Henny Penny

Split Vat & Full Vat

Open Fryers – Gas

Model LVG-202

Model LVG-203

Model LVG-204

TECHNICAL MANUAL

TABLE OF CONTENTS

Section Page

Section 1. TROUBLESHOOTING .............................................................................................. 1-1

1-1 Introduction .................................................................................................... 1-1

1-2 Safety .............................................................................................................. 1-1

1-3 Troubleshooting .............................................................................................. 1-2

1-4 Error Code Table ............................................................................................ 1-7

Section 2. INFO, FILTER & TEMP BUTTON STATS ............................................................... 2-1

2-1 INFO Button Stats .......................................................................................... 2-1

2-2 FILTER Button Stats ...................................................................................... 2-1

2-3 TEMP Button Stats ......................................................................................... 2-1

2-4 HP Info Mode ................................................................................................. 2-2

Section 3. LEVEL 1 PROGRAMMING ...................................................................................... 3-1

3-1 Modifying Product Settings ........................................................................... 3-1

3-2 AIF Clock ....................................................................................................... 3-3

3-3 Deep Clean Mode ........................................................................................... 3-4

3-4 Fryer Setup ..................................................................................................... 3-5

Section 4. LEVEL 2 PROGRAMMING ...................................................................................... 4-1

4-1 Advanced Product Settings ............................................................................ 4-1

4-2 E-Log (error code log) .................................................................................... 4-2

4-3 Passwords ....................................................................................................... 4-3

4-4 Alert Tone (and volume) ................................................................................ 4-3

4-5 Filter After ...................................................................................................... 4-4

4-6 Filter Time ...................................................................................................... 4-4

Section 5. LEVEL 3 PROGRAMMING ...................................................................................... 5-1

5-1 Additional Advanced Product Settings .......................................................... 5-1

5-2 Special Programming ..................................................................................... 5-2

5-3 Clock Set ........................................................................................................ 5-7

5-4 Data Comm & Heat Control ........................................................................... 5-7

5-5 Tech Mode ...................................................................................................... 5-8

5-6 Stats Mode ...................................................................................................... 5-13

Section 6. INFORMATION MODE ............................................................................................. 6-1

6-1 Info Mode ....................................................................................................... 6-1

Section 7. MAINTENANCE SECTION ...................................................................................... 7-1

7-1 Preventive Maintenance ................................................................................. 7-1

7-2 Maintenance Hints .......................................................................................... 7-1

7-3 Complete Control Replacement ..................................................................... 7-2

7-4 Power Switch Replacement ............................................................................ 7-2

7-5 Burner Tube Removal .................................................................................... 7-3

7-6 Pilot Replacement .......................................................................................... 7-3

Section 7. MAINTENANCE SECTION (Continued)

7-7 High Limit Thermocouple .............................................................................. 7-4

7-8 High Limit Control ......................................................................................... 7-5

7-9 Probe Replacement ......................................................................................... 7-6

7-10 Back Shroud Removal .................................................................................... 7-6

7-11 Blower Replacement ...................................................................................... 7-7

7-12 Vacuum Switch Replacement ......................................................................... 7-7

7-13 JIB Pump Replacement .................................................................................. 7-8

7-14 Selector Valve Drive Motor Replacement ...................................................... 7-9

7-15 Gas Valve Replacement .................................................................................. 7-12

Section 8. PARTS SECTION

8-1 Introduction .................................................................................................... 8-1

8-2 Genuine Parts ................................................................................................. 8-1

8-3 When Ordering Parts ...................................................................................... 8-1

8-4 Prices .............................................................................................................. 8-1

8-5 Delivery .......................................................................................................... 8-1

8-6 Warranty ......................................................................................................... 8-1

8-7 Recommended Spare Parts for Distributors ................................................... 8-1

Apenndix A A-1 Wiring Diagrams & Scematics ....................................................................... A-1

Technical Data for CE Marked Products

Nominal Heat Input: Natural (I2H) = 19,8, kW (67,560 Btu/h)

(Net) Natural (I2E) = 19.8 kW (67,560 Btu/h)

Natural (I2E+) = 19.8 kW (67,560 Btu/h)

Natural (I2L) = 19.8 kW (67,560 Btu/h)

Natural (I2HS) = 19.8 kW (67,560 Btu/h)

Liquid Propane (I3P) = 19,8, kW (67,560 Btu/h)

Liquid Propane/Butane (I3B/P) = 19,8, kW (67,560 Btu/h)

Nominal Heat Input: Natural (I2H) = 21,98 kW (75,000 Btu/h) (79.13 MJ/h)

(Gross) Natural (I2E) = 21,98 kW (75,000 Btu/h)

Natural (I2E+) = 21,98 kW (75,000 Btu/h)

Natural (I2L) = 21,98 kW (75,000 Btu/h)

Natural (I2HS) = 21,98 kW (75,000 Btu/h)

Liquid Propane (I3P) = 21,98 kW (75,000 Btu/h) (79.13 MJ/h)

Liquid Propane/Butane (I3B/P) = 21,98 kW (75,000 Btu/h) (79.13 MJ/h)

Supply Pressure: Natural (I2H) = 20 mbar (2.0 kPa)

Natural (I2E) = 20 mbar

Natural (I2E+) = 20/25 mbar

Natural (I2L) = 25 mbar

Natural (I2HS) = 25 mbar

Liquid Propane (I3P) = 30/37/50 mbar (3.0/3.7/5.0 kPa)

Liquid Propane/Butane (I3B/P) = 30/50 mbar

Test Point Pressure: Natural (I2H) = 8.7 mbar (.87 kPa)

