H.E.R.O. H2K 3819, H2K 5523 Owner's Manual

TABLE OF CONTENTS

Warranty Information 2

Important Safety Precautions 3

Introduction 4

Set Up, Priming, Spraying 5

Flushing & Priming 5

Shut Down and Pressure Relief Procedures 6

Airless Spray Painting Suggestions 7-8

Tip Selection 8-9

Troubleshooting 9

Repair Procedures 10-11

Piston Cartridge Assembly Repairs 12-13

Pressure Control Calibration 14

Prime Valve Service 14-15

Unit Parts Breakdown 16

Cart Parts Breakdown 17

Wiring Schem atic 18

Parts List and Descriptions 19-22

Owner’s Manual HK3819 / HK5523

Page 1

WARRANTY

H.E.R.O. WARRANTY

H.E.R.O., guarantees this airless pump to be free of defects in materials and workmanship to the

original owner, for a period of one full year from the date of purchase.

The warranty entitles the owner to parts replacement at no charge. The parts replacement

warranty is valid for any necessary replacement, weather caused by material or workmanship

defect or simple wear. H.E.R.O. Industries offers no warranty on the hoses, gun, tip or

accessories, plastic, rubber, other soft goods or motor used in or supplied with the H.E.R.O.

sprayer.

In addition to the genera l coverage list ed above, a 5 YEAR WARRANT Y is offered on the Drive

Train components. T he drive train c omponents are defined as the item s contained within, b ut not

including, the “Drive Housing”. Drive motor and clutch not included.

Furthermore, this warranty does not cover, damage or wear caused by faulty installation, abrasion,

corrosion, inadequate or improper maintenance, negligence, or accident.

Motor, accessories, etc., which are supplied by other manufacturers and are attached to or

supplied with the H.E.R.O. air less pump, are warranted onl y to the extent that these parts are

warranted by their respective manufacturers. Warranty claims on these items must be made

directly to such manufacturers or their local authorized service depots.

The warranty is only appl icable to the original purchas er and provided the equipment has been

properly used, operated and maintained in accordance with all instructions, precautions and

warnings contained in this manual. For the purpose of this warranty, damage resulting from

accident, abuse, improper cleaning, storage, fire, flood, or Act of God, is not covered.

H.E.R.O.’s liability is limited to replacing par ts found to be defective or worn and does not i nc lude ;

transportation costs, damage or other expenses of any kind incurred in connection with the

purchase and use of this sprayer.

Repairs claimed under warranty must be performed b y an authorized H.E.R.O. Service C enter,

using only genuine H.E.R.O. parts. Parts required under warranty will be supplied by your local H.

E.R.O. Service Center.

DO NOT return warranty parts to factory without authorization.

To qualify for the warranty, the warranty card (attached to this page) supplied with this H.E.R.O.

airless pump, must be completed with equipment serial number and signed by the purchaser, and

postmarked within ten (10) days of purchase.

Owner’s Manual HK3819 / HK5523

Page 2

IMPORTANT SAFETY PRECAUTIONS

IMPORTANT

AS WITH ALL MECHANICAL EQUIPMENT, PROPER OPERATING AND MAINTENANCE

PROCEDURES ARE REQUIRED TO KEEP YOUR H.E.R.O. AIRLESS PUMP PERFORMING TO

YOUR SATISFACTION. THE FOLLOWING SAFETY, OPERATING AND MAINTENANCE

INSTRUCTIONS ARE IMPORTANT.

Read and understand th is manual completel y, esp ec i ally with regard to a ll saf ety precautions. Read and follow

instructions on a ll warnin g labe ls on your equ ipm ent. Kee p thes e warn ing labels c lean an d reada ble at a ll tim es.

Order new labels from your local distributor or from H.E.R.O. if needed.

This system is capable of producing 3000 psi (spray pressure). To avoid rupture and injury DO NOT operate this

pump with com ponents rat ed less than 30 00 psi working pressur e (inclu ding but not lim ited to spra y guns, h ose

and connections).

Before servicing, cleaning or removal of any part, shut off power and relieve pressure.

