INSTRUCTION MANUAL

FOR

LABORATORY CENTRIFUGE

Berthold Hermie GmbH & Co

industriestrasse 8-12

D-7209

Phone: (0 74 26) 67-0

T!x.:760

Fax: (0 74 26) 67-170

Gosheim / Fed. Rep. of Germany

613bhgd

Z320

,1

HERMLE

Z320

Universal

Laborzentrifuge

Laboratory

centrifuge

Centrifugeuse

de laboratoire

Centrifugadora

t

de laboratorio

INDEX Page

1.

General Information 2

1.1 Description 2

1.2 Safety precautions to be observed before operating the centrifuge 2

1.3 Safety standards 2

1.4 Technical data 3

1.5 Accessories supplied with each centrifuge unit 4

1.6 Warranty 4

2.

Installation 5

2.1 Unpacking the centrifuge 5

2.2 Required space 5

2.3 Installation 6

3. Howto install and load a rotor 7

3.1 Mounting and securing a swing out rotor 7

3.2 Mounting and securing a microtiter rotor 8

3.3 Mounting and securing an angle rotor 8

3.4 Mounting and securing a hematocrit rotor 11

3.5 Overloading of rotors 13

4.

Operation , 14

4.1 Power switch 14

4.2 Lid release 14

4.3 Rotor installation 15

4.4 Lid lock 15

4.5 Speed preselection 15

4.6 Preselection of operating time 16

4.7 Preselection of brake intensity 16

5. Safety facilities 16

5.1 Imbalance 16

6. Service and Maintenance 17

6.1 Service of centrifuge 17

6.2 Cleaning the centrifuge 17

6.3 Cleaning of centrifuge after breakage of glass tubes/bottles 17

6.4 Disinfection 18

7. Breakdown 19

7.1 Emergency Lid release 19

7.2 Check list / Trouble shooting 20

8. Nomograms 21

8.1 Acceleration and deceleration values of the Z 320 21

8.2 RCF - (g-value) - diagrams 22

9. Appendix 23

9.1 Chart for determining g-values 24

9.2 Circuit diagram 25

1.

General Information

1.1 Description

Model"

application by offering a wide range of accessories. It accomodates swing out

rotors up to a max. capacity of 4 x 100 ml, as well as angle rotors up to 10.000 rpm

(microtiter rotor and hematocrit rotor see brochure).

1.2 Safety precautions to be observed before operating the centrifuge

Do not operate if:

- the centrifuge has not been installed correctly

- the centrifuge is partly dismantled

- service has been attempted by non-authorized or non-qualified

- the rotor has not been installed securely on the motor shaft

Do not operate the centrifuge with rotors and accessories not belonging to the

standard range of accessories of this centrifuge without obtaining the prior

Z 320" is a universal bench top centrifuge which covers many fields of

personnel

permission of the manufacturer. Exception: tubes and bottles made of glass or

plastic normally available in the laboratory.

Do not operate the centrifuge in explosive atmospheres.

1.3 Safety standards

The centrifuge corresponds to the general requirements set by German law for

medical apparatus, "Med GV" group 3.

The following standards have been considered for the production of our

centrifuges:

- Accident prevention rules for centrifuges UW-VBG 7z

- Accident prevention rules for electrical equipment & installations

UW-VBG4

- DIN 58970, part 1,2 and 4 for centrifuges and centrifuge tubes

- Electrical interference suppression according to interference degree

NasperVDE0875

1.4 Technical Data

Manufacturer

BHG HERMLE GmbH & Co.

industriestrasse 8-12

7209 Gosheim/Fed. Rep. of Germany

TIx: 760613 bhgd, Fax: (07426)67 170

Type No.

Z320

Dimensions:

Width

Depth

Height

390 mm

390 mm

340 mm

Weight 29 kg

Noise level

64 dB(A)

max. speed

max. volume

max.RCF

Admiss. density

Admiss. kinetic energy

Electrical connection

Current

Connected load

Interference suppression

Service Dept. at HERMLE:

Address of agent:

10.000 rpm +/-

5%

400,0 ml

6.580

x g

1,2 kg/dm

2.400

220 V/50 Hz

0,71 A

0,155 KVA

3

Nm

115V/60HZ

1,7 A

0,195 KVA

interference degree N as per VDE 0875

074 26 / 67-438

•1.5 Accessories supplied with each centrifuge unit

2 spare fuses

2 plastic plugs

1 instruction manual

1 warranty certificate

1 spanner wrench for

mounting and removing

the rotor

1 hook for mechanical lid

release

1.6 Warranty

The centrifuge has been subjected to thorough testing and quality control.

In the unlikely event of any manufacturing faults occuring, the centrifuge and rotors

are covered by warranty for a period of 1 year from date of delivery.

This warranty becomes invalid in case of wrong operation, use of non-appropriate

Figure 1

spare parts or accessories and non-authorized modification of rotor or centrifuge.

