Page 1

Installation Instructions

8000/8300 Series Electric Strike

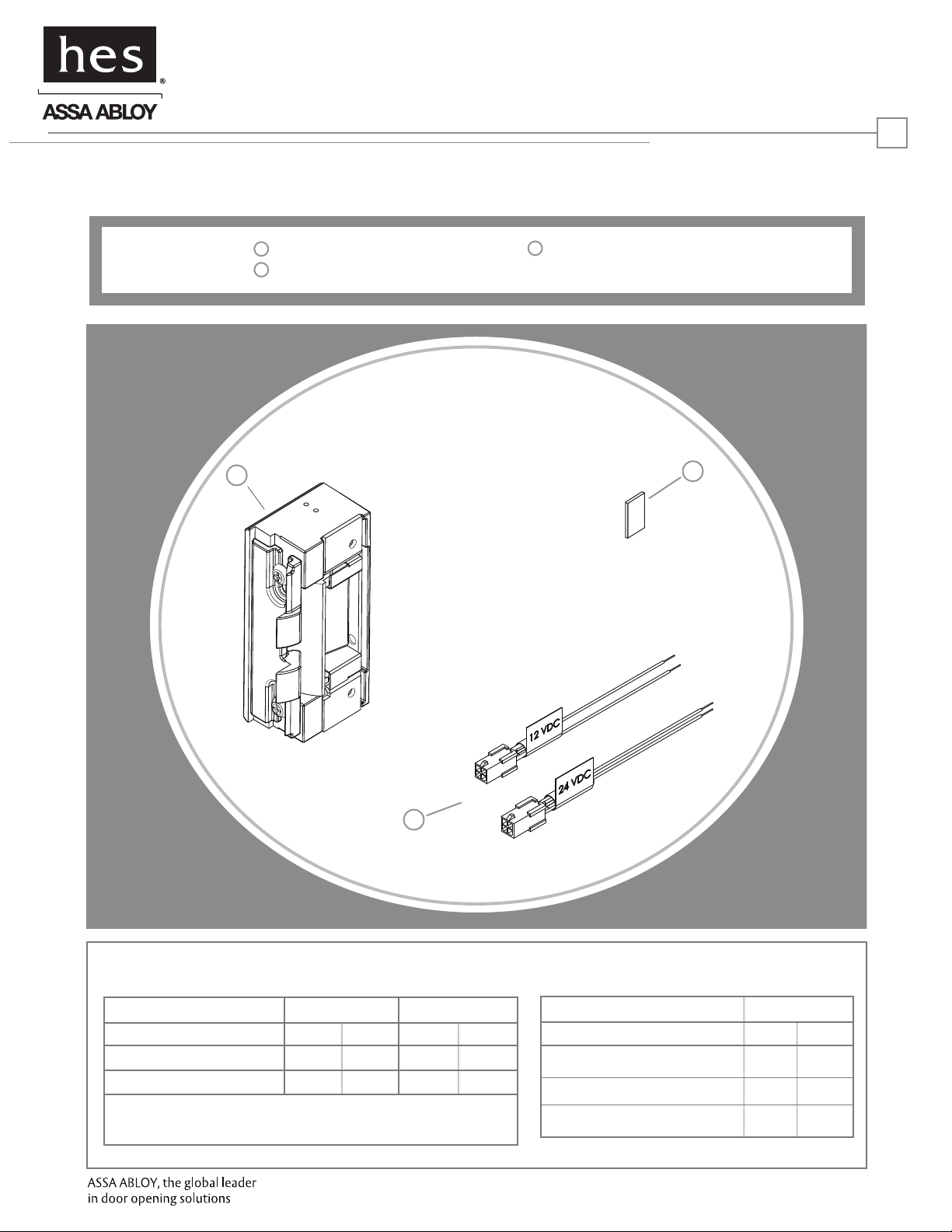

Product Components

1

8000/8300 Electric Strike Body

2

Sticky Shims (optional use)

3

12 & 24 Volt Pigtails

HES, Inc.

22630 N. 17th Ave.

Phoenix, AZ 85027

800-626-7590

www.hesinnovations.com

1

1

3

2

Diagram 1: Electrical Specifications

ELECTRICAL RATINGS FOR SOLENOID

Resistance in Ohms

Amps

Solenoids are rated at +/- 10% indicated value.

*10% max duty cycle (2 min. max on time)

CONTINUOUS DUTY

12VDC

50

.24

24VDC

200 50 200

.12 .12

INTERMITTENT DUTY*

12-16VAC 24VAC

.24-.32

MINIMUM WIRE GAUGE REQUIREMENTS SOLENOID VOLTAGE

200 feet or less

200 - 300 feet

300 - 400 feet

12VDC

18 gauge

16 gauge

14 gauge

24VDC

20 gauge

18 gauge

16 gauge

Page 2

Installation Directions

CAUTION! Before connecting any device at the installation site, verify input voltage using a multimeter.

