Hermle Z-306 Service manual

Service Manual

for

Universal Centrifuge

Z 306

© Hermle Labortechnik GmbH Service Manual Z 306 V2.13/2013

CONTNET

Content

8. Technical Data .......................................................................................................................1

8.1 Acceleration times Z 306 (120 V / 230 V) in min/sec .............................................................................................. 1

8.2 Decelertaion times Z 306 (120 V / 230 V) in min/ sec ............................................................................................. 2

8.3 Imbalance shut off data Z 306 (120V / 230 V ) ......................................................................................................... 3

9. Service Instructions ...........................................................................................................4

9.1 General technical description........................................................................................................................... 4

9.2 Electrical and electronically components ....................................................................................................... 4

9.2.1 Power board .................................................................................................................................................... 4

9.2.2 Control board ................................................................................................................................................... 5

9.2.3 LCD Display .................................................................................................................................................... 6

9.2.4 Control panel ................................................................................................................................................... 7

9.2.5 Frequency converter........................................................................................................................................ 8

9.2.6 Rotor recognition ............................................................................................................................................. 8

9.2.7 Over speed protection ..................................................................................................................................... 9

9.2.8 Speed signal .................................................................................................................................................... 9

9.2.9 Lid contact ....................................................................................................................................................... 9

9.2.10 Imbalance detection ...................................................................................................................................... 10

9.3 Operation/service menu .................................................................................................................................. 11

9.3.1 Activation of the operation menu (Part 1) ...................................................................................................... 11

9.3.1.1 Submenu motor starts .......................................................................................................................... 13

9.3.1.2 Submenu duty cycle ............................................................................................................................. 13

9.3.1.3 Submenu running time of the motor ..................................................................................................... 14

9.3.1.4 Submenu software status ..................................................................................................................... 14

9.3.1.5 Submenu software status of the frequency converter: .......................................................................... 15

9.3.1.6 Submenu error memory ........................................................................................................................ 15

9.3.1.7 Submenu setup of the signal transmitter .............................................................................................. 16

9.3.1.8 Submenu setup of the keypad tone ...................................................................................................... 17

9.3.1.9 Submenu setup volume of the signal generator ................................................................................... 18

9.3.1.10 Submenu Setup of the signal melody ................................................................................................... 19

9.3.1.11 Submenu Check and calibration of the imbalance sensor (Movement sensor Setup of the signal

melody) 20

9.3.1.12 Submenu Indication of the imbalance value of the rotor ....................................................................... 21

9.3.1.13 Submenu keyboard test ........................................................................................................................ 22

9.3.1.14 Submenu indication of the revision number of the control panel; Check of the external imbalance

sensor 22

9.3.2 Activation of the service menu (Part2) ........................................................................................................... 23

9.3.2.1 Submenu Adjustment of the centrifuge type ......................................................................................... 23

9.3.2.2 Submenu adjustment of the operation mode ........................................................................................ 24

9.3.2.3 Submenu Adjustment/Correction of the imbalance cut off value: ......................................................... 25

© Hermle Labortechnik GmbH Service Manual Z 306

CONTENT

9.4 Mounting support ............................................................................................................................................ 27

9.4.1 Replacing the front housing, the incremental shaft encoder (potentiometer) and the display ....................... 27

9.4.2 Replacing the incremental shaft encoder (potentiometer) ............................................................................. 28

9.4.3 Replacing the display .................................................................................................................................... 28

9.4.4 Replaicing the foil keyboard .......................................................................................................................... 29

9.4.5 Removing the housing ................................................................................................................................... 29

9.4.6 Replacing the lid gasket ................................................................................................................................ 30

9.4.7 Removing the lid ............................................................................................................................................ 31

9.4.8 Replacing the hinges ..................................................................................................................................... 31

9.4.9 Replacing the aerial (antenna or rotor sensor) .............................................................................................. 31

9.4.10 Replacing the motor resp. the motor rubber bearings ................................................................................... 32

9.4.11 Replacing the power board ............................................................................................................................ 35

9.4.12 Replacing the frequency converter ................................................................................................................ 35

9.4.13 Checkup the imbalance sensor ..................................................................................................................... 36

9.4.14 Replacing the control board ........................................................................................................................... 36

9.4.15 Replacing the break resistance ..................................................................................................................... 36

9.4.16 Replacing the signal generator ...................................................................................................................... 37

9.4.17 Replacing the lid lock..................................................................................................................................... 38

10. Trouble Shouting .......................................................................................................... 39

10.1 Error messages: Cause / Solution ................................................................................................................. 39

10.2 Survey of possible error messages and their solutions .............................................................................. 39

10.2.1 Lid release during power failure .................................................................................................................... 39

10.2.2 Description of the error message system ...................................................................................................... 40

10.2.3 Errors that may be indicated in the LCD display ........................................................................................... 40

11. Maintenance .................................................................................................................. 42

11.1 Maintenance and cleaning .............................................................................................................................. 42

11.1.1 General .......................................................................................................................................................... 42

11.1.2 Cleaning and disinfection of the unit .............................................................................................................. 43

11.1.3 Cleaning and disinfection of the rotor ............................................................................................................ 43

11.1.4 Disinfection of aluminium-rotors .................................................................................................................... 43

11.1.5 Disinfection of PP-rotors ................................................................................................................................ 43

11.1.6 Glass breakage ............................................................................................................................................. 44

11.1.7 Service life of rotors, round and rectangular buckets, accessories ............................................................... 44

12. Flow diagrams ............................................................................................................... 45

12.1 Flow diagram 230 V / 120 V / 50-60 Hz, page 1 .............................................................................................. 45

12.2 Flow diagram 230 V / 120 V / 50-60 Hz, page 2 .............................................................................................. 46

12.3 Control board ................................................................................................................................................... 47

13. Spare part list ................................................................................................................ 48