The manufacturer reserves the right for any technical modifications of the

product in respect to technical improvement.

Installation

2.1 Unpacking the centrifuge

The centrifuge

Z 320 is sup-

plied in a

carton protected by PU

foam.

Open

the carton and

take off the

upper foam

part (including

the accesso-

ries) and

remove the

centrifuge.

The instruction

manual and the

accessories mentioned under 1.5 should be kept with the centrifuge.

2.2 Required space

The centrifuge should be installed on a

be operated on a stable laboratory table/cabinet etc..

To guarantee sufficient ventilation, please ensure that the centrifuge has at least

rigid,

even surface. The Z 320 should only

Figure 2

15 cm free space around the unit

It is recommended that the centrifuge is not sited in positions subject to excessive

heat, e.g. strong sunlight, radiators etc. as heat-build-up can occur within the

centrifuge bowl.

2.3 Installation

1.

Before operating the centrifuge check that the power supply corresponds to that

on the manufacturer's rating label which is mounted on the rear panel.

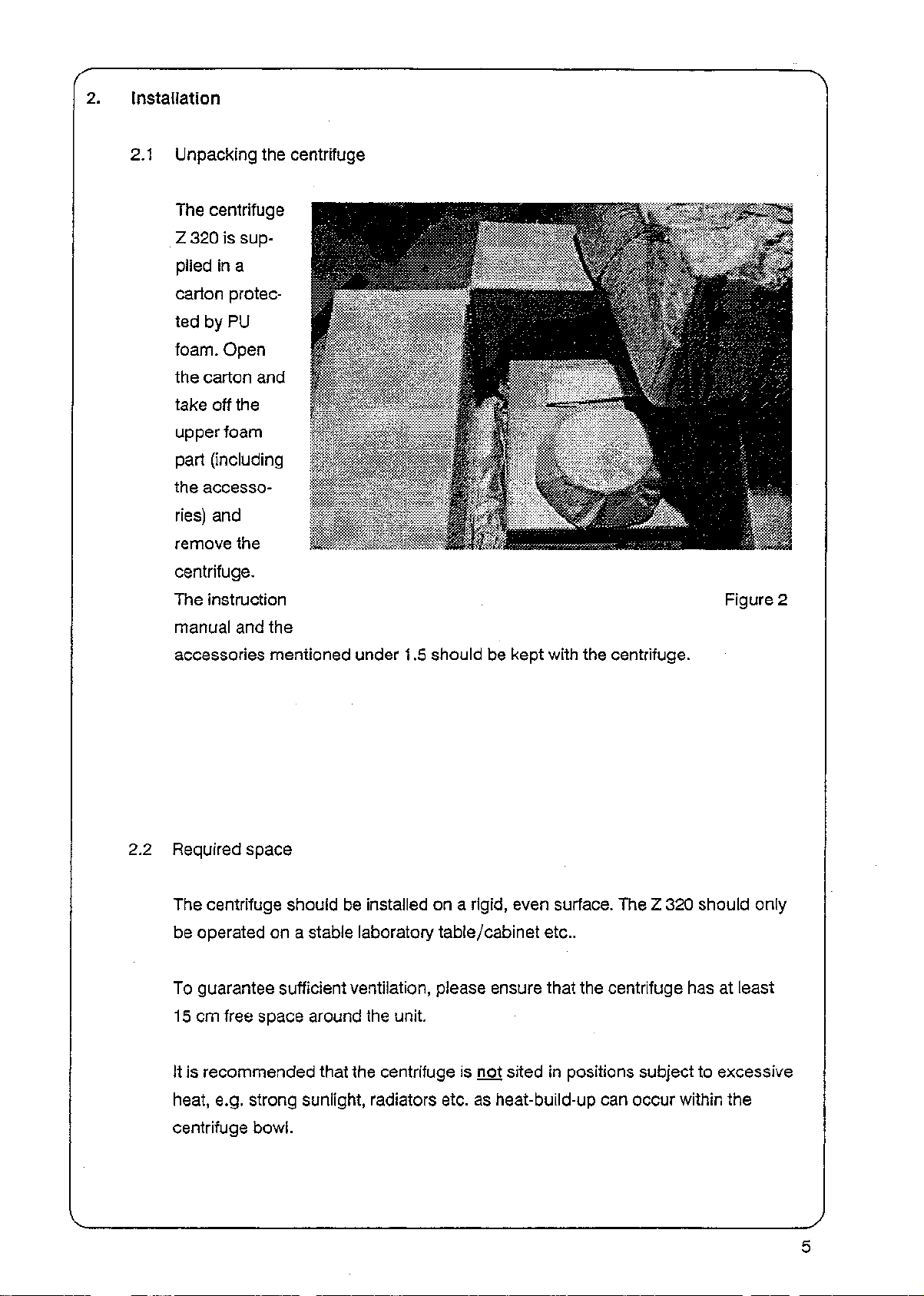

2.

