Page 1

Engineered Humidification Systems

READ AND SAVE THESE INSTRUCTIONS

Herrtronic® MDD

Supplemental Manual

Herrmidifier® | www.herrmidifier-hvac.com

Page 2

Installation, Operation, & Maintenance Manual

TABLE OF CONTENTS

I. Preface ..............................................................................................................................................3

II. Unit Operation ...................................................................................................................................3

Product Diagram ......................................................................................................................... 3

III. Mounting Instructions .......................................................................................................................4

Mounting Location ....................................................................................................................... 4

Unit Dimensional Data ................................................................................................................4

IV. Plumbing Instructions ...................................................................................................................... 5

Bottom View – Plumbing Connections ........................................................................................ 5

Drain Diagram ............................................................................................................................. 6

V. Steam Distribution ............................................................................................................................ 7

VI. Supply Power ..................................................................................................................................7

Steam Output Chart .................................................................................................................... 7

VII. MDD Control Circuit Connections ..................................................................................................7

Dependent Control ...................................................................................................................... 7

Independent Control ...................................................................................................................7

Electrical Compartment ............................................................................................................... 7

VIII. Factory Wiring Between the Master and Slave Controls ............................................................... 8

Dependent Controls .................................................................................................................... 8

Independent Controls .................................................................................................................. 8

IX. Turning the Master and Slave “ON” After Servicing the Unit ........................................................... 8

X. Plumbing Components Diagram ......................................................................................................9

XI. Plumbing Components Parts List .................................................................................................... 9

XII. Electrical Components Diagram ..................................................................................................... 10

XIII. Electrical Components Parts List ..................................................................................................10

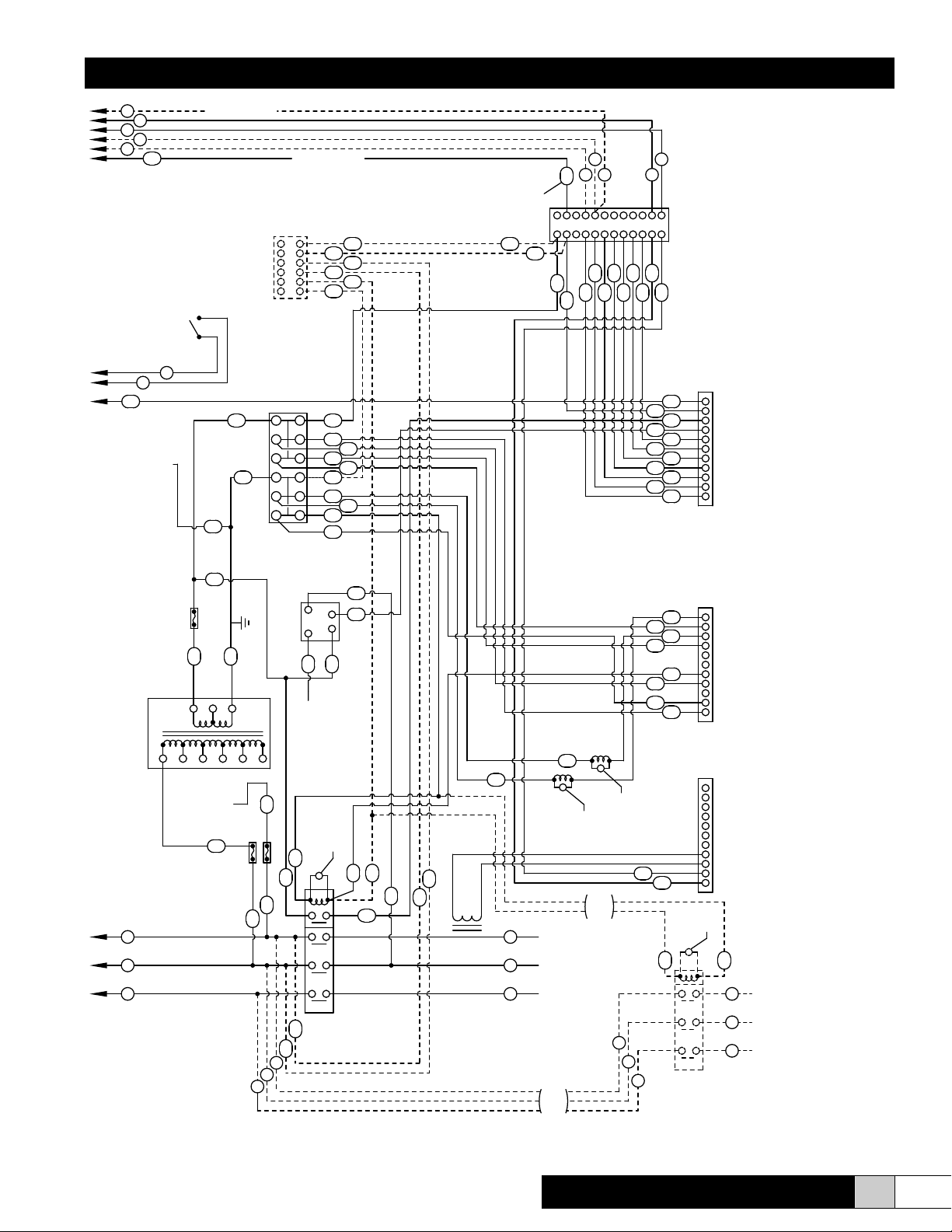

XIV. Wiring Diagram (208/230/460) ...................................................................................................... 12

XV. Alternate Wiring Diagram (For units with 380 or 600 Volt Primary Circuits) ................................... 14

2 www.herrmidifier-hvac.com

Herrtronic® MDD Supplement

Page 3

Installation, Operation, & Maintenance Manual

I. PREFACE

These instructions are designed to cover the specic differences in the installation of a Herrmidier Herrtronic MDD Electronic Steam

Humidier (110-250 lbs/hr. unit) versus an MDM or MDS Electronic Steam Humidier (5-100 lbs/hr. unit). These instructions are to

be used in conjunction with the Herrtronic MD Series Installation and Operations Manual (OM-93) as there are cross references

between that manual and this supplement. The primary intent of this supplement is to deal with the installation differences between

the MDD and the MDS or MDM. The operating, start-up and troubleshooting sections are common to all the MD’s and can be found

in the Herrtronic MD Series Installation and Operations Manual (OM-93). The one exception to this is the fact that you must turn

on both the master and the slave unit with their respective “On/Off” button.

II. UNIT OPERATION

All MDD units are operationally tested before shipment. They have been setup and run with the control signal and power supply spec-

ied on the purchase order. Any changes in power supply or control technique will cause the unit to require changes prior to start-up.

All MDD units have two steam cylinders, two ll assemblies, two drain assemblies, two sets of power contactors, two main circuit

boards and one display board. There are two knockouts for power wiring, a knockout for control wiring, one water inlet, two steam

cylinder drains, and two cabinet drains. The steam cylinder on the right is the master and the one on the left is the slave. Simply put,

the components for two independent steam boilers are housed in one cabinet.

