Henny Penny LVE-202, LVE-203, LVE-103, LVE-104 Operation Manual

OPERATION

SPLIT/FULL VAT OPEN FRYER (Electric)

MANUAL

MODEL

LVE-202

LVE-203

LVE-204

REGISTER WARRANTY ONLINE AT WWW.HENNYPENNY.COM

Compliance Information

These are the original version controlled Henny Penny instructions for Low oil Volume Electric (L VE)

model 20 number of vats 2 (LVE-202/203/204). Read these instructions completely prior to installation

and operation of this appliance to ensure compliance to all required installation, operation and safety

standards. Read and obey all safety messages to avoid damage to the appliance and personal injury . This

appliance is intended for commercial use in kitchens of restraunts, bakeries, hospitals, etc. but not for the

continuous mass production of food such as in a factory setting. This fryer must be installed and used

in a way that water does not contact the oil which can cause splashing and boiling over of oil and steam

leading to personal injury; excludes normal product moisture. Proper daily , weekly, monthly, quarterly and

yearly maintenance must be performed on this appliance to ensure safe and continuous operation. Proper

maintenance also increases the usable life of the appliance and oil, which reduces lifetime operating costs.

Additionally, old oil increases the possibility of surge boiling and re due to the reduced ash point of the

oil. This appliance must never be cleaned with a water jet or steam cleaning tool. Cleaning brushes are

shipped with the appliance and proper cleaning instructions are included in this manual.

Model LVE-202, 203, 204

TABLE OF CONTENTS

Section Page

Section 1. INTRODUCTION ..............................................................................1-1

1-1 Introduction ..............................................................................1-1

1-2 Proper Care ...............................................................................1-1

1-3 Assistance .................................................................................1-1

1-4 Safety ........................................................................................1-2

Section 2. INSTALLATION................................................................................ 2-1

2-1 Introduction ..............................................................................2-1

2-2 Unpacking .................................................................................2-1

2-3 Selecting the Fryer Location .....................................................2-2

2-4 Leveling the Fryer ....................................................................2-2

2-5 Ventilation of Fryer ...................................................................2-3

2-6 Adjusting Height of Top Cap ....................................................2-3

2-7 Removal of Top Cap .................................................................2-3

2-8 Electrical Requirements ...........................................................2-4

2-9 Dimensions ...............................................................................2-6

2-10 LonWorks Function Conrmation ............................................2-7

Section 3. OPERATION ......................................................................................3-1

3-1 Operating Components .............................................................3-1

3-2 Set-Up Mode .............................................................................3-5

3-3 Filling or Adding Oil ................................................................3-6

3-4 Morning Start-Up Procedures ..................................................3-7

3-5 Cooking with Dedicated Display ..............................................3-8

3-6 Cooking with Multi-Product Display .......................................3-9

3-7 Change from Breakfast to Lunch & Lunch to Breakfast ..........3-9

3-8 Change from Multi-Product Display to Dedicated Display ....3-10

3-9 Change from Dedicated Display to Multi-Product Display ....3-10

3-10 Change from Multi-Product Display to Multi-Product

Display with Different Setpoint Temperatures ........................3-10

3-11 Auto Top-Off ...........................................................................3-11

3-12 Automatic Intermittent Filtration (AIF) ..................................3-12

3-13 Maintenance Filter ...................................................................3-14

3-14 Discarding Oil from Vat Using RTI .........................................3-16

3-15 Discarding Oil from Vat Using Oil Discard Shuttle ................ 3-17

3-16 Discarding Oil from Vat Using Non-RTI (REAR) System .....3-18

3-17 Changing the Filter Pad ...........................................................3-19

3-18 Removing and Cleaning Basket Rest ......................................3-21

3-19 Info Button Stats ......................................................................3-22

3-20 Filter Button Stats ....................................................................3-22

3-21 Temp Button Stats ...................................................................3-22

3-22 Information Mode ....................................................................3-23

Aug. 2012

i

Model LVE-202, 203, 204

TABLE OF CONTENTS (Continued)

Section Page

Section 4. LEVEL 1 PROGRAMMING ............................................................4-1

4-1 Modifying Product Settings ......................................................4-1

4-2 AIF Clock ..................................................................................4-3

4-3 Deep Clean Mode ......................................................................4-4

4-4 Fryer Setup ................................................................................4-8

Section 5. LEVEL 2 PROGRAMMING ............................................................5-1