Natural (I2E) = 8,7 mbar

Natural (I2E+) = N/A

Natural (I2L) = 8.7 mbar

Natural (I2HS) = 8.7 mbar

Liquid Propane (I3P) = 25 mbar (2.5 kPa)

Liquid Propane/Butane (I3B/P) = 30/50 mbar (3.0/5.0 kPa)

Injector Size: Natural (I2H) = 2.08 mm

Natural (I2E) = 2.08 mm

Natural (I2E+) = 1.70 mm

Natural (I2L) = 2.30 mm

Natural (I2HS) = 2.30 mm

Liquid Propane/Butane (I3B/P) = 1.30 mm

Liquid Propane (I3P) *30 mbar = 1.18 mm

Liquid Propane (I3P) *50 mbar = 1.04 mm

This appliance must be installed in accordance with the manufacturer’s instructions and the regulations

in force and only used in a suitable ventilated location. Read the instructions fully before installing or

using the appliance.

Noise generated from this equipment is less than 70 dB(A)

SECTION 1. TROUBLESHOOTING

Model LVG-202, 203, 204

1-1. INTRODUCTION

1-2. SAFETY

This section provides troubleshooting information in the

form of an easy to read table.

If a problem occurs during the rst operation of a new fryer,

recheck the Installation Section of the Operator’s Manual.

Before troubleshooting, always recheck the Operation

Section of the Operator’s Manual.

Where information is of particular importance or is safety

related, the words DANGER, WARNING, CAUTION, or

NOTE are used. Their usage is described on the next page:

SAFETY ALERT SYMBOL is used with DANGER,

WARNING or CAUTION which indicates a personal

injury type hazard.

NOTICE is used to highlight especially important

information.

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

CAUTION used wih the safety alert symbol indicates a

potentially hazardous situation which, if not avoided,

could result in minor or moderate injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

DANGER INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, WILL RESULT IN DEATH OR SERIOUS

INJURY.

Aug. 2012

1-1

Model LVG-202, 203, 204

1-3. TROUBLESHOOTING To isolate a malfunction, proceed as follows:

1. Clearly dene the problem (or symptom) and when it

occurs.

2. Locate the problem in the Troubleshooting table.

3. Review all possible causes. Then, one-at-a-time work

through the list of corrections until the problem is solved.

4. Refer to the maintenance procedures in the Maintenance

Section to safely and properly make the checkout and

repair needed.

If maintenance procedures are not followed correctly,

injuries and/or property damage could result.