Steam Hose Outlets

Slave Section

Steam Cylinder Assembly

Drain Assembly

Steam Hose Outlets

Master Section

Steam Cylinder Assembly

(2) Fill Assemblies

Drain Assembly

Electrical Section

Contactors

Transformers

Cylinder Interface

Terminal Blocks

Circuit Boards - Master

Slave

Display

Power wiring

Plumbing Connections

(2) Steam Cyliner/Cabinet Drains

Controls

Wiring

Plumbing Connections

(1) Water Inlet

Figure 1

As mentioned earlier, there are two main circuit boards, and one display board. The master and slave control board keypads are

accessible through the front panel. Communication between the Master and the Slave is accomplished through the networking

capability of the main circuit board (Page 15, MD IOM). The address of the master will always be 00 and the address of the slave

will always be 01. Each cylinder (Master or Slave) will ll, boil, and drain independently, based on the commands from their respective main circuit board. Establishing set points, operating the units, fault reporting and general monitoring of performance for both

Master & Slave is typically done from the master control keypad and display using menu 4 of the master control. When in menu 4 of

the Master, access the Slave and use the Master keypad to make any necessary changes to the Slave control board. (See step 13

Operating Instructions of MD Manual.)

Herrtronic® MDD Supplement

www.herrmidifier-hvac.com

3

Page 4

Installation, Operation, & Maintenance Manual

III. MOUNTING INSTRUCTIONS

The Operating Weight of the MDD Series is 258 lbs. See Page 6 of the MD IOM for further information.

16.00

4.00

3.00

22.38

1.81 21.89 17.00

Figure 2 - Mounting Location (Back View of Unit)

5-3/4"

6.2516.004.25

.75 Typ.

Ø.38" x Ø.75"

Keyhole Slot

Typ.

Ø.25 Typ.

28"

19 5/16"

11 1/2"

REF.

4"

17"

4"

Steam Outlet

1 1/2" I.D. Hose

(4 places)

3"

43"

Recessed Bottom

Figure 3 - Unit Dimensions

4 www.herrmidifier-hvac.com

Herrtronic® MDD Supplement

Page 5

Installation, Operation, & Maintenance Manual

IV. PLUMBING INSTRUCTIONS

Figure 4 details the unit’s plumbing connections. All plumbing connections are through the bottom of the unit. There are two unit

drains and one ll connection.

33 1/8"

Fill Connection

1/4" Compression

4 1/4"

17"

2"

Knockout for

Control Wiring

(7/8 X 1 1/8)

2 11/32"

Typ.

Unit/Cabinet Drain Resevoir

3/4" I.D. Hose

2 19/32""

Typ.

Figure 4 - Plumbing Connections

17"

16"

3"

3"

6 1/2"

(2) Knockouts

for Main Power Supply

(1 1/4 x 1 3/4)

Herrtronic® MDD Supplement

www.herrmidifier-hvac.com

5

Page 6

Installation, Operation, & Maintenance Manual

MASTER DRAIN RESEVOIR

Figure 5 - Drain Diagram

3/4" MIN. I.D./1" MAX O.D.

FLEXIBLE DRAIN CONNECTION

SLAVE DRAIN RESEVOIR

8"

RECOMMENDED

T YP.

BALANCE OF DRAIN LINE TO BE 1" MIN. I.D.

WITH A MINIMUM PITCH OF 1/8" PER 12" OF RUN

4"

RECOMMENDED TYP.

6" MIN. LENGTH OF 1-1/4" MIN. I.D. COPPER LINE.

IF PVC IS USED, LOCAL CODES REQUIRE A LOWER

TEMPERATURE DRAIN WATER IS NOT UNCOMMON.

6 www.herrmidifier-hvac.com

6" MIN. LENGTH OF 1-1/4" MIN. I.D. COPPER LINE.

IF PVC IS USED, LOCAL CODES REQUIRE A LOWER

TEMPERATURE DRAIN WATER IS NOT UNCOMMON.

BALANCE OF DRAIN LINE TO BE 1" MIN. I.D.

WITH A MINIMUM PITCH OF 1/8" PER 12" OF RUN

Herrtronic® MDD Supplement

Page 7

Installation, Operation, & Maintenance Manual

V. STEAM DISTRIBUTION

Refer to Herrtronic MD IOM for detailed instructions. See Figure 3 on page 9 – Unit Dimensional Data for steam outlet locations.

VI. SUPPLY POWER

Power Block is supplied in the lower right hand side of the electrical compartment for eld connection of the main power supply legs

(always three phase) and a ground wire. Engineering Data: Steam Output / Electrical Characteristics

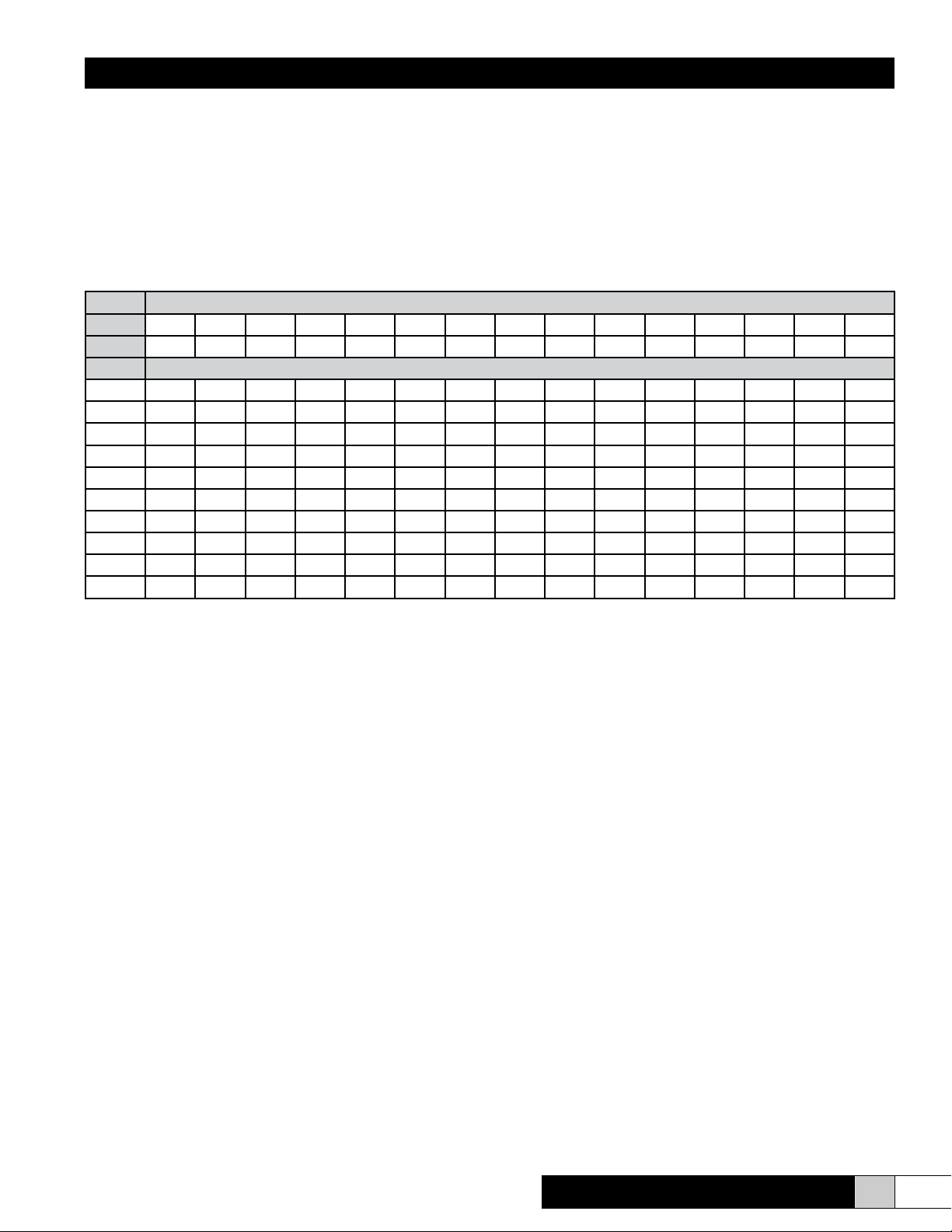

Figure 6 - Steam Output/Electrical Characteristics:

Steam Output

Lb/hr 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250

Kg/hr 50.0 54.4 59.1 63.6 68.2 72.6 77.3 81.7 86.4 90.9 95.5 100 104.5 109.1 113.6

Voltage Electrode Current (amps)

208

101.7A 110.9A 120.2A 129.4A 138.6A 147.9A 157.1A 166.4A 175.6A 184.9A

220

230

240

380

440

460

480

575

600

KW = .333 X Lbs/Hr

Amps(3Ph) = KW X 1000 / (Voltage X 1.732)

Min. Circuit Ampacity = 1.25 X Rated Electrode Current (Note: with RDU add .5 Amps @ 208/240 Volts or add .25 Amps @ 480 Volts)

Minimum Circuit Ampacity determines wire size (AWG)

96.1A 104.9A 113.6A 122.3A 131.1A 139.8A 148.6A 157.3A 166.0A 174.8A

91.9A 100.3A 108.7A 117.0A 125.4A 133.7A 142.1A 150.5A 158.8A 167.2A

88.1A 96.1A 104.1A 112.2A 120.2A 128.2A 136.2A 144.2A 152.2A 160.2A

55.7A 60.7A 65.8A 70.8A 75.9A 81.0A 86.0A 91.1A 96.1A 101.2A 106.2A 111.3A 116.4A 121.4A 126.5A

48.1A 52.4A 56.8A 61.2A 65.5A 69.9A 74.3A 78.7A 83.0A 87.4A 91.8A 96.1A 100.5A 104.9A 109.2A

46.0A 50.2A 54.3A 58.5A 62.7A 66.9A 71.1A 75.2A 79.4A 83.6A 87.8A 91.9A 96.1A 100.3A 104.5A

44.1A 48.1A 52.1A 56.1A 60.1A 64.1A 68.1A 72.1A 76.1A 80.1A 84.1A 88.1A 92.1A 96.1A 100.1A

36.8A 40.1A 43.5A 46.8A 50.2A 53.5A 56.8A 60.2A 63.5A 66.9A 70.2A 73.6A 76.9A 80.2A 83.6A

35.2A 38.5A 41.7A 44.9A 48.1A 51.3A 54.5A 57.7A 60.9A 64.1A 67.3A 70.5A 73.7A 76.9A 80.1A

Refer to Herrtronic MD Installation, Operation, & Service manual for additional information.

VII. MDD CONTROL CIRCUIT CONNECTIONS

Dependent Control

This is the typical control circuit application for the MDD units. In this conguration, the MASTER and SLAVE equally share the total

output That is, for a 140 lbs/hr. MDD, the MASTER will produce 70 lbs/hr. and the SLAVE will also produce 70 lbs/hr. If the MDD

has the capability to modulate its output (MDDI or MDDP), the output of the MASTER and the SLAVE will remain equal throughout

the proportioning range.

The Dependent MDD requires one set of controls; a control input, a recommended limit input and air proving switch. See pages 10

and 11 of the MD IOM for proper placement of the control wires to the appropriate pole(s) on the master unit terminal strip.

Independent Control

In this conguration, the MASTER and the SLAVE may be rated for different output capacities. The data plate will reect the combined output and current draw. If the output capacities of the MASTER and SLAVE are different, the MASTER will always be the

larger of the two unless specied otherwise when ordering.

The Independent MDD requires two sets of controls; two control inputs along with the recommended individual limit inputs and air

proving switches. The MASTER and SLAVE input connections will be made on their respective terminal strips (Figure 7). Refer to

the Control Circuit Connections section of the MD IOM (pages 10 and 11) for proper terminal connections for your particular type of

controls. The units will operate independently of one another, with the circuit boards responding to their individual inputs.

Herrtronic® MDD Supplement

www.herrmidifier-hvac.com

7

Page 8

Installation, Operation, & Maintenance Manual

MASTER TERMINAL STRIP

DISCONNECT THE POWER

CAUTION:

SUPPLY BEFORE SERVICING

ATTENTION:

DECONNECTER DU

CIRCUIT D'ALIMENTATION

ELECTRIQUE AVANT L'ENTRETIEN

1 32 4 65 1 32 654

2

50 to 600 VAC

50/60 Hz

EST1003PB

Control

24

PCB

VAC

3

4

1

2

50 to 600 VAC

50/60 Hz

EST

003PB

24

Control

VAC

SLAVE BOARD

COMMON DISPLAY

MASTER BOARD

PCB

4

3

1 3 5 7 119

82 64 1210

SLAVE TERMINAL STRIP

WARNING

TO REDUCE THE RISK

OF FIRE, REPLACE

ONLY WITH THE SAME

TYPE 2 AMP FUSE.

WARNING

TO REDUCE THE RISK

OF FIRE, REPLACE

ONLY WITH THE SAME

TYPE 4 AMP FUSE.

2 4 6 8

7531

119

1210

CAUTION

USE SUPPLY WIRING

SUITABLE FOR 90°C

USE COPPER CONDUCTORS ONLY

FOLLOW TORQUE REQUIREMENTS

LISTED ON THE SIDE OF THE

POWER BLOCK.

ETL LISTED

HUMIDIFIERS

Conforms to

R

LISTED

ANSI/UL-998

33964

ETL TESTING LABORATORIES, INC.

CORTLAND, NEW YORK 13045

MODEL NO.

VOLTS/Ph/Hz

/ /

AMPS

MAX.

MAX.

LBS/HR

/ /

SER.NO.

DATE

HERRTRONIC

TRION INC.

HERRMIDIFIER

A TRION Company

SANFORD, NC USA

Figure 7 - Electrical Compartment

VIII. FACTORY WIRING BETWEEN THE MASTER AND SLAVE CONTROLS

Dependent Controls: Factory Wiring Included the Following:

1. Jumpers between Master terminal strip, terminals 11 & 12 to the Slave terminal strip, terminals 11 & 12. This wiring allows communication from the Master to the Slave via the Master Keypad, utilizing the communication functions of Menu 4 in the Master

menu.

2. Jumpers between Master terminal strip, terminal 2 to the Slave terminal strip, terminal 2. This wiring allows the use of an optional

air ow switch wired to the Slave terminal strip. This wire would negate the use of second air ow switch.

3. For Proportional and Proportional/Integral Control Units Only (See MDD wiring diagram). Wiring from the Master Molex connector J1, terminals 1 & 2 to the Slave terminal strip, terminals 4 & 5. This wiring passes the humidity sensor or BMS control input

that has been received by the Master to the Slave control board. This allows the Slave to “share” the control input with the Master

and operate in parallel with the Master.

4. For On/Off Control Units Only (See MDD wiring diagram). Wiring from Master terminal strip, terminal 5 to the Slave terminal

strip, terminal 5. This wiring passes the On/Off control signal that has been received by the Master to the Slave control board.

Independent Control: Factory Wiring Includes the Following:

1. Jumpers between Master terminal strip, terminals 11 & 12 to the Salve terminal strip, terminals 11 & 12. This wiring allows

communication from the Master to the Slave via the Master keypad, utilizing the communication functions of Menu 4 in the

Master menu.