WARNING

Prior to the use of the sprayer, ensure that the grounded continuity between the gun and the sprayer is

maintained. The hose shall be at least 50 feet in length. All hoses, guns, and accessories shall be suitable for

the maximum pressure ( 3000 PSI ). The gun shall be provided with a “Safety” which locks the trigger in the

“OFF” position. DO NOT point the gun at another person or spray at operator’s exposed skin. If there are any

special or unique conditions for this appliance, they shall be further noted and addressed and must be followed.

The manufacturer shall not be responsible for any loss, damages, or injury of any kind or nature whatsoever

resulting from the use of equipment other than in strict compliance with the instructions, cautions and warnings

contained in this operating and instruction manual and as displayed on the face of the equipment.

Never place fingers near spray tip of gun. Never point gun toward any part of the body, or that of any other

person. Material issuing from the spray tip is at high pressure. If fingers, or any part of the body are placed near

the tip of the spray gun, it is possible that the spray could break the skin and inject some of the material. If injury

does occur, seek the immediate medical attention. Be prepared to inform the doctor what fluid was injected,

if the injury is of an injection nature. Never treat the situation as a simple matter. Equipment and chemicals,

when used improperly can be dangerous .

IMPORTANT SAFETY PRECAUTIONS

NEVER place any part of the body in front of the spray tip or aim the gun toward any part of the body.

NEVER point the gun toward any individua l.

NEVER treat any inj ury as a sim ple cut. If injur y does occur, seek immediate m edical attention . Be pre-

pared to inform the doctor what fluid was injected.

NEVER allow another p erson to use the spra yer unless they are thoroughl y instructed on its operation

and have read all safety precautions in this manual and all safety warning labels attached to unit.

NEVER use around children.

NEVER attempt to perform any maintenance or service on any part of the unit spray system without first;

1. Shutting the motor ON/OFF switch to OFF.

2. Relieving all pressure in the pump by triggering the gun.

3. Locking gun trigger in "LOCKED" position, with gun locked closed.

4. Open prime valve to drain.

NEVER operate the sprayer without the tip guard complete and in place.

NEVER spray any material in the vicinity of open flame, pilot lights, electrical outlets or any other source of

ignition.

NEVER spray volatile materials with flash points lower than 140 F (60 C).