© Hermle Labortechnik GmbH Service Manual Z 306

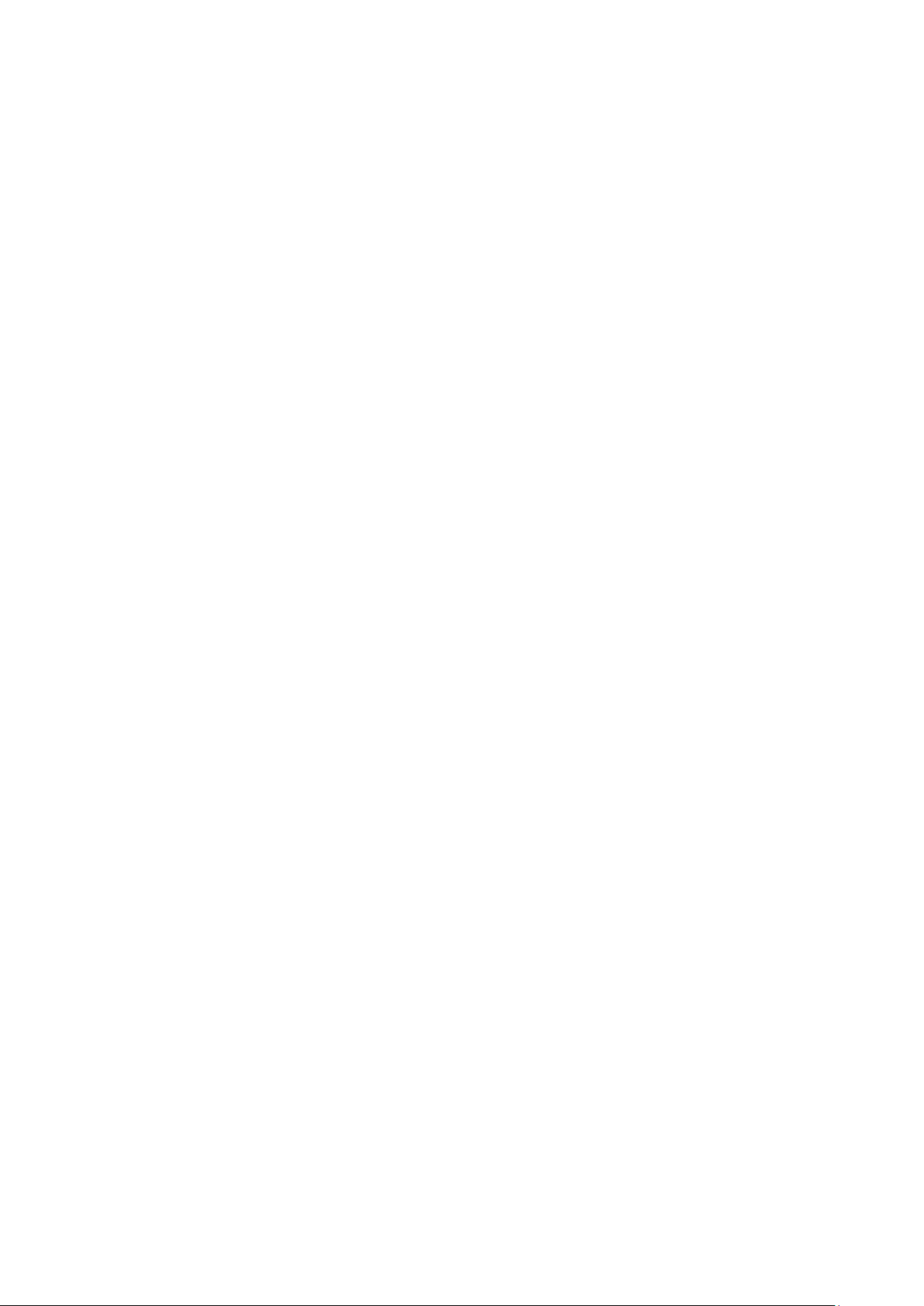

8. Technical Data

Rotor-Number

Level 0

Level 1

Level 2

Level 3

Level 4

Level 5

Level 6

Level 7

Level 8

Level 9

220.50 V06

1:55

0.59

0.40

0:31

0:26

0:21

0:19

0:17

0:14

0:14

220.72 V06

1:40

0:52

0:35

0:26

0:21

0:18

0:16

0:15

0:13

0:11

220.87 V09

3:18

1:38

1:06

0:50

0:40

0:33

0:29

0:26

0:23

0:23

221.54 V02

1:42

0:50

0:34

0:26

0:21

0:18

0:15

0:14

0:14

0:14

221.55 V02

1:41

0:51

0:34

0:26

0:21

0:18

0:15

0:14

0:14

0:14

221.12 V03

1:52

0:57

0:39

0:29

0:24

0:20

0:18

0:16

0:14

0:14

221.16 V03

3:48

1:55

1:19

1:01

0:47

0:40

0:35

0:30

0:28

0:25

221.17 V03

4:13

2:01

1:21

1:02

0:50

0:42

0:36

0:32

0:29

0:26

221.18 V02

6:21

3:09

2:08

1:37

1:16

1:05

0:57

0:49

0:44

0:40

221.19 V02

2:36

1:16

0:50

0:39

0:32

0:27

0:24

0:21

0:19

0:19

221.24 V02

1:35

0:46

0:32

0:26

0:20

0:17

0:15

0:14

0:12

0:11

221.25 V03

3:32

1:43

1:11

0:51

0:43

0:36

0:32

0:27

0:25

0:24

221.87 V10

3:19

1:39

1:07

0:50

0:40

0:34

0:30

0:26

0:25

0:25

8.1 Acceleration times Z 306 (120 V / 230 V) in min/sec

TECHNICAL DATA

Table 1: Acceleration times

© Hermle Labortechnik GmbH Service Manual Z 306 1