5-1 Advanced Product Settings .......................................................5-1

5-2 E-Log (error code log) ...............................................................5-2

5-3 Password....................................................................................5-3

5-4 Alert Tone ..................................................................................5-3

5-5 Filter Aftr ...................................................................................5-4

5-6 Filter Time .................................................................................5-4

Section 6. TROUBLESHOOTING ....................................................................6-1

6-1 Troubleshooting Guide ..............................................................6-1

6-2 Error Codes ...............................................................................6-3

Aug. 2012

ii

Model LVE-202, 203, 204

SECTION 1. INTRODUCTION

1-1. INTRODUCTION

1-2. PROPER CARE

The Henny Penny open fryer is a basic unit of food processing

equipment. This unit is used only in institutional and commercial

food service operations.

As of August 16, 2005, the Waste Electrical and Electronic

Equipment directive went into effect for the European Union.

Our products have been evaluated to the WEEE directive. We

have also reviewed our products to determine if they comply with

the Restriction of Hazardous Substances directive (RoHS) and

have redesigned our products as needed in order to comply. To

continue compliance with these directives, this unit must not be

disposed as unsorted municipal waste. For proper disposal, please

contact your nearest Henny Penny distributor.

As in any unit of food service equipment, the Henny Penny open

fryer does require care and maintenance. Requirements for the

maintenance and cleaning are contained in this manual and must

become a regular part of the operation of the unit at all times.

1-3. ASSISTANCE

Should you require outside assistance, call your local independent

distributor in your area, or call Henny Penny Corp. at 1-800-4178405 or 1-937-456-8405.

Aug. 2012

1-1

Model LVE-202, 203, 204

1-4. SAFETY

OR

The Henny Penny open fryer has many safety features

incorporated. However, the only way to ensure a safe operation

is to fully understand the proper installation, operation, and

maintenance procedures. The instructions in this manual have

been prepared to aid you in learning the proper procedures.

Where information is of particular importance or safety related,

the words DANGER, WARNING, CAUTION, and NOTICE are

used. Their usage is described below.

This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a

person responsible for their safety

SAFETY ALERT SYMBOLS are used with DANGER, WARNING,

or CAUTION which indicates a personal injury OR type hazard.

NOTICE is used to highlight especially important

information.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

CAUTION used with the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

DANGER INDICATES AN IMMINENTLY

HAZARDOUS SITUATION WHICH, IF NOT AVOIDED,

WILL RESULT IN DEATH OR SERIOUS INJURY.

