Page 1

Engineered Humidification Systems

READ & SAVE THESE INSTRUCTIONS

Herrmersion RE Series

Installation, Operation, & Maintenance

Herrmidifier® | www.herrmidifier-hvac.com

Page 2

Installation, Operation, & Maintenance Manual

TABLE OF CONTENTS

Warranty ................................................................................................................................................................ 3

General Warnings & Installer Responsibility .......................................................................................................... 4

Model Number Nomenclature ................................................................................................................................ 4

Overall Unit Dimensions ........................................................................................................................................ 4

Receiving Instructions ............................................................................................................................................ 4

Pre-Installation Instructions ................................................................................................................................... 5

General Safety Requirements ............................................................................................................................... 5

Installation .............................................................................................................................................................. 5

Unit Location & Mounting ............................................................................................................................. 5

Plumbing ...................................................................................................................................................... 6

Steam Distribution ..................................................................................................................................... 6-8

Electrical ...................................................................................................................................................... 8

Installation Checklist .................................................................................................................................... 9

Wiring Diagrams.................................................................................................................................... 10-15

Control System .................................................................................................................................................... 16

Parameters Menu ...................................................................................................................................... 16

Status Menu ............................................................................................................................................... 17

Setpoints Menu .......................................................................................................................................... 17

Alarm Screen ............................................................................................................................................. 18

Clockset Screen ......................................................................................................................................... 18

User Password Settings ............................................................................................................................. 18

Control Conguration (Admin Only) ...................................................................................................... 18-19

Control Module Specications ........................................................................................................................ 20-21

Replacement Parts .............................................................................................................................................. 22

Maintenance Record Sheet ................................................................................................................................. 23

2 www.herrmidifier-hvac.com

Herrmersion RE

Page 3

Installation, Operation, & Maintenance Manual

I. WARRANTY

Limited 2-Year Warranty

Seller warrants the equipment of its manufacturing to be free

from defects in workmanship and material for a period of 24

months after shipment or 24 months after initial commissioning,

whichever occurs rst. This warranty is limited, however, to the

repair or replacement of defective equipment, which is returned,

freight prepaid, to Seller’s factory.

This limited warranty does not apply to any part or component

that is damaged in transit or when handling, has been subject

to misuse, negligence or accident, has not been installed, operated or serviced according to Seller’s instructions, or has been

operated beyond the factory-rated capacity or has been altered

in any way.

Seller’s liability is limited to replacement of defective parts or

components and does not include any cost of labor (including,

but not limited to, labor required to remove and/or reinstall any

defective part) other than Trion/Herrmidier factory labor.

Each of the Herrtronic series of steam generating humidiers

contains a plastic steam generating cylinder that is to be considered a routinely disposable part to be changed at regular maintenance intervals at the user’s expense. This steam generating

cylinder is not covered by this Warranty. If, after the rst installation of your Herrtronic humidier, you feel the steam generat-

ing cylinder is not operating normally, you should contact your

Herrmidier Representative with an explanation of the problem.

However, in the continuing operation of this humidier, replace-

ments of this part are your responsibility as part of routine maintenance.

Trion/Herrmidier shall not be responsible for loss of use of

any product, loss of time, inconvenience, or damage to other

equipment, or any other indirect or consequential damage with

respect to property whether as a result of breach of warranty,

neglect, or otherwise.

THE WARRANTIES AND LIABILITIES SET FORTH ARE IN

LIEU OF ALL OTHER WARRANTIES AND LIABILITIES, EXPRESSED OR IMPLIED, IN LAW OR IN FACT, INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR PARTICULAR PURPOSE.

ATTENTION

READ THIS MANUAL, FACTORY INSTALLED OPTIONS

MANUAL, UNIT SUBMITTAL DATA SHEETS AND ALL LABELS

ATTACHED TO THE UNIT CAREFULY BEFORE ATTEMPTING TO INSTALL, OPERATE OR SERVICE THESE UNITS.

CHECK DATA PLATES FOR ELECTRICAL SPECIFICATIONS

AND MAKE CERTAIN THAT THESE AGREE WITH THOSE AT

THE POINT OF INSTALLATION. RECORD THE UNIT MODEL

AND SERIAL NUMBER IN THE SPACE PROVIDED. RETAIN

THIS DOCUMENT FOR FUTURE REFERENCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH. THIS APPLIANCE MUST

BE INSTALLED BY A LICENSED CONTRACTOR OR QUALIFIED SERVICE PERSONNEL. READ THESE INSTALLATION,

OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THE UNIT.

WARNING

INSTALL, OPERATE AND MAINTAIN UNIT IN ACCORDANCE

WITH MANUFACTURER’S INSTRUCTIONS TO AVOID ANY

CIRCUMSTANCES THAT MAY CAUSE PERSONAL INJURY

OR PROPERTY DAMAGE.

INSTALLER’S RESPONSIBILITY

THIS EQUIPMENT HAS BEEN RUN TESTED AND INSPECTED THOROUGHLY. IT HAS BEEN SHIPPED FREE FROM DEFECTS FROM OUR FACTORY. HOWEVER, DURING SHIPMENT AND INSTALLATION, PROBLEMS SUCH AS LOOSE

WIRES, LEAKS OR LOOSE FASTENERS MAY OCCUR. IT

IS THE INSTALLER’S RESPONSIBILITY TO INSPECT AND

CORRECT ANY PROBLEMS THAT MAY BE FOUND.

RECEIVING INSTRUCTIONS

INSPECT SHIPMENT IMMEDIATELY UPON ARRIVAL TO DETERMINE IF ANY DAMAGE HAS OCCURRED TO THE UNIT

DURING SHIPMENT. AFTER THE UNIT HAS BEEN UNCRATED, CHECK FOR ANY VISIBLE DAMAGE TO THE UNIT. IF

ANY DAMAGE IS FOUND, THE CONSIGNEE SHOULD SIGN

THE BILL OF LADING INDICATING SUCH DAMAGE AND IMMEDIATELY FILE A CLAIM FOR DAMAGE WITH THE TRANSPORTATION COMPANY.

The foregoing shall constitute the total liability of seller in the

case of defective performance of all or any of the equipment or

services provided to Buyer. Buyer agrees to accept and hereby

accepts the foregoing as the sole and exclusive remedy for any

breach or alleged breach of warranty by Seller.

Herrmersion RE

www.herrmidifier-hvac.com

3

Page 4

Installation, Operation, & Maintenance Manual

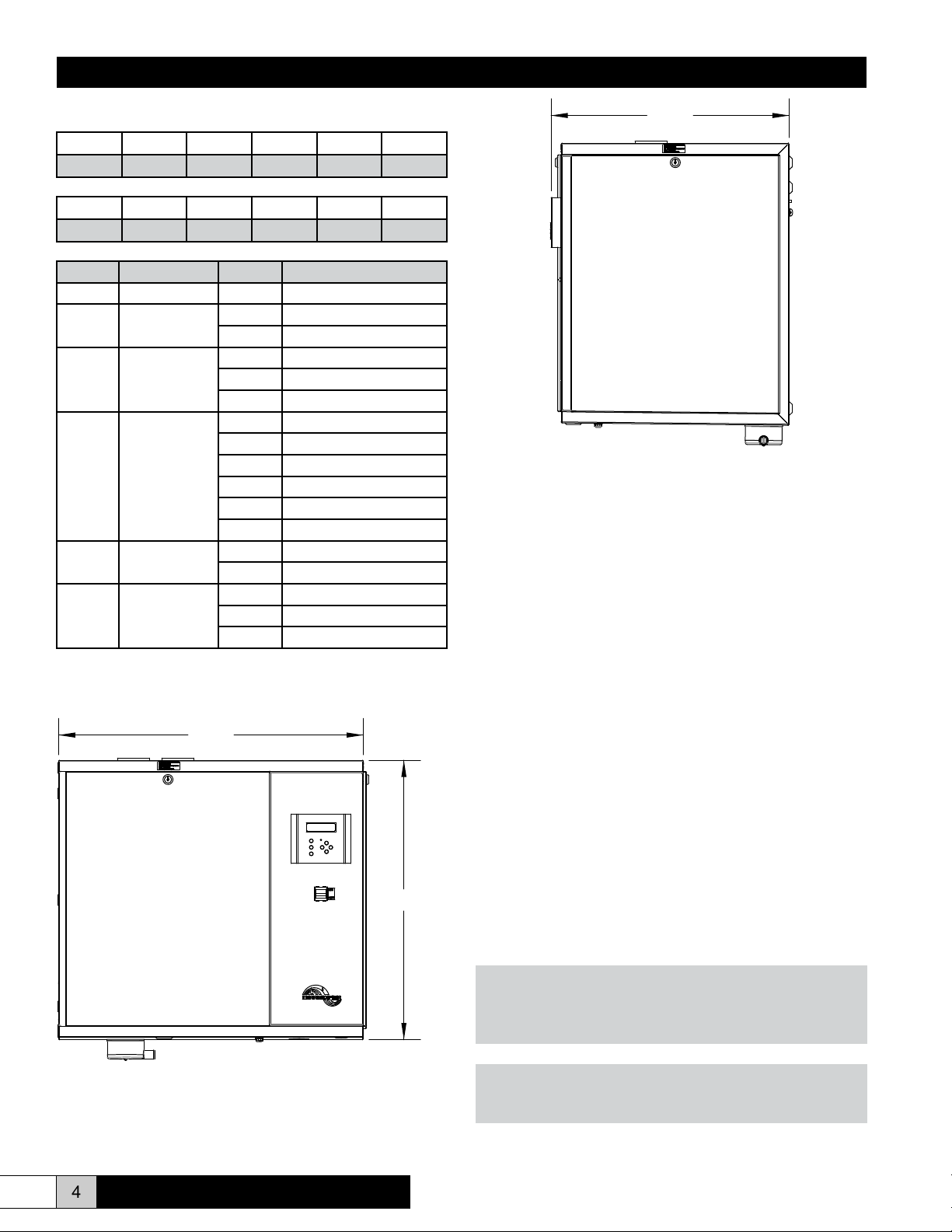

MODEL NUMBER NOMENCLATURE

RE * * * * *

Model Prex

RE S P 480 3 45

Model Prex

Position Meaning Option Description

Prex Product Family RE RE Electric-to-steam

1

2 Control Type

3 Voltage

4 Phase

5 Capacity (lb/hr)

1 2 3 4 5

1 2 3 4 5

Size (number

of tanks)

