Page 1

Engineered Humidification Systems

READ & SAVE THESE INSTRUCTIONS

Herrtronic® MD Series

Installation, Operation, & Maintenance

Herrmidifier® | www.herrmidifier-hvac.com

Page 2

Installation, Operation, & Maintenance Manual

TABLE OF CONTENTS

SECTION I WARRANTY

Warranty ...............................................................................................................................................3

SECTION II UNIT OPERATION

Herrtronic MD: Basic Operation ............................................................................................................ 4

Types of Control ....................................................................................................................................5

SECTION III INSTALLATION INSTRUCTIONS

Allowable Operating Conditions ............................................................................................................6

Mounting ............................................................................................................................................... 6

Plumbing ............................................................................................................................................... 6

Supply Power ........................................................................................................................................7

Steam Distributor Pipes ........................................................................................................................ 8

Steam Distributoin for Ducted Systems ................................................................................................ 9

Controls ................................................................................................................................................10

Control Circuit Connections .................................................................................................................. 10

External Off Switch ...............................................................................................................................11

Remote Alarm Output ........................................................................................................................... 12

Unit Networking ....................................................................................................................................12

SECTION IV OPERATION INSTRUCTIONS

Operating Instructions ...........................................................................................................................13

Programming ........................................................................................................................................14

Start-up with Check List ........................................................................................................................ 16

Diagnostics ...........................................................................................................................................19

System Fault Conditions ....................................................................................................................... 20

Maintenance .........................................................................................................................................20

SECTION V TROUBLESHOOTING GUIDE

General Maintenance Notes ................................................................................................................. 22

Operating The Humidier Without External Controls ............................................................................ 22

Unit Detected Faults: (Red “Service” Light On) ....................................................................................24

Non-Fault Indicated Problems ..............................................................................................................25

Troubleshooting Without Unit-Detected Faults .....................................................................................27

Output / Input of Terminal Strips and Terminal Block ............................................................................ 28

2 www.herrmidifier-hvac.com

Herrtronic® MD Series

Page 3

Installation, Operation, & Maintenance Manual

I. WARRANTY

Limited 2-Year Warranty

Seller warrants the equipment of its manufacturing to be free

from defects in workmanship and material for a period of 24

months after shipment or 24 months after initial commissioning,

whichever occurs rst. This warranty is limited, however, to the

repair or replacement of defective equipment, which is returned,

freight prepaid, to Seller’s factory.

This limited warranty does not apply to any part or component

that is damaged in transit or when handling, has been subject

to misuse, negligence or accident, has not been installed, operated or serviced according to Seller’s instructions, or has been

operated beyond the factory-rated capacity or has been altered

in any way.

Seller’s liability is limited to replacement of defective parts or

components and does not include any cost of labor (including,

but not limited to, labor required to remove and/or reinstall any

defective part) other than Trion/Herrmidier factory labor.

Each of the Herrtronic series of steam generating humidiers

contains a plastic steam generating cylinder that is to be considered a routinely disposable part to be changed at regular maintenance intervals at the user’s expense. This steam generating

cylinder is not covered by this Warranty. If, after the rst installation of your Herrtronic humidier, you feel the steam generat-

ing cylinder is not operating normally, you should contact your

Herrmidier Representative with an explanation of the problem.

However, in the continuing operation of this humidier, replace-

ments of this part are your responsibility as part of routine maintenance.

Trion/Herrmidier shall not be responsible for loss of use of

any product, loss of time, inconvenience, or damage to other

equipment, or any other indirect or consequential damage with

respect to property whether as a result of breach of warranty,

neglect, or otherwise.

THE WARRANTIES AND LIABILITIES SET FORTH ARE IN

LIEU OF ALL OTHER WARRANTIES AND LIABILITIES, EXPRESSED OR IMPLIED, IN LAW OR IN FACT, INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR PARTICULAR PURPOSE.

The foregoing shall constitute the total liability of seller in the

case of defective performance of all or any of the equipment or

services provided to Buyer. Buyer agrees to accept and hereby

accepts the foregoing as the sole and exclusive remedy for any

breach or alleged breach of warranty by Seller.

Herrtronic® MD Series

www.herrmidifier-hvac.com

3

Page 4

Installation, Operation, & Maintenance Manual

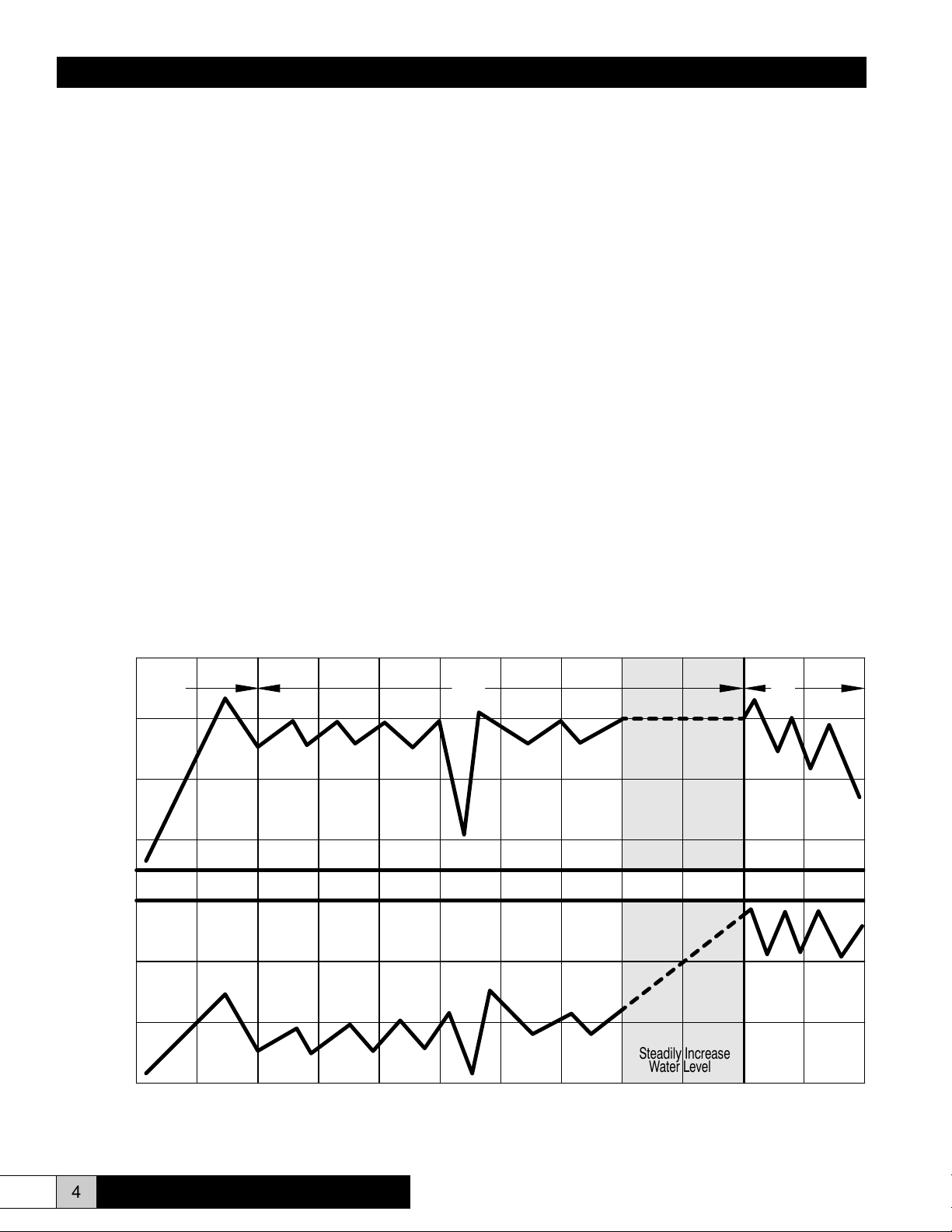

Water Level

Output

II. UNIT OPERATION

Herrtronic MD: Basic Operation

Controlled humidication requires a very precise control system. The Herrtronic MD utilizes a microprocessor to monitor

performance and maintain humidity. Further, the Herrtronic

MD evaluates the operation and alerts the operator to problem conditions and prevents undesirable operation:

1. Start-up: On initial start-up (prompted by a call-for-hu-

midity), the ll valve opens allowing water to enter the

cylinder. When the water level rises to the electrodes,

current will ow and the water will begin heating. As

the water temperature increases, its conductivity also increases, accelerating the rate of temperature increase.

When the output reaches the “capacity set point,” the ll

valve closes. The output capacity may continue to rise

slightly beyond the “capacity set point.” As the water

boils away, the water level falls. This results in a reduction in output capacity.

2. Normal Operation: Upon achieving “capacity set point,”

the system begins operation in a steady state mode.

Output capacity slowing decreases until the elapsed “cy-

cle time” opens the ll valve to replenish the water level

until the “capacity set point” output is achieved. As the

mineral concentration in the water increases, the water

conductivity also increases. Accordingly, the rate of boiling increases. Eventually, the rate of boiling reduces the

output capacity below the “low drain threshold” before

the “cycle time” initiates the ll cycle.

At this point, the drain valve opens discarding the mineral laden (highly conductive) water, replacing it with

fresh water, that lowers the mineral concentration until

the system is restored to the steady state mode.

The steady state operating mode continues with small

increases in the water level to maintain output capacity

(by exposing new electrode surface).

3. End-of-Cylinder Life: Steady State operation continues

with “ll and boil” and periodic drain cycles with ever increasing water levels. Eventually, the water level reaches the cylinder full electrode, representing the maximum

allowable water level inside the cylinder. The system

output begins to decrease since there is no new electrode surface to expose. If the system operates continuously without achieving “capacity set point,” an “end of

cylinder life” fault will be displayed.

High Drain

Threshold

Capacity

Set Point

Low Drain

Threshold

Cylinder

Full

HERRTRONIC MD: Basic Operation

1. 2.

Hours of Operation

Steadily Increase

Water Level

3.

4 www.herrmidifier-hvac.com

Herrtronic® MD Series

Page 5

Installation, Operation, & Maintenance Manual

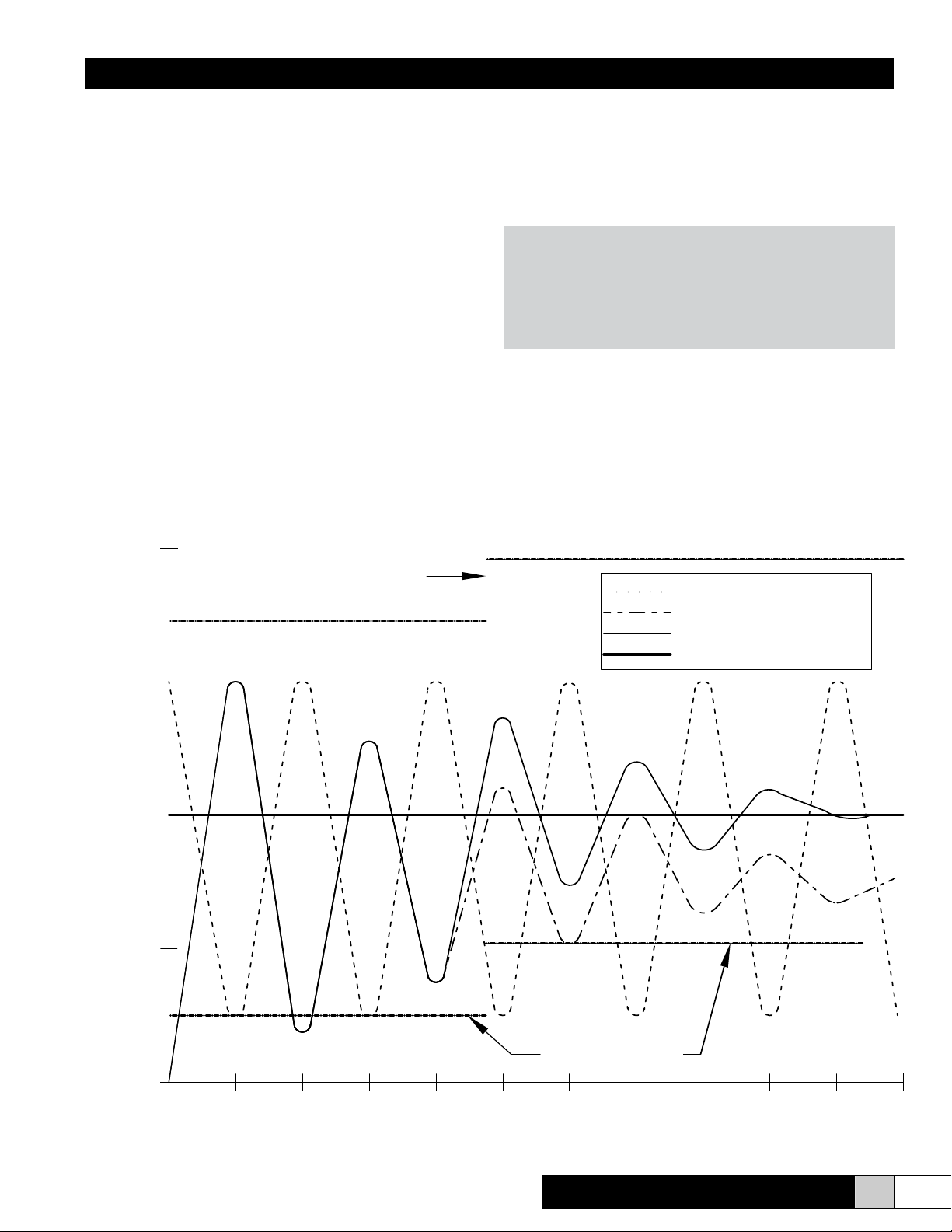

Relative Humidity %

Time

Types of Control

The Herrtronic MD System is available with (3) types of control ---(1) On/Off, (2) Proportional, (3) Proportional + Integral:

1. On/Off – Humidity is sensed by a humidistat that pro-

vides an On/Off input to the humidier. Humidity varies

above and below the setpoint based on the tolerance

and accuracy of the humidistat.

2. Proportional – A proportional controller produces a signal (ohms, volts DC, or milliamps DC) corresponding to

the difference between the control humidity and the hu-

midity setpoint. The humidier’s output increases as this

difference (and signal) increases. Humidity variations

will be smaller than with “On/Off” control and the control

humidity will be maintained within the bandwidth, tolerance, and accuracy of the controller.

Types of Control

60

3. Proportional + Integral – Over a repeating time period

the “P+I” control simply evaluates the difference between the average control humidity and the control humidity setpoint and adjusts the bandwidth to minimize

the “offset.” Optimal control is attained in most cases

with this alternative.

NOTE

If your application is unique or water is excessively

“clean” or “dirty,” consult Herrmidier for assistance in matching your humidier, water treatment,

and its control scheme to your application!

55

50

45

Offset Correction

On/Off Control

Proportional Control

Proportional + Integral Control

Set Point

40

0 5 10 15 20 25 30 35 40 45 50 55

Herrtronic® MD Series

P + I Bandwith

www.herrmidifier-hvac.com

5

Page 6

Installation, Operation, & Maintenance Manual

III. INSTALLATION INSTRUCTIONS

Allowable Operating Conditions:

Ambient Temperature: 40ºF - 120ºF (4ºC - 50ºC)

Ambient Relative Humidity: 0% to 90%

Line Voltage: -15% to +10% of Nominal

Frequency: 50/60 Hz.

Supply Water Temperature: 40ºF-100ºF (4ºC-38ºC)

Supply Water Pressure: 20-100 psig

Supply Water Conductivity:

• 70-1000 mincromho (on-off control)

• 200-1000 micromho (prop or P + I control)

(See Figure 30 & 31 on page 27 for alternative water conditions)

Maximum Duct Static Pressure: 5” MDM, 7” MDS/MDD

units

NOTE: If units are mounted in outdoor enclosures, conditions

inside enclosure must be maintained as shown above.

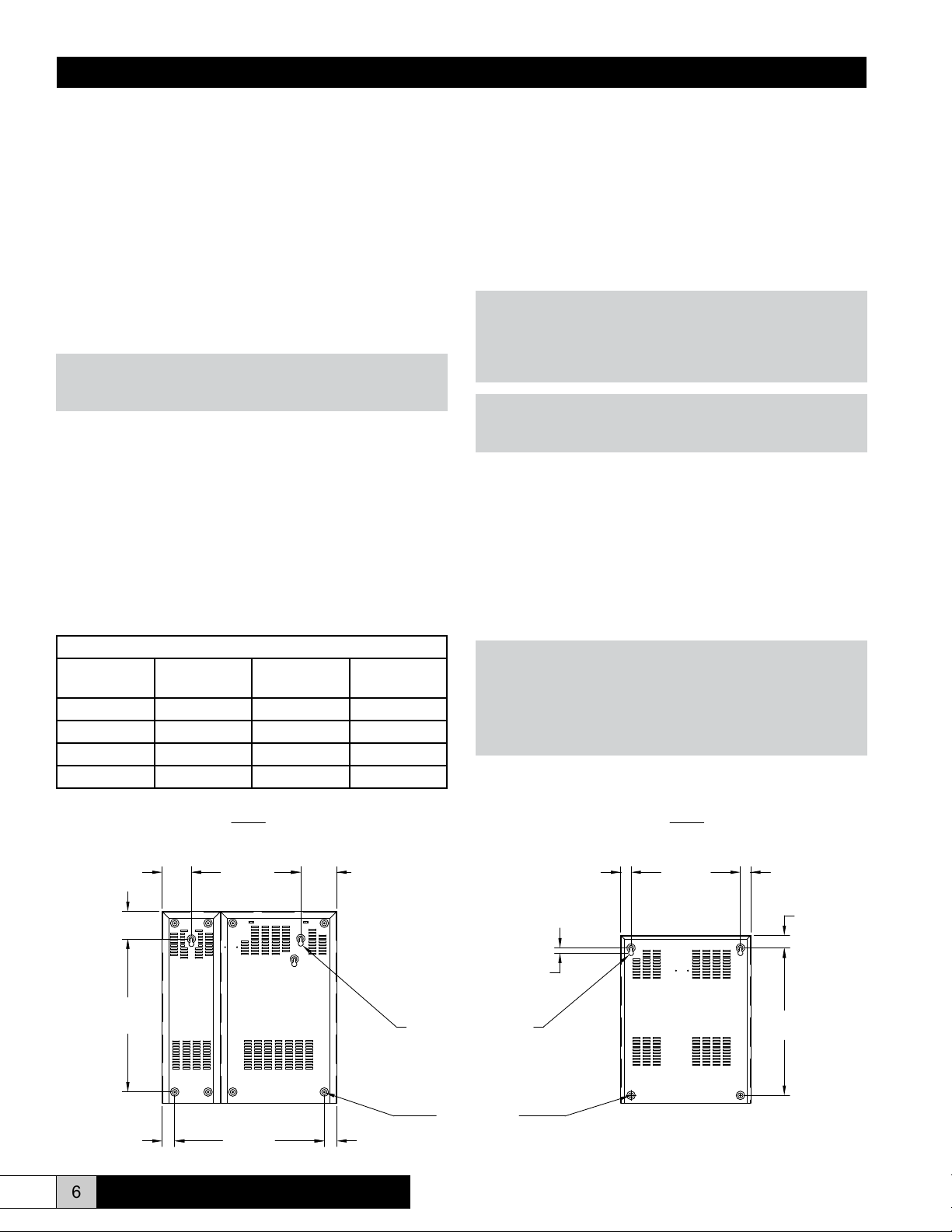

Mounting

The cabinet is designed to safely contain the working com-

ponents of the Herrtronic MD humidier and dissipate heat to

protect the electronics. Herrtronic MD Series electronic steam

humidiers, room distribution units, steam pipes, and any accessories should be located in a manner to facilitate routine inspection and any necessary maintenance. The unit should not

be located above (such as false ceilings) or around valuable

property, where a malfunction could cause damage. Correct

positioning of the Herrtronic MD humidier is important to allow

for proper operation and easy maintenance. Minimum clearance

around the cabinet should be maintained as follows:

Unit Clearances By Model

Unit Series MDM

5-30 Lbs.

Left 2” 2” 2”

Right 20” 20” 20”

Top 12” 12” 12”

Bottom 10” 10” 10”

MDS

10-100 Lbs.

MDD

110-250 Lbs.

Four lag bolts, (2) 5/16” and (2) 1/4”, are supplied with the MDS

and MDM units which are designed to be secured to a wall. Install the top two lag bolts (5/16”) according to the dimensions in

Figure 1. Hang the unit on the wall, and then install the bottom

two lag bolts (1/4”) and secure all four bolts. Be sure the unit is

level and mounted directly to the wall to wood studs at least 2”

thick (or equivalent).

Operating weights are as follows:

• MDM - 82 lbs.

• MDS - 131 lbs.

• MDD - 258 lbs.

WARNING!

Do not mount any controls inside the unit or tap power from

any location in the unit, except as stated in these instructions. Do not place objects near the cabinet. Do not attach

to dry wall without studs.

NOTE

To mount the Room Distribution Unit, refer to the “supplemental” RDU Installation Instructions.

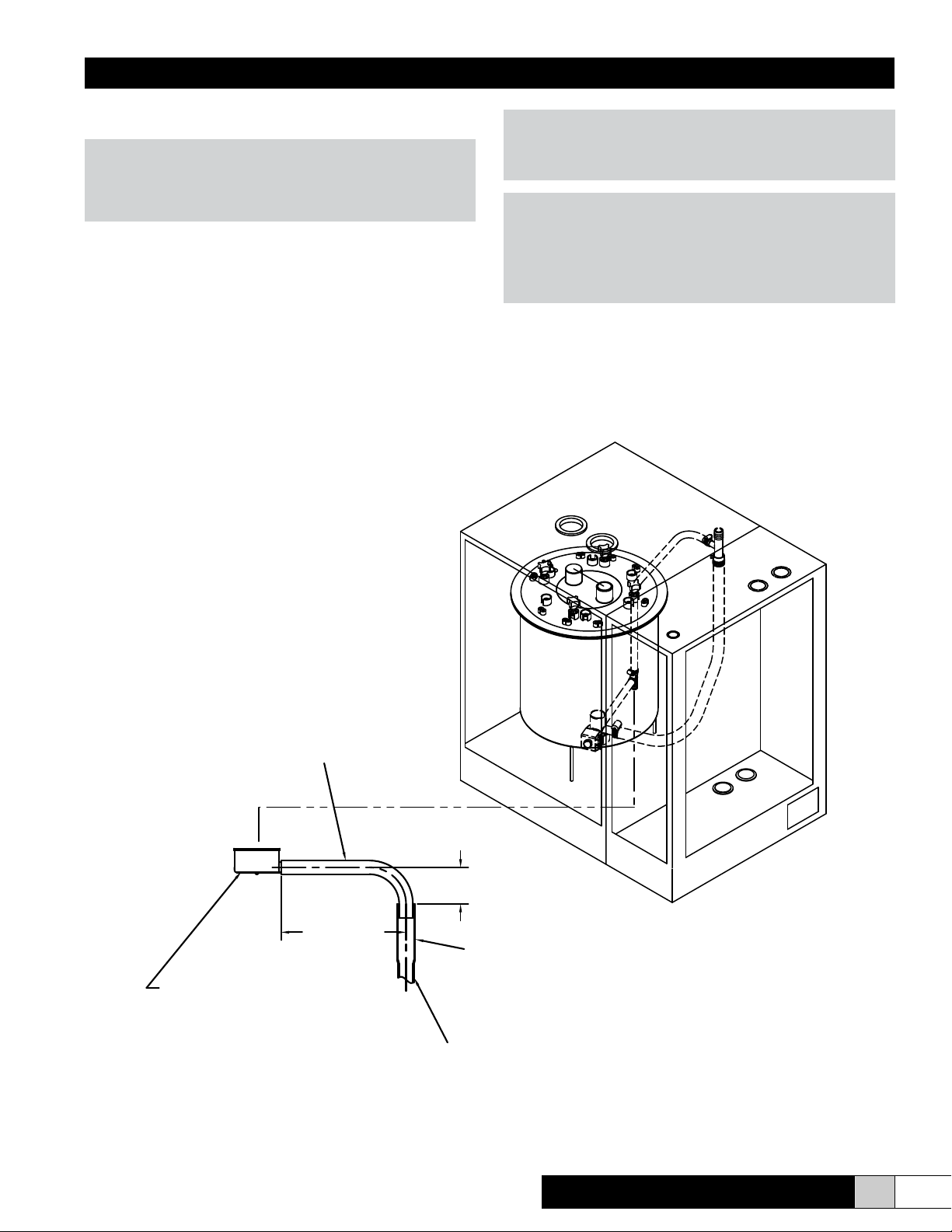

Plumbing

To make the necessary connections for water ll and drain,

the following steps are required: (refer to Figure 2 for drain

location)

1. Install an external shutoff valve between the water supply

and the humidier for ease in servicing the unit.

