Page 1

®

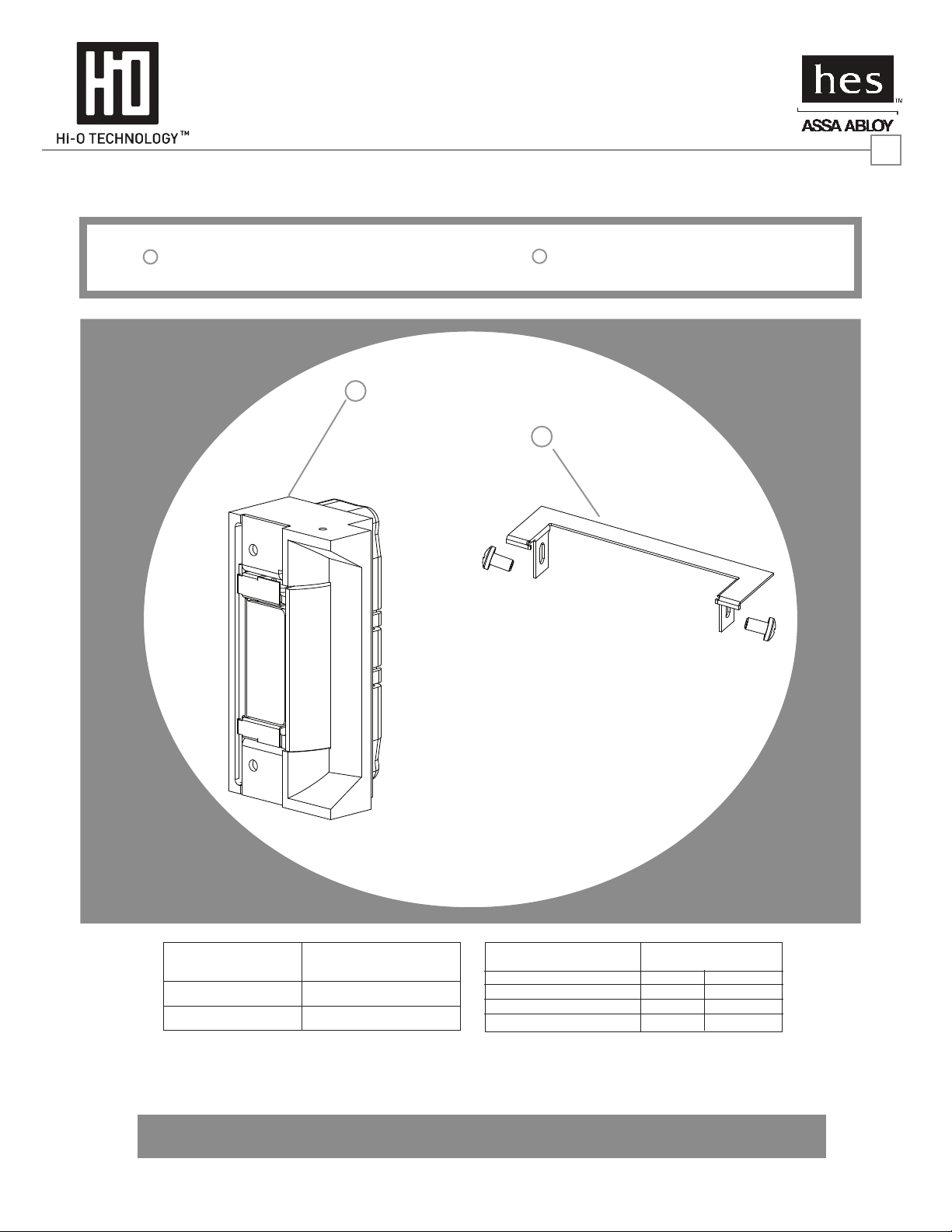

HT5000 Series Electric Strike

Installation Instructions

1

Product Components

1

2

ASSA ABLOY, the global leader

in door opening solutions

1

FIVE YEAR LIMITED WARRANTY

For any questions regarding this information, call HES Customer Support at 1-800-626-7590

22630 N. 17th Ave. Phoenix, AZ 85027 www.hesinnovations.com

For UL Listed applications, the unit shall be connected to a UL Listed Class 2 power supply or a UL 294 Listed

control unit.