IX. TURNING THE MASTER AND SLAVE “ON” AFTER SERVICING THE UNIT

During servicing, the Master and Slave cabinet access doors are typically removed to gain access to the unit. Both of these cabinets have a door interlock switch for safety purposes. Whether the door interlock switches are taped closed or jumped-out during

service, when the tape/jumpers are removed from the interlock switches, and the cabinet access doors are re-installed following

maintenance, BOTH THE MASTER AND SLAVE MUST BE TURNED “ON” at the keypad to put the unit back in service. Both the

Master and Slave must be in the Menu 1 default menu for “on/off” button to work. If only the Master is turned ON, the Slave cabinet

will remain inoperative.

Prevent the unit from operating at only 50% capacity by ensuring that BOTH THE MASTER AND SLAVE ARE

TURNED “ON” after servicing the equipment.

Options for Turning ON/OFF Slave:

1. Use “Slave” On/Off button

2. Use “Master” Keypad to address “Slave” via communications. (Menu #4)

8 www.herrmidifier-hvac.com

Herrtronic® MDD Supplement

Page 9

Installation, Operation, & Maintenance Manual

Model MDD - Plumbing Components

EST-122-1

X. PLUMBING COMPONENTS PARTS LIST

X. PLUMBING COMPONENTS DIAGRAM

EST-1092

DRAIN KIT

ASSEMBLY

354537-001

DRAIN SUB-ASSEMBLY

120096-003

EST-1080

EST-076

EST-1225-KIT

EST-1060-3

454320-001

EST-165

EST-1002-6-2

1845

EST-117

EST-1092

DRAIN KIT

ASSEMBLY

EST-1225-KIT

354537-001

DRAIN SUB-ASSEMBLY

EST-1080

FV-12 (INCLUDED w/4060)

PART OF 4060

121078-011

EST-076

EST-165

MASTER

FILL SUB-ASSEMBLY

354415-002

FV-11 (INCLUDED w/4060)

121078-011

4060

120096-003

1845

GT-116

GT-118

GT-116

GT-153

SLAVE FILL SUB-ASSEMBLY

354538-001

GT-116

GT-118

EST-117

EST-122-1

XI. PLUMBING COMPONENT PARTS LIST

EST-076 Lock Washer, Stainless Steel

EST-117 Grommet, Steam Hose

EST-122-1 Cabinet Lock with Keys

EST-165 Steam Hose Clamp

EST-171 Steam Hose, 1-1/2" Diameter

EST-1002-6-2

Steam Cylinder

EST-1060-3 "O" Ring, 13/16 x 1-1/16"

EST-1080 Electrode Knob

EST-1092 Drain Kit Assembly

EST-1225-KIT Drain Reservoir Kit

FV-11 Sleeve, Brass, 1/4" Compression

FV-12 Brass Compression Nut

EST-1002-6-2

EST-1060-3

454320-001

GT-116 Celcon Compression Nut

GT-118 Metering Fill Solenoid

GT-153 Strainer

1845 Door Interlock Switch

4060 1/4" Compression x 1/4"

Compression Brass Bulkhead Union

120096-003 Hole Plug

121078-011 Sealing Washer

354415-002 Master Fill Sub-assembly

354537-001 Drain Sub-assembly

354538-001 Slave Fill Sub-assembly

Herrtronic® MDD Supplement

www.herrmidifier-hvac.com

9

Page 10

Installation, Operation, & Maintenance Manual

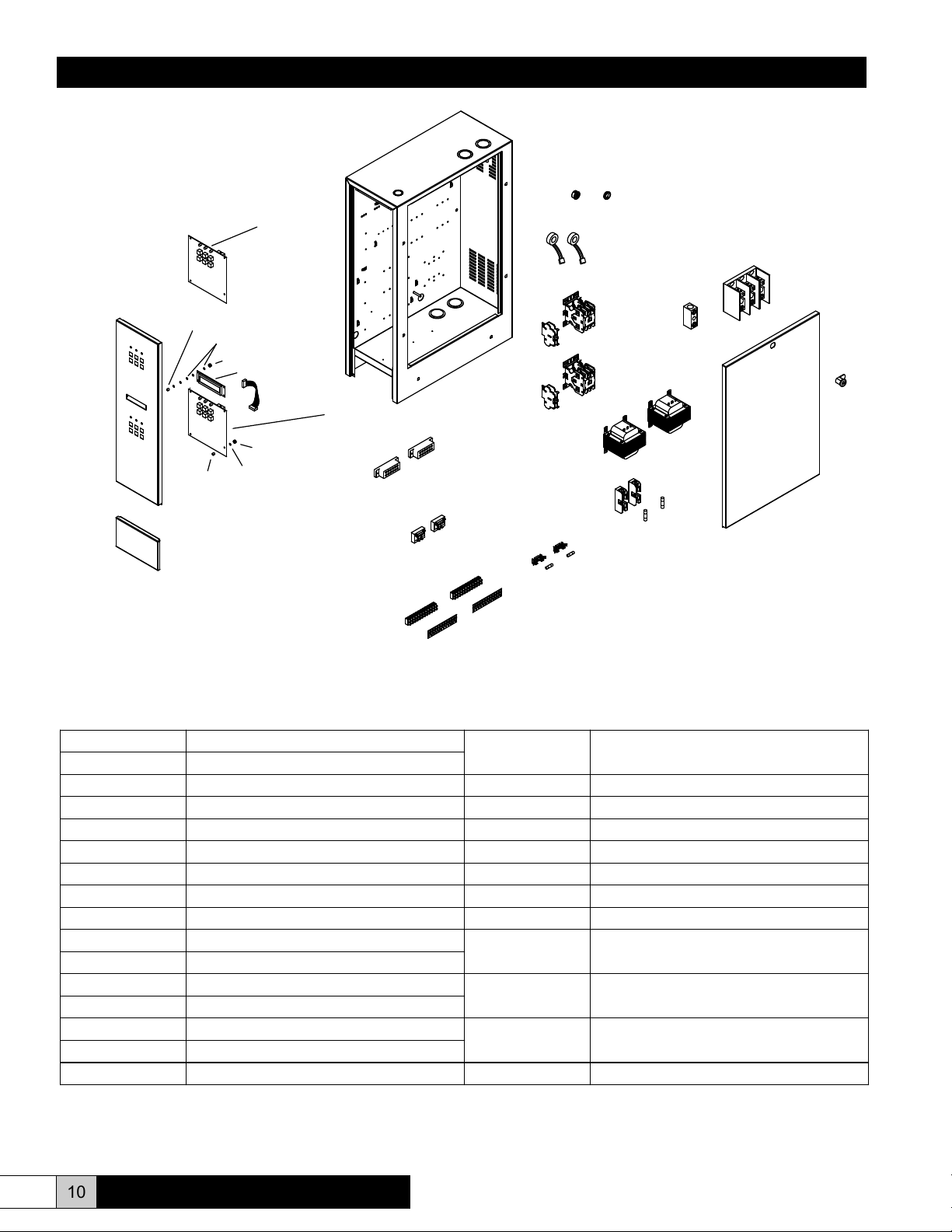

MDD ELECTRICAL COMPONENTS

XII. ELECTRICAL COMPONENTS PARTS LIST

XII. ELECTRICAL COMPONENT DIAGRAM

EST-1409

EST-1127

EST-1127

EST-1250

SLAVE

EST-1136

121800-001

265171-001

EST-1368

EST-1250

MASTER

121800-001

EST-1136

EST-1123

EST-003B

EST-1124-1

EST-105A

EST-109-2

155045-001

EST-1612

EST-353

EST-109

or

EST-109-3

141622-001

EST-120 (4A)

or

158481-001 (6-1/4A)