Owner’s Manual HK3819 / HK5523

Page 3

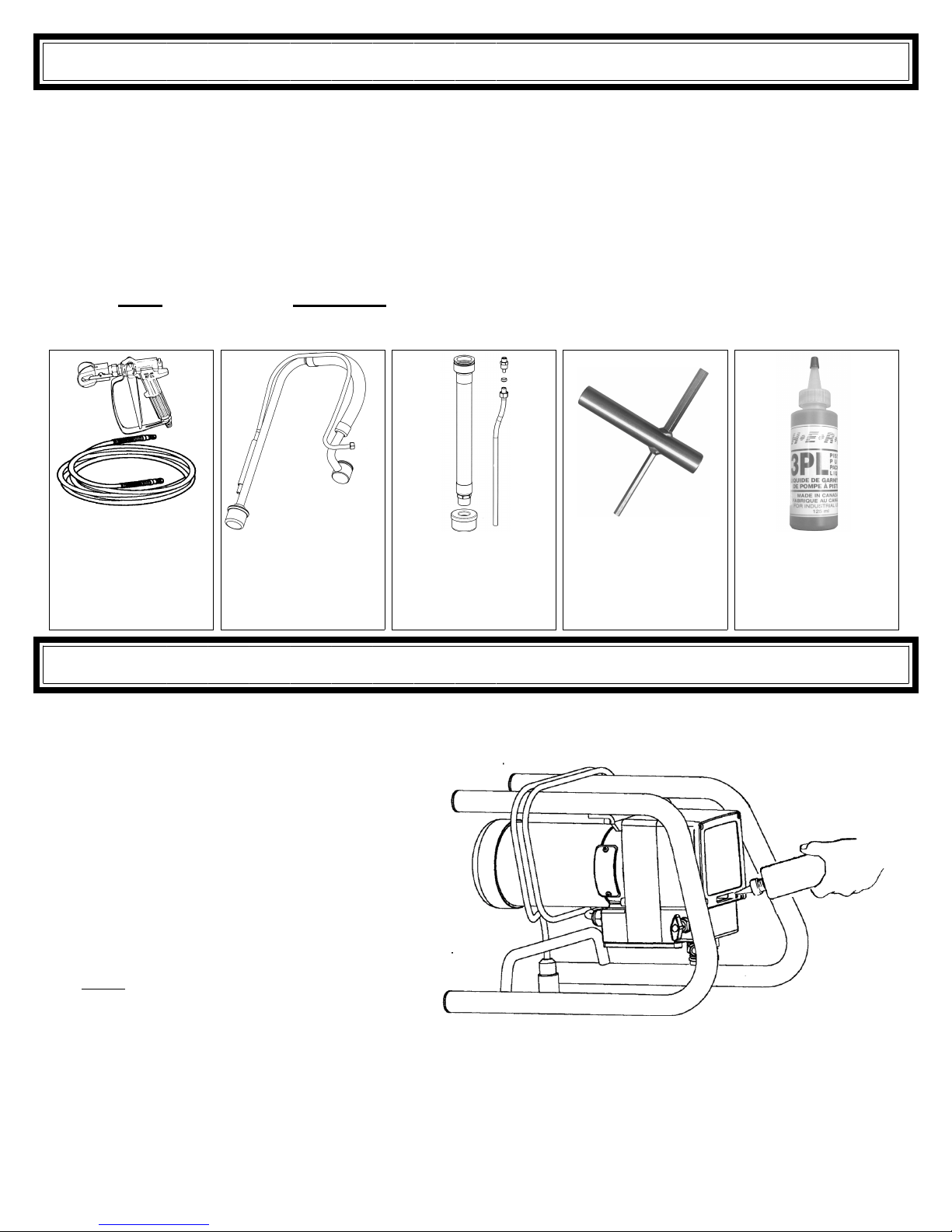

INTRODUCTION & UNPACKING

Congratulations on your purchase of a new H.E.R.O. H2K airless paint sprayer. We are sure you will enjoy owning and operating

your new sprayer. With H.E.R.O. airless spray equipment you will enjoy the features and benefits of this airless. You are spraying

paint, not air, and the paint is driven to the painting surface in a clean, fan shaped spray which penetrates all cracks and corners.

To attain these results, you must adjust the pressure as low as possible. We recommend that you become familiar with your

H.E.R.O. unit. Discuss with your dealer the useful accessory items they do offer - various types of tips, extension poles for hard to

reach areas, extra hose, et c. Use o f accessory ite ms is often the di fference b etween a goo d job and an ex cellent one !

Your H.E.R.O. airless sprayer has been fully tested and carefully packaged to avoid damage. It should be carefully

examined upon arri val to determ ine that the unit sh ows no signs of freight dam age. If any parts are found broken or

damaged, immediately contact the carrier and arrange for an inspection o f the concealed damaged. Claims for

damage MUST

safe delivery of merchandise upon pick-up from the shipper.

The unit shipping carton contains:

be made by the CONSIGNEE and not the shipper. The carr ier accepts full responsibility for the

Gun & Hose

Package

50’ Hose, Airless

Gun, 517 Tip

(Optional)

EC-2560

Siphon Hose

Assembly

(S and C models)

SET UP, FLUSHING, PRIMING, SPRAYING, SHUT DOWN

Setting Up:

1. Attach siphon assembly to intake valve.

2. Connect Bleed hose to return fitting.

3. Attach gun to hose.

4. Attach paint hose to outgo nipple .

5. Check packing lubricant. This will help prevent

buildup of materials on the piston rod thus extending packing life. To add lubricant, tilt back unit and

insert pointed nozzle of the 3PL liquid into the slotted area in the front of the unit. Add only a small

amount . This should be done each time it is used.