April 2012

1-2

Model LVE-202, 203, 204

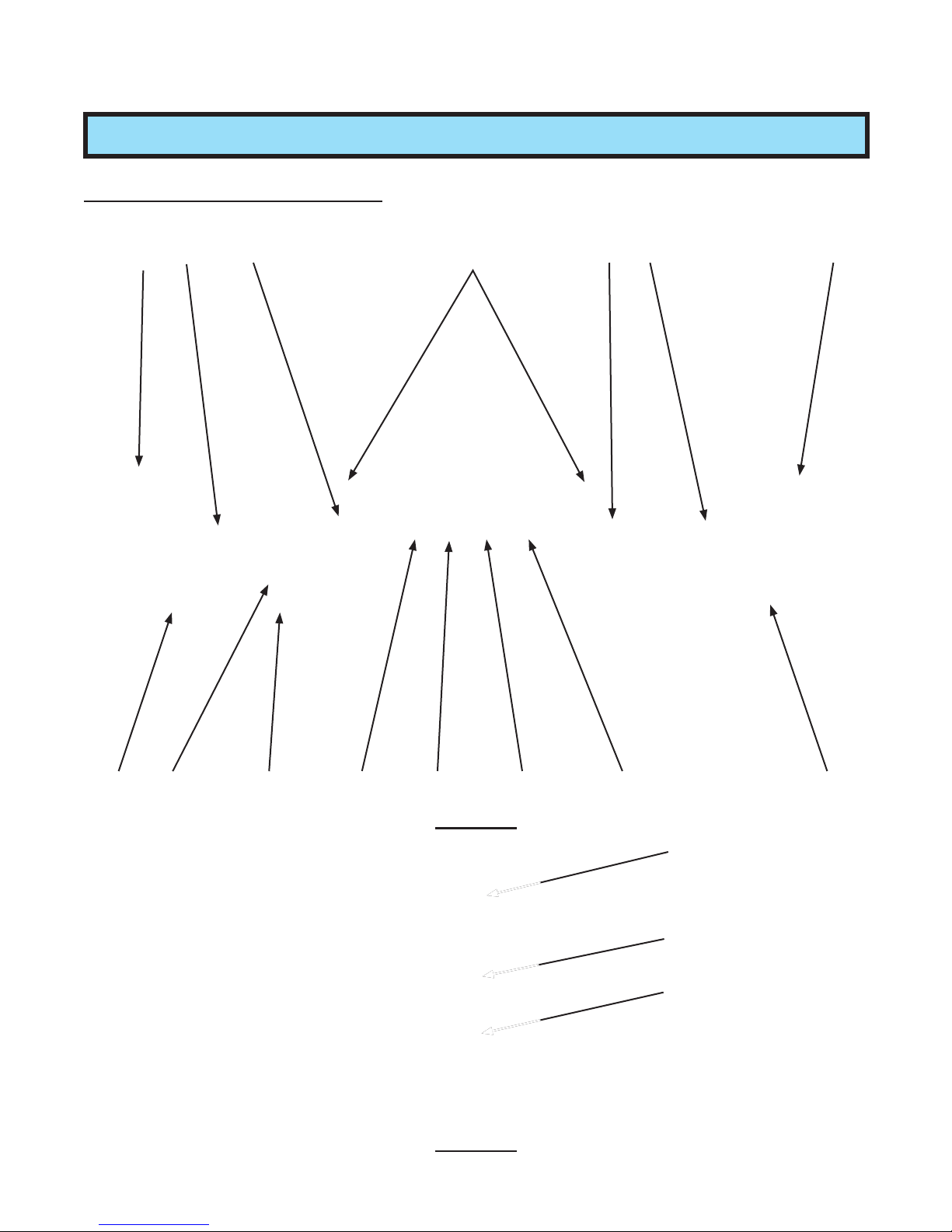

1-4. SAFETY (Continued)

OR

Equipotential Ground Symbol

Waste Electrical and Electronic Equipment (WEEE) Symbol

Shock Hazard Symbols

OR

Hot Surface Symbols

To Check or Conrm

Noise generated from this equipment is less than 70 dB(A)

Aug. 2012

1-3

Model LVE-202, 203, 204

SECTION 2. INSTALLATION

2-1. INTRODUCTION

2-2. UNPACKING

INSTRUCTIONS

This section provides the installation and unpacking instructions

for the Henny Penny LVE fryer.

Installation of this unit should be performed only by a

qualied service technician.

Do not puncture the fryer with any objects such as drills

or screws as component damage or electrical shock could

result.

Any shipping damage should be noted in the presence of the

delivery agent and signed prior to his or her departure.

1. Cut and remove the metal bands from the carton.

2. Remove the carton lid and lift the main carton off the fryer.

Figure 1

3. Remove corner packing supports (4).

4. Cut the stretch lm from around the carrier/rack box and

remove it from the top of the fryer lid.

5. Cut and remove the metal bands holding the fryer to the pallet.

• Do not r emove shipping brace from right side of fryer until

unit is in nal location as damage to fryer could result.

• Remove lter drain pan and JIB shelf from fryer before

removing fryer from pallet or damage to the unit could

result. Figure 1.

6. Remove the fryer from the pallet.

Take care when moving the fryer to prevent personal

injury. The fryer weighs approximately 600 lbs. (272 kg)

to 800 lbs. (363 kg)

.

Aug. 2012

2-1

Model LVE-202, 203, 204

2-3. SELECTING THE

FRYER LOCATION

2-4. LEVELING THE FRYER

The proper location of the fryer is very important for operation,

speed, and convenience. The location of the open fryer should

allow clearances for servicing and proper operation. Choose a

location which will provide easy loading and unloading without

interfering with the nal assembly of food orders. Operators have

found that frying from raw to nish, and holding the product in

warmers provides fast continuous service. Keep in mind, the best

efciency will be obtained by a straight line operation, i.e. raw in

one side and nished out the other side. Order assembly can be

moved away with only a slight loss of efciency.

To avoid re and ruined supplies, the area under the fryer

should not be used to store supplies.

To prevent severe burns from splashing hot oil, position

and install fryer to prevent tipping or movement.

Restraining ties may be used for stabilization.

