Page 1

Installation Instructions

9400 Series Electric Strike

HES, Inc.

22630 N. 17th Ave.

Phoenix, AZ 85027

800-626-7590

www.hesinnovations.com

1

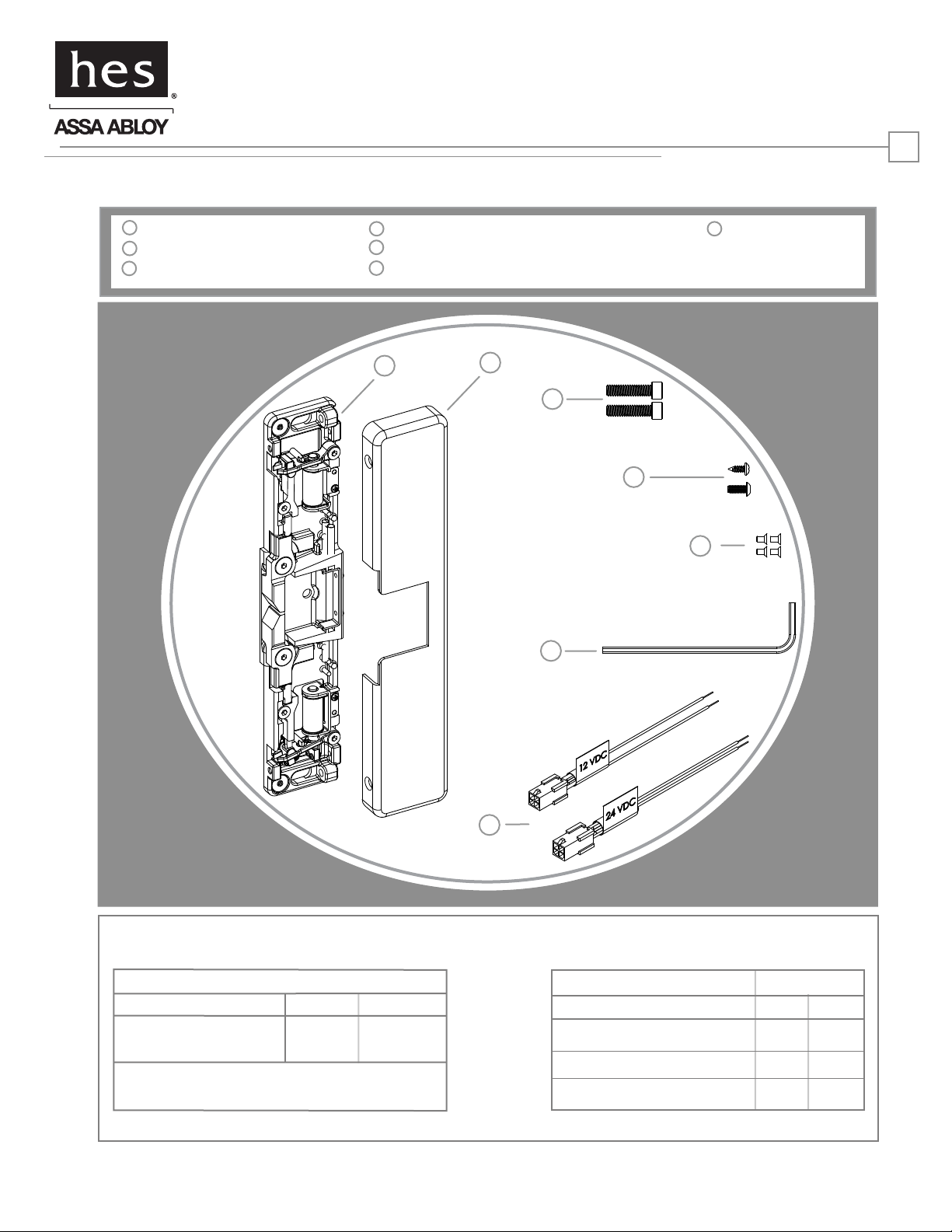

Product Components

1

9400 Electric Strike Body

2

9400 Cover

3

1/4”-20 x 1” Mounting Screws

4

#10-32 & 10-24 Lockdown Screws (optional)

5

#6-32 x 1/4” Cover Screws

6

5/64” Hex Key

1

2

7

Plug In Connectors

3

4

5

7

Diagram 1: Electrical Specifications

ELECTRICAL RATINGS FOR SOLENOID

CONTINUOUS DUTY

Resistance in Ohms

Amps

Solenoid voltage +/ - 10%

12VDC

24

.50

24VDC

96

.25

6

MINIMUM WIRE GAUGE REQUIREMENTS SOLENOID VOLTAGE

12VDC 24VDC

200 feet or less

200 - 300 feet

300 - 400 feet

18 gauge

16 gauge

14 gauge

18 gauge

18 gauge

16 gauge

ASSA ABLOY, the global leader

in door opening solutions

Page 2

Installation Directions

CAUTION! Before connecting any device at the installation site, verify input voltage using a multimeter.

