Page 1

Installation Instructions

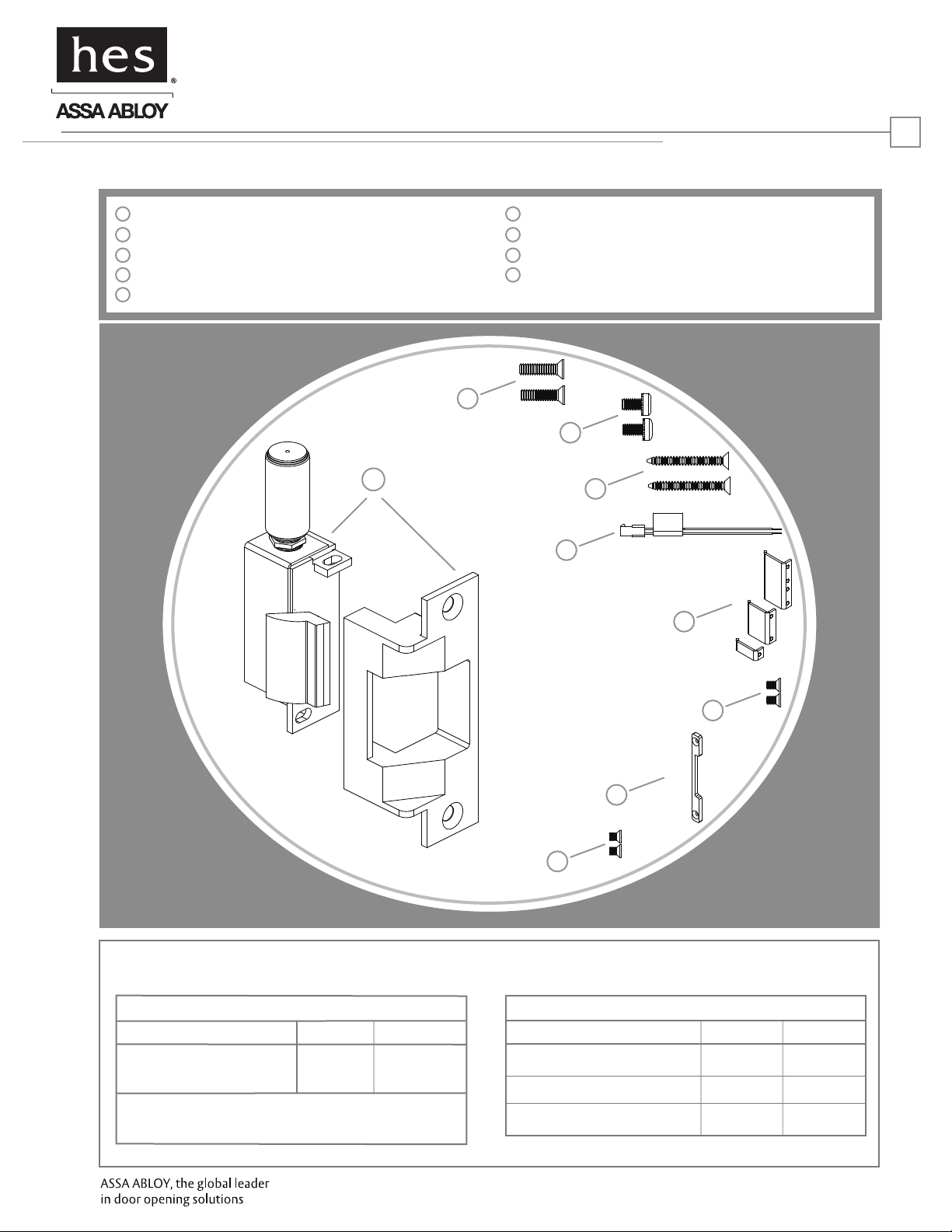

Folger Adam 700 Series Electric Strike

Product Components

HES, Inc.

