Page 1

INSTALLATION MANUAL

FlexFuison® PLATINUM ELECTRIC COMBI

FPE-615

FPE-621

FPE-115

FPE-121

FPE-215

FPE-221

Page 2

Directory of Contents

2

1

Introduction

4

1.1

About this manual

4

1.1.1

Explanation of signs

4

1.2

Use of the unit

6

1.3

Warranty

6

2

Safety information

7

3

Description of the unit

9

3.1

Overview of the unit

9

3.2

Planning drawing

11

3.3

Equipment and connection data

12

4

Transporting the unit

14

4.1

Information about transporting

14

4.2

Transporting to the installation site

14

4.2.1

Transporting on a pallet

15

4.2.2

Transporting without a pallet

15

4.2.3

Transporting by lifting and lowering

17

4.3

Unpacking the unit

17

5

Setting up the unit

18

5.1

Lifting the unit off the pallet

18

5.2

Setting up the unit on the equipment legs

19

5.3

Setting up the unit on a work surface

19

5.4

Aligning the unit

20

5.4.1

Aligning countertop units

21

5.4.2

Aligning floor-standing units

21

Directory of Contents

Page 3

Directory of Contents

3

5.5

Minimum clearances

22

6

Connecting the unit

24

6.1

Opening and closing the housing

24

6.1.1

Removing and attaching the side panel

24

6.2

Making the electrical connection

26

6.2.1

Connected loads for various connection voltages

26

6.2.2

Connecting to the electric mains

27

6.2.3

Connecting the electric power cable to the unit

28

6.3

Connecting the power optimizing system

30

6.4

Connecting the unit to the network

30

6.5

Basic settings

32

6.6

Making the water connection

34

6.6.1

Information about the water connection

34

6.6.2

Connecting hard and soft water

34

6.6.3

Connecting soft water twice

36

6.7

Making the wastewater connection

37

6.7.1