Switch on the power switch (1), the green control lamp of the power supply (1),

as well as the white control lamp of the lid release (2) will light. The lid can then be

opened by pressing firstly the lid release switch (2), as well as secondly the mechanical lid lock (3), (see figure 3).

Figure 3

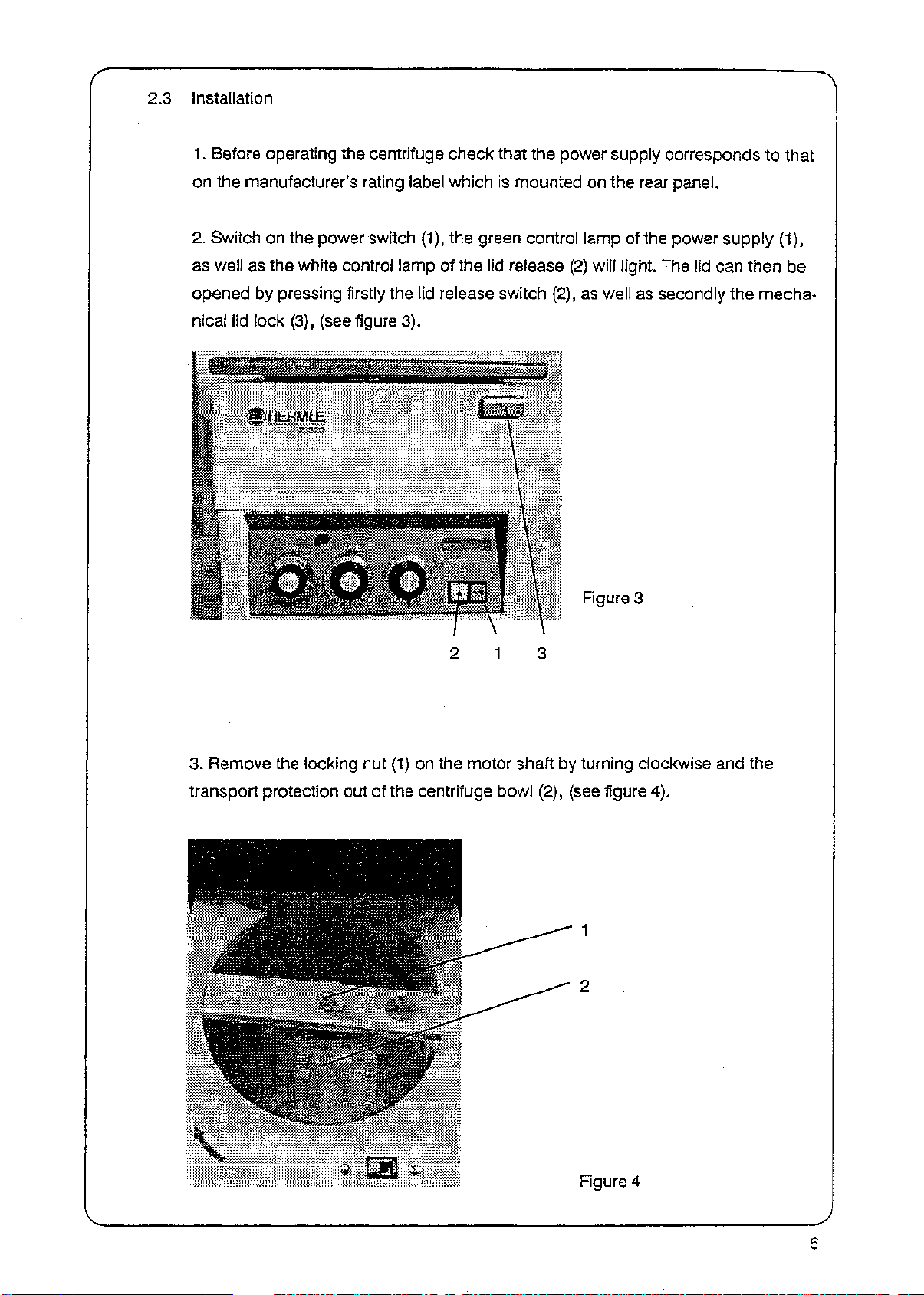

3. Remove the locking nut (1) on the motor shaft by turning clockwise and the

transport protection out of the centrifuge bowl (2), (see figure 4).

