1 4 2 5 6

3

1.

2.

1.

2.

S2,5

4xM4 Countersunk Bolts

4xØ8 mm Plastic Dowels

4x4,8x50 mm

Flat Head Screws

A

B

C

D

E

F

4 11/

64

2 3/

32

A

4.

3.

B C D E F

4xM4 Countersunk Bolts

S2,5

4xM4 Security Torx

Countersunk Bolts

2.

1.

1.

2.

3.

4xM5 Washers

0°

S2,5

2xM4 Countersunk Bolts

TX20

HEPER USA LLC

W227 N546 Westmound

Drive Waukesha

WI 53186 – USA

Tel: +1 917 244 20 32

infoUS@hepergroup.com

www.heperlighting.com

Inch

Inch

Inch

3

/

4

Inch

3

/

8

Inch

63

Inch

/

64

5

/

16

1,8 lb ft

DOGO EX

Installation&Maintenance Instructions

4,4 lb ft

1.8 lb ft

2020-0/09.10.2020

1.8 lb ft

1.8 lb ft

7

8

1.

2.

3.

1.

2.

0,7 lb ft

2xM3 Flat Head Screws

2xM3 Flat Head Screws

0,7 lb ft

English

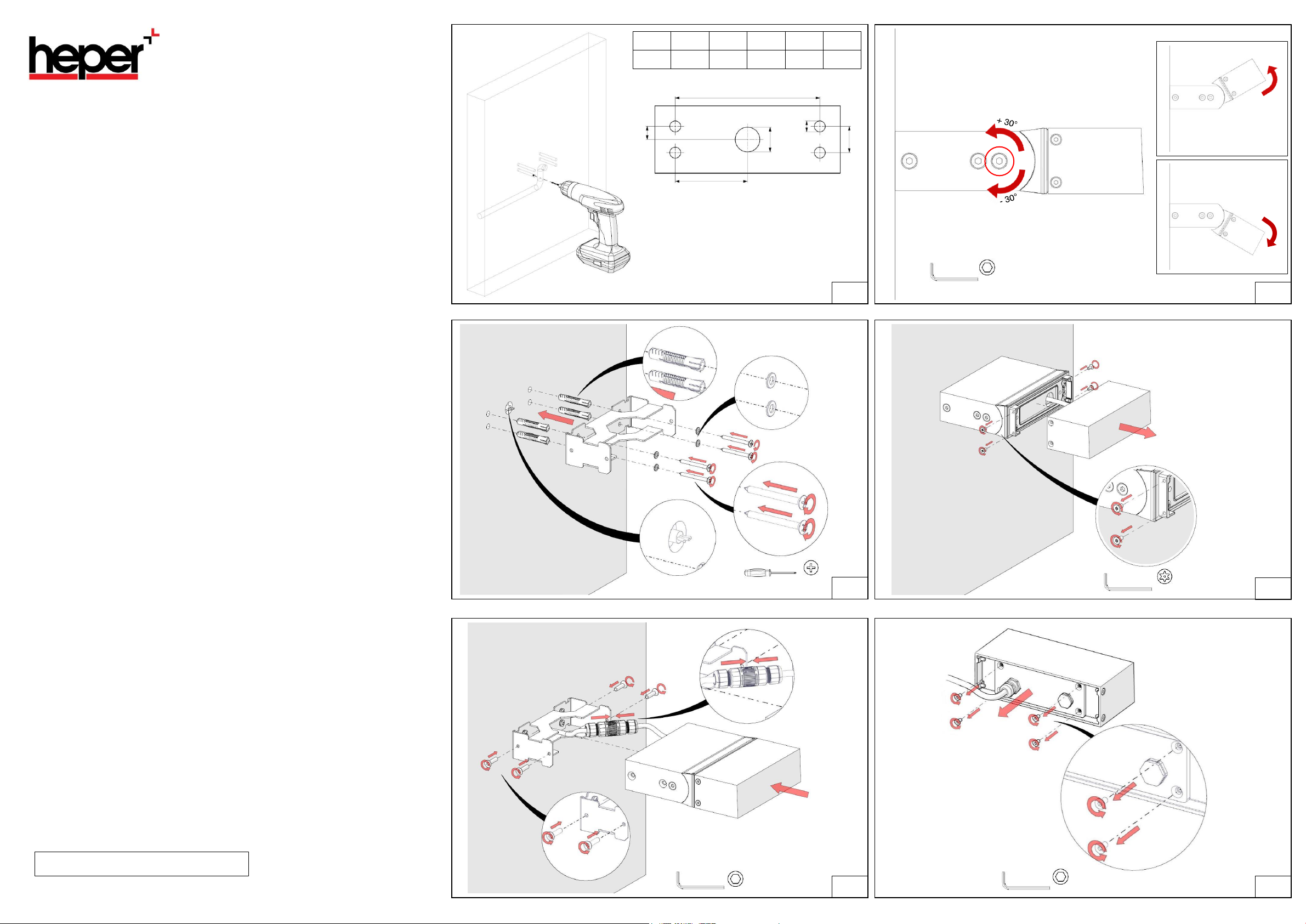

ASSEMBLY INSTRUCTIONS

To make the wall mounting of the product;

