notices carefully to ensure the safety and to avoid any improper usage.

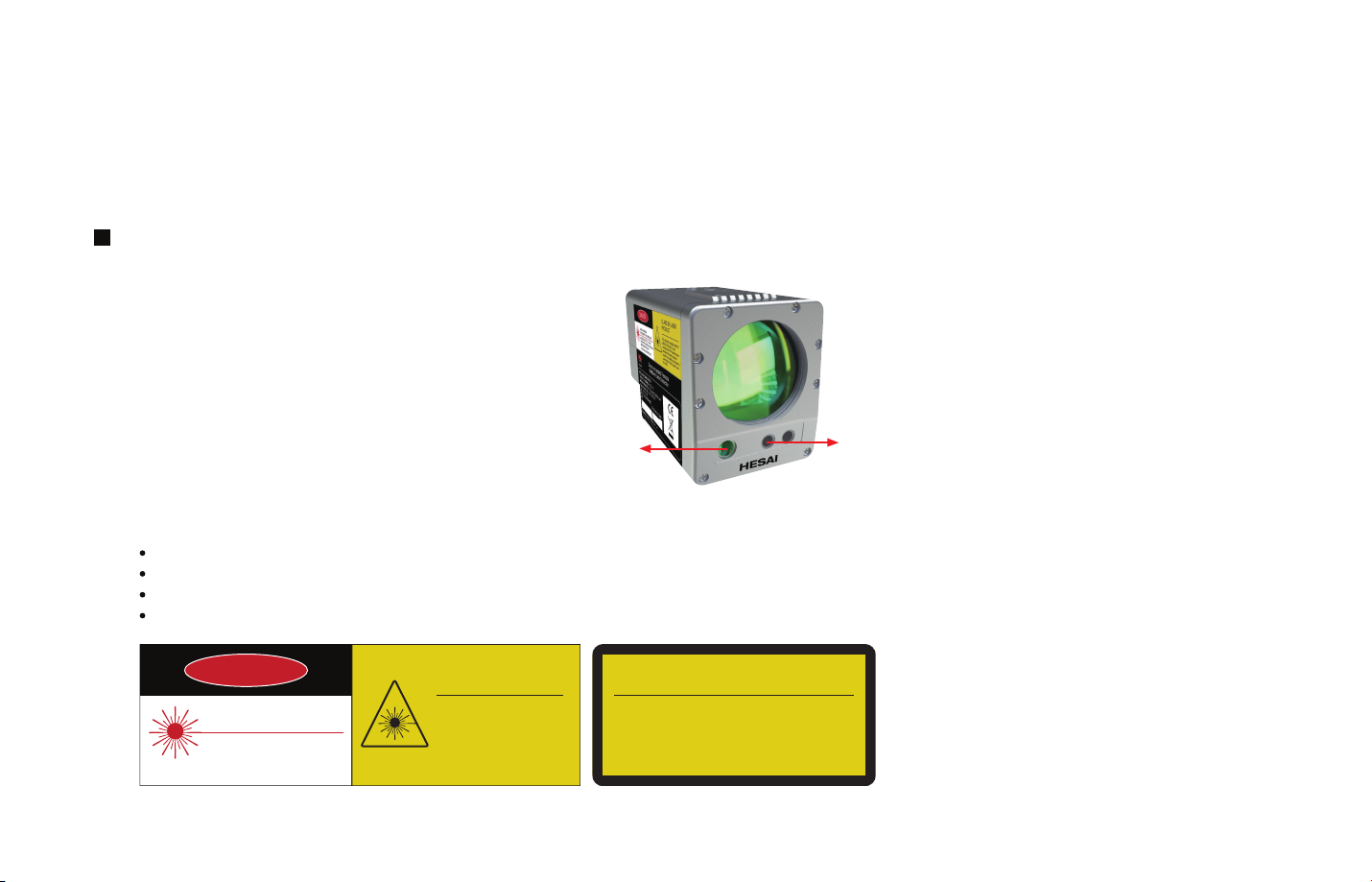

Laser Safety Notice – Laser Class 3R

Infrared Measurement Laser: Class 1 Eye Safe,

wavelength: 1651 nm, <10 mW

Green Indication Laser: Class 3R,

wavelength: 520 nm, <5 mW

Avoid Direct Eye Exposure

Infrared measurement

laser aperture

The device satisfies the requirements of:

IEC 60825-1:2014;

IEC 60825-1:2007;

21 CFR 1040.10 and 1040.11 except for deviations pursuant to Laser Notice No.50, dated June 24, 2007;

GB7247.1-2012.