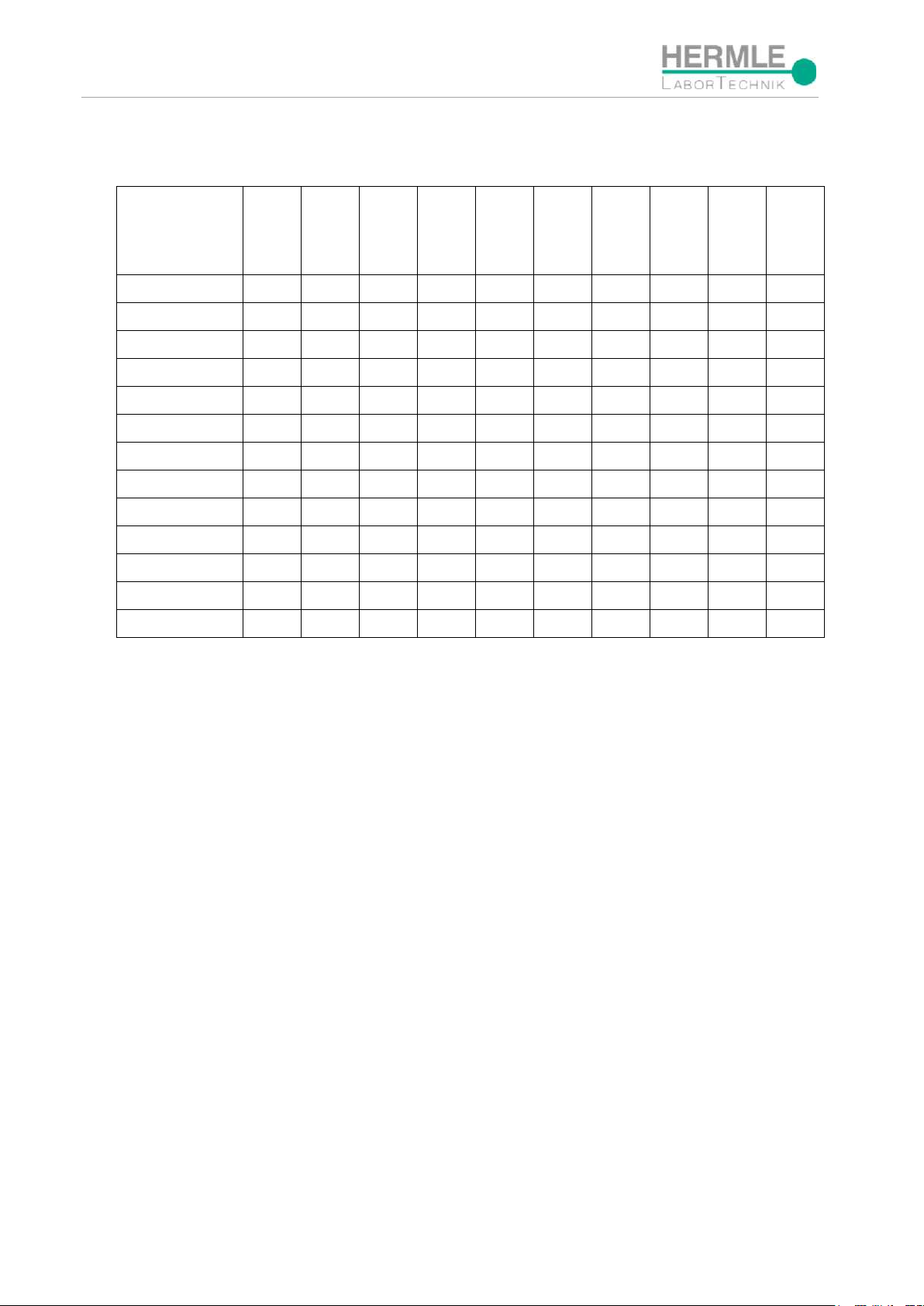

8.2 Decelertaion times Z 306 (120 V / 230 V) in min/ sec

Rotor-Number

Level 0

Level 1

Level 2

Level 3

Level 4

Level 5

Level 6

Level 7

Level 8

Level 9

220.50 V06

4:11

1:03

0:43

0:34

0:28

0:24

0:22

0:20

0:19

0:17

220.72 V06

1:40

0:55

0:34

0:30

0:25

0:22

0:19

0:17

0:18

0:16

220.87 V09

3:33

2:33

1:43

1:18

1:03

0:54

0:47

0:42

0:37

0:34

221.54 V02

3:25

0:40

0:27

0:22

0:19

0:17

0:15

0:14

0:12

0:11

221.55 V02

3:25

0:39

0:27

0:22

0:19

0:17

0:15

0:14

0:12

0:11

221.12 V03

2: 51

0:52

0:39

0:31

0:28

0:25

0:22

0:22

0:20

0:19

221.16 V03

5:18

1:35

1:04

0:50

0:41

0:36

0:32

0:28

0:26

0:25

221.17 V03

4:39

2:35

1:43

1:18

1:02

0:53

0:46

0:41

0:37

0:33

221.18 V02

12:53

6:26

4:18

3:13

2:37

2:10

1:52

1:39

1:26

1:18

221.19 V02

6:10

0:49

0:34

0:28

0:25

0:23

0:22

0:20

0:18

0:18

221.24 V02

2:57

0:45

0:31

0:25

0:22

0:19

0:17

0:16

0:16

0:14

221.25 V03

9:34

2:10

1:27

1:06

0:53

0:45

0:40

0:36

0:32

0:30

221.87 V10

3:49

2:33

1:43

1:18

1:04

0:54

0:47

0:42

0:37

0:35

TECHNICAL DATA

Table 2: Deceleration times

The acceleration and deceleration times may have slight fluctuations that depend on the unit and are therefore

guidelines only.

