Page 1

Installation Instructions

®

Vista V3 Electric Strike

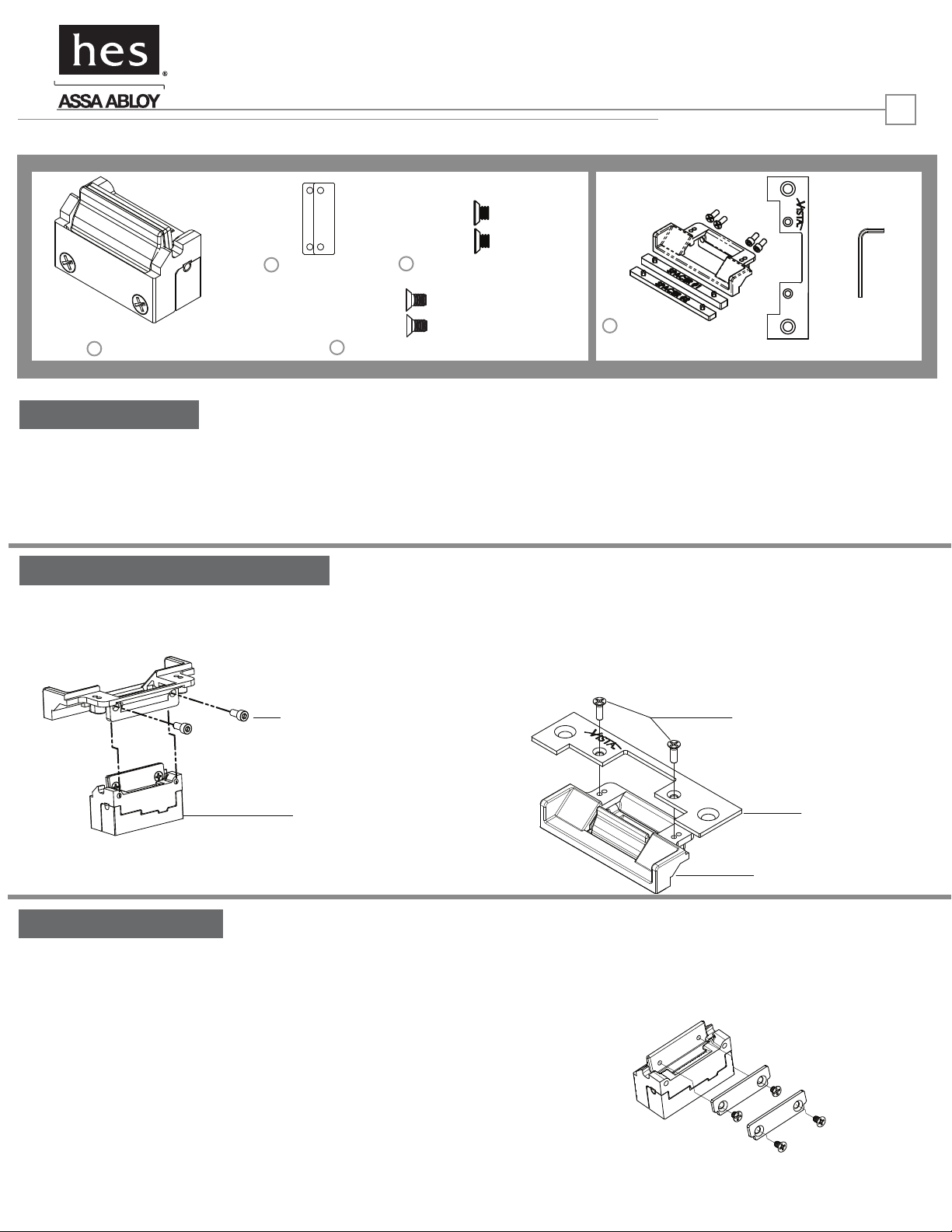

Product Components

HES, Inc.