ELECTRICAL RATINGS

Average Amp: 0.25 Seated

Average Amp: 0.04 Unseated

+12 to +24 (+/-10%) Volts DC

MINIMUM WIRE GAUGE Solenoid Voltage

REQUIREMENTS

24 VDC

200 feet or less

200 - 300 feet

300 - 400 feet

Trim Enhancer (with screws)

2

18 gauge

16 gauge

14 gauge

20 gauge

18 gauge

16 gauge

12 VDC

HT5000 Electric Strike Body

Page 2

2

Installation Instructions

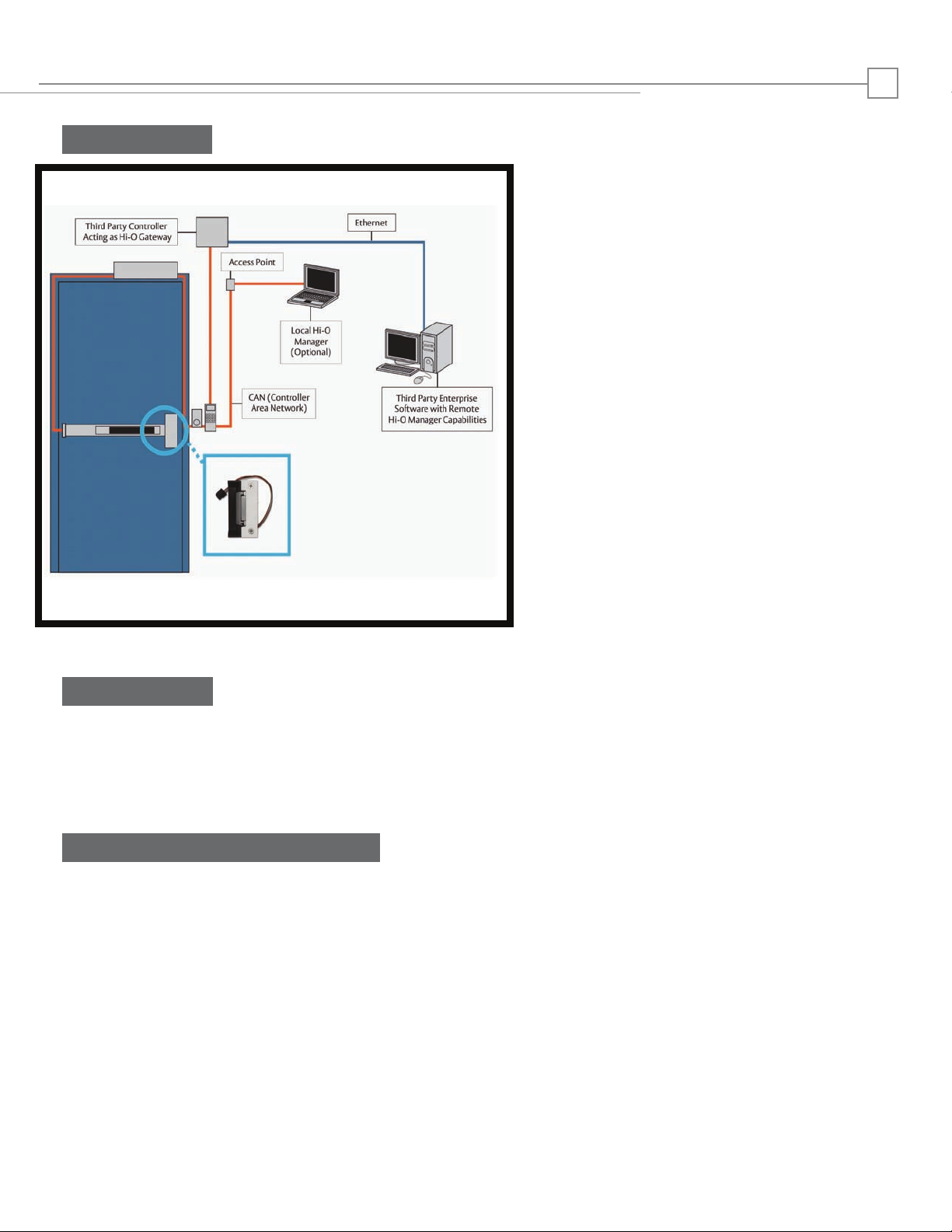

ASSA ABLOY’s standard-based Hi-O system—

Highly Intelligent Opening—connects electronic

(Controller Area Network) data network,

allowing them to communicate and monitor the

health of the opening. Intelligence is built into

each device instead of one centralized logic

unit, creating a plug-and-play system. Each

device is instantly recognized when plugged

into the system—similar to what happens wh

en

a USB device is plugged into a computer.