© Hermle Labortechnik GmbH Service Manual Z 306 2

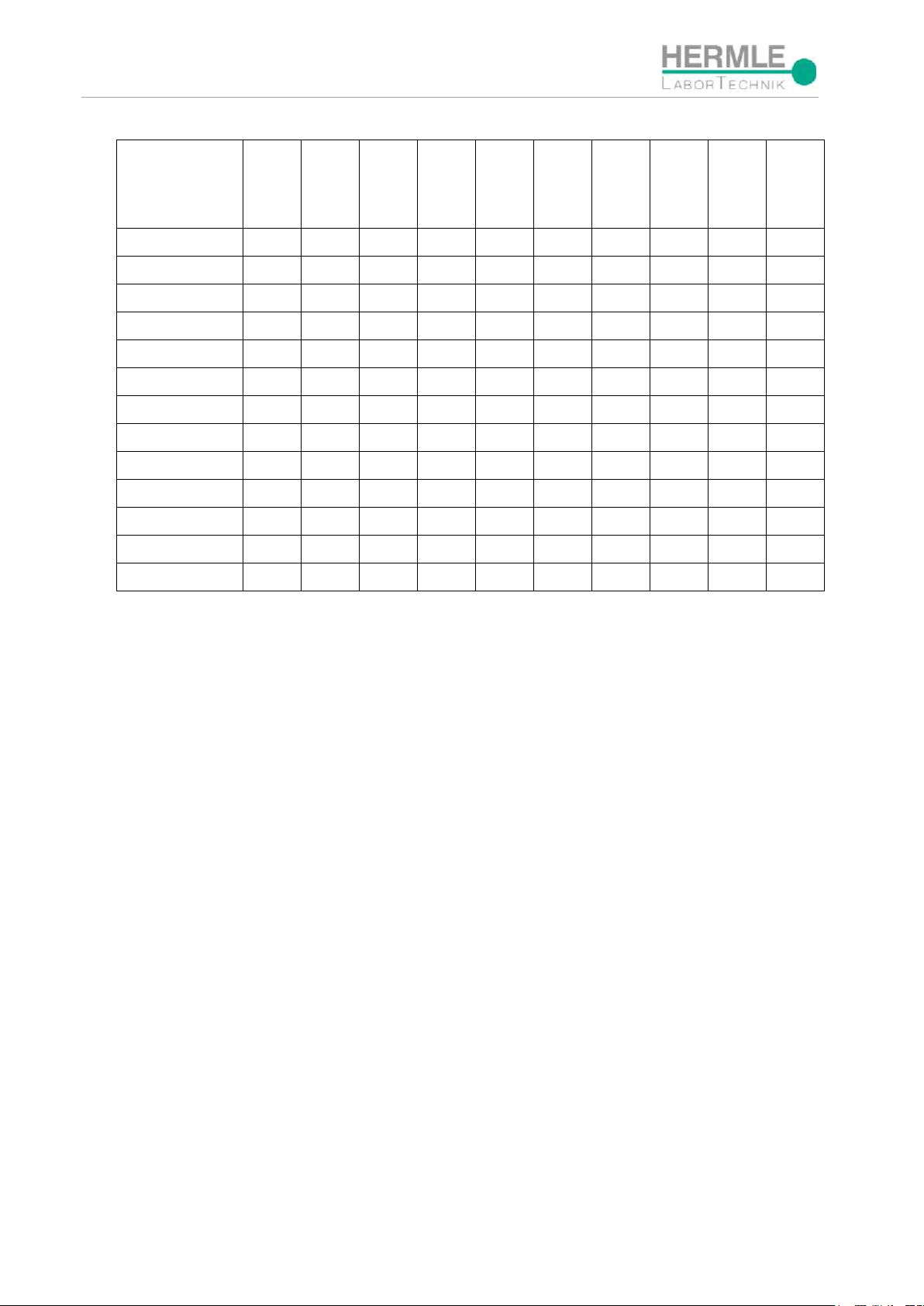

TECHNICAL DATA

Rotor-Number

Shut off speed in rpm

Permitted imbalance in

gram

Imbalance shut off in gram

220.50 V06

890 8 9

220.72 V06

580

20

26

220.87 V09

890 4 5

221.54 V02

780 8 8

221.55 V02

940 8 6

221.12 V03

800

14

10

221.16 V03

970 8 7

221.17 V03

11800 4 4

221.18 V02

4750 4 3

221.19 V02

3700 4 7

221.24 V02

900

12

31

221.25 V03

1040

16

19

221.87 V10

780 4 6

8.3 Imbalance shut off data Z 306 (120V / 230 V )

All rotors are set by the work of using motion detectors. They cannot be adjusted.

Table 3: Imbalance shut off

The shut off weight and speed may have slight fluctuations that depend on the unit and are therefore guidelines

only.

© Hermle Labortechnik GmbH Service Manual Z 306 3

9. Service Instructions

9.1 General technical description

Model Z 306 is a micro processor controlled cooled laboratory centrifuge.

The actuation is a three phase asynchronous motor which is controlled by frequency converter.

Model Z 306 has an independent error detection program, displaying possible errors and therefore

supporting the trouble shooting process.

The unit is equipped with several safety features:

• Imbalance detection

• Motor over temperature protection

• Lid lock does not open until the standstill of the centrifuge

• Rotor over speed protection

SERVICE INSTRUCTIONS

• Sample over temperature after the end of a run

Please follow below mentioned safety instructions for any kind of service actions:

• The capacitor of the frequency converter can be under voltage even when the unit is switched

off.

• Do not leave units unsupervised, when parts of the housing have been removed and the

unit is still connected to the main power supply.

• Do not bypass the lid’s safety contacts and never work with the unit’s lid open.

• The VDE regulations are valid for all electrical work that has to be done.

9.2 Electrical and electronically components

9.2.1 Power board

The power board is serving the low voltage supply of the centrifuge control system. The power board

is electrically isolated and has a dielectric strength of DC 2.2 kV.

Figure 1: Power board

© Hermle Labortechnik GmbH Service Manual Z 306 4

9.2.2 Control board

The control board consists of one plate. The board can only be exchanged completely. If there is a

defect you have to exchange the complete board.

All signal lines lead to the control board.

The PCB controls the entire centrifuge.