Figure 4

3. How to install and load a rotor

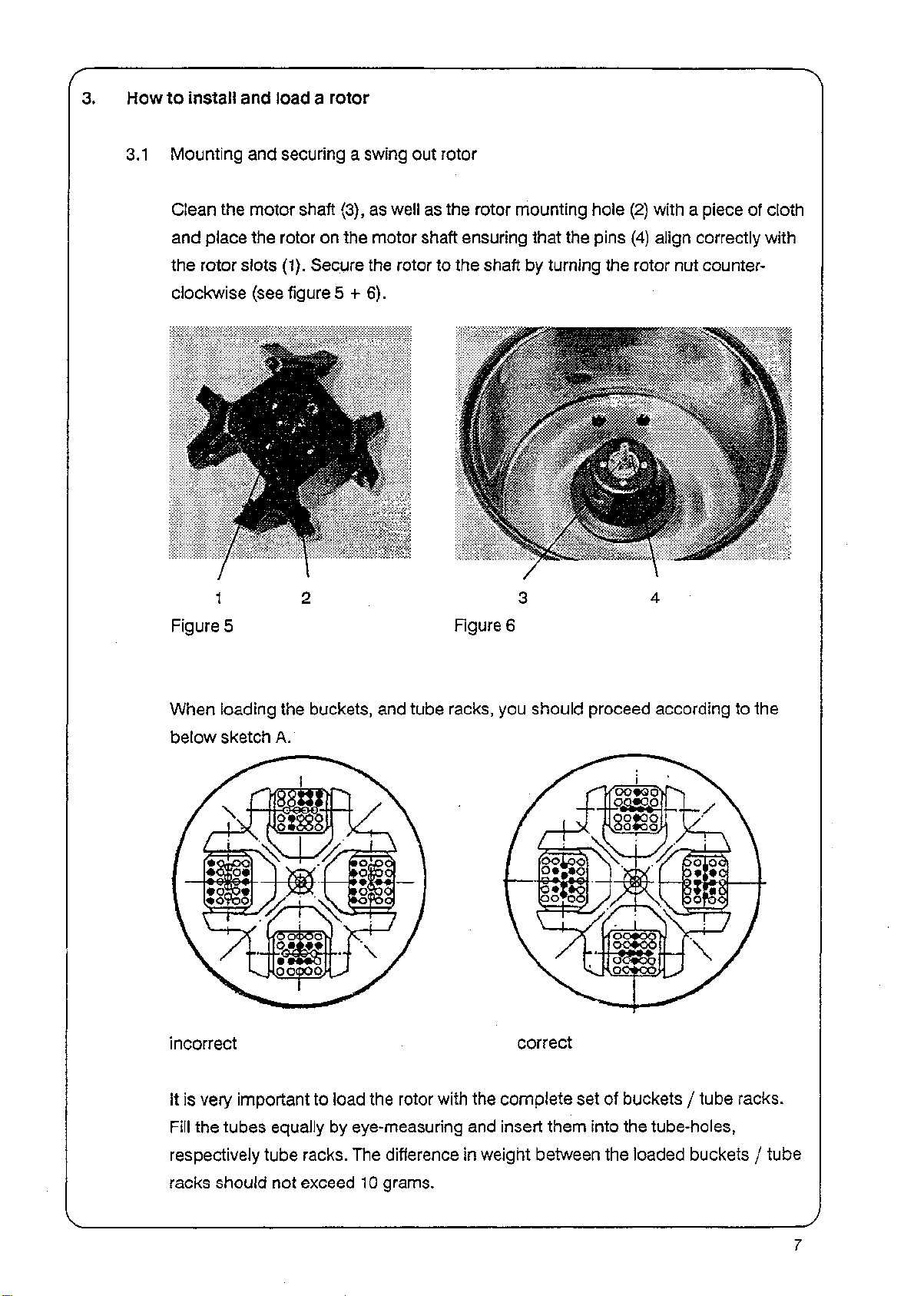

3.1 Mounting and securing a swing out rotor

Clean the motor shaft (3), as well as the rotor mounting hole (2) with a piece of cloth

and place the rotor on the motor shaft ensuring that the pins (4) align correctly with

the rotor slots (1). Secure the rotor to the shaft by turning the rotor nut counter-

clockwise (see figure 5+6).

1

Figure 5

When loading the buckets, and tube racks, you should proceed according to the

below sketch A.

incorrect

Figure 6

correct

it is very important to load the rotor with the complete set of buckets / tube racks.

Fill the tubes equally by eye-measuring and insert them into the tube-holes,

respectively tube racks. The difference in weight between the loaded buckets / tube

racks should not exceed 10 grams.

It is also allowed to operate, (for example) a 4-place swing out rotor with 2 loaded

and 2 unloaded buckets, but it is important that the loaded buckets are then

opposite each other (see sketch A, page 7).

To remove the rotor from the shaft turn the rotor nut clockwise repeatedly until the

rotor nut has lifted the rotor from its former position on the motor shaft,

3.2 Mounting and securing a micro titre plate rotor

Is same as for swing out rotors.

3.3 Mounting and securing an angle rotor

Clean the motor shaft (1) and the rotor mounting hole (2) with a piece of cloth and

place the rotor on the motor shaft ensuring that the pins (3) align correctly with the

rotor slots (4), (see figure 7).