Green indication

laser aperture

-01-

DANGER

LASER RADIATIONAVOID DIRECT EYE EXPOSURE

MAXIMUM OUTPUT: <5 mW

OPERATION: CW (100 ms/200 ms)

WAVELENGTH: 520 nm

CLASS IIIa LASER PRODUCT

CLASS 3R LASER

PRODUCT

(This product complies with IEC

60825-1:2014 Ed 3.0 and

complies with FDA performance

standards for laser products

except for deviations pursuant to

Laser Notice No.50, dated June

24, 2007.)

AVOID DIRECT EYE EXPOSURE

VISIBLE AND INVISIBLE LASER RADIATION

CLASS 3R LASER PRODUCT

MAXIMUM OUTPUT: <5 mW

OPERATION: CW (100 ms/200 ms)

WAVELENGTH: 520 nm

IEC 60825-1:2014 IEC 60825-1:2007

Introduction2

Hesai Drone-mounted Remote Methane Leak Detector is an ultralight and highly sensitive module that utilizes an infrared laser to remotely

detect methane leaks. It can be mounted on the drones, vehicles, and ships for applications such as pipeline survey, residential area

detection, etc.

The detector measures the methane concentration by emitting an infrared laser and receiving the laser reflection.

The reading is expressed by a methane column density (ppm*m). It is the integral of the methane concentration (ppm) and the distance (m)

on the optical path.

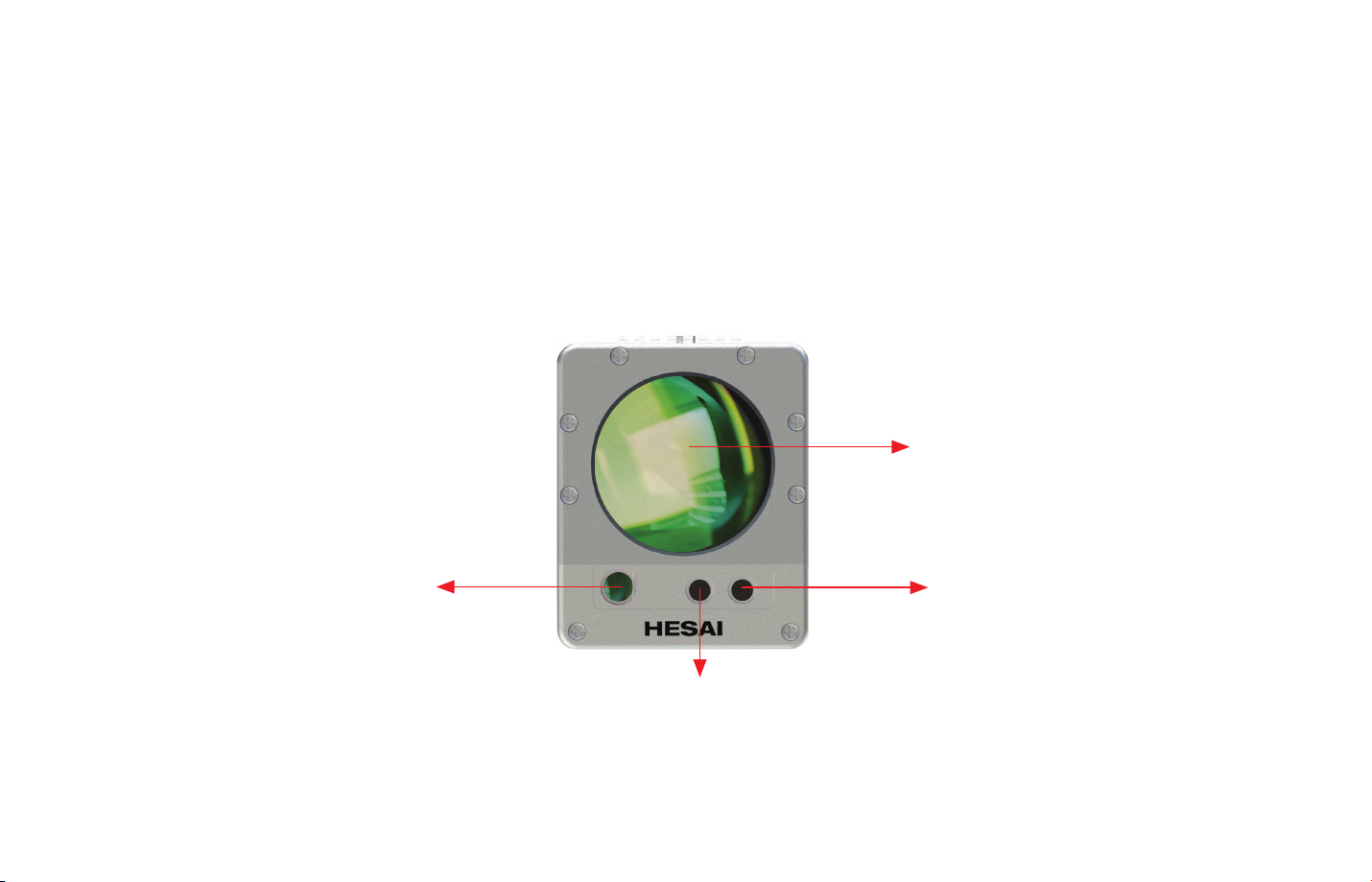

Receiving Lens

Infrared Measurement

Laser Emitter

Working Light (Blue)