SERVICE INSTRUCTIONS

Figure 2: Control board

© Hermle Labortechnik GmbH Service Manual Z 306 5

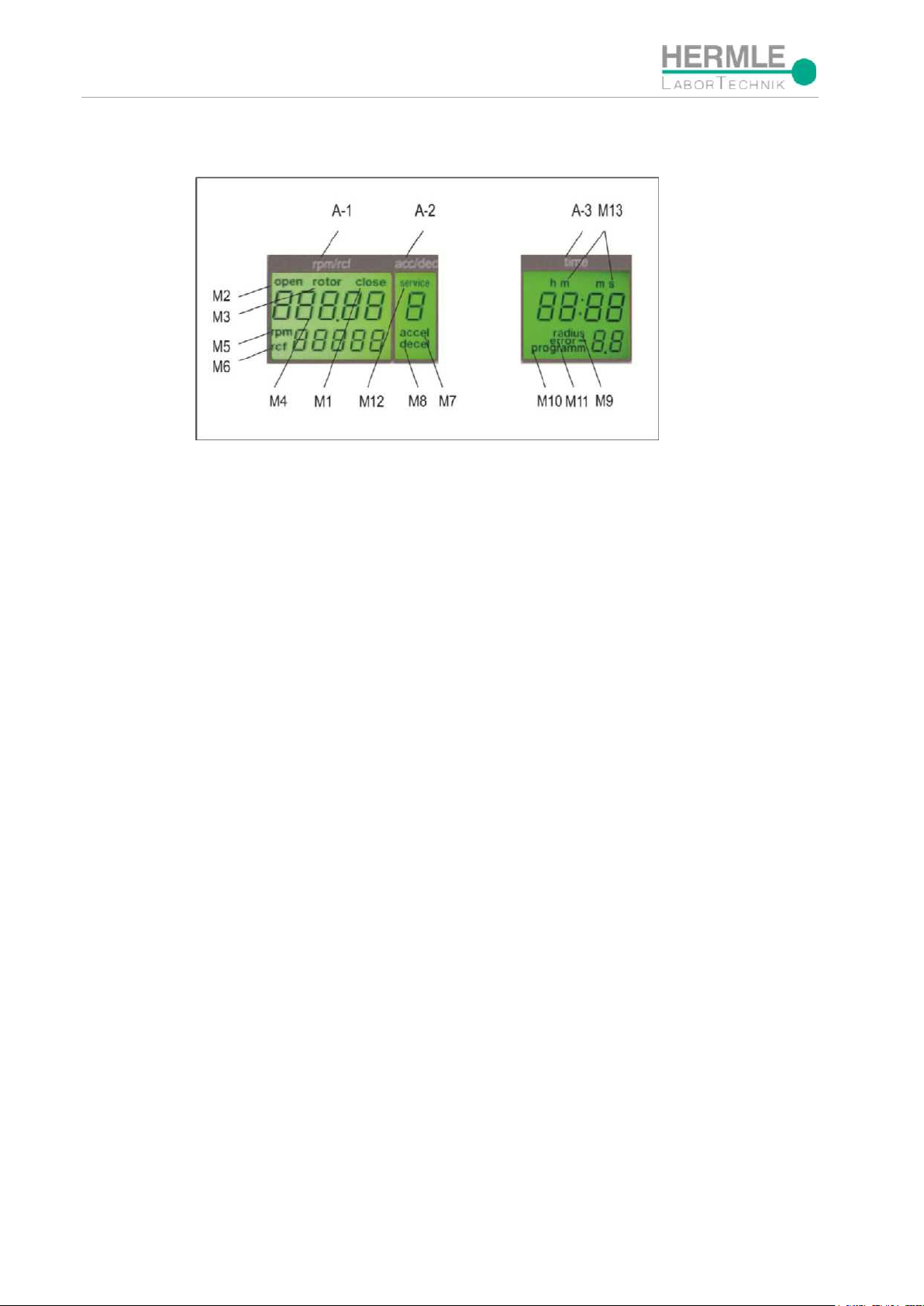

9.2.3 LCD Display

The following picture shows the individual elements of the LCD-display.

Figure 3

SERVICE INSTRUCTIONS

Display fields:

A-1 Display field – „rpm/rcf“

A-2 Display field – „acc/dec“

A-3 Display field – „time“

Messages/logos of the display fields:

M1 „close“ M8 „decel“

M2 „open“ M9 „radius“

M3 „rotor“ M10 „program“

M4 „Rotor-No. “ M11 „error“

M5 „rpm“ M12 „service“

M6 „rcf“ M13 h m s

M7 „accel“

© Hermle Labortechnik GmbH Service Manual Z 306 6

SERVICE INSTRUCTIONS

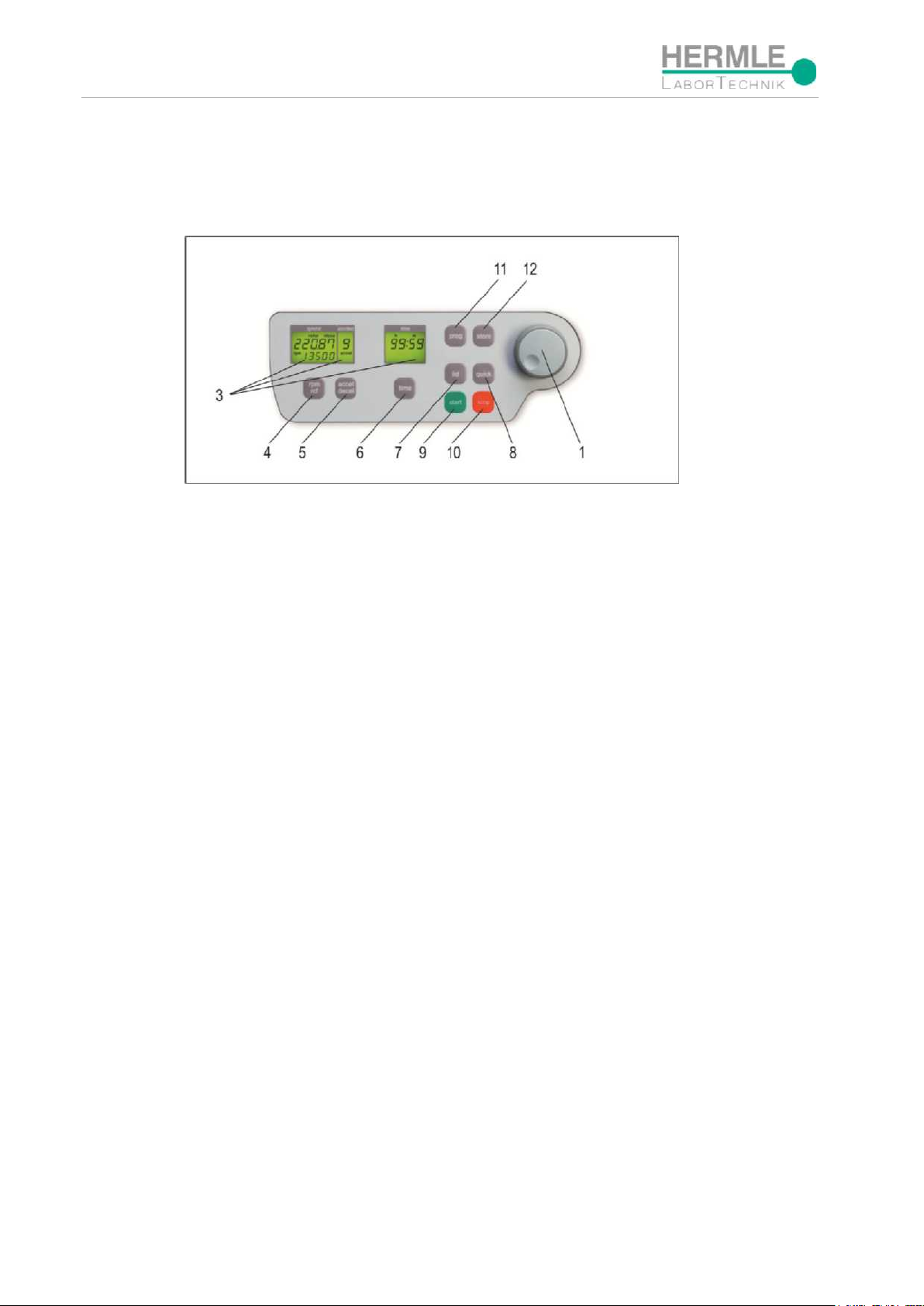

9.2.4 Control panel

The control panel consists of one LCD-display, one potentiometer (1), the upper front housing and the

foil keyboard. These parts can be exchanged separate. The potentiometer (1) regulates all parameters

which are adjustable by pressing a key and which are indicated in the LCD-display. Inside the time

display of the control panel the error message is indicated if there occur any troubles.