Figure 7

8

Secure the rotor to the shaft by turning the rotor nut (1) counter-clockwise. When

doing this, hold the rotor with the other hand (see figure 8).

Figure 8

ATTENTION:

Before operation, secure the rotor lid to the rotor by pressing the snap

connector onto the rotor nut (see figure 9).

Figure 9

To remove the rotor from the motor shaft, turn the rotor nut clockwise, screw it off

and take the rotor vertically off the shaft.

When loading the rotor you

should proceed according to

sketch B. Fill the tubes equally

by eye-measuring and insert

them into the tube-holes of the

rotor (see sketch B).

The difference in weight between

the tubes should not exceed

2 - 3 grams.

empty tube-holes

loaded tube-holes

Sketch B

It is also allowed to operate, (for example) a 6-piace rotor with 2 or 4 loaded tubes

only, but it is important that the 2 occupied tube-holes are opposite each other

(see sketch B).

To remove the rotor from the motor shaft, turn the rotor nut clockwise, screw it off

and take the rotor vertically off the shaft.

10

3.4 Mounting and securing a hematocrit rotor

Clean the motor shaft (1) and the rotor mounting hoie (2) with a piece of cloth and

place the rotor on the motor shaft ensuring that the pins (3) align correctly with the

rotor slots (4), (see figure 10).

Figure 10

Secure the rotor to the shaft by turning the rotor nut (1) counter-clockwise. When

doing this, hold the rotor with the other hand (see figure 11).

Figure 11

11

ATTENTION:

Before operation, secure the rotor lid to the rotor by pressing the snap connec-

tor onto the rotor nut (see figure 12),

Figure 12

To install or remove the lid, press both locking bolts together (see figure 13).

To remove the rotor from the motor shaft, turn the rotor nut clockwise, screw it

off and take the rotor vertically off the shaft.