2. Connect water supply to 1/4” compression tting on the

bottom of the cabinet.

CAUTION!

Do not use reverse osmosis or demineralized water treatment

without rst consulting the factory. This water may not be sufciently conductive to allow proper operation. Consult factory

if water is outside the range of allowable conductivities. Do

not use hot water.

MDS MDM

10-100#

5.2516.004.25

4.00

22.38

1.81 21.89 1.81

6 www.herrmidifier-hvac.com

Figure 1

.75 Typ.

Both units

Ø .38" x Ø .75"

Keyhole Slot

Typ.

Ø .25 Typ.

5-30#

16.001.50 1.50

1.82

21.56

Herrtronic® MD Series

Page 7

Installation, Operation, & Maintenance Manual

3. Connect the ¾” tube from the accessory pack to the drain

reservoir. Cut hose to necessary length.

WARNING!

Be sure that the ¾” drain tube is not kinked or bent in a man-

ner to prevent free owing drainage from the drain reservoir

to the drain pipe.

4. Insert the other end of the tube into a minimum 6” length of

1 ¼” minimum I.D. copper line. The balance of the drain

line should be 1” I.D. minimum with a minimum 1/8” per foot

slope. (See Figure 2)

Figure 2

WARNING!

If the drain line is exposed, it is recommended that it be insulated for safety. Do not use PVC drain line unless “Drain

Tempering” is enabled (see page 16-17).

NOTE

Inlet water pressure must be in the range of 20-100 psig.

Consult the factory if you are outside this range. Softened water may be used but requires that the low drain threshold be

adjusted (refer to Fig. 30 page 27). Drain water can be tempered to lower its temperature (refer to page 16).

3/4" MIN. I.D./1" MAX O.D.

FLEXIBLE DRAIN CONNECTION

RECOMMENDED

DRAIN RESEVOIR

4" RECOMMENDED

8"

6" MIN. LENGTH OF 1-1/4" MIN. I.D.

COPPER LINE. IF PVC IS USED, LOCAL

CODES REQUIRE A LOWER TEMPERATURE

DRAIN WATER, ADD DRAIN TEMPERING.

BALANCE OF DRAIN LINE TO BE 1" MIN. I.D.

WITH A MINIMUM PITCH OF 1/8" PER 12" OF RUN

Herrtronic® MD Series

www.herrmidifier-hvac.com

7

Page 8

Installation, Operation, & Maintenance Manual

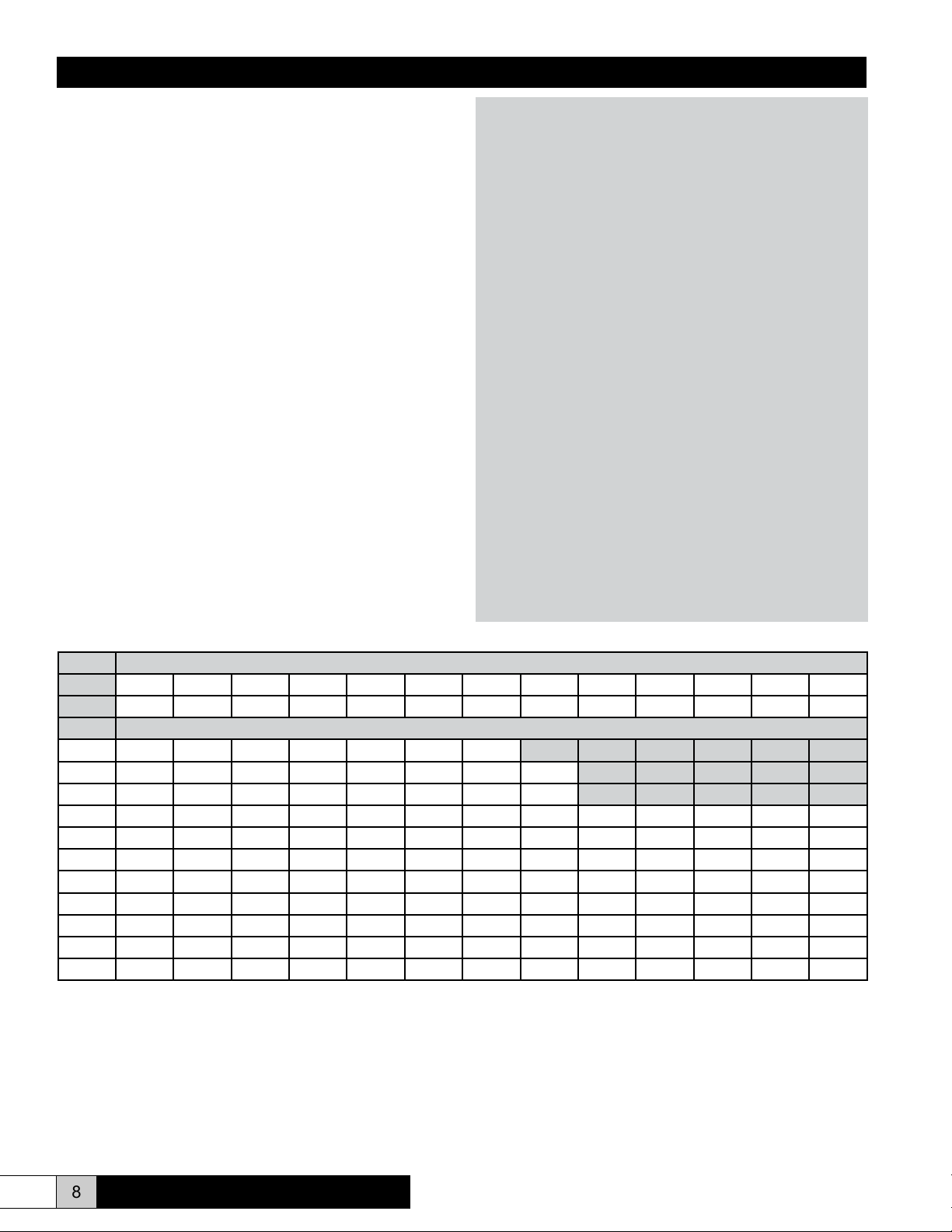

Supply Power (See Electrical Characteristics Table Below)

1. Ensure that adequate service is available to carry 125% of

rated amp level.

2. Field wiring of the main power supply is connected directly

to the contactor (single contactor units) or to a power distribution block (multiple contactor units) located in the electrical compartment. A ground lug is provided for the ground

wire.

3. Install external overcurrent protection and provide wiring in

accordance with the NEC, state and local code.

4. Power supply must be “clean”; free of spikes, surges and

sags; -15% to +10% of Nominal. Ground should be a true

earth ground.

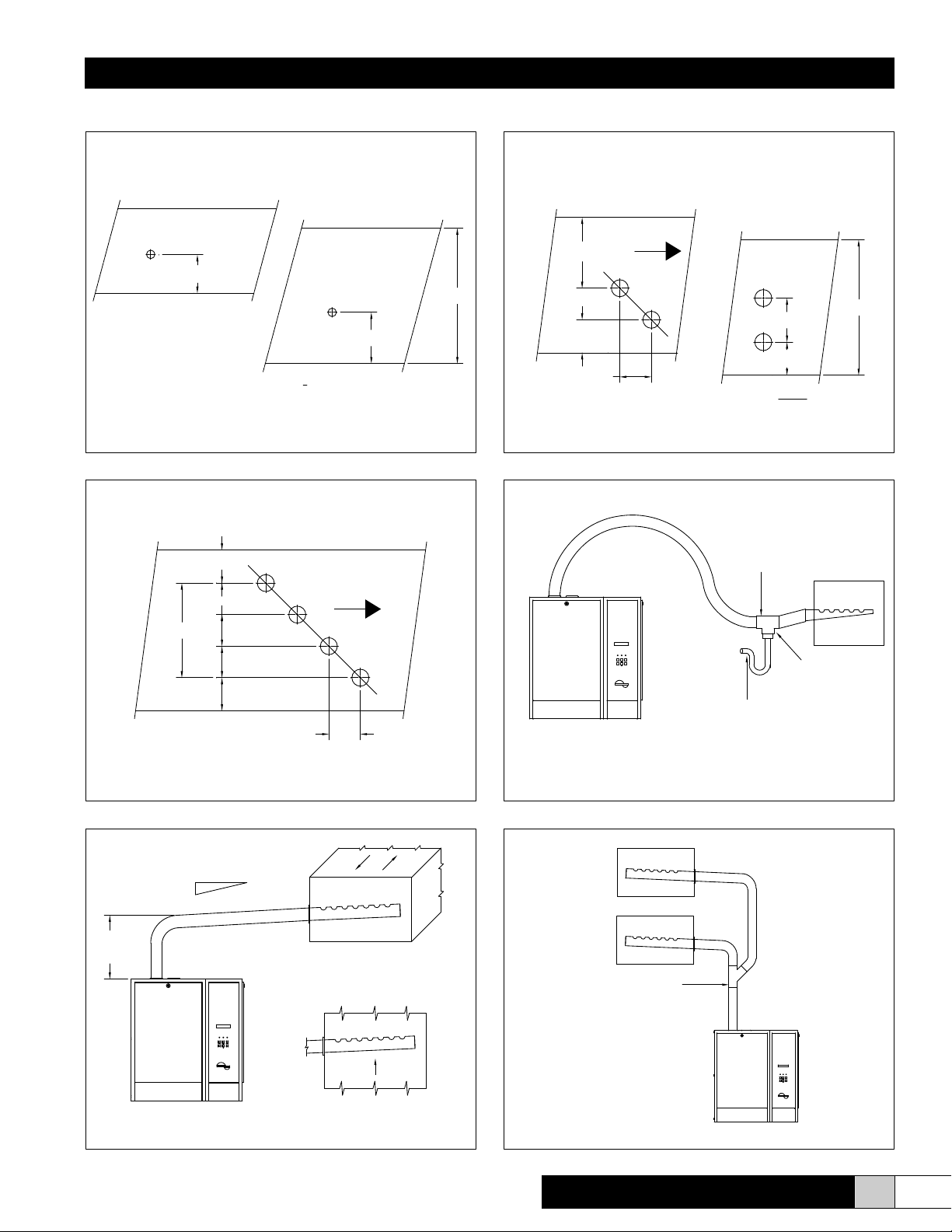

Steam Distribution for Ducted Systems

Each steam cylinder requires at least one outlet for steam via

a duct distributor or Room Distribution Unit. (See RDU supplement for Room Distribution Unit)

Steam Distributor Pipes

Herrmidier supplies stainless steel duct distributor pipe(s) for

use in injecting pure steam into ducts. Refer to Figure 3, 4, or 5

for proper placement. A minimum of 3’ clearance downstream

is required for most applications. However, differing pyschrometric conditions may require a greater or lesser steam absorption distance. Consult the factory if you have any questions or

need to exchange your standard distribution system for a rapid

absorption CS-Series Distribution system.

NOTE

• The rubber steam hose carries steam to the distributor pipe

and condensate back to the unit. It must have an 8% (1”

per foot) pitch back to the unit. Support the steam hose so

it will maintain the proper pitch when in operation or at rest.

• If any low spots are in the steam line or the unit is mounted

higher than the distribution system, spitting may occur from

the steam distribution pipes. A condensate separator (EST-

250) is available from the factory. (See Fig. 6)

• If you must split the discharge of one steam outlet into two

ducts with the same static pressure, a “Y” connector (EST-

255) is available from the factory. The length of steam hose

after the “Y” connector must be the same for equal distribution of steam. (See Fig. 8)

• Mount the unit as close to the distribution pipe as possible.

