Page 1

OPERATOR’S

MANUAL

FlexFusionTM GAS PLATINUM COMBI

MODEL

FPG-615

FPG-621

FPG-115

FPG-121

FPG-215

FPG-221

REGISTER WARRANTY ONLINE AT WWW.HENNYPENNY.COM

REGISTER WARRANTY ONLINE AT WWW.HENNYPENNY.COM

Read instructions before operating the appliance

Page 2

Operating and display elements

2

a

On Off

button

f

"Automatic cooking" button

b

FlexiHelp

button

g

"Equipment functions" button

c

Operating element with

touchscreen

h

Back

button

d

"Manual cooking" button

i

Information bar

e

Language selection

button

a

b

c d e

i h g

f

Operating and display elements

Page 3

Directory of contents

3

1

Introduction

8

1.1

About this manual

8

1.1.1

Explanation of signs

9

1.2

Intended use

11

1.3

Warranty

11

2

Safety information

12

3

Rules of conduct when the smell of gas is detected

16

4

Description of the unit

17

4.1

Overview of the unit

17

4.1.1

Countertop unit

17

4.1.2

Floor-standing unit

18

4.2

Features

19

4.2.1

Characteristics

19

4.2.2

Operating modes

19

4.2.3

Types of cooking

20

4.2.4

Expanded cooking functions

21

4.2.5

Core temperature measurement

23

4.2.6

Barcode scanner

24

4.2.7

USB port

24

4.2.8

HACCP logging

24

4.2.9

VideoAssist

24

4.2.10

ChefsHelp

25

4.2.11

WaveClean automatic cleaning

25

4.2.12

CombiDoctor (self-diagnostic program)

25

4.3

Operating, control and display element functions

25

Directory of contents

Page 4

Directory of contents

4

4.4

Application

26

4.4.1

Plate capacity during regeneration

26

4.4.2

Loading capacity

27

4.4.3

Temperature standard setting

27

4.4.4

Core temperature standard setting

28

4.5

Chef’s Touch equipment controls

28

4.5.1

Touchscreen operation

28

4.5.2

Display elements

31

5

Putting the unit into service

33

6

Operating the unit

34

6.1

Switching the unit on and off

34

6.1.1

Switching on

34

6.1.2

Switching off

34

6.2

Opening and closing the cooking zone door

35

6.2.1

Opening the single-stage door latch

35

6.2.2

Closing the single stage door latch

35

6.2.3

Opening the two-stage door latch

36

6.2.4

Closing the two-stage door latch

36

6.3

Loading and emptying the unit

37

6.3.1

Loading and emptying

37

6.3.2

Loading and emptying with a tray rack trolley

38

6.3.3

Loading and emptying with a tray trolley

39

6.4

Using the core temperature sensor

41

6.4.1

Measuring with a 4-point core temperature sensor

41

6.4.2

Measuring with a sous-vide core temperature sensor

42

6.4.3

Measuring the core temperature when cooking frozen food

42

6.5

Making the basic settings

43

6.5.1

Opening the Setting menu

43

Page 5

Directory of contents

5

6.5.2

Retrieving equipment information

44

6.5.3

Setting the date and time

45

6.5.4

Presetting the language selection

46

6.5.5

Activating and cancelling inhibit operation

47

6.6

Basic functions

48

6.6.1

Setting the cooking temperature

48

6.6.2

Setting the cooking time and continuous operation

49

6.6.3

Setting the core temperature

51

6.6.4

Setting the fan speed and direction of rotation

52

6.6.5

Preparing the USB flash drive for initial use

52

6.6.6

Inserting and removing a USB flash drive

53

6.6.7

Exporting the HACCP log

53

6.7

Equipment functions

53

6.7.1

Opening the Equipment function menu

54

6.8

Manual cooking

54

6.8.1

Opening the Manual cooking menu

54

6.8.2

Creating a cooking program

54

6.9

User's own cooking programs

55

6.9.1

Creating a cooking program

55

6.9.2

Saving the cooking program

58

6.9.3

Exporting a cooking program

61

6.10

Automatic cooking (autoChef)

61

6.10.1

Opening the Automatic cooking menu

61

6.10.2

Finding and opening a cooking program

62

6.10.3

Starting the cooking program

63

6.10.4

Ending the cooking program

64

6.10.5

Modifying the cooking program

65

6.10.6

Delete cooking program

66

6.10.7

Exporting and importing a cooking program

66

Page 6

Directory of contents

6

6.11

Pausing and finishing use

68

7

Cleaning and caring for the unit

69

7.1

Preventing corrosion

69

7.2

Remove rust spots

69

7.3

Cleaning the housing

70

7.4

Cleaning the handle, operating elements and operating panel

membrane

70

7.5

Cleaning the touchscreen

71

7.6

Cleaning the door seal

72

7.7

Cleaning the cooking zone door

73

7.7.1

Cleaning the door with hygienic glazing

73

7.8

Cleaning the steam outlet

73

7.9

Cleaning the condensation hood (optional)

74

7.10

Removing calcium deposits from the unit

75

7.11

Cleaning the cooking zone automatically with WaveClean

75

7.11.1

Preparing for cleaning

75

7.11.2

Selecting the cleaning level

76

7.11.3

Inserting the cleaning cartridge

76

7.11.4

Starting automatic cleaning

77

7.11.5

Cancelling automatic cleaning

77

7.11.6

Ending automatic cleaning

77

7.12

Cleaning the cooking zone manually

78

7.12.1

Preparing the cooking zone

78

7.12.2

Starting the cleaning program

78

7.12.3

Spraying the cleaner

79

7.12.4

Allowing the cleaner to act

79

7.12.5

Starting cleaning

79

7.12.6

Rinsing the cooking zone

80

Page 7

Directory of contents

7

7.12.7

Drying the cooking zone

80

7.13

Swinging the air diverter open and closed

81

7.14

Inspecting the unit

82

7.14.1

Performing a visual inspection

82

7.14.2

Running CombiDoctor (self-diagnostic program)

82

8

Troubleshooting

84

8.1

Causes of errors and remedies

84

8.2

Nameplate

84

9

Dispose of unit in an environmentally responsible manner

85

Page 8

1

Introduction

About this manual

8

1

1.1

Target group

Figures

Introduction

About this manual

The instruction manual is part of the unit and contains information:

▪ on safe operation

▪ on cleaning and care

▪ on remedial actions in case of faults

Observe and adhere to the following instructions:

▪ Read the instruction manual completely before operating the unit for the

first time.

▪ Make the instruction manual available to the operator at all times at the

operating site of the unit.

▪ Insert any supplements from the manufacturer.

▪ Preserve the instruction manual throughout the service life of the unit.

▪ Pass on the instruction manual to any subsequent operator of the unit.

The target group of the instruction manual is the operator, who is entrusted

with the operation, cleaning and care of the unit.

All figures in this manual are intended as examples. Discrepancies between

these and the actual unit can arise.

Page 9

Introduction

1

About this manual

9

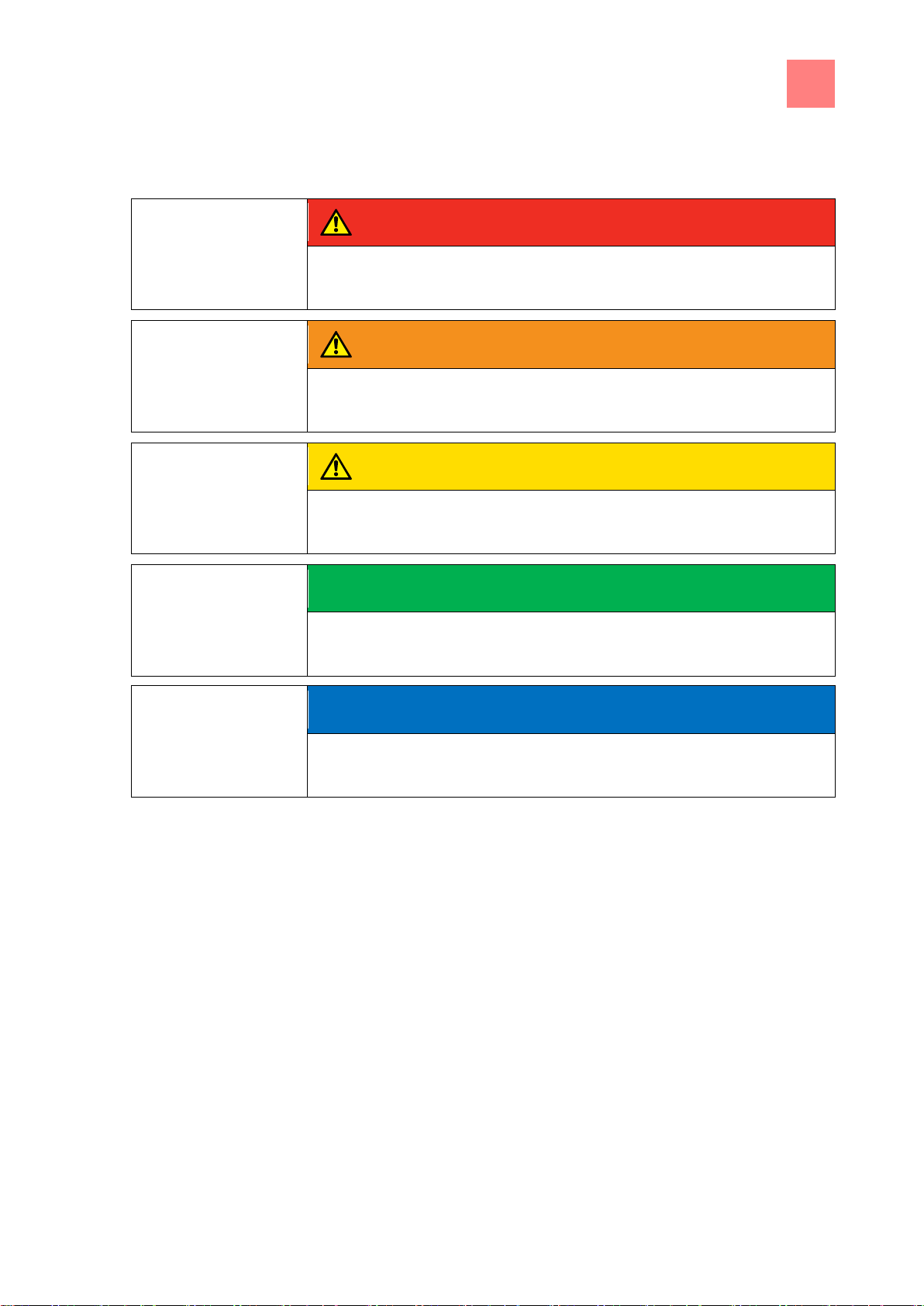

DANGER

Imminent threat of danger

Failure to comply will lead to death or very severe injuries.

WARNING

Possible threat of danger

Failure to comply can lead to death or very severe injuries.

CAUTION

Dangerous situation

Failure to comply can cause minor or moderate injuries.

SAFETY INSTRUCTIONS

Material damage

Failure to comply can cause material damage.

NOTICE

Information

Notes for better understanding and operation of the unit.

