Page 1

HES, Inc.

Phoenix, AZ

1.800.626.7590

www.hesinnovations.com

KS200-640 Server Cabinet Lock Series

Installation Instructions

3085006.002 Rev. 3 1

Page 2

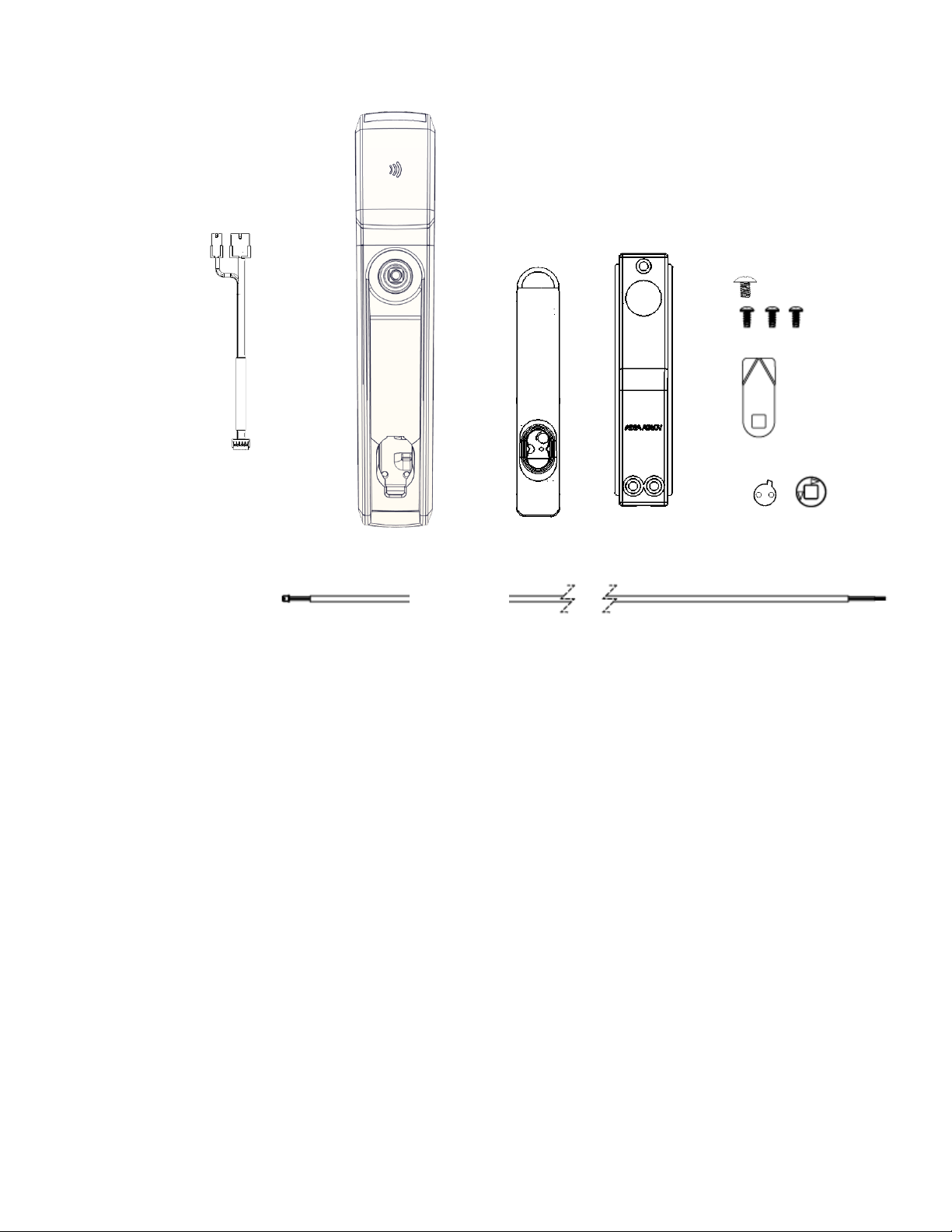

Package Contents

Recommended Tools

Approved RFID Credential

Phillips P2 driver

WT-2 Wiegand Test Box

Optional Additional Tools:

SFIC Core for key override or

SFIC Blank Plastic Core

Normally Open DPS Switches

System Side Interface Cable

Specifications

Voltage: 12–24 VDC ±10% (Power Supply not provided)

KS200-640 (Reader) Current Consumption:

12 VDC: 37 mA peak for Red and Green LED only

470 mA peak for Red and Green LED and Motor Drive

24 VDC: 18 mA peak for Red and Green LED only

245 mA peak for Red and Green LED and Motor Drive

Operating Temperature: -10C to 50C

Holding Force: 250 lbs

Handling

Selector

Lock

Handle

Mounting Plate

Mounting Screws

Cam

DPS Cable

SFIC

Cam

Lock Side

Interface Cable

3085006.002 Rev. 3 2

Page 3

Connector Pin Wiring:

Molex 8-Pin Connector Pin

Wire Color

Description

1

Black

12 VDC Reader (–)

2

White

Wiegand Data (1)

3

N/A

N/A

4

N/A

N/A

5

Red

12 VDC Reader (+)

6

Green

Wiegand Data (0)

7

Blue

Red LED

8

Yellow

Green LED

Molex 4-Pin Connector Pin

1

Violet

12/24 VDC / Lock (COM, –)

2

Pink

Tamper / DPS (NC, +)

3

Gray

12/24 VDC / Lock (COM, +)

4

Tan

Tamper / DPS (COMM, –)

LED Function: LED states are controlled and defined by the User’s EAC. Enabling the red and green

LEDs on the KS200 occurs via an active low (ground) signal.

Output Type: SIAAC-01-1996 Wiegand Output Compliant.

FCC Part 15 Compliant, Industry Canada Compliant, European Commission Compliant

BHMA: A156.3, A156.36, A156.25 Compliant

NOTE: Contact HID Global Technical Support at (866) 607-7339 for additional configuration cards to

enable the credential capabilities of “iCLASS Elite” and “NFC over HCE.”

Credentials Supported: 125 kHz Proximity or 13.56 MHz iCLASS, iCLASS Elite, iCLASS SEOS, iCLASS

SE, ISO 15693 ICLASS, ISO 14443A Mifare, Mifare Plus, Desfire SE, Desfire EV1, and NFC over HCE.

