Page 1

Installation Instructions

®

Multi-Purpose Lock

Product Components

HES, Inc.

Phoenix, AZ 85044

800-626-7590

www.hesinnovations.com

1

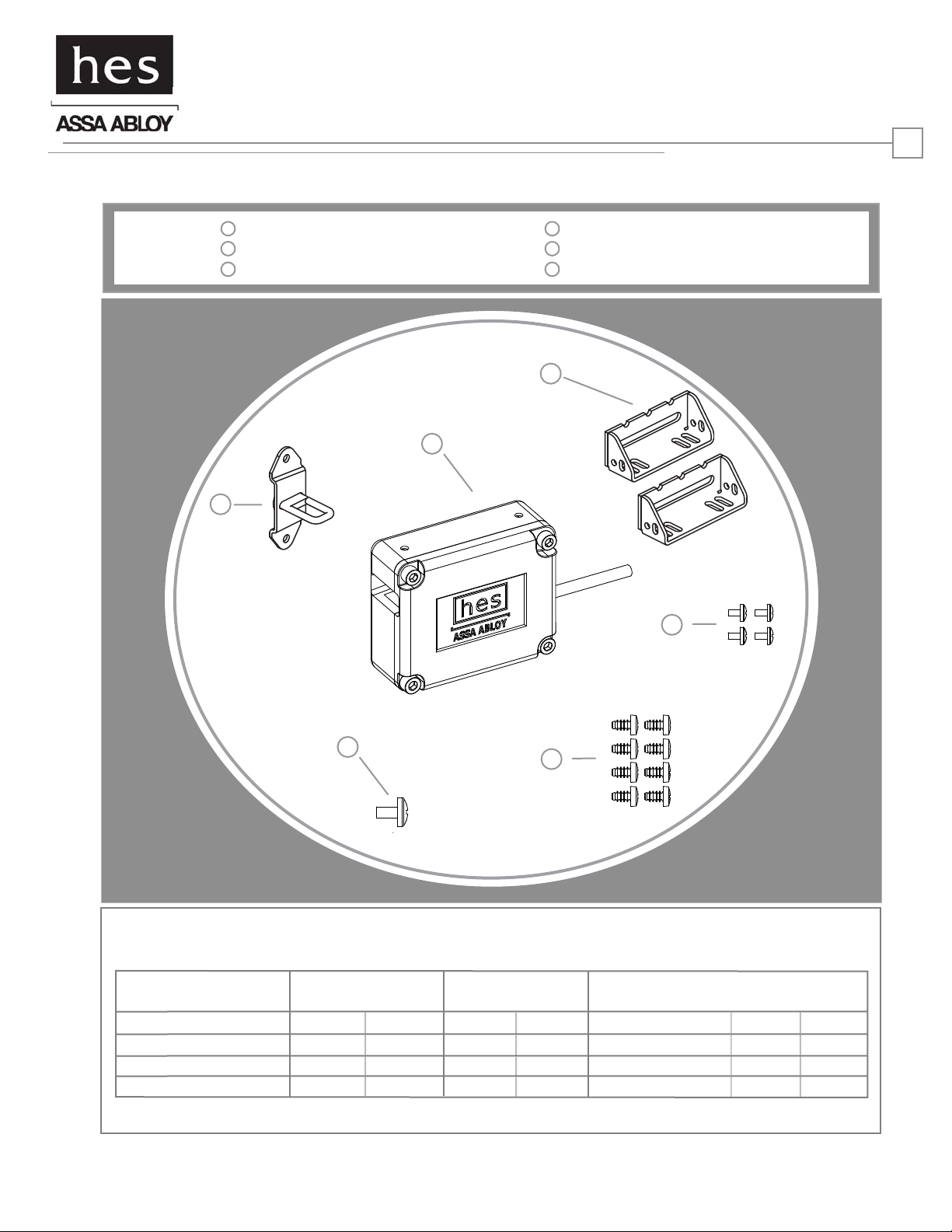

1

Hook Bracket Assembly

2

660 Multi-Purpose Lock Body

3

Lock Mounting Brackets

1

4

#6-32 X 3/16” Screws

5

#10 X 1/2” Screws

6

#8-32 X 5/8” Screw

3

2

4

6

Electrical Specifications

ELECTRICAL RATINGS

FOR SOLENOID

Operating Voltage +/- 10%

Resistance in Ohms

Watts Seated

Amps Seated

ASSA ABLOY, the global leader

in door opening solutions

CONTINUOUS DUTY

STANDARD

12VDC

48

33

250mA 125mA

24VDC

192

5

INTERMITTENT DUTY

PRELOAD

12VDC1724VDC

67.8

8.4 8.4

700mA 350mA

MINIMUM WIRE GAUGE REQUIREMENTS

SOLENOID VOLTAGE 12VDC 24VDC

200 feet or less

200 - 300 feet

300 - 400 feet

14 gauge

12 gauge

12 gauge

18 gauge

18 gauge

16 gauge

Page 2

Installation Directions

CAUTION! Before connecting any device at the installation site, verify input voltage using a multimeter.