1.1.1

Explanation of signs

Page 10

1

Introduction

About this manual

10

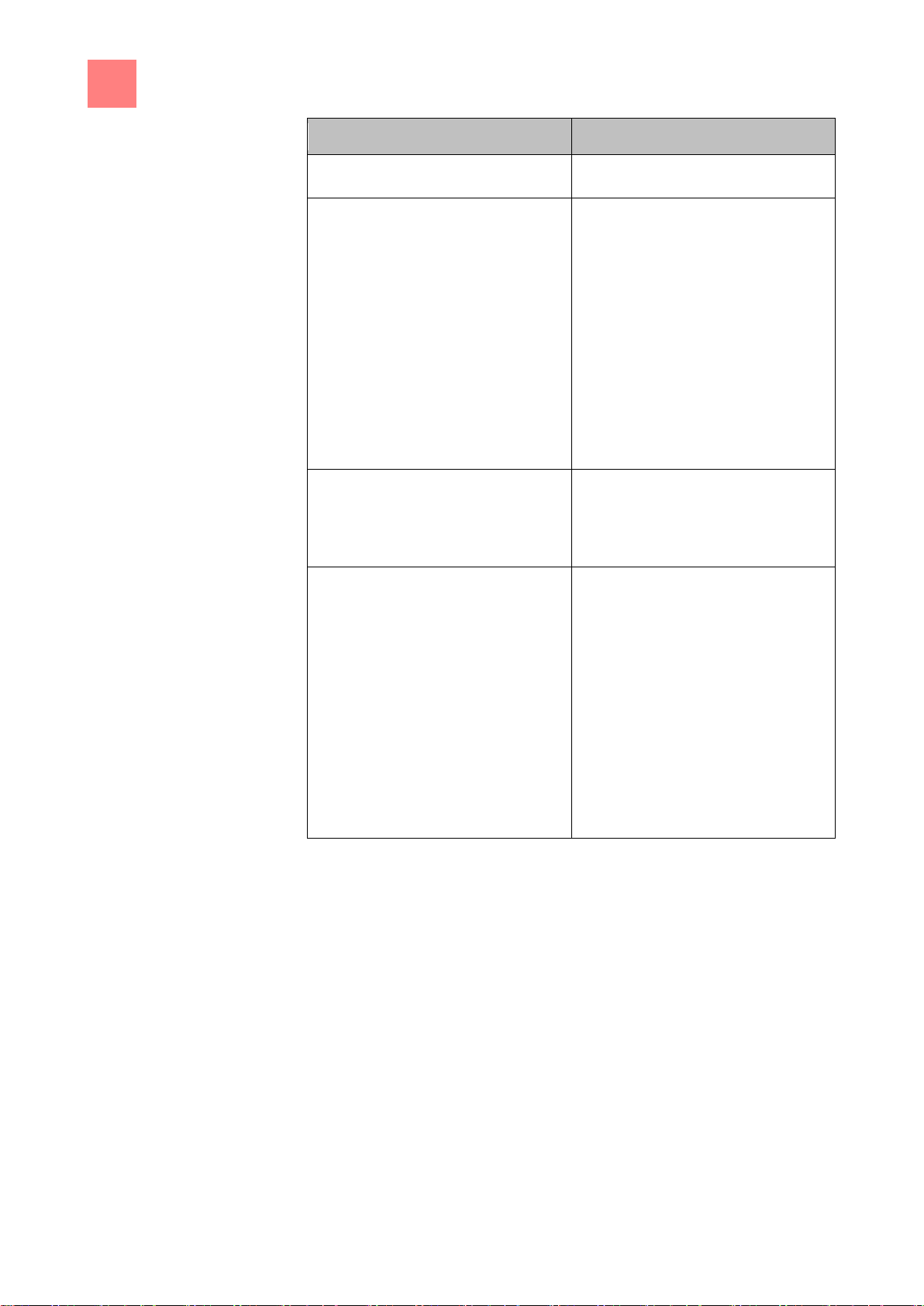

Symbol / sign

Meaning

▪

Listing of information.

Action steps, which can be

performed in any sequence.

1.

2.

Action steps, which must be

performed in the prescribed

sequence.

Result of a listed action.

Page 11

Introduction

1

Intended use

11

1.2

1.3

Intended use

This unit is intended to be used solely for commercial purposes, particularly

in commercial kitchens.

This unit may only be used with suitable accessories and for the cooking of

food.

It is forbidden to use the unit for purposes, which include the following:

▪ Washing dishes

▪ Storing supplies

▪ Drying cloths, paper or dishes

▪ Heating acids, alkaline solutions or other chemicals

▪ Heating preserved food

▪ Heating flammable liquids

▪ Heating rooms

▪ Cleaning air filters

This unit is certified in the following:

Warranty

The warranty is void and safety is no longer assured in the event of:

▪ Modifications or technical changes to the unit,

▪ Improper use,

▪ Incorrect startup, operation or maintenance of the unit,

▪ Problems resulting from failure to observe these instructions.

Page 12

2

Safety information

12

2

Operation

Hot surfaces

Hot liquids

Defective unit

Safety information

The operator must be familiar with regional regulations and observe them.

During operation, the following group of individuals must be supervised by

an individual who is responsible for safety:

▪ Individuals with physical, sensory, or mental handicaps, or who lack the

knowledge and experience to operate the unit properly.

The supervising individual must be familiar with the unit and the risks

associated with it.

Risk of burns from hot surfaces

▪ Protect arms and hands by wearing suitable protective gloves.

▪ Allow surfaces to cool prior to cleaning.

▪ Remove hot cookware only with suitable protective gloves or potholders.

▪ Remove containers and baking sheets only with suitable protective

gloves or potholders.

Risk of burns from hot liquids

▪ Protect arms and hands by wearing suitable protective gloves.

▪ Remove, transport and empty containers carefully.

Risk of chemical burns from evaporating cleaners

▪ Follow the instructions of the cleaning agent manufacturer.

▪ Allow the cooking so to clean to a temperature below 60°C (140°F) and

then clean.

Risk of burns from steam

▪ Protect arms and hands by wearing protective gloves.

▪ Do not hold hands in front of the extractor hood.

▪ First open the cooking zone door slightly and allow the steam to escape.

Then open the cooking zone door completely.

▪ Dry unit completely after cleaning it.

Risk of injury from a defective unit

▪ Disconnect a defective unit from the electric mains.

Page 13

Safety information

2

13

Escaping gas

Fire prevention

Unit on casters

▪ Use gas shut-off valve to isolate unit from gas supply.

▪ Do not operate a defective unit.

▪ Allow only an authorized technician to repair the unit.

Risk of asphyxiation and explosion from escaping gas

▪ Follow the rules of conduct when the smell of gas is detected (see

"Rules of conduct when the smell of gas is detected").

Risk of fire from dirt and grease deposits

▪ Clean the unit when finished using it.

▪ Do not use the unit as a deep fat fryer.

▪ Do not store any combustible objects or plastic containers in the cooking

zone.

Risk of fire from objects

▪ Do not obstruct the exhaust gas duct.

Firefighting

▪ In the event of a fire, disconnect the unit from the electric mains.

▪ In the event of a fire, use the gas shut-off valve to isolate the unit from

the gas supply.

▪ Use a Fire Class F fire extinguisher, never water, to extinguish grease

fires. Other fires, for instance, can be extinguished with fire extinguishers

suitable for Fire Classes A, B, C, CO2 fire extinguishers or extinguishing

media suitable for the fire class confronted.

Risk of injury from a unit on casters

▪ Move the unit only for cleaning or maintenance.

▪ Lock casters during operation.

▪ Only move an empty unit.

Risk of electric shock from live components

▪ Security electric power cable to the wall at the installation location by

means of a chain as strain relief.

Page 14

2

Safety information

14

Improper cleaning

Hygiene

Core temperature

measurement

Improper use

Risk of chemical burns from cleaning agent

▪ Follow the instructions of the cleaning agent manufacturer.

▪ Take appropriate protective measures when handling aggressive

cleaning agents.

Risk of falling on smooth floors

▪ Keep the floor in front of the unit clean and dry.

Risk of injury from improper cleaning

▪ Clean the cooking zone carefully. The cooking zone sensor protrudes

into the cooking zone.

Risk of physical damage from improper cleaning

▪ Clean the unit after using it.

▪ Do not clean the unit with a high-pressure cleaner.

▪ Do not clean the housing with highly abrasive or chemically aggressive

cleaning agents.

▪ Do not clean the housing with highly abrasive sponges.

▪ Follow the instructions of the cleaning agent manufacturer.

▪ Do not cool shock the unit by cooling it abruptly.

▪ Clean the cooking zone carefully. The cooking zone sensor protrudes

into the cooking zone.

▪ Do not use any bleaching or chlorine-containing cleaners.

▪ Remove rust spots with an abrasive.

▪ Keep the unit free of calcium deposits.

Health risk from insufficient hygiene

▪ Observe applicable regional hygiene regulations.

Risk of injury from overheated core temperature sensor

▪ Do not heat the core temperature sensor over an open flame.

Risk of physical damage from improper use

▪ Use only original accessories.

Page 15

Safety information

2

15

▪ Train operators regularly.

▪ Do not heat food warmer plates or tins of preserved food.

▪ Do not cover air inlet and outlet openings.

▪ Do not operate the unit at temperatures below 4°C (39°F).

▪ Remove the core temperature sensor before the cooked food is

removed.

▪ Insert the core temperature sensor back into the holder after use.

Page 16

3

Rules of conduct when the smell of gas is detected

16

DANGER

Risk of asphyxiation and explosion from escaping gas

Follow the rules of conduct when the smell of gas is detected.

3

Rules of conduct when the smell of

gas is detected

▪ Remain calm.

▪ Open windows and doors and ventilate rooms.

▪ Avoid rooms with the smell of gas.

▪ Do not smoke.

▪ Do not ignite any flames. Extinguish flames.

▪ Do not strike any sparks. Do not operate any switches, electrical devices

or use telephones.

▪ Remove mobile phones and radio-controlled devices from the hazard

area.

▪ Close gas shut-off valves at the gas meter, at the main feed and, if

possible, at the units.

▪ Warn other individuals in the building. Call out and knock, do not ring

doorbells.

▪ Leave the building and prevent entry by others.

▪ Observed the safety instructions of the gas utility.

▪ Once outside the building, notify responsible parties:

– If the smell of gas comes from the unit, notify customer service.

– If the source of the smell of gas cannot be localised immediately,

notify the gas utility.

– If the escaping gas is audible, leave the building immediately,

prevent others from entering and notify the fire brigade, police and

gas utility.

– If the smell of gas comes from inaccessible rooms, notify the fire

brigade, police and gas utility.

Page 17

Description of the unit

4

Overview of the unit

17

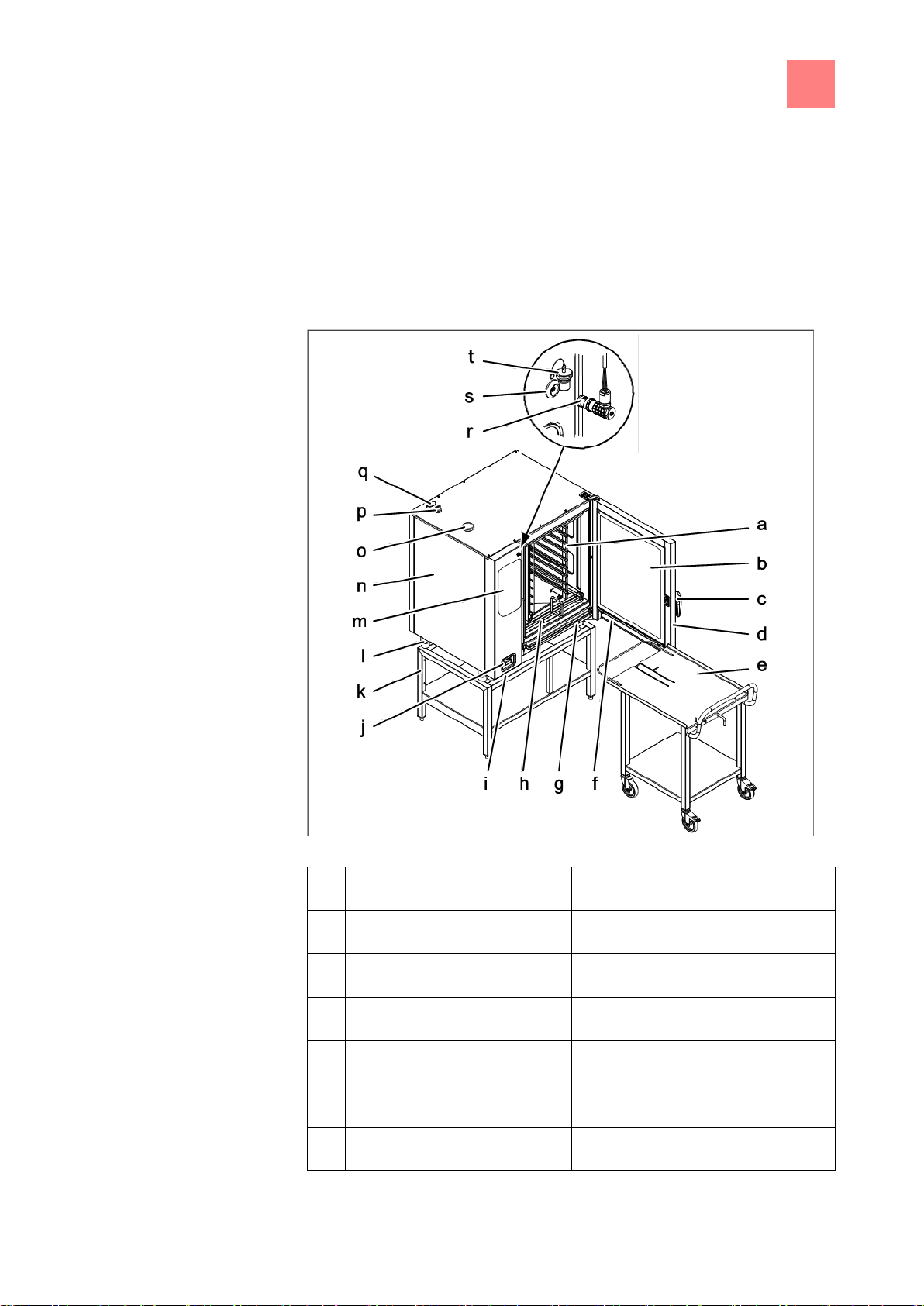

a

Tray rack

k

Base frame (optional)

b

Insulated window

l

Equipment foot

c

Door handle

m

Operating control

d

Cooking zone door

n

Housing

e

Tray rack trolley (optional)

