Page 1

An ASSA ABLOY Group company

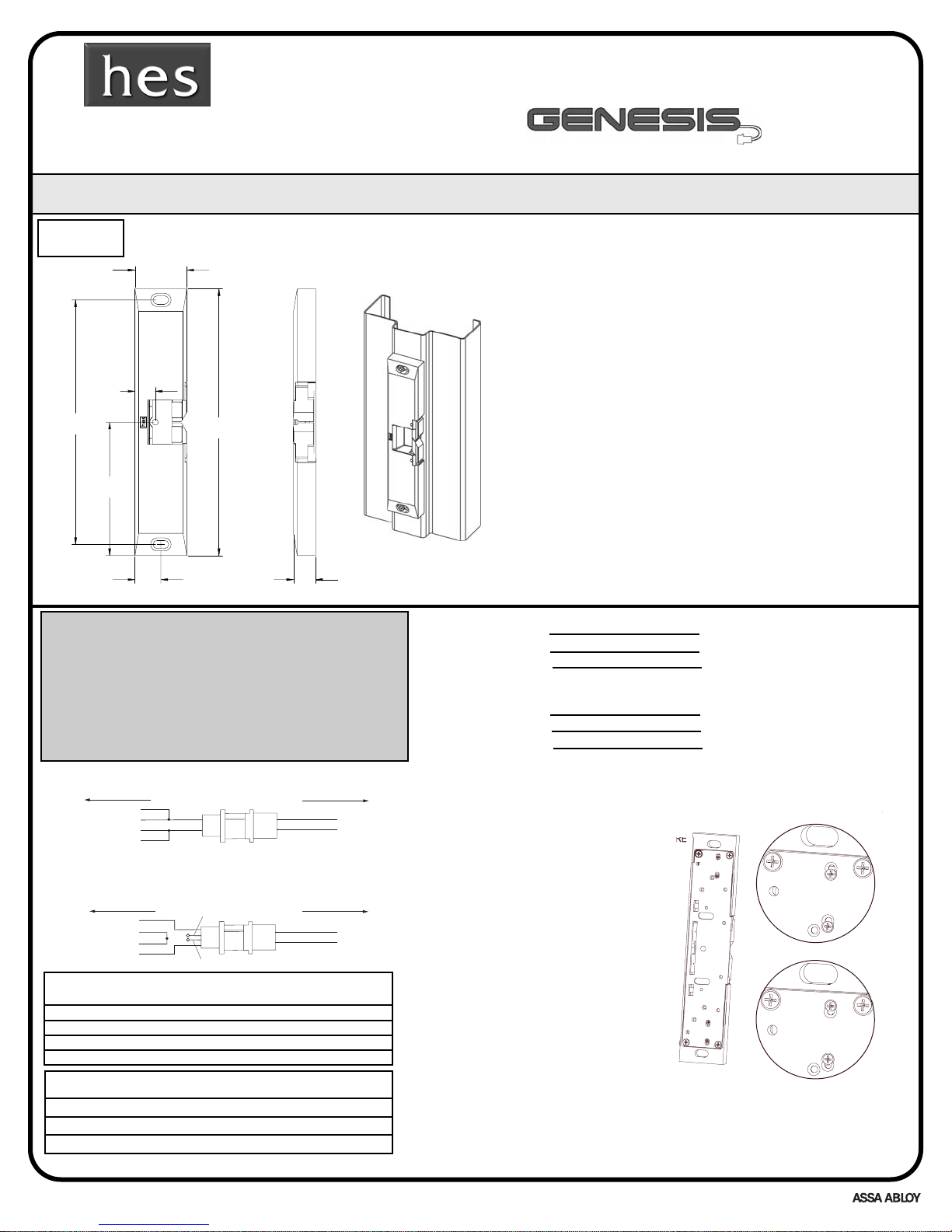

99550000 SSEERRIIEESS DDIIMMEENNSSIIOONNSS

DIMENSIONS:

INCH [[MM]

INSTALLATION INSTRUCTIONS •

PPlleeaassee rreeaadd ccaarreeffuullllyy bbeeffoorree aatttteemmppttiinngg iinnssttaallllaattiioonn

©HES 2005

1

Hanchett Entry Systems, Inc.