Indication Laser (Green)

Figure 1. Light Instructions

-02-

3 Specifications

Target Gas

Working Principle

Sensitivity

Detection Range (CH4)

Measurement Accuracy

Response Time

Detection Distance

Weight

Size

* Specifications are subject to change without notice

Methane(CH4)and methane-containing gases

Tunable Diode Laser Absorption Spectroscopy

(TDLAS)

5 (Actual) ppm*m

0 ~ 99999 ppm*m

±10% (100~50000 ppm*m)

0.1 s (configurable)

5 m~50 m (Actual distance may vary due to

background type and conditions)

< 600 g

Operating Voltage

Rated Current

Data Output

Laser Classes

Operating Temperature

Operating Humidity

Enclosure Level

Beam Size Divergence angle: 2 mrad(4 cm at 20 m)70 mm*87 mm*120 mm

Table 1. Main Specifications

DC 7~12 V

<1 A

0.3 A (typical value) under 8 V power supply

Methane concentration, light intensity,

temperature, etc.

Infrared Laser: Class I Eye Safe

Wavelength: 1651 nm, <10 mW

Green Indication Laser: Class 3R, Avoid direct

eye exposure

Wavelength: 520 nm, <5 mW

-20℃~+50℃

< 80%RH, Non-condensing

IP54

-03-

Installation Guide4

4.1 Installation Notice

Prior to installing the detector, please read the notes carefully to ensure safe and appropriate usage:

Supply the detector as required (DC 7~12 V).

1)

Provide good heat dissipation to the laser.

2)

Pay attention to static electricity. Please release the body static electricity or wear antistatic bracelet before the installation.

3)

Do not weld/replace any component unless it is recognized by Hesai.

4)

Do not unplug the laser fiber. Do not bend the fiber even at a small angle.

5)

Do not attempt to remove any circuit boards unless it is recognized by Hesai.

6)

Do not use the PCB of detector A on detector B.

7)

Do not disassemble or repair the device on your own accord. For repairs and maintenance inquiries, please contact an authorized Hesai

8)

Technologies service personnel.

It is recommended that the length of the external cable should not exceed 3m.

9)

-04-

4.2 Mechanical Installation

There are two mechanical mounting holes on the top of the detector for the horizontal installation, and four mechanical mounting holes at the

back of the detector for the vertical installation. The mechanical drawing of the detector is shown below.

2 mm×M3 4

60.00 mm

4 mm×M4 5

52.50 mm

28.00 mm

-05-

Figure 2. Detector Mechanical Drawing

Interface Introduction4.3

The interfaces are at the back of the detector. Descriptions of the interfaces are shown below.

2

3

Type A 4-conductor plug Type A 4-conductor socket

1

1

4

Figure 3. Detector Interfaces

Interface Description

1 Positive power supply, DC 7-12V, Rated Current <1A

2 Negative power supply, GND

3 Data output, TX

4 Data input, RX

Table 2. Detector Interfaces

2

3

4

-06-

5

UART Serial Port Data and Parameter Configuration

UART Serial Port Data Output5.1

Serial Port Configuration

Baud Rate: 57600; Data: 8 bytes; Stop: 1 byte; Parity: None.

Data Format

After power-on, the detector will use around 3 seconds to complete the self-test. If there is an issue, the detector will

repeat self-testing until the problem is solved. After booting up, the serial port will send out data in the following format:

-07-

$

Methane

Concentration

5 bytes

00318,

Header

Data Description

Methane Concentration the unit is ppm*m

Light Intensity the light intensity of infrared detection laser

Relevancy reference value of whether the signal is distorted, <00980, no outputs

Environment Temperature measured from PCB board thermistor

SNR signal to noise ratio reference value

Version Number used to record the software version number, e.g. 011

Light

Intensity

5 bytes

02147,

5 bytes

00735,

Relevancy

*1000

5 bytes

00999,

Environment

Temperature

5 bytes

00036,

Table 3. Outputs Data Format

5 bytes

00024,

5 bytes

-0078,

5 bytes

00000,

SNR

3 bytes

003,

Reserved

Bytes

3 bytes

000,

Version

Number

3 bytes

010,

Error

Code

3 bytes

000

Checksum

*3C

Data Description

000

Error Code

Checksum

normal operation;

001

temperature control failure;

002

laser diode error;

Starting character is ‘*’, and the Checksum value is obtained by the data difference or operation between '$' and' * '.