o

Air intake connection fitting

f

Steam drain channel, door

p

Waste gas connection

g

Steam drain channel, unit

q

Steam outlet connection fitting

4

4.1

4.1.1

Description of the unit

Overview of the unit

Countertop unit

Gas FlexFusion with tray rack trolley

Page 18

4

Description of the unit

Overview of the unit

18

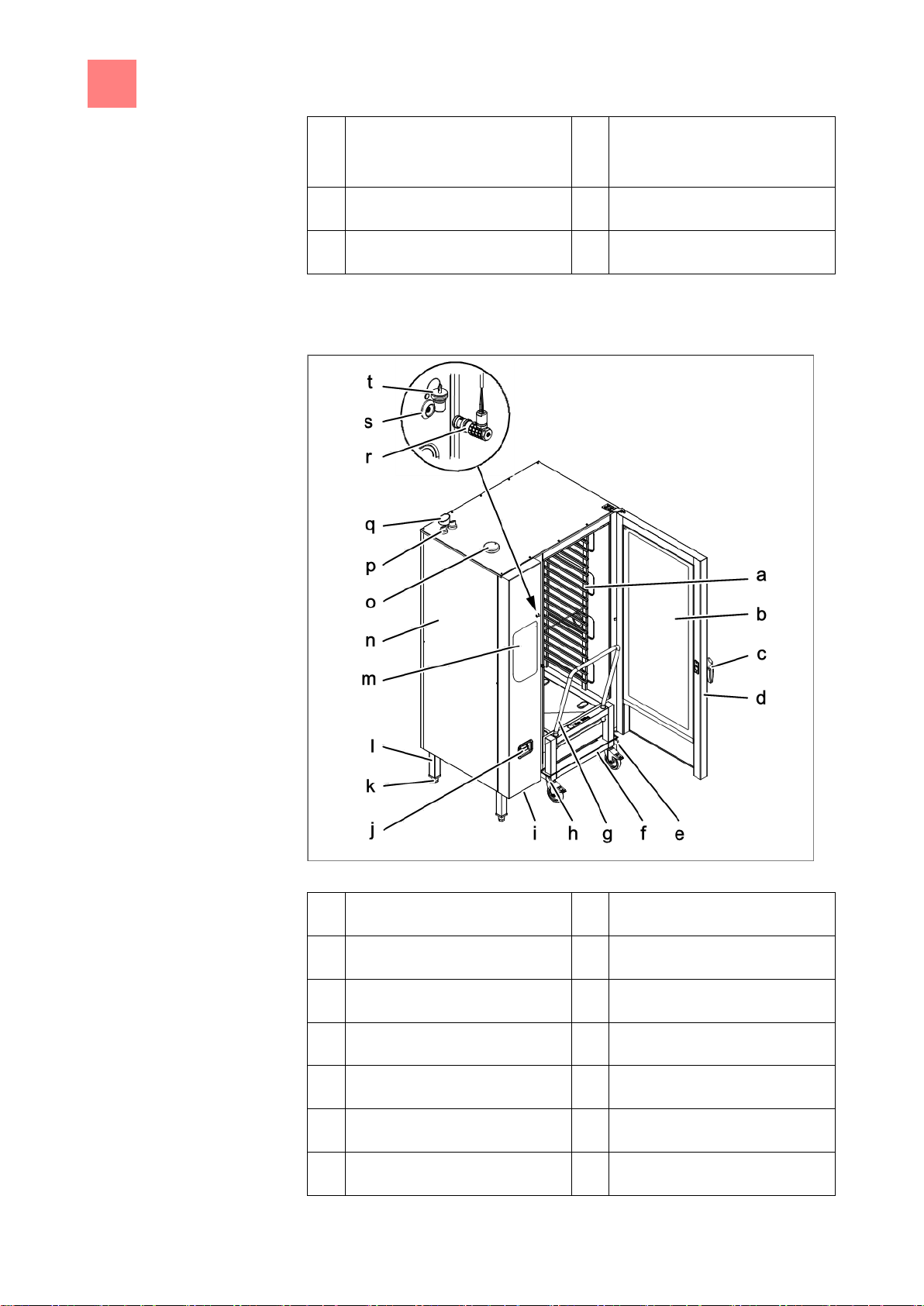

h

Guide rail for tray rack

(optional)

r

Core temperature sensor

(optional)

i

USB port (covered)

s

Connection (optional)

j

Hand shower

t

Protective cap (optional)

a

Tray rack

k

Equipment leg

b

Insulated window

l

Equipment foot

c

Door handle

m

Operating control

d

Cooking zone door

n

Housing

e

Guide rail (right)

o

Air intake connection fitting

f

Tray trolley

p

Waste gas connection

g

Push handle

q

Steam outlet connection fitting

4.1.2

Floor-standing unit

Gas FlexFusion with tray trolley

Page 19

Description of the unit

4

Features

19

h

Guide rail (left)

r

Core temperature sensor

(optional)

i

USB port (covered)

s

Connection (optional)

j

Hand shower

t

Protective cap (optional)

4.2

4.2.1

4.2.2

Features

Characteristics

▪ 4-point core temperature sensor

▪ Sous-vide core temperature sensor or a second 4-point core

temperature sensor (optional)

▪ Hand shower

▪ Cooking zone door with hygienic glazing

▪ Single-stage door latch

▪ Two-stage door latch (optional); this feature is standard on size 20 units

▪ Power optimizing system (optional)

▪ Ethernet connection (optional)

▪ Cooking zone door hinged at right

▪ Cooking zone door hinged at left (optional), not on size 20 floor-standing

units

▪ WaveClean

▪ Barcode scanner (optional)

▪ Steam Exhaust System (SES)

Operating modes

Manual cooking

In the manual cooking mode, individual cooking programs and equipment

functions can be actuated directly. The various cooking modes and

equipment functions can be modified individually.

Page 20

4

Description of the unit

Features

20

4.2.3

Automatic cooking (autoChef)

In the automatic cooking mode, stored cooking programs can be actuated

and adapted as necessary.

Types of cooking

Steaming

Steaming is a cooking mode where the food to be cooked is cooked gently in

steam in a temperature range of 30°C (86°F) to 130°C (266°F).

Combi-steaming

Combisteaming is a cooking mode that can be used to cook large roasts,

casseroles and baked goods in a temperature range of 30°C (86°F) to

250°C (482°F).

Hot air

Hot air is a cooking mode where the food to be cooked is cooked without

additional moisture in a temperature range of 30°C (86°F) to 250°C (482°F).

Perfection (regeneration)

Perfection is a cooking mode that can be used to prepare cooled cooked

food quickly in a temperature range of 30°C (86°F) to 150°C (482°F) and

then keep it warm.

Delta-T cooking

Delta-T cooking is a cooking mode where the cooking temperature depends

on the core temperature of the food being cooked.

The cooking temperature is always higher than the current core temperature

by the set value (Delta-T value, cooking temperature difference). The

resulting cooking time is longer than with other cooking modes.

Delta-T cooking is especially well-suited for general cooking. The food being

cooked remains tender and juicy with little weight loss.

Low-temperature cooking

Low-temperature cooking is a cooking mode where the food to be cooked is

cooked in an especially gentle manner in a temperature range of 30°C

(86°F) to 100°C (212°F).

Page 21

Description of the unit

4

Features

21

NOTICE

When using the start time delay, temperatures that promote the growth of

harmful microorganisms on the food being cooked can occur in the cooking

zone. Observe food processing regulations.

4.2.4

The cooking time is considerably longer than at higher temperatures, but no

supervision is required and the cooking time can be extended considerably

without any loss in quality.

The food being cooked remains tender and juicy with little weight loss.

Baking

Baking is a cooking mode where the food to be cooked is cooked and

browned by hot air in a temperature range of 30°C (86°F) to 220°C (428°);

this opens up the texture of the food. Humidification and an associated idle

time may precede baking.

Expanded cooking functions

Expanded cooking functions can be used to modify individual cooking steps

for the particular food being cooked.

The following expanded cooking functions are available:

PerfectHold

PerfectHold is a cooking function where the prepared food is held in the unit

in a temperature range of 50°C (122°F) to 100°C (212°F) after the actual

cooking process until it is ready to be served.

Ready2Cook (preheating)

For many cooking programs such as baking, for instance, the correct starting

temperature is important.

With Ready2Cook, the cooking zone can automatically be heated or cooled

to the correct starting temperature.

Start-time preselection

The start time delay can be used to set a waiting period until the program

starts.

In this way, bottlenecks in production and preparation can be avoided.

Page 22

4

Description of the unit

Features

22

The prepared food can be loaded into the unit and the desired cooking

program selected.

Steam Exhaust System (SES)

This function is activated by default for all cooking programs that have a

cooking time longer than 6 minutes.

The Steam Exhaust System (SES) is activated automatically shortly before

the end of cooking.

After the cooking time, the Steam Exhaust System (SES) extracts the steam

from the cooking zone. It is then possible to open the cooking zone door

without risk of injury.

RackControl

With the expanded cooking function RackControl, different foods such as

potatoes, cauliflower, peas, carrots and meat can be cooked simultaneously

for different times.

RackControl monitors the various cooking times in one process. When one

cooking time has elapsed, a signal sounds and the food being cooked can

be removed. RackControl is ideal for rolling cooking.

FamilyMix

With the expanded cooking function FamilyMix, the appropriate cooking

programs are displayed in the

Automatic cooking (autoChef)

menu for the

currently set cooking mode. The cooking programs displayed have the same

cooking climate and an identical or shorter cooking time. Tapping the

individual suggestions transfers the cooking times for the individual products

to the RackControl function and these can then be started when desired

during the cooking process.

Manual humidification

Manual humidification allows the cooking zone humidity to be increased

during operation.

Manual humidification can be used only in the hot air and Delta-T hot air

cooking modes.

Page 23

Description of the unit

4

Features

23

4.2.5

248°F

140°F

104°F

140°F

Idle time

With the idle time expanded cooking function, a cooking step can be inserted

during which the heating and the fans are programmed to switch off for a

certain period of time.

Core temperature measurement

When using core temperature measurement, the temperature inside the food

being cooked is measured by means of a sensor.

The core temperature sensor measures the core temperature at one or more

points, depending on the version. The temperature measured at the coldest

spot is used to control the cooking process.

As soon as the target core temperature has been reached, the cooking

process is ended automatically or, in the case of a multi-step cooking

program, advances to the next cooking step.

The use of core temperature measurement offers the following benefits:

▪ Reduced energy and water consumption

▪ No overcooking

▪Less weight lost by the food being cooked

The following core temperature sensors are available:

▪ 4-point core temperature sensor

or

▪ a second 4-point core temperature sensor (optional)

Core temperature measurement with a 4-point core temperature sensor

or

▪ Sous-vide core temperature sensor (optional)