22630 N. 17th Ave.

Phoenix, AZ 85027

800-626-7590

www.hesinnovations.com

1

1

Electric Strike Body & Faceplate

2

#12-24 Faceplate Mounting Screws

3

#8-32 Body Mounting Screws

4

#12 x 2 1/2” Wood Faceplate Mounting Screws

5

Plug In Connector

1

6

Deadlatch Tabs (742-75 only)

7

#6-32 x 5/16” Deadlatch Tabs Screws (742-75 only)

8

Keeper Shim (742-75 only)

9

#6-32 x 3/16” Keeper Shim Screws (742-75 only)

2

3

4

5

6

Electrical Specifications

ELECTRICAL RATINGS FOR SOLENOID

CONTINUOUS DUTY

Resistance in Ohms

Amps

12VDC

41

.29

Solenoids are rated at +/- 10% indicated value.

24VDC

160

.15

7

8

9

MINIMUM WIRE GAUGE REQUIREMENTS

SOLENOID VOLTAGE

200 feet or less

200 - 300 feet

300 - 400 feet

12VDC

18 gauge

16 gauge

14 gauge

24VDC

18 gauge

18 gauge

16 gauge

Page 2

Installation Directions

CAUTION! Before connecting any device at the installation site, verify input voltage using a multimeter.

Many power supplies and low voltage transformers operate at higher levels than listed. Any input voltage exceeding

10% of the solenoid rating may cause severe damage to the unit and will void the warranty.

2

Prepare Strike

1. Attach the faceplate to the strike body using the

#8-32 Body Mounting screws as illustrated on page 3,

Diagram 2.

2. If using the LCBLCM (Latchbolt & Locking Cam Monitor),

see Diagram 1 for wiring

instructions.

3. The strike body ships as either a 12 or 24 volt

unit and is not field selectable. Verify the available

voltage is +/- 10% of the rated voltage of the strike body.

Prepare Frame

4. If using a mortise lockset, calculate offset using Diagram

3 on page 3.

5. Prepare frame using the template for your strike

located on pages 4-6. If using the 742-75, see the 742-75

template on page 3 to install the Deadlatch Tab and

Keeper Shim. Note: Drawing shows only one shim.

Finish Installing

6. Connect the Plug In Connector to the electric strike, and

connect wires from the Plug In Connector leads to the

power source.

7. Install the electric strike unit in jamb cutout, using the

#12-24 x 1/2” faceplate mounting screws for metal

applications, or #12 x 2-1/2: wood screws for wood

applications.