Many power supplies and low voltage transformers operate at higher levels than listed. Any input voltage exceeding

10% of the solenoid rating may cause severe damage to the unit and will void the warranty.

2

Prepare Strike

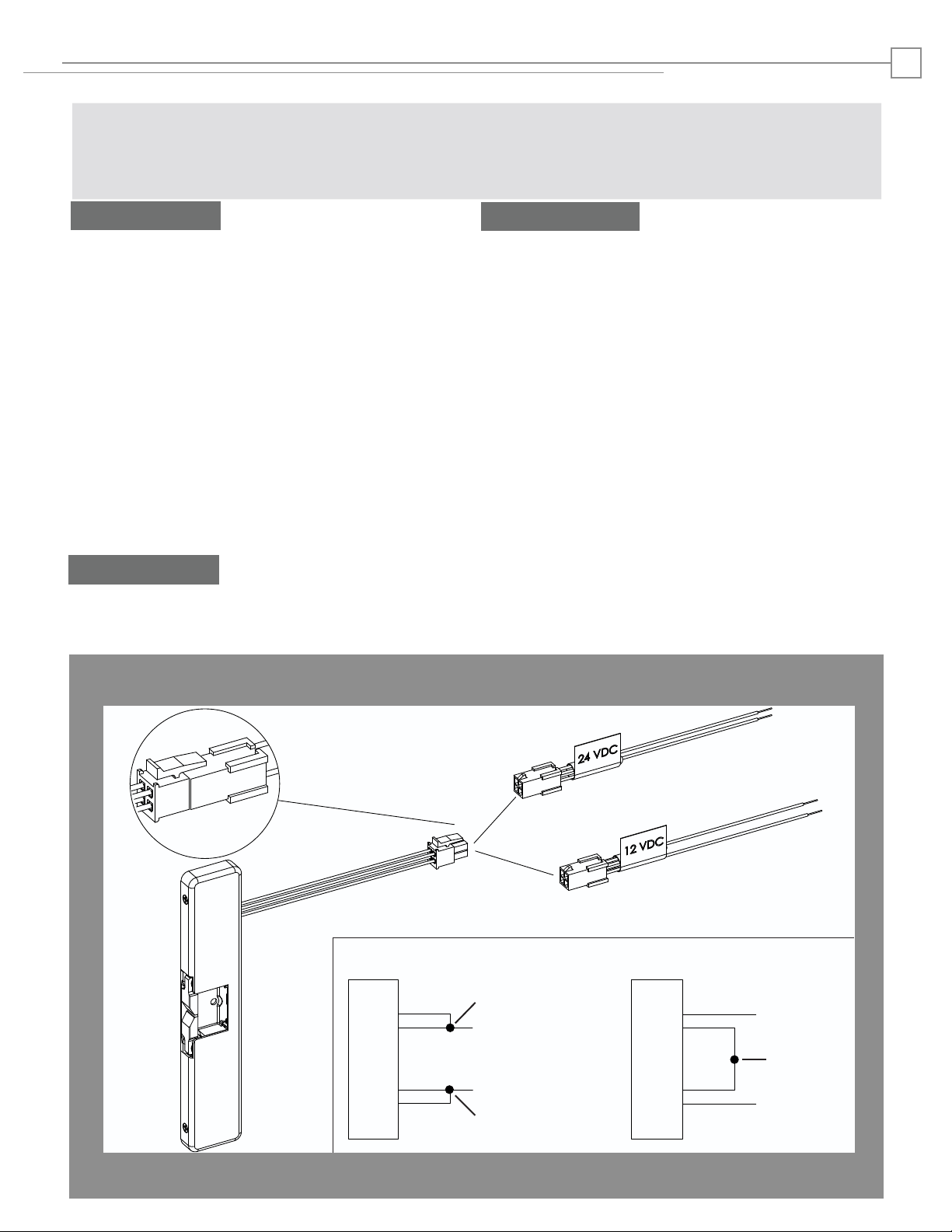

1. Select the appropriate Plug In Connector that

matches system power and electrically connect as

illustrated in Diagram 2. For 12V DC, the pigtail

marked “12 VDC” should be used. For 24V DC, the

pigtail marked “24 VDC” should be used. If no

connector is present, configure the wires as illustrated within Diagram 2.