Page 24

4

Description of the unit

Features

24

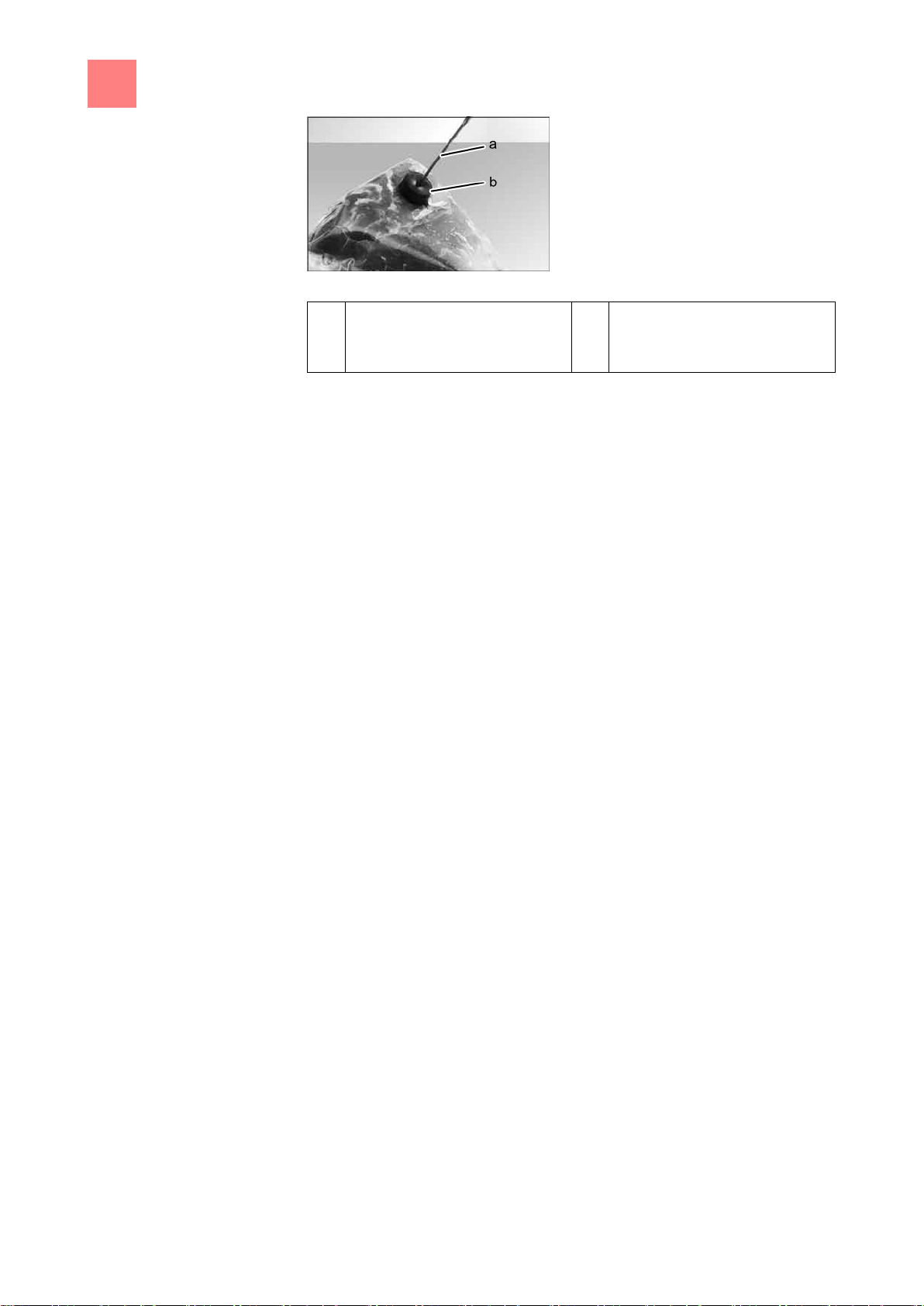

a

Sous-vide core temperature

sensor

b

Foam rubber

4.2.6

4.2.7

4.2.8

4.2.9

Core temperature measurement with sous-vide core temperature sensor

Barcode scanner

The barcode scanner scans the barcode on the packaging of the food to be

cooked and transmits it to the unit. The unit then searches for the

appropriate cooking program for the food to be cooked. If several

appropriate cooking programs are found, they are displayed in a list.

A prerequisite is that the cooking programs are assigned a corresponding

identification when saved.

USB port

The unit is equipped with a USB port (USB 2.0).

HACCP logs can be exported via the USB port.

A wireless or corded barcode scanner (optional) can be connected to the

USB port.

HACCP logging

All cooking steps are recorded with a log number in the HACCP log.

The data are exported via the USB port.

VideoAssist

VideoAssist can be used to display videos with additional explanations

regarding operation.

Page 25

Description of the unit

4

Operating, control and display element functions

25

NOTICE

To see the operating and display elements, see next page.

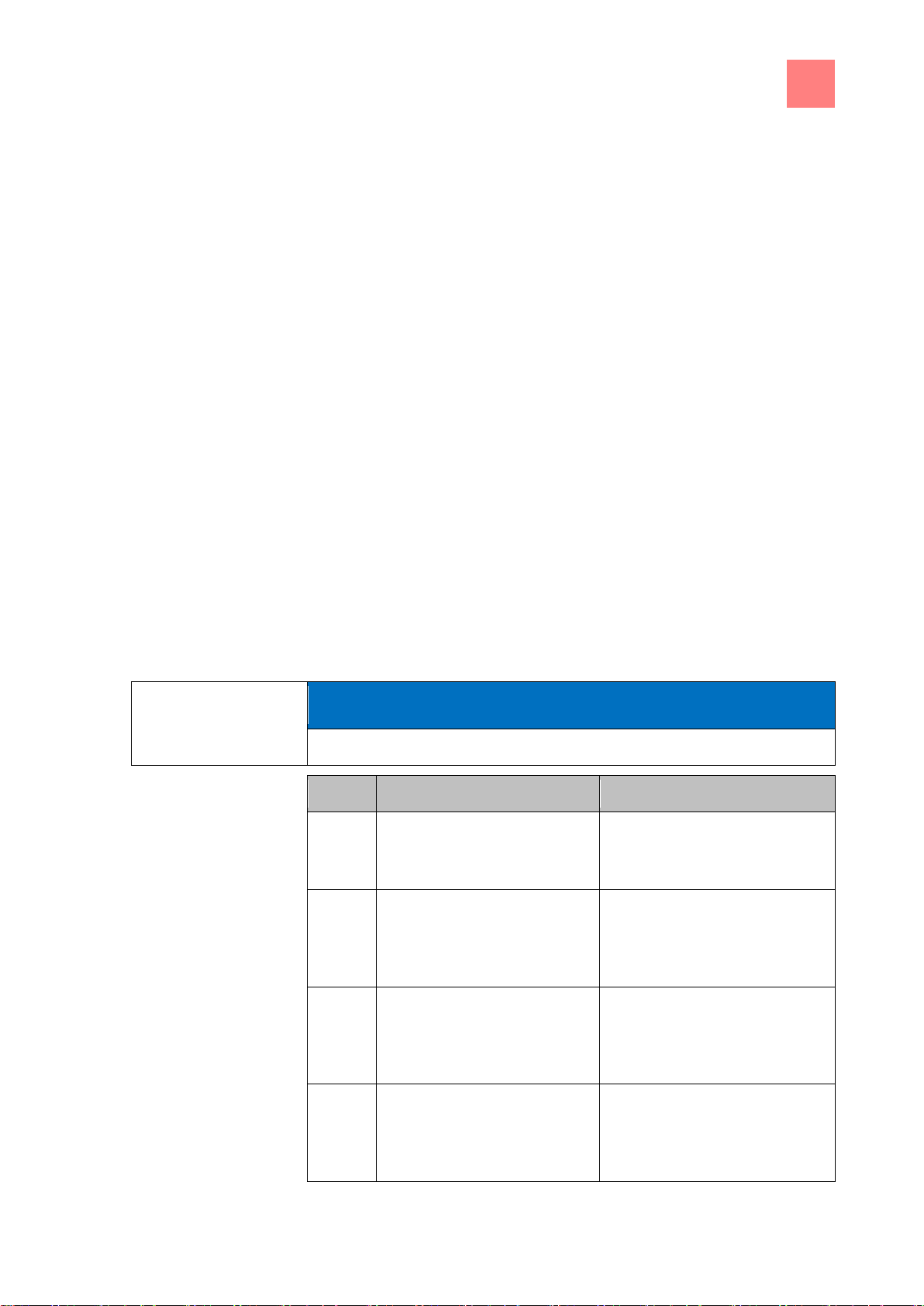

Symbol

Operating and display element

Function

On Off

button

▪ "I" switches on the unit

▪ "O" switches off the unit

"Automatic cooking" button

▪ Opens the

Automatic

cooking

menu for selection

of programs

"Manual cooking" button

▪ Opens the

Manual cooking

menu for selection of the

cooking modes

"Equipment functions" button

▪ Opens the

Equipment

function

menu for selection

of cleaning and settings

4.2.10

4.2.11

4.2.12

4.3

ChefsHelp

Using ChefsHelp, information in the form of text and image can be added to

a specific cooking step at a specific point in time.

WaveClean automatic cleaning

With WaveClean automatic cleaning, the cooking zone is cleaned with the

aid of a cleaning cartridge intended specifically for the program and then

rinsed clean.

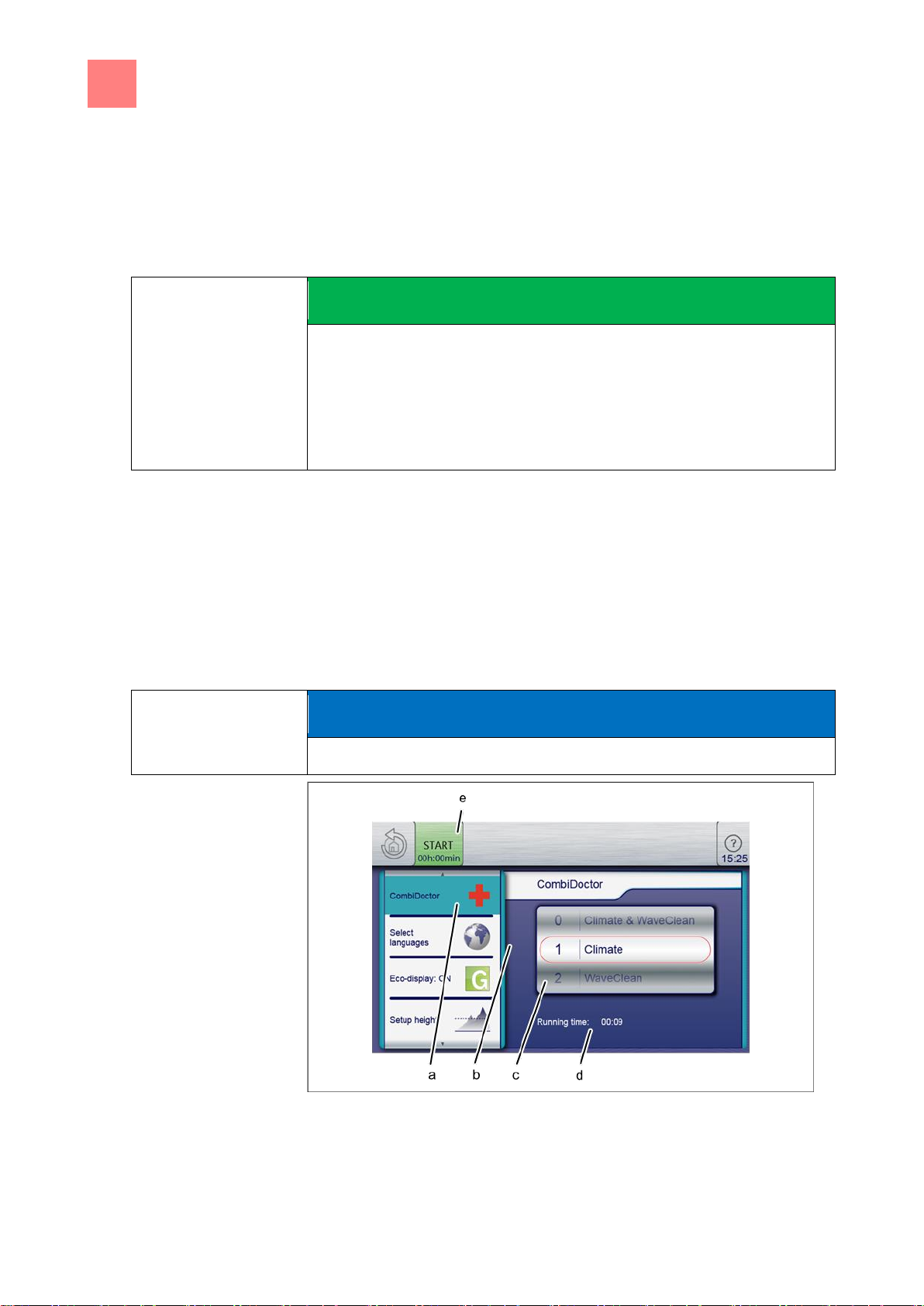

CombiDoctor (self-diagnostic program)

CombiDoctor uses a selectable self-diagnostic program to check the

components used for climate control and cleaning.

Operating, control and display element

functions

Page 26

4

Description of the unit

Application

26

Symbol

Operating and display element

Function

Language selection

button

▪ Indicates that the operating

language for the unit can be

selected here by tapping a

country's flag

Selection and the number of

selectable languages can be

specified in the

Equipment

functions

menu in the settings

field "Languages".

Back

button

▪ Tapping once returns the

user to the previous menu

▪ Tapping twice returns the

user directly to the main

menu

FlexiHelp

button

▪ Displays the help texts for

the active menu or window.