For proper operation, the open fryer should be level from side-

to-side and front to back. Using a level placed on the at areas

around the vat collar, on the middle well, and adjust the casters

until the unit is level.

Casters adjustable up to 1.562 in (40mm)...see below.

Feb. 2011

2-2

Model LVE-202, 203, 204

2-5. VENTILATION OF

FRYER

2-6. ADJUSTING HEIGHT

OF TOP CAP

The fryer should be located with provision for venting into

adequate exhaust hood or ventilation system. This is essential

to permit efcient removal of steam exhaust and frying odors.

Special precaution must be taken in designing an exhaust

canopy to avoid interference with the operation of the fryer. We

recommend you consult a local ventilation or heating company to

help in designing an adequate system.

Ventilation must conform to local, state, and national codes.

Consult your local re department or building authorities.

Adjustable top cap to be used on all series exhaust hoods with

the exception of the universal exhaust hood (UH SERIES).

For UH SERIES top cap is to be removed - see Section 2-7.

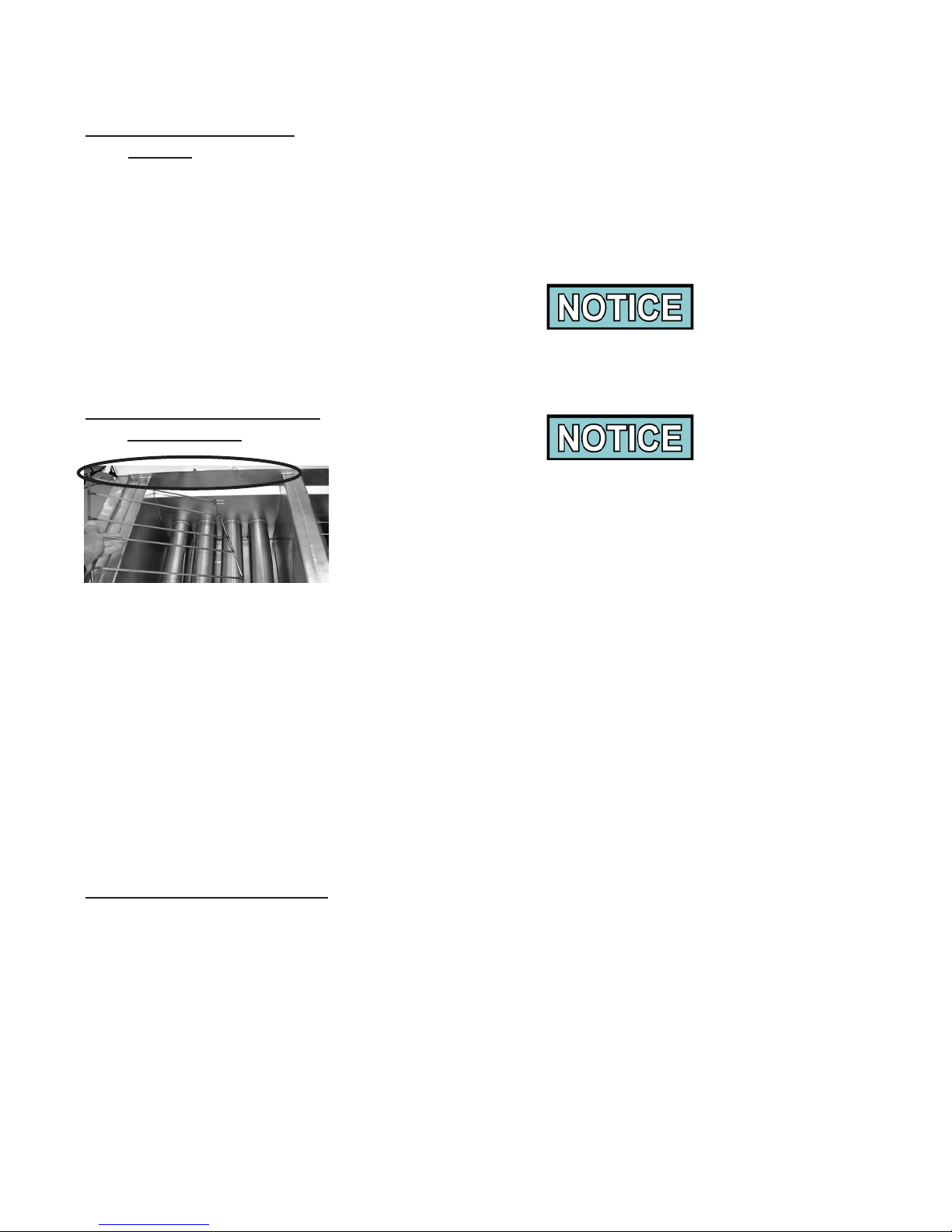

Figure 1

Figure 2

2-7. REMOVAL OF TOP CAP

On the rear shroud of the fryer is an adjustable panel that must t

up against the vent hood. Figure 1.