Aug. 2012

1-2

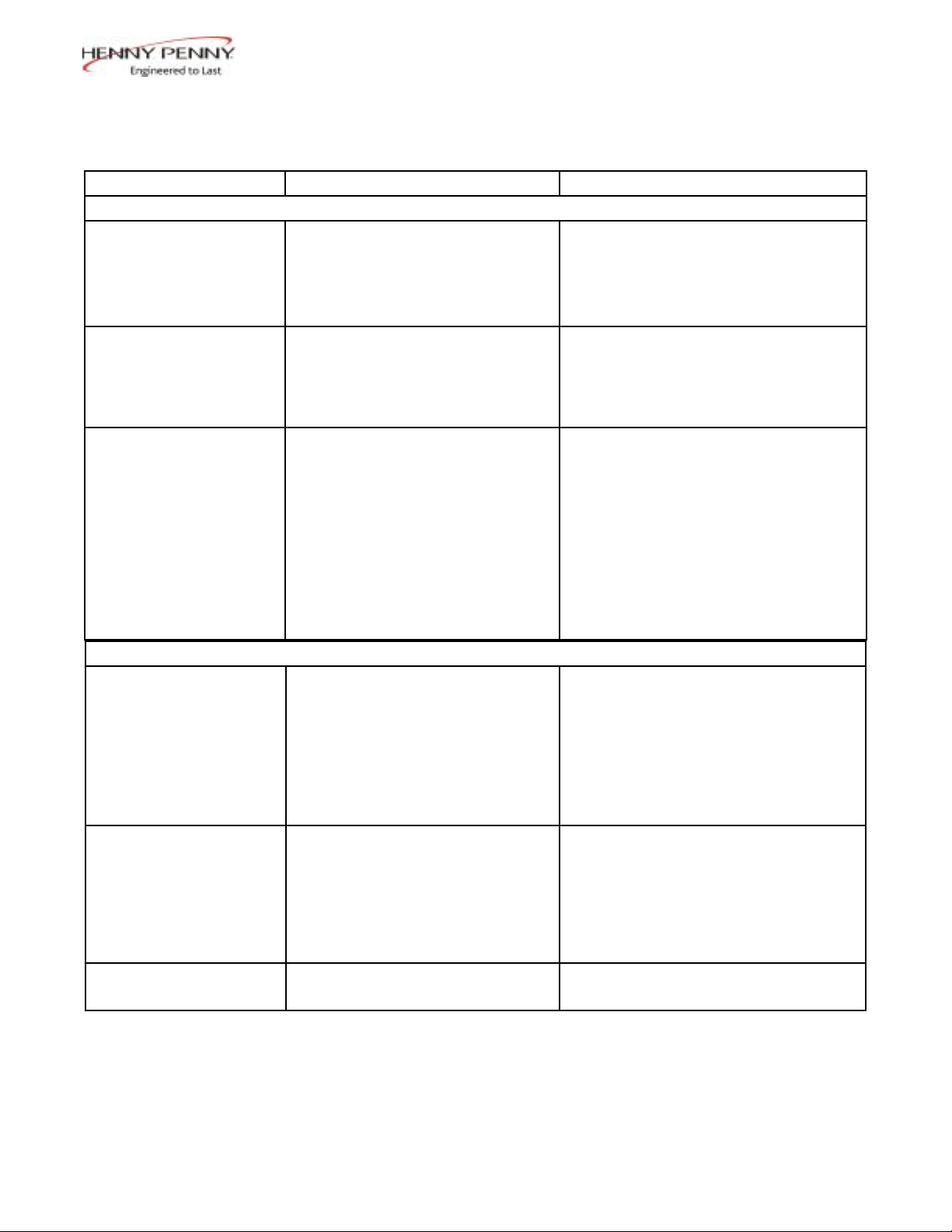

Problem Cause Correction

With power switch in ON position,

the fryer is completely inoperative

(NO POWER)

HEATING OF SHORTENING SECTION

Oil will not heat but lights

are on

No Heat error “E-22”

• Blown fuse or tripped

• Faulty power switch.

• Faulty cord and plug

• Faulty drain switch

• Faulty PC Board

• High limit control switch

tripped

POWER SECTION

• Open circuit

“E-10”

Model LVG-202, 203, 204

• Check to see that unit is plugged in

• Check the breaker or fuse at supply

box

• Check voltage at wall receptacle

• Check MAIN POWERswitch; replace if defective

• Check cord and plug

• Reset transformer circuit breaker

• Reset breaker or replace fuse circuit

breaker at supply box or control panel

• Check power switch

• Check cord and plug

• Check power at receptacle

• Check drain switch

• Check control panel per maintenance

section and replace as needed

• Allow fryer to cool for 15-20

minutes; reset high limit by

pressing down & releasing raised

side of the switch for the vat that is

not operating; a single reset switch

is found behind the door of each

well; if high limit does not reset,

high limit must be replaced

Aug. 2012

1-3

Problem Cause Correction

Oil will not heat (continued)

HEATING OF SHORTENING SECTION (Continued)

• Drain valve open

• Faulty temperature probe

• Faulty gas valve

• Close drain valve

• Replace temerature probe

• Check gas valve

Model LVG-202, 203, 204

Oil heating too slow • Low gas pressure

• Wire(s) loose

• Burnt or charred wire

connection

Oil overheating • Programming wrong

• Faulty PC board

• Faulty temperature probe

• Faulty gas valve

OIL LEVEL SECTION

Oil foaming or boiling

over vat

• Water in oil

• Improper or bad oil

• Improper ltering

• Cold zone (bottom of vats) full

of crumbs

• Improper rinsing after cleaning

the fryer

Oil will not drain from vat

• Drain valve clogged with

crumbs

• Faulty actuator

• Oil channel clogged

Oil leaking through drain

valve

• Obstruction in drain

• Faulty drain valve

• Have gas pressure checked

• Tighten

• Replace wire and clean connections

• Check Temperature setting in the

program mode

• Replacecontrol board if heat

indicator stays on past ready

temperature

• Check probe calibration and

replace if temperature is off ± 5

degrees

• Check gas calve

• At end of a Cook Cycle, drain and

clean vat; add fresh oil

• Use recommended oil

• Refer to the procedure on ltering

the oil.

• Open valve. using cleaning brush,

force crumbs through drain valve

• Replace actuator

• Access the clean-out plug on the

sides of the unit (see Oil Channel

Clean-out Section)

