Page 1

HES, Inc.

Latchbolt

DeadLatch

Keeper

Ramp

®

®

READ ME

Phoenix, AZ

800-626-7590

www.hesinnovations.com

8000/8300 SERIES ELECTRIC STRIKE

NOTE: Thank you for purchasing the new HES 8000/8300 series electric strike. Before you begin installation, please take

a few minutes to familiarize yourself with this product to understand how it functions and what makes it dierent from

a standard electric strike.

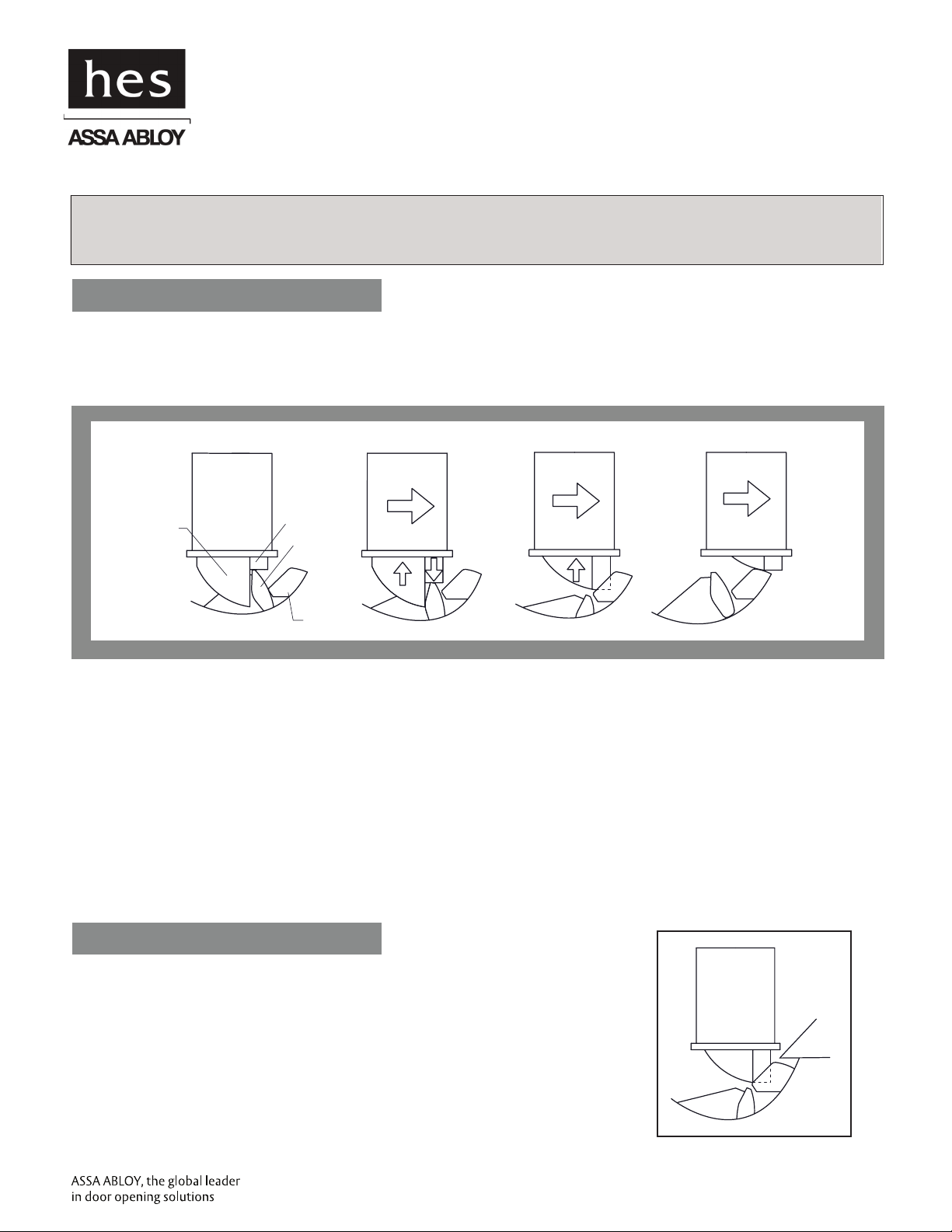

A NEW KIND OF ELECTRIC STRIKE

A standard electric strike requires a cutout on the side of the door frame to allow the extended latchbolt to exit the frame.