Using a 3/8” socket, wrench or nutdriver, loosen the 3 acorn nuts

securing the panel. Figure 2.

Move the panel to t against the vent hood and then tighten the 3

acorn nuts.

Some installations (UH SERIES) may require the adjustable rear

shroud to be removed.

Using a Phillip’s-head screwdriver, remove two screws (one at

each end) securing the rear shroud and pull shroud from unit.

Aug. 2010

2-3

Model LVE-202, 203, 204

2-8. ELECTRICAL

REQUIREMENTS

Check the data plate, mounted on the inside of the left door, to

determine the correct power supply.

This fryer must be adequately and safely grounded

(earthed) or electrical shock could result. Refer to

local electrical codes for correct grounding (earthing)

procedures or in absence of local codes, with The National

Electrical Code, ANSI/NFPA No. 70-(the current edition).

In Canada, all electrical connections are to be made in

accordance with CSA C22.1, Canadian Electrical Code

Part 1, and/or local codes.

To avoid electrical shock, this appliance must be equipped

with an external circuit breaker which will disconnect all

ungrounded (unearthed) conductors. The main power

switch on this appliance does not disconnect all line

conductors.

(FOR EQUIPMENT WITH CE MARK ONLY!)

To prevent electric shock hazard this appliance must be

bonded to other appliances or touchable metal surfaces

in close proximity to this appliance with an equipotential

bonding conductor. This appliance is equipped with an

equipotential lug for this purpose. The equipotential lug is

marked with the following symbol

.

Aug. 2010

2-4

Model LVE-202, 203, 204

2-8. ELECTRICAL

REQUIREMENTS

(Continued)

An all pole, separate disconnect switch, with proper capacity

fuses or breakers must be installed at a convenient location

between the fryer and the power source, and must be installed

according to national and local codes. It should be an insulated

o

copper conductor rated for 600 volts and 90

C. For runs longer

than 50 feet (15.24 m), use the next larger wire size. CE units

require a minimum wire size of 6 mm to be wired to the terminal

block.

It is recommended that a 30 mA rated protective device such as

a residual current circuit breaker (RCCB), or ground fault circuit

interrupter (GFCI), be used on the fryer circuit.

Permanently connected electric fryers with casters must be

installed with exible conduit and a cable restraint, when

installed in the United States. See illustration at left. Holes are

available in the rear fryer frame for securing the cable restraint

to the fryer. The cable restraint does not prevent the fryer from

tipping.

The fryer is supplied with 2 different, 7 ft. (2.13 m) power

cord assemblies. The cord assembly with the NEMA L21-

20P twistlock plug is wired specically for McDonald’s Hood

Interlock Receptacle only, and supplies power to the controls.

DRYWALL CONSTRUCTION

Secure I-bolt to a building

stud. Do not attach to drywall

only. Preferred installation is

approximately six inches to either

side of service. Cable restraint

must be at least six inches

shorter than exible conduit.

The other power cord, supplying power to the heating system,

uses NEMA 15-60P Straight Plug, and each vat has its own power

cord assembly.

The supply power cords shall be oil-resistant, sheathed exible

cable, no lighter than ordinary polychloroprene or other

equivalent synthetic elastomer-sheathed cord.

Aug. 2010

2-5

Model LVE-202, 203, 204

2-9. DIMENSIONS

Aug. 2010

Casters adjustable up to 1.562 in (40mm)

2-6

Model LVE-202, 203, 204

2-10. LONWORKS FUNCTION

CONFIRMATION

Once the installation of the Henny Penny fryer is complete,

perform this procedure to verify that the LonWorks control in the

LVE is communicating with the computer console in the store.

1. Access the LonWorks system on the store’s computer console.

2. Turn the Main Power switch to the ON position on the Henny

Penny LVE fryer.