S Single Tank

D Dual Tank

P Proportional Control

I Proportional + Integral

H Custom (on/off humidistat)

208

240

380

415

480

600

1 Single Phase

3 Three Phase

30 (2) 5 KW heaters

45 (3) 5 KW heaters

90 (6) 5 KW heaters

21.29

RECEIVING INSTRUCTIONS

Inspect shipment immediately upon arrival to determine if

there is any noticeable freight damage to the packaging.

After the unit has been unpacked, check for any damage

to the unit. Take notice that the drain cup mounted to the

underside of the unit is not cracked or damaged.

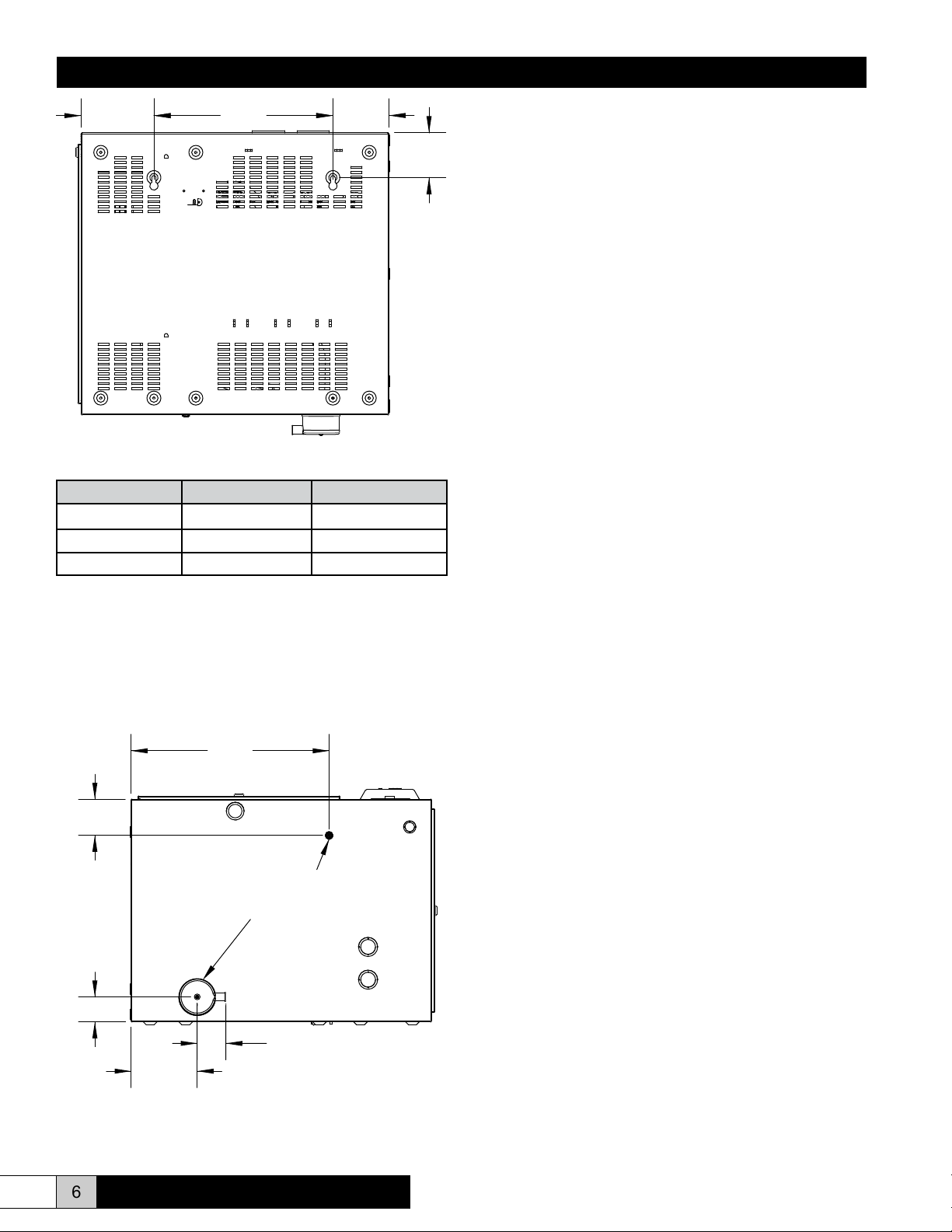

OVERALL UNIT DIMENSIONS

27.75

25.20

If any damage is found, the consignee should sign the bill of

lading indicating such damage and immediately le a claim

for that damage with the transportation company.

PRE-INSTALLATION INSTRUCTIONS

After the unit is received and unpacked, check the external

data plate and all labels on the unit for electrical and

operational specications to conrm that these agree with

those at point of installation.

Note: It is the owner’s responsibility to provide any

scaffolding or other apparatus required to perform emergency

service or annual/periodic maintenance to this equipment.

GENERAL SAFETY REQUIREMENTS

WARNING

Open all disconnect switches before installing the unit.

Failure to do so could result in personal injury or death from

electrical shock.

WARNING

Failure to comply with the general requirements may result in

extensive property damage, severe personal injury or death.

4 www.herrmidifier-hvac.com

Herrmersion RE

Page 5

Installation, Operation, & Maintenance Manual

WARNING

Never service any component without rst disconnecting all

electrical supplies to the unit or severe personal injury or

death could occur.

CAUTION

Insure that all power sources conform to the unit requirements

or damage to the unit may result.

These units have been designed for any tap, softened, de-

ionized (DI) or reverse osmosis (RO) water applications.

With tap/softened water, an adjustable drain cycle and

skimmer cycle are provided to automatically drain away

some water contaminants; reducing cleaning intervals. For

DI/RO water, the system is virtually maintenance free. The

skimming cycle may be deactivated via the keypad.

Follow installation instructions CAREFULLY to avoid creating

unsafe conditions. All electrical wiring should be done and

checked by a qualied electrician using copper conductors

only. All piping connections should be made and leak-tested

by a qualied service technician, per instructions in this

manual.

Make certain that the power source conforms with to the

electrical requirements of the unit. Disconnect power before

installing or servicing the unit. If power disconnect is out of

visual sight, lock it into open position and tag it to prevent

unexpected application of power. Failure to do so could

result in fatal electrical shock.

WARNING

Do not depend upon a unit control switch or other switch as

the sole means of disconnecting power when installing or

servicing the unit. Always disconnect power at main circuit

breaker. Failure to do so could result in fatal electrical shock.

Special attention should be given to grounding this unit. To

prevent the risk of electrocution, the unit must be securely

and adequately grounded. This should be accomplished by

connecting a grounded conductor from the service panel to

the grounding lug located inside the control section of the

unit. To ensure proper ground, a qualied eld technician

must test the grounding means.

Do not defeat safety interlocks, such as the high temperature

limit or door switch. Do not attempt to operate the unit without

the doors installed.

In cases in which property damage may result from

malfunction of this unit, a backup system should be used.

INSTALLATION

WARNING

Open all disconnect switches and secure in that position

before installing unit. Failure to do so may result in personal

injury or death from electrical shock.

UNIT LOCATION & MOUNTING

The Herrmersion – RE unit is designed to be mounted on a

wall and should be located as close to the dispersion means

as possible (i.e. close to the duct being served with the

steam). This will minimize energy losses.

The unit requires electrical and plumbing connections and

should be mounted in such a way to facilitate access to these

connections.

In order for the magnetic water level switches and the

skimmer function to operate properly, the unit must be

mounted level and plumb with reference to the front and top

of the unit.

The cabinet is designed to safely dissipate heat to protect

the electronics. Herrmersion – RE humidiers, steam piping

and any other accessories should be located in a manner to

facilitate routine inspection and any necessary maintenance.

The unit should not be located above (false ceilings) or

around valuable property where a malfunction could cause

damage. Minimum clearance around the cabinet must be

maintained.