Use 1 ½” Type L insulated copper pipe whenever the length

of run exceeds 20 feet. Do not exceed a 30 foot run as the

capacity of the unit will be decreased by as much as 15%

and the increased static pressure could cause problems

with the ll system.

• Maximum duct static pressure: 5” MDM units, 7” MDS and

MDD units.

• Internal duct insulation should be removed in the “bulk

evaporation” zone (Consult factory representative).

• Steam holes in the distribution pipe are located 2” from

mounting plate and designed for a maximum duct wall

thickness of 1”. Consult factory if special hole locations

are required.

• Do not mount the standard distribution pipe in a vertical

downow or vertical position in a horizontal ow system.

Special pipes are available, consult the factory.

Steam Output

Lb/hr 5 10 15 20 25 30 40 50 60 70 80 90 100

Kg/hr 2.3 4.5 6.8 9.1 11.4 13.6 18.2 22.7 27.2 31.8 36.3 40.9 45.4

Voltage Electrode Current (amps)

208/1

240/1

277/1

208/3

240/3

380/3

440/3

460/3

480/3

575/3

600/3

KW = .333 X Lbs/Hr

Amps(1Ph) = KW X 1000 / (Voltage)

Amps(3Ph) = KW X 1000 / (Voltage X 1.732)

Min. Circuit Ampacity = 1.25 X Rated Electrode Current (Note: with RDU add .5 Amps @ 208/240 Volts or add .25 Amps @ 480 Volts)

Minimum Circuit Ampacity determines wire size (AWG)

8.0A 16.0A 24.0A 32.0A 40.0A 48.0A 64.0A

6.9A 13.9A 20.8A 27.8A 34.7A 41.6A 55.5A 69.4A

6.0A 12.0A 18.0A 24.0A 30.1A 36.1A 48.1A 60.1A

4.6A 9.2A 13.9A 18.5A 23.1A 27.7A 37.0A 46.2A 55.5A 64.7A 73.9A 83.2A 92.4A

4.0A 8.0A 12.0A 16.0A 20.0A 24.0A 32.0A 40.1A 48.1A 56.1A 64.1A 72.1A 80.1A

2.5A 5.1A 7.6A 10.1A 12.6A 15.2A 20.2A 25.3A 30.4A 35.4A 40.5A 45.5A 50.6A

2.2A 4.4A 6.6A 8.7A 10.9A 13.1A 17.5A 21.8A 26.2A 30.6A 35.0A 39.3A 43.7A

2.1A 4.2A 6.3A 8.4A 10.4A 12.5A 16.7A 20.9A 25.1A 29.3A 33.4A 37.6A 41.8A

2.0A 4.0A 6.0A 8.0A 10.0A 12.0A 16.0A 20.0A 24.0A 28.0A 32.0A 36.0A 40.1A

1.7A 3.3A 5.0A 6.7A 8.4A 10.0A 13.4A 16.7A 20.1A 23.4A 26.7A 30.1A 33.4A

1.6A 3.2A 4.8A 6.4A 8.0A 9.6A 12.8A 16.0A 19.2A 22.4A 25.6A 28.8A 32.0A

8 www.herrmidifier-hvac.com

Herrtronic® MD Series

Page 9

Installation, Operation, & Maintenance Manual

Steam Distribution for Ducted Systems

DUCT HEIGHT

10" - 16"

(254MM) - (406MM)

(76mm)

3"

DUCT HEIGHT > 16"

(406mm)

DUCT HEIGHT

10" - 16"

(254MM) - (406MM)

AIR

6.5" (165mm)

FLOW

H

3.00" (76mm)

8.00

(203mm)

H

-5" (127mm)

h=

2

h

FIGURE 3 - SINGLE DISTRIBUTOR PIPE FIGURE 4 - DUAL DISTRIBUTION PIPES

DUCT HEIGHT>16"

(406MM)

6.5" (165mm)

h/3

AIR

FLOW

DUCT HEIGHT > 16"

(406mm)

h

3"

(76mm)

EST-250

SEPARATOR

(H-15)

2

h (in) = 6 +

CONDENSATE

H

h

h/3

h/3

3.0"

FIGURE 5 - MULTIPLE DISTRIBUTION PIPES

MIN. 8% (1" PER FOOT)

10" MIN.

(254mm)

NO SAGS

ALLOWED

CYL FULL

FAULTPOWER

ON/OFF

BACK

ENTER

FAULTS

HERRTRONIC MD

STEAM DISCHARGE MUST ALWAYS

BE FROM THE TOP OF DISTRIBUTOR

FIGURE 7 - STANDARD DUCT DISTRIBUTION

8.00

(typ.)

HORIZONTAL DUCT

VERTICAL DUCT

CYL FULL

FAULTPOWER

ON/OFF

BACK

ENTER

FAULTS

HERRTRONIC MD

½" TUBE

TO NEAREST

OPEN GRAVITY DRAIN

FIGURE 6 - INSTALLATIONS WITH UNAVOIDABLE LOW SPOT

EST-255

"Y" CONNECTOR

POWER FAULT

CYL FULL

BACK

ON/OFF

ENTER

FAULTS

HERRTRONIC MD

FIGURE 8 - TWO SEPARATE DUCTS

AT LOWEST

POINT

Herrtronic® MD Series

www.herrmidifier-hvac.com

9

Page 10

Installation, Operation, & Maintenance Manual

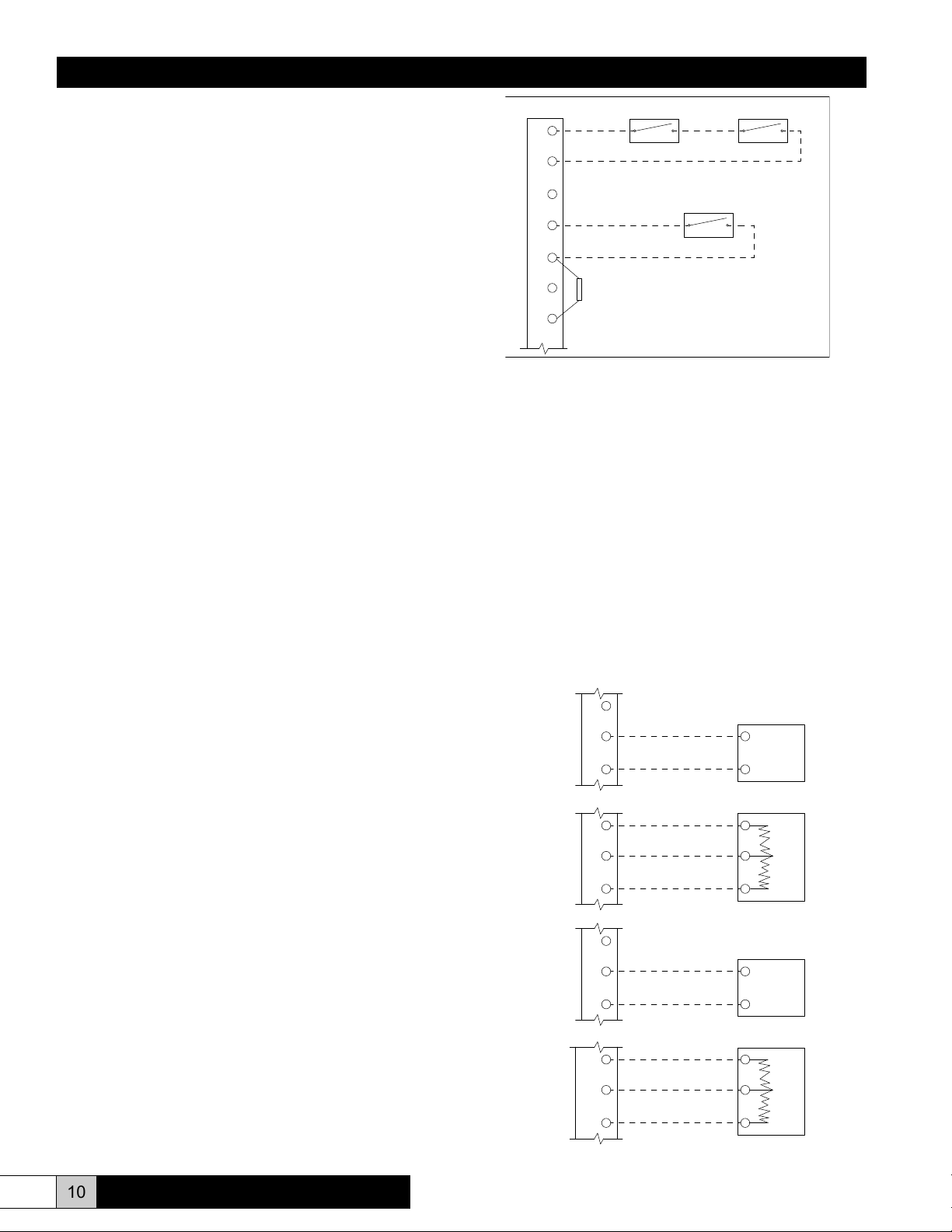

Controls

The Herrtronic MD Series Humidier has the capability to utilize

one of three types of control schemes.

1. On/Off

2. Proportional

3. Proportional + Integral

Controls may be supplied by the factory or others. The following

information applies to all controls factory supplied or furnished

by others. All external electrical control circuits are to be connected to the unit using the twelve pole terminal strip located

in the electrical compartment. The terminal strip is accessed

through the side electrical compartment door. Field wiring from

humidistat to humidier and between safety devices, such as

high limit humidistat and air proving switches, should be 18

AWG stranded or 20 AWG solid wire. If conduit is not used with

the controls wiring, install the black plastic ngered bushing (in

accessory pack) and completely seal with RTV silicone.

Wall devices should be mounted at a height similar to that of a

typical thermostat and should be located in an area that will pro-

vide good representation of the overall space being humidied.

Do not mount wall devices directly in the air stream of a supply

grille or room distribution unit.

Duct control devices should be mounted in a location where the

humidity and temperature are uniform, usually the return duct.

Do not mount in front of the steam distributor or in a mixing,

turbulent, or isolated area.

Duct high limit devices should be mounted downstream of the

steam distributors-far enough that under normal conditions in

the air stream, the steam has been completely absorbed, typically 10 ft. The device should be located such that it can sense

humidied air as it approaches saturation. Do not mount in dead

air spaces such as inside of corners or erroneous operation may

result.

Air proving devices should be mounted so that they sense air

ow (or the absence of it). Wire the device so that it closes when

air ow is present and will open when there is no air ow. The

purpose of the device is to prove that air ow is present before

steam is distributed into the duct.

The following information and diagrams are shown for each control scheme. Please refer to the control scheme that your humidier was set up for and follow the diagram for control circuit connections. The factory-set control type and signal are indicated

on a label adjacent to the controls terminal strip.