Many power supplies and low voltage transformers operate at higher levels than listed. Any input voltage exceeding

10% of the solenoid rating may cause severe damage to the unit and will void the warranty.

2

WARNING: The Multi-Purpose Lock Body must

be wired to a power source prior to insertion of the

Hook Bracket Assembly. Failure to do so may result

in a permanently locked cabinet/drawer.

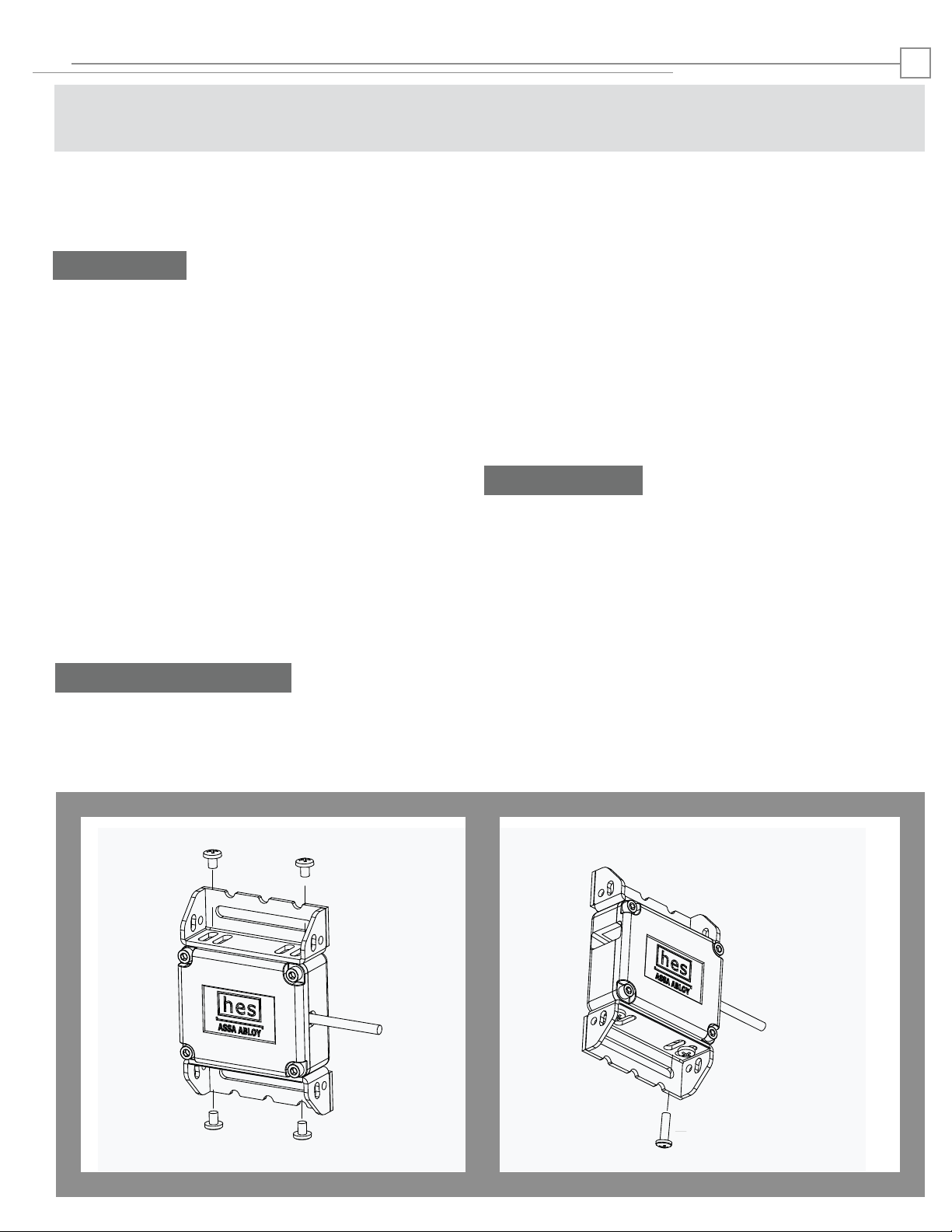

Prepare Lock

1. Attach both Lock Mounting Brackets to the

Multi-Purpose Lock Body using four #6-32 x 3/16”

screws as illustrated in Diagram 1.

2. To prevent accidental capture of the Hook

Bracket Assembly prior to the Multi-Purpose Lock

Body being wired, gently thread the #8-32 X 5/8”

screw into the #8-32 threaded hole depicted in

Diagram 2. The #8-32 X 5/8“ screw must only be

tightened snug by hand.