Information about the wastewater connection

37

6.7.2

Connecting the wastewater line permanently

37

6.8

Making the exhaust air connection

38

6.8.1

Information about the exhaust air connection

38

7

Putting the unit into service

39

7.1

Filling out the commissioning report

39

Page 4

1

Introduction

About this manual

4

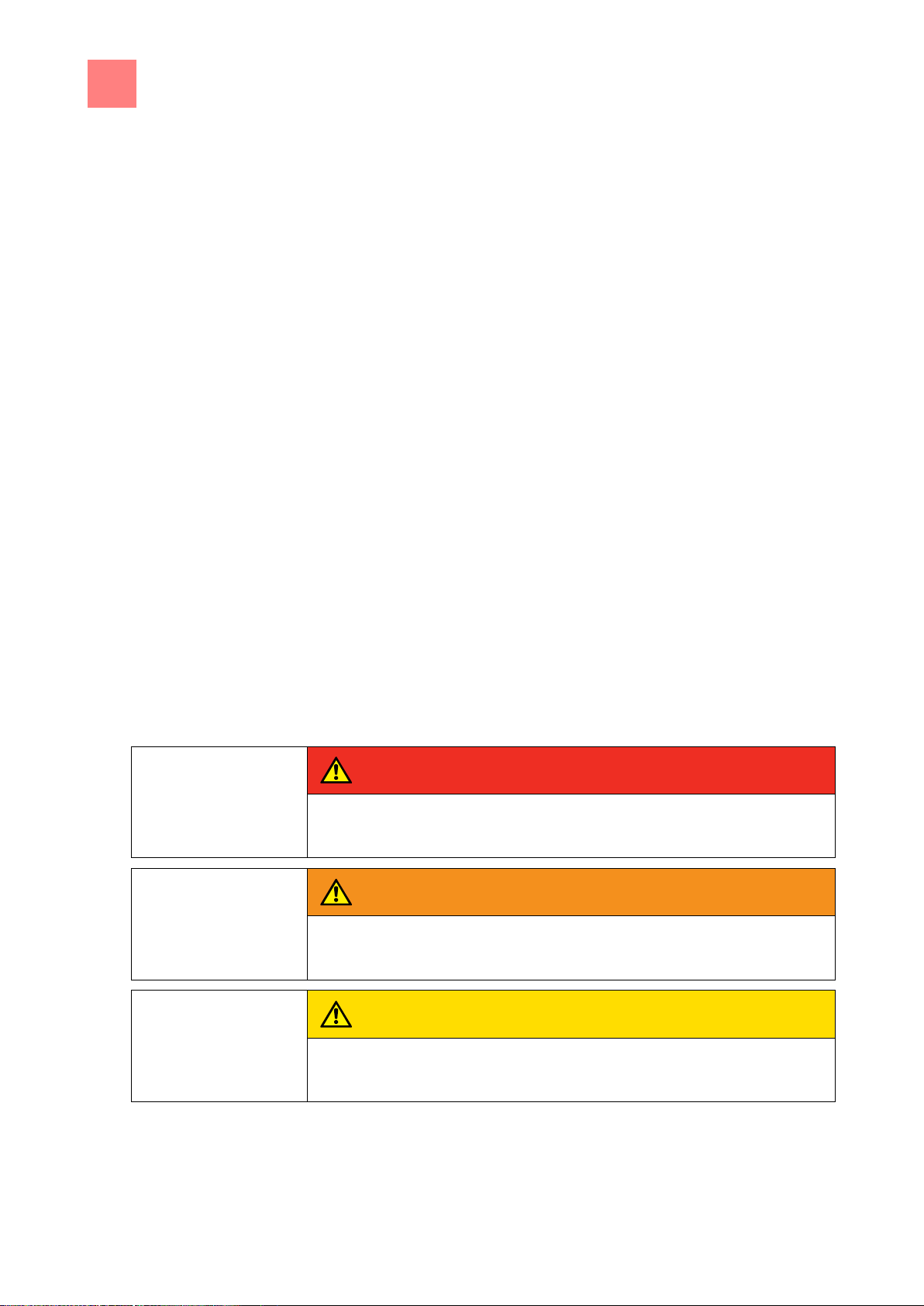

DANGER

Imminent threat of danger

Failure to comply will lead to death or very severe injuries.

WARNING

Possible threat of danger

Failure to comply can lead to death or very severe injuries.

CAUTION

Dangerous situation

Failure to comply can cause minor or moderate injuries.

1

1.1

Target group

Figures

1.1.1

Introduction

About this manual

The target group for the installation manual is trained technical personnel

that is familiar with installing and operating the unit.

All figures in this manual are intended as examples. Discrepancies between

these and the actual unit can arise.

The instruction manual is part of the unit and contains information on safe

installation of the unit.

Observe and adhere to the following instructions:

▪ Read the instruction manual in its entirety prior to installation.

▪ Make the instruction manual available to the installer at the operating site

at all times.

▪ Preserve the installation manual throughout the service life of the unit.

▪ Insert any supplements from the manufacturer.

▪ Pass on the installation manual to any subsequent operator of the unit.

Explanation of signs

Page 5

Introduction

1

About this manual

5

SAFETY INSTRUCTIONS

Material damage

Failure to comply can cause material damage.

NOTICE

Information

Notes for better understanding and operation of the unit.