Figure 4

1 potentiometer run parameters

3 LCD control panel display

4 rpm/rcf speed/ g-force

5 accel/decel acceleration- / Deceleration intensity

6 time centrifugation time

7 lid lid release

8 quick short running

9 start start centrifugation

10 stop stop centrifugation

11 prog calling stored programs

12 store program store

© Hermle Labortechnik GmbH Service Manual Z 306 7

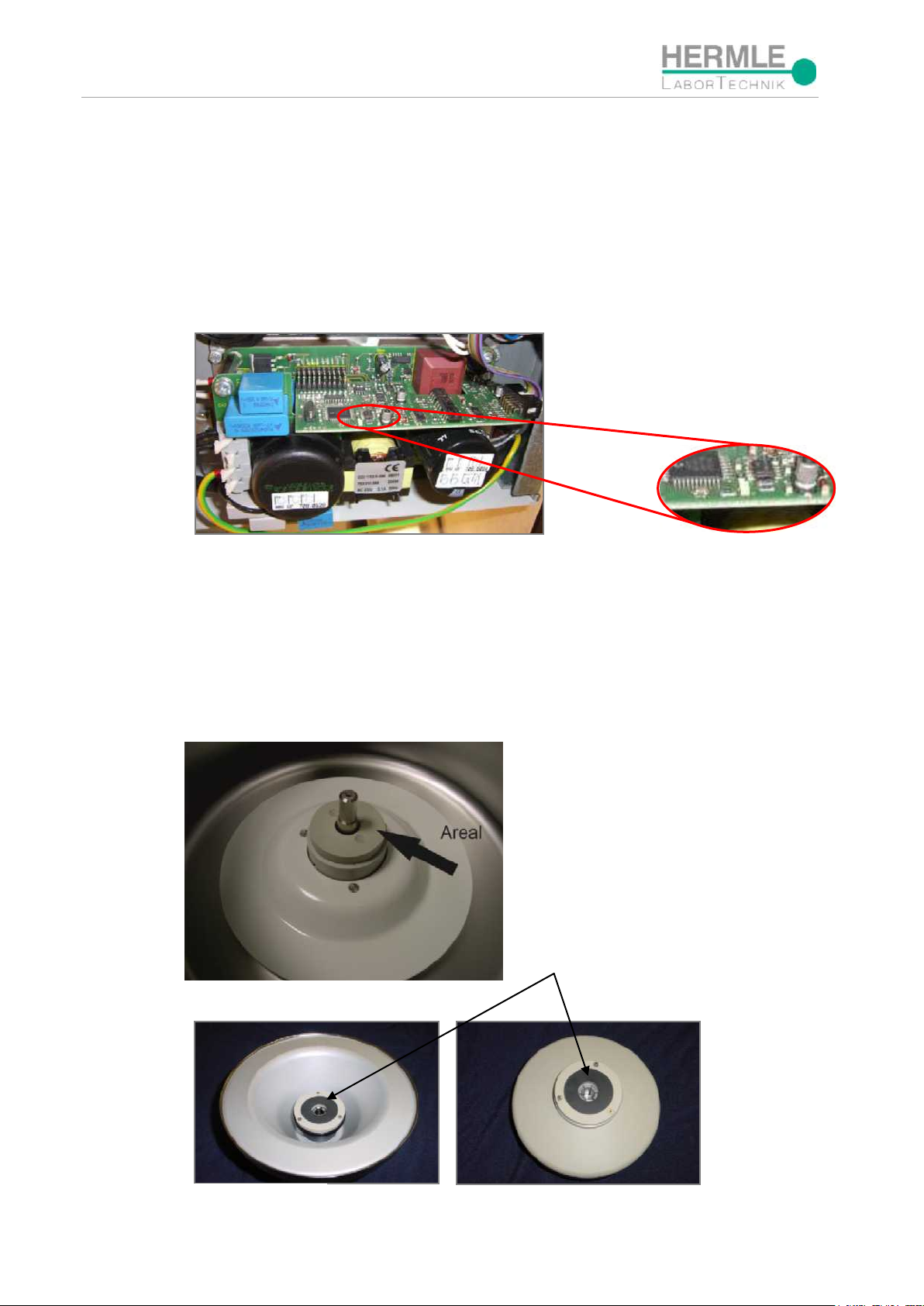

9.2.5 Frequency converter

Transponder

Figure 7

The frequency converter generates the drive signals for the asynchronous motor.

The converter leads the current generated by the motor during deceleration to a heating resistor to

reduce the current.

The frequency converter is connected with the power board by a serial interface.

There is a green LED on the converter which light up when the frequency converter is working

correctly.

A defect of the converter will be indicated in the TIME display as an error no. (See chapter 10).

SERVICE INSTRUCTIONS

Figure 5

9.2.6 Rotor recognition

The centrifuge will recognize the inputted rotor through the rotor identification transponder and the

aerial belonging to it right after the insert automatically. As soon as the lid is closed the rotor number

will be indicated in the speed display (see figure 3).

Figure 6

© Hermle Labortechnik GmbH Service Manual Z 306 8

9.2.7 Over speed protection

If the pre-selected rpm is higher as the permitted rpm of the rotor, the speed indication in the display

will be regulated to the max. speed permitted for this rotor after the rotor recognizion.

The regulation will accelerate the rotor only to the permitted rpm of the rotor.

9.2.8 Speed signal

The actual speed is extracted by a hall-effect-sensor placed on the lower side of the motor.

There is a “preset/actual“ comparison in the control board. Thereupon a new “actual-signal” is given

by the control board to the converter.

(see figure 8)

SERVICE INSTRUCTIONS

Figure 8

9.2.9 Lid contact

The micro switch in the mechanism of the lid lock controls the correct closing of the centrifuge lid.

The switch may never be bypassed.

The lid lock is unlatched by an electro motor, receiving its signal from the control board.

The actual state is indicated in the display (see M1, M2).