Minimum Access Requirements

Left 2”

Right 24”

Top 12”

Bottom 10”

Front 36”

Minimum access is 36” to the front for periodic removal of the

steam tank for service and 24” to the right side for access to

the electrical components.

Four lag bolts (2) 5/16” and (2) ¼” are supplied for securing

the unit to the wall. Install the top two lag bolts (5/16”)

according to the dimensions shown below. Hang the unit

on the wall, and then install the bottom two lag bolts (1/4”).

Finally, secure all four lag bolts. Be sure the unit is level and

mounted directly to a wall constructed of wood studs at least

2” thick (or equivalent).

WARNING

Do not place unit in a location where service personnel can

not safely service this equipment or personal injury could

occur.

Herrmersion RE

Mounting location must be capable of supporting the entire

weight of the unit. Please refer to the previous table for

operating weight of the unit.

www.herrmidifier-hvac.com

5

Page 6

Installation, Operation, & Maintenance Manual

6.50 16.00

5.00

4.00

Back View (Mirror the hole pattern on mounting surface)

Model Number Shipping Weight Operating Weight

RESX-XXX-X-30 125 lbs. 237 lbs.

RESX-XXX-X-45 128 lbs. 240 lbs.

RESX-XXX-X-90 134 lbs. 246 lbs.

“X” denotes weight independent portion of model number

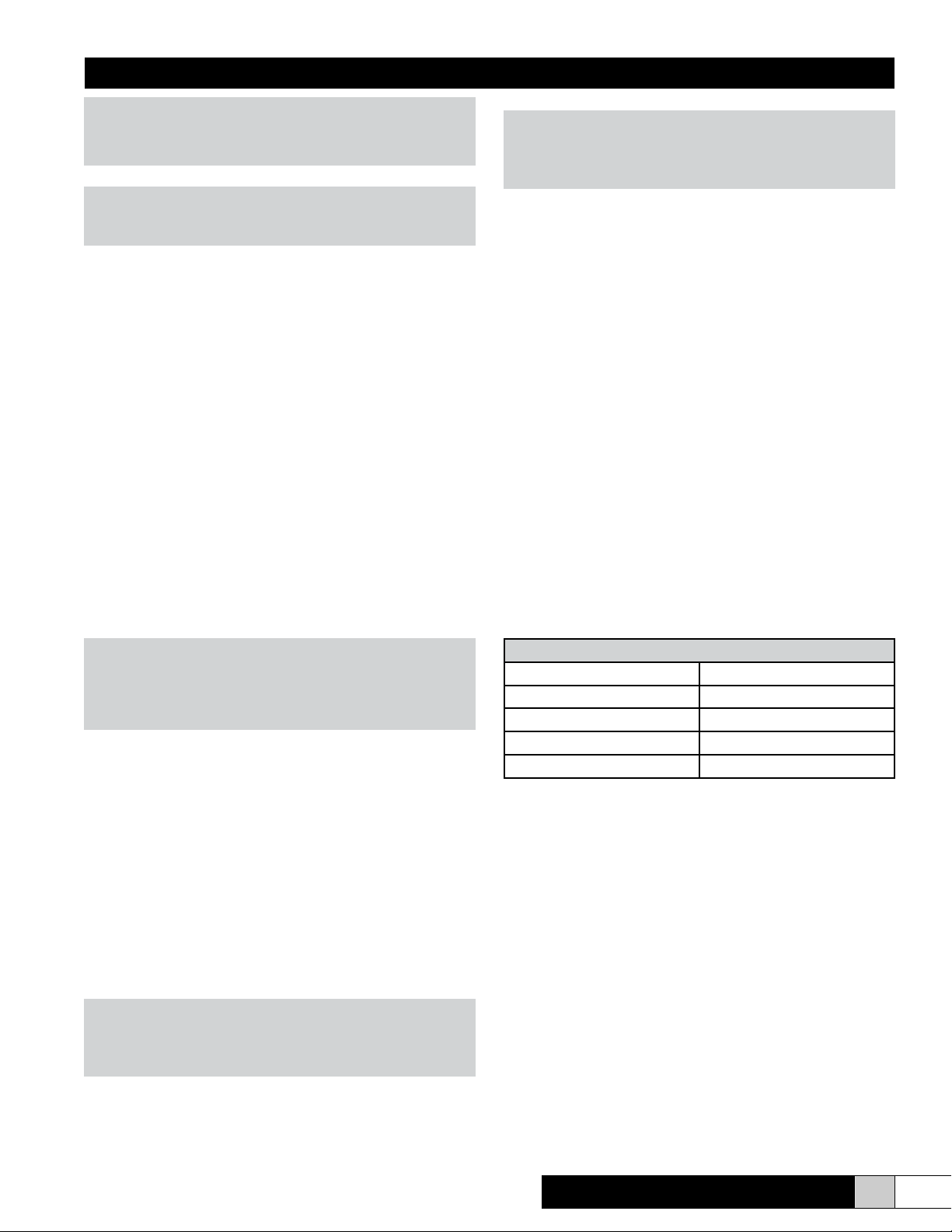

PLUMBING

2. Connect the water supply to the bottom of the unit using

1/4” push-to-lock tting. Supply water line should be

sized so that line pressure loss is minimal.

3. A drain line should be extended from the drain

connection to a sanitary waste. A minimum 1” ID copper

tube is recommended. If PVC is used, local codes

may require lower drain water temperature; enable the

drain tempering feature (see the control section of this

manual).

4. The skim/overow connection on the front of the tank only

needs to be connected if the humidier is being supplied

raw water containing signicant mineral concentrations.

Deionized or reverse osmosis (technical waters) may be

used and do not require the use of this feature. The

skimming cycle allows oating debris to leave the tank

through the overow drain and will reduce maintenance

intervals.

5. If using the skimmer connection, a trap must be installed

in the line so that steam can not escape from the

skimming connection during operation.

STEAM DISTRIBUTION

Herrmersion units may be used with stainless steel duct

dispersion tubes for injecting steam directly into the ductwork.

A minimum of 3 feet downstream clearance is required

for many applications; however differing psychrometric

conditions may require a greater distance. If required, consult

the factory to design a guaranteed absorption Herricane –

CS Steam Distribution System.

To make the necessary connections for water ll, drain, and

overow/skim; the following steps are required. Refer to the

illustration below for dimensional information regarding the

ll & drain connections.

18.13

3.31

Supply Connection

Drain Connection

2.29

2.63 REF.

6.05

Mount the unit as close to the dispersion tube as possible.

Use 1.5” Type L insulated copper whenever the length of run

exceeds 20 feet. Do not exceed a 30 foot run as the capacity

of the humidier may be decreased by as much as 15% and

the increased static pressure could cause problems with the

ll system. The maximum duct static pressure is 5” W.C.

Any insulation inside the bulk evaporation zone (inside the

ductwork) should be removed.

Steam holes in factory supplied duct dispersion tubes are

located 2” from the mounting plate and are designed for a

maximum 1” thick duct wall. Consult the factory if special

hole locations are required.

Do not install or mount standard dispersion tubes in a vertical

position or in a vertical airow application. Special dispersion

tubes are available from the factory for installations which

require vertically mounted tubes or horizontal tubes with

vertical airow.

1. Install an external shut-off valve between the water

supply and the humidier for ease in servicing the unit.