Many power supplies and low voltage transformers operate at higher levels than listed. Any input voltage exceeding

10% of the solenoid rating may cause severe damage to the unit and will void the warranty.

Evaluate Opening

2

1. Verify opening is plumb and square. For important detail,

see “Read Me” guide.

Prepare Strike

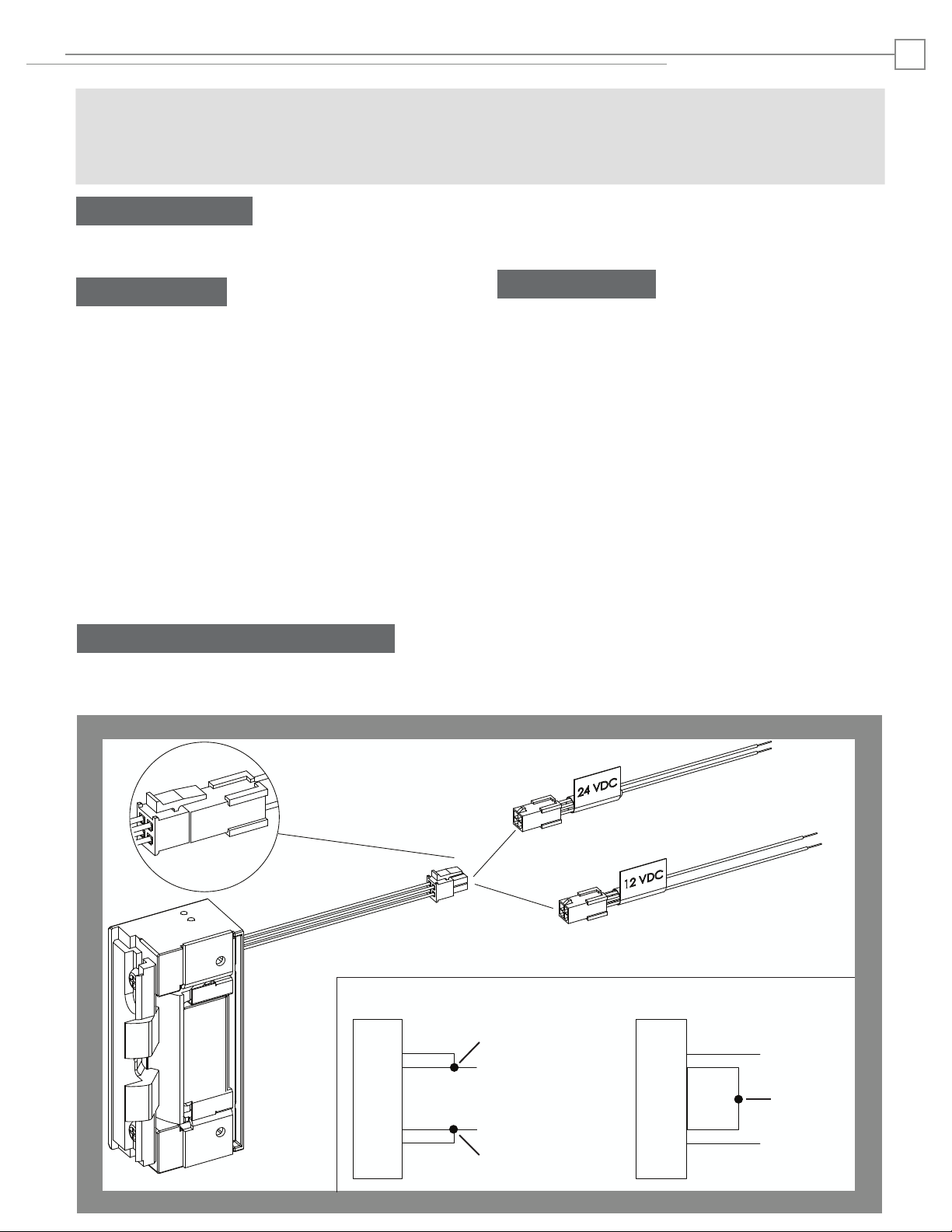

2. Select the appropriate Plug In Connector that matches

system power and electrically connect as illustrated in

Diagram 2. For 12V AC/DC or 16V AC, the pigtail marked “12

VDC” should be used. For 24V AC/DC, the pigtail marked

“24 VDC” should be used. If no connector is present,

configure the wires as illustrated within Diagram 2.

3. Make sure that the electric strike is in correct mode of

operation. This electric strike ships in fail secure mode. If

you need to convert the unit to fail safe, see Diagram 3 on

page 3.

4. If using Latchbolt Monitor (LBM), see Diagram 4.

5. Attach the faceplate to the electric strike, using the #8-32

screws provided. Be sure that the ramps are on top of the

faceplate. (see Diagram 5 on page 3).