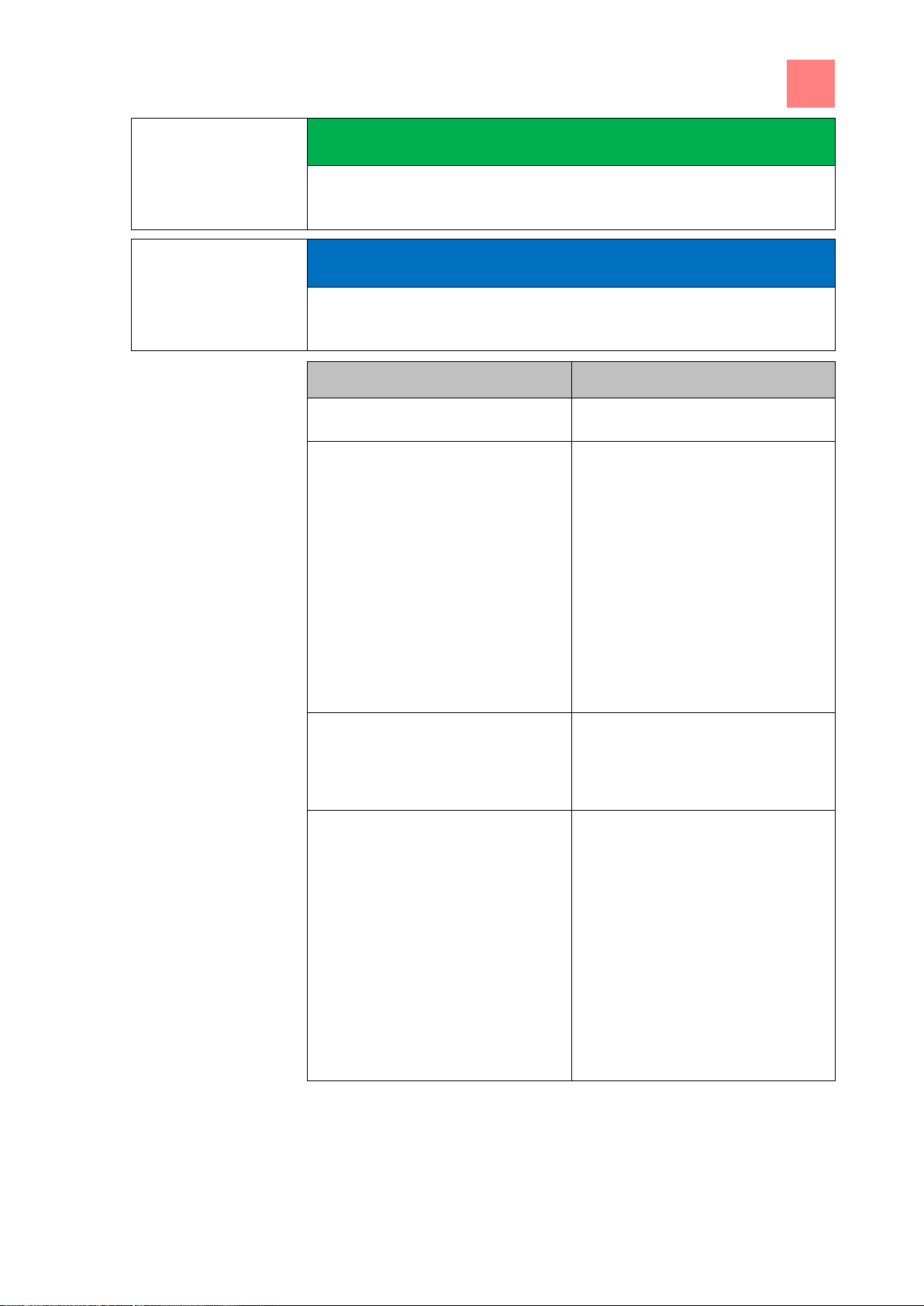

Symbol / sign

Meaning

▪

Listing of information.

Action steps, which can be

performed in any sequence.

1.

2.

Action steps, which must be

performed in the prescribed

sequence.

Result of a listed action.

Page 6

1

Introduction

Use of the unit

6

1.2

1.3

Use of the unit

This unit is intended to be used solely for commercial purposes, particularly

in commercial kitchens.

This unit is certified in the following:

Warranty

The warranty is void and safety is no longer assured in the event of:

▪ Modifications or technical changes to the unit,

▪ Improper use,

▪ Incorrect startup, operation or maintenance of the unit,

▪ Problems resulting from failure to observe these instructions.

Page 7

Safety information

2

7

2

Ensuring conformity with

standards

Improper installation

Fire prevention

Organisational measures

Transportation and storage

Safety information

Observe applicable international, European and national laws, regulations,

standards and directives for the unit when transporting, setting up and

connecting it.

Risk of property damage and personal injury from improper

installation

▪ Install the unit only as specified in these installation instructions.

▪ Use only original spare parts.

Risk of fire from combustible surfaces

▪ Observe general fire prevention regulations.

Risk of property damage and personal injury from lack of

organizational measures

▪ Identify hazard areas when transporting, setting up and connecting the

unit.

▪ Prior to starting the installation work, notify any operators present about

the procedure.

▪ Prior to starting the installation work, discuss how to behave in an

emergency.

▪ Use equipment and protective gear suitable for the activity.

▪ Brace housing components to prevent them from falling over and

dropping.

Risk of personal injury and property damage from improper

transportation and improper storage.

▪ Store the unit in a dry, frost-free environment.

▪ Observe the safety regulations for the lifting gear used.

▪ Attach the unit to the lifting gear securely during transport and setup, and

prevent it from dropping.

▪ Transport the unit in an upright position, do not tilt or stack.

▪ Pay attention to protruding parts when transporting the unit without

packaging.

Page 8

2

Safety information

8

Setup

Electrical connection

Commissioning

Risk of property damage and personal injury from improper

setup

▪ Ensure that the installation area has adequate load-bearing capacity.

▪ Where safety shoes and protective gloves.

Risk of fire from improper connection

▪ Observe applicable regional regulations of the electrical utility.

▪ Ensure that only licensed electricians connect the unit.

▪ Ensure that the electrical system is earthed by a protective earthing

conductor.

▪ Note the information on the nameplate.

Risk of electric shock from live components.

▪ Prior to working on the electrical system, switch off the unit, disconnect

the electrical system from the mains and prevent power from being

switched on again. Check to ensure absence of voltage.