In contrast, the 8000/8300 is designed to utilize special internal ramps to eject the latchbolt from an unmodified frame. For the

8000/8300 to operate correctly, it is important for you to first understand the relationship between the unit’s internal ramps and

the position of the latchbolt.

Image # 1

1. Initially, the 8000/8300 operates very much like a standard electric strike. With the door in the closed position, the latchbolt

held secure by the 8000/8300’s keeper (Image 1).

2. When energized, the keeper releases the latchbolt and as the door moves forward the deadlatch begins to

drop (Image 2).

3. As the door continues to move forward the deadlatch and latchbolt will become fully released. The latchbolt will then

pass from the keeper and begin to slide up the internal ramps (Image 3). Note: It is important that the deadlatch pass

between the two internal ramps without contacting either ramp. The ramp adjustment is explained in detail

within installation instructions.

4. As the door continues to open, the latchbolt and deadlatch will continue to slide up the internal ramps and out of the

door frame to release the door. (Image 4)

Image # 2

Image # 3 Image # 4

WHY ANGLES ARE IMPORTANT

The 8000/8300 ramps are designed with critical angles that minimize both latchbolt

wear and the force required for exit. For optimum performance, the latchbolt should

be positioned at a 40 to 45 degree angle in relation to the ramps of the 8000/8300. An

angle more than 45 degrees will steepen the ramp and impact the performance of

the 8000/8300 (Image 5).

We understand that correctly measuring this angle in the field may be difficult. The

next section is designed to help you understand some simple techniques to evalu ate the condition and relationships between the door, the latchbolt, the frame and

the 8000/8300.

Image # 5

45

o

Page 2

HES, Inc.

TROUBLE SHOOTING TIPS

®

Phoenix, AZ

800-626-7590

8000/8300 SERIES ELECTRIC STRIKE

www.hesinnovations.com

NOTE! The 8000/8300 electric strike requires that the opening be plumb and square to insure proper catch

and release of the latchbolt.