Air Flow Switch High Limit Stat

1

2

3

Control Humidistat

4

5

68.1 k Resistor

6

Ω

7

See Note Pg. 28

Mode 2 - Proportional Operation

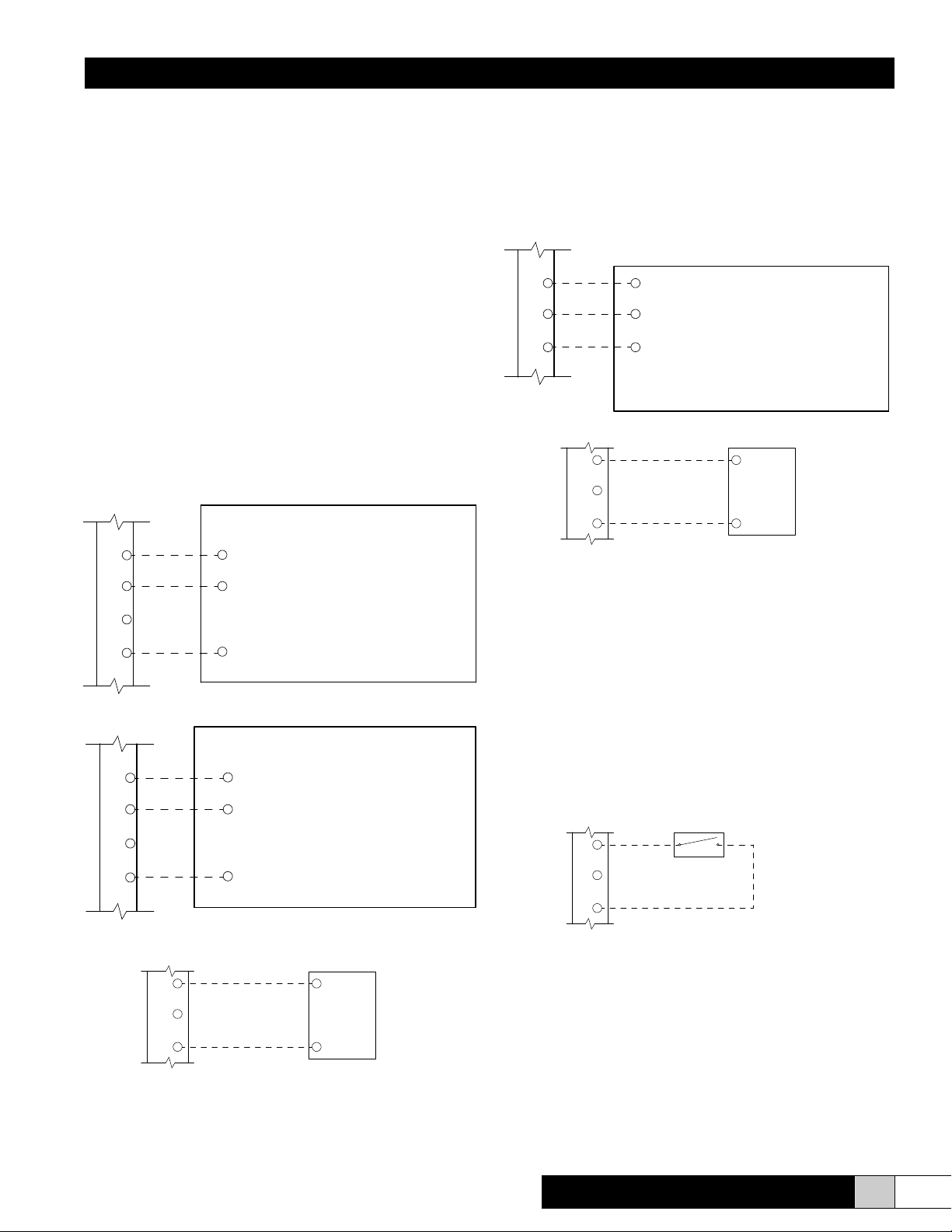

1. If two position airow and/or high-limit humidistat is used

wire as shown in Figure 9.

2. Control Input - Interpreted by the humidier as a demand of

output signal. Input device should be linear. Unit can accept

any VDC or mADC signal within a range of 0-20 VDC or

mADC (See Fig. 10). Unit may also accept a resistive signal

0-135 ohms (See Fig. 11).

3. Limit Input - Unit may accept any modulating input within

the same ranges as the control inputs listed above.

a. Proportional VDC or mADC (See Fig. 12)

b. Resistive (See Fig. 13)

Additionally, a P + I sensor may be used as a limit

input.

c. VDC (See Fig. 16)

d. mADC (See Fig. 17)

_

4

FIGURE 10

5

+

_

4

5

OUT

FIGURE 11

6

+

FIGURE 9

VDC or

mADC

Signal

W

R

B

Control Circuit Connections

Mode 1 - ON/OFF Operation

1. Control Input - Unit will operate with any two position device

(See Fig. 9). Demand for humidity will close the contact.

2. Limit Input - Unit will operate with any two position device

(See Fig. 9). The humidistat contact will open on humidity

rise.

10 www.herrmidifier-hvac.com

FIGURE 12

FIGURE 13

8

9

8

9

10

_

VDC or

mADC

Signal

+

_

W

OUT

+

R

B

Herrtronic® MD Series

Page 11

Installation, Operation, & Maintenance Manual

Mode 3. (Proportional + Integral)

1. If two position airow and/or high-limit humidistat is used,

wire as shown in Figure 9, page 10.

2. Control Input - Unit will accept any sensor input that pro-

vides a VDC (See Fig. 14A, wall or Fig. 14B, duct) or nmADC (See Fig. 15) signal within a range of 0-20 VDC or

mADC that is proportional to the humidity level in the air.

The sensor may be direct or indirect acting but must not

have an impedance greater than 500 ohms, and should be

linear. Example - A direct acting 2 - 10 VDC wall sensor will

send a 2 VDC signal if the R.H. level in the space is 10%; it

would send a 10 VDC signal if the R.H. level is 90%. The

humidier receives this input and compares it to the control

setpoint that has been programmed into the unit. The microprocessor modulates the output capacity of steam. The

adjustable integration period will review performance over

the given time and will make tuning adjustments by shifting

the proportional bandwidth to correct for over or under hu-

midication offsets automatically.

3. Limit Input - Unit can accept any sensor input as specied

above.

a. VDC sensor input (See Fig.16).

b. mADC sensor input (See Fig. 17).

7

8

9

FIGURE 16

PWR

GND

RH (0 -10 vdc Output)

HED3VSX

Duct

Sensor

(EST-1600)

4

5

6

7

FIGURE 14A

4

5

6

7

GND

RH (0-10 vdc Output)

PWR

GND

RH (0-10 vdc Output)

PWR

HEW3VSX

Wall

Sensor

(EST-1601)

HED3VSX

Duct

Sensor

(EST-1600)

External Off Switch

Should a eld installed remote off switch be required, follow

the wiring diagram below (See Fig. 18). Be sure to remove the

jumper wire between poles 1 and 3 on “Controls Terminal Strip.”

The remote off switch is to be wired between poles 1 and 3. This

switch will override the unit on/off switch to turn the unit off only,

it will not restart the unit. The unit must be turn back on by the

unit on/off switch.

Herrtronic® MD Series

www.herrmidifier-hvac.com

11

Page 12

Installation, Operation, & Maintenance Manual

Remote Alarm

The Herrtronic MD Humidier is equipped with a remote alarm

output. It is a triac output that may be used to energize an external relay or buzzer to indicate an alarm condition is present. The

alarm output is activated whenever an indicating fault condition

exists. When units are networked together, the master’s alarm

contacts will close if a fault occurs at either the master or one of

the slave units. The contacts are connected at poles 1 and 2 of

the remote alarm terminal strip 3.

In order to use the remote alarm output with a Building Management System, the remote alarm output must be used to energize

a mechanical relay. The contacts of the external relay may then

be wired to an input on the BMS to indicate if an alarm condition

is present. The remote alarm output may not be used like a dry

contact to a BMS.

Do not exceed the contact specications!

Contact rating:

• 24 VAC - 3.0 A

• 24 VDC - 2.1 A

Unit Networking

When networking units together in a master/slave conguration, be sure to maintain polarity between poles 11 and 12 on

all units. Units are to be wired as a parallel circuit. More than

one branch is allowable so that the master unit can be centrally

located (See Fig. 19). A maximum of 29 slave PC boards (29

MDS or MDM units or 14 MDD units) may be congured as a

network. Included in each installation pack is a 120 ohm resistor.

This resistor should be inserted into R28 on the microprocessor

board (see Fig. 32) on the appropriate end units of the chain.

(Refer to Fig. 19)

12 www.herrmidifier-hvac.com

Herrtronic® MD Series

Page 13

Installation, Operation, & Maintenance Manual

IV. OPERATING INSTRUCTIONS

Your unit has been pre-set for 1 of 3 control modes:

1. On/Off

2. Proportional

3. Proportional and Integral

With each control mode, there is a specic set of operating parameters and setpoints that apply. All of the setpoints have been preset

at the factory to simplify the start-up procedure. The following table identies the parameters, setpoints and preset values that apply

to each mode. Below the table is a more detailed description of the setpoint parameters. All setpoints have pre-set default values to

simplify programming. Instructions for adjustment follow.

Setpoint Parameters

Control Mode

1 2 3

Menu to

Adjust

Adjust Setpoint Range

MDM

Preset Values

MDS/MDD

Preset Values

Control Setpoint X 2 20-98% 35% 35%

Limit Setpoint (Note 3) X X 2 20-99% 75% 75%

High Humidity Alarm X 2 20-100% 99% 99%

Low Humidity Alarm X 2 10-98% 10% 10%

Capacity Setpoint X X X 2 10-100% 100% 100%

Auto Drain X X X 2 0-99 Days 7 Days 7 Days

Low Drain Threshold X X X 2 50-100% 85% 80%

Steam Output Rating X X X 3 0-999 lbs/hr. 5-30 lbs/hr. 10-100 lbs/hr.

Electrode Current Rating X X X 3 0-999 Amps As required As required

High Drain Threshold X X X 3 100-120% 110% 110%

Cycle Time X X X 3 30-300 Sec. 75 /(90) See note 1 130 /(150) See note 2

Proportioning Band X 3 +/- 2 to 15% +/- 10% +/- 10%

Integration Period X 3 0-60 Min. 30 Min. 30 Min.

Throttling Range (Note 3) X X 3 0-25% 10% 10%

Unit Address X X X 3 0-99 01 01 MDS (00, 01 MDD)

Low Drain Limit X X X 3 25-75% 50% 50%

Manual Drain X X X 5 Active/Inactive Active Active

Leakage Protection X X X 5 On/Off Off Off

End of Cyl. Life Setpoint X X X 5 1-500 hrs. 6 hrs. 6hrs.

Electrode Run Time X X X 5 0-999,999 hrs. 0 0

Limit Input (Note 3) X X 5 Enable / Disable Enable Enable

Control Input X X X 5 Enable / Disable Enable Enable

Drain Tempering X X X 5 Active/Inactive Inactive Inactive

Notes:

1. On units where voltage is 380 VAC or greater, the cycle time is 75 seconds. On units where voltage is 240 VAC or less, the cycle time is 90 seconds.

2. On units where voltage is 380 VAC or greater, the cycle time is 130 seconds. On units where voltage is 240 VAC or less, the cycle time is 150 seconds.

3. If a unit is ordered with the modulating high limit, the Limit Input will be ENABLED. If an “On/Off” type or no high limit is used, the Limit Input and Throttling Range

screens will have been eliminated.

Parameter Denitions: All Control Modes

• Output Rating - Unit design capacity (lbs/hr).

• Electrode Rating - Current rating that corresponds to unit design capacity.

• Capacity Rating - Output capacity as a % of the output rating.

• Low Drain Threshold - Minimum output capacity % that initiates a drain cycle.

• High Drain Threshold - Maximum output capacity % that initiates a drain cycle.

• Auto Drain - Time in days between system shutdown and cylinder drain.

• Manual Drain - Operator activated cylinder drain

• Drain Tempering - Allows mixing of cool inlet water with drain water for tempering

• Cycle Time - Time in seconds between ll cycles.

• Unit Address -In network installation; “master unit” is “00”, slaves “01” to “99”.

• Leakage Protection - Electrically disconnect electrodes during drain cycle.

• Electrode Run Time - Hours of cylinder operation.

• Control Input - Space condition humidity input device.

• End of CYL Life Setpoint - Unit has not achieved desired output within specied

time.

Specic Control Modes (See Chart)

• Control Setpoint - Desired % RH

• Limit Input - Modulating high limit from a controller or sensor

• Limit Setpoint - Maximum allowable % RH limit

• Low Humidity Alarm - Indication of control humidity level below alarm setpoint.

• High Humidity Alarm - Indication of control humidity level exceeding alarm set-

point.

• Proportioning Band - Humidity span around control setpoint where modulation

occurs.

• Integration Period - Length of time period for %RH evaluation and adjustment.

• Throttling Range - Humidity range below limit setpoint where modulation occurs.

All setpoints have pre-set default values to simplify programming -Instructions for

adjustment follow.

Herrtronic® MD Series

www.herrmidifier-hvac.com

13

Page 14

Installation, Operation, & Maintenance Manual

SETPOINT 35%

Programming

When power is initially applied (i.e. close the disconnect), the

liquid crystal display (LCD) will become active (without user action). A “signature” screen will appear:

HERRMIDIFIER INC.

HERR 002 VER 5.X

“Ver 5.X” denotes the program level of the microprocessor. The

specic “Ver 5.X” level should be included in any inquiry to a

Herrmidier representative or the factory. After a brief pause, the

‘”Main Menu” will appear:

SYSTEM OFF 000% X 01

MENU Y

The contents of the display provide the following

information:

“System Off” - The “ON/OFF” button is in the “OFF” position.