1. . Holes and cable hole are drilled to allow the product to be mounted on the wall

2. . Assembling the wall connection apparatus

2.1. Make sure that the line power cable is up to the product.

2.2. Plastic dowels are driven into the holes (4 pieces, Ø8 Plastic Dowels)

3. Note: The dowels should not be damaged during this process.

2.3. The wall bracket is leaning against the wall by aligning the holes.

2.4. The wall connection apparatus is screwed to the wall with a torque of 4.8 lb ft (4

pieces, 4,8x50 Pointed Star Cylindrical Head Bolt)

4. . Mounting the product to the wall connection apparatu

3.1. The cable coming from the wall and the cable coming out of the product are assembled

with the help of a socket.

Note: The socket for connecting the cables is not supplied with the product. Please supply

socket with minimum IP66 certification suitable for the product.

3.2. The product is placed on the wall connection apparatus.

3.3.The countersunk Imbus bolts that connect the product to the body are tightened to their

places with 1.8 lb ft torque (4 pieces, M4 Countersunk Imbus Bolts).

5. The product can rotate up and down with an angle of 30 °. In order to angle the lighting

fixture, 2 countersunk Imbus bolts marked in the visual are loosened mutually, after the

luminaire is brought to the desired angle, the countersunk head Imbus bolts are mutually

tightened with 1.8 lb ft torque (2 pieces, M4 Countersunk Imbus Bolts).