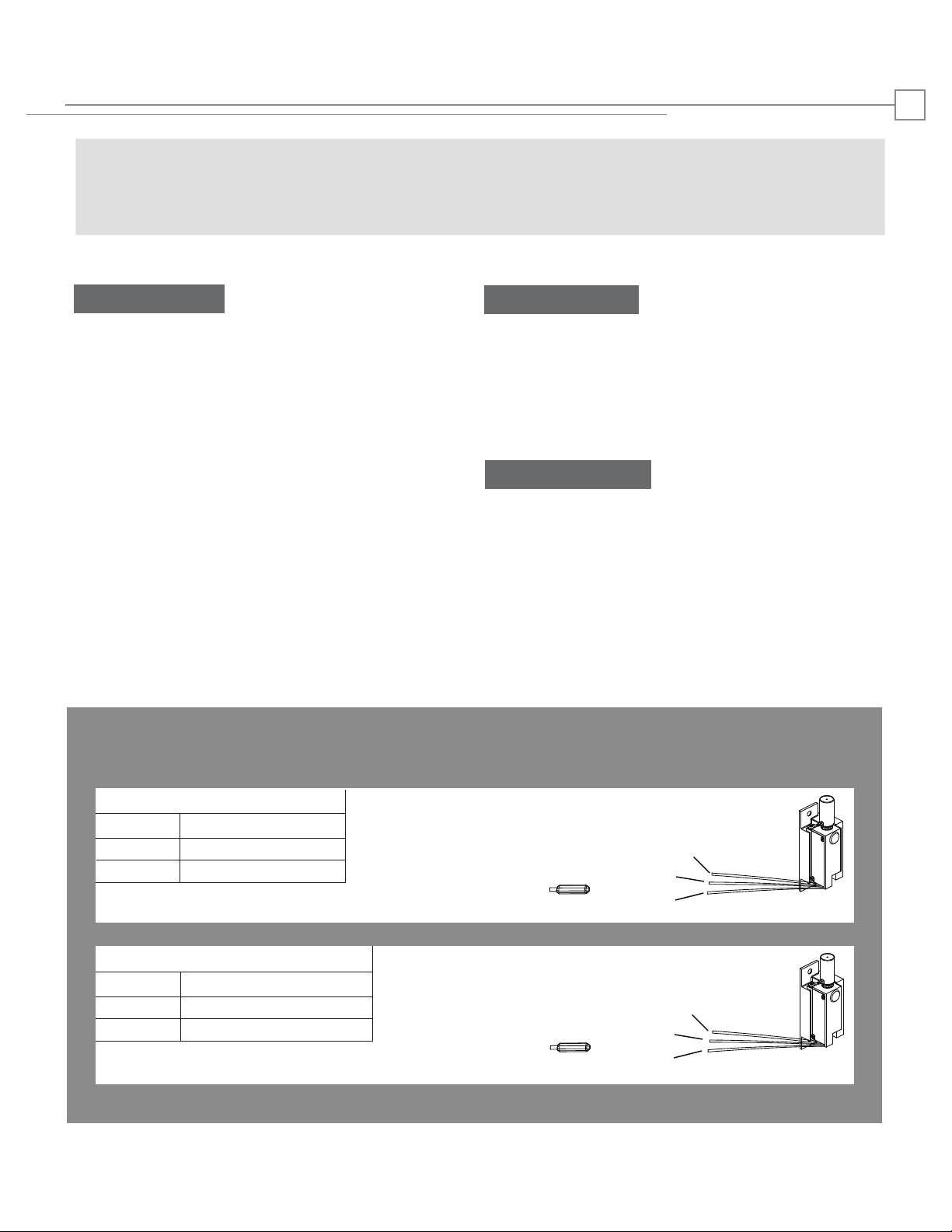

Diagram 1: Monitoring Switches

Latchbolt Monitor (LBM)

White

Orange

Green

Locking Cam Monitor (LCM)

Brown

Blue

Yellow

Common

Normally Open

Normally Closed

Common

Normally Open

Normally Closed

White

Orange

Green

Brown

Blue

Yellow

Page 3

Installation Directions

Diagram 2: Faceplate Attachment

To install the 700 series electric strike body to the

faceplate, install two #8-32 Body Mounting screws

as shown. Make sure bolts are tightened and secured.

Keeper position can be adjusted by loosening the #8-32

body mounting screws, and repositioning the strike body

as needed. Retighten body mounting screws after

adjustment is made

3

C

L

Mortise

Door Prep

[101.60]

8”

[203.20]

4”

Diagram 3: Determining Mortise Offset

MORTISE LOCK B

CORBIN/RUSSWIN

ARROW, FALCON

B

BEST 34H-37H 1/4"

SARGENT (8200)

C

L

Strike

YALE (8800)

SCHLAGE

YALE (8700) 7/8"

BEST 45H & 47H* 1/8"

0"

3/16"

3 /4"

*Best 45H & 47H are recommended for

use with the 742-75 only.