“000%” - Output capacity in % “0%” = 0 lbs /hr. Range is 0-100%

“X” - Control Mode:

1. On/Off

2. Proportional

3. Proportional + Integral

“01” - Unit Address

“Menu Y”- Designates program MENU:

Menu 1 - Status Items (non-adjustable)

Menu 2 - Setpoint Adjust (non-secured)

Menu 3 - Setpoint Adjust (secured by “password”)

Menu 4 - Network Communication

Menu 5 - Maintenance Adjust (infrequently used options)

Prior to start-up, the operator should review and/or adjust all

setpoints and, if needed, establish the network conguration.

Programming is accomplished as follows:

1. Press the “up” arrow for Menu 2. The LCD screen will read:

2. Press “Enter” to initiate the Menu program. The LCD will

read:

CONTROL 3 01

3. Press the “up” or “down” arrow button to increase or decrease the pre-programmed setting as desired.

4. Press “Enter” to register the setpoint and move to the next

setpoint.

5. Repeat steps “3” and “4” until all of that Menu’s setpoints

are registered.

6. Press “Back” to return to the MAIN MENU. (Menu 1)

7. Press the “up” arrow for Menu 3. The LCD will read:

SYSTEM OFF 000% 3 01

MENU 3

8. Press “Enter”. The LCD will read:

ENTER PASSWORD

NOTE!

Menu 3 is password secured. The setpoints in this menu are

protected from routine adjustment. The unit is shipped new

with three presses of the “Enter” key as the password.

9. To set a new password, six keystrokes are required. The

rst three keystrokes tell the unit that a new password is

being set. The last three keystrokes are the actual password. To set a new password, press “On/Off”, “up” arrow,

“Enter” and any (3) additional keystrokes - i.e. “up” arrow,

“down” arrow, “Back”. These last (3) keystrokes become

your “password.” Any subsequent revisions to Menu 3 setpoints will require use of this three keystroke “password.”

SYSTEM OFF 000% 3 01

MENU 2

NOTE!

Control Mode may be: (1), (2), or (3). This example pertains

to mode (3). In control modes (1) and (2), not all setpoints will

appear (The table on page 13 identies parameters visible in

each mode).

14 www.herrmidifier-hvac.com

NOTE!

If the wrong password is entered, the LCD will read:

INCORRECT

PASSWORD

Refer to step 9. The last (3) keystrokes become the new password.

Herrtronic® MD Series

Page 15

Installation, Operation, & Maintenance Manual

10. After establishing the “password”, repeat steps 3 through 5

to program Menu 3. Press “Back” to return to MAIN MENU.

(Menu 1)

11. Press “up” arrow for Menu 5. The LCD will read:

16. Press “up arrow” if you would like to access slave 2 and “up

arrow” again for slave 3, etc.

17. From the screen described in step 15, press “Enter” to access Slave 01. The LCD will read:

SYSTEM OFF 000% 3 01

MENU 5

12. Repeat steps 3 and 4 to complete Menu 5. The press “Back”

to return to the MAIN MENU (Menu 1)

NOTE!

Programming of the setpoints for the unit is now complete. If

there are multiple Herrtronic MD’s networked together OR you

are programming a MDD (110-250 lbs/hr.) unit, continue to

step 13. Otherwise proceed to STARTUP with CHECK LIST,

page 16.

Access Menu 4 for MDD Models only (2 tanks) or Networked

Units. This allows you to program the slave circuit board.

NOTE!

The address in the below screen is now 00. This allows the

‘Master” unit access to any “Slave” in the “Network.” Only one

Master unit “00” per Network can be used.

13. Press the “up” arrow for Menu 4. The LCD screen will read:

SYSTEM OFF 000% 3 00

MENU 4

SYSTEM OFF 000% 2 01

MENU 1

NOTE!

On MDD units, the address of the slave unit is factory set as

01. To reprogram the Slave, repeat steps 1 through 12 described on previous page.

NOTE!

If communications are not successful, the LCD will read:

NO REPLY ENTER TRY

AGAIN BACK TO EXIT

Possible sources for failed communication attempt:

A. Chosen Slave does not exist.

B. Slave unit does not have power connected.

C. Faulty communications wiring

1. Improper polarity of RS-485 (Controls Terminal

Strip Poles 11 & 12).

2. Resistor required to signify the beginning and end

of the “Network” is not installed correctly. On individual MDD units, these resistors are not necessary. See “Installation/Networking” section for clari-

cation.

D. It is possible for high levels of Electro-Magnetic Interfer-

ence (EMI) to impede communications between units.

Press “Enter” to try communications again, or “Back” to

return to “Master” units’ Main Menu.

14. Press “Enter”. The LCD will read:

POLLING SLAVE PRESS

BACK FOR MASTER MENU

This screen will appear only when power has been initially applied or reapplied. Wait about (5) minutes to allow the microprocessor to “Poll” the network.

15. After returning to the screen described in step 13, press

“Enter”. The LCD will read:

ENTER SLAVE

NUMBER 01

Herrtronic® MD Series

18. To return to “Master” unit (unit address 00) press the “up”

arrow (3) times. The LCD will read:

SYSTEM OFF 000% 2 01

MENU 4

19. Press “Enter”. The LCD will read:

LEAVING SLAVE PRESS

BACK FOR MASTER MENU

20. Press “Back” and return to “Master” unit (unit address 00)

Main Menu.

21. To program additional slaves, repeat steps 13-20. Programming is complete. Proceed with START- UP section.

www.herrmidifier-hvac.com

15

Page 16

Installation, Operation, & Maintenance Manual

Start-up with Check List

After all programming is completed (and the total installation is

complete), the Herrtronic MD system is ready to start. At the

end of START-UP section is a CHECK-LIST. The CHECK-LIST

is intended to highlight critical installation points. A poor installa-

tion frequently results in start-up difculties, and always results

in less than ideal operation of the humidier.

IMPORTANT- Before any Herrmidier representative or the

factory is contacted with a start-up problem; please have the

checklist completed as far as possible.

1. Set all controls to their lowest setting (control and high limit

if applicable). In systems using distributor pipes, make sure

the fan is operating. By placing the controls at their lowest

setting and turning the unit “ON” at the “ON/OFF” button,

the unit should not try to initiate production of steam. On

MDD units it is necessary to turn the Slave “on” through the

communications, Menu 4.

Find the lowest setting in each Control Mode as follows:

• Mode 1 (On-Off)-Turn the dial to the OFF position or

its lowest setting.

• Mode 2 (Proportional) - Set the controller to send the

lowest signal in the range (i.e. 4 mA in a direct 4-20

mA range).

• Mode 3 (P + I) - Set “Control Setpoint” through Menu

2 at least 11% below the “Control RH” displayed in

Menu 1.

2. Set high limit to its highest setting (all control modes).

3. Set CONTROL input to get the Herrtronic MD to attempt

100% of capacity as follows:

• Mode 1 (On-Off) - An audible “click” will be heard

when the humidistat is asking for full output.

• Mode 2 (Proportional) - Set controller to send

Herrtronic MD a full signal (i.e. 20 mA in a direct 4-20

mA output range).

• Mode 3 (P + I) – Set “Control Setpoint” through Menu

2 20% Above “Control RH” displayed in Menu 1.

4. TURN UNIT ”ON”. (ON MDD UNITS, BOTH MASTER AND

SLAVE BOARDS MUST BE TURNED “ON”.) Slave units

can be turned on via the Master board through communications or directly from the slave circuit board. Once the unit

gets the signal to run and unit is turned “On”, the contactor

will pull in within 5 seconds, followed by the ll valve being energized. The unit will attempt to ll to FULL OUTPUT

(100%) or CYLINDER FULL. If the unit fails to reach 75%

of capacity on the initial ll (as shown by CYLINDER FULL

light illuminated and <75% Output), you should use the

jumper wires enclosed in the accessory envelope and arrange them as shown on the diagrams on Figure 28, page

21. Be sure to disconnect power rst and re-tighten each of

the electrode knobs.

NOTE!

THIS WILL NOT BE POSSIBLE ON UNITS WHICH ALREADY HAVE POWER TO EACH ELECTRODE OR ANY

MDM. Before restarting the unit, drain half the water from the

cylinder using “Manual Drain” found in Menu 5.

5. If low conductivity water is being supplied, as indicated by

a low percentage of output (70% and under) and the CYL-

INDER FULL light is illuminated, you may want to articially

increase the output. This is accomplished by the following

procedure:

• Drain 1/2 the water from the tank using the manual

drain option in Menu 5.

• Add 1 Alka-Seltzer tablet

• Restart

• Repeat if needed

6. Fill System (Fig. 20) Check Points

• No leaks in system

• Virtually all the water entering the FILL TEE should

be going down the FILL TUBE as opposed to the

OVERFLOW TUBE. A slight adjustment may be

needed to the Metering Screw (Fig. 21) if water supply pressure is too high. Turn the screw clockwise to

close, or counter clockwise to open.

Figure 20

7. If you need to “TEMPER” the drain water because of local codes or low temperature drain piping is used, activate

“DRAIN TEMPERING” (Menu 5)

NOTE!

The drain water is TEMPERED or COOLED by the addition of

fresh water while the drain solenoid is open. The proper rate

of fresh water will cool the drain water and still allow the hu-

midier to drain freely. Use the ll valve adjusting screw (Fig.

21) to regulate the owrate of the cool inlet water. The amount

of tempering will depend on incoming temperature and pressure of the water supply.

8. Once the water is boiling and steam is being produced,

check the following:

• No leaks in the steam distribution lines or connections.

• The steam has a clear path from the cylinder to its

distribution points. Any low spots in the steam distribution line must be trapped. (See Fig. 6)

9. Unit needs to drain hot water to check proper drain line installation. Unit may be draining through normal operation,

but if not, initiate a drain through the MANUAL DRAIN in

16 www.herrmidifier-hvac.com

Herrtronic® MD Series

Page 17

Installation, Operation, & Maintenance Manual

Menu 5. Once hot water is being drained, check the following:

• Steam condensing on the bottom of the cabinet.

Correct by lowering the drain line or adding DRAIN

TEMPERING.

• Flash steam entering the steam cylinder compartment due to inadequate drain line.

• Flash steam entering the electrical compartment if

the knockout for the control wires isn’t sealed. This

should be sealed even if there doesn’t appear to be

any steam entering into the compartment. If conduit

is not used with the controls wiring, install black plas-

tic ngered bushing and completely seal with RTV

Silicone.

• Water must drain from unit freely. If there are restrictions in the drain line, it will send hot water/steam up

into the CABINET DRAIN and/or the OVERFLOW

TUBE which will pool inside the cabinet and could

leak out of the unit onto the oor.

START-UP IS COMPLETED. MAKE SURE CONTROLLING

DEVICES ARE SET FOR DESIGNED CONDITIONS. PROCEED TO AND COMPLETE CHECK-LIST. AFTER INITIAL

WARM UP, SHUT UNIT DOWN, TURN OFF MAIN POWER

AND RECHECK TIGHTNESS OF POWER CONNECTIONS

WHILE UNIT IS WARM (TORQUE TO 15-20 in-lbs.).

Figure 21

Herrtronic® MD Series

www.herrmidifier-hvac.com

17

Page 18

Installation, Operation, & Maintenance Manual

1. MATCHES DATA PLATE

2. IS PROPERLY GROUNDED

3. CAN CARRY AT LEAST 125%

OF RATE AMP DRAW

4. DISCONNECT SUPPLIED BY

OTHERS.

MAKE SURE ALL HIGH VOLTAGE

ARE TIGHT.

ELECTRICAL CONNECTIONS

POWER SUPPLY:

PRE-STARTUP CHECKLIST

NO UNTRAPPED LOW SPOTS

IN STEAM SUPPLY.

ELECTRICAL CONNECTIONS ON

MAKE SURE ALL HIGH VOLTAGE

(15-20 in/lbs)

STEAM CYLINDER(S) ARE TIGHT

SEALED TO PREVENT FLASH STEAM FROM

KNOCKOUT FOR CONTROL WIRING MUST BE

ENTERING ELECTRICAL COMPARTMENT.