Before each use, flush the pump with the correct

thinner for the paint being used. NOTE: The unit

MUST

be stored with mineral spirits at all times.

EC-2600

Siphon Hose

Assembly

(H models)

EC-1000

Unitool

4-02-40-3PL1

Piston Lube

(8 Ounce Bottle)

Owner’s Manual HK3819 / HK5523

Page 4

SETTING UP, FLUSHING, PRIMING, SPRAYING, SHUT DOWN

Flushing:

1. Have two pails ready; one for flushing fluid and one for waste.

2. If you are using latex paint, fill the flushing pail with approximately 1 gallon of warm soapy

water. For oil based paints, use approximately 1 gallon of mineral spirits.

3. Place the siphon hose in the “flushing” pail and the bleed tube in the “waste” pail.

4. Flip open prime valve lever (Ref # 60) to fully opened position, Or on older models turn

knob counter-clockwise to fully open position

5. Lower the pressure setting by turning the pressure control knob (Ref # 78) all the way

counter-clockwise.

6. Plug unit in outlet.

7. Turn unit on and slowly increase the pressure until the unit starts to run and “flushing” fluid

begins to exit the bleed hose.

8. Turn off unit and close the prime valve by flipping lever to closed position, or on older

models turn knob clockwise to fully closed position.

9. Place bleed hose back onto the siphon hose assembly.

10.Disengage gun trigger lock and trigger gun into waste container.

11.Start unit and trigger gun into the waste container until “flushing” fluid appears.

12.Move gun to “flushing” pail and resume triggering gun into pail. Re-circulate fluid for

approximately one to two minutes. Turn unit off.

13.Re-open the prime valve. Turn unit on and allow the “flushing” fluid to re-circulate through

bleed valve for approximately one minute. Turn unit off.

14.When spraying latex paint, repeat the “flushing” procedures with clear water. When

spraying oil based paints continue with “Priming” instructions.

Priming:

(Priming the sprayer follows the same basic step used in the “Flushing” procedures.)

1. Place the siphon hose in a clean 5 gallon pail. Install a strainer bag and secure with rubber

band. Keep strainer bag at least 4 inches from the bottom of pail.

2. Pour your paint through the strainer bag. Leave the strainer in place while spraying.

3. Place bleed tube in the “waste” pail.

4. Flip open prime valve lever (Ref # 60) to fully opened position. Or on older models turn

counter-clockwise fully to open position.

5. Lower the pressure setting by turning the pressure control knob (Ref # 78) all the way

counter-clockwise

6. Turn unit on and slowly increase the pressure until the unit starts to run and paint begins

to exit the bleed hose.

7. Close the prime valve by flipping back to closed position, or on older models turn knob

clockwise to fully closed position .

8. Place bleed hose back onto the siphon hose assembly.

9. Disengage gun trigger lock and trigger gun into waste container.

10.Start unit and trigger gun into the waste container until paint appears. Stop.

11.Move gun to the paint pail and resume triggering gun into pail. Re-circulate fluid for

approximately one to two minutes.

12.Turn unit off and follow the Pressure Relief Procedures

13.Install the tip guard and tip. You are now ready to start spraying.

Owner’s Manual HK3819 / HK5523

Page 5

SPRAYING & SHUT DOWN

Spraying:

1. Turn unit on.

2. Trigger gun, and increase pressure slowly. Continue to increase the pressure until the spray

pattern is uniformed from top to bottom, with no heavy areas. If heavy areas are still visible at

maximum pressure settings, thin paint with the correct thinner, according to the paint manufacturer’s instructions. Spray test patterns onto old newspaper or other scrap material.

Always use the lowest possible pressure setting to atomize paint fully. Replace worn

tips immediately, as it is not possible to obtain satisfactory spray pattern with a worn

tip.

3. Check all fluid connection points for possible leaks. Correct before continuing.

4. Spray Paint. NOTE: For best results, read and practice the spray techniques shown on pages

6-7.