22630 N. 17th Ave,

Phoenix, AZ 85027

www.hesinnovations.com

(623) 582-4626

Technical Service Dept. Helpline (800) 626-7590

9"

[

]

8-1/4"

[

]

"

[44.5]

"

[

]

5/8"

[

]

3/4"

[

]

/8"

[

]

1-3/8"

[

]

4055006.001 rev C

Installation Instructions

1. Prepare door jamb using the installation template,

located on page 2 (with the exception of the 10-32 UNF

threaded hole.)

2. Connect wires coming from the low voltage power

source to the electric strike.

3. Make sure the mounting surface is smooth and

square.

4. Align and attach electric strike to jamb, using 1/4 x 20

cap screws. (Further adjustments may be made through

the # 10-32 set screws)

5. Drill and tap the 10-32 UNF threaded hole and install

the 10-32 cap screw provided (9600 optional).

NOTES:

1. The electric strike is factory supplied as a 12 Volt DC unit.

2. The electric strike is factory configured as fail secure.

3. Before supplying power to electric strike, verify source voltage and current limits are within “ELECTRICAL RATINGS FOR

SOLENOID“

4. Application on door frames only.

5. For retrofit applications, reinforcement plate must be 18

gauge minimum.

LBM WIRING COLOR CODE (optional)

WHITE COMMON

ORANGE NO-NORMALLY OPEN

GREEN NC-NORMALLY CLOSED

LBSM WIRING COLOR CODE (optional)

(in addition to wires listed above)

BROWN COMMON

BLUE NO-NORMALLY OPEN

YELLOW NC-NORMALLY CLOSED

MINIMUM WIRE GAUGE Solenoid Voltage

REQUIREMENTS

24VDC 12VDC

200 feet or less 18 gauge 14 gauge

200-300 feet 18 gauge 12 gauge

300-400 feet 16 gauge

ELECTRICAL RATINGS Continuous Duty

FOR SOLENOID

Input voltage (+ or - 5%) 24VDC 12VDC

Resistance in Ohms 106.6 26.6

Amps Seated .225 .45

E

E

1. Loosen both screws on the back.

NOTE: Do not remove screws

at any time.

2. Move up or down depending on

the operation.

3. Tighten screws.

FAIL SECURE

Field Reversible:

Fail secure - Fail safe

CAUTION! Before connecting any device at the

installation site, verify input voltage and current using

a multimeter. Many power supplies and transformers

operate at higher levels than listed. Any input voltage

exceeding 5% of the solenoid rating may cause severe

damage to the unit and will void the warranty.

12V

24V

1. Loosen the pair of 2-56 flathead

screws on the back of the electric

strike.NOTE: Do not fully remove

screws at any time.

2. Shift screws to fail safe configuration as shown at right.

3. Tighten screws.

4. Repeat steps 1-3 at other end of

electric strike.

5. Remove UL 10C label for fail safe

configuration.