4"

RECOMMENDED

8"

RECOMMENDED

WITH A MINIMUM PITCH OF 1/8" PER 12" OF RUN

3/4" MIN. I.D./1" MAX O.D.

FLEXIBLE DRAIN CONNECTION

BALANCE OF DRAIN LINE TO BE 1" MIN. I.D.

AIR FLOW IS HORIZONTAL OR VERTICAL UPFLOW

A SPECIAL PIPE IS REQUIRED FOR VERTICAL DOWNFLOW,

AIR FLOW.

OR A VERTICAL DISTRIBUTOR PIPE IN A HORIZONTAL

18 www.herrmidifier-hvac.com

DURING FILL CYCLE CHECK TO SEE IF ANY

WATER IS DRAINING FROM UNIT. A LOT OF

WATER FLOWING OUT OF THE UNIT WOULD

INDICATE EXCESSIVE WATER PRESSURE.

AMOUNT OF WATER IS NOT UNCOMMON.

OR SUPPLY VALVE TO HUMIDIFIER. A SMALL

REDUCE THROUGH METERING FILL SOLENOID

TEMPERATURE DRAIN WATER. THIS IS NOT UNCOMMON

AND DRAIN TEMPERING SHOULD BE ENABLED.

6" MIN. LENGTH OF 1-1/4" MIN. I.D. COPPER LINE.

IF PVC IS USED, LOCAL CODES MAY REQUIRE A LOWER

Herrtronic® MD Series

Page 19

Installation, Operation, & Maintenance Manual

Diagnostics

The Herrtronic MD humidier includes built-in diagnostics capability to identify potential problems, protect the system, and

minimize service/repair time. Should the system detect a critical

condition, a “fault” warning will be displayed on the LCD. Certain faults prompt immediate system shutdown to protect the

MD unit or ductwork. Other faults allow the unit to continue to

operate but alert the operator to potential problems that require

maintenance. Other faults, which are designed for initial system

tune-up or preventative maintenance, are classied as “non-indicating.” These faults are viewed by pressing the “fault” key on

the control panel. The table reects all of the faults the system

is capable of detecting. Please note, however, that certain faults

are unique to certain control modes or networked systems and

are only visible where applicable.

During operation, when an “indicating” fault occurs, the word

FAULT will be visible in the lower right hand section of the LCD.

The red fault light will also be illuminated.

If an “indicating” fault has been detected or a preventative check

is being performed, follow this procedure to determine the cause

of the fault:

1. The LCD must be in the MAIN MENU to access diagnostics. Press “FAULT” key to determine the type of fault.

2. Press the up arrow to determine if there is more than one

fault.

3. If possible, correct the condition causing the fault signal or

plan corrective action.

4. Press “ENTER” to clear the fault signal from the display.

When “ENTER” is pressed, all faults registered in the unit

will be cleared. If the condition causing the fault is not corrected, another fault signal will occur.

5. Under normal operating conditions, pressing the “FAULT”

button will prompt the following display:

NO FAULTS PRESENT

IN SYSTEM

In a multi-unit network, the master (“00”) unit will indicate a fault

within the entire network. To nd the fault(s), follow steps 1 and

2 for the master unit. If the display indicates “No Faults Present

In System,” then neither the Master, nor any Slave unit, has any

faults.

If any slave has a fault, the LCD will read:

System Fault Conditions

(See Troubleshooting Section for corrective action)

Fault Operation Status Comments

Current Overload (4) Shutdown and Drain

Contactor Failed (4) Continued Operation Humidication Re-

Cylinder Full Zero

Current

Fill System Fault (4) Shutdown and Drain

Zero Electrode Current

Non-zero Slowly Decreasing Amps

Non-zero Non-Decreasing Amps

Non-zero Non- Increasing Amps

Non-zero Slowly Increasing Amps

Cylinder Full Continued Operation Caused by low water

End of Cylinder Life

(4)

Air Flow / High Limit System Shutdown,

Hi Humidity Alarm (3)

(4)

Lo Humidity Alarm

(3)(4)

Humidity Sensor

Failed (3)

Slave “XX” Has Fault

(4)

Communication Port

Fault

Manual Reset(1)

Continued Operation Humidication re-

Manual Reset (1)

Continued Operation Humidication re-

Continued Operation Defective drain sys-

Continued Operation Defective drain sys-

Continued Operation Defective ll system

Continued Operation Defective ll system

Continued Operation Cannot achieve ca-

Automatic Reset (2)

Continued Operation Alarm threshold

Continued Operation Alarm threshold

Continued Operation

unless both fail

Continued Operation

of Master

Continued Operation

of Master

138% of Capacity

Setpoint Exceeded

quired

quired; unit not functioning properly

Fill for 15 min. – cannot achieve capacity

setpoint or cyl. Full

quired, no current

draw

tem

tem

conductivity, foaming, or end of cyl.

Life.

pacity and on cylinder

full or programmed

duration

Insufcient airow /

high limit setting exceeded

achieved

achieved

Humidity less than

4% or greater than

100%

Slave has fault

Slave operation unknown

SLAVE XX HAS FAULTS

Utilize the communications (Menu 4) from the Master to access

the particular slave with fault(s) to determine the fault. (Refer to

communication instructions in the programming section). Press

the “up” arrow button to determine if there is more than one

“slave” that has a “fault.”

Herrtronic® MD Series

1. Manual reset requires the problem be corrected and the unit turned “on” at

the keypad

2. Automatic reset will resume normal operation once the circuit is closed.

3. Proportional + Integral Control Only

4. Indicating Fault

www.herrmidifier-hvac.com

19

Page 20

Installation, Operation, & Maintenance Manual

Maintenance

To maintain efciency of the unit, the water level in the cylinder

will slowly rise as the electrodes become coated with minerals.

Progressively, the water level reaches the cylinder full electrode,

representing the maximum allowable water level. Eventually, all

of the usable electrode surfaces will be coated. After the end

of cylinder life setpoint has been reached, the LCD will read

“End of Cylinder Life” fault. Cylinder replacement should occur

to maintain satisfactory humidity levels. “End of Cylinder Life”

varies with water conductivity. Refer to the chart that follows:

Conductivity (micro-mhos)

(approximately)

70 2000

100 2000

135 1900

170 1800

250 1300

500 800

750 650

1000 500

Average Cylinder Life

(Hours)

on, allow cylinder to ll and check for leaks. AFTER INITIAL WARM UP, SHUT UNIT DOWN, TURN OFF MAIN

POWER AND RECHECK TIGHTNESS OF POWER CONNECTIONS WHILE UNIT IS WARM (TORQUE TO 15-20

in-lbs.).

Extended Shutdown:

The humidier is set by the factory to drain if the unit doesn’t

operate for seven days. However, the drain time can be revised

through reprogramming (Refer to Page 14). Always drain the

cylinder completely if it will be off of an extended period of time

(see Auto drain feature, menu 2, page 13).

NOTE

Many factors in addition to water conductivity effect cylinder

life. Total dissolved solids (TDS) and exact mineral content

of the water can have negative effects on cylinder life. Your

representative will be happy to review your water analysis.

If you don’t have an analysis and are on a municipal system,

the municipal water authority will provide one free of charge.

Conductivity between 70 and 200 micromho is best handled

with “on/off” control. Discuss your application with the factory

if your water is in this range and “Proportional” or “Proportional + Integral” control is required. Water with less than 70

micromho may not be sufcient to allow the unit to operate.

Herrmidier has considerable experience optimizing the performance of your humidier on “fringe” water conditions. Con-

sult your representative.

To Remove the Cylinder:

1. Turn the unit “off” by pressing the “on/off” button. Drain the

cylinder completely using the manual drain (Menu 5).

2. Disconnect the power to the unit..

3. Disconnect the electrode power wires (and jumpers if used)

- noting the orientation, and the cylinder full electrode wire

from the cylinder. Remove the expired cylinder from the

cabinet.

4. Position the new cylinder in the cabinet. Place the new “O”

ring as shown in Fig. 22. Lubricate the “O” ring with water

only and install cylinder into drain cup, EST-1062, pushing

down rmly with a twisting motion.

5. Reconnect the power wiring (and jumpers if required) referring to appropriate Figure on the next page that matches

the power wiring conguration of the unit. Be certain to use

lock washers on each electrode and tighten the electrode

knob (Fig. 25 or 29).

6. Installation is now complete, Reconnect power, turn unit

20 www.herrmidifier-hvac.com

Herrtronic® MD Series

Page 21

Installation, Operation, & Maintenance Manual

FIGURE 23FIGURE 22

EST-1060-3

O-RING

POWER WIRE B

POWER WIRE A

CYLINDER

FULL

ELECTRODE

FIGURE 24

POWER WIRE A

POWER WIRE C

FIGURE 26

POWER WIRE H

POWER WIRE B

FIGURE 28

POWER WIRE G

POWER WIRE B

CYLINDER

FULL

ELECTRODE

POWER WIRE A

CYLINDER

FULL

ELECTRODE

JUMPER WIRE

FIGURE 25

FIGURE 27

POWER WIRE

C OR F

POWER WIRE

H OR K

POWER WIRE

B OR D

POWER WIRE G OR J

FIGURE 29

ELECTRODE CAP

LOCKWASHER

POWER WIRE

LOCKWASHER

POWER WIRE I OR L

POWER WIRE

A OR D

CYLINDER

FULL

ELECTRODE

ELECTRODE CAP

POWER WIRE

C OR F

JUMPER WIRE

POWER WIRE

B OR E

JUMPER WIRE

FIGURE 30

Herrtronic® MD Series

POWER WIRE

CYLINDER

FULL

ELECTRODE

ELECTRODE CAP

LOCKWASHER

POWER WIRE

JUMPER WIRE

LOCKWASHER

A OR D

LOCKWASHER

POWER WIRE

LOCKWASHER

www.herrmidifier-hvac.com

21

Page 22

Installation, Operation, & Maintenance Manual

V. TROUBLESHOOTING GUIDE

General Maintenance Notes

WARNING!

High Voltage components are present in both the cylinder and

electrical compartments. Maintenance must be performed by

qualied individuals. Absolutely no other components may be

mounted inside or electrically tapped into humidier without

voiding the warranty.

A. Externally, controls of many congurations may be used

with your new MD series humidier. Herrmidier strongly

recommends the use of some type of control humidistat,

a high limit humidistat, and an air proving switch to insure

proper operation of your humidication system.

B. Electrode boilers operate by passing current through the

water utilizing the conductivity of the water itself as a cur-

rent path. The ow of current through the water generates

heat which boils the water and produces the steam required

for humidication. The diagnostic features of the MD series

humidier are designed to help you maintain and optimize

your system for years of service. If the fault light is illuminated, see the diagnostic section on page 19.

C. The wiring diagram, illustrated on page 34 (for MDD units,

the wiring diagram is located on pages 11 and 12 of the

“MDD Supplement”), clearly shows the path of the 24 VAC

control circuit. Control voltage leaves the transformer,

passes through a fuse and then into the circuit board. The

microprocessor has inputs and outputs for the humidistats

or sensors, contactor auxiliary pole, differential pressure

switch and the control loop. Power for the control loop goes

through the external off switch (optional), the door interlock

switch, and then back to the microprocessor. Understanding the wiring diagram will give you a better idea of the logic

of the MD series humidier and simplify your troubleshooting.

D. If any changes to the physical board set-up are made, i.e.

capacity changes or resistor, the unit must be reset. You

may reset the unit by depressing the “reset” button on the

back of the board or turning the unit off and on through the

disconnect (See PC Board diagram on page 28).

E. If the circuit board needs to be changed, make sure the

ribbon cable connector from the main board to the display

board is as originally supplied (red stripe on top at LCD and

on the right at PCB). Reattach the (three) 11 Pin connectors

in the same manner. (J1, J3 and J5)

Operating The Humidier Without External Controls

The humidier has the capability to operate without any external

signals being sent to the unit. Being able to isolate the humidier

from the external controls is invaluable in troubleshooting. The

unit can be “jumped-out” whether it’s mode 1, 2, 3.

capacity setpoint) or cylinder full.

6. After conrming proper operation, reattach controls for

normal operation and remove added jumpers.