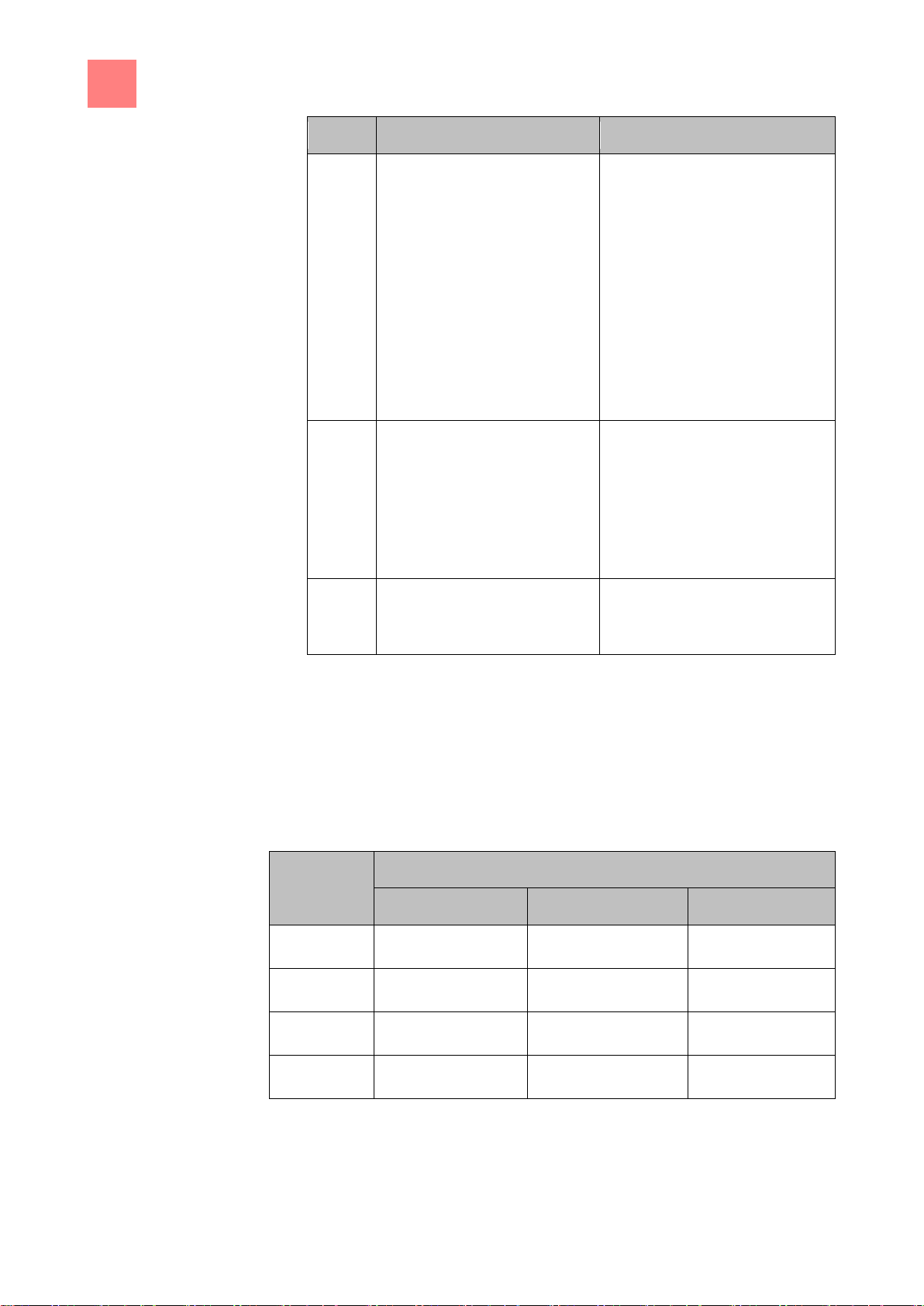

Version

Plate diameter

26 cm (10.24 in)

28 cm (11.02 in)

32 cm (12.1 in)

6.15

30 (11.81)

24 (9.45)

22 (8.66)

6.21

30 (11.81)

24 (9.45)

22 (8.66)

10.15

50 (19.69)

40 (15.75)

40 (15.75)

10.21

50 (19.69)

40 (15.75)

40 (15.75)

4.4

4.4.1

Application

Plate capacity during regeneration

Cooking time and cooking temperature depend on the number of plates.

Page 27

Description of the unit

4

Application

27

Version

Plate diameter

26 cm (10.24 in)

28 cm (11.02 in)

32 cm (12.1 in)

20.15

100 (39.37)

80 (31.5)

80 (31.5)

20.21

120 (47.24)

120 (47.24)

80 (31.5)

on

1/1 GN grate

Tray rack or tray

trolley

Version

Max. per tray

(kg) (lbs)

Max. per unit

(kg) (lbs)

6.15

15

33

50

110

6.21

15

33

50

110

10.15

15

33

80

176

10.21

15

33

80

176

20.15

15

33

150

330

20.21

15

33

150

330

Type of cooking

Standard value

(°C) (°F)

Setting range

(°C) (°F)

Change

increments (°C)

Steaming

100

212

0 - 99

86 - 320

1-steps

Combisteaming

150

302

30 - 250

86 - 482

1-steps

Hot air

180

356

30 - 250

86 - 482

1-steps

Regeneration

50

122

30 - 150

86 - 302

1-steps

4.4.2

4.4.3

Loading capacity

Tray rack trolley and tray trolley

Temperature standard setting

The setting range for the cooking zone temperature depends on the type of

cooking.

Page 28

4

Description of the unit

Chef’s Touch equipment controls

28

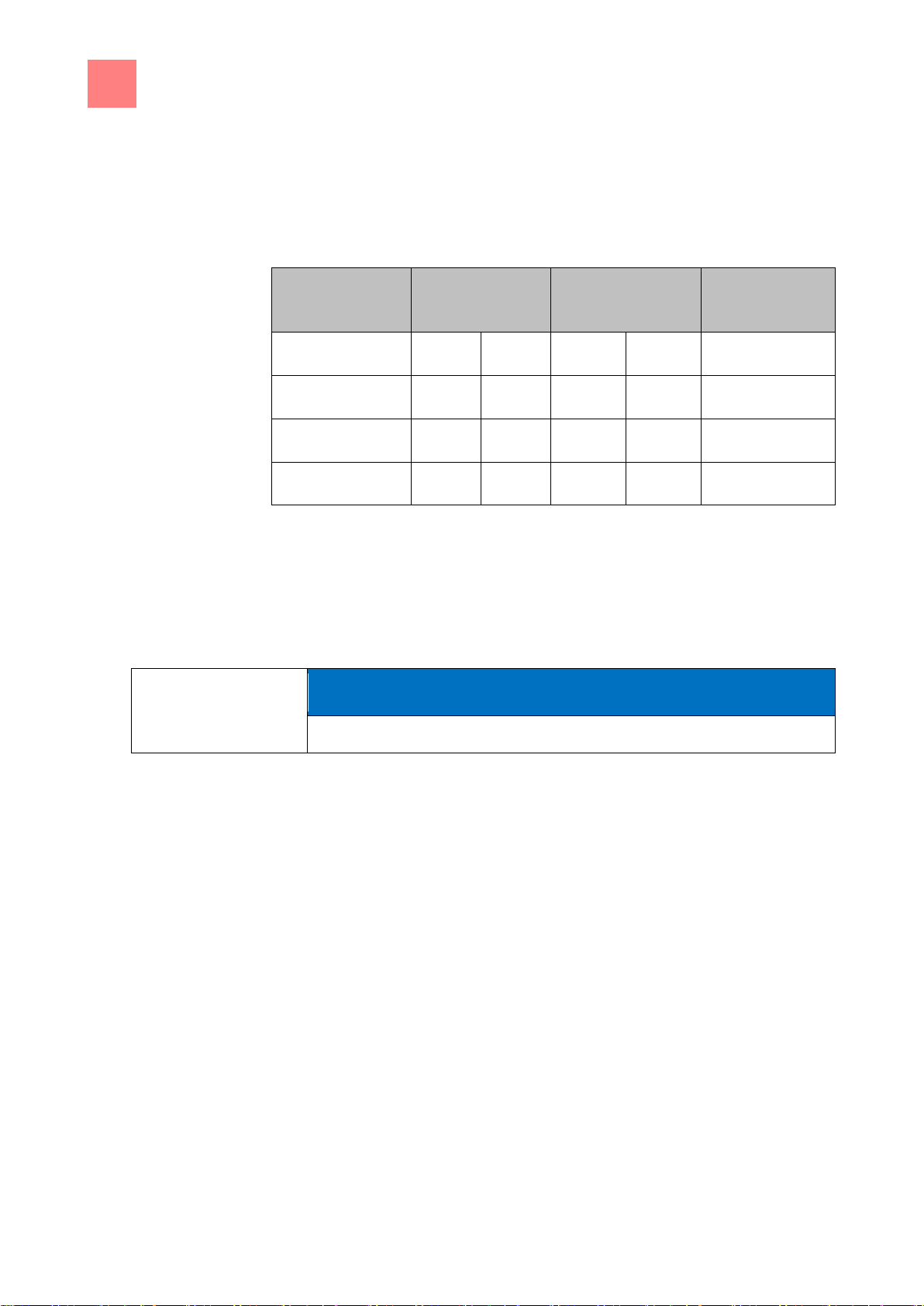

Type of cooking

Standard value

(°C) (°F)

Setting range

(°C) (°F)

Change

increments (°C)

Steaming

70

158

0 - 99

32-210

1-steps

Combisteaming

70

158

0 - 99

32-210

1-steps

Hot air

70

158

0 - 99

32-210

1-steps

Regeneration

50

158

20 - 99

68-210

1-steps

NOTICE

The touchscreen can be operated with latex gloves.

4.4.4

4.5

4.5.1

Core temperature standard setting

The setting range for the core temperature depends on the type of cooking.

Chef’s Touch equipment controls

Touchscreen operation

The unit is operated solely from the touchscreen. Buttons, windows and

rollers are provided for settings.

Fields and buttons are operated by tapping, rollers by wiping. Tapping a

button once executes commands that operate the unit.

To change the page or the set value, use a wiping gesture up, down, to the

left or to the right with the fingertip after first tapping and then maintaining

contact with the field to be changed.

Page 29

Description of the unit

4

Chef’s Touch equipment controls

29

a

Back

button

e

"Manual cooking" button

b

Information bar

f

"Equipment functions" button

c

FlexiHelp

button

g

"Automatic cooking" button

d

Language selection

button

a

Back

button

d

Window

b

Information bar

e

Clean touchscreen

field

c

FlexiHelp

button

f

N

ext page

arrow symbol

g

f

e

d

a b c

Main menu

Equipment functions menu

Page 30

4

Description of the unit

Chef’s Touch equipment controls

30

a

Back

button

e

FlexiHelp

button

b

"autoChef" button

f

"Perfection" field

c

Barcode scanner

button

g

Next page

arrow symbol

d

Information bar

h

Separating bar

a

Back

button

d

"Hot air" field

b

Information bar

e

Next page

arrow symbol

c

FlexiHelp

button

f

Separating bar

Automatic cooking, AutoChef menu

Manual cooking menu

Page 31

Description of the unit

4

Chef’s Touch equipment controls

31

Display element

Function

Information bar

The information bar is the uppermost bar on

the touchscreen and visible at all times.

The information bar is used to display current

information, for instance, categories or

cooking programs.

Menu

Menus have a coloured border that identifies

the associated subject.

▪ Blue for equipment functions

and

▪ Violet for cooking functions.

Menus frequently contain vertical separating

bars to simplify wiping gestures.

Menus represent central entry points and

provide an overview of the selectable

functions and submenus.

Window

Windows have a coloured border and are

opened from menus or higher-level windows.

Functions are executed and settings

displayed in windows.

Depending on the function, there are several

window types, for instance, Find.

Field

Fields are areas in windows or menus

defined by separating bars.

Tapping fields opens functions and settings.

Button

Buttons are areas enclosed by borders in

windows or menus.

Tapping buttons confirms settings. Buttons

control functions and are used to navigate in

4.5.2

Display elements

The following table lists the basic display elements of the unit's control

system with examples.

Page 32

4

Description of the unit

Chef’s Touch equipment controls

32

Display element

Function

menus and windows.

Page

Pages are the areas with content in windows

and menus. Several pages can follow one

another in sequence.

An arrow symbol displays further pages.

Changing to the next or the previous page is

accomplished by wiping up or down.

Tab

A

blue

and a

green

tab are located on the left

side of the touchscreen. The tabs are

available only in the cooking step display.

Tapping the tabs offers quick access to

equipment functions and cooking program

functions.

Display

Displays are information-containing areas in

windows.

Displays show entries and current information

some of which may be operated by tapping.

Symbol

Symbols are graphical elements in windows

and in the toolbar.

Symbols indicate current states and possible

functions some of which may be operated by

tapping.

Roller

Rollers are areas where settings can be

made by means of wiping gestures.

Page 33

Putting the unit into service

5

33

5

Requirement

Putting the unit into service

➢ Any remaining packaging removed from the cooking zone

➢ Protective film pulled off the housing

a) Clean the unit.

b) Enter the data on the nameplateNameplate [➙ 84].

c) Switch on the unit and select the cooking program

"Manual cooking: menu.

d) Set the temperature to 200°C (392°F) Setting the cooking temperature

[➙ 48].

⇨ Operate the unit for 20 minutes.

Combisteaming

in the

Page 34

6

Operating the unit

Switching the unit on and off

34

NOTICE

Explanatory video clips can be selected under VideoAssist by press the

Help button.

NOTICE

Fans may continue to run for cooling; the unit's control system is

disconnected from power.

6

6.1

6.1.1

6.1.2

Operating the unit

Switching the unit on and off

Switching on

a) Press "I" on the

⇨ The unit is now on

⇨ The control system starts the power-on process automatically. The

progress bar at the lower edge of the touchscreen displays the status

of the process.