EST-239

259097-001

or

255991-001

or

253402-002

141622-001

EST-354

EST-354

EST-236 (175A)

or

EST-237 (335A)

454320-001

EST-122-1

XIII. ELECTRICAL COMPONENT PARTS LIST

EST-003B Cylinder Full Interface

EST-1250

EST-105A Toroid Transformer

EST-109 Contactor, 3-Pole, 40 Amp

EST-109-2 Auxiliary Contact, 24 VAC

EST-109-3 Contactor, 3-Pole, 65 Amp

EST-120 Control Fuse, 4 Amp

EST-122-1 Cabinet Lock with Keys

EST-236 Power Block, 175 Amp

EST-237 Power Block, 335 Amp

EST-239 Ground Block

EST-1368

EST-1409

EST-1612 Marking Strip for EST-1124-1

121800-001 KEP Nut, #4-40

141622-001 High Voltage Fuse Holder

155045-001 Fuse Holder

158481-001 Control Fuse, 6-1/4 Amp

253402-002 Control Transformer, 208/230/

EST-353 Shorty Bushing

EST-354 High Voltage Fuse, 2 Amp

255991-001 Control Transformer, 208/230/

EST-1123 Terminal Block, 12 Position

EST-1124-1 Terminal Strip, 12-Pole

259097-001 Control Transformer, 208/230/

EST-1127 Spacer, Nylon, #6

EST-1136 Washer, Nylon, #6

265171-001 LCD Display

Microprocessor Board. Provide Specic

Model # and Control Arrangement.

Ribbon Cable Assembly for LCD Display

Universal Bushing

240/460/480V Primary, 150VA

380/460/600V Primary, 96VA

460V Primary, 100VA

10 www.herrmidifier-hvac.com

Herrtronic® MDD Supplement

Page 11

Installation, Operation, & Maintenance Manual

THIS PAGE INTENTIONALLY LEFT BLANK

Herrtronic® MDD Supplement

www.herrmidifier-hvac.com

11

Page 12

Installation, Operation, & Maintenance Manual

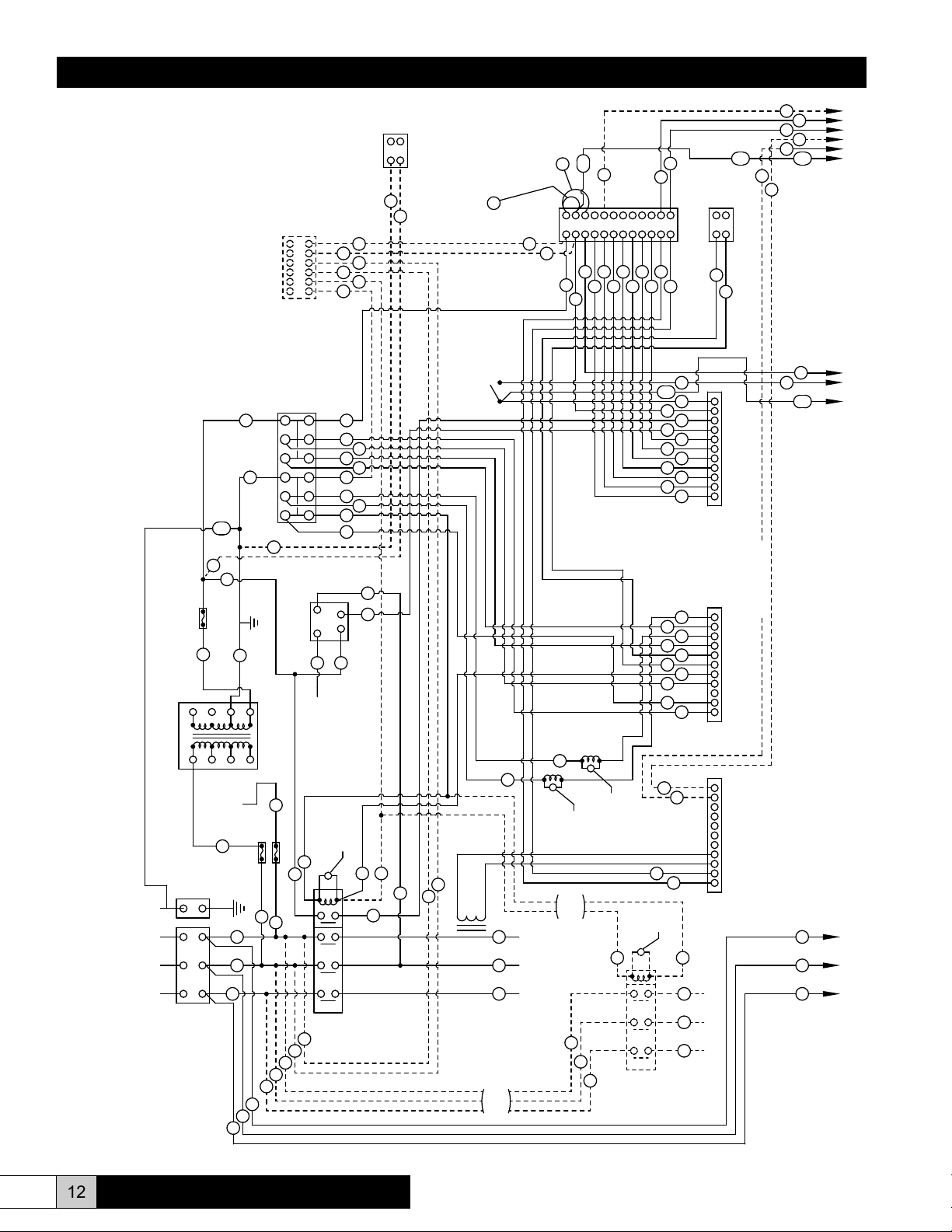

MDD WIRING DIAGRAM

SLAVE SECTION

(TL)

BLK

S

BLK

BLK

U

BLK

T

BLK

129

BLK

130

BLK

(TR)

131

BLK

BLK

3

1

5

7

9

11

126

128

BLK

114

126

WHT

127

BLK

TERMINAL STRIP 5

(RDU)

FUSE 5

(2A)

FUSE 4

(2A)

BLK

132

(COM) (NO)

INTERLOCK 2

DOOR

BLK

option2

TO GND LUG

480

230

X3

208

0

X1

XF

X2

TRANSFORMER

VOLTAGE LEG OF

TO INCOMING LINE

WIRE #132 CONNECTED

IF FUSE IS MOUNTED ON TRANSFORMER

AND 127 CONNECT TO TRANSFORMER

WIRE 128 IS OMITTED AND WIRES 114

TERMINAL XF

(24 VAC)

BLK

FUSE 6

BLK

(4 A FOR 100 VA)

(6 1/4 A FOR 150 VA)

WHT

(24 RET)

GRN/YEL

BLOCK 2

TERMINAL

TRANSFORMER 2

153

WHT

WHT

137

58

16

54

139

53

R

BLK

BLK

Q

BLK

P

56

57

55

XIV. WIRING DIAGRAM

MASTER SECTION

MDD WIRING DIAGRAM

GRN/YEL

FUSE 3

27 & 75 CONNECT TO TRANSFORMER

WIRE 28 IS OMITTED AND WIRES 14,

IF FUSE IS MOUNTED ON TRANSFORMER

TERMINAL XF

X1

TRANSFORMER 1

0

GRN

GND

GND

L1

L2

POWER INPUT

L3

POWER DISTRIBUTION

BLK

BLK

(24 VAC)