B. Mode 2 - Proportional

This signal is typically supplied by others. The MD has 2 separate VDC power supplies accessible from the controls terminal

strip (as shown on page 26). Either one of these outputs will be

sufcient to bring the MD into an operational state. You will need

to know the control signal being supplied and select the 5 VDC

or 2O VDC output from the control terminal strip. The humidier

will react in proportion to its programmed signal range.

Example: The humidier is set up for 0-10 VDC signal from the

BMS. The humidier is being jumped-out with the 5 VDC signal

from pole 6 to pole 5 on the control terminal strip. You can ex-

pect the humidier to ll to 50% output or cylinder full.

1. Remove any eld installed control wires; mark for re-

attachment.

2. Through Menu 5, disable limit input (if applicable).

3. Jump terminals 1 & 2 on controls terminal strip.

4. Jump terminals 1 & 3 on controls terminal strip.

5. Select 5 VDC from control terminal strip pole 6 or 20

VDC from control terminal strip pole 7 to jump to pole 5

on the controls terminal strip.

6. If signal provided is other than VDC, use the following

comparisons: mADC; 20mA = 20 VDC, resistance; 135

ohms = 2 VDC

C. Mode 3 - Proportional + Integral

If a problem is detected in the sensors, the diagnostics will pick

up the problem and display a fault with the sensor. To jump-out,

follow the steps 1-4 listed for Mode 2 above, then follow steps 1

through 3 below.

1. If the control signal is a DC voltage type with a maximum

signal level of 5 VDC or greater, or a DC millilamp type with

a maximum signal level of 20 mA or greater, apply a jumper

wire between poles 5 & 6 on the controls terminal strip.

2. A control RH level will be indicated based on the jumped

input signal and the factory board set up for the actual eld

control signal. i.e., board factory set for a 0-10 VDC control

signal, jumper wire applied between poles 5 & 6, the indicated control RH level (via Menu #1) will be approximately

50%.

3. Adjust the control setpoint relative to the control RH level

via Menu #2, keeping in mind the bandwidth, i.e., control

RH level is 50%, Bandwidth is +/- 10%, adjust the control

setpoint to 60%, or greater, to obtain 100% output from the

unit.

A. Mode 1 - On/Off

1. Remove any control wiring supplied by others; mark

wires for re-attachment.

2. Jump terminals 1 & 2 on controls terminal strip.

3. Jump terminals 1 & 3 on controls terminal strip

4. Jump terminals 4 & 5 on controls terminal strip.

5. After unit is turned ON, it should ll to 100% output (or

22 www.herrmidifier-hvac.com

Herrtronic® MD Series

Page 23

Installation, Operation, & Maintenance Manual

Unit Detected Faults (Red Light is Illuminated)

Problem / Symptom Probable Cause Reason - Correction

Restricted Drain System Clean and replace as necessary

Overcurrent

When this condition occurs, the system

has sensed an excessive current draw

(138% of rated current) and has shut itself

down and drained completely to prevent

possible damage. The system has already

taken preventative action by attempting to

drain down prior to the fault condition occurring. Therefore, further analysis is required before restart is attempted.

Fill System Fault

The unit has been in ll cycle for 15 minutes continuously without reaching required output or cylinder full. System will

shutdown and drain completely.

End of Cylinder Life

The cylinder is full and humidier has not

been able to achieve desired output within

setpoint.

High Humidity

Humidity in the space being measured by

the control sensor has exceeded the preset alarm level. This alarm is only avail-

able on units congured with P + I control

(mode 3).

Use of softened water without adjusting

operating parameters

Water conductivity in excess of 750

micromho

Expired steam cylinder – a mineral bridge

has developed allowing a short between

two electrodes.

If drain tempering is enabled and the rate

of ll is exceeding the rate of draining,

the tank will ll whenever the unit tries to

drain.

Restricted or blocked ll system (strainer,

solenoid, external shut-off valve.)

Partially or completely open drain valve.

Extremely low conductivity supply water

Cylinder expired-electrodes have been

consumed.

Extremely low conductivity supply water Add a 1/4 teaspoon of salt to the cylinder.

Tampering with the control humidity setpoint.

Alarm set-point too close to control setpoint

Humidier is powered but not operating

and RH is above setpoint

Sensor or wiring has failed.

See Fig. 30

See Fig. 30 and 31

Replace steam cylinder

Adjust the ll valve metering screw to

slow the rate of ll so the unit can drain

properly. See Fig. 21 for adjusting screw

location.

Replace

1. Reset your alarm setpoint.

2. Turn off humidier at main disconnect

until humidication season.

Low Humidity

Humidity in the space being measured

by the control sensor has dropped below

the preset alarm level. This alarm is only

available on units congured with P + I

control (mode 3).

Slave Fault

One of the 6 indicating faults has been detected in a slave unit.

Contactor Failed

Unit has tried to turn on but contactor has

not closed, or unit should be off, but contactor is still closed.

Alarm setpoint too close to control setpoint

Humidier is powered but turned “off” and

the RH is below the alarm setpoint.

Sensor or wiring has failed

Review of the slave units is required to

determine specic fault conditions.

Failed contactor - It’s common to nd

metal chips or other construction debris

lodged in the contactor preventing proper

operation

Faulty control wiring.

Auxiliary contact dislodged from proper

position.

Faulty auxiliary contact

Installation with RDU’s--the jumper between control terminal strip poles 1 & 2

needs to be removed.

1. Turn the humidier “on” to satisfy demand.

2. Adjust the low humidity alarm.

Repair or replace

Herrtronic® MD Series

www.herrmidifier-hvac.com

23

Page 24

Installation, Operation, & Maintenance Manual

Cylinder Full Zero Current

Cylinder full condition is present but zero

amp draw is being sensed. Unit will continue to operate.

Zero Electrode Current

The electrode current is zero and it should

not be.

Non-Zero Slowly Decreasing Current

The current is decreasing more slowly

than it should during any automatic drain.

The system will continue to operate but

maintenance is required.

Non-Zero Non-Decreasing Current

A worsening of the condition above. A

complete blockage has occurred.

Non-Zero Non-Increasing Amps

System is not detecting increase in cur-

rent draw during ll.

Air Flow / High Limit

Unit has detected loss of airow in air handling system or room distribution unit, or

the optional on/off high limit setting has

been reached

Cylinder Full

Unit has detected water level at the top of

the steam cylinder.

Humidity Sensor Failed

Only available on units congured with a

P+I control. The sensor has registered a

humidity reading of 100% of more, or 4%

or less for more than 5 seconds.

Repair or replace. To check the toroid,

Faulty toroid transformer or wiring

Loss of one leg of main power

Very clean water-less than 100 micromho

Faulty toroid transformer or wiring

Failed drain system (stuck open)

Failed ll system (stuck closed)

Excessively long cycle time (>150 seconds).

Defective drain system

Block drain valve or drain system

Failed drain valve or defective wiring

Faulty ll valve or wiring

Water supply is shut off

High limit setpoint has been exceeded at

high limit humidistat

Fan has stopped while there is still a de-

mand for humidication.

Insure proper wiring for both air ow

switch and high limit humidistat.

Failed blower or air ow switch in RDU. Repair or replace.

Low conductivity water supply – start-up

condition

Softened supply water

Overconcentrated water in cylinder causing foaming

Approaching end-of-cylinder life

Failed humidity sensor or wiring

Position of humidity sensor too close to

steam discharge

measure the resistance of the toroid transformer. It should be approximately 8.5

ohms (+/- 1.5 ohm).

Check main terminal blocks. If line voltage

is not present, check external fusing.

Contact your local water authority. If you

are on a well, a complete water analysis

should be performed. If you have any

questions about the analysis, contact the

factory.

Repair or replace. To check the toroid,

measure the resistance of the toroid transformer. It should be approximately 8.5

ohms (+/- 1.5 ohm).

Repair or replace. Operate drain valve

with manual drain switch (Menu 5) to determine whether it is operating freely.

Repair or replace. Check that external ll

valve is open. Check that strainer is not

blocked. Check to see that 24 VAC is at

the coil of the ll solenoid.

.

Clean and/or replace as necessary. Check

for partial blockage of drain valve, drain

cup, or drain plumbing.

Repair or replace as necessary.

Repair or replace.Blocked strainer

Check air handling system.

.

Install electrode jumper wires if not already connected ( See page 21).

See softened water operating parameters

in Fig. 30.

See hard water operating parameters in

Fig. 30 or 31.

24 www.herrmidifier-hvac.com

Herrtronic® MD Series

Page 25

Installation, Operation, & Maintenance Manual

Communications Fault

A short has been detected in the RS-485

communications loop.

Green power lamp and LCD are not illuminated.

Unable to turn unit on after pressing “on/

off” button

Water always draining when drain solenoid is closed

Display shows erroneous number and

titles (such as “%*#~?/*@”)

Blown 24 VAC control fuse

Blown high voltage fuses

Main transformer failure

Incorrect voltage to primary side of transformer

Obstruction keeping the drain solenoid

from closing

Maintenance is required.

Short in control wiring or microprocessor

board if fuse blows immediately.

Short in contactor or control wiring if fuses

blow as unit energizes contactor.

Short in ll valve or wiring if fuses blow

after unit is attempting to energize the ll

valve.

Short in drain valve or wiring if fuses blow

after unit has cycled and is now attempting to energize the drain valve.

Spike in power supply.

Short in terminal blocks or contactor

Check for 24 VAC on secondary side of

transformer between X1 and X2.

If secondary side is insufcient and proper

voltage is being supplied to primary side

of transformer, replace transformer.

Conrm voltage supplied compared to tap

on transformer and data plate.

Measure AC voltage across the primary

of the transformer for supplied voltage

If insufcient, check path through terminal

blocks, contactor and fuses for a potential

drain.

If every point of connection within the

humidier reads the same insufcient

number, then the disconnect should be

checked.

Open door and press “on/off” button again.

If unit comes on, place 1 and 2 wires to the

opposite side of the door interlock switch.

Poles 1 & 3 on the controls terminal strip

need to be jumped.

Clean and/or replace.

Press reset button on the back of the PC

board

Check for proper ribbon cable connections to LCD and PC board (see page 22,

Item E)

Replace ribbon connector, LCD and PC

board.

Herrtronic® MD Series

www.herrmidifier-hvac.com

25

Page 26

Installation, Operation, & Maintenance Manual

Summary of Troubleshooting Tips for the Inputs and Outputs of the EST-1250 Circuit Board

Turn power ON to the unit (green power light should be ON) & verify proper sensor installation. If all of the 24 VAC inputs to the

circuit board are energized, but ANY of the outputs from the circuit board are NOT indicated, the circuit board may not be operating

properly.

1) Verify that these inputs to the circuit board are energized:

24 VAC Input to Board Source of 24 VAC Input to Board

At Connector J3 At Terminal Block

PIN 1, wire # 17 Terminal 10, wire # 17

PIN 4, wire # 18 Terminal 9, wire # 18

PIN 8, wire # 19 Terminal 8, wire # 19

PIN 10, wire # 20 Terminal 7, wire # 20

At Connector J5 At Terminal Strip

PIN 1, wire # 37 Terminal 3, wire # 16 (thru door interlock)

PIN 2, wire # 45 Terminal 2, wire # 45

At Connector J5 At Auxiliary contact

PIN 3, wire # 3 Wire # 3

2) Verify that these outputs from the circuit board are energized:

24 VAC Output from Board Function of 24 VAC Output from Board

At Connector J3

PIN 5, wire # 34 Energize contactor coil, wire # 34

PIN 9, wire # 23 Energize drain solenoid, wire # 23

PIN 11, wire # 13 Energize ll solenoid, wire # 13

DC Output from Board Function of DC Output from Board

At Connector J5 At Terminal Strip

5 VDC at PIN 5, wire # 5 5 VDC available at terminal #10, wire # 5

20 VDC at PIN 8, wire # 8 20 VDC to power sensors from terminal #7, wire # 8

5 VDC at PIN 9, wire # 9 5 VDC to simulate sensor input at terminal #6, wire # 9

Output to Unit Display

From Connector J4

Board generates clear and legible two line display instead of a single row of black or gray blocks.

26 www.herrmidifier-hvac.com

Herrtronic® MD Series

Page 27

Installation, Operation, & Maintenance Manual

Inputs / Outputs of Terminal Strips and Terminal Block

Terminal Block