Figure 9

© Hermle Labortechnik GmbH Service Manual Z 306 9

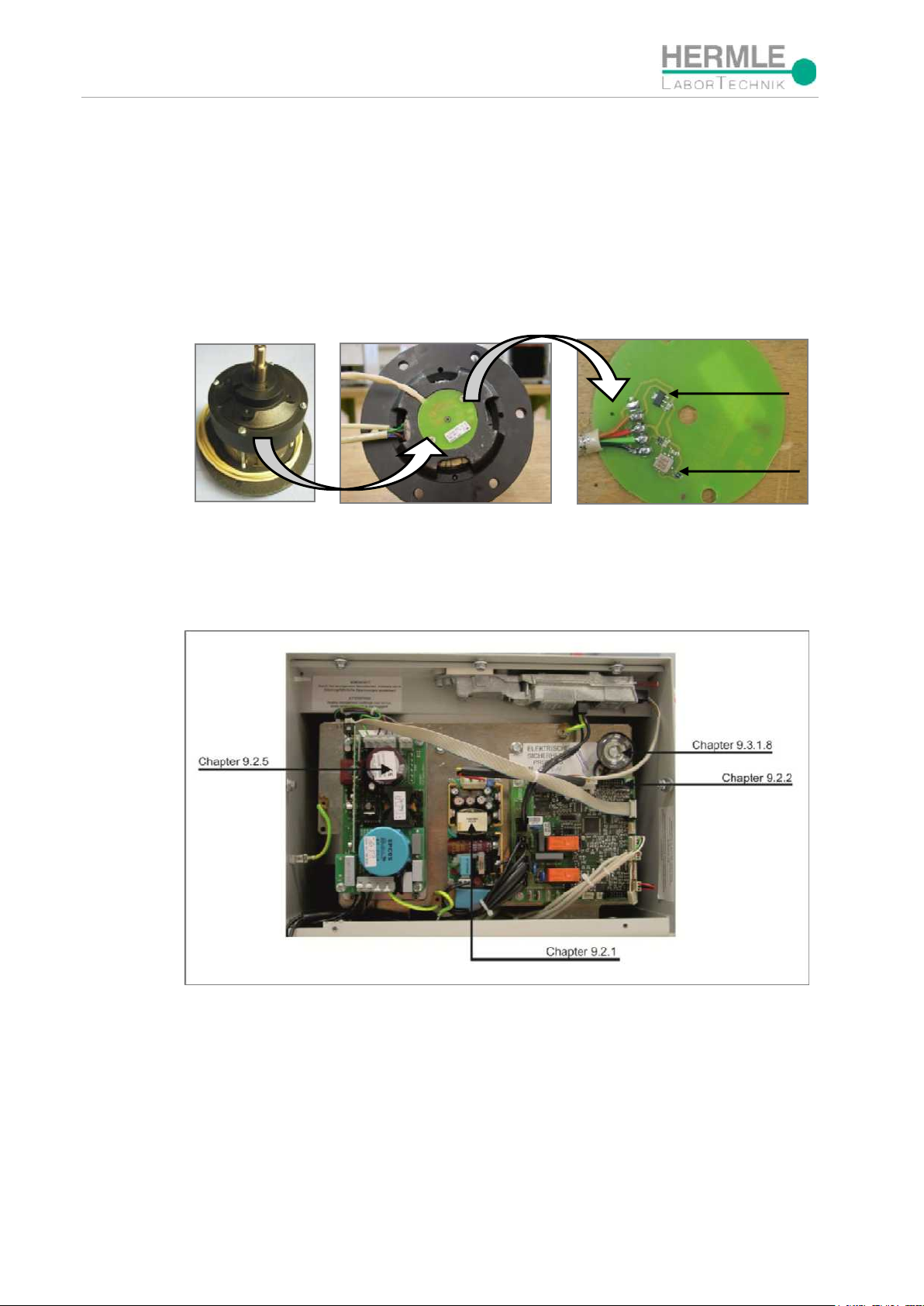

9.2.10 Imbalance detection

Chapter 9.2.10

Chapter 9.2.7

The imbalance detection is done in two ways.

A micro switch, controls for certain rotors, the displacement of the motor and shut off if there is too

much imbalance. The micro switch should be adjusted according to the instruction of the company.

(see chapter 9.4.13. and table 3).

A movement sensor, which is mounted underneath the motor, is controlling the oscillating motion of

the motor. The unit stops when the oscillating motions are too strong. Setup data specified by the

manufacturer for rotors controlled by the movement sensor cannot be changed.

SERVICE INSTRUCTIONS

Figure 10

© Hermle Labortechnik GmbH Service Manual Z 306 10

Figure 11

9.3 Operation/service menu

Valid for the units of the category with frequency converter.

Units: 20r, Z 216MK, Z 32HK, Z 326K, Z 326, Z 36HK, Z 366, Z 306, Seta2

The operation menu helps the service personnel to locate defects. It is divided in two parts, which

are graded in several areas again from chapter 9.3.1 to 9.3.2.2.

Part 1 is accessible for the USER and different points can be read respectively settled. This is also

described in the instruction manual.

Part 2 is for internal use respectively for trained service personnel outdoors Hermle LaborTechnik

only. The control board can be adjusted to different units. Here the different parameters are

determined on the respective unit after an exchange of the control board.