BLOCK

28

XF

208

75

BLK

(4 A FOR 100 VA)

(6 1/4 A FOR 150 VA)

WIRE #32 CONNECTED

BLK

153

BLK

14

(24 RET)

WHT

26

X3

X2

230

480

TO INCOMING LINE

VOLTAGE LEG OF

TRANSFORMER

31

GROUNDED

TO CHASSIS

V

BLK

W

BLK

X

BLK

BLK

Q

BLK

R

27

26

BLK

P

BLK

TERMINAL

WHT

(2A)

FUSE 2

(TR)

BLK

30

BLK

O

6

5

4

3

2

1

TERMINAL STRIP 2

(RDU)

12

11

9

10

8

7

5

WHT

6

3

4

2

1

BLOCK 1

76

CYLINDER FULL

INTERFACE 1

BLK

BLK

32

(2A)

FUSE 1

BLUE

46

(TL)

15

BLK

BLK

29

BLK

BLK

35

BLK

36

M

BLK

N

BLK

BLK

BLK

ORG

WHT

2

1

RED14BLK

24

CYLINDER

FULL

ELECTRODE

L1

L2

L3

CONTACTOR

BLUE

BLUE

BLK

BLUE

ORG

WHT

WHT

ORG

WHT

BLUE

WHT

3

4

(SENSOR)

VARISTOR

T1

T2

T3

M1

55

57

56

53

54

+

-

40

139

TERMINAL STRIP 6

24 VAC, 4 VA MAX.

WHT

BLK

76

75

42

41

36

35

38

33

12

17

18

19

20

33

22

47

46

21

DOOR

INTERLOCK 1

AIR FLOW SWITCH

(OPTION 3, SEE NOTE BELOW)

39

42

BLK

41

BLUE

(NO)

(COM)

55

WHT

WHT

2

1

BLUE

BLUE

12

WHT

WHT

WHT

356

BLK

16

45

GRN

7

4

RED

RED

WHT

8

10

9

11

GRN

8

BARE

7

WHT

56

57

BLUE

BLUE

9

11

10

12

A B

TERMINAL STRIP 1

BLK

RED

WHT

6

43

5

44

58

137

37

45

3

4

5

6

7

8

9

10

11

WHT

RED

ORG

RED

WHT

GRN

RED

RED

WHT

GRN

BLUE

2

1

RED

RED

49

48

11

10

9

4

3 5 76 8

2

1

139

TERMINAL STRIP 3

REMOTE ALARM

WHT

BOARD TERMINAL

139

54

53

J5

16

58

WHT

137

25

BLK

4

ORG

1

DRAIN

VALVE 1

22

ORG

47

WHT

FILL

POWER ELECTRODES

VALVE 1

THESE WIRES NOT

USED ON DOUBLE

V3

ORG

ORG

RED

38

34

3

RED

BLK

BLK

BLK

BLK

RED

BLK

25

RED

BLK

36

35

TOROID 1

A

B

C

THESE WIRES NOT

USED ON DOUBLE

CONTACTOR UNITS

V1

VARISTOR

V2

VARISTOR

CONTACTOR UNITS

ORG

51

BLK

L1

BLK

M

N

L2

BLK

L3

O

13

WHT

20

WHT

23

ORG

19

ORG

49

RED

48

RED

34

ORG

18

BLUE

21

WHT

17

BLK

53

WHT

*

54

GRN

*

RED

RED

44

WHT

43

BLK

V4

VARISTOR

BLUE

52

G

BLK

T1

H

BLK

T2

I

POWER ELECTRODES

BLK

T3

M2

CONTACTOR

(See note below)

11

10

9

8

J3

5

4

3 76

BOARD TERMINAL

2

1

11

10

9

J1

4

3 5 76 8

BOARD TERMINAL

2

1

option 1

BLK

BLK

BLK

P

Q

R

12 www.herrmidifier-hvac.com

Herrtronic® MDD Supplement

Page 13

55

56

54

MDD WIRING DIAGRAM

57

53

SLAVE SECTION

58

137

WHT

Installation, Operation, & Maintenance Manual

(See note below)

option2

139

6

5

4

3

2

1

TERMINAL STRIP 5

(RDU)

DOOR

INTERLOCK 2

(COM) (NO)

16

BLK

WHT

127

BLK

12

11

9

10

8

7

126

TO GND LUG

153

WHT

TERMINAL

BLOCK 2

6

5

3

4

2

1

BLK

BLUE

BLK

BLK

ORG

WHT

BLUE

BLK

BLUE

ORG

WHT

WHT

ORG

WHT

BLUE

WHT

option 3

141

135

133

112

117

118

119

120

133

122

147

146

121

(See note below)

AIR FLOW SWITCH

(OPTIONAL)

142

136

138

142

BLK

141

BLUE

53

55

54

139

WHT

WHT

GRN

BLUE

2

1

BLUE

BLUE

112

145

356

4

WHT

GRN

111

7

RED

RED

110

109

56

57

BARE

BLUE

BLUE

8

9

11

10

12

GRN

BLK

RED

WHT

WHT

143

106

108

105

144

107

145

104

106

108

110

A B

TERMINAL STRIP 4

J5

137

WHT

BLUE

103

RED

ORG

105

RED

WHT

107

GRN

RED

109

RED

WHT

111

GRN

11

10

9

4

3 5 76 8

BOARD TERMINAL

2

1

359100-001 REV B

114

BLK

BLK

GRN/YEL

FUSE 6

(24 RET)

BLK

WHT

(4 A FOR 100 VA)

(6 1/4 A FOR 150 VA)

126

128

IF FUSE IS MOUNTED ON TRANSFORMER

AND 127 CONNECT TO TRANSFORMER

WIRE 128 IS OMITTED AND WIRES 114

TERMINAL XF

(24 VAC)

208

230

TO INCOMING LINE

WIRE #132 CONNECTED

BLK

X3

480

TRANSFORMER

VOLTAGE LEG OF

131

X1XFX2

TRANSFORMER 2

0

P

BLK

Q

BLK

R

BLK

FUSE 5

(TR)

BLK

130

BLK

CYLINDER FULL

INTERFACE 2

RED

124

BLK

CYLINDER

FULL

BLK

132

(2A)

(2A)

FUSE 4

BLUE

146

(TL)

115

BLK

BLK

129

L1

L2

L3

BLK

135

BLK

BLK

136

S

BLK

T

U

2

1

ELECTRODE

CONTACTOR

3

4

BLK

114

2

(SENSOR)

V7

VARISTOR

T1

T2

T3

S1

125

BLK

104

ORG

DRAIN

VALVE 2

122

147

WHT

ORG

ORG

134

138

103

RED

BLK

BLK

BLK

BLK

RED

BLK

BLK

125

135

RED

RED

136

TOROID 2

ORG

V6

VARISTOR

THESE WIRES NOT

USED ON DOUBLE

CONTACTOR UNITS

V5

VARISTOR

144

S

T

U

FILL

VALVE 2

D

E

F

POWER ELECTRODES

THESE WIRES NOT

USED ON DOUBLE

CONTACTOR UNITS

J3

113

WHT

120

119

118

121

143

ORG

151

BLK

BLK

BLK

11

WHT

10

123

ORG

9

ORG

134

ORG

BLUE

4

3 5 76 8

WHT

BOARD TERMINAL

2

117

BLK

1

J1

11

10

9

RED

4

RED

3 5 76 8

VARISTOR

T1

T2

T3

S2

2

1

V8

152

BLK

BLK

BLK

BOARD TERMINAL

BLUE

J

K

L

POWER ELECTRODES

OPTION 1. WIRE NOS. 53 AND 54 USED FOR MDDI/MDDP, PROPORTIONAL AND PROPORTIONAL & INTEGRAL

OPTION 2. WIRE NO 55 USED FOR ON/OFF CONTROL

OPTION 3. REMOVE WIRE 139 AND 39 WHEN SEPARATE AIR FLOW SWITCHES OR RDU'S ARE USED.