Risk of property damage and personal injury from improper

commissioning

▪ Read the operating instructions prior to commissioning. Observe the

safety instructions in this installation manual and in the "Safety

information" chapter of the operating instructions.

▪ Put the unit into service only after a successful function test following

assembly.

▪ Put the unit into service only after it has reached room temperature.

Page 9

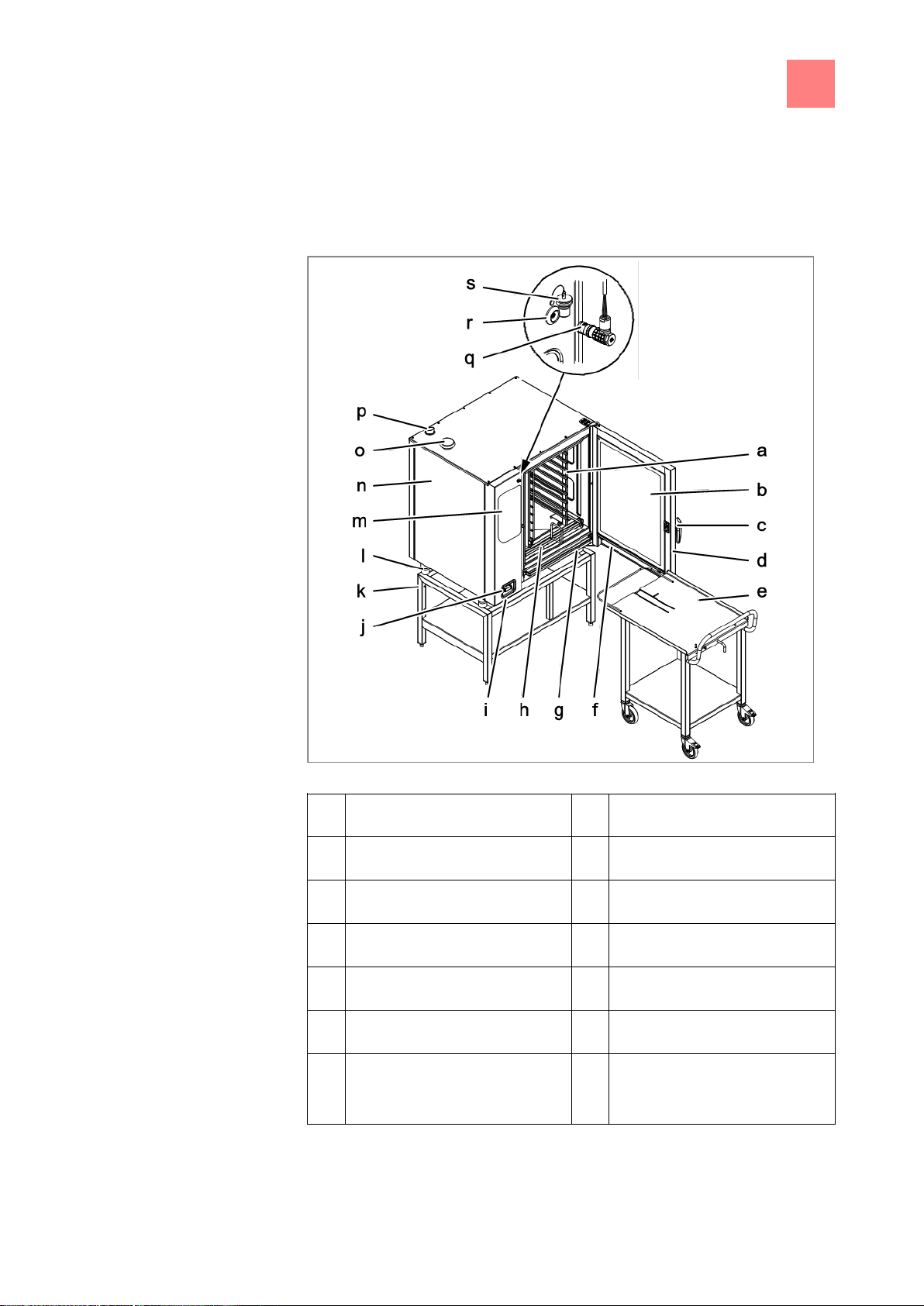

Description of the unit

3

Overview of the unit

9

a

Tray rack

k

Base frame (optional)

b

Insulated window

l

Equipment foot

c

Door handle

m

Operating control

d

Cooking zone door

n

Housing

e

Tray rack trolley (optional)

o

Air intake connection fitting

f

Steam drain channel, door

p

Steam outlet connection fitting

g

Steam drain channel, unit

q

Core temperature sensor

(optional)