Every unit is connected with a four-wire cable

and has ElectroLynx® plug-in connectors for

quick installation.

Hi-O is based on devices with built-in

intelligence and a CANbus that links all the

devices together. Data traffic on the Hi-O

CANbus can be encrypted. Each Hi-O device

(such as a push plate, electric strike, card

reader, door operator, etc.) i

s connected to the

CANbus through a single, four-wire cable. Two

of the wires supply power and the other two

are used for data communication.

Refer to the Hi-O Systems Manual (A8002).

Hi-O Overview

2. For available faceplate options, see page 8.

Prepare Strike

Prepare Frame

1. Evaluate opening and reset Dip Switch if needed (see

page 4 (ADJUSTMENT INSTRUCTIONS).

1. Prepare frame using the appropriate template for your

lockset and faceplate combination (see page 3-4).

2. Connect to system using electrolynx connectors (see Page

3).

Diagram A

3. Install the HT5000 strike body into the door frame.

4. Set up the Hi-O system (see pages 5-7.

Installation Instructions

3

The HT5000 series drawing below show the Hi- O application.

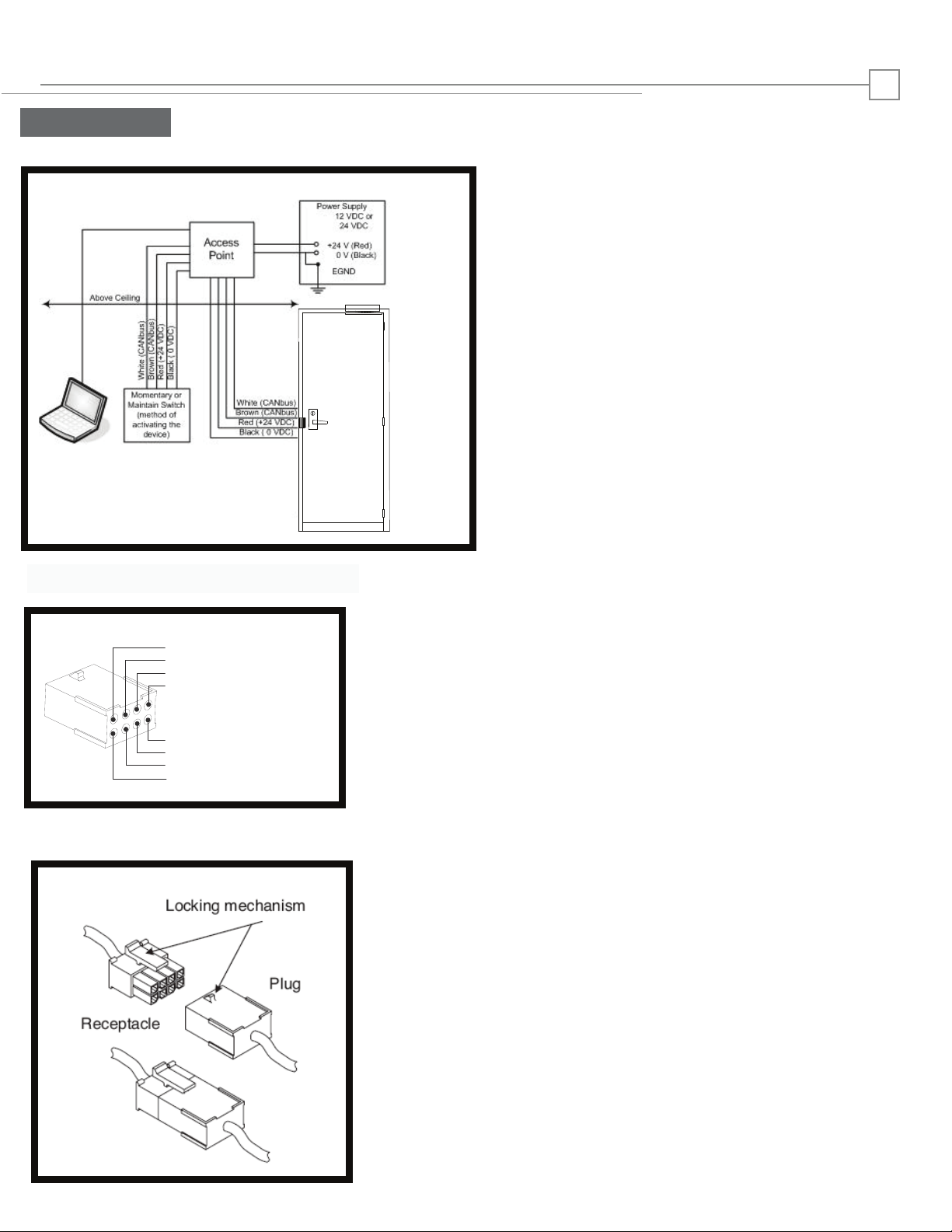

Voltage: 12-24VDC

(11-28VDC range) operation

Filtered and Regulated Power Supply

Current: .5 Amp Seated

.04 Amp Unseated

PIN 1 Black (0 VDC)