2. If using the Latchbolt Monitor (LBM) or Latchbolt

Strike Monitor (LBSM), refer to Diagram 3 & 4 on

page 3 to complete wiring.

3. The 9400 ships in the Fail Secure mode of operation. If you need to convert to Fail Safe Operation

see Diagram 5 on page 3.

Prepare Frame

4. Prepare the door jamb using the Installation

Template located on page 4 (with the exception of

the hole for final lockdown).

Finish Installing

5. Electrically connect the 9400 to the Plug In Connector, and attach the electric strike to the jamb

using the 1/4”-20 cap screws provided.

6. Check latchbolt interaction to determine if

horizontal adjustment is needed, and adjust as

needed. Lockdown horizontal adjustment using the

#10-32 setscrews as illustrated on page 4.

7. OPTIONAL LOCKDOWN FEATURE: Install the

#10-24 UNC or 10-32 UNF lockdown screw if additional security is required. Remove the strike

before drilling hole.

8. Install the cover plate, and fix in place using the

#6-32 x 1/4” Cover Screws as illustrated on page 4.

DIAGRAM 2: 12V to 24V CONVERSION

or

IF CONNECTOR IS MISSING

CONNECT

RED

VIOLET

STRIKE

BLACK

ELECTRIC

RED/GREEN

TOGETHER

(+ 12 VDC)

(-NEG)

CONNECT

TOGETHER

ELECTRIC

RED

VIOLET

STRIKE

BLACK

RED/GREEN

(+ 24 VDC)

CONNECT

TOGETHER

(-NEG)

Page 3

Installation Diagrams

3

DIAGRAM 4: STRIKE MONITORDIAGRAM 3: LATCHBOLT MONITOR

LBM WIRING

White

Orange

Green

Common

Normally Open

Normally Closed

White

Orange

Green

DIAGRAM 5: CYLINDRICAL LOCKSETS

DIAGRAM 5: FAIL SAFE CONVERSION

Convert Mode

The 9400 series Electric Strike is pre-set

for FAIL SECURE OPERATION as shown in

Figure 1.

There are Selector Stop Pins, one on the left

side and one on the right side. Both Selector

Stop Pins must be repositioned to convert

the strike to Fail Safe Operation.

LBSM WIRING

Brown

Blue Normally Open

Yellow

Yellow

Common

Normally Open

Normally Closed

Normally Closed

Brown

Blue

Yellow

Figure 1: FAIL SECURE OPERATION

1. To convert to Fail Safe Operation, remove

the Selector Stop Pins on each side of the

strike body using the 5/64” hex key

provided.

2. Move the Selector Stop Pins to the Fail

Safe Operation position as pictured

(towards the center of the strike) in Figure 2.

3. Tighten both Selector Stop Pins after they

have been moved to the Fail Safe Operation

Verify

Verify that both keepers are in Fail Safe

Operation. Both keepers should be

unlocked without power, but lock when

power is applied.

Selector Stop

Pin Location

Figure 2: FAIL SAFE OPERATION

Selector Stop

Pin Location

Page 4

Frame Preparation

HORIZONTAL ADJUSTMENT & LOCKDOWN

Inches [mm]

4

SETSCREW

LOCATION

MOUNTING

SCREW

LOCKDOWN

SCREW

(optional)

SETSCREW

LOCATION

MOUNTING

SCREW

1. Loosen the two #1/4-20 mounting screws.

2. Adjust strike to appropriate horizontal position.

3. Tighten the two #1/4-20 mounting screws.

4. Lock down adjustment by tightening the setscrews.

5. Install the #10-32 UNF or 10-24 UNC lockdown

screw (optional).

COVER INSTALLATION

9"

Final Lockdown Feature

1-5/16"

[228.6]

[44.5]

1-3/4"

1/2” [12.7]

CLEARANCE FOR

LBM/LBSM WIRING

10-32 UNF or 10-24 UNC (optional)

1-1/16"

4-1/8"

[27.0]

[33.3]

[104.8]

CENTERLINE OF LATCHBOLT

THIS EDGE TOWARD DOOR

Attach the cover using the #6-32 x 1/4” Cover Screws

1-5/16"

[33.3]

3/4” [19]

POWER WIRING

CLEARANCE FOR

4-1/8"

[104.8]

LOCATIONS FOR

2X MOUNTING HOLE

1/4-20 UNC CAP SCREWS

3075006.002 rev B

© 2009 HES, Inc.

7/8"

4X

[22.2]

Loading...

Loading...