6 www.herrmidifier-hvac.com

Herrmersion RE

Page 7

Installation, Operation, & Maintenance Manual

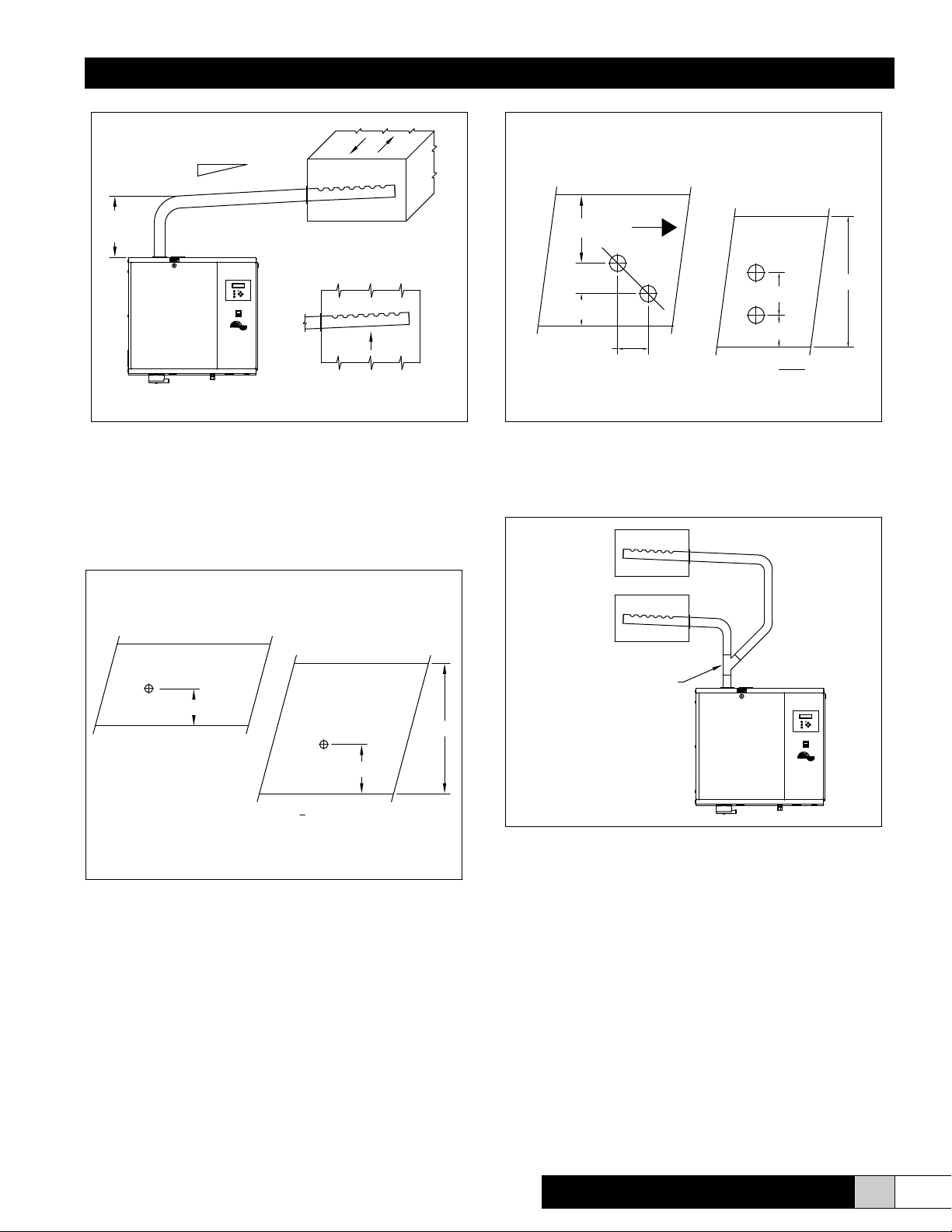

Standard Duct Distribution

MIN. 8% (1" PER FOOT)

10" MIN.

(254mm)

NO SAGS

ALLOWED

HORIZONTAL DUCT

STEAM DISCHARGE MUST ALWAYS

BE FROM THE TOP OF DISTRIBUTOR

VERTICAL DUCT

The rubber vapor hose carries the steam to the dispersion

tube and condensate back to the unit tank. It must have an

8% (1” per foot) pitch back to the unit. Support the vapor

hose so that it maintains proper pitch when the unit is in

operation.

Dual Distribution Tubes

DUCT HEIGHT

10" - 16"

(254MM) - (406MM)

DUCT HEIGHT > 16"

(406mm)

AIR

6.5" (165mm)

3.00" (76mm)

8.00

(203mm)

FLOW

(76mm)

h (in)=6+

h

3"

(H-15)

2

H

Units above 45 pounds per hour of steam will use two duct

dispersion tubes. Refer to the diagram above for mounting

location.

Single to Dual Duct Distribution

Single Distribution Tube

DUCT HEIGHT

10" - 16"

(254MM) - (406MM)

DUCT HEIGHT > 16"

(406mm)

(76mm)

3"

H

h

H

-5" (127mm)

h =

2

Units up to 45 pounds per hour of steam will use one steam

distribution tube. Refer to the diagram above for mounting

location.

EST-255

"Y" CONNECTOR

If you must split the discharge of one steam outlet into two

ducts with the same static pressure, a “Y” connector is

available from the factory. The length of vapor hose after

the “Y” connector must be the same to ensure equal steam

distribution.

Herrmersion RE

www.herrmidifier-hvac.com

7

Page 8

Installation, Operation, & Maintenance Manual

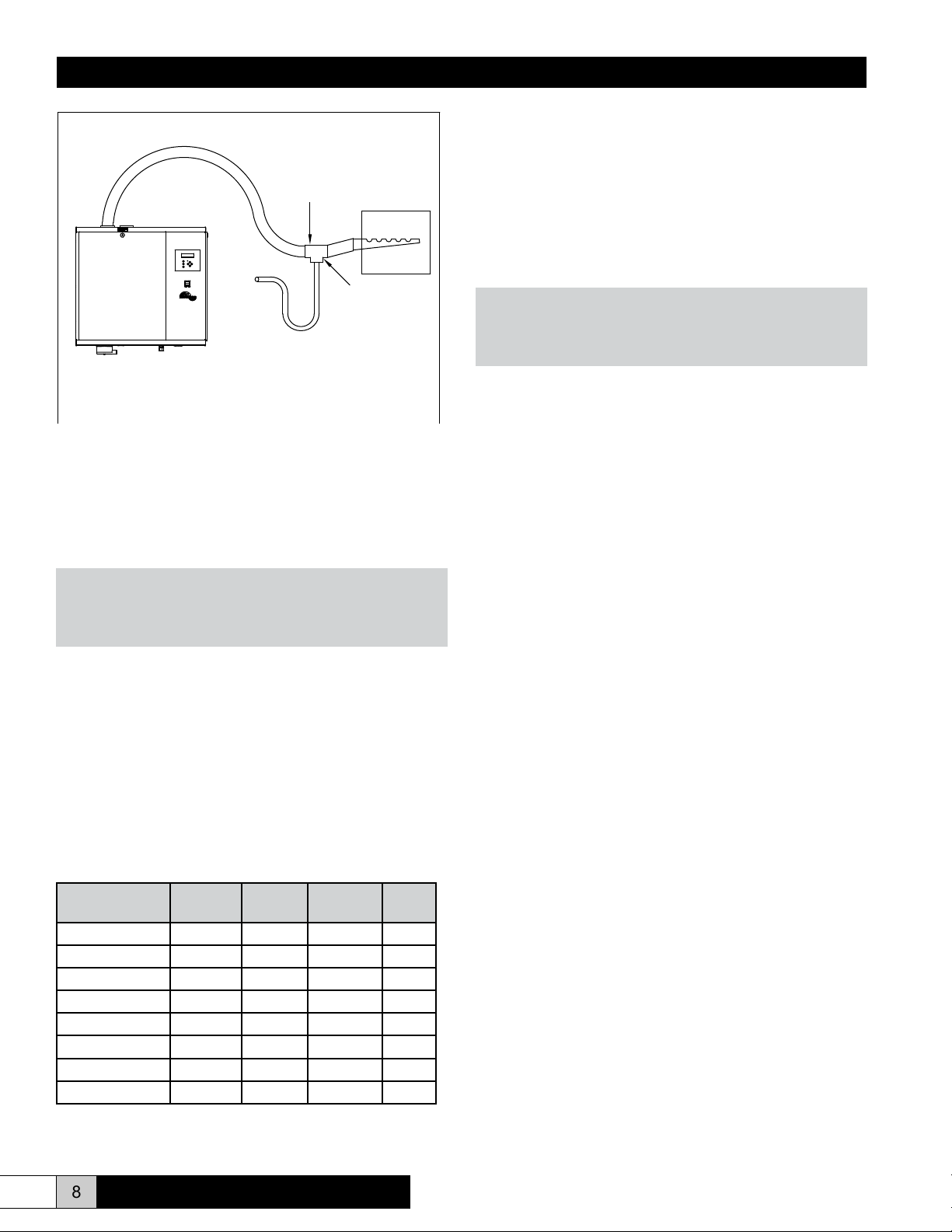

Unavoidable Low Spot or Sagging Vapor Hose

EST-250

CONDENSATE

TRAP

1/2"

TUBE

TO

DRAIN

AT LOWEST

POSSIBLE

POINT

If any low spots are present in the vapor line or the unit is

mounted higher than the dispersion system, a condensate

trap must be mounted at the lowest point in the line. This will

act to remove any pooled condensate from the steam line

and prevent spitting in the duct.

ELECTRICAL

WARNING

Open all disconnect switches before installing the unit.

Failure to do so could result in personal injury or death from

electrical shock.

A wiring diagram is located inside the control cabinet. The

wiring between the control cabinet and the humidier unit

must be 105 °C rated wire. Use copper conductors only.

Please refer to the Control section in this manual for

information regarding electrical connections to be made

directly to the control system.

NOTE: Only qualied electrical personnel should perform

installation and start-up procedures.

WARNING

Open all disconnect switches before installing the unit.

Failure to do so could result in personal injury or death from

electrical shock.

The following pages contain unit wiring diagrams. Please

identify the applicable wiring diagram primarily by the number

of heating elements present on your unit. Refer to the chart

above. Units designed for 30 lbs/hr of steam output will have

2 heating elements, units designed for 45 lbs/hr of steam

output will have 3 heating elements and units designed for

90 lbs/hr of steam output will have 6 heating elements. The

only other difference between these diagrams pertains to the

control transformer. Please identify the appropriate wiring

diagram for your unit on the following pages.

Ensure that adequate service is available to carry 125% of

the rated unit amperage. Field wiring of the main power

supply is connected directly to the main power contactor

located inside the right side electrical compartment. Please

refer to the wiring diagram appropriate for the model

Herrmersion you have. A separate grounding lug is provided

for the ground wire. This is also located inside the right side

electrical compartment. Install short circuit & over-current

protection in accordance with the National Electric Code,

State, and local electrical codes.

Model Capacity/Amperage Table

Unit Model Max.