⇨ The main menu appears after 1 minute and the unit is ready for use.

Switching off

On Off

button.

a) Press "O" on the

On Off

⇨ The unit is now off.

button.

Page 35

Operating the unit

6

Opening and closing the cooking zone door

35

NOTICE

The single-stage door latch is standard on sizes 6 and 10.

NOTICE

The two-stage door latch is standard on size 20, and optional on sizes 6

and 10.

NOTICE

If the door handle is released, it returns automatically to its initial position.

6.2

6.2.1

6.2.2

Requirement

Opening and closing the cooking zone

door

Opening the single-stage door latch

Opening the single-stage door latch

a) Rotate the door handle anti-clockwise or clockwise.

⇨ The cooking zone door opens.

a) Open the cooking zone door completely.

Closing the single stage door latch

Closing the single stage door latch

➢ Door handle in initial position

a) Close the cooking zone door with pressure.

Page 36

6

Operating the unit

Opening and closing the cooking zone door

36

NOTICE

On size 6 and size 10, first rotate the door handle anti-clockwise.

NOTICE

If the door handle is released, it returns automatically to its initial position.

6.2.3

6.2.4

Requirement

⇨ The cooking zone door is closed.

Opening the two-stage door latch

Opening the two-stage door latch

a) Rotate the door handle to a horizontal position.

⇨ The cooking zone door opens, but is still held.

b) Continue rotating the door handle upwards.

⇨ The cooking zone door is no longer held.

a) Open the cooking zone door completely.

Closing the two-stage door latch

Closing the two-stage door latch

➢ Door handle in initial horizontal position

a) Close the cooking zone door with pressure.

⇨ The cooking zone door latches.

b) Rotate the door handle downwards.

⇨ The cooking zone door is closed.

Page 37

Operating the unit

6

Loading and emptying the unit

37

CAUTION

Risk of burns from hot liquid

a) Never insert a food-carrying tray with cooking liquid above eye level.

b) Use only suitable trays to hold food. The food-containing trays must

rest securely on the support brackets.

c) Always insert the food-containing trays into the U-rails.

CAUTION

Risk of physical damage and personnel injury from exceeding the loading

capacity

a) Do not exceed the maximum loading capacity.

NOTICE

To not use bent or damaged support racks.

6.3

6.3.1

Loading and emptying the unit

Loading and emptying

Loading

a) Open the cooking zone door.

b) Insert food-containing trays into the support racks.

c) Close the cooking zone door.

d) Start the cooking process.

Emptying

a) Open the cooking zone door.

b) Remove the food-containing trays.

c) Remove all food residues from the drain screen.

d) Leave the cooking zone door slightly ajar.

⇨ This extends the service life of the door seal.

⇨ No moisture builds up in the cooking zone.

Page 38

6

Operating the unit

Loading and emptying the unit

38

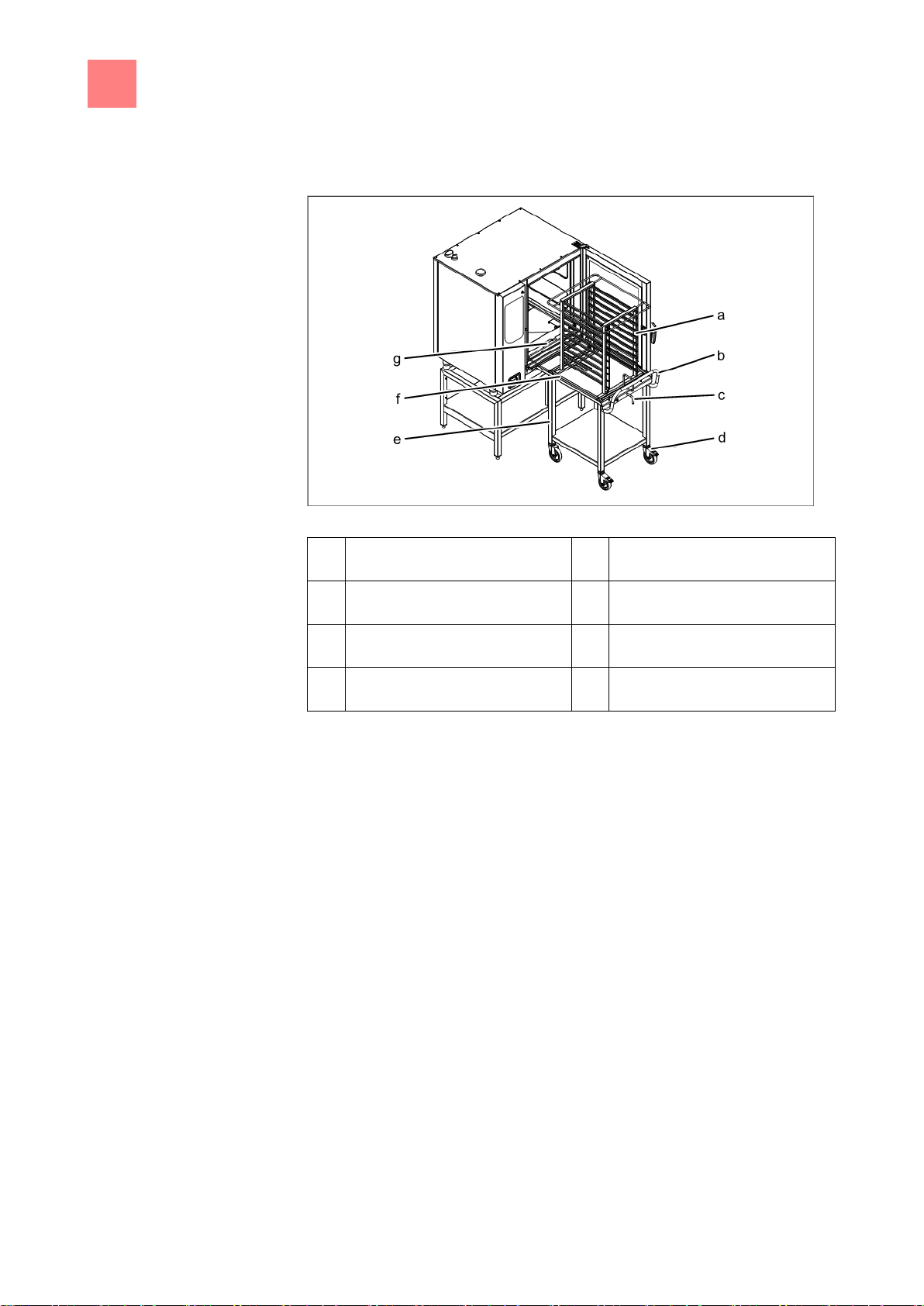

a

Tray rack

e

Tray rack trolley

b

Push handle

f

Tray rack support plate

c

Lever

g

Guide rail

d

Locking casters

6.3.2

Requirement

Loading and emptying with a tray rack trolley

Loading and emptying with a tray rack trolley

Loading with a tray rack trolley

➢ Remove support racks and place guide rails on pins.

➢ Food-containing trays resting securely on the tray rack

a) Open the cooking zone door.

b) Rotate the lever on the tray rack trolley.

⇨ The tray rack is secured to prevent its rolling down.

⇨ Check that the tray rack is locked in place by pulling on it slightly.

c) Load the tray rack.

d) Position the tray rack trolley at the unit.

⇨ Lock the casters to prevent the trolley's rolling away.

e) Rotate the lever.

⇨ The tray rack is now free to move.

f) Insert the tray rack completely until the rollers rest in the openings in the

guide rail.

g) Retract the tray rack support plate and secure in place with the lever.

h) Move the tray rack trolley away from the unit.

i) Close the cooking zone door.

Page 39

Operating the unit

6

Loading and emptying the unit

39

a

Tray rack

e

Cleaning cartridge holder

b

Push handle

f

Guide rail (left)

c

Tray trolley

g

Guide rail (right)

d

Locking casters

6.3.3

Requirement

j) Start the cooking process.

Emptying with a tray rack trolley

a) Open the cooking zone door.

b) Position the tray rack trolley at the unit.

⇨ Lock the casters to prevent the trolley's rolling away.

c) Insert the tray rack support plate and secure the tray rack on the plate.

d) Pull the tray rack onto the tray rack trolley and secure in place.

e) Release the locking casters and move the tray rack trolley away from the

unit.

f) Remove all food residues from the drain screen.

g) Leave the cooking zone door slightly ajar.

⇨ This extends the service life of the door seal.

⇨ No moisture builds up in the cooking zone.

Loading and emptying with a tray trolley

Loading and emptying with a tray trolley

Loading with a tray trolley

➢ Food-containing trays resting securely on the tray trolley

a) Load the tray trolley.

Page 40

6

Operating the unit

Loading and emptying the unit

40

b) Insert the tray trolley completely.

c) Pull the push handle out of the tray trolley.

d) Close the cooking zone door.

e) Start the cooking process.

Emptying with a tray trolley

a) Open the cooking zone door.

b) Insert the push handle into the tray trolley.

c) Retract the tray trolley.

d) Remove all food residues from the drain screen.

e) Leave the cooking zone door slightly ajar.

⇨ This extends the service life of the door seal.

⇨ No moisture builds up in the cooking zone.

Page 41

Operating the unit

6

Using the core temperature sensor

41

WARNING

Risk of injury from a bursting core temperature sensor

a) The core temperature sensor can burst as the result of overheating of

the measuring tip.

b) Never heat a core temperature sensor with a cigarette lighter or other

heat source.

NOTICE

Measuring the core temperature is recommended for all types of cooking to

achieve an optimal result.

The unit has a core temperature sensor in the cooking zone and can be

equipped with an optional connection for an external core temperature

sensor.

6.4

6.4.1

248°F

140°F

104°F

140°F

Using the core temperature sensor

Measuring with a 4-point core temperature

sensor

Core temperature sensor with four measuring points

a) Completely insert the core temperature sensor into the food to be

cooked.

b) Insert the core temperature sensor into the thickest section of the food to

be cooked.

c) When cooking food with a bone, insert the core temperature sensor

close to the bone.

d) When cooking longer pieces of food, insert the core temperature sensor

across the food to a void a hole in the centre of the slice.

e) When cooking fowl, insert the core temperature sensor into the inside of

the leg.

Page 42

6

Operating the unit

Using the core temperature sensor

42

NOTICE

When cooking frozen food, measuring with a sous-vide core temperature

sensor is not possible.

6.4.2

6.4.3

Measuring with a sous-vide core temperature

sensor

Sous-vide core temperature sensor with sous-vide pads

a) Attach foam rubber or expanded rubber sous-vide pads to the vacuum-

packed food to be cooked.

b) Always insert the sous-vide core temperature sensor through the sous-

vide pads completely into the food to be cooked.

c) Insert the sous-vide core temperature sensor into the thickest section of

the food to be cooked.

d) When cooking food with a bone, insert the sous-vide core temperature

sensor close to the bone.

e) When cooking longer pieces of food, insert the sous-vide core

temperature sensor across the food to a void a hole in the centre of the

slice.

f) When cooking fowl, insert the sous-vide core temperature sensor into

the inside of the leg.

Measuring the core temperature when cooking

frozen food

Drilling a hole with a hand drill

Page 43

Operating the unit

6

Making the basic settings

43

6.5

6.5.1

Requirement

1. Use a hand drill to make a hole for inserting the sensor.

2. Place the food to be cooked on the baking sheet or into the cooking pan.

3. Place the cooking sheet or cooking pan into the unit.

4. Insert the core temperature sensor into the food being cooked.

Making the basic settings

The basic settings for operation can be displayed and changed by entering

the password "111".

Opening the Setting menu

PIN entry window

➢ The unit is on

➢ The main menu is displayed

a) Tap the "Equipment functions" button.

⇨ The

Equipment functions

menu is displayed.

b) Tap the "Settings" field.

⇨ The

PIN

window opens.

c) Enter the password.

d) Tap the

⇨ The

Confirm

button.

Equipment settings

menu is displayed.

⇨ The basic settings can be changed.

The unit has default settings when it is delivered.

These fields can be modified in the " Setting" window:

▪ Equipment information

▪ Export HACCP

Page 44

6

Operating the unit

Making the basic settings

44

NOTICE

The equipment information contains data on the software and hardware

version, the serial number of the unit and contact data.

6.5.2

Requirement

▪ Settings for Favourites

▪ CombiDoctor

▪ Select languages

▪ Installation height

▪ Audio settings

▪ Select signal tones

▪ Date and time

▪ Select cookbook

▪ Import the manufacturer's cookbook

▪ Lock the cookbook

▪ Import HansDampf programs

▪ Software update

▪ Import additional content

▪ Export log data

▪ Setting units

These fields are switched on or off in the "Setting" window:

▪ QualityControl on or off

▪ Inhibit operation on or off

Retrieving equipment information

➢ The

a) Tap the "Equipment information" field.

Setting

⇨ The

menu is displayed

Equipment information

window is displayed.

⇨ Equipment information can now be read.