• Remove obstruction

• Replace drain valve

Aug. 2012

1-4

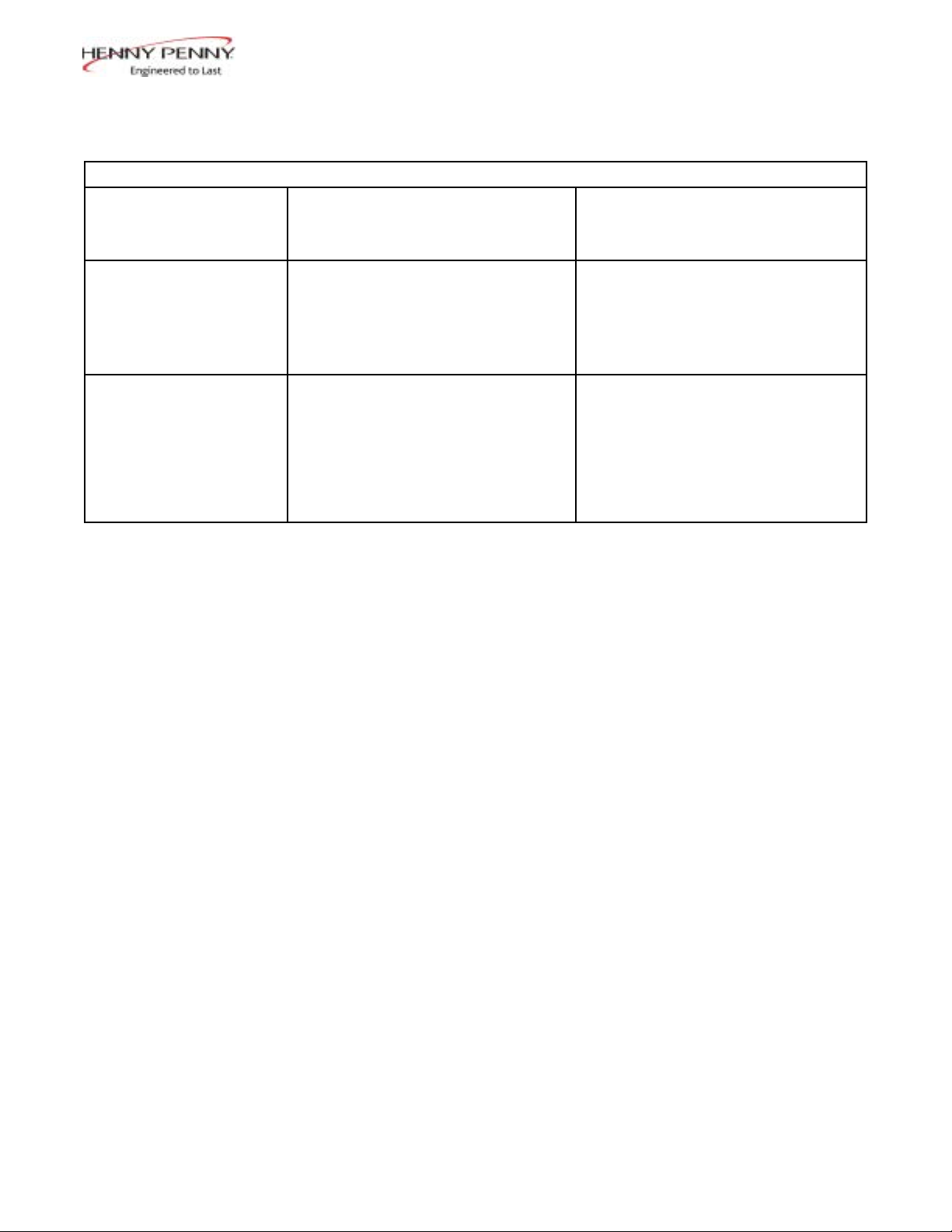

Problem Cause Correction

Vat is under-lled

Bubbles in oil during

entire ltering process

OIL LEVEL SECTION (Continued)

• Locations with RTI, the 3-way

valve is stuck open

• Filter pan needs cleaned

• JIB is low or empty

• JIB oil line is clogged or

collapsed

• Quick Disconnect O-ring may

be worn or missing

• Filter pan needs cleaned

• Filter pan not completely

engaged

• Filter pan clogged

• Damaged o-ring on lter line

tube on fryer

Model LVG-202, 203, 204

• The RTI system can be

disconnected until RTI repairs the

valve

• Clean lter pan and change pad

• Fill the JIB

• Check JIB line

• Check JIB Disconnect O-ring

for wear or cracking. Replace if

missing or torn

• Clean lter pan and change pad

• Make sure lter pan return line

is pushed completely into the

receiver on the fryer

• Clean pan and change pad

• Change o-ring

FILTER MOTOR SECTION

Filter motor runs but

pumps oil slowly

Filter motor will not run • Thermal reset button on the rear

• Filter line connections loose

• Drain pan o-rings damaged or

missing

• Filter paper or pad clogged

of the pump motor is tripped

To prevent burns caused by splashing shortening, turn the unit’s

POWER switch to the OFF position

before resetting the lter pump motor’s manual reset

protection device.

• Tighten all lter line connections

• Install new o-rings

• Change lter paper or pad

• Allow time for the motor to cool.

Open front door and using at

least a 12 in. (305 mm) Phillip’s head

screwdriver, press on the thermal reset

button by prying hard between the

button and the door frame until button

clicks

July 2013

1-5

“IS POT FILLED” lter

error prompt

DISPLAYED PROMPT SECTION

• All oil did not completely return

after a lter cycle

• Filter pad clogged

Model LVG-202, 203, 204

• Have manager follow prompts

• Is JIB full? If not, ll JIB

• Replace lter pad/clean pan.

“CHECK PAN” prompt • Filter drain pan missing

• Filter drain pan not completely

engaged

• Filter drain interlock switch not

• engaged

“CHANGE FILTER PAD”

prompt appears

• Filter pad has not been changed

within a 24hr time period; Main

power switch was turned off during

lter pad change

• Drain pan microswitch stuck

• Find pan and install

• Adjust lter drain pan position

• Check drain microswitch

• Replace old lter pad with NEW

lter pad with main power switch

turned on.

• *NOTE* 24/7 store replace lter

twice a day.

• Check drain microswitch

Aug. 2012

1-6

Model LVG-202, 203, 204

1-4. ERROR CODES

In the event of a control system failure, the digital display

shows an error message. The message codes are shown in the

DISPLAY column below. A constant tone is heard when an error code is displayed, and to silence this tone, press any button.

DISPLAY CAUSE CORRECTION

“E-4” Control board overheating Turn switch to OFF position, then turn switch back

to ON; if display shows “E-4”, the control board is

getting too hot; check the louvers on each side of

the unit for obstructions

Oil overheating Turn switch to OFF position, then turn switch back

“E-5”

to ON; if display shows “E-5”, the heating circuits

and temperature probe should be checked

Temperature probe open Turn switch to OFF position, then turn switch back

“E-6A”

to ON; if display shows “E-6A”, the temperature

probe should be checked

Temperature probe shorted checked Turn switch to OFF position, then turn switch back

“E-6B”

to ON; if display shows “E-6B”, temperature probe

should be

“E-10” E-10A- tripped above 300F

E-10B- tripped below 300F

E-10C- tripped while cooking

E-10D- tripped <5min. of Auto Filter

E-10F- tripped during lter cycle

E-10M- tripped during melt mode

Allow fryer to cool for 15-20 minutes; reset high

limit by pressing down & releasing raisedside of

the switch for the vat that is not operating; a single

reset switch is found behind the door of each well;

if high limit does not reset, high limit must be

replaced

E-10Y- tripped <5min of “YES” to

“IS THE POT FULL?” prompt

“E-15”