Phoenix, AZ

800-626-7590

www.hesinnovations.com

1

2

15/16”

Keeper Shims

1-13/16”

1

Strike Body

13/16”

4

4-40 x 3/16” Shim Screws

Strike Installation

1. If this is a new installation, consult pages 2-3 for the

proper template for your option.

Faceplate and Housing Assembly

3. Attach Electric Strike body to Housing as illustrated

below using the 6-32 x 5/16” socket head screws and hex key

packaged with the Option Kit.

6-32 x 5/16”

Socket Head

Screws

3

4-40 x 1/8” Shim Screws

2. If you are replacing another manufacturer’s electric strike,

rst determine the manufacturer and model number to be

replaced. Using the chart on page 4, choose the appropriate

Option Kit and spacer to be used with the new install and

proceed to step 3.

4. If using Options 1-4, attach Faceplate to Housing as illustrated

below using the 6-32 x 7/16” at-head screws provided with the

Option Kit.

Note: A second set of mounting holes is provided in the Housing

for additional Forward Horizontal Adjustment.

5

Option Kit

(sold separately)

6-32 x 7/16” Faceplate

screws

Strike Body

Complete Installation

5. Install Electric Strike assembly into frame to test latchbolt

interaction.

7. Remove Electric Strike from frame and connect power.

Faceplate

Housing

6. If additional horizontal adjustment is needed, 1 or 2 keeper

shims can be added as illustrated below. If adding a single shim

use the 4-40 x 1/8” screws, or if adding both shims, the longer

4-40 x 3/16” screws should be used.

8. Re-install the electric strike into jamb cutout using the

12-24 at-head screws provided in the Option Kit to complete

installation.