Page 4

Cutout Templates

712 Template & Dimensions

Method of install may vary per door & frame manufacturer

1-1/4”

[31.75]

5/8”

[15.88]

4-7/8"

[123.83]

(RHRB APPLICATION SHOWN)

Inches [mm]

1-5/8”

[41.3]

4

3-3/8"

[85.72]

1-1/4”

[31.75]

5/8”

[15.88]

1-1/2"

[38.10]

4-1/8"

4-1/8”

[104.78]

4-7/8”

[123.83]

[104.78]

3-3/8”

[85.72]

1/2”

[13]

1-1/4”

[31.75]

712-75 Template & Dimensions

Method of install may vary per door & frame manufacturer

(RHRB APPLICATION SHOWN)

6”

[152.4]

1/8”

[3.5]

1-1/2”

[38.10]

1-7/8”

[47.6]

3-3/8"

[85.72]

1-1/2"

[38.10]

[123.83]

4-1/8"

[104.78]

4-7/8"

3-3/8”

[85.7]

1/2”

[13]

1-1/4”

[31.8]

4-1/8”

[104.8]

4-7/8”

[123.8]

6”

[152.4]

1/8”

[3.5]

1-1/2”

[38]

Page 5

Cutout Templates

732 Template & Dimensions

Method of install may vary per door & frame manufacturer

1-1/4”

[31.75]

5/8”

[15.88]

[123.83]

4-1/8"

[104.78]

3-3/8"

[85.72]

(RHRB APPLICATION SHOWN)

4-7/8"

Drill 1" Dia. Hole thru,

for wires & solenoid.

C

L

1-5/16”

[26.34]

3-3/8”

[85.72]

1/2”

[12.70]

1-1/4”

[31.75]

4-1/8”

[104.78]

4-7/8”

[123.83]

1-5/8”

[41.3]

1-1/2”

[38.10]

5

Inches [mm]

1-1/4”

[31.75]

5/8”

[15.88]

3-3/8"

[85.72]

1-1/2"

[38.10]

C

L

31/32”

[24.5]

[19.05]

732-75 Template & Dimensions

Method of install may vary per door & frame manufacturer

4-7/8"

[123.83]

4-1/8"

[104.78]

Drill 1" Dia. Hole thru,

for wires & solenoid.

(RHRB APPLICATION SHOWN)

1-5/16”

[26.34]

3/4”

[12.70]

3-3/8”

[85.72]

1/2”

3-5/8”

[92.2]

1-1/4”

[31.75]

4-1/8”

[104.78]

1/8”

[3.5]

4-7/8”

[123.83]

1-7/8”

[47.6]

1-1/2”

[38.10]

1-1/2"

[38.10]

C

L

C

L

31/32”

[24.5]

3/4”

[19.05]

3-7/8”

[98.4]

1/8”

[3.5]

Page 6

Frame Preparation

742-75 Dimensions and Template

4500 WITH SCHLAGE AND YALE MORTISE LOCKS

Method of install may vary per door & frame manufacturer

1-1/4”

[31.75]

5/8”

[15.88]

4-7/8"

[123.83]

(RHRB APPLICATION SHOWN)

3/4"

[18.8]

3/8"

[9.3]

Inches [mm]

Ø

3/4"

[19.1]

1/8"

[3.2]

6

3-3/8"

[85.72]

1-1/2"

[38.10]

4-1/8"

[104.78]

4-7/8"

[123.4]

3-3/8"

[85.7]

9/16"

[14.8]

4-1/8"

[104.8]

5/8"

[15.9]

1-1/4"

[31.5]

6-5/16"

[159.9]

1-15/16"

[49]

1-1/2"

[38.1]

If additional horizontal adjustment is

needed, install the keeper shim using

the #6-32 x 3/16” keeper shims screws

as illustrated.

3831006.001 rev B

Several deadlatch tabs are included for

use with the 742-75. Choose, and position

the deadlatch tab so that the deadlatch is

depressed when the door is closed, while

staying clear of the latchbolt.

Install the deadlatch tab using the

#6-32 x 5/16” deadlatch tab screws as

illustrated.

© 2010 HES, Inc.

Loading...

Loading...