Shut Down:

1. Turn off unit.

2. Perform the Pressure Relief Procedures as shown on page 4.

3. Remove tip guard and gun filter. Place in your “flushing” bucket.

4. Perform the “Flushing” procedures as shown on page 5. Ensure you continue to flush the

sprayer until the “Flushing” fluid is running clear and no spray materials remain in the sprayer.

5. Before storing, the final “Flu shing” rinse must be made with mineral spirits, regardless of what

is to be sprayed next. NEVER leave water or paint in the unit, even over night.

6. Clean tip guard, tip and gun filter. Re-assemble spray gun and store for next use.

Owner’s Manual HK3819 / HK5523

Page 6

AIRLESS SPRAY PAINTING SUGGESTIONS

A good airless spray application is the result of many factors. Surface preparation, which includes cleaning and

degreasing, priming, material co mpatibility , quality finish p rodu ct and corre ct appli cation te chnique. All are all i mportant to

the finished results.

The key to all good applications is a good spray gun technique. Proper application techniques can easily be learned by

using the following simple guidelines. If you are not familiar with the basic spray techniques we recommend that you

study this portion of the manual and practice the techniques shown. Practice your technique on scrap cardboard or old

newspaper until you feel confident.

FOR EXCELLENT RESULTS, READ AND PRACTICE THESE TECHNIQUES

1. Always strain all paint through a H.E.R.O. strainer bag. The m ost common r eason for a irless spra yer’s to

malfunction is foreign matter jamming the valves or plugging the tip. Always strain the paint before putting through

the pump.