Page 2

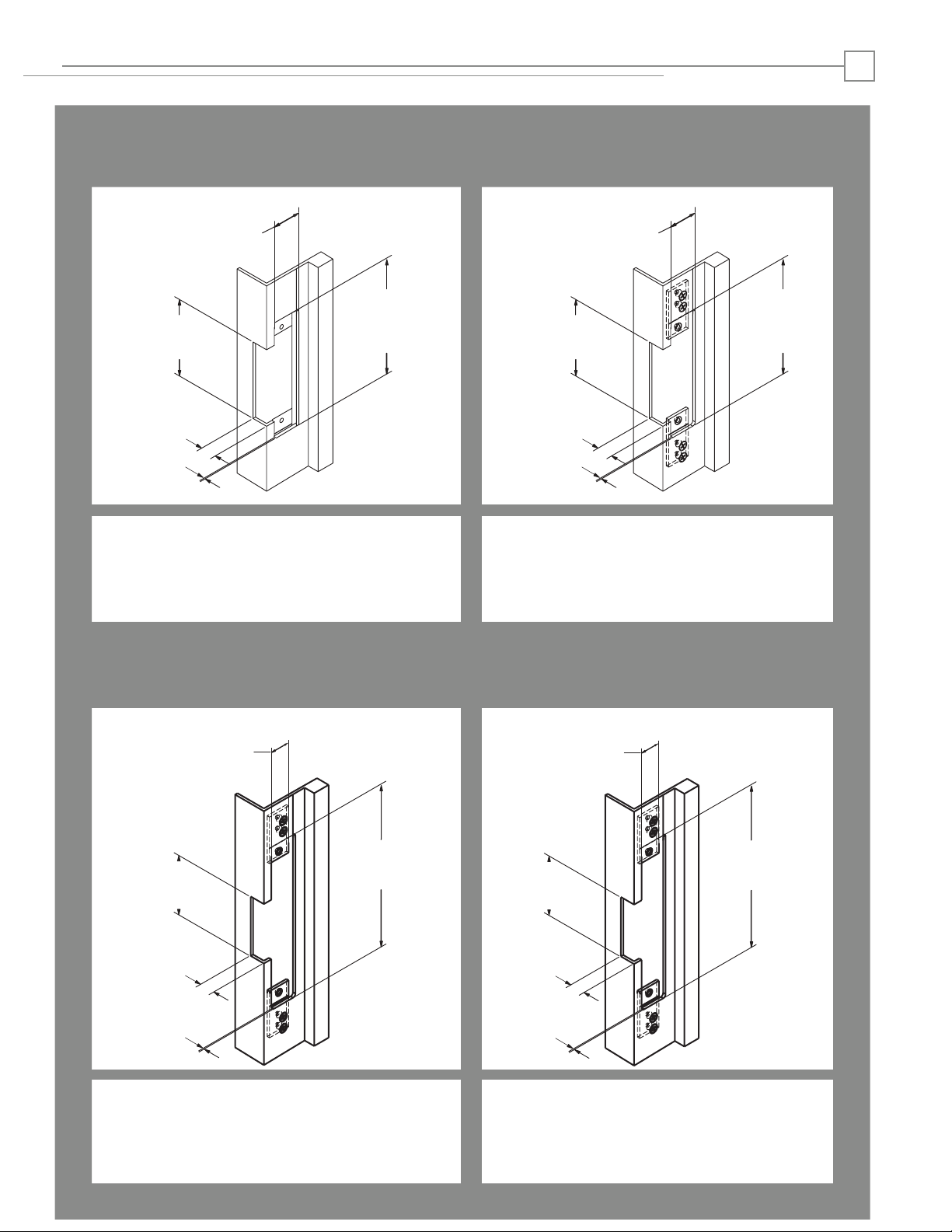

Cutout Templates

2

OPTION 1

4-7/8” x 1-1/4” Square Corner Faceplate

ANSI Metal Jamb Installations

NEW INSTALLATION

1 -1/4"

[31.8]

3 -3/8"

[85.7]

21/32"*

[16.7]

3/32"

[2.3]

RETROFIT: COMPATIBLE CUTOUTS

RCI 4114

RCI 7114

*Dimension shown without spacer

ROFU 1702

ROFU 1802

4 -7/8"

[124]

Trine 012

Trine 2007

Trine 2012

Inches

[mm]

OPTION 1A

4-7/8” x 1-1/4” Radius Corner Faceplate

Metal Frame Installations With Mounting Tabs

NEW INSTALLATION

1 -1/4"

[31.8]

3 -3/8"

[85.7]

21/32"*

[16.7]

3/32"

[2.3]

RETROFIT: COMPATIBLE CUTOUTS

RCI 4104

RCI 7104

*Dimension shown without spacer

4 -7/8"

[124]

Inches

[mm]

OPTION 2

7-15/16” x 1-7/16” Radius Corner Faceplate

Metal Frame Installations With Mounting Tabs Metal Frame Installations With Mounting Tabs

NEW INSTALLATION

1 -7/16"

[36.5]

3 -3/8"

[85.7]

21/32"*

[16.7]

3/32"

[2.3]

RETROFIT: COMPATIBLE CUTOUTS

RCI 7108

RCI 4108

ROFU 1704

ROFU 1804

7 -15/16"

[201.6]

Trine 2002WR

Inches

[mm]

OPTION 3

6 -7/8” x 1-1/4” Radius Corner Faceplate

NEW INSTALLATION

1 -1/4"

[31.8]

3 -3/8"

[85.7]

21/32"*

[16.7]

3/32"

[2.3]

RETROFIT: COMPATIBLE CUTOUTS

RCI 4107

RCI 7107

ROFU 1703 Trine 2678

ROFU 1803

6 -7/8"

[174.3]

Inches

[mm]

*Dimension shown without spacer *Dimension shown without spacer

Page 3

Cutout Templates

3

OPTION 4

9” x 1-3/8” Radius Corner & Flat Faceplate

Wood Frame Installations

NEW INSTALLATION

1 -3/8"

[34.9]

1 -1/4"

3 -3/8"

[85.7]

21/32"*

[16.7]

3/32"

[2.3]

RETROFIT: COMPATIBLE CUTOUTS

ANSI 9” X 1-3/8” CUTOUTS

[230]

[31.8]

9"

Inches

[mm]