When installed the #8-32 X 5/8” screw will prevent

the capture of the Hook Bracket Assembly by the

Multi-Purpose Lock Body. When wiring is complete,

remove the #8-32 X 5/8” screw. The Multi-Purpose

Lock Body will now be able to capture and

electrically release the Hook Bracket Assembly.

Prepare Cabinet/Drawer

4. Refer to Diagram 4 on page 3 to connect power to the

Multi-Purpose Lock Body. If your Multi-Purpose Lock is

equipped with the RJ-45 option, a diagram for pin

assignments is also provided on page 3, Diagram 4.

If applicable, the LBSM should also be electrically

connected at this time. Remove the #8-32 X 5/8” screw

installed in step 2. Verify catch and release of the

unmounted Hook Bracket Assembly after power is

connected.

5. Mark mounting holes for the Hook Bracket Assembly as

illustrated on page 4, Diagram 5. Drill two 1/16” X 1/2”

deep pilot holes for the Hook Bracket Assembly, and mount

the Hook Bracket Assembly using two #10 X 1/2” screws.

Finish Installing

6. If lock body adjustment is needed to ensure a smooth

capture and release of the hook bracket assembly, loosen

the #10 X 1/2” and #6-32 X 3/16“ screws to adjust the

Multi-Purpose Lock Body until desired clearance is reached.

7. If additional stability is desired, drill two 1/16” pilot holes

and use two remaining #10 X 1/2” screws for final lockdown

of the Multi-Purpose Lock Body as illustrated in Diagram 6,

on Page 4.

3. Drill four 1/16” diameter pilot holes in the cabinet

using the Mounting Template on page 3, and mount

the Multi-Purpose Lock Body to the inside of the

cabinet/drawer using four #10 X 1/2” screws.

8. If the optional key override is used, prepare the

cabinet/drawer as illustrated in Diagram 7, on Page 4.

DIAGRAM 1: MOUNTING BRACKET INSTALLATION DIAGRAM 2: #8-32 X 5/8” SCREW INSTALLATION

#8-32 X 5/8” SCREW

*SHOWN IN LH CONFIG

Page 3

Installation Directions

/

DIAGRAM 3: MOUNTING TEMPLATE

DIAGRAM 6: HOOK BRACKET INSTALLATION

Align dotted line with outer edge of cabinet.

Tape Model 660 Mounting Template to inside

surface of cabinet.

Drill four 1/16” holes through paper template.

Model 660 Mounting Template

DRAWER

MODEL 660

LOCK ASSEMBLY

OLD LINE ON EDGE OF DOOR

FOLD LINE ON EDGE OF CABINET

3

DIAGRAM 4: POWER & LBSM SWITCH WIRING

POWER WIRING*

RED

BLACK Negative -

*CAUTION! The Multi-Purpose Lock

Body is provided as either a 12 or 24

volt unit. Verify the power supply

output before operating this device.

Positive +

RED +

BLACK -

LBSM WIRING*

White

Orange Normally Open

Green Normally Closed

Common

PIN4: LBSM (COMMON) - BLUE

PIN5: POWER (NEGATIVE) - BLUE/WHITE

12345678

RJ-45 OPTION

PIN6: LBSM (NORMALLY CLOSED) - GREEN

PIN7: POWER (POSITIVE) - BROWN/WHITE

PIN8: LBSM (NORMALLY OPEN) - BROWN

RJ-45 PLUG

PIN1

White

Orange

Green

*If applicable

o O g B b G br BR

Clip is pointed

away from you

Page 4

Installation Directions

DIAGRAM 5: HOOK BRACKET INSTALLATION

4

7/16”

1/16”

1-11/16”

config

shown

Inside surface

of Cabinet

Inside surface

of cabinet

DIAGRAM 6: FINAL LOCKDOWN DIAGRAM 7: OPTIONAL KEY OVERRIDE

X=1/4” + R1

Y= 2-1/8” + R1

2-1/8” + R1

Left hand

Y

(2) #10 X 1/2” SCREWS FOR

FINAL LOCKDOWN

3/16”

[5]

1”

[25.4]

1-11/16”

[43.1]

1-11/16”

[43.1]

DIAGRAM 8: DIMENSIONS

1/8”

[3.8]

1”

[25.3]

1-7/8”

[46.9]

3/16”

[5]

PADDLE: 660

KO OPTION

R1

X

1/4” + R1

MOUNTED TO

DOOR/DRAWER

2-11/16”

[68.5]

3-3/8”

[85.4]

3056006.001 rev B.

15/16”

[23.3]

1-5/8”

[40.6]

2-5/16”

[58.4]

© 2012 HES, Inc.

Loading...

Loading...