Capacity

RES_-240-1-30 30 lb/hr 240/1 2 41.7

RES_-480-1-30 30 lb/hr 480/1 2 20.8

RES_-208-3-45 45 lb/hr 208/3 3 41.6

RES_-240-3-45 45 lb/hr 240/3 3 36.1

RES_-480-3-45 45 lb/hr 480/3 3 18.0

RES_-600-3-45 45 lb/hr 600/3 3 14.4

RES_-480-3-90 90 lb/hr 480/3 6 36.1

RES_-600-3-90 90 lb/hr 600/3 6 28.9

Voltage/

Phase

Qty.

Elements

Total

Amps

8 www.herrmidifier-hvac.com

Herrmersion RE

Page 9

Installation, Operation, & Maintenance Manual

INSTALLATION CHECK LIST

AIR FLOW IS HORIZONTAL OR VERTICAL UPFLOW

*A SPECIAL PIPE IS REQUIRED FOR VERTICAL DOWNFLOW,

OR A VERTICAL DISTRIBUTOR PIPE IN A HORIZONTAL

AIR FLOW.

MAKE SURE ALL HIGH VOLTAGE

ELECTRICAL CONNECTIONS ON

STEAM CYLINDER ARE TIGHT

DURING FILL CYCLE CHECK TO SEE IF ANY

WATER IS DRAINING FROM UNIT. A LOT OF

WATER FLOWING OUT OF THE UNIT WOULD

INDICATE EXCESSIVE WATER PRESSURE.

REDUCE THROUGH METERING FILL SOLENOID

OR SUPPLY VALVE TO HUMIDIFIER. A SMALL

AMOUNT OF WATER IS NOT UNCOMMON.

(15-20 in/lbs)

3/4" MIN. I.D./1" MAX O.D.

FLEXIBLE DRAIN CONNECTION

8"

RECOMMENDED

NO UNTRAPPED LOW SPOTS

IN STEAM SUPPLY.

4"

RECOMMENDED

MAKE SURE ALL HIGH VOLTAGE

ELECTRICAL CONNECTIONS

ARE TIGHT.

POWER SUPPLY:

1. MATCHES DATA PLATE

2. IS PROPERLY GROUNDED

3. CAN CARRY AT LEAST 125%

OF RATE AMP DRAW

4. DISCONNECT SUPPLIED BY

OTHERS.

6" MIN. LENGTH OF 1-1/4" MIN. I.D. COPPER LINE.

IF PVC IS USED, LOCAL CODES REQUIRE A LOWER

TEMPERATURE DRAIN WATER IS NOT UNCOMMON.

BALANCE OF DRAIN LINE TO BE 1" MIN. I.D.

WITH A MINIMUM PITCH OF 1/8" PER 12" OF RUN

ENSURE OVERFLOW PIPING IS INSTALLED

AND TIGHT IF USING RAW WATER. A 5-6” P-TRAP IS

REQUIRED TO ENSURE STEAM DOES NOT ENSUE

FROM THE OVERFLOW PIPING. OVERFLOW

IS NOT REQUIRED WITH DI/RO WATER. SKIMMING

MUST BE DISABLED IN THE CONTROL SETTINGS.

Herrmersion RE

www.herrmidifier-hvac.com

9

Page 10

Installation, Operation, & Maintenance Manual

LEVEL SWITCH

VALVE

FILL

REAR OF KEYPAD/DISPLAY UNIT

0-5VDC HIGH LIMIT HUMIDITY

0-5VDC HUMIDITY SIGNAL

0-5VDC DEMAND SIGNAL

SIGNAL (IF REQUIRED)

AIR PROVING SWITCH

YELLOW

YELLOW

VALVE

DRAIN

BLACK

BLACK

FUSE 2 (2A)

FUSE 1 (2A)

FIELD CONTROL WIRING CONNECTIONS

OR

0

H3H4 H2 H1

208

REAR OF ON/OFF SWITCH

X1

240

480

BLACK

BLACK

X3

RED

TRANSFORMER

RED

X2

24V

WHITE

FUSE 3 (4A)

BLUE

WHITE

TERMINAL

BLOCK

RED

BLUE

BUS

2

4

6

8

10

12

COMMON

24V

24V

HIGH

LOW

BROWN

BROWN

YELLOW

WHITE

BLACK

RED

YELLOW

1

3

RED

5

RED

BROWN

7

9

11

WHITE

RED

RED

YELLOW

YELLOW

GR AY

SEE VIEW BELOW FOR

FIELD CONTROL WIRING

CONNECTIONS

GR AY

CONTROLLER

YELLOW

BLACK

RED

WHITE

BLUE

OVERTEMPERATURE

SWITCH

BLUE

DOOR INTERLOCK SWITCH

BLUE

GROUNDED

TO CHASSIS

GR AY

BLACK

265154-001 REV. B

1-PHASE INPUT

BY INSTALLER

208/240/480V

2-HEATER UNIT (1-PHASE)

TRANSFORMER

BLACK

14

L3

L2

L1

BLUE

BLUE

13

T3

T2

T1

CONTACTOR

A1

A2

SSR = SOLID STATE RELAY

10 www.herrmidifier-hvac.com

WHT/ORG

RED

BROWN

YELLOW

GR AY

WHITE/ORANGE

WHITE/ORANGE

SSR1

L1

-

T1

+

BLUE

WHT/ORG

BLUE

WHITE

RED

IMMERSION

HEATERS

RED

WHITE

Herrmersion RE

Page 11

Installation, Operation, & Maintenance Manual

LEVEL SWITCH

VALVE

FILL

REAR OF KEYPAD/DISPLAY UNIT

0-5VDC HIGH LIMIT HUMIDITY

0-5VDC HUMIDITY SIGNAL

0-5VDC DEMAND SIGNAL

SIGNAL (IF REQUIRED)

AIR PROVING SWITCH

YELLOW

YELLOW

VALVE

DRAIN

BLACK

BLACK

FUSE 2 (2A)

FUSE 1 (2A)

FIELD CONTROL WIRING CONNECTIONS

OR

0

H3H4 H2 H1

208

REAR OF ON/OFF SWITCH

X1

240

480

BLACK

BLACK

X3

RED

TRANSFORMER

RED

X2

24V

WHITE

FUSE 3 (4A)

BLUE

WHITE

TERMINAL

BLOCK

RED

BLUE

BUS

2

4

6

8

10

12

COMMON

24V

24V

HIGH

LOW

BROWN

BROWN

YELLOW

WHITE

BLACK

RED

YELLOW

1

3

RED

5

RED

BROWN

7

9

11

WHITE

RED

RED

YELLOW

GR AY

YELLOW

GR AY

SEE VIEW BELOW FOR

FIELD CONTROL WIRING

CONNECTIONS

CONTROLLER

YELLOW

BLACK

RED

WHITE

BLUE

OVERTEMPERATURE

SWITCH

BLUE

DOOR INTERLOCK SWITCH

BLUE

GROUNDED

TO CHASSIS

3-PHASE INPUT

BY INSTALLER

265153-001 REV. B

TRANSFORMER

208/240/480V

3-HEATER UNIT

Herrmersion RE

WHT/ORG

RED

BROWN

YELLOW

GR AY

BLACK

BLACK

14

L3

L2

L1

BLUE

BLUE

A1

SSR = SOLID STATE RELAY

WHT/ORG

SSR1

WHT/ORG

GR AY

13

T3

T2

T1

CONTACTOR

A2

-

+

WHITE/ORANGE

WHITE/ORANGE

SSR2

L1

T1

L1

-

T1

+

BLUE

WHT/ORG

www.herrmidifier-hvac.com

BLUE

WHITE

RED

IMMERSION

HEATERS

RED

WHITE

11

Page 12

RED

LEVEL SWITCH

VALVE

FILL

BLUE

OVERTEMPERATURE

SWITCH

HIGH

LOW

BROWN

BROWN

BLUE

YELLOW

YELLOW

RED

FIELD CONTROL WIRING

SEE VIEW BELOW FOR

CONNECTIONS

WHITE

YELLOW

BLACK

GR AY

GR AY

RED

DOOR INTERLOCK SWITCH

BLUE

CONTROLLER

Installation, Operation, & Maintenance Manual

REAR OF KEYPAD/DISPLAY UNIT

0-5VDC HIGH LIMIT HUMIDITY

0-5VDC HUMIDITY SIGNAL

0-5VDC DEMAND SIGNAL

SIGNAL (IF REQUIRED)

AIR PROVING SWITCH

YELLOW

YELLOW

VALVE

DRAIN

BLACK

BLACK

FUSE 2 (2A)

FUSE 1 (2A)

FIELD CONTROL WIRING CONNECTIONS

OR

0

H3H4 H2 H1

208

REAR OF ON/OFF SWITCH

X1

240

480

BLACK

BLACK

X3

RED

TRANSFORMER

RED

X2

24V

WHITE

FUSE 3 (4A)