3

3.1

Description of the unit

Overview of the unit

FlexFusion with tray rack trolley

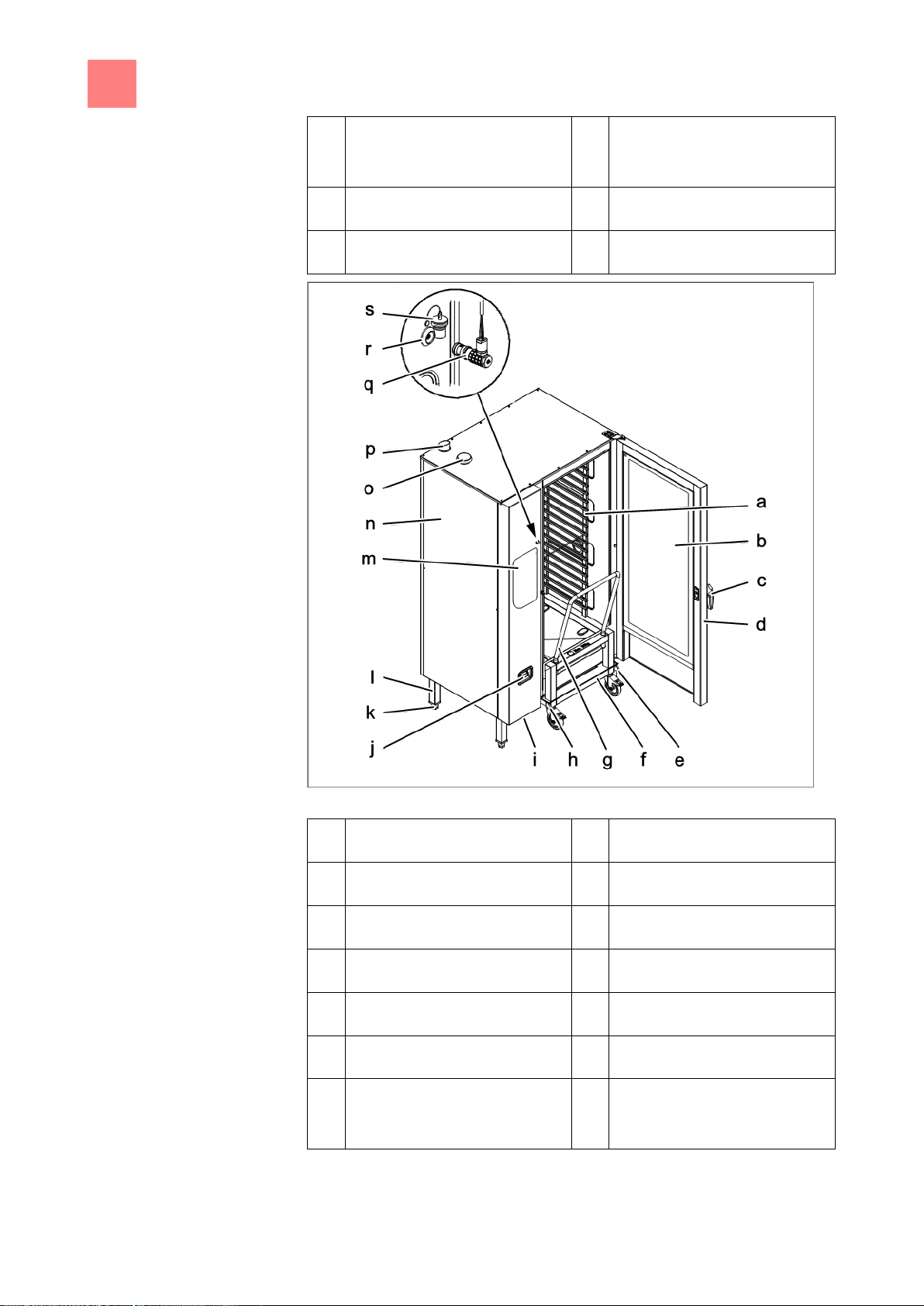

Page 10

3

Description of the unit

Overview of the unit

10

h

Guide rail for tray rack

(optional)

r

Connection (optional)

i

USB port (covered)

s

Protective cap (optional)

j

Hand shower (optional)

a

Tray rack

k

Equipment leg

b

Insulated window

l

Equipment foot

c

Door handle

m

Operating control

d

Cooking zone door

n

Housing

e

Guide rail (right)

o

Air intake connection fitting

f

Tray trolley

p

Steam outlet connection fitting

g

Push handle

q

Core temperature sensor

(optional)