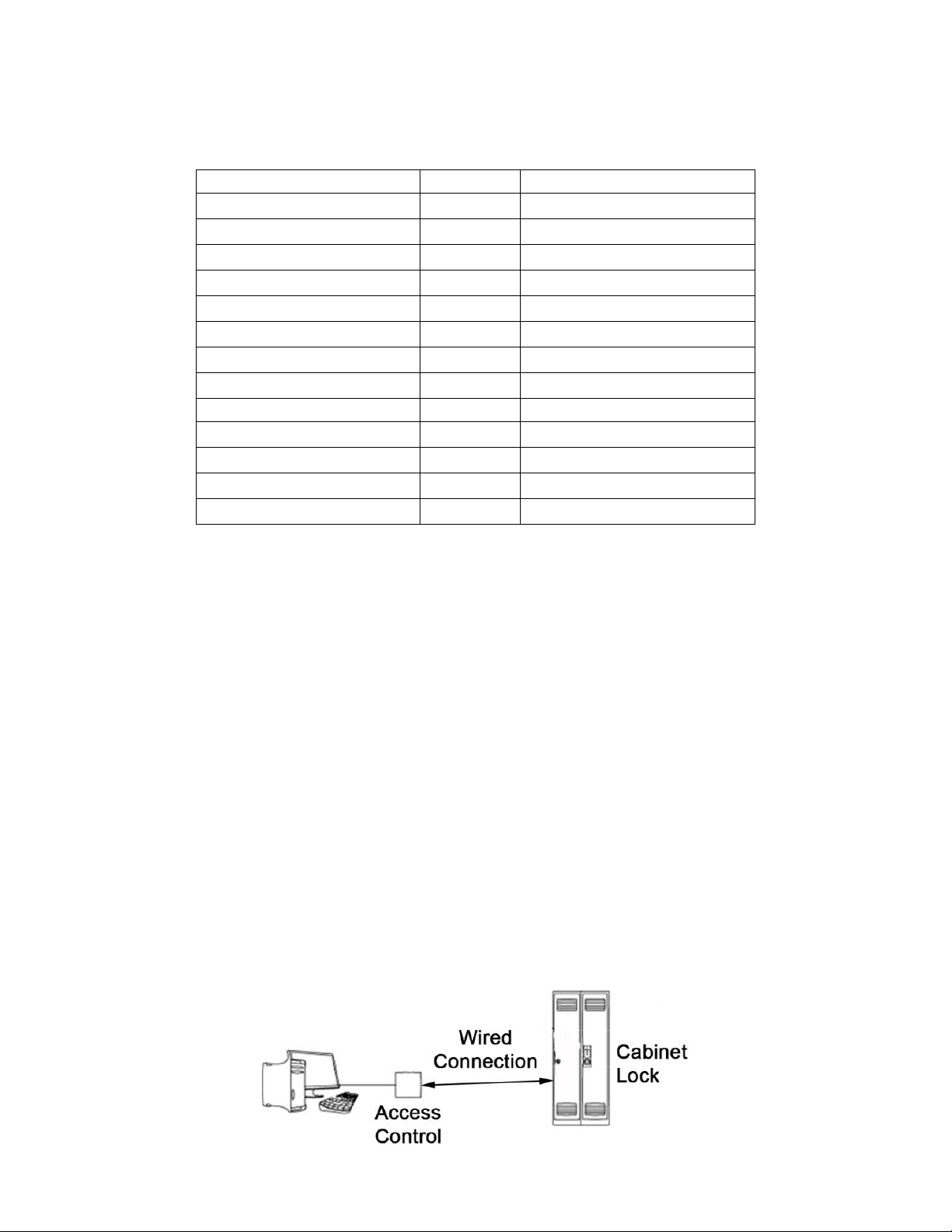

System Overview

The KS200 is a radio-frequency identification (RFID) lock for server cabinet installation applications.

The lock is capable of reading RFID credentials and providing that data to an electronic access control

(EAC) system via Wiegand data signaling. The EAC determines whether user access should be granted

or denied. When the EAC provides an active-high unlock signal to the lock in the access granted case,

the KS200-640 drives a motor to complete the unlock/lock cycle. EAC indication of user access/denial is

provided to the user by way of LED control inputs on the lock. Additional lock monitoring features (e.g.,

door position, tamper) are monitored within the lock and status provided to the EAC.