BLUE

WHITE

TERMINAL

BLOCK

RED

BLUE

BUS

2

4

6

8

10

12

COMMON

24V

24V

YELLOW

WHITE

BLACK

RED

YELLOW

1

3

RED

5

RED

7

9

11

BROWN

WHITE

GROUNDED

TO CHASSIS

GR AY

BLACK

BLACK

3-PHASE INPUT

BY INSTALLER

265152-001 REV. B

TRANSFORMER

208/240/480V

6-HEATER UNIT

14

L3

L2

L1

BLUE

BLUE

SSR = SOLID STATE RELAY

A1

WHT/ORG

SSR1

WHT/ORG

13

T3

T2

T1

CONTACTOR

A2

L1

-

T1

+

12 www.herrmidifier-hvac.com

WHT/ORG

BLUE

RED

BROWN

YELLOW

GR AY

WHITE/ORANGE

WHITE/ORANGE

SSR2

L1

-

T1

+

WHT/ORG

BLUE

WHITE

RED

IMMERSION

HEATERS

RED

WHITE

Herrmersion RE

Page 13

Installation, Operation, & Maintenance Manual

LEVEL SWITCH

VALVE

FILL

REAR OF KEYPAD/DISPLAY UNIT

0-5VDC HIGH LIMIT HUMIDITY

0-5VDC HUMIDITY SIGNAL

0-5VDC DEMAND SIGNAL

SIGNAL (IF REQUIRED)

AIR PROVING SWITCH

YELLOW

YELLOW

VALVE

DRAIN

BLACK

FUSE 2 (2A)

FUSE 1 (2A)

FIELD CONTROL WIRING CONNECTIONS

OR

H6

600

480

H4H5 H3 H1H2

380

REAR OF ON/OFF SWITCH

X1

240

208

BLACK

BLACK

BLACK

0

X3

RED

TRANSFORMER

RED

24V

WHITE

WHITE

FUSE 3 (4A)

BLUE

TERMINAL

BLOCK

RED

BLUE

BUS

2

4

6

8

10

12

COMMON

24V

24V

HIGH

LOW

BROWN

BROWN

YELLOW

WHITE

BLACK

RED

YELLOW

1

3

RED

5

RED

BROWN

7

9

11

WHITE

RED

RED

YELLOW

GR AY

YELLOW

GR AY

SEE VIEW BELOW FOR

FIELD CONTROL WIRING

CONNECTIONS

CONTROLLER

YELLOW

BLACK

RED

WHITE

BLUE

OVERTEMPERATURE

SWITCH

BLUE

DOOR INTERLOCK SWITCH

BLUE

GROUNDED

TO CHASSIS

1-PHASE INPUT

BY INSTALLER

TRANSFORMER

208/240/415/480/600V

2-HEATER UNIT (1-PHASE)

265157-001 REV. A

Herrmersion RE

WHT/ORG

RED

BROWN

YELLOW

GR AY

BLACK

BLACK

14

L3

L2

L1

BLUE

BLUE

A1

SSR = SOLID STATE RELAY

GR AY

13

T3

T2

T1

CONTACTOR

A2

WHITE/ORANGE

WHITE/ORANGE

SSR1

-

+

L1

T1

BLUE

WHT/ORG

www.herrmidifier-hvac.com

BLUE

WHITE

RED

IMMERSION

HEATERS

RED

WHITE

13

Page 14

RED

LEVEL SWITCH

VALVE

FILL

BLUE

OVERTEMPERATURE

SWITCH

HIGH

LOW

BROWN

BROWN

BLUE

YELLOW

YELLOW

RED

SEE VIEW BELOW FOR

FIELD CONTROL WIRING

CONNECTIONS

WHITE

YELLOW

BLACK

GR AY

GR AY

RED

DOOR INTERLOCK SWITCH

BLUE

CONTROLLER

Installation, Operation, & Maintenance Manual

REAR OF KEYPAD/DISPLAY UNIT

0-5VDC HIGH LIMIT HUMIDITY

0-5VDC HUMIDITY SIGNAL

0-5VDC DEMAND SIGNAL

SIGNAL (IF REQUIRED)

AIR PROVING SWITCH

YELLOW

YELLOW

VALVE

DRAIN

BLACK

FUSE 2 (2A)

FUSE 1 (2A)

FIELD CONTROL WIRING CONNECTIONS

OR

H6

600

480

H4H5 H3 H1H2

380

REAR OF ON/OFF SWITCH

X1

240

208

BLACK

BLACK

BLACK

0

X3

RED

TRANSFORMER

RED

24V

WHITE

WHITE

FUSE 3 (4A)

BLUE

TERMINAL

BLOCK

RED

BLUE

BUS

2

4

6

8

10

12

COMMON

24V

24V

YELLOW

WHITE

BLACK

RED

YELLOW

1

3

RED

5

RED

7

9

11

BROWN

WHITE

GROUNDED

TO CHASSIS

GR AY

BLACK

BLACK

3-PHASE INPUT

BY INSTALLER

TRANSFORMER

208/240/415/480/600V

265156-001 REV. A

3-HEATER UNIT

14

L3

L2

L1

BLUE

BLUE

SSR = SOLID STATE RELAY

A1

WHT/ORG

SSR1

WHT/ORG

13

T3

T2

T1

CONTACTOR

A2

L1

-

T1

+

14 www.herrmidifier-hvac.com

WHT/ORG

BLUE

RED

BROWN

YELLOW

GR AY

WHITE/ORANGE

WHITE/ORANGE

SSR2

L1

-

T1

+

WHT/ORG

BLUE

WHITE

RED

IMMERSION

HEATERS

RED

WHITE

Herrmersion RE

Page 15

RED

LEVEL SWITCH

VALVE

FILL

BLUE

OVERTEMPERATURE

SWITCH

HIGH

LOW

BROWN

BROWN

BLUE

YELLOW

YELLOW

RED

SEE VIEW BELOW FOR

FIELD CONTROL WIRING

CONNECTIONS

WHITE

YELLOW

BLACK

GR AY

GR AY

RED

DOOR INTERLOCK SWITCH

BLUE

CONTROLLER

Installation, Operation, & Maintenance Manual

REAR OF KEYPAD/DISPLAY UNIT

0-5VDC HIGH LIMIT HUMIDITY

0-5VDC HUMIDITY SIGNAL

0-5VDC DEMAND SIGNAL

SIGNAL (IF REQUIRED)

AIR PROVING SWITCH

YELLOW

YELLOW

VALVE

DRAIN

BLACK

FUSE 2 (2A)

FUSE 1 (2A)

FIELD CONTROL WIRING CONNECTIONS

OR

H6

600

480

H4H5 H3 H1H2

380

REAR OF ON/OFF SWITCH

X1

240

208

BLACK

BLACK

BLACK

0

X3

RED

TRANSFORMER

RED

24V

WHITE

WHITE

FUSE 3 (4A)

BLUE

TERMINAL

BLOCK

RED

BLUE

BUS

2

4

6

8

10

12

COMMON

24V

24V

YELLOW

WHITE

BLACK

RED

YELLOW

1

3

RED

5

RED

BROWN

7

9

11

WHITE

GROUNDED

TO CHASSIS

3-PHASE INPUT

BY INSTALLER

TRANSFORMER

208/240/415/480/600V

265155-001 REV. A

6-HEATER UNIT

Herrmersion RE

WHT/ORG

RED

BROWN

YELLOW

GR AY

BLACK

BLACK

14

L3

L2

L1

BLUE

BLUE

A1

SSR = SOLID STATE RELAY

WHT/ORG

SSR1

WHT/ORG

GR AY

13

T3

T2

T1

CONTACTOR

A2

-

+

WHITE/ORANGE

WHITE/ORANGE

SSR2

L1

T1

L1

-

T1

+

BLUE

WHT/ORG

www.herrmidifier-hvac.com

BLUE

WHITE

RED

IMMERSION

HEATERS

RED

WHITE

15

Page 16

Installation, Operation, & Maintenance Manual

CONTROL SYSTEM

The Herrmersion – RE is supplied with a microprocessor

based native BACnet controller that provides complete

control of humidier operations. The controller comes pre-

programmed for optimum performance. System settings

can be adjusted via the on-board keypad user interface.

When connected to a building management system,

the Herrmersion – RE communicates via some typical

communication protocols; such as, BACnet, Modbus, N2,

or LonWorks. LonWorks requires an additional expansion

card.

Display Unit

SSR Output Status, Fill Valve Output Status, and Drain Valve

Output Status. A “0” indicates an “open” or “OFF” condition.

A “1” indicates a “made” or “ON” condition.

Home Screen

The Home screen displays a list of menus which allow

the user to modify system parameters, check the status of

inputs/outputs/alarm, congure set-points, set the clock,

or access the factory conguration menu. The Set-points

menu will only be displayed if the unit is congured for standalone P+I control. The Cong menu will only be displayed

if the operator is logged into the system as Administrator.

The standard Administrator password is factory set to 2222.

Setpoints and Parameters may only be changed if a User is

logged into the system.

The display unit is a 2 line by 16 character backlit LCD display

that provides easy access to system input information,

system status, adjustable system parameters, and system

alarms. An intuitive button selection allows simple navigation

of the menu system. An LED illuminates when the system

encounters an alarm condition or enters an automatic drain

cycle congurable through the keypad.