Figure 13

12

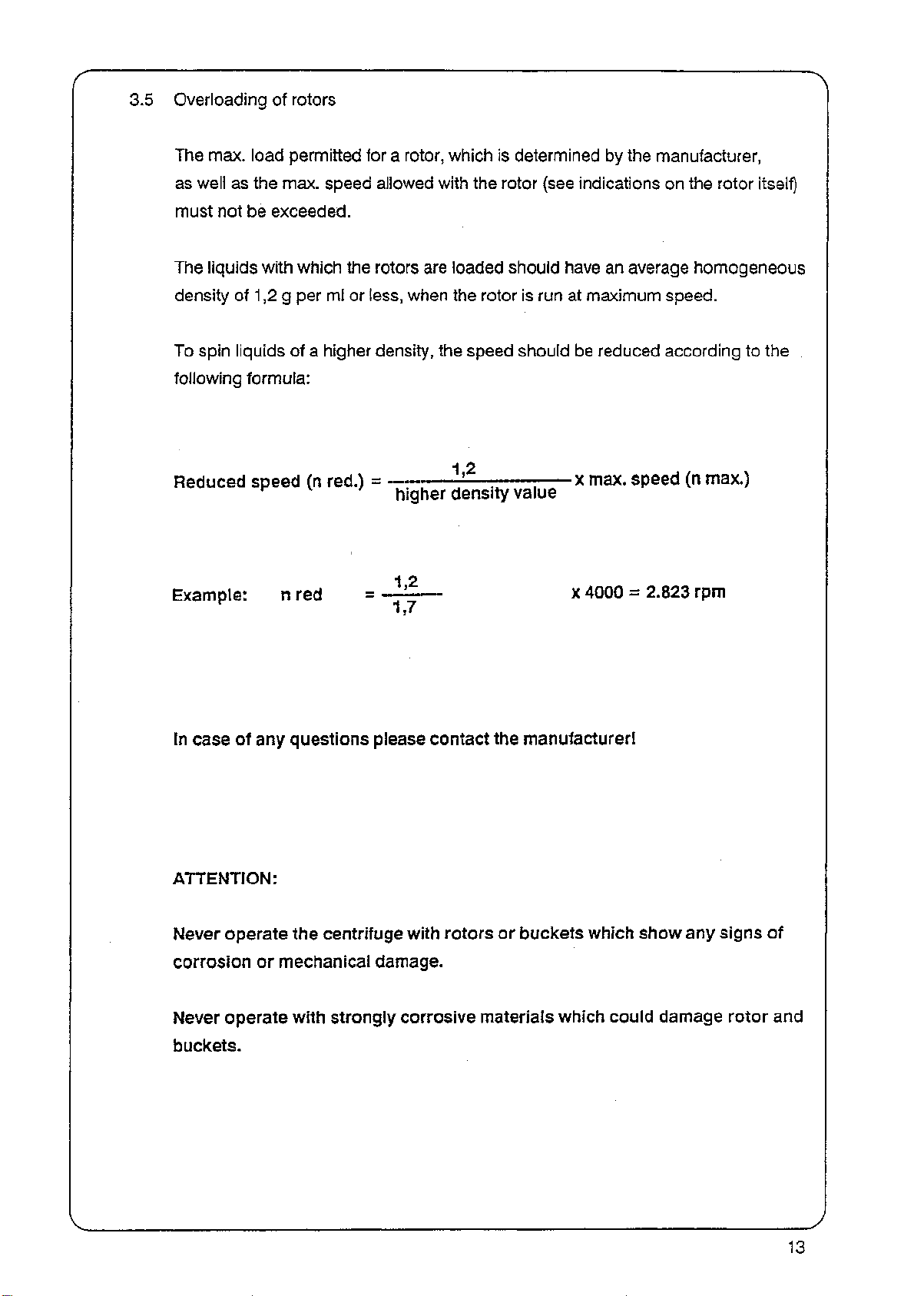

3.5 Overloading of rotors

The max. load permitted for a rotor, which is determined by the manufacturer,

as well as the max. speed allowed with the rotor (see indications on the rotor itself)

must not be exceeded.

The liquids with which the rotors are loaded should have an average homogeneous

density of 1,2 g per ml or less, when the rotor is run at maximum speed.

To spin liquids of a higher density, the speed should be reduced according to the

following formula:

Reduced speed (n red.) = '— x max. speed (n max.)

K

higher density value

1 2

Example: n red = -!£-— x 4000 = 2.823 rpm

In case of any questions please contact the manufacturer!

ATTENTION:

Never operate the centrifuge with rotors or buckets which show any signs of

corrosion or mechanical damage.

Never operate with strongly corrosive materials which could damage rotor and

buckets.

13

4. Operation

4.1 Power switch

The power supply switch (1) (green light), switches the centrifuge on and the

control lamp of the lid release (2), as well as the digital indication of the speed (3)

will light. The power switch (1) should always be the first to be switched on and the

last to be switched off, (see figure 14).

4.2 Lid release

When the lid release lamp (2) is on and the rotor is stationary, the lid can be

opened.

indicator lamp (2) will go out,and then press the lid release button (4) of the

mechanical lid lock.

The lid can only be opened when the rotor is stationary and the white control lamp

(2) lights up (lid lock according to UW-VBG 7z).

To open the lid, press the lid release switch (2) of the electrical lid lock, the

Figure 14

14

4.3 Rotor installation

see part 3. of the manual.

4.4 Lid lock

After correct fitting and loading of the rotor, close the lid. The white control lamp of

the lid release (1) will light, indicating that the rotor is stationary and the lid closed

correctly.

The centrifuge can only be started with the lid closed (lid lock according to

UW-VBG7Z).

When the rotor starts accelerating, the lid release indication (1) switches off and the

lid cannot be opened, (see figure 15). .

4.5 Speed preselection

The speed (rpm) can be steplessly preselected between 100 and 10.000 rpm

(depending on the rotor type) with the knob SPEED (2).

Once set, the speed can be reproduced to within +/- 2%. The actual speed is

indicated in steps of 100 rpm on the digital indication SPEED (3).

Figure 15

15

4.6 Preselection of operating time

Turning the timer switch (1) clockwise, sets the operating time (max. 60 mins.) and

starts the centrifuge. If the required operation time is 5 minutes or less, the timer

should be switched over the 30 minute position and then back to the desired value.

When the set time expires, the centrifuge switches off automatically. For continuous

operation,

4.7 Preselection of brake intensity

To reduce the risk of resuspending samples, during deceleration, it is possible to

steplessly pre-select the brake intensity with the knob BRAKE (2), (see figure 16). In

addition,

point 8.1!

switch the knob TIME (1) to the position HOLD, (see figure 16).

please have a look at the acceleration and deceleration curves under

5. Safety facilities

5.1 Imbalance

In case of unequal loading of opposite buckets / tube racks or tube-holes, the

operation is interrupted during the acceleration phase, and the centrifuge switches

off. To indicate, when the digital LED speed display blinks on and off, an imbalance

cut off has occured.

The centrifuge cannot be re-started until the Imbalance has been corrected and the

lid has been opened and re-closed.

Figure 16

16

r

6. Service and Maintenance

6.1 Service of centrifuge

Centrifuge service and maintenance should be done regularly and only by

authorized and qualified personnel.

6.2 Cleaning the centrifuge

Always keep the centrifuge housing, rotor chamber, rotors and rotor accessories

clean.

Cleaning is not merely for hygenic or aesthic purposes, but also is necessary to

Anodized parts such as rotors, reduction plates etc., should only be cleaned with

neutral cleaning agents (pH value 6 - 8). Never use an alkaline cleaning agent

warm-air-cabinet (max. temp. + 50°C).

It is recommended that all anodized aluminium parts are regularly treated with

anti-corrosion oil, so that their durability will be increased and the corrosion risk

reduced.