WHT

BLK

L1

L2

L3

CONTACTOR

Herrtronic® MDD Supplement

www.herrmidifier-hvac.com

13

Page 14

Installation, Operation, & Maintenance Manual

TRANSFORMER 2

600

480

380

230

208

0

X3

X1

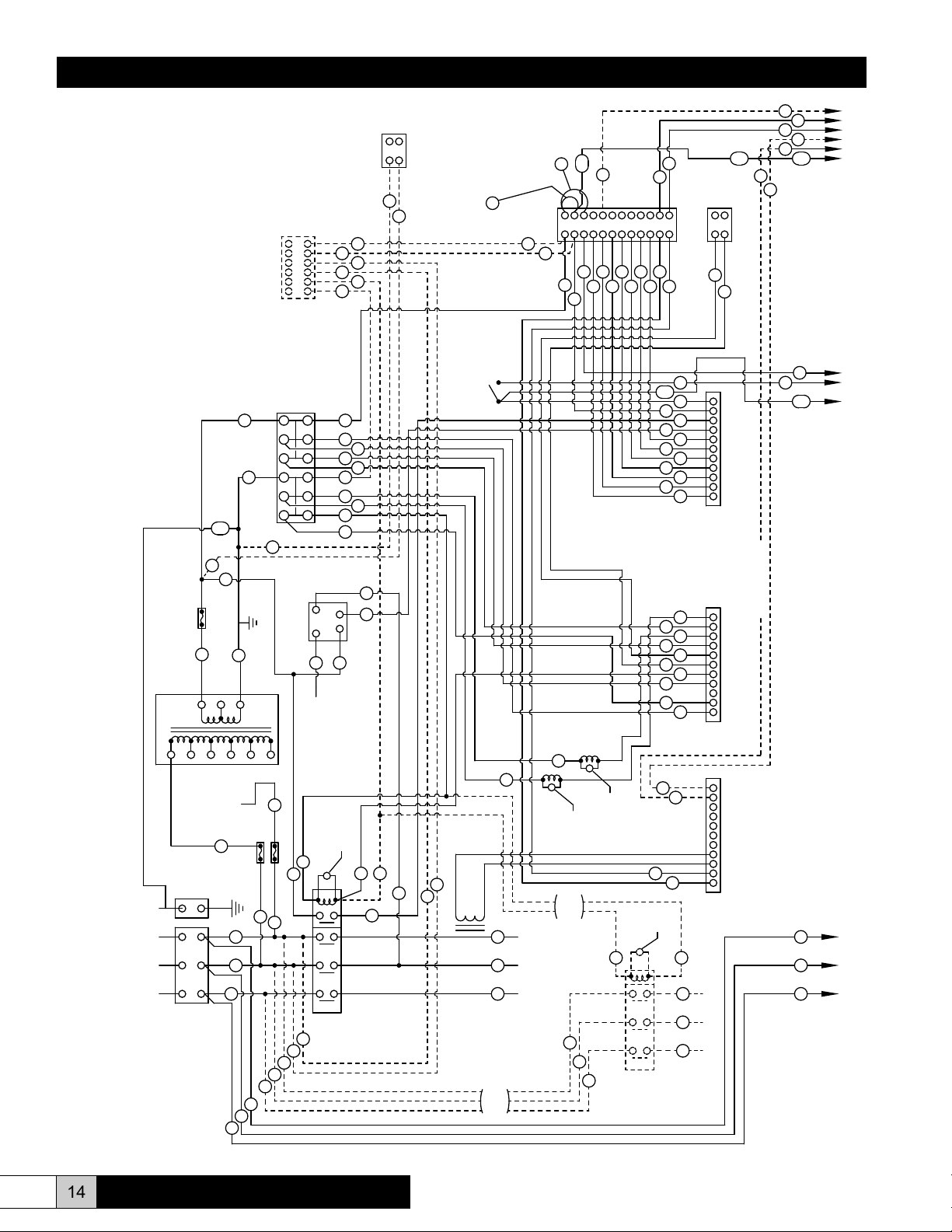

MDD WIRING DIAGRAM

SLAVE SECTION

(TL)

BLK

S

BLK

BLK

U

BLK

T

BLK

129

BLK

130

BLK

(TR)

131

BLK

BLK

3

1

5

7

9

11

126

128

BLK

114

126

WHT

127

BLK

TERMINAL STRIP 5

(RDU)

FUSE 5

(2A)

FUSE 4

(2A)

BLK

132

(COM) (NO)

INTERLOCK 2

DOOR

BLK

option2

TO GND LUG

TRANSFORMER

VOLTAGE LEG OF

TO INCOMING LINE

WIRE #132 CONNECTED

IF FUSE IS MOUNTED ON TRANSFORMER

AND 127 CONNECT TO TRANSFORMER

WIRE 128 IS OMITTED AND WIRES 114

TERMINAL XF

(24 VAC)

BLK

FUSE 6

BLK

(4 A FOR 100 VA)

(6 1/4 A FOR 150 VA)

WHT

(24 RET)

GRN/YEL

BLOCK 2

TERMINAL

153

WHT

WHT

137

58

16

54

139

53

R

BLK

BLK

Q

BLK

P

56

57

55

XV. WIRING DIAGRAM

MASTER SECTION

MDD WIRING DIAGRAM

GRN/YEL

27 & 75 CONNECT TO TRANSFORMER

WIRE 28 IS OMITTED AND WIRES 14,

IF FUSE IS MOUNTED ON TRANSFORMER

TERMINAL XF

TRANSFORMER 1

0

208

GRN

GND

L1

L2

POWER INPUT

L3

POWER DISTRIBUTION

BLK

FUSE 3

BLK

(24 VAC)

X1

GND

BLOCK

28

230

75

BLK

(4 A FOR 100 VA)

WIRE #32 CONNECTED

BLK

153

BLK

14

(24 RET)

WHT

(6 1/4 A FOR 150 VA)

26

380

TO INCOMING LINE

VOLTAGE LEG OF

TRANSFORMER

31

GROUNDED

TO CHASSIS

V

BLK

W

BLK

X

BLK

BLK

BLK

R

27

26

WHT

X3

480

FUSE 2

(TR)

BLK

BLK

P

Q

TERMINAL STRIP 2

(RDU)

BLK

11

9

7

5

WHT

3

1

TERMINAL

BLOCK 1

76

CYLINDER FULL

BLK

600

BLK

32

(2A)

(2A)

FUSE 1

(TL)

