Hercules 1.5 HP, 175 RPM Safety, Operation And Maintenance Manual With Parts List

© 2012 Copy Rights Reserved Mercury Floor Machines, Inc.

© 2012 Copy Rights Reserved Mercury Floor Machines, Inc.

Mercury Floor Machines, Inc.

New Equipment Warranty

Limited Warranty

Mercury Floor Machines, Inc. warrants new equipment against defects in material and

workmanship under normal use and service to the original purchaser. Any statutory implied

warranties, including any warranty of merchantability or tness for a particular purpose, are

expressly limited to the duration of this written warranty. Mercury Floor Machines, Inc. will not be

liable for any other damages, including but not limited to indirect or special consequential damages

arising out of or in connection with the furnishing, performance, use or inability to use the machine.

This remedy shall be the exclusive remedy of the purchaser. The warranty period is subject to the

conditions stated below.

5-Year Warranty on Motor, Transmission and Chassis,

1-Year Service Labor

Mercury Floor Machines, Inc. warrants electric motors and chassis on all Mercury Floor Machines

to be free from defects in material and workmanship, under normal use and service for ve (5)

years to the original purchaser. Parts replaced or repaired under this warranty are warranted for the

remainder of the original warranty period. Service labor charges are covered for one (1) year from

the date of purchase, when performed by a Mercury-authorized service provider. Freight charges

to and from this service provider will be covered for ninety (90) days from the purchase date.

After this ninety (90) day period, these freight charges will be paid by the equipment owner. Travel

expenses are not covered.

Wear Items on all Machines

Critical Wear Items - bearings, capacitors, clutches, pulleys, rectiers, relays, switches, wheels,

tires and casters are warranted for manufacturing defects for one (1) year from the purchase date.

Normal Wear Items - belts, brushes, bumpers carbon brushes, cords, nishes, squeegees, actuating

cables and gaskets are warranted for manufacturing defects for ninety (90) days from the purchase

date.

All warranties of motors and associated components will be voided: if the machine is used as

a oor sander; if the machines is serviced by anyone other than a Mercury-authorized service

provider; if the machine is mechanically modied; or if the machine is misused or abused.

The warranty starts on the purchase date by the original purchaser from an authorized Mercury

Floor Machines, Inc. distributor, subject to proof of purchase. The machine registration card must

be completed and returned immediately at the time of purchase. If proof of purchase cannot be

identied, the warranty start date is ninety (90) days after the date of sale to an authorized Mercury

Floor Machines, Inc. distributor.

Mercury Floor Machines, Inc.

110 South Van Brunt Street

Englewood, NJ 07631

Phone: (201) 568-4606

Toll Free: (888) 568-4606

Fax: (201) 568-7962

www.mercuryoormachines.com

Important Information and Safety Instructions

Register your Machine at mercuryoormachines.com/registration.aspx

Serial No:

Hercules Floor Machine

6 Apron Sizes

Precision Balanced

All Metal Chassis

High Torque

Interlock Switches

Heavy-Duty

Safe & Easy to Use

REGISTER

YOUR

MACHINE

ONLINE!

Safety, Operation and Maintenance

Manual with Parts List

Please read before use!

1.5 HP, 175 RPM

13”, 15”, 17”, 19”, 20” and 21” Apron Sizes

1.0 Safe Operating Conditions

READ THIS MANUAL BEFORE USING FLOOR MACHINE. KNOW THE

PROPER OPERATION, CORRECT APPLICATIONS AND THE LIMITATIONS OF

THIS EQUIPMENT BEFORE USE.

Reduce the Risk of Fire, Electric Shock or

Injury:

• This oor machine is designed for indoor use only. Do

not use outdoors. Do not expose to rain.

• Do not wash the motor with owing water. If the motor

gets wet, seek authorized service.

• Keep the vents on this air-cooled motor free from

debris. Do not operate with the motor covered or with

vents blocked. Do not use this machine as a oor

sander.

• Never operate this oor machine near ammable

dusts, liquids or vapors. Never use ammable

solvents as a cleaning agent. Engine sparks and

operating heat can cause re.

• Never handle electrical equipment with wet hands.

Never operate this oor machine with bare feet.

• Unplug the oor machine when not in use and when

servicing the equipment. To unplug, grasp the plug

not the cord.

• Do not operate a oor machine with damaged

handle controls, cord or plug. If the equipment is not

performing properly, seek repair from a qualied

service supplier.

• This oor machine is constructed with electrical

grounding at the plug. Operate only when connected

to a properly grounded outlet. See section 1.2 for

grounding details.

• Prevent electrical cord abuse. Do not close a door

upon the cord, drive equipment over it, or run the oor

machine over it. Do not expose the cord to hot surfaces.

Do not lift, pull or carry this oor machine by the cord.

• Never operate the oor machine over sharp objects that

can be thrown out and harm the operator and damage

the oor. Sweep hard oors before scrubbing or bufng.

Vacuum clean carpets before shampooing or bonnet

cleaning.

• Train your staff in proper use of this oor machine.