FlexFusion with tray trolley

Page 11

Description of the unit

3

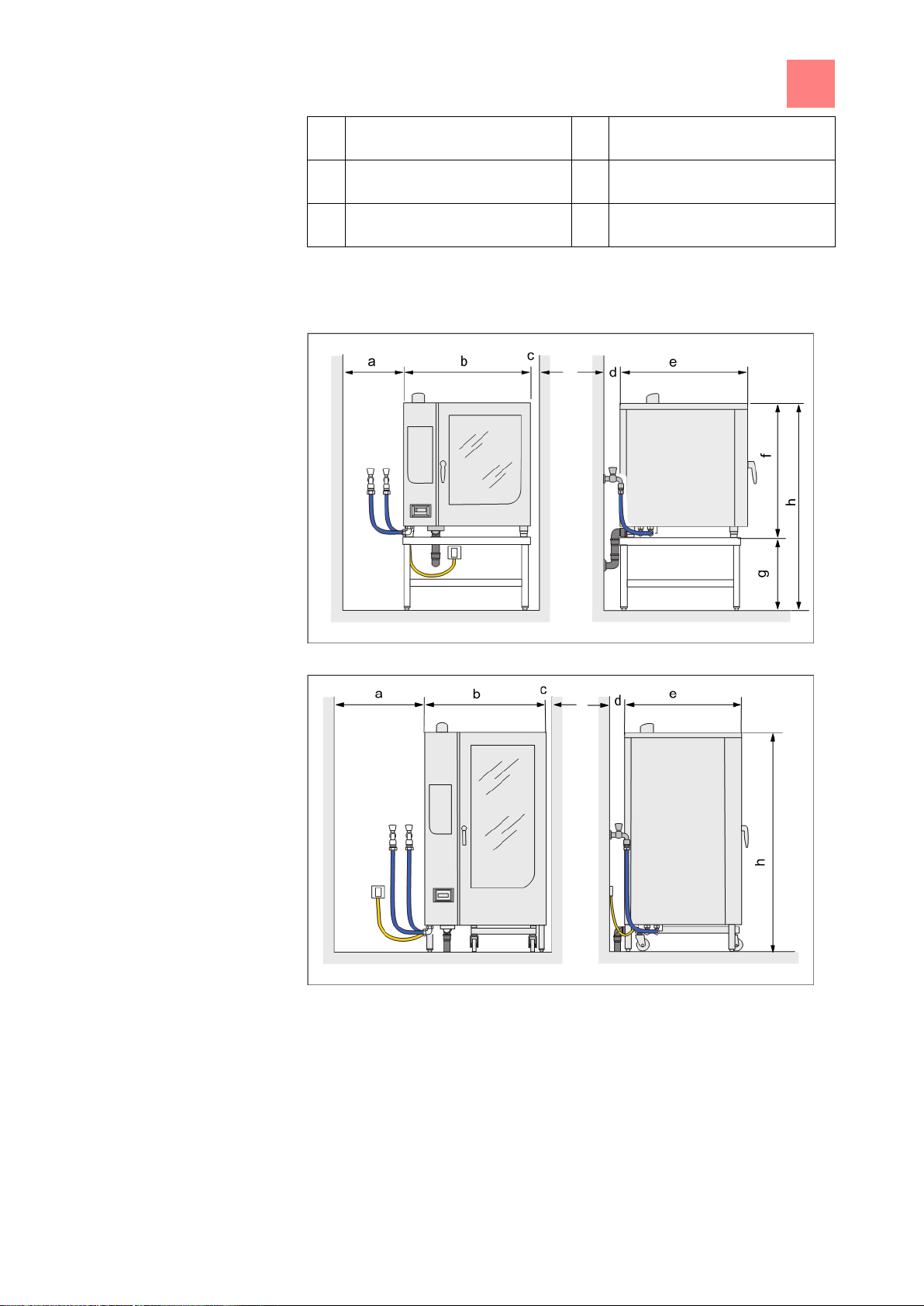

Planning drawing

11

h

Guide rail (left)

r

Connection (optional)

i

USB port (covered)

s

Protective cap (optional)