Standby Screen

The Standby Screen is active only when the keypad is not

being used. It displays basic information such as the unit

model conguration, Operating Status, Output Percentage,

and Input Signal Percentage. This may be a demand signal

input or a relative humidity percentage received from a

humidity transmitter depending upon how the equipment is

congured. In the upper right corner, a string of 1’s and 0’s

provides a quick glance at the status of some key I/O points.

From left to right, these are Air Flow Switch Input Status, Low

Water Level Switch Input Status, Contactor Output Status,

To select a menu option, use the < and > buttons to navigate

vertically through the menu selections until the desired menu

is surrounded by brackets. Pressing the ENTER button one

time will navigate the system to the menu screen you have

selected.

To exit a menu, press HOME once, and the display will return

to the Home screen.

Parameters Screen

The Parameters menu contains a list of system parameters

that may be congured by the operator.

• Auto DRN – If ON, unit will drain periodically according to

the values set by the DRN Int & DRN Time parameters. If

OFF, the unit will never initiate a timed drain. De-ionized

16 www.herrmidifier-hvac.com

Herrmersion RE

Page 17

Installation, Operation, & Maintenance Manual

or reverse osmosis water applications rarely require the

Auto DRN feature to be enabled as the water contains

very low dissolved solids.

• DRN Int – Drain Interval is the interval at which the unit

will initiate a timed drain. The default interval is factory

set at 24 hours.

• DRN Time – Drain Time is the amount of time the drain

valve will remain open if a timed drain is active. The

DRN Time is factory set at 5 minutes.

• Skim Time – Skim Time is the amount of time the unit

will continue lling to skim the surface of the water every

time a ll cycle is active. This feature may be set to zero

if the system is operating with very clean water; such as

de-ionized water. The factory Skim Time is 60 seconds.

Low water pressure may require that this setting be

increased so that the unit will skim.

• DRN Tmpr – Drain Tempering will activate the ll valve

anytime the drain valve is active. This feature acts to

lower the drain water temperature by diluting the drain

water with cold ll water. Water ensuing from the

skimmer port on the tank is not tempered. An external

drain water tempering device may be required. Please

consult the factory for information about the Drain

Tempering Reservoir, available separately.

• Force DRN – Force Drain is used to manually initiate a

drain cycle. The drain valve will remain active until this

parameter is set to OFF by the operator.

• RETURN – Returns the operator to the Home screen.

output.

• AF Switch – This displays whether the air proving switch

is OPEN or MADE. OPEN indicates a lack of airow.

MADE indicates that the switch contacts are closed

indicating that airow is present.

• Contactor – This displays ON/OFF status of the main

power contactor. This is monitoring the status of the

auxiliary contact on the main power contactor.

• Drain Val. – This displays the ON/OFF status of the drain

valve output.

• Fill Valve – This displays the ON/OFF status of the ll

valve output.

• Full Water – This displays the OPEN/MADE status of

the upper water level oat switch. Each time this switch

opens, the unit will act to rell the tank for continued

humidication if a demand is present.

• Low Water – Displays the OPEN/MADE status of the

lower water level oat switch. This switch must be

MADE in order for the heating elements to be energized.

• HL Input – Displays the relative humidity percentage

being sensed by the High Limit humidity sensor.

This item will not show in the menu unless the unit is

congured for stand-alone P+I control. If the unit has a

High Limit humidistat in lieu of a transmitter, this menu

item will read High Limit and the status will read OPEN

or MADE to indicate the status of the humidistat (switch).

Setpoints Screen

Status Menu

The Status menu contains a list of system inputs/outputs that

may be monitored by the operator.

• Input – This displays the percentage of demand when the

unit is congured for Proportional only operation. The

demand signal is received from a building management

system or from a remote humidity controller. This

displays the controlled relative humidity percentage

when the unit is congured for stand-alone P+I control.

The signal is received from a humidity transmitter

mounted in the controlled environment.

• Output – This displays the percentage of maximum unit

The Setpoints Screen will only be visible on units that are

congured for stand-alone P+I control. The HOME screen

will display RES-I. This means that a control humidity sensor

and high limit humidity sensor need to be connected to inputs

1 & 2 of the control board. Please see the wiring diagram

appropriate for the unit model being installed.

• Hum. SP – The user may enter the control humidity

setpoint here. Default = 40%RH.

• Max HL% – The operator may enter the maximum

allowable duct high limit %RH here. Default = 80%RH

• HL Range – The High Limit range sets the percentage

offset where the unit will begin to throttle the unit output

proportionally between the Max. HL% minus the HL

Range. Example: If the Max. HL% is set to 80% and

the HL Range is 10%, the unit will be limited to 50% of

maximum output if the high limit duct sensor is reading

75% relative humidity in the duct.

• Max. Cap. – Maximum Capacity allows the operator to

limit the maximum unit output based on a percentage.

Example: If the unit has a maximum capacity of 90 lb/

Herrmersion RE

www.herrmidifier-hvac.com

17

Page 18

Installation, Operation, & Maintenance Manual

hr, the user may limit the unit to 80 lb/hr by setting this

to 89%.

• Low Hum. – This allows the operator to trigger a low

humidity alarm if the control humidity falls below a

certain value.

NOTE: Some units may be congured with High Limit

humidistats in lieu of proportional high limit devices. If the unit

is using a humidistat for the high limit device, the setpoints

menu will only contain Humidity SP and Low Hum. The other

items do not pertain to high limit humidistat operation.

Alarm Screen

DST link on this screen allows the user to set-up the day-light

saving time start and stop dates. It is recommended that the

date/time be set and conrmed before operating the unit.

UserPW Screen

Upon attempting to change parameters or set-points, the

control system will prompt the user for a password. The

USER password is 1111 by default. Logging into the keypad

as the USER will allow any of the items in the Parameters

Menu or the Set-points Menu to be changed by the user. The

CONFIG menu is typically for factory use only and should not

be modied by any operator without guidance from factory

technical personnel or a factory trained service technician.

If the ADMIN has logged into the system he may set a new

user password. The ADMIN password is 2222 by default.

Again, items in the CONFIG menu should not be changed by

untrained personnel.

The Alarm Screen allows the operator to check the status

of the system alarms. This screen can scroll through the

currently active alarms; as well as alarm conditions that have

returned to normal. The date/time of the alarm is recorded

when the alarm goes active and when the alarm returns to

normal. Some alarms will lock out the unit and will require a

manual reset. This is performed by turning the unit ON/OFF

switch to the OFF position, waiting until the red LED goes out,

and then returning the switch to the ON position. Timed Drain

operations will illuminate the alarm LED. The drain will show

up as an active alarm while the unit is draining and return to

normal upon completion of the drain cycle. This allows the

control system to date/time stamp the drain operation so the

user may refer to it if needed. Upon completion of the timed

drain the unit will return to normal operation.

Clockset Screen

Cong Screen

The Clockset Screen allows the user to adjust the system

clock. Time is only used for logging alarm times, so accurate

system time is not critical to proper system operation. The

18 www.herrmidifier-hvac.com

The Conguration Screen allows the operator to adjust

system parameters that the typical operator usually would not

need to adjust under normal circumstances. The unit type

may be selected as P or I. A “P” unit operates according to

Herrmersion RE

Page 19

Installation, Operation, & Maintenance Manual

a 0-5VDC demand signal sent from another control system;

such as a building management system or DDC controller.

A unit congured for “I” is ready to accept 0-5VDC input

signal(s) from a humidity transmitter and a high limit humidity

transmitter. The unit will then modulate the unit according to

the setpoint entered by the operator.

• P/I Control – The Administrator may change the unit

control type so that the unit will react to a demand signal

from an external control system or the unit can control

itself according to an operator setpoint by reacting to a

signal from a humidity transmitter connected directly to

the control board.

• Overll – The Administrator may adjust the length of a

ll cycle using this conguration parameter. Default =

60s. This is the length of time the ll valve will remain

open during a ll cycle plus the skim time set in the

Parameters menu.

• Interval – This allows the Administrator to change the

interval at which the PID loop calculates and updates the

unit output. Default = 60s. Increasing this time will slow

down the reaction time of the unit. Decreasing this time

will cause the unit to react faster to changes in humidity

level.

• P-Gain – The Proportional Gain adjusts the control band

in which the unit will begin to adjust capacity. As the

sensed humidity approaches the setpoint, the unit will

reduce the output percentage.

• I-Gain – The Integral Gain changes how the controller

will adjust the output percentage as time passes during

operation. If the setpoint is not achieved quickly enough,

increasing this gain will cause the unit to increase the

output percentage.

• Deadband – This may be adjusted to allow for a range

of input percentage or setpoint where no action is to be

taken. Default = 0%.

• Ramp Time – This Ramp Time allows the system to be

slowed by setting a minimum allowable time for the unit

to ramp from 0 to 100% output. Default = 0%.

Alarm Descriptions

The following alarm messages may appear. Refer to the

specic alarm message below for a description of what

circumstances will cause the alarm to become active.

the unit will cease to produce steam. This will indicate

a problem with the sensor only. The default setting is

5% rh. This alarm can only become active on units

congured for proportional + integral control (RES-I).

• Low Humidity: If the controlled humidity falls below the

low humidity setpoint, the unit will cease to operate until

the problem is corrected and the alarm is acknowledged

and reset via the ON/OFF switch.