6.3 Cleaning of centrifuge after breakage of glass tubes/glass bottles

With high g-values, there is a possibility that tube breakage will occur.

The bucket insert bolts of a swing out rotor should be regularly greased.

prevent corrosion and damage to the centrifuge.

(pH > 8). After cleaning ensure that all parts are dried thoroughly by hand or in a

Should this happen, the centrifuge rotor and rotor chamber must be thoroughly

cleaned and all broken particles must be removed immediately. If this is not done,

they could scratch the protecting coat of the rotor or stick to the bucket insert bolts

and hinder the buckets to swing out properly.

If the rotor chamber has not been properly cleaned, this will produce a fine black

dust which can cause significant damage to the centrifuge.

17

6.4 Disinfection

If, due to tube breakage, infectious material contaminates the centrifuge, rotor, rotor

chamber, buckets etc. should be disinfected ! ! !

Rotor and swing-out buckets must not be autociaved.

Rotor and rotor chamber should then be treated with a neutral disinfection agent.

This would be the best way to achieve a good result upon all surfaces.

18

Breakdown

7.1 Emergency lid release

In case of power failure or any malfunction, the lid can be opened manually by the

following procedure:

1.

Switch off the centrifuge

and unplug the power

2.

Remove the plastic plug

(1) on the left side of the

housing.

3. Insert the lid release

hook (2) (supplied with the

centrifuge) into the hole

and pull out the pin (3) by

hooking the lid release

hook into it before.

The lid can then be opened,

(see figure 17./

sketch C).

cord.

Figure 17

Sketch C

19

7.2 Check list / Trouble shooting

FAULT

Centrifuge will not start - no

indication on front panel.

POSSIBLE REASON

No power supply.

Defective fuse.

SOLUTION

Check mains (power) and

centrifuge fuses. Replace if

necessary.

****************************** ***•****•*•••*****•*•*•**•••** ************•***•*****•**•*••

Lid cannot be released.

1

I

Defective lid lock.

Lid lock is jammed.

Open manually (see 7.1)

Re-adjust lid lock.

No power from PC board. Call service.

****************************** ••*****•••***•*****•****•**•••* ••***•**•******••*•**•***•*•**

Centrifuge cannot be started, Lid not closed correctly (white Close lid correctly,

although power is on. indicator lamp does not light).

No speed or time preselected. Check and set the time.

Fuse on front panel is defecti- Check fuses and replace if

ve.

necessary.

20

8.

Nomograms

8.1 Acceleration and deceleration values of the Z 320

21

8.2 RCF - (g-value) - diagrams

22

9. Appendix

9.1 Chart for determining g-values

23

CHART

For +he Deferminai ion of +he g ~ Value

pie :

£-40

To determine the spinning radius you

measure the distance from the center

of the drive shaft up to the most outer

part of your sample tube when it Is In

spinning position.

Thus,

you will get with a radius

r=16 cm (point A) and with a speed

n = 4000 rpm/mln (point C) a relative

-25

centrifugal force of 2860 x g (point B)

Alternatively, when you know the

nlng radius and the g~value7 you can

determine the

centrifugal

forc» In "g'

30 000-=3

20 000-

10 000-3

spin"

HERMLE

(RPM)

mlnui*

p»r

20

000

fe-15 000

fe=-10 000

•6000

-14

-12

This chart Is based upon the following

m

formula:

-10

=lL18

-9

g = relative centrifugal force (RCF),

1.3 relative to the acceleration

of the earth which has the constant

value g = 9.81 m/s

r = spinning radius in cm

n = revolutions per minute (RPM)