j

Hand shower

3.2

Planning drawing

Combisteamer – sizes 6 and 10

Combisteamer – size 20

Page 12

3

Description of the unit

Equipment and connection data

12

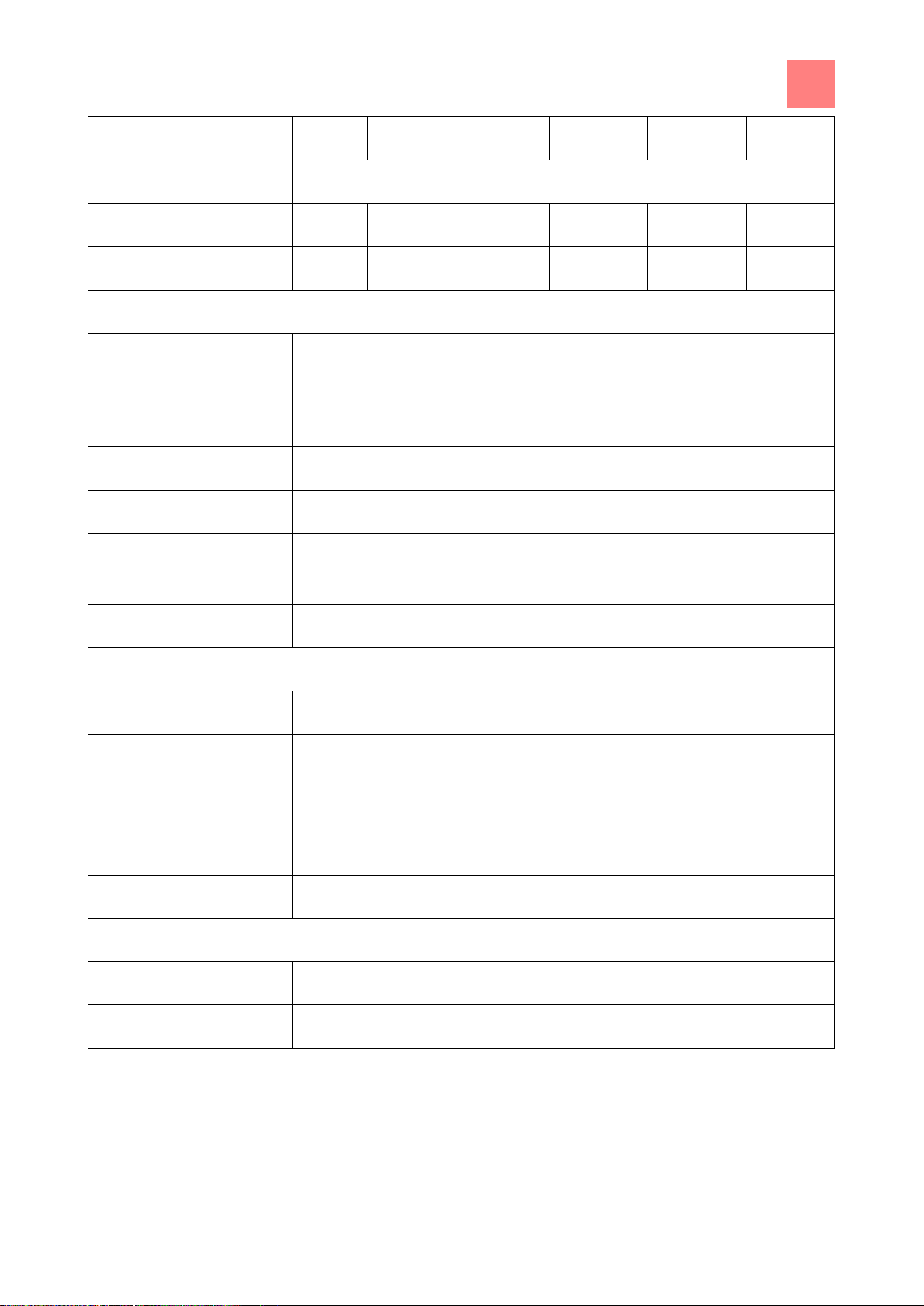

Size

a mm (in)

b mm (in)

c mm (in)

d mm (in)

e mm (in)

f mm (in)

g mm (in)

h mm (in)

6.15, 6.21

500 (20)

997 (39)

50 (2)

50 (2)

799 (31)

790 (31)

850 (33)

1640 (65)

10.15, 10.21

500 (20)

997 (39)

50 (2)

50 (2)

799 (31)

1060 (42)

580 (23)

1640 (65)

20.15, 20.21

500 (20)

1075 (42)

50 (2)

50 (2)

813 (32)

--

--

1960 (65)