“E-18-A”

“E-18-B”

“E-18-C”

“E-20-A”

“FAN

SENSOR

STUCK

CLOSED”

Feb. 2013

Drain valve open Clean and/or close sh vat drain valve; if clean and

closed, have drain switch continuity checked

Left level sensor open

Right level sensor open

Both level sensors open

Turn switch to OFF position, then turn switch back

to ON; If display still indicates a failed sensor,

check the connectors at the control board; check

sensor & replace, if necessory

Pressure switch failure/ Wiring

problem

If fan is not running, have pressure switch

checked; should be open circuit, if no air pressure

If fan is running, wiring error

1-7

1-4. ERROR CODES (CONTINUED)

Model LVG-202, 203, 204

“E-20-B”

“NO

DRAFT”

“CHECK

FAN”

“E-20-D”

Pressure Switch failure/ hose loose

Draft Fan failure/ low voltage/ Flue

or hood obstruction

• Failure to ignite/ no ame sense

• Plugged atmospheric

equalization hole in regulator cap

resulting in pilot ame slowly

fading

Press power button to vat off and back on again,

if E-20-B persists, have pressure switch checked;

should be open circuit if no air pressure; make sure

hose is connected to fan and pressure switch

Have draft fan checked; low voltage going to fan

Check the fryer ue and hood system for

obstructions

• Press power button to vat off and back on

again, if E-20-D persists, check gas line

connections; check gas shutoff valve; check

ignition module; check gas valve; check ame

sensor gap; check gas valve, and check ignition

module wiring

• Clear obstruction from hole

“E-21”

“E-22”

“NO

HEAT”

“E-41” ,

“E-46”

“E-47”

“E-48”

“E-54-C”

Slow heat recovery Have a certied service technician check the fryer

for correct gas supply and pressure to the unit;

have the gas valves checked; have unit checked

for loose or burnt wires

Burner not igniting Have gas valve and heat circuit checked

Programming failure Turn switch to OFF, then back to ON; if display

shows any of these error codes, re-initialize the

controls; if error code persists, check control board

and replace as needed

Analog converter chip or 12 volt

supply failure

Turn switch to OFF, then back to ON; if “E-47”

persists, replace the PC board

Input system error Turn switch to OFF, then back to ON; have control

PC board replaced if “E-48” persists

Temperature input error Turn switch to OFF, then back to ON; have control

PC board replaced if “E-54C” persists

July 2013

1-8

1-4. ERROR CODES (CONTINUED)

Model LVG-202, 203, 204

AIF PC board not communicating

with control PC board

“E-60”

Turn switch to OFF, then back to ON; if “E-60”

persists, check 1.5 amp fuse on AIF PC board on

International units only; check connector between

the PC boards; replace AIF PC board or control PC

board if necessary

Communication error -Verify the OQM senser wiring is correct.

“E-62A”

-Replace cable.

-Replace Sensor

“E-62B” Wrong calibration parameter Replace OQM Sensor

“E-62C” Shorted capacitance Replace OQM Sensor

“E-62D” Shorted RTD Replace OQM Sensor

“E-62E” Open RTD Replace OQM Sensor

”E-62F” Open capacitance Replace OQM Sensor

”E-62G”

“E-70-C”

Out of range (TPM value over 35) Replace oil and take a TPM reading, if the error is

still present replace OQM sensor.

Drain valve jumper wire missing or

disconnected

Have the jumper wire checked on the PC board at

drain switch interlock position

Selector Valve not detected Have wiring checked between Selector Valve and

“E-82A”

AIF board

“E-82B”

Selector Valve failed Have the “Home” switch on Selector Valve

checked

Selector Valve failed Have wiring checked between the “Home” &

“E-82C”

“Position” encoder and the Selector Valve; Have

Selector Valve Motor checked; Have drive chain

checked

“E-82-D”

“E-83”

“PRES-

Selector Valve failed Have the “Home” switch and the “Position” switch

on Selector Valve checked

Pressure Trasducer senses too high

pressure in AIF system

Check AIF system or the RTI quick-disconnect;

See details below;

SURE ”

“TOO

HIGH”

“E-83-A” Pressure too high Check AIF system in Vat #1

“E-83-B” Pressure too high Check AIF system in Vat #2

“E-83-C” Pressure too high Check AIF system in Vat #3

“E-83-D” Pressure too high Check AIF system in Vat #4

“E-83-E” Pressure too high Check AIF system in Vat #5

“E-83-J”

“E-83-R”

RTI “JIB FILL” switch ON when

pressure too high

RTI “DISPOSE” switch ON when

pressure too high

Check JIB ll valves

Check RTI quick-disconnect behind fryer; RTI

phone no. if needed: 888-796-4997

“E-83-Z” Unknown source Check RTI system & JIB ll valve

“E-93-A” 24VDC tripped Have drain actuator checked

May 2014

1-9

Model LVG-202, 203, 204

1-10

Model LVG-202, 203, 204

SECTION 2. INFO, FILTER & TEMP BUTTON STATS

2-1. INFO BUTTON STATS

2-2. FILTER BUTTON STATS

Recovery Information for each Vat/OQM Information

1. Press and release and REC shows in left display and

the recovery time that oil temperature went from 250°F

(121°C) to 300°F (149°C) shows in the right display. For

example, means it took 5 minutes and

30 seconds for the oil temperature to recover to 300°F

(149°C) from 250°F (121°C).