3085006.002 Rev. 3 3

Page 4

Installation

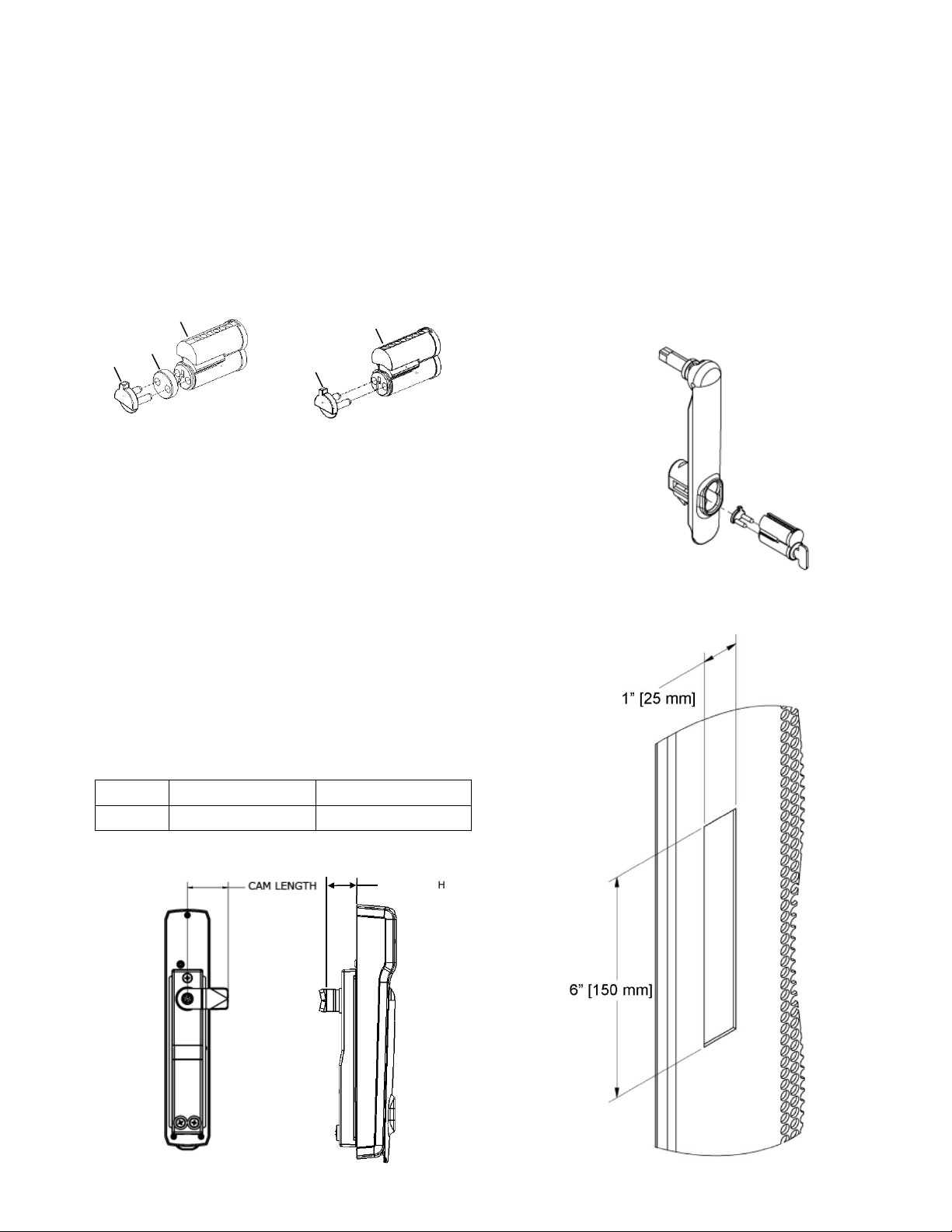

1. Installing an SFIC Core

NOTE 1: A key override (SFIC) provides a backup entry method in the rare case the KS200 or EAC

is inactive (Recommended).

NOTE 2: The included SFIC cam has been tested with Medeco and Sargent 6- or 7-pin SFIC cores.

2. Preparing the Cabinet

1. LOCATE the 1” [25 mm] x 6” [150 mm] lock cutout on

the door (some doors may require modification).

2. ENSURE power is available at the rack.

3. RE-USE the existing cam, if possible.

NOTE: One cam is supplied.

CAM

CAM LENGTH

CAM DEPTH

CAM 1

1-1/2” [38 mm]

15/16” [24 mm]

SFIC

Core

Cam

SFIC

Core

7-pin

6-pin

1. Insert Cam into SFIC

Use the included Spacer

with 6-pin SFICs.

2. INSERT SFIC

into lock

CAM DEPTH

Cam

6-pin

Spacer

3085006.002 Rev. 3 4

Page 5

3. Installing the Lock

1. SLIDE lock into cutout.

NOTE: (Optional) The DPS signal is closed when the handle is

resting in its locked position. The DPS circuit can be

extended to include normally open DPS switches

arranged in a series to monitor additional doors and

panels.

DPS Extension Cable

DPS

Needed

Switch #1

(SPST-NO):

2. PERFORM the following to

extend the DPS Circuit.

a. REMOVE the DPS jumper.

b. CONNECT the included

DPS extension cable.

c. CONNECT additional

normally-open DPS

switches as shown to

monitor additional panels.

3. CONNECT the female, 10-position

Hirose™ connector on the lock side

interface cable to the KS200.

4. ENSURE the lock side interface

cable will properly protrude from

the bottom of the KS200

prior to attaching the rear bracket.

ENSURE the wiring is not

obstructing the mounting holes prior

to securing the rear bracket.

Provided

Switches

(SPST-

NO): As

3085006.002 Rev. 3 5

Page 6

4. Installing the Handing Selector

CAUTION! Inserting/snapping the handle all the way in will lock the lever

2. POSITION the arrows to

point toward the door

edge.

1. INSERT handing

selector into lock.

6. ENSURE that the lock is fully

secured and flush to the mounting

surface in order to depress

tamper switch on back of device

for correct operation.

NOTE: If the tamper switch is

not fully depressed, the

lock opens the

Tamper/DPS+/- contact.

5. ATTACH rear bracket with screws.

7. IF the tamper switch is not fully

closed,

THEN REMOVE the tamper

contact,

AND ENSURE the lock is closed.

3. INSERT and SECURE

cam with screw.