PIN 3 White (CANbus)

PIN 5

PIN 7 Brown (CANbus)

PIN 8

PIN 6

PIN 4

PIN 2 Red (+12 – 24 VDC)

-)]

NOTE:

For HT5000 (On the 8-Pin Connector):

PIN 2 Red (Power +12 - 24VDC)

PIN 1 Black [Power 0 VDC/Common(-)]

PIN 3 White CAN bus HIGH

PIN 7 Brown CAN bus LOW

endly with quick

cable lengths to a minimum.

.

The System is designed to be installation friendly with quick

connectors.

The total length of the bus should not be more then 50 meters

(164 feet) and stub (star) connections should not be more then

10 meters (33 feet). The optimal solution places the door

controller close to the door to keep cable lengths to a minimum.

IMPORTANT:

ElectroLynx connectors plug and lock together in only one way,

as

shown.

Do NOT force connectors together.

Prepare Strike

Wiring

A. Electrolynx Connectors

B. Electrolynx Connector System Notes

Page 3

Installation Instructions

3

The HT5000 series drawing below show the Hi- O application.

Voltage: 12-24VDC

(11-28VDC range) operation

Filtered and Regulated Power Supply

Current: .5 Amp Seated

.04 Amp Unseated

PIN 1 Black (0 VDC)

PIN 3 White (CANbus)

PIN 5

PIN 7 Brown (CANbus)

PIN 8

PIN 6

PIN 4

PIN 2 Red (+12 – 24 VDC)

-)]

NOTE:

For HT5000 (On the 8-Pin Connector):

PIN 2 Red (Power +12 - 24VDC)

PIN 1 Black [Power 0 VDC/Common(-)]

PIN 3 White CAN bus HIGH

PIN 7 Brown CAN bus LOW

endly with quick

cable lengths to a minimum.

.

The System is designed to be installation friendly with quick

connectors.

The total length of the bus should not be more then 50 meters

(164 feet) and stub (star) connections should not be more then

10 meters (33 feet). The optimal solution places the door

controller close to the door to keep cable lengths to a minimum.

IMPORTANT:

ElectroLynx connectors plug and lock together in only one way,

as

shown.

Do NOT force connectors together.

Prepare Strike

Wiring

A. Electrolynx Connectors

B. Electrolynx Connector System Notes

Page 4

4

Installation Instructions

The default factory settings will be used in almost every application. They are:

Group 1

Terminator OFF

NOTE: If necessary, follow the procedure below to change the DIP switch settings before installing strike.

IMPORTANT: Ensure that the serial number of the unit is retained. Once the device is locked and

encryption enabled, access to the device requires the serial number. If the serial number is lost, the device

must be returned to the factory to be reset.

A.

B. SWITCH 1: Set the manual group switch. Default is OFF and is appropriate for most applications. Most

installations use Group 1 only.

Switch 1 OFF = membership in Group 1.

Switch 1 ON = membership in Group 2.

B. SWITCH 2: Set the termination resistor (Default is OFF). In a Hi-O CANbus network, it is necessary to

terminate the communication bus to avoid interference. Termination should take place in Activators, for

example in a card reader, opening button, or a gateway.

Switch 2 OFF removes the 120 ohm connection between CAN-Low and CAN-High.

Switch 2 ON terminates a 120 ohm resistor between CAN-Low and CAN-High.

Use only one termination resistor per application.

Refer to the Hi-O Systems Manual (A8002) for additional information.

Adjustment Instructions

DO NOT DAMAGE LABEL. This label

will be re-applied after DIP switch

setting is complete.

After label is removed, carefully use a

small screwdriver to set DIP switch (see

instructions 2 and 3).

When setting is complete, re-apply the

serial label to the back of the strike.

To change the settings, remove the label from the back of the strike.

Switch

position

default

settings

ON

1 2

Page 5

5

Installation Instructions

Step 3

Step 3

Step 4

Step 5

Step 6

Step 1: Install hardware according to installation

instructions and the Hi-O System Manual.