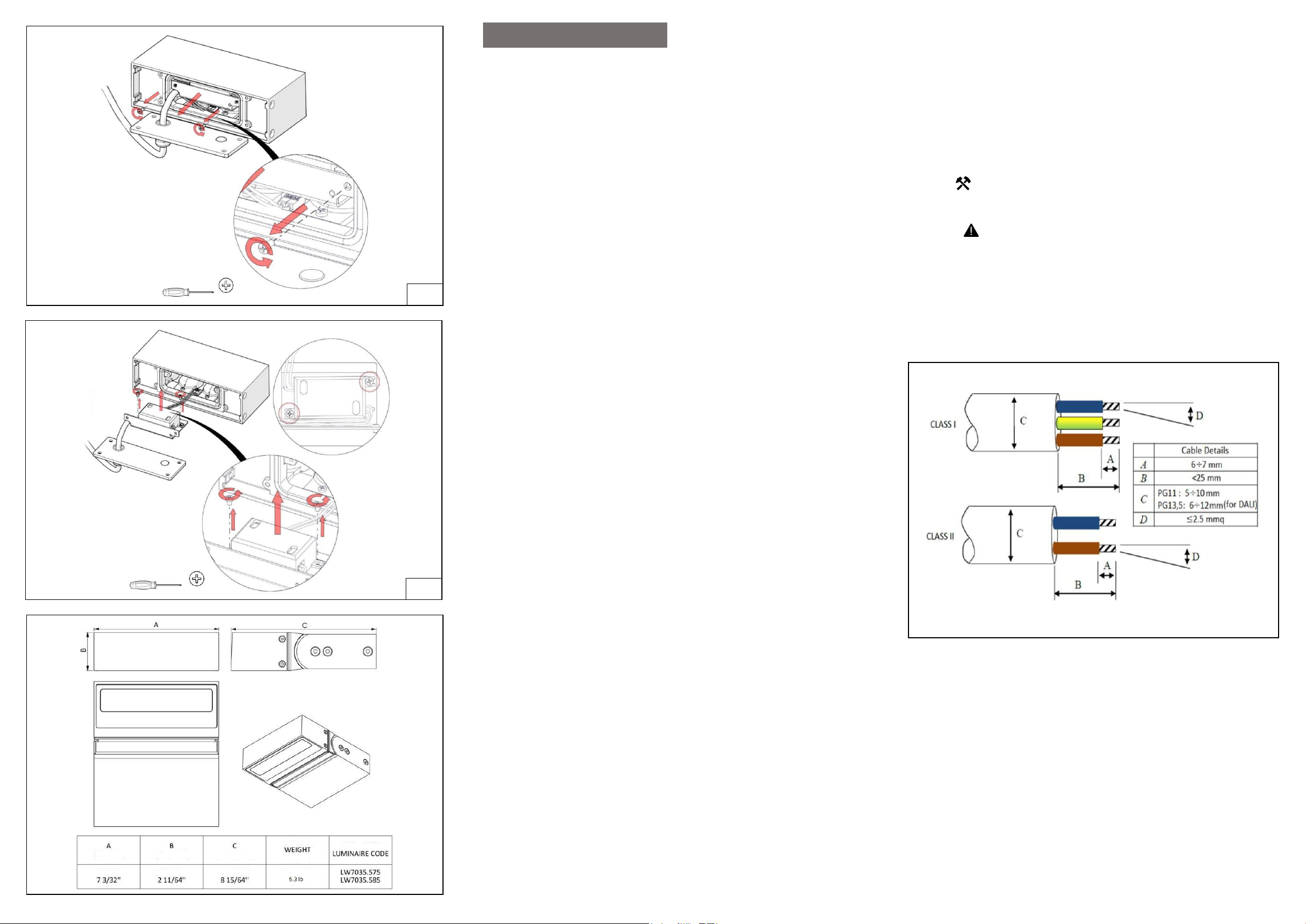

To replace the LED driver;

Note: Before starting this process, the electrical connection to the product must be

disconnected.

5. . To disassemble the produc

5.1. The safety torx bolts with countersunk head that connect the product to the body It is

removed (4 pieces, M4 Countersunk Head Safety Torx Bolts).Note: After the LED driver

replacement is completed, the product is placed in its place and the countersunk head safety

torx bolts are tightened with 1.8 lb ft torque (4 pieces, M4 Torx Bolts with Countersunk Head

Safety).

5.2. The product is displaced.

6. . To remove the back cover of the product

6.1. The countersunk Imbus bolts holding the rear cover are removed from their places (4

pieces, M4 Countersunk Bolt).

6.2. The back cover is removed.

Note 1: While removing the cover, care should be taken not to damage the electrical

connections inside the product. This should be done sensitively.

Note 2: After the LED driver replacement is completed, the rear cover is placed in its place and

the countersunk head bolts are tightened with 1.8 lb ft torque (4 pieces, M4 Countersunk Imbus

Bolts).

7. . Removing the cartridge group

7.1. The star cylindrical head bolts holding the cartridge sheet are removed.

7.2. The cartridge group is removed.

Note 1: While removing the cartridge group, care should be taken not to damage the electrical

connections inside the product. This should be done sensitively.

Note 2: After the LED driver replacement is completed, the cartridge group is placed in its

place and the star cylindrical head bolts are tightened with a torque of 0.7 lb ft (2 pieces of

M3 Star Cylindrical Head Bolt).

8. . To remove the LED drive

8.1. The star cylindrical head bolts holding the LED drive are removed and the cables

connected to the LED driver are disconnected.

8.2. The LED driver is removed.

Note 1: While removing the cables on the LED driver, care should be taken not to damage the

cables and the product. This should be done sensitively.

Note 2: The new LED driver is placed in its place and the star cylindrical head bolts

are tightened with a torque of 0.7 lb ft (2 pieces, M3 Star Cylindrical Head Bolt).

Note 3: Cables are mounted to the new LED driver.

Note 4: The procedures for changing the LED driver are reversed and the product is turned off.

WARNINGS AND REMARKS FOR INSTALLATION AND

MAINTENANCE

• The light source contained in this

service agent or a similar qualified person. Always switch off the power prior to installation,

maintenance or repair activities.

• The manufacturer is then discharged from liability when damage is caused by improper use or

installation.

• If any luminaire is subsequently modified, the persons responsible for the modification shall be

considered as manufacturer.

• To reduce the risk of death, personal injury or property damage from fire, electric shock, falling

parts, cuts, abrasions and other hazards, please read all warnings and instructions included with

the luminaire, on the luminaire’s packaging and affixed to the luminaire itself..

• Installatio n

• LEDs are high-quality electronic components! Please avoid contacting the light output opening of

the LED directly during installation or relamping.

IMPORTANT

• To ensure secure connection, the luminaire housing must be positioned precisely in relation to

the mounting plate.

Cleaning And Maintenance

• Clean luminaire regularly with solvent-free cleaners from dirt. Please do not clean the luminaire

with using high-pressure liquids.

Replacing the LED module

The designation of the LED module is noted on a label in the luminaire.

The light colour and light output of HEPER replacement modules correspond to those of the

modules originally fitted. The module can be replaced by qualified persons using

luminaire shall only be replaced by the manufacturer or his

Loading...

Loading...