1a. Press and release

reading, date of the last TPM reading, and time stamp of

last TPM reading (only if OQM sensor is installed and

enabled).

Selected Languages

2. Press twice and the primary language shows in the

left display and the secondary language shows in right dis-

play. Press

operation to that language.

REC 5:30

, the display will show the last TPM

ü

button under either language to switch unit

2-3. TEMP BUTTON STATS

If no buttons are pressed within 5 seconds in any of stats

modes, the controls revert back to normal operation.

Cook Cycles Remaining before Filtering

1. Press and release either or and left display

shows “COOKS REMAIN” and right display shows the

number of cook cycles before the next auto lter. For

example,

means after 3 more cook cycles on the left vat, the controls

ask operator if they are ready to lter or not. But, 6 more

cook cycles remain on the right vat.

Time and Date

2. Press either or twice and time-of-day and date

shows in the displays.

Filter Pad Usage

3. Press either or three times and number of hours

the present lter has been used is shown in the displays.

REMA IN

3 6

May 2016

Actual Oil Temperature

1. Press and the actual oil temperature shows in the

display, for each vat.

2-1

Model LVG-202, 203, 204

Set-point Temperature

2. Press twice and SP shows in the display, along with

the set-point (preset) temperature of each vat.

2-4. HP INFO MODE

Cook Cycles Remaining before Filtering

Press and release both and at the same time to

enter HP Info Mode. You can view the following option in HP

Info Mode:

1. E-Log

2. Last Load

3. Daily Stats

4. Review Usage

5. Inputs HDE (to check: high limit, drain switch jumper,

and tilt switch)

6. Outputs S_H (saftey contactor / heat contactor)

7. Oil Temperature

8. CPU Temp

9. Communication OQM Sensor

10. Analog

11. Activity Log

12. Oil Levels (see if low level sensing temperature difference

between probes).

13. Pumps and Valves

14. AIF Info (check for drain pan recognition: Left F button

1X and down arrow 2X.

15. Print Report to USB

16. Remove USB

17. Oil Quality Support

a. Software Version (SVN); hardware (HVN)

b. Serial Number

c. RTC Date

d. RTC Time

e. Vat-1

f. Vat-2

g. Vat-3

h. Vat-4

i. Vat-5

j. Vat-6

k. Vat-7

l. Vat-8

May 2016

2-2

SECTION 3. LEVEL 1 PROGRAMMING

Level 1 contains the following:

• Modify product settings

• Set the AIF clock for products

• Perform the Deep Clean procedure

• Fryer Setup Mode

Model LVG-202, 203, 204

3-1. MODIFYING PRODUCT

SETTINGS

1. Press and hold and buttons until LEVEL - 1

shows in the display, followed by ENTER CODE.

2. Enter code 1, 2, 3, 4 (rst 4 product buttons).

“PRODUCT” and “SELECTN” show in the displays.

3. Press right √ button and ‘SELECT PRODUCT’ and “-P 1-”

(ex: NUGGETS) show in the displays.

Change Product Names

4. Use the ◄ and ► buttons to scroll through 40 products,

or press desired product button

5. Press right √ button and the product (ex: NUGGETS)

shows in left display and “MODIFY”, and “YES NO”

shows in right display. Press √ button to change this

product, or press the X button to choose another product.

6. If √ button was pressed, press and release a product button

and the ashing letter changes to the rst letter under the

product button that was pressed. For example, if

pressed, the ashing letter changes to an “A”.

Aug. 2012

Press same button again and the ashing letter changes to a

“B”. Press it again and the ashing letter changes to a “C”.

Once desired letter shows in the display, press ► button

to continue to the next letter and repeat the procedure.

Press and hold the right X button to exit Program Mode, or

press ▼ button to continue on to “1. COOK TIME”.

To Change Times and Temperatures

7. Press ▼ button until “COOK TIME” shows in display,

and then use product buttons

to change the time in minutes and seconds, to a maximum

of 59:59.

3-1

Model LVG-202, 203, 204

3-1. MODIFYING PRODUCT

SETTINGS (CONTINUED)

8. Press and release▼ button and “TEMP” shows in the dis-

play, along with the preset temperature on the right side of

the display.

Press the product buttons

to change the temperature. The temperature range is 190°F

(88°C) to 380°F (193°C).

Cook ID Change

9. Press ▼ button until “COOK ID” shows in the display

along with the product ID. For example, NUG would be

the ID for nuggets. Use the product buttons to change the

ID, following the same procedure as Step 6 above.

Alarms (Duty 1 & 2)

10. Press ▼ button until “DUTY 1” shows in left display,

and an alarm time in the right display. Press the product

buttons to set an alarm.

Ex., If a Cook Cycle was set at 3 minutes, and an alarm

was to go off after 30 seconds into the Cook Cycle, “0:30”

would be set in the display at this time. When the timer

counts down to 2:30 the alarm sounds.

After alarm time is set, press ▼ button and “DUTY 2”

shows in display, and a second alarm can be programmed.

Quality Timer

11. Press ▼ button until QUAL TMR shows in display along

with preset holding time. Press product buttons to adjust

hold time (2 hrs., 59 min. max.).

AIF Disable

12. Press ▼ button until “AIF DISABLE” shows in display

along with “YES” or “NO”. Using ◄ and ► buttons

change the display to “YES” if that product is to not be

included in the automatic intermittent ltration operation,

or “NO” if it is to be included.