Step 2: Download and install the latest release of Hi-O

Manager and Logger software, and DDF files

according to the Hi-O System Manual.

Step 3: Open Hi-O Manager and click the Next button to

determine what devices are attached to the system.

Step 4: Icons representing system appear in the left pane.

Step 5: Click the Push Button icon.

Step 6: In the Properties tab of the right pane, click the

Advanced Properties arrow to view the Properties

pane.

Step 7: In the Property Group pane, set security locking

and timers, and set the values that will generate

system messages. In the Property Group menu,

select from

the following:

Information – Read-only information from the

device.

Device Offline Behavior – Set unlock, delay

and egress timing for Lock.

Voltage Out of Range Limits – Set low and

high thresholds for voltage. When thresholds are

exceeded system messages will be generated.

Jam Timers – Set time to dictate when a jam

message is sent when the strike is locked and

keeper open.

Transmit Command Validation – Set the

above Locking, Security Locking, Opening,

Holding, Activator State, and System Voltage to

valid or invalid.

Refer to the Hi-O System Manual (A8002) for additional information.

Hi-O System Software

Page 6

6

Installation Instructions

Select the Properties tab.

Click the Push Button icon in

the view pane.

Click the Advance Properties

arrow to expand the menu.

Choose from the Properties

Groups list:

Information

Device Offline Behavior

Voltage Out of Range Limits

Jam Timers

Transmit Command Validation

Information

Displays read-only general

information from the device,

including:

Serial Number

Node ID

Host Node ID

Product Class

Application Name (Model

Number)

Hardware Version

Hi-O Stack Version

Hardware Group

ACP Active (Address Claiming

Process)

Hi-O Systems Settings

Page 7

7

Installation Instructions

De v ic e O f fl i ne Be h avi or

Device Offline Behavior

No Change

Lock

Unlock

Vo l ta g e O ut of

Ra n ge Li m it s

Set Voltage Out of Range Limits

Establishes Out of Range entries in

Log.

Low Overflow Voltage in Volts

High Overflow Voltage in Volts

11 to 28 is the normal range.

Ja m T i me r s

Set Jam Timers

Set time to dictate when a jam

message is sent when the strike is

locked and keeper open.

Jam Delay Timer in seconds

(0 – 255)

Tr a ns m it Co m man d

Va l id a ti o n

Set Transmit Command

Validation

Sets Locking, Security Locking,

Opening, Holding, Activator

State, and System Voltage

entries to valid or invalid,

determining if the entries are read

or ignored.

NOTE: If it is not possible to set

respective entries, check to see if

they are set to valid.

Hi-O System Settings

Refer to the Hi-O System Manual (A8002) for additional information

Page 8

4500 WITH SCHLAGE AND YALE MORTISE LOCKS

8

Cutout Templates

Inches [mm]

HT5000 WITH 501 FACE PLATE HT5000 WITH 501A FACE PLATE

HT5000 WITH 502 FACE PLATE

HT5000 WITH 501B FACE PLATE

3 3/8"

[85.7]

1 1/4"

[31.8]

4 7/8"

[124]

11/16"

[17.5]

[2.3]

3/32"

4 7/8"

[124]

1 1/4"

[31.8]

3 3/8"

[85.7]

11/16"

[17.5]

[2.3]

3/32"

4 7/8"

[124]

3 3/8"

[85.7]

11/16"

[17.5]

1 1/4"

[31.8]

[2.3]

3/32"

11/16"

[17.5]

3 3/8"

[85.7]

1 7/16"

[36.5]

7 15/16"

[201.6]

Page 9

4500 WITH SCHLAGE AND YALE MORTISE LOCKS

9

Cutout Templates

Inches [mm]

HT5000 WITH 503 FACE PLATE HT5000 WITH 503B FACE PLATE

HT5000 WITH 504 FACE PLATE

11/16"

[17.5]

[2.3]

3/32"

3 3/8"

[85.7]

1 7/16"

[36.5]

6 7/8"

[174.3]

11/16"

[17.5]

1 1/4"

[31.8]

6 7/8"

[174.3]

3 3/8"

[85.7]

10"

[254]

3 3/8"

[85.7]

11/16"

[17.5]

[2.3]

3/32"

1 3/8"

[34.9]

1 1/2"

[38.1]

Page 10

2008 HES Inc.

3019006.002 rev A

HT5000

ELECTRIC STRIKE

INSTALLATION INSTRUCTIONS

Loading...

Loading...