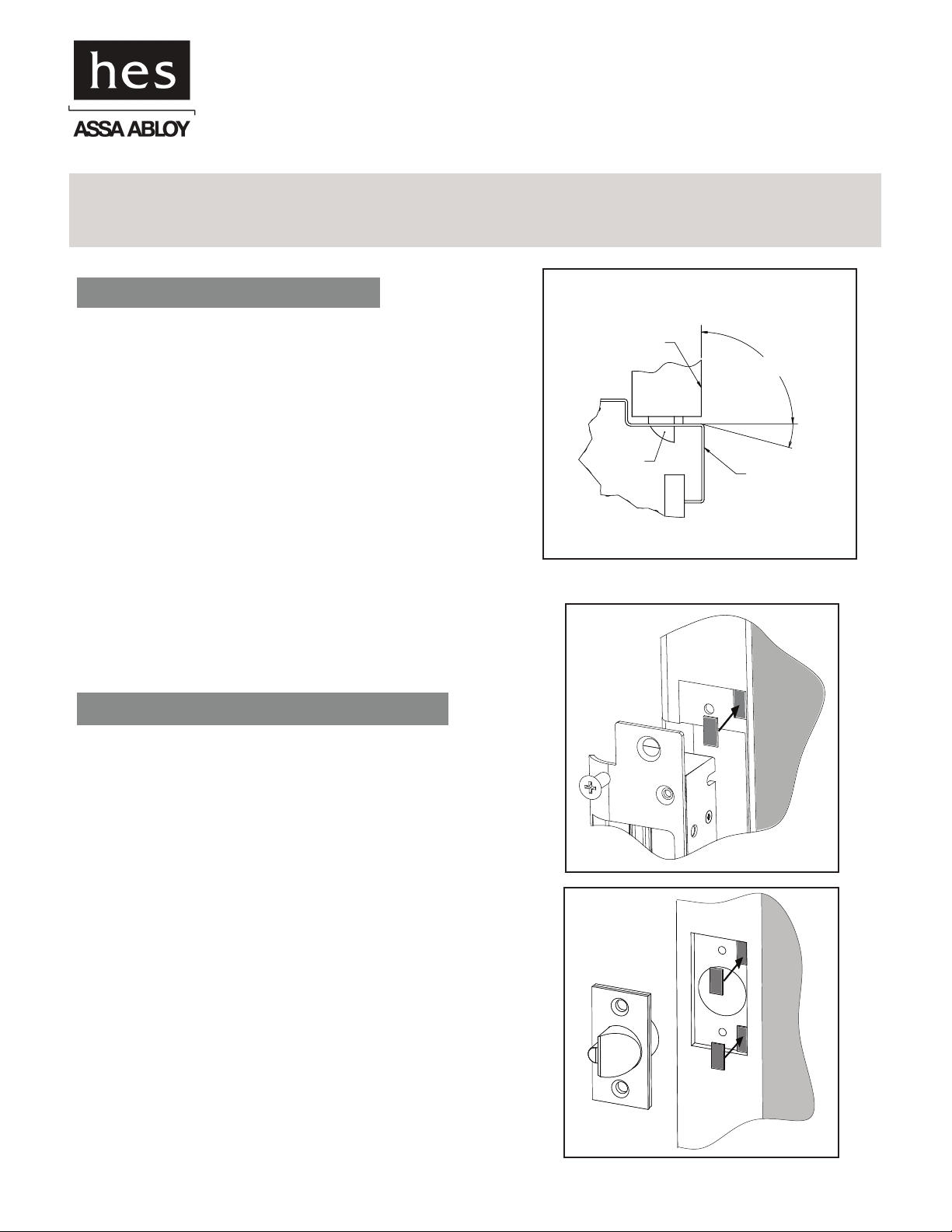

EVALUATE OPENING

Although the design of the 8000/8300 provides adjustability to

compensate for frame and door irregularities, in some cases, adjust

ing the frame and door back to industry standards is just not

an option. Here are some tips to quickly compensate for frame

twist and to determine the condition of the latch bolt.

One way to measure frame twist is to place a carpenter square

on the stop and the face of the door. If the angle is less than 90

degrees, the 45 degree ramp angle of the 8000/8300 is steepened and

may need to be corrected as shown at right.

DOOR FACE

LATCH BOLT

90°

OPTIMUM ANGL E

FRAME SECTION

FACE OF

FRAME RABBET

IMPROVED

PERFORMANCE

ZONE

We also recommend you check the condition of the latch bolt

prior to installing the 8000/8300. Poorly constructed, worn out or

damaged latch bolts may not slide along a ramp at any angle. To

check the condition of your latch bolt, we recommend applying

a slight force to the tip of the latch bolt (about 45 degrees to

door face). Make sure the latch bolt can be pushed up into the

door.

ACCOMMODATING FRAME TWIST

When a frame is twisted, the relationship between the face of a

closed door and of the inside face of the frame (i.e. Rabbet) may

not meet the 90 degree industry standard. Untrue frames and

doors impact latch bolt wear and the force required to exit, so

we recommend you ensure that the angle is between 90 ~ 95

degrees.

If manipulating the frame is not possible, we recommend plac ing several shims under the top and bottom (stop side) of the

faceplate (Image right). This eectively increases the 8000/8300 ramp

angle and compensates for frame twist. This can also be per formed by placing shims under the top and bottom (bevel side)

of the latchbolt (Image below right).

3068006.002 rev B.

© 2009 HES, Inc.

Loading...

Loading...