OPTION 5

3-1/2” x 1-3/8” Square Corner & Flat Faceplate

Wood Frame Installations

NEW INSTALLATION

1 -3/8"

[34.9]

1-1/2 "

1 -7/8"

[38.1]

3/8"

[9.5]

3/32"

[2.4]

RETROFIT: COMPATIBLE CUTOUTS

Trine 005

[46]

3 -1/2"

[88.9]

Inches

[mm]

*Dimension shown without spacer

OPTION 6

7-15/16” x 1-7/16” Radius Corner Faceplate

Metal frame with mounting tabs or Wood Installations

NEW INSTALLATION

1 -7/16"

[36.5]

7 -15/16"

2-7/8"

[201.6]

[73]

13/16"

[20.6]

3/16"

[4.8]

Inches

[mm]

OPTION 7 & 7E

2-3/4” x 1-1/8” Square Corner Faceplate

ANSI A156.115 2-3/4”Metal Jamb Installation*

NEW INSTALLATION

1 -1/8"

[28.6]

A

C

1/8"

[3.2]

2 -3/4"

[69.9]

B

Inches

[mm]

RETROFIT: COMPATIBLE CUTOUTS

ROFU 1509

RETROFIT: COMPATIBLE CUTOUTS

ANSI A156.115 2-3/4 CUTOUTS*

A B C

Option 7* 1-1/2” [38.1] 1-7/8”[46] 5/8” [15.8]

Option 7E

2” [ 50.8] 2” [50.8] 21/32”[16.7]

Page 4

Compatibility Chart & Specications

OPTION KIT SELECTION

1. Using the chart below determine which Vista 3 Option Kit is required for your application.

Note: Depending on the product being retrotted, you are choosing both a faceplate, and spacer option.

For example, when replacing a Trine 2002WR series strike, an Option Kit 2 should

be used, as well as spacer #2. No spacer is needed if “None” is listed under spacer.

Trine

Model Vista Option Kit Spacer

2002WR 2 Spacer #2

Red/Green

Black

4

Model Vista Option Kit Spacer Used

RCI

4104 1A

Yes: Spacer #1

4114 1 Yes: Spacer #1

4107 3 Yes: Spacer #1

4108 2 Yes: Spacer #1

7104 1A

7114 1 Yes: Spacer #1

Yes: Spacer #1

Yes: Spacer #1

7107 3 Yes: Spacer #1

7108 2 Yes: Spacer #1

21/32"

[16.7]

Housing With No Spacer

7/8"

[22.2]

Housing With Spacer #1

Model Vista Option Kit Spacer Used

ROFU

1509 6 None

1702 1 None

1703 3 None

1704 2 None

1802 1 None

1803 3 None

1804 2 None

TRINE

005 5 None

012 1 Yes: Spacer #2

2002WR 2 Yes: Spacer #2

2007 1 None

2012 1 Yes: Spacer #2

2678 3 Yes: Spacer #2

13/16"

Housing With Spacer #2

ELECTRICAL SPECIFICATIONS

CAUTION! This strike is provided as either a 12 or 24 volt unit. Before connecting any device at the installation site,

verify input voltage using a multimeter. Many power supplies and low voltage transformers operate at higher levels

than listed. Any input voltage exceeding 10% of the solenoid rating may cause severe damage to the unit and will void

the warranty.

ELECTRICAL RATINGS FOR SOLENOID CONTINUOUS DUTY

12VDC

Resistance in Ohms

Amps

Solenoids are rated at +/- 10% indicated value.

*10% max duty cycle (2 min. max on time).

3603006.001 rev E

60

.20

[20.6]

INTERMITTENT DUTY*

24VDC

12-16VAC 24VAC

240 60 240

.10 .20 .10

inches

[mm]

MINIMUM WIRE GAUGE REQUIREMENTS SOLENOID VOLTAGE

12VDC 24VDC

200 feet or less

200 - 300 feet

300 - 400 feet

18 gauge

16 gauge

14 gauge

18 gauge

18 gauge

16 gauge

© 2012 HES, Inc.

Loading...

Loading...