15

BLK

BLK

30

29

BLK

BLK

36

M

BLK

N

BLK

O

6

5

4

3

2

1

12

10

8

6

4

2

INTERFACE 1

CYLINDER

BLUE

46

BLK

35

BLK

BLUE

BLK

BLK

ORG

WHT

BLK

ORG

WHT

WHT

ORG

WHT

WHT

2

3

4

1

RED14BLK

24

FULL

ELECTRODE

T1

L1

L2

T2

L3

T3

CONTACTOR

41

35

33

12

BLUE

17

BLUE

19

33

22

46

BLUE

21

1

(SENSOR)

V3

VARISTOR

M1

55

57

56

53

54

+

-

40

139

TERMINAL STRIP 6

24 VAC, 4 VA MAX.

WHT

BLK

76

75

42

36

38

18

20

47

DOOR

INTERLOCK 1

AIR FLOW SWITCH

(OPTION 3, SEE NOTE BELOW)

39

42

BLK

41

BLUE

(NO)

(COM)

55

WHT

WHT

2

1

BLUE

BLUE

12

45

WHT

WHT

WHT

356

4

BLK

GRN

16

11

WHT

7

RED

RED

8

10

9

GRN

BARE

8

7

WHT

56

57

BLUE

BLUE

9

11

10

12

A B

TERMINAL STRIP 1

BLK

RED

WHT

6

43

5

44

58

137

37

WHT

45

3

RED

4

ORG

5

RED

6

WHT

7

GRN

8

RED

9

RED

10

WHT

11

GRN

BLUE

2

1

RED

RED

49

48

11

10

9

4

3 5 76 8

2

1

139

TERMINAL STRIP 3

REMOTE ALARM

WHT

BOARD TERMINAL

139

54

J5

53

58

WHT

16

137

25

BLK

4

ORG

DRAIN

VALVE 1

22

ORG

47

WHT

FILL

VALVE 1

ORG

ORG

RED

38

34

3

RED

BLK

BLK

BLK

BLK

RED

BLK

25

RED

BLK

36

35

TOROID 1

A

B

C

THESE WIRES NOT

USED ON DOUBLE

CONTACTOR UNITS

POWER ELECTRODES

THESE WIRES NOT

USED ON DOUBLE

V1

VARISTOR

V2

VARISTOR

CONTACTOR UNITS

ORG

51

BLK

L1

BLK

M

N

L2

BLK

L3

O

13

WHT

20

WHT

23

ORG

19

ORG

49

RED

48

RED

34

ORG

18

BLUE

21

WHT

17

BLK

53

WHT

*

54

GRN

*

RED

RED

44

WHT

43

BLK

V4

VARISTOR

BLUE

52

G

BLK

T1

H

BLK

T2

I

POWER ELECTRODES

BLK

T3

M2

CONTACTOR

(See note below)

11

10

9

8

J3

5

4

3 76

BOARD TERMINAL

2

1

11

10

9

J1

4

3 5 76 8

BOARD TERMINAL

2

1

option 1

BLK

BLK

BLK

P

Q

R

14 www.herrmidifier-hvac.com

Herrtronic® MDD Supplement

Page 15

55

56

54

MDD WIRING DIAGRAM

57

53

SLAVE SECTION

58

137

WHT

Installation, Operation, & Maintenance Manual

(See note below)

option2

139

6

5

4

3

2

1

TERMINAL STRIP 5

(RDU)

DOOR

INTERLOCK 2

(COM) (NO)

16

BLK

WHT

127

BLK

12

11

9

10

8

7

TO GND LUG

126

153

TERMINAL

WHT

BLOCK 2

6

5

3

4

2

1

BLK

BLK

BLK

ORG

WHT

BLK

ORG

WHT

WHT

ORG

WHT

WHT

option 3

(See note below)

AIR FLOW SWITCH

(OPTIONAL)

142

141

BLUE

136

135

138

133

112

BLUE

117

118

BLUE

119

120

133

122

147

146

BLUE

121

142

BLK

141

BLUE

53

55

54

139

WHT

WHT

GRN

BLUE

2

1

BLUE

BLUE

112

145

356

4

WHT

GRN

111

7

RED

RED

108

110

109

GRN

56

57

BARE

BLUE

BLUE

8

9

11

10

12

BLK

RED

WHT

WHT

143

106

105

144

107

145

104

106

108

110

A B

TERMINAL STRIP 4

137

WHT

BLUE

103

RED

ORG

105

RED

WHT

107

GRN

RED

109

RED

WHT

111

GRN

J5

11

10

9

4

3 5 76 8

2

1

354325-001 REV D

BOARD TERMINAL

GRN/YEL

TRANSFORMER 2

P

BLK

Q

BLK

R

BLK

IF FUSE IS MOUNTED ON TRANSFORMER

AND 127 CONNECT TO TRANSFORMER

WIRE 128 IS OMITTED AND WIRES 114

TERMINAL XF

0

208

FUSE 6

X1

114

BLK

BLK

(24 RET)

BLK

WHT

(4 A FOR 100 VA)

(6 1/4 A FOR 150 VA)

126

128

(24 VAC)

CYLINDER FULL

INTERFACE 2

BLK

RED

124

X3

CYLINDER

FULL

230

380

600

480

BLK

132

(2A)

FUSE 5

(TR)

BLK

130

(2A)

FUSE 4

BLUE

146

(TL)

115

BLK

BLK

129

L1

L2

L3

BLK

135

BLK

BLK

136

S

BLK

T

BLK

U

WIRE #132 CONNECTED

BLK

TRANSFORMER

VOLTAGE LEG OF

TO INCOMING LINE

131

2

1

ELECTRODE

CONTACTOR

3

4

BLK

114

2

(SENSOR)

VARISTOR

T1

T2

T3

S1

125

BLK

104

ORG

DRAIN

VALVE 2

122

147

WHT

V7

ORG

ORG

134

138

103

RED

BLK

BLK

BLK

BLK

RED

BLK

BLK

125

135

RED

RED

136

TOROID 2

ORG

V6

VARISTOR

THESE WIRES NOT

USED ON DOUBLE

CONTACTOR UNITS

V5

VARISTOR

144

S

T

U

FILL

VALVE 2

D

E

F

POWER ELECTRODES

THESE WIRES NOT

USED ON DOUBLE

CONTACTOR UNITS

J3

113

WHT

120

119

118

121

143

ORG

151

BLK

BLK

BLK

11

WHT

10

123

ORG

9

ORG

134

ORG

BLUE

4

3 5 76 8

WHT

BOARD TERMINAL

2

117

BLK

1

J1

11

10

9

RED

4

RED

3 5 76 8

T1

T2

T3

S2

V8

VARISTOR

BOARD TERMINAL

2

1

BLUE

152

J

BLK

K

BLK

L

BLK

POWER ELECTRODES

OPTION 1. WIRE NOS. 53 AND 54 USED FOR MDDI/MDDP, PROPORTIONAL AND PROPORTIONAL & INTEGRAL

OPTION 2. WIRE NO 55 USED FOR ON/OFF CONTROL

OPTION 3. REMOVE WIRE 139 AND 39 WHEN SEPARATE AIR FLOW SWITCHES OR RDU'S ARE USED.

WHT

BLK

L1

L2

L3

CONTACTOR

Herrtronic® MDD Supplement

www.herrmidifier-hvac.com

15

Page 16

Engineered Humidification Systems

Herrmidifier

®

101 McNeill Rd. | Sanford, NC 27330

P: 800.884.0002 | F: 800.458.2379 | www.herrmidifier-hvac.com | cs@herrmidifier-hvac.com

Form No. OM-107 09/11 ©Herrmidier 2011. All Rights Reserved.

Loading...

Loading...