3. On one of the fryer controls, press both buttons

and “1. E-LOG” shows in the display.

4.

Press button until “9. COMM” & “LONWORKS ü”

show in the displays. (If “LONWORKS ---” shows in

display, the LonWorks control is not being acknowledged by

the main controls.)

5. Press button twice and “SRVC” & “PIN” show in the

displays. Press button under “SRVC”.

6. From the store’s console, click the WINK DEVICE button

and the displays on ALL LVE controls should ash, verifying

that the system is working properly.

If the the fryer and the store’s computer console is not

communicating, please contact the Technical Support Department

at 1-800-417-8405, 1-937-456-8405, or

technicalservice@hennypenny.com.

Oct. 2012

2-7

Model LVE-202, 203, 204

SECTION 3. OPERATION

3-1. OPERATING COMPONENTS Refer to explanations on the next pages.

1 2

4 5 73

6

8 9 1311 12

Aug. 2010

10 15

14

Figure 3-1

16

17

18

Figure 3-2

3-1

Model LVE-202, 203, 204

3-1. OPERATING

COMPONENTS

(Continued)

Refer to Figures 3-1 & 3-2 in conjunction with the description of

the functions below.

Fig.

No.

3-1 1

3-1 2

3-1 3

3-1 4

3-1 5

Item

No.

Description Function

This LED lights when the control calls for heat for the left vat(s), and

the elements come on and heat the oil

During normal operation, press this button to start and stop cook

cycles for the left basket; press to change displayed product; also used

ü

for

During normal operation, press this button to start and stop cook

cycles for the left basket; press to change displayed product; also used

for X to indicate NO or cancel

Digital Display Digital Display Shows the product codes; shows the timer countdown

during cook cycles; shows the prompts during the lter modes; shows

the selections in the Program Mode; shows the temperature of the

oil by pressing

languages)

During normal operation, press this button to start and stop cook

cycles for the right basket; press to change displayed product; press to

conrm prompts in the lter modes; also used for

or conrmation

to indicate YES or to conrm

; shows error codes (also displays in several

ü

to indicate YES

3-1 6

3-1 7

3-1 8

3-1 9

3-1 10

During normal operation, press this button to start and stop cook

cycles for the right basket; press to change displayed product; press

to deny prompts in the lter modes; also used for X to indicate NO or

cancel

This LED lights when the control calls for heat for the right vat(s), and

the elements come on and heat the oil

Press to turn on and off the heat system for the left vat(s)

Each product button LED lights when that particular product has been

selected

Press to select the desired product; press, during naming a product, to

place the letters under the button, in the name

Aug. 2010

3-2

Model LVE-202, 203, 204

3-1. OPERATING

COMPONENTS

(Continued)

Fig. No. Item No. Description Function

3-1 11 & 14

3-1 12

3-1 13

3-1 15

Used in the Programming and Filtering Modes;

also used for or buttons ; press to view the

following ltering stats:

a. the number of cook cycles before next lter

b. time and date of last lter cycle

c. the number of hours the existing lter has been used

Used in the Programming Modes; used in the Filtering

Modes; used in lling and emptying the vats; also used

for

button; press to view the following temperature

stats:

a. actual oil temperature in each vat

b. setpoint temperature for each vat

Used in the Programming Modes; also used for

button; press to display the following fryer information

and stats:

a. recovery information for each vat

b. selected primary and secondary display languaages

Press to turn on and off the heat system for the right

vat(s)

3-2 16

3-2 17

3-2 18

Aug. 2010

When turned to the ON position, power is supplied to

the controls and lter pumps

When lit blue , indicates an Automatic

Intermittent Filtration should be done at this time

When lit amber, indicates the JIB needs lled or

replaced

3-3

Model LVE-202, 203, 204

Figure 3-3

Fig.

No.

Item

No.

Description Function

3-3 1 Filter Drain Pan

Assy.

3-3 2 Basket Rest The baskets hang on this when not in use, or to drain the product

3-3 3 RTI Switch Only on fryers that have the RTI System at the location

3-3 4 Vat Covers Covers the vat when not in use

3-3 5a JIB Jug-in-a-Box for locations without RTI systems; holds oil

3-3 5b JIB Jug for locations with RTI systems; holds oil

Aug. 2010

Oil is drained into this pan and then is pumped through lters to

help prolong the use of the oil

after a cook cycle

3-4

Loading...

Loading...