Door edge

3085006.002 Rev. 3 6

Page 7

5. Attaching the Wiring

New 4-/8-Pin Molex

Integrated Wiegand: K/KS200 Cabinet Locks, ElectroLynx Wire Color/Function Assignments

Connector

8-Pin Molex Connector

4-Pin Molex Connector

Pin/Wire

Color

1

Black

2

White

3

N/A 4 N/A 5 Red 6 Green

7

Blue

8

Yellow

1

Violet 2 Pink 3 Gray 4 Tan

Function

12 VDC

Reader

Wiegand

Data

N/A

N/A

12 VDC

Reader

Wiegand

Data

LED

12/24

VDC/

Lock

Tamper/

DPS

12/24

VDC/

Lock

Tamper/

DPS

Setting

NEG

Data 1

N/A

N/A

POS

Data 0

RED

Green

COM, -

NC, +

COM, +

COM, -

Legacy 10-Pin Molex to 4-/8-Pin Molex

Integrated Wiegand: K/KS200 Cabinet Locks, ElectroLynx Wire Color/Function Assignments

Connector

8-Pin Molex Connector

4-Pin Molex Connector

Pin/Wire

Color

1

Black

2

White

3

N/A 4 N/A 5 Red 6 Green

7

Orange

8

Brown

1

Gray

2

Yellow

3

Violet 4 Blue

Function

12 VDC

Reader

Wiegand

Data

N/A

N/A

12 VDC

Reader

Wiegand

Data

LED

12/24

VDC/

Lock

Tamper/

DPS

12/24

VDC/

Lock

Tamper/

DPS

Setting

NEG

Data 1

N/A

N/A

POS

Data 0

RED

Green

COM, -

NC, +

COM, +

COM, -

1. CONNECT the Lock Side Interface Cable to the lock.

2. CONNECT the Lock Side Interface Cable to the optional System Side Interface Cable (see

Connector and Cable Diagram).

3. RUN the System Side Interface Cable, as required (see Server Cabinet Wiring Example).

4. ATTACH the included 4-Pin and 8-Pin Molex Female Connectors to the bare wire side of the

System Side Interface Cable.

NOTE: It is recommended that 10-conductor, 24 AWG, cable be used.

5. ENSURE the following power cabling guidelines are followed:

Wire AWG

Supply Voltage

Allowed Cable Length (ft.)*

20 AWG

12

419

24

3217

22 AWG

12

264

24

2023

24 AWG

12

166

24

1272

* Round trip loss. V = 2 x I x R x xft xft = V / (2 x I x R)

3085006.002 Rev. 3 7

Page 8

Connector and Cable Diagram

3085006.002 Rev. 3 8

Page 9

Server Cabinet Wiring Example

3085006.002 Rev. 3 9

Page 10

6. Testing the Lock with the Access Control System

1. TEST the lock with a known good

credential to confirm it will open as

desired when installed.

a. PRESENT a credential known to the EAC.

b. LIFT lever and TURN to open the cabinet.

3085006.002 Rev. 3 10

Page 11

This page intentionally left blank

3085006.002 Rev. 3 11

Page 12

FCC Statement

For Technical Support, please call 1-800-626-7590

For information on other HES cabinet lock solutions,

visit hesinnovations.com

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired operation.

IC Statement

This device complies with Industry Canada license-exempt RSS standards(s). Operation is subject to the following

two conditions:

(1) this device may not cause interference, and

(2) this device must accept any interference, including interference that may cause undesired operation.

CE Statement

HES hereby declares that these proximity readers are in compliance with the essential requirements and other

relevant provisions of Directive 1999/5/EC (http://ec.europa.eu/enterprise/sectors/rtte/files/guide2009-04-

20_en.pdf).

Conformité aux normes FCC

Cet appareil est confrome à la Partie 15 des règlements de la FCC. Son fonctionnement est souimes aux deux

conditions suivantes:

(1) cet appareil ne peut causer d’interférences, et

(2) cet appareil doit accepter toute interference, y compris des interférences qui peuvent provoquer un

fonctionnement indésirable du périphérique.

Conformité aux normes IC

Cet appareil est confrome avec Industrie Canada exempt de license RSS standard(s).

Son fonctionnement est souimes aux deux conditions suivantes:

(3) cet appareil ne peut causer d’interférences, et

(4) cet appareil doit accepter toute interference, y compris des interférences qui peuvent provoquer un

fonctionnement indésirable du périphérique.

Conformité aux normes CE

HES déclare par la présente que ces lecteurs à proximité sont conformes aux exigences essentielles et aux autres

stipulations pertinentes de la Directive 1999/5/CE (http://ec.europa.eu/enterprise/sectors/rtte/files/guide2009-0420_en.pdf).

3085006.002 Rev. 3 12

Loading...

Loading...