Prepare Frame

6. Prepare door jamb per the appropriate template detail

(see pages 4-6).

7. If applicable, install mounting tabs using #10-32 screws.

Do not tighten.

Finish Installing

8. If opening is not plumb and square, see “Read Me” guide

for recommended corrections.

9. Install the electric strike unit in jamb cutout, using

#12-24 screws provided (or wood screws where

necessary).

10. The deadlatch must not interfere with the 8000/8300

ramps (see Diagram 6 on page 3). If you need to adjust the

ramps, mark the centerline of the deadlatch onto the

8000/8300 faceplate. Remove the 8000/8300 electric strike

from jamb. Loosen screws and slide internal ramp until the

groove between the ramps aligns with the mark made on

the faceplate. Tighten the screws. (see Diagram 7 on page

3).

11. Connect wires from power source to the electric strike.

12. Reinstall electric strike, tighten the #12-24 screws and

verify clearance of deadlatch.

13. If applicable, tighten the #10-32 screws holding the

mounting tabs.

DIAGRAM 2: 12V to 24V CONVERSION

IF CONNECTOR IS MISSING

CONNECT

RED

VIOLET

STRIKE

BLACK

ELECTRIC

RED/GREEN

TOGETHER

(+ 12 VDC)

(-NEG)

CONNECT

TOGETHER

RED

VIOLET

STRIKE

BLACK

ELECTRIC

RED/GREEN

(+ 24 VDC)

CONNECT

TOGETHER

(-NEG)

Page 3

Installation Diagrams

3

DIAGRAM 4: LATCHBOLT MONITORDIAGRAM 3: FAIL SAFE TO FAIL SECURE

Loosen screws, but do not

a

remove them

Move screws to the Fail Safe

b

position as shown

Tighten screws

c

Fail Safe*

*Fire rating only applies to Fail

Secure units. Conversion to Fail

Safe negates fire rating on 8300

LBM WIRING

Common

White

Orange Normally Open

Green Normally Closed

White

Orange

Green

DIAGRAM 5: FACEPLATE INSTALLATION

DIAGRAM 6: VERTICAL ALIGNMENT

DIAGRAM 7: VERTICAL ADJUSTABILITY

Centerline

Page 4

Cutout Templates

8000/8300 with 801 Faceplate

1-1/4” X 4-7/8” Square Corner Faceplate

ANSI Metal Jamb Installations

1-1/4" [32]

3-3/8" [86]

4

Inches [mm]

4-7/8" [124]

4-1/8" [105]

1/8" [3]

NOTE: The 8000/8300 electric strike

with 801faceplate will fit right into

most standard ANSI A115.2, 1”

deep dustboxes (e.g. the Curries

®

E-1 preparation), requiring no

cutting.

If you elect to place the 8000/8300

into the existing dustbox, simply

drill for wire connections.

DIAGRAM 8: WIRE DRILLING

3/16" [4.8]

1-1/32” [26.2]

3/8"

[9.5]

3/4" [19]

Diameter

Page 5

Cutout Templates

5

Inches [mm]

8000/8300 with 801A Faceplate

1-1/4” x 4-7/8” Radius Corner Faceplate

Aluminum Jamb Installations

1-1/4"[32]

4-7/8" [124]

4-1/8" [105]

3-3/8" [86]

8000/8300 with 801E Faceplate

1-1/4” x 4-7/8” Faceplate with Extended Lip

‘Knock Down’ Type Jamb Installations

1-1/4"[32]

4-7/8" [124]

4-1/8" [105]

3-3/8" [86]

Snap-On Molding

No Notching

Required

R 5/32" [4]

1/8" [3]

8000/8300 with 802 Faceplate

1-7/16” x 7-15/16” Radius Corner Faceplate

Aluminum and Wood Jamb Installations

1-7/16" [36.5]

Remove additional material as

needed to provide clearance for

electric strike and wires. Then drill

for wires (see Diagram 8)

3-3/8" [86]

7-5/32" [182]

7-15/16" [202]

R 5/32" [4]

1/8" [3]

Page 6

Cutout Template

8000/8300 with 803 Faceplate

1-1/4” x 6-7/8” Radius Corner Faceplate

1-1/4" [32]

3-3/8" [86]

6

Inches [mm]

Aluminum Jamb Installations

6-7/8" [175]

6-1/8" [156]

1/8" [3]

8000/8300 with 805 Faceplate

1-3/8” x 9” Radius Corner Faceplate

Aluminum or Wood Jamb Installations

1-3/8" [35]

Remove additional material as

needed to provide clearance for

electric strike and wires. Then drill

for wires (see Diagram 8)

3-3/8" [86]

1-1/16

9" [228.4]

3068006.003 rev B.

3/32" [2.4]

1/8" [3]

© 2009 HES, Inc.

Loading...

Loading...