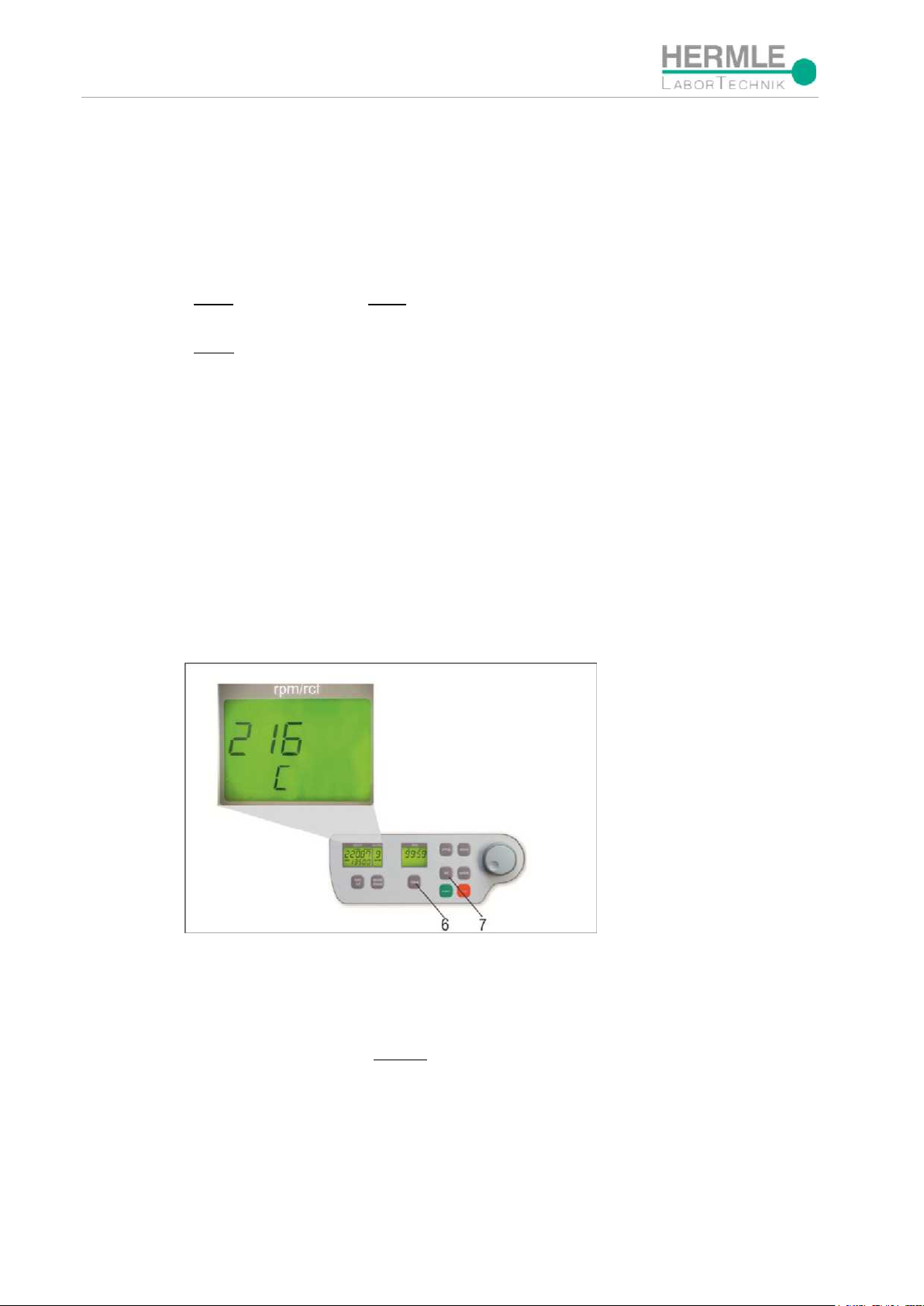

9.3.1 Activation of the operation menu (Part 1)

SERVICE INSTRUCTIONS

The menu can be started as follows:

• Open lid of the centrifuge and switch off main switch.

• From software version 1.58 press the key „time“ (6) and „lid“ (7) hold them and at the same time

switch on the unit.

Figure 12

• After the indication displays flash on, led go off the keys „time“ (6) and „lid“ (7).

In the display “rpm/rcf“ (4) the stored type of the centrifuge (i.e. 216 see figure 12) and below a letter

(i.e. c, see figure 12) is indicated for about 2 seconds. The letter stands for the different versions of

the units (see 9.3) which are currently stored in the control board:

c for cool

h for heat

no for nothing

© Hermle Labortechnik GmbH Service Manual Z 306 11

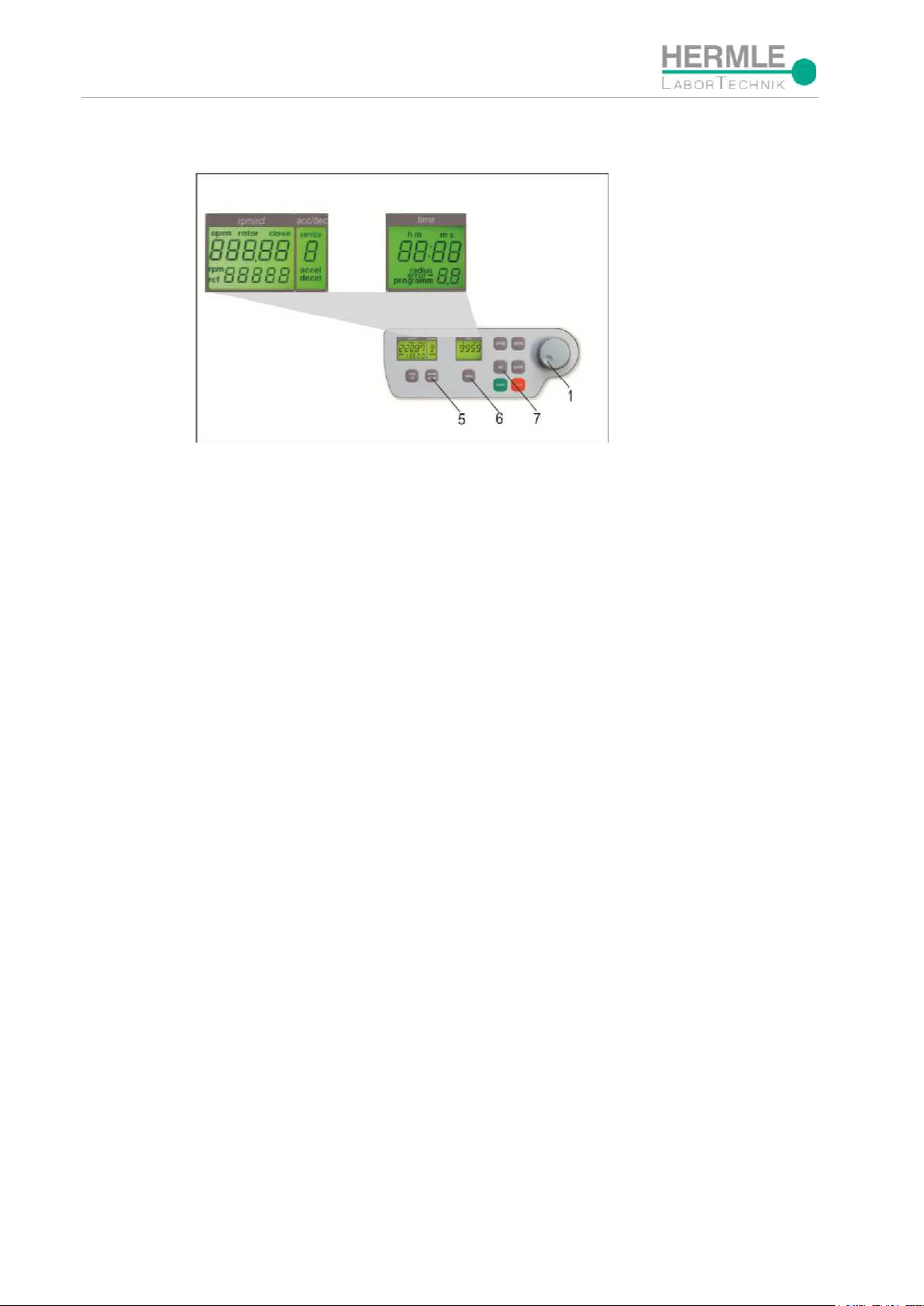

SERVICE INSTRUCTIONS

Now it follows a display test for about 5 seconds as shown here under in figure 13.

Figure 13

Now you have entered the Service mode. By pressing the key „accel/decel“ (5) you will get to the

submenus.

Now in the display “acc/dec“ (A-2) the word “service“ (M12) will flash. Only as long as this word is

flashing, you can scroll through the further submenus with the potentiometer (1).

You have to repeat this step continously to enter the different submenus!

© Hermle Labortechnik GmbH Service Manual Z 306 12

Loading...

Loading...