(2) Super Heavy-Duty Floor Machine Super Heavy-Duty Floor Machine (11)

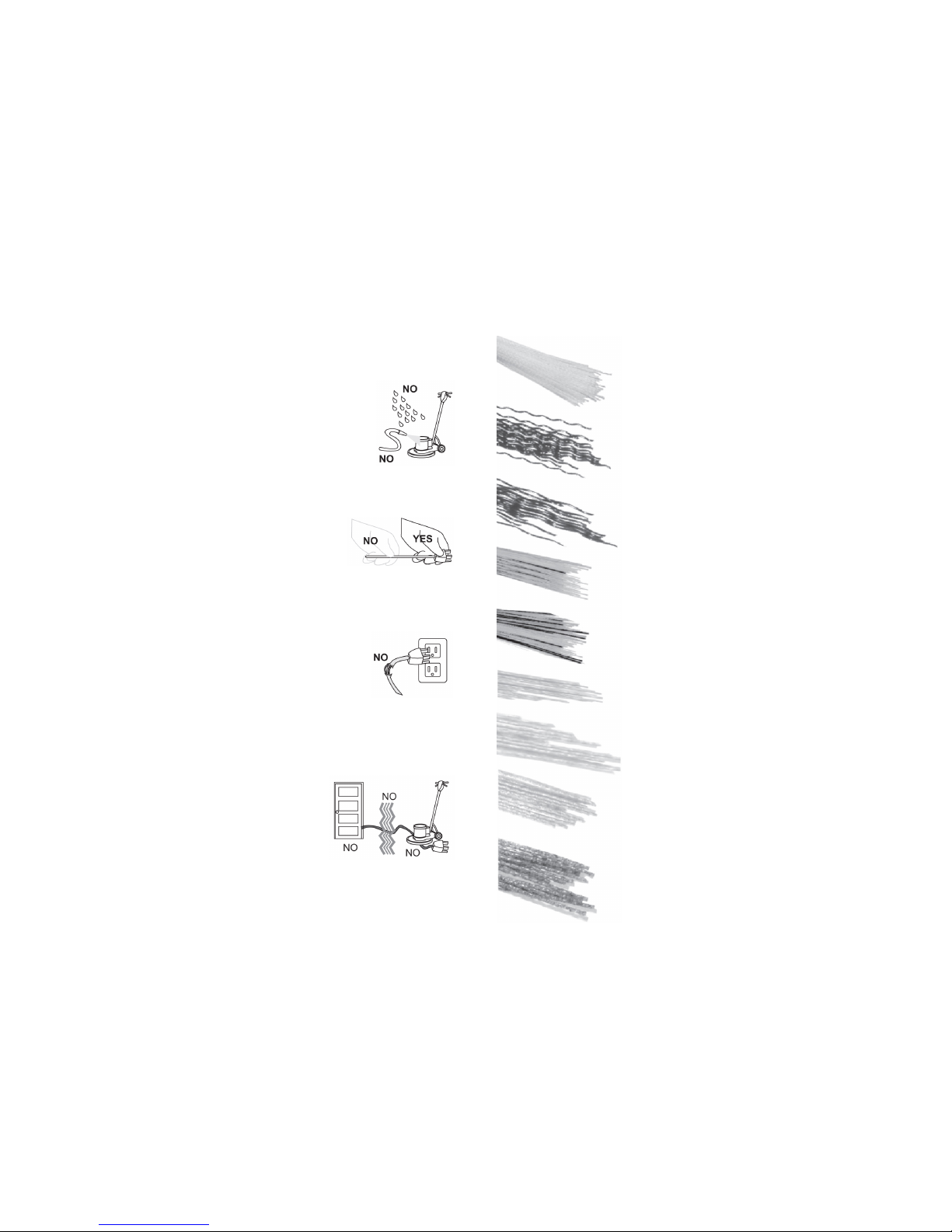

7.2 Scrubbing Brush Filaments

Scrubbing brushes are available with a range of bristle types - from the softest for

high-gloss oors, to the most aggressive for heavy soils. Match your brush to the

oor as you match a detergent with the soils.

Nylon is used for general scrubbing. Because nylon softens

when wet, it is great for gentle scrubbing, mopping and

polishing of decorative oors. Nylon will not scratch tile,

terrazzo or coated surfaces. Nylon brushes are durable and long

lasting.

Polypropylene is a common choice for general purpose

scrubbing and works well on both concrete and on coated

oors. Polypropylene brushes typically cost less than nylon, but

do not last as long.

Non-scuff poly is a ner diameter (0.015-0.018”) lament used

for lighter duty scrubbing conditions and on waxed or nished

oors.

Bassine is a soft, natural ber. The end of the bristle splits or

“ags” to build a polishing surface.

Union mix is a mixture of bassine and tampico (another natural

ber). The mixture is stiffer than bassine alone and is used by

more traditional cleaners for scrubbing. It is often replaced by

poly.

Soft abrasive bristle is a 0.018” nylon lament extruded

with a 500 grade grit. It is used for gentle scrubbing and is as

aggressive as a white scrub pad.

Daily abrasive bristle is a 0.035” nylon lament with 180

grade grit. It is used for daily scrubbing of resilient tile and

nished oors and is as aggressive as a red scrub pad.

Stripper abrasive bristle is a 0.022” nylon lament with 120

grade grit. It is used for aggressive scrubbing and light stripping

of resilient oors, terrazzo and concrete. It is as aggressive as a

blue scrub pad.

Heavy-duty stripper abrasive bristle is a 0.050” nylon

lament with 80 grade grit. It is used for very aggressive

scrubbing and stripping of concrete, brick and quarry le. It is

as aggressive as a black scrub / strip pad.

Loading...

Loading...