Assign Button

13. Press ▼ button until “ASSIGN BTN” shows in the display, along with the product (ex: NUGGETS). If this product already has a product button assigned to it, that LED

will be lit. To assign other product buttons to that product,

press and hold the product button for 3 seconds and that

LED stays lit. To remove a product from a button, press

and hold the product button with a lit LED and the LED

goes out.

Aug. 2012

3-2

Model LVG-202, 203, 204

3-2. AIF CLOCK

This feature allows controls to be set for periods of the day that

block the automatic “Filter Now” prompts. For example, the

controls could be set not interrupt with “Filter Now” prompts

during the lunch rush, and during the supper rush. But, if ltering is desired during this time, press and hold a button to

access the lter menu.

Each AIF Blocking period is dened by a start time (a time of

day, XX:XX A, etc) and a duration in minutes.

Weekdays M-F are all grouped together. Up to four different

AIF blocking periods may be programmed throughout the day

for Monday - Friday. (All days share the same settings.)

A separate set of four blocking periods may be programmed

for Saturdays, and a nal set of four blocking periods may be

programmed for Sundays.

1. Press and hold and buttons until LEVEL - 1

shows in the display, followed by ENTER CODE.

2. Enter code 1, 2, 3, 4 (rst 4 product buttons). “PRODUCT”

and “SELECTN” show in the displays.

3. Press ▼ button once and “AIF CLOCK” show in

displays.

4. Press √ button and use ◄ and ► buttons to scroll

through “ENABLE” and “DISABLE” and then press √

button again to select one.

5. If “ENABLE” is chosen, then ▲ and ▼ buttons can be

used to scroll through following list of blocking periods:

Left Display Right Display

M-F 1 XX:XX A XX

M-F 2 XX:XX A XX

M-F 3 XX:XX A XX

M-F 4 XX:XX A XX

SAT 1 XX:XX A XX

SAT 2 XX:XX A XX

SAT 3 XX:XX A XX

SAT 4 XX:XX A XX

SUN 1 XX:XX A XX

SUN 2 XX:XX A XX

SUN 3 XX:XX A XX

SUN 4 XX:XX A XX

Aug. 2012

3-3

Model LVG-202, 203, 204

3-2. AIF CLOCK

(CONTINUED)

In 12-hour clock mode, there are three items on each line: the start

time “XX:XX”, the A or P (am/pm) setting, and the “XX” duration.

Use the ◄ and ► buttons to set these items, which ashes when the

item is selected.

To set a new start time setting, use the product buttons,

to enter the new value.

Press the ► button to step over to the AM/PM setting. The A or P

can be toggled by pressing the ‘0’ product button.

Press the ► button again to step over to the duration value (in minutes). Enter a new value using the product buttons,

In 24-hour clock mode, there are only two items on each line: the

time (XX:XX) and the duration (XX). Again, the ◄ and ►

buttons step you between these items.

Press the right-side X button to exit out of AIF Clock programming

mode.

3-3. DEEP CLEAN MODE

This procedure allows a thorough cleaning of the vat by removing caramelized oil from vat. See Section 4-3 in the Operator’s

Manual for complete set of instructions.

Aug. 2012

3-4

Model LVG-202, 203, 204

3-4. FRYER SETUP

This mode has the same settings as seen upon initial start-up of the

fryer.

1. Press and hold and buttons until LEVEL - 1

shows in the display, followed by ENTER CODE.

2. Enter code 1, 2, 3, 4 (rst 4 product buttons). “PRODUCT”

and “SELECTN” show in the displays.

3. Press ▼ button 3 times and “FRYER SETUP” show in

the displays.

4. Press √ button and *SETUP* *MODE* shows in displays,

followed by, “LANGUAGE” on the left display,

“ENGLISH” on the right display.

Use ◄ or ► buttons to change the operation display to,

“FRANCAIS”, “CAN FREN”, “ESPANOL”, “PORTUG”,

“DEUTSCHE”, “SVENSKA”, “РУССКИИ”.

Press ▼ to continue with other set-up items which include:

• ZONE - USA or NON-USA

• TEMP FORMAT - oF or oC

• TIME FORMAT - 12-HR OR 24-HR

• ENTER TIME - Time of day (use product buttons to change)

• ENTER TIME - AM OR PM

• DATE FORMAT - US OR INTERNATIONAL

• ENTER DATE - Today’s date (use product buttons to change)

• FRYER TYPE - GAS or ELEC

• VAT TYPE - FULL OR SPLIT

• DISPOSE BULK OIL - YES/NO (BULK has RTI system)

• SUPPLY BULK OIL - YES/NO (BULK has RTI system)

• DAYLIGHT SAVING TIME - 1.OFF; 2.US (2007 & after);

3.EURO; 4.FSA (US before 2007)

• OIL QUALITY ENABLED (yes or no)

• TPM WARN (value can be set to 0% - 40%)

• TPM MAX (value can be set to 0% - 40%)

Unless otherwise indicated, use ◄ or ► to change settings.

May 2016

3-5

SECTION 4. LEVEL 2 PROGRAMMING

Used to access the following:

• Advanced changes to product settings

• Error code log

• Password programming

• Alert Tone/Volume

• No. of cook cycles before lter is suggested

• Automatic lter time

Model LVG-202, 203, 204

4-1. ADVANCED PRODUCT

SETTINGS

1. Press and hold and buttons until LEVEL - 2

shows in the display, followed by ENTER CODE.

2. Enter code 1, 2, 3, 4 (rst 4 product buttons). “PROD”

and “COMP” show in the displays.

3. Press right √ button and ‘SELECT PRODUCT’ and “-P 1-”

show in the displays.