Page 45

Operating the unit

6

Making the basic settings

45

NOTICE

Observe the displayed date and time format carefully. If values are invalid,

the entry is not accepted.

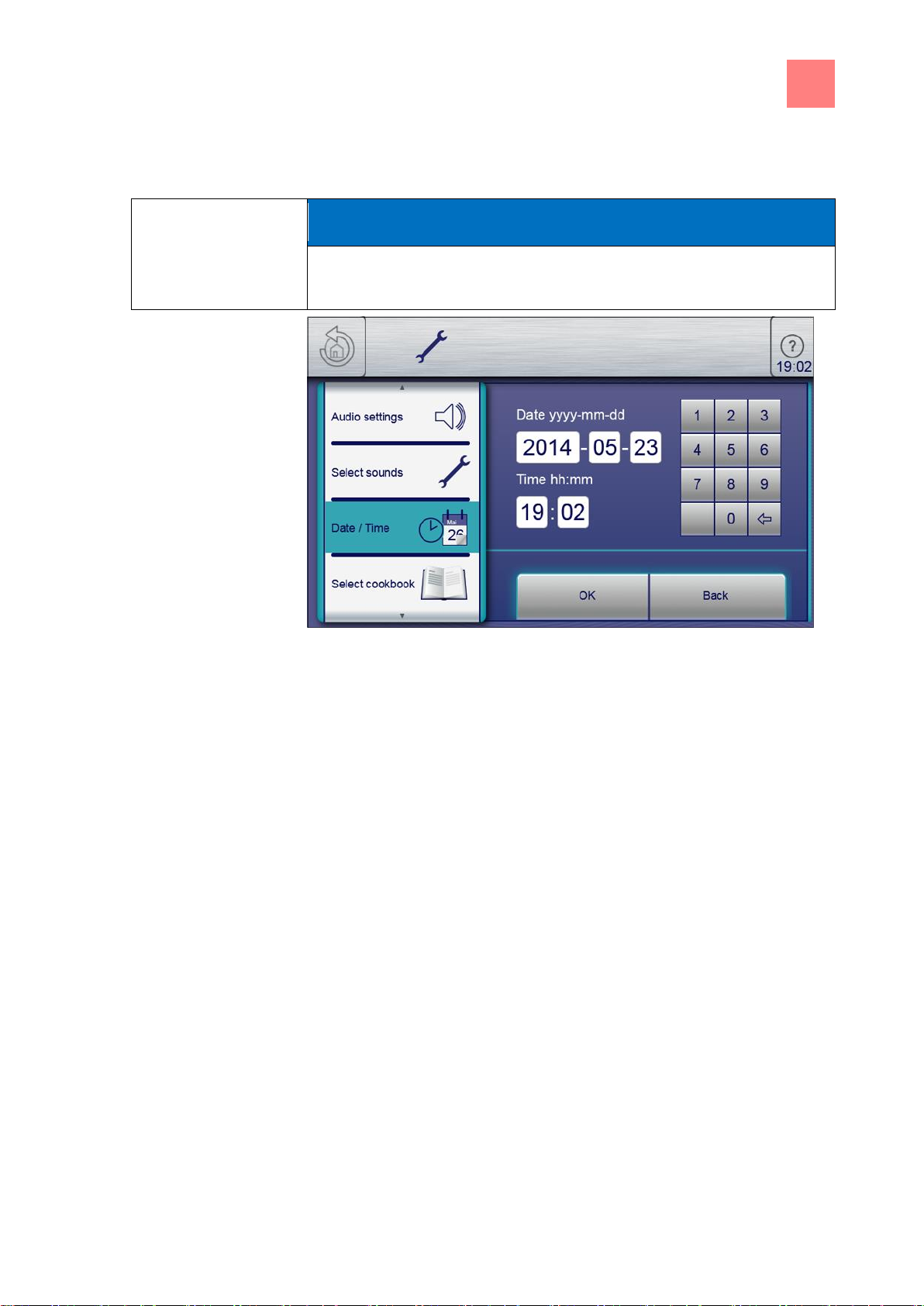

6.5.3

Requirement

Setting the date and time

Date and time setting window

➢ The

Settings

menu is displayed

a) Tap the "Set date and time" field.

⇨ The

⇨ The

Setting

Keypad

window opens.

opens.

b) Enter the date and time.

c) Tap the Confirm button.

⇨ The

Keypad

closes.

⇨ The date and time are set.

Page 46

6

Operating the unit

Making the basic settings

46

NOTICE

A maximum of 5 languages can be specified for language selection in the

main menu.

NOTICE

Highlighted fields represent the specified languages.

Fields that are not highlighted are languages that have not been specified.

NOTICE

The currently set language cannot be deselected.

6.5.4

Requirement

Presetting the language selection

Language setting window

➢ The

Setting

menu is displayed

a) Tap the "Select language" field.

⇨ The

Languages

menu is displayed.

b) Select or deselect the language by tapping the fields with the country's

flag.

⇨ The selected languages are displayed.

c) Tap the "OK" button.

⇨ Languages have been preset for language selection and are available in

the main menu.

Page 47

Operating the unit

6

Making the basic settings

47

6.5.5

6.5.5.1

Requirement

6.5.5.2

Requirement

Activating inhibit operation

Activating and cancelling inhibit operation

➢ The "Inhibit operation ON" function is activated in the

Setting

menu

a) Tap and hold the centre of the information bar for 3 seconds.

⇨ The FlexiHelp button disappears and the lock symbol appears in the

information bar.

⇨ The touchscreen is locked.

Cancelling inhibit operation

Unlock the main menu by entering the PIN

➢ The touchscreen is locked

a) Tap the lock symbol.

⇨ The Keypad opens.

b) Enter the password.

⇨ Inhibit operation is cancelled by entering the password "369".

⇨ The lock symbol and the keypad disappear. The

FlexiHelp

button

appears in the information bar and the touchscreen is unlocked.

Page 48

6

Operating the unit

Basic functions

48

NOTICE

The temperature range differs, depending on the cooking mode. At a

cooking temperature outside the allowed temperature range, the display

turns red.

a

Temperature

field

c

Roller

b

Setting

window

d

Confirm

button

6.6

6.6.1

Requirement

Basic functions

Setting the cooking temperature

Cooking temperature setting window

➢ Cooking program selected

a) Tap the

⇨ The

b) Tap the

Cooking temperature

Setting

Temperature

window is displayed.

field.

field.

c) Using a wiping gesture, set the rollers to the desired temperature.

⇨ Wipe up / down to increase / decrease the cooking temperature.

d) Tap the

⇨ The

⇨ The

Confirm

Setting

button.

window closes.

Cooking mode

window displays the set cooking temperature.

⇨ The cooking temperature is set.

Page 49

Operating the unit

6

Basic functions

49

a

Cooking time

field

c

Continuous operation

button

b

Setting

window

d

Confirm

button

6.6.2

Requirement

Setting the cooking time and continuous

operation

Setting the cooking time to continuous operation

➢ Cooking program selected

a) Tap the

⇨ The

b) Tap the

c) Tap the

⇨ The

⇨ The

Cooking time

Setting

field.

window is displayed.

Continuous operation

Confirm

Setting

Cooking mode

button.

window closes.

window displays the cooking time.

button.

⇨ The cooking time is set to continuous operation and will end after

24 hours.

Page 50

6

Operating the unit

Basic functions

50

a

Cooking time

field

d

Cooking time

button

b

Setting

window

e

Confirm

button

c

Roller

Requirement

Setting the cooking time

Setting the cooking time

➢ Cooking program selected

a) Tap the

⇨ The

b) Tap the

Cooking time

Setting

window is displayed.

Cooking time

field.

button.

c) Using a wiping gesture, set the rollers to the desired temperature.

⇨ Wipe up / down to increase / decrease the cooking time.

d) Tap the

⇨ The

⇨ The

Confirm

Setting

button.

window closes.

Cooking mode

window displays the cooking time.

⇨ The cooking time is set.

Page 51

Operating the unit

6

Basic functions

51

a

Core temperature

field

d

Temperature

roller

b

Setting

window

e

Confirm

button

c

Core temperature sensor type

roller

6.6.3

Requirement

Setting the core temperature

Core temperature setting window for internal and external display

➢ Cooking program selected

➢ Cooking time set

a) Tap the

⇨ The

b) Tap the

⇨ The

Cooking time

Cooking time

field.

setting window is displayed.

Core temperature

Core temperature

button.

setting window is displayed.

c) Using a wiping gesture, set the rollers to the desired temperature.

⇨ Wipe up / down to increase / decrease the core temperature.

d) Tap the

⇨ The

⇨ The

Confirm

Setting

button.

window closes.

Cooking time

field changes to the

Core temperature

field.

Page 52

6

Operating the unit

Basic functions

52

a

Fan setting

field

d

Fan rotation direction

roller

b

Setting

window

e

Confirm

button

c

Fan speed

roller

6.6.4

Requirement

6.6.5

Requirement

Setting the fan speed and direction of rotation

Setting the fan speed and direction of rotation

➢ Cooking program selected

a) Tap the

Fan setting

field.

⇨ The Setting window opens.

b) Using a wiping gesture, set the

c) Using a wiping gesture, set the

Fan speed

roller to the desired value.

Fan rotation direction

roller to the desired

value.

d) Tap the

⇨ The fan speed and fan rotation direction are set.

Confirm

button.

Preparing the USB flash drive for initial use

➢ USB flash drive is formatted

➢ USB flash drive not write-protected

a) Create a folder structure for importing and exporting.

b) Create a folder named "autoChefImages".

⇨ Data exchange of photos in PNG format, resolution of 95x69 pixels,

maximum resolution 150 KB.

c) Create a folder named "FCBrowserFiles".

⇨ Data exchange of text in HTML format.

d) Create a folder named "FCImport".

Page 53

Operating the unit

6

Equipment functions

53

6.6.6

Requirement

Requirement

6.6.7

Requirement

6.7

⇨ Data exchange from cookbooks.

e) Create a folder named "MMIContent".

⇨ Data exchange of additional imported content.

f) Create a folder named "MMiUpdate".

⇨ Data exchange of update files.

⇨ Once the folder structure has been completed, the USB flash drive is

ready for use.

Inserting and removing a USB flash drive

Inserting a USB flash drive

➢ USB flash drive with a minimum of 2 GB and maximum of 32 GB

available storage capacity (not included with delivery)

➢ USB flash drive not write-protected

a) Insert the USB flash drive.

⇨ The USB flash drive is ready after at most 20 seconds.

Removing the USB flash drive

➢ Exporting or importing of data completed

a) Remove the USB flash drive.

Exporting the HACCP log

➢ USB flash drive inserted

➢ User logged in with password under equipment settings

a) Tap the "Export HACCP" field.

⇨ The

b) Tap the

Operating instructions

Confirm

button.

window opens.

⇨ The HACCP log is exported to the USB flash drive.

⇨ The

c) Tap the

⇨ the

⇨ The HACCP log is exported to the USB flash drive.

Confirm

Confirm

Confirm

window opens.

button.

window closes.

Equipment functions

Various functions or settings can be selected in the "Equipment functions"

menu.

Page 54

6

Operating the unit

Manual cooking

54

NOTICE

All equipment functions can also be accessed from within a cooking

program by tapping the

blue

tab.

6.7.1

Requirement

6.8

6.8.1

Requirement

6.8.2

Requirement

Opening the Equipment function menu

➢ The unit is on

➢ The main menu is displayed

a) Tap the Equipment functions button.

⇨ The Equipment functions menu is displayed.

Manual cooking

Cooking modes and other functions are available in the manual cooking

mode. Selecting one of the components automatically creates a single-step

cooking program.

Opening the Manual cooking menu

➢ The unit is on

➢ The main menu is displayed

a) Tap the "Manual cooking" button.

⇨ The

Manual cooking

menu is displayed.

Creating a cooking program

➢ The unit is on

➢ The

Manual cooking

➢ Cooking mode selected

a) Tap the

⇨ The

Cooking temperature

Setting

window is displayed.

b) Using a wiping gesture, set the rollers to the desired value.

c) Tap the

⇨ The

d) Tap the

⇨ The

e) Tap the

Confirm

Setting

button.

window closes.

Cooking time

Setting

window is displayed.

Continuous operation

Core temperature

f) Using a wiping gesture, set the rollers to the desired value.

menus is displayed

field.

field.

button or the

button.

Cooking time

button or the

Page 55

Operating the unit

6

User's own cooking programs

55

NOTICE

Up to 20 steps can be added to a cooking program.

6.9

6.9.1

Requirement

g) Tap the

Confirm

button.

⇨ The

Setting

window closes.

h) Tap cooking zone humidity.

⇨ The

Setting

window is displayed.

i) Using a wiping gesture, set the roller to the desired value.

j) Tap the

⇨ The

Confirm

Setting

button.

window closes.

k) Use a wiping gesture to change to the next page and make further

settings.

l) Tap the

⇨ The

Fan

field.