• Slow Drain: If during a timed drain cycle, the upper water

level oat switch remains closed. This alarm will become

active thirty seconds before the end of the timed drain

cycle. The unit will cease to operate. The operator

should verify that the drain line is clear by invoking a

manual drain cycle. If the drain is open, the alarm may

be reset via the ON/OFF switch. The unit will return to

normal operation.

• Slow Fill: During any ll cycle, if both water level oat

switches do not close within thirty minutes, this alarm

will become active. This may be caused by low water

pressure, an obstruction in the ll line, or a failed ll

solenoid valve. The unit will cease to operate until the

alarm is reset via the ON/OFF switch.

• Timed Drain: During any timed drain cycle, the alarm

light will illuminate for the duration of the drain cycle.

This is to provide indication only. The drain cycle will

be time stamped and stored in the ALARM screen of the

display module. No user intervention is needed. The unit

will commence normal operation upon the completion of

the drain cycle. Timed drain cycles may be deactivated

via the keypad.

• Water Lvl Err: This alarm indicates that the oat switches

may be dirty and stuck open or closed. If the upper water

level oat switch is closed and the lower water level oat

switch is open, this alarm will become active. The tank

should be cleaned and the oat switches checked for

proper operation. The alarm may be reset via the ON/

OFF switch.

• AF Switch Open: Upon a call for humidity or anytime

during the operation of the humidier, if the air proving

switch opens, the unit will cease to produce steam until

the air proving switch closes again; indicating that airow

is present again.

• EOS Drain: If a call for humidity is absent for greater

than 72 hours, the humidier will drain the tank and

shutdown. Upon a new call for humidity, the unit will

rell the tank and commence normal operation.

• High Humidity: If the high limit humidity transmitter value

falls below the HL Fault setpoint (in CONFIG menu),

Herrmersion RE

www.herrmidifier-hvac.com

19

Page 20

Installation, Operation, & Maintenance Manual

Control Module Specications:

Power 24 Vac ± 10%, 50-60 Hz, 18 VA power consumption (24 VA with Bacview attached), 26 Vdc (25 V

min, 30 V max), Single Class 2 source only, 100 VA or less

Physical Rugged GE C2950 Cycoloy plastic

Operating Range -0° to 130°F (-18.5° to 54.4°C); 10 to 90% relative humidity, non-condensing

Digital Outputs 5 digital outputs, relay contacts rated at 1 A resistive @ 24 Vac, congured as dry contact, normally

open

Analog Outputs 3 analog outputs, rated as 0-10Vdc, 5mA (max). 8 bit D/A resolution

Universal Inputs 8 universal inputs. Inputs 1-6 congurable as thermistor or dry contact; inputs 1 and 2 also congu-

rable as 0-5 Vdc type inputs; inputs 7 and 8 are reserved to use with 1k-10 koHm adjustment potentiometers. Resolution of 10 bit A/D.

Communication

Ports

Optional Card Port LonWorks Option Card for connection to Free Topology LON networks (TP/FT-10 Channel)

Status Indication Visual (LED) status of serial communication, running, errors, power, and all digital outputs

Battery Battery CR123A has a life of 10 years with 720 hours of cumulative power outage

Protection Built-in surge transient protection circuitry. Module protected by internal solid state Polyswitches on

Listed by FCC Part 15 - Subpart B - Class A. Pending listings at the time of publishing this document: UL 916

Port 1: Jumper congurable for ARCNET or EIA-485 communication. In ARCNET mode, the port

speaks BACnet (at 156k bps). In EIA-485 mode, the communication protocol and baud rate desired

are DIP switch selectable between BACnet MS/TP, Modbus RTU, or N2. Rnet port: Interface with a

BACview5, BACview6 , RS sensors, or local laptop

incoming power and network connections. Polyswitches do not need to be replaced as they will reset

themselves once the condition that caused them to “trip” returns to normal.

(PAZX), cUL C22.2 No. 205-M1983 (PAZX7), CE (1997).

BTL (BACnet Test Labs) - BACnet Advanced Application Controller (B-AAC) http://www.bacnetinter-

national.net/btl/index.php?m=47

Display Module Specications:

Power Supplied by the 4 conductor cable (+12Vdc @ 250mA).

Physical Rugged aluminum enclosure for protection and easy backplane mounting.

Operating Range 32° to 130°F (0° to 54.4°C), 10%-90% RH non-condensing.

Backlit LCD 4-line by 40-character display.

Listed by UL 916 (PAZX), CE (1997), FCC Part 15 - Subpart B - Class A.

Weight 1.2 lbs. (0.54 Kg)

Mounting Wall or panel mounting; remote mounting up to 500 feet. Standard J box may be used.

Dimensions. 9-5/8” (width) by 4-15/16” (height) by 1” (recommended panel depth)

245mm (width) by 125mm (height) by 25mm (recommended panel depth).

20 www.herrmidifier-hvac.com

Herrmersion RE

Page 21

Installation, Operation, & Maintenance Manual

BT485

Net +

Net -

Comm

Shield

7

689

0

5

4 1

23

10's

7

689

0

5

4 1

23

1's

Gnd

Rnet +

Rnet -

R n e t

+12V

IN-1

Inputs 1 & 2

Gnd

0-5V, therm,

or dry

IN-2

Gnd

IN-3

Inputs 3 & 4

Gnd

Therm or dry

IN-4

24Vac, 50-60 Hz

Gnd

Conductors Only

Gnd

Inputs 5 & 6

IN-5

Therm or dry

IN-6

CAUTION:

To Reduce The Risk of Fire

LED

or Electric Shock, Do Not

Interconnect the Outputs of

Different Class 2 Circuits.

Rx

Tx

Batt

-

+

CR

2032

Card

Option

Local

Access

Class 2

15VA, 0.63A

Use Copper

Sense

+12V

RnetRnet+

Gnd

BAUD RATES

9600 Off Off

19.2 K Off On

38.4 K On Off

76.8 K On On

E143900

Communications Selection

EIA-485

BACnet

over ARC156

Comm DIP Switches

SW2

SW1

®

Management Equipment

PROTOCOLS

BACnet

MS/TP

N2

Modbus Off On

Option Card On On

I/O ZONE 583

U.S. Patent No. 6,715,690 B2

TYPE: 002102

Enclosed Energy

88FO

SW4

SW3

Off Off

On Off

Outputs

24V Max,

1A Max

BACnet

LStat

Format

Short pins

LStat =

or IN-5 =

Power

Run

Error

IN-1

Thermistor/dry contact

0-5Vdc

IN-2

Thermistor/dry contact

0-5Vdc

AO: 0-10 Vdc

Power for DOs

®

Made in USA

Rnet

Gnd

Hot

24V ac

IN-7

+3V

Pot.

Only

Gnd

IN-8

On

4

3

2

1

Gnd

AO-3

Gnd

AO-2

Gnd

AO-1

5mA Max

DO-5

DO-4

DO-3

DO-2

DO-1

BUS

Herrmersion RE

www.herrmidifier-hvac.com

21

Page 22

Installation, Operation, & Maintenance Manual

Replacement Parts

No. Part Number Description Comments/Application

1 155787-001 Knurled Knob For top tank access

2 155793-001 3-Prong Knob Tank wiring connector

3 GT-118 Fill Solenoid With metering screw

4 265136-001 Float Switch Assembly (2) oats

5 259895-002 5KW Heater 208VAC

5 259895-004 5KW Heater 240VAC

5 259895-001 5KW Heater 480VAC

5 259895-003 5KW Heater 600 VAC

6 EST-120 Fuse 4 amp

7 259097-001 Control Transformer 208/230/460 Pri.

7 255991-001 Control Transformer 208/230/380/460/600 Pri.

8 265135-001 Main Control Board

9 265134-001 Display Module

10 EST-109 Contactor 50 Amp rated

11 265005-001 Solid State Relay 50 Amp rated

12 EST-1225-KIT Drain Reservoir Kit Under unit

13 GT-142 Drain Valve Under tank

14 GT-153 Fill Strainer In ll line before solenoid

15 EST-109-2 Auxiliary Contact Contactor side mount

16 265004-001 High Temp. Limit Switch On front of tank (235F)

17 1845 Door Switch Top-right tank compartment

18 EST-112 Control Switch On front of unit

19 EST-428-1 Tank Strainer (not shown)

20 EST-1060-3 O-Ring (not shown) on tank stem

21 EST-354 Fuse 2 Amp

2

3

17

1

16

20

12

13

22 www.herrmidifier-hvac.com

9

4

5

14

18

8

6

7

21

15

11

10

11

Herrmersion RE

Page 23

Installation, Operation, & Maintenance Manual

Maintenance Record Sheet

Installation Date (MM/DD/YYYY)

Model #:

Serial #:

Service Dates (below):

Notes:

Herrmersion RE

www.herrmidifier-hvac.com

23

Page 24

Engineered Humidification Systems

Herrmidifier

®

101 McNeill Rd. | Sanford, NC 27330

P: 800.884.0002 | F: 800.458.2379 | www.herrmidifier-hvac.com | cs@herrmidifier-hvac.com

Form No. 165158-001 0712 ©Herrmidier 2012. All Rights Reserved.

Loading...

Loading...