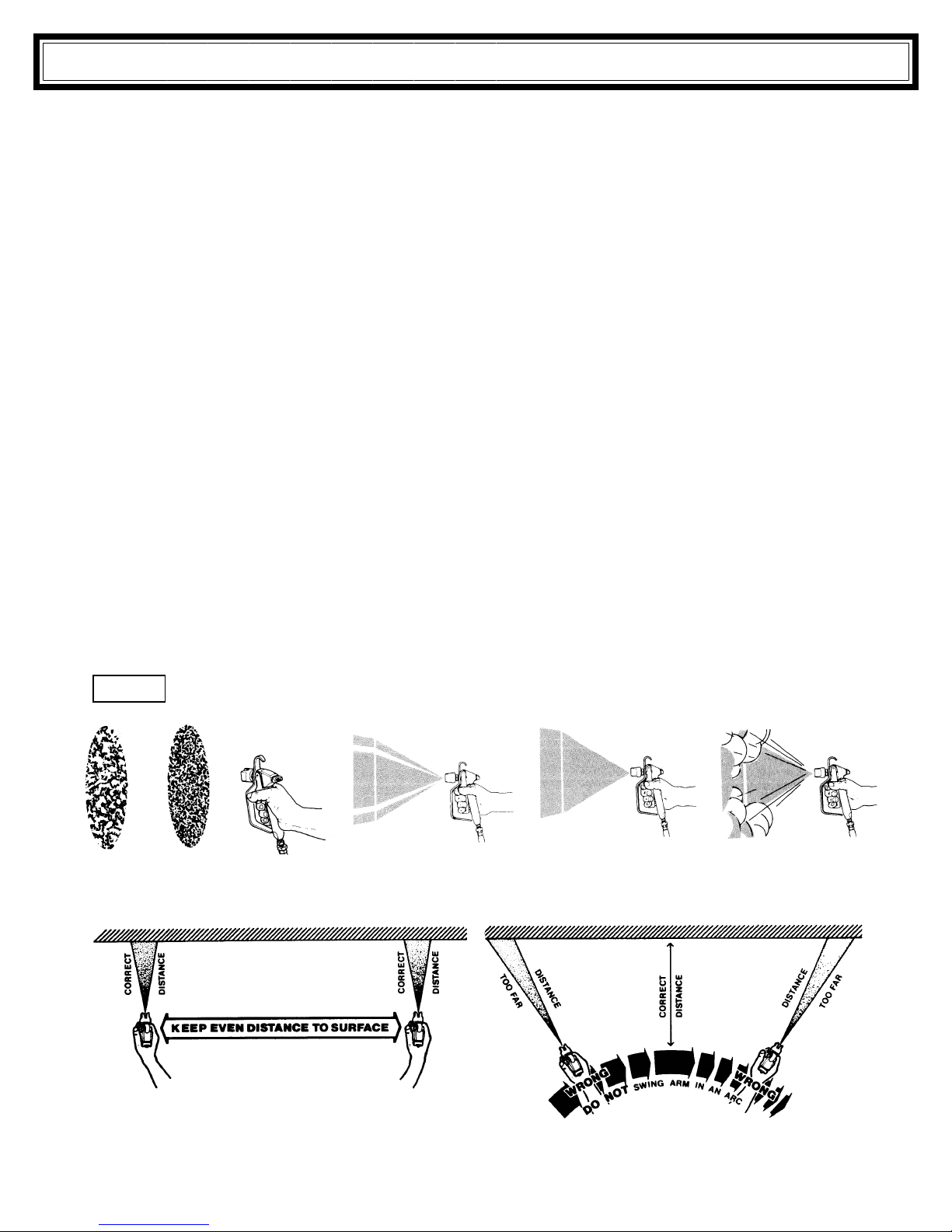

2. Always spray at the lowest pressure setting which will provide a uniform spray fan( fig. 1 ). Adjust pressure

control knob so that paint is completely atomized. Insufficient pressure will result in "tailing". Too much pressure will

result in excess fog and over spray, excess tip wear, and increased sprayer wear and tear. See setting up to spray,

page 8.

3. Always spray at right angles to the surface being sprayed ( fig. 2 ). Angling or arcing the nozzle toward the

surface will cause uneven coverage and excessive over spray.

4. Alw ays hold spra y gun 11-12 inches f rom spray surf ace( fig. 3 ). Too close and the fan width will be reduced

and material will be applied too heavily (runs). Too far from the surface and you will have excessive over spray and

light coverage (transparent).

5. Always move the gun parallel to the surface being sprayed, at a consistent speed. This avoids uneven

coverage.

6. Always start the spray stroke before triggering the gun and release the trigger before completing the stroke

( fig. 4 ).This avoids heavy build up of paint at eithe r end of the spray stroke.

7. Always lap your spr ay p atte rn by one half ( fi g. 5 ). This assures full coverage of the surface being painted.

FIG. 1

Poor Good Tailing Good Pattern Fog, Overspray

Owner’s Manual HK3819 / HK5523

Page 7

AIRLESS SPRAY PAINTING SUGGESTIONS

FIG. 3

FIG. 4

FIG. 5

SPRAY TIP SELECTION

It is advisable to obtain a spray tip recommendation from the supplier of the material to be sprayed.

The following table is a general guide and will assist in selecting the optimum tip to use.

TIP SIZE USED TYPICALLY FOR SPRAYING THESE MATERIALS APPROX. GPM Suggested filter (color)

.019 Exterior Latex on large unobstructed areas. .47 white

.017 Interior Latex, Exterior Latex, Shake Paint, Exterior Flat Paints. .31

.015 Alkyd Flat Enamel, Interior Latex, Semi-Gloss Enamel, Stains. .23

.013 Fine ground Gloss Enamels, and good quality Stains. .18

.011 Clear Varnishes and Lacquers. .12

NOTE: In order to test if a tip is worn, spray a small amount of suitable material on to a test surface and observe the spray

pattern produced on the wall. Try to obtain an even elliptical spray pattern by first adjusting the pressure down, then gradually

increasing pressure until full atomization is achieved. This should result in a crisp spray pattern with sharp edges and even

concentration, see diagram below. If a satisfactory pattern is unattainable ( look for edges to be rounded with heavier

concentration ), then the tip is worn and should be replaced. Other causes of poor spray fan are insufficient spray pressure

and material viscosity ( may requiring thinning ).

Good

Tip

NOTE: Use of excessively worn tip can result in apparent poor performance of pump.

Owner’s Manual HK3819 / HK5523

Worn

Tip

Page 8

Uneven Spray Pattern

Loading...

Loading...