Checksum calculation example:

unsigned char CalcChecksum(unsigned char* str, int len)

{

unsigned char cs;

int i;

cs = 0;

for (i=0; i<len; i++)

{

cs ^= str[i];

}

return cs;

}

004

circuit board temperature exceeds -20~80℃;

008

laser case temperature exceeds -20~80 °C;

016

reference channel error.

Table 4. Data Description

Error Code Proper Handling Method

When the error message appears, try restarting the device. If error code 001, 004, or 008 appears, please try to restart the device after it is

completely cooling down. If the error still exists, please contact Hesai for the technical support.

NOTE Do not try to repair the device on your own accord.

-08-

5.2

Parameter Configuration

Users can use the serial port debugging tool to configure parameters for the detector. The specific configuration parameters are as follows:

Functions

Enter configuration mode

Set measurement time

Set save power

Set wakeup

Set SNR

Set light intensity threshold

Get device information “DSP\r\n” “DeviceSN:%s\r\n

Set green indication laser “SGL,ON\r\n”

Reset

Exit

Command

“+++\r\n”

“SSPD,%f\r\n”

“SD,Savepower\r\n”

“SD,Wakeup\r\n”

“SSNR,%f\r\n”

“SITH,%d\r\n”

“SGL,OFF\r\n”

“SF,1\r\n”

“---\r\n”

DM100 Return Description

“WELCOME\r\n”

“AOK\r\n”

“AOK\r\n”

“AOK\r\n”

“AOK\r\n”

“AOK\r\n”

LaserSN:%s\r\n

SetTld:%x\r\n

IS1651:%d\r\n

SNRThreshX10:%d\r\n

IntensityThresh:%d\r\n”

“AOK\r\n” Default setting: ON

“AOK\r\n”

“END\r\n”

Table 5. Parameter Configuration

Serial port configuration is only valid in configuration mode

Default setting: 0.1 s. Options: 0.1 s~10 s

-

-

Default setting: 2. Options: 0.1~10

Default setting: 100,Options: 50~1000 (integer)

Example:

“DeviceSN:HESAI194

LaserSN:ABCD1234

SetTld:825

IS1651:1

SNRThreshX10:10

IntensityThresh:100”

Restore system default setting

Enter test mode after exiting configuration mode

* After sending the configuration command, the system returns the value "AOK\r\n"; if the command is incorrect, it returns "ERR\r\n".

End a command with “\r\n”.

-09-

Appendix I Warranty and Maintenance

Warranty

During the warranty period, Hesai will provide free maintenance service when the device can't operate due to the problem of software or

hardware. But Hesai will not provide the service if the problem is caused by rule-breaking operations. Situations that break the warranty

include but are not limited to the following:

1)

Missing warranty document or effective purchase vouchers;

2)

Did not use the instrument as per instructed;

3)

Unauthorized modification, disassembly, or repair;

4)

Intentional damages;

5)

Stolen, lost or discarded device;

6)

Damaged device due to use with unauthorized accessories and services;

7)

Those damages caused by natural disasters, such as fire, lightning, flood, earthquake, etc.

Maintenance

For maintenance requirement, please follow the following steps:

1)

Report the problem to Hesai for the preliminary problem diagnosis.

2)

Return the product to Hesai.

3)

Hesai conducts the maintenance test report, calculates maintenance fee (if any), and provides the maintenance agreement.

4)

Sign the maintenance agreement and pay the maintenance fee if needed.

5)

Receive the repaired instrument and finish the delivery inspection.

Normal Maintenance Time (after receiving the product): 7 days. The specific maintenance time shall be determined according to the actual

situation.

-10-

Appendix II EC-Declaration of Conformity

-11-

Appendix III FCC Statement

FCC ID:2ASO2DM100

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that

may cause undesired operation.

Please note that changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to

operate the equipment.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by one or more of the following measures:

—Reorient or relocate the receiving antenna.

—Increase the separation between the equipment and receiver.

—Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

—Consult the dealer or an experienced radio/TV technician for help.

-12-

Hesai Photonics Technology Co., Ltd

Address: 10th Floor, Building L2-B, Hongqiao World Centre, Shanghai

Sales: 021-80394947-802

Business Email: info@hesaitech.com

Website: www.hesaitech.com

Technical Support: 021-80394947-896

Service Email: service@hesaitech.com

HESAI WeChat

Loading...

Loading...