Setting

window is displayed.

m) Set the fan speed and direction of rotation.

n) Using a wiping gesture, set the rollers to the desired value.

o) Tap the

⇨ The

p) Tap the

⇨ The

q) Save or start the cooking program.

Confirm

Setting

green

tab.

green

tab opens.

button.

window closes.

User's own cooking programs

Cooking modes and other functions are available in the

menu. Using these components, users can create their own programs.

Creating a cooking program

➢ The

a) Tap the field for the desired cooking mode.

b) Modify the desired settings for the first step.

Adding cooking program steps

Manual cooking

menu opens

⇨ The first step of the cooking program is created.

⇨ The cooking program step display reads "Step 1 of 1".

⇨ The first step of the cooking program has been created.

Manual cooking

Page 56

6

Operating the unit

User's own cooking programs

56

NOTICE

If a cooking program has only one step, it cannot be deleted. The function

is not active.

Requirement

Adding a step in the menu item

➢ Cooking program is created and is open

a) A wiping gesture upward opens the next page.

⇨ The next page is displayed.

b) Tap the field " Add step at the left".

or

a) the field "I had step at the right".

⇨ The "New step" window opens.

b) Select the cooking mode or function in the window by tapping it.

⇨ The cooking program step display in the window shows the current

position of the new step in the cooking program.

c) Modify the settings for the step.

⇨ The new step is added.

Deleting a cooking program step

Page 57

Operating the unit

6

User's own cooking programs

57

Requirement

Deleting a step

➢ Cooking program is created and is open

a) Select the step.

b) A wiping gesture upward opens the next page.

⇨ The next page for the step is displayed.

c) Tap the "Delete step" field.

⇨ The

Delete

window is displayed.

d) Tap the "Yes" button.

⇨ This deletes the step.

⇨ The positions of the remaining steps in the cooking program are

updated.

⇨ The step is deleted.

Page 58

6

Operating the unit

User's own cooking programs

58

NOTICE

Cooking programs that have been created can be saved prior to starting or

after completion of the cooking program.

NOTICE

To save a cooking program, at least one cooking program name and one

category must be specified.

a

Green

tab

e

"Subcategory" field

b

"Save cooking program" field

f

"Image" field

c

"Cooking program name" field

g

Next page

arrow symbol

d

"Category" field

h

"Save" button

6.9.2

Requirement

6.9.2.1

Saving the cooking program

Green tab and cooking program in the Save window

➢ Cooking program is created and displayed

a) Tap the

⇨ The

green

tab.

Tab

window is open.

b) Tap the "Save cooking program" field.

⇨ The

Save

window is open.

Saving the cooking program name

a) Tap the "Cooking program name" field.

Page 59

Operating the unit

6

User's own cooking programs

59

6.9.2.2

6.9.2.3

6.9.2.4

6.9.2.5

⇨ The

Keypad

menu is displayed.

b) Views the keys to enter the desired program name.

c) Tap the

⇨ The

⇨ The program name is displayed in the

Confirm

Keypad

button.

menu closes.

Save

window.

Entering a category

a) Tap the "Category" field.

⇨ The

b) Tap the field with the desired

Automatic cooking (autoChef)

Category

menu is displayed.

.

⇨ The category is set.

⇨ The

⇨ The category is displayed in the

Automatic cooking (autoChef)

Save

menu closes.

window.

Entering a subcategory (optional)

a) Tap the "Subcategory" field.

⇨ The

b) Tap the field with the desired

Subcategory

menu is displayed.

Subcategory

.

⇨ The subcategory is set.

⇨ The

⇨ The subcategory is displayed in the

Subcategory

menu closes.

Save

window.

Assigning an image (optional)

a) Tap the "Image" field.

⇨ The

Image

menu is displayed.

b) Select a photo by tapping it.

c) Select the location to save the photo.

d) Tap the "Photos in unit" button or the "Photos on USB flash drive"

button.

⇨ The photo is selected.

⇨ The

⇨ The name of the photo is displayed in the Save window.

Image

menu closes.

Assigning a recipe (optional)

a) Tap the "Recipe" field.

⇨ The

Recipe

menu is displayed.

b) Tap the "Empty recipe" field.

Page 60

6

Operating the unit

User's own cooking programs

60

6.9.2.6

6.9.2.7

6.9.2.8

6.9.2.9

c) Select the save location.

d) Tap the "Recipes in unit" button or the "Recipes on USB flash drive"

button.

⇨ The recipe is set.

⇨ The

⇨ The name of the recipe is displayed in the

e) Tap the "Save" button in the

Recipe

menu closes.

Save

window.

Save

window.

⇨ The cooking program is saved.

⇨ The

Confirm

window is displayed.

f) Tap the Confirm button.

⇨ The

⇨ The cooking program is saved.

green

tab closes.

Selecting favourites (optional)

a) Tap the "Show favourites" field.

⇨ The

Show favourites

menu is displayed.

b) Tap the "Yes" button or the "No" button.

⇨ Tapping Yes displays the cooking program in the Favourites menu.

Selecting characteristics of the food to be

cooked (optional)

a) Tap the "Frozen food" field.

⇨ The

Frozen food

menu is displayed.

b) Tap the "Yes" button or the "No" button.

⇨ Tapping Yes selects the food to be cooked as a frozen food.

Assigning an identification (optional)

a) Tap the "Identification" field.

⇨ The

b) Tap the

Identification

menu is displayed.

Barcode scanner

button.

⇨ Scan the barcode and assign to a cooking program or to food to be

cooked.

Selecting QualityControl

a) Tap the "QualityControl" field.

⇨ The

QualityControl

menu is displayed.

b) Tap the "No" button.

Page 61

Operating the unit

6

Automatic cooking (autoChef)

61

NOTICE

Previously exported cooking programs on the USB flash drive will be

overwritten.

6.9.3

Requirement

6.10

6.10.1

Requirement

⇨ QualityControl is switched off for the cooking program.

c) Tap the "Yes" button.

⇨ Tapping Yes sets the cooking program for a minimal amount of food

to be cooked.

⇨ QualityControl automatically adjusts the cooking time for a larger charge.

Exporting a cooking program

➢ Cooking program open

➢ Cooking program saved

➢ USB flash drive inserted

a) Tap the

⇨ The

b) Tap the "Export cooking programs" field.

⇨ The

c) Read and then close the displayed operating instructions.

d) Close the

green

tab.

Tab

window is open.

Operating instructions

Operating instructions

window opens.

window.

e) Tap the

Confirm

button.

⇨ The cooking program is exported to the USB flash drive.

⇨ The

f) Tap the

⇨ The

⇨ The cooking program is exported.

Confirm

Confirm

window is displayed.

button.

green tab

window closes.

Automatic cooking (autoChef)

In the "Automatic cooking" mode, all cooking programs stored in the unit are

available. The cooking program is selected in the

Opening the Automatic cooking menu

➢ The unit is on

➢ The main menu is displayed

a) Tap the "Automatic cooking" button.

Automatic cooking

menu.

⇨ The

Automatic cooking (autoChef)

menu is displayed.

Page 62

6

Operating the unit

Automatic cooking (autoChef)

62

NOTICE

Arrow symbols in a window always display the next or previous page. A

wiping gesture upward or downward opens the corresponding window.

a

"autoChef" button

d

Category

field

b

BarcodeScan

button

e

Next page

arrow symbol

c

Information bar

f

Separating bar

6.10.2

Requirement

Finding and opening a cooking program

Finding and opening a cooking program by category

Cooking programs can be found in the

Automatic cooking

menu by category

and subcategory.

Automatic cooking menu

➢ The unit is on

➢ Main menu is displayed

a) Tap the "Automatic cooking" button.

⇨ The

Automatic cooking

menu is displayed.

⇨ An additional menu page is displayed.

b) Tap the field with the desired category.

⇨ The Subcategory menu is displayed.

c) Tap the field with the desired subcategory.

⇨ The Recipe menu with all recipes in the subcategory is displayed.

d) Tap the field with the desired recipe.

⇨ The cooking program is selected and being loaded.

Page 63

Operating the unit

6

Automatic cooking (autoChef)

63

NOTICE

The current step in the cooking program is highlighted. Upon completion,

the following step automatically appears in the display.

Requirement

6.10.3

Requirement

⇨ The cooking program steps are displayed.

⇨ The cooking program is open.

Finding and opening a cooking program in the cookbook

All cooking programs are saved in the cookbook in alphabetical order.

Find cooking program window

➢ The unit is on

➢ Main menu is displayed

a) Tap the "Automatic cooking" button.

⇨ The Category menu is displayed.

b) Tap the "autoChef" button in the information bar.

⇨ The

c) Tap the

⇨ The

autoChef

window is displayed.

Find cooking program

Entry

window is displayed.

field.

d) Using the keypad, enter the letters for the name to be found.

⇨ A filtered list is displayed in the

Result

window.

e) Tap the field with the name found.

⇨ The cooking program is selected and being loaded.

⇨ The cooking program steps are displayed.

⇨ The cooking program is open.

Starting the cooking program

➢ Cooking program open

Page 64

6

Operating the unit

Automatic cooking (autoChef)

64

6.10.4

Requirement

a) Tap the "START" button in the information bar.

⇨ The cooking program starts.

⇨ The "START" button in the information bar changes to the "STOPP"

button.

⇨ The remaining cooking program time is displayed in the "STOPP"

button.

⇨ The cooking program is started.

Ending the cooking program

➢ Cooking program started

➢ Cooking program time has not elapsed

a) Tap the "STOPP" button in the information bar.

or

a) Wait for the cooking time to end.

⇨ Cooking program has ended.

⇨ The "STOPP" button in the information bar changes to the "START"

button

⇨ The cooking program has ended.

Page 65

Operating the unit

6

Automatic cooking (autoChef)

65

NOTICE

If the cooking zone door is not opened, the fan continues to run at a low

speed at intervals. This achieves even cooking.

NOTICE

Tabs available only within cooking programs. Tapping the tabs provides

faster access to their functions.

NOTICE

The current step in the cooking program is highlighted and can be modified.

All settings of a step can be modified.

NOTICE

After the settings are made, the modified cooking program can be saved.

The cooking program is overwritten if a new cooking program name is not

specified.

6.10.5

Requirement

Requirement

Modifying the cooking program

Modifying a cooking program after the program has started

➢ Cooking program started

➢ Cooking program has not elapsed

a) Modify the settings for the current step.

⇨ The modifications of the step become active immediately.

⇨ The modifications of the step are displayed.

b) Tap the "Continue" field.

⇨ The active step is being ended.

⇨ The next step is being started.

⇨ Steps advance in the

Settings

window.

⇨ The cooking program is modified.

Modifying a cooking program before the program has started

➢ Cooking program open

➢ Cooking program not started

a) Modify various steps.

b) Use a wiping gesture to reach the individual step to be modified.

c) Modify the settings for the step.

Page 66

6

Operating the unit

Automatic cooking (autoChef)

66

NOTICE

Previously exported cooking programs on the USB flash drive will be

overwritten.

6.10.6

Requirement

6.10.7

⇨ The modifications of the step are displayed.

⇨ The cooking program can be started without being saved.

⇨ If the modifications are to be saved, continue with the next step.

d) Tap the

⇨ The

green

tab.

Tab

window is open.

e) Save the cooking program.

⇨ All modifications to the cooking program are saved.

⇨ The saved cooking program is modified.

Delete cooking program

➢ Cooking program open

➢ Cooking program not started

a) Tap the

b) The

c) Tap the "Delete cooking program" field.

⇨ The

d) Tap the "Yes" button.

⇨ The cooking program is being deleted.

⇨ The

green

tab.

Tab

window is open.

Delete

window is displayed.

Confirm

window is displayed.

e) Tap the

⇨ The

⇨ The cooking program is deleted.

Confirm

green

tab closes.

button.

Exporting and importing a cooking program

Exporting a cooking program

When exporting, all user-created cooking programs in the cookbook are

exported.

Page 67

Operating the unit

6

Automatic cooking (autoChef)

67

NOTICE

Existing cooking programs can be overwritten or the file names of the

imported cooking programs can have a supplement added.

Requirement

Requirement

Export cooking program window

➢ USB flash drive inserted

➢

Automatic cooking

open

➢ User-created cooking programs are saved in the cookbook

a) Tap the "autoChef" button in the information bar.

⇨ The

autoChef

window opens.

b) Tap the "Export cooking programs" field.

⇨ The

Operating instructions

window opens.

⇨ Read the displayed operating instructions.

c) Tap the

Confirm

button.

⇨ All user-created cooking programs are exported to the USB flash

drive from the cookbook.

⇨ The

d) Tap the

⇨ The

Confirm

Confirm

Confirm

window is displayed.

button.

window closes.

⇨ The cooking programs are exported.

Importing cooking programs

When importing, new cooking programs are added to the cookbook.

➢ USB flash drive inserted