4. Use the ◄ and ► buttons to scroll through 40 products,

or press the desired product button.

5. Press right √ button and product (ex: NUGGETS) shows in

the left display and “MODIFY” “YES NO” shows in the

right display. Press the √ button to change this product, or

press the X button to choose another product.

>Load Compensation, Load Compensation

Reference, Full Heat, PC Factor<

6. If √ button was pressed, “LD COMP” shows in the display

along with the load compensation value. This automatically adjusts the time to account for the size and temperature

of the cooking load. Press the product buttons

to change this value of 0 to 20.

Aug. 2012

7. Press ▼ button until “LCMP REF” shows in the display

along with the load compensation average temperature.

(if load compensation is set to “OFF”, then “_ _ _” shows

in display and setting cannot be programmed) This is the

average cooking temperature for each product. The timer

speeds up at temperatures above this setting and slows

down at temperatures below this setting. Press the product

buttons to change this value.

4-1

Model LVG-202, 203, 204

4-1. ADVANCED PRODUCT

SETTINGS (CONTINUED)

4-2. E-LOG

(ERROR CODE LOG)

8. Press ▼ button until “FULL HT” shows in display along

with full heat value in seconds, which means heat is on as

soon as a timer button is pressed, for a programmed length

of time. Press product buttons

to change this value of 0 to 90 seconds.

9. Press ▼ button until “PC FACTOR” shows in display

along with the proportional temperature, which helps keep

the oil from over-shooting the setpoint temperature. Press

product buttons to change this

value of 0 to 50 degrees.

• Use ▲ button to go back to previous menu items.

• Press X button when nished with the current product, to

return to the PRODUCT SELECTN step.

• Press X button a second time to exit PROD COMP mode.

1. Press and hold and buttons until LEVEL - 2

shows in the display, followed by ENTER CODE.

2. Enter code 1, 2, 3, 4 (rst 4 product buttons). “PROD”

and “COMP” show in the displays.

3. Press ▼ button and “E-LOG” shows in the display.

4. Press right √ button and “A” plus the present date & time

ashes on the display, along with “*NOW*”.

5. Press ▼ and if an error was recorded, “B” and date, time,

and error code information shows in display. This is the

latest error code that the controls recorded.

6. Press ▼ and the next latest error code information can be

seen. Up to 10 error codes (B to K) can be stored in the

E-Log Section.

Press and hold the right √ button to view a brief description

of the error.

Aug. 2012

4-2

Model LVG-202, 203, 204

4-3. PASSWORDS

The 4-digit passwords can be changed for access to Set-Up,

Usage, Level 1, Level 2, & Get Mgr.)

1. Press and hold and buttons until LEVEL - 2

shows in the display, followed by ENTER CODE.

2. Enter code 1, 2, 3, 4 (rst 4 product buttons). “PROD”

and “COMP” show in the displays.

3. Press ▼ button twice and “PASSWORD” shows in the

display.

4. Press right √ button and “SET UP” shows in display. The

Set up password can be changed at this time, or press ▼

once to change the USAGE password, twice for LEVEL 1

password, 3 times for LEVEL 2 password, or 4 times for

GET MGR password. And then, follow instructions below.

5. If the password for Set Up Mode (for example) is to be

changed, press right √ button and “MODIFY? “YES NO”

shows in the display. Press right √ button to change the

4-digit password for the Set Up Mode, using the product

buttons

4-4. ALERT TONE

(AND VOLUME)

6. Once new password is entered, “CONFIRM PASSWORD”

shows in the display. Press √ button to conrm, or press X

to choose another password.

1. Press and hold and buttons until “LEVEL - 2”

shows in the display, followed by “ENTER CODE”.

2. Enter code 1, 2, 3, 4 (rst 4 product buttons). “PROD”

and “COMP” show in the displays.

3. Press ▼ button 3 times and “ALERT TONE” shows in

the display.

4. Press right √ button and “VOLUME” shows in display,

along with volume value. Use the product buttons

to set volume from 1 (softest) to

10 (loudest).

5. Once volume is set, press √ button and “TONE” shows in

display, along with the tone value. Use the product buttons

to set tone from 50 to 2000 Hz.

Aug. 2012

6. Press X to exit Alert Tone Mode.

4-3

Model LVG-202, 203, 204

4-5. FILTER AFTER

4-6. FILTER TIME

The number of cook cycles between ltering the oil can easily

be programmed for all products.

1. Press and hold and buttons until LEVEL - 2

shows in the display, followed by ENTER CODE.

2. Enter code 1, 2, 3, 4 (rst 4 product buttons). “PROD”

and “COMP” show in the displays.

3. Press ▼ button 4 times and “FILR AFTR” shows in the

left display.

4. Use the product buttons to set the

number to cook cycles between ltering procedures from 0

to 99.

5. Once set, press

The length of time the fryer remains idle between cook cycles

before the controls suggest ltering.

ü

button to conrm.

1. Press and hold and buttons until LEVEL - 2

shows in the display, followed by ENTER CODE.

2. Enter code 1, 2, 3, 4 (rst 4 product buttons). “PROD”

and “COMP” show in the displays.

3. Press ▼button 5 times and “FILR TIME” shows in the

left display (hours:minutes).

4. Use the product buttons to set a

time between cook cycles from 0 to 18:00 hours.

For example, if “5:00” is programmed in the right display,

if the vat was not used for 5 hours after a cook cycle, the

controls would display “FILR NOW?” “YES NO”.

5. Once set, press übutton to conrm.

Aug. 2012

4-4

Loading...

Loading...