9500 Intended for UL 10C, 90 min.

9500/9600

Electric Strikes

Fire rated 9500, surface mounted

1-3/4

34.9

228.6

209.6

4-1/2

114.3

17.4

7

22.2

19.1

TO ELECTRIC STRIKE

RED

VIOLET

BLACK

RED/GREEN

TO ELECTRIC STRIKE

RED

VIOLET

BLACK

RED/GREEN

VIOLET

BLACK

TO 12V DC

POWER SOURCE

TO 24V DC

POWER SOURCE

FAIL SECUR

FAIL SAF

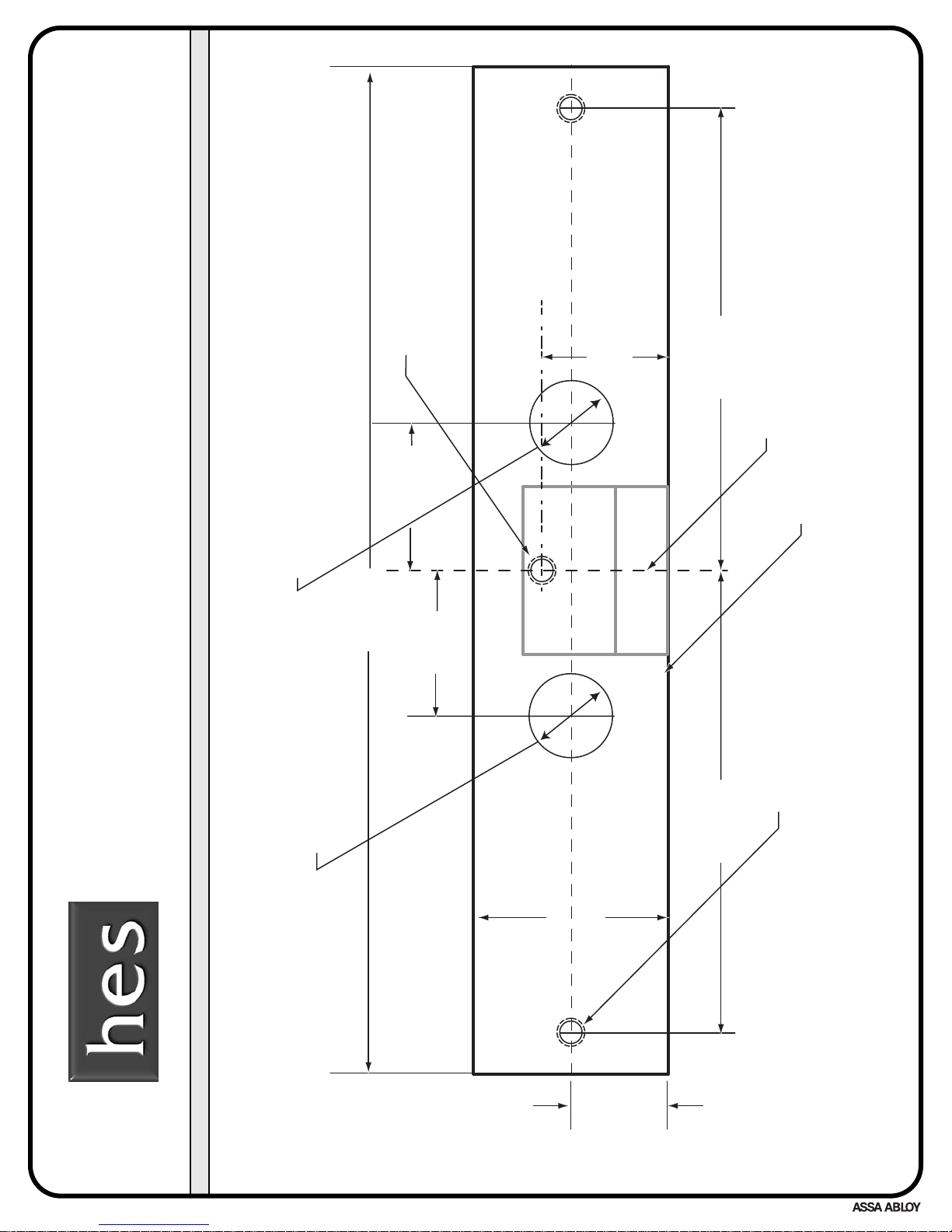

Page 2

9"

[228.6]

CENTERLINE OF LATCHBOLT

THIS EDGE TOWARD DOOR

2X MOUNTING HOLE

LOCATIONS FOR

1/4-20 UNC CAP SCREWS

7/8"

[22.2]

4-1/8"

[104.8]

1-3/4"

[44.5]

[

]

OR

BM/

B

M

WIRING

[

]

O

POWER WIRING

Final Lockdown Feature

10-32 UNF (9600 OPTIONAL)

1-5/16"

[33.3]

1-5/16"

[33.3]

1-1/16"

[27.0]

4-1/8"

[104.8]

©HES 2005

An ASSA ABLOY Group company

9500/9600 LBM/LBSM

Installation Template

2

4055006.001 rev C

19.0

S

3/4"

L

CLEARANCE F

L

R

19.0

3/4"

CLEARANCE F

Loading...

Loading...