x

r x

(,1000

2

1000

500

400-

300—i

20-=

br~3000

•2000

•1000

-500

•200

24

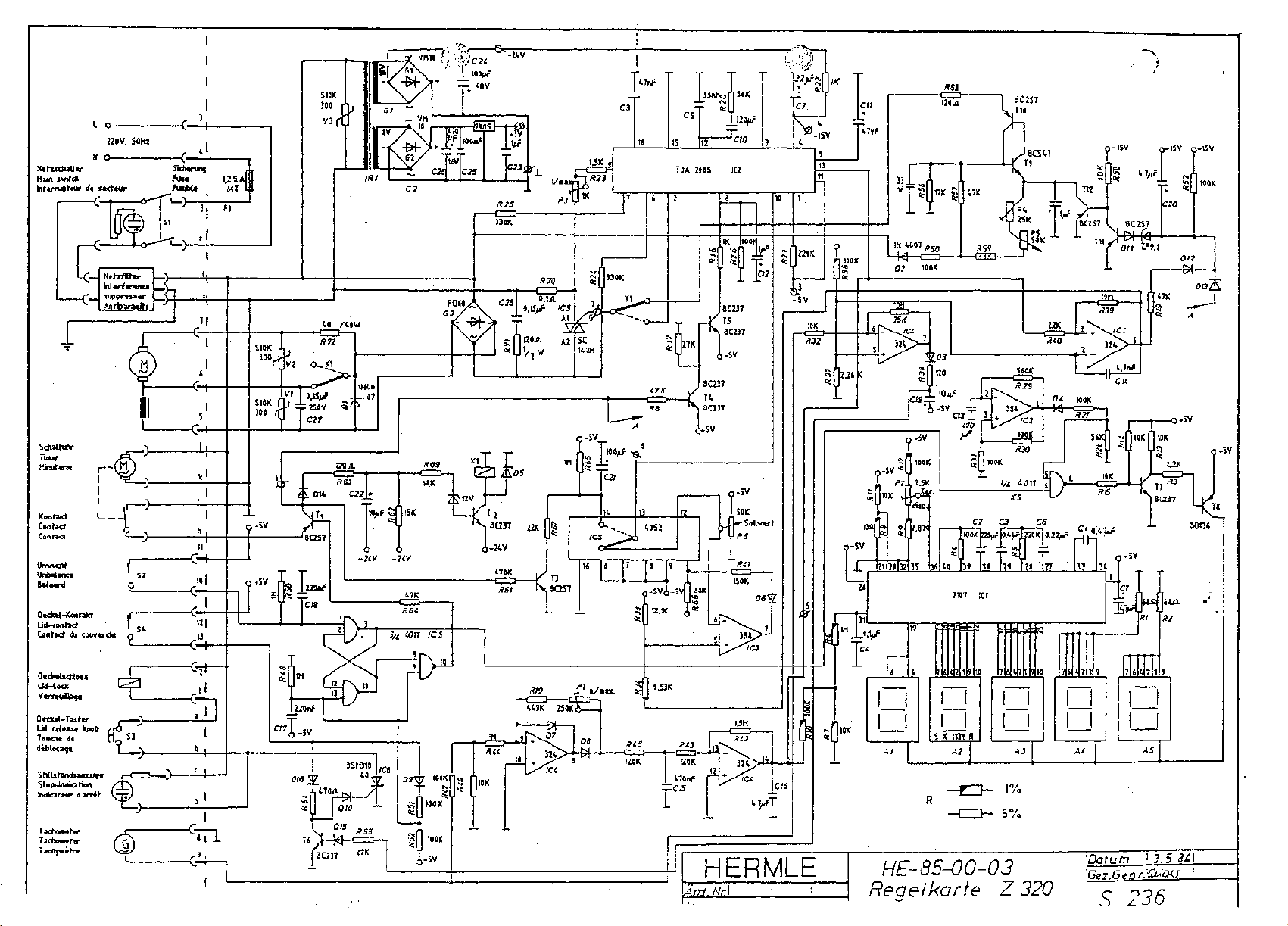

9.2 Circuit diagram

25

HE-85-00-03

\

Netzfilter-UI

Interference

suppressor

Antiparasite

'—!™-"X-—J—

\

T I

lOrehzahl

speed

y Vitesse

—L v

v

\ T '

V ^ ^

U— i «-"c>n>

eeeeeeeeeeeee

brake

frein

Elektr. Zeit

lt ^ I

"*"-)

\ |

schaituhr

schaltuhr

Electronic-

timer

Minuterie

electriqe

Deckelzuhaltung

Ud lock

Fermeture

jautomatique

J

-

L

Bedienschild

/QOperatina

S^ Mnrlp rl omnini

Mode d emploi

Schutzkessel

o

Guard bowl ,Cater

instruction

O Gehause

Housing

Cabinet

HERMLE

Andr.

Nr

Name

de

protection

Schaltplan

Diagram

fur

Zentrifuge

for

centrifuge with

Schema avec syste'me

Bezeichnung •

Schaltplan

Circuit diagram Z 320

Circout pour Z320

mit

de

fur Z

Fremdbeluftung

air

purge facility

ventilation

320

.

Datum

Gez.

26.4.85

Gepr.

S2L2

Hiia swifdt

I

o-

220V. SQrtz

H

O-

i-

:•

^

_i'

fu»«

1,2 5

halbU

MT

-11

sr^^

CJ7

S10K

300

V3

s

tf

;

COiL

-07

5M100K

.—I

i/i ion

IC5

C2

a cs

lOOKfcBpf OAVmOK

I

T r^U

39 ba I29

~N

V-1SY o-'SV

OQ/\

O-5V

0.;

Oeck*i-)G>nfc*t

Lid-coo

r^cf \

Contact

du

couvvrdc

Ud-lodc

O«tlt«<-Tjsfef

Indlcattor

S4

X

<Tt

^

^

^

a 1

1

Datum

'*3.5.3t\

S

236

4/TC/.

Nr.\

HE-

85-00

Regelkarfe

-03

Z

320

Loading...

Loading...