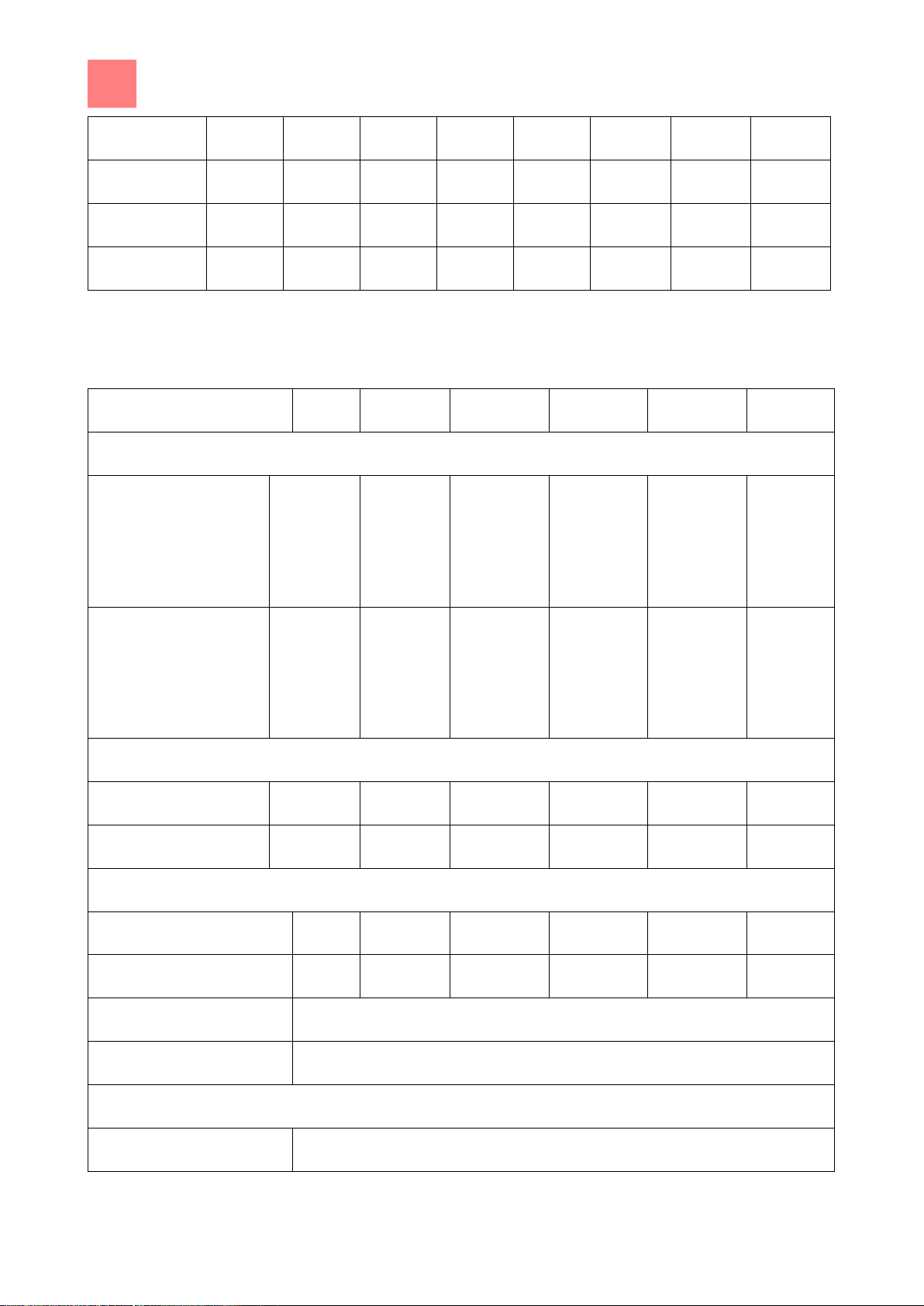

Unit size

6.15

6.21

10.15

10.21

20.15

20.21

Dimensions

Unit

Length x width x height

mm

(in)

1000 x 800

x 790

(39 x 31 x

31)

1000 x 800

x 790

(39 x 31 x

31)

1000 x 800 x

1060

(39 x 31 x

42)

1000 x 800 x

1060

(39 x 31 x

42)

1075 x 813 x

1722

(42 x 32 x

68)

1075 x 813

x 1722

(42 x 32 x

68)

Packaged unit

Length x width x height

mm

(in)

1080 x 960

x 1020

(39 x 38 x

40)

1080 x 960

x 1020

(39 x 38 x

40)

1080 x 960 x

1280

(39 x 38 x

50)

1080 x 960 x

1280

(39 x 38 x

50)

1160 x 960 x

2200

(46 x 38 x

87)

1160 x 960

x 2200

(46 x 38 x

87)

Weight

Unit kg (lbs)

120 (265)

125 (276)

140 (309)

145 (320)

305 (672)

313 (690)

Packaged unit kg (lbs)

140 (309)

145 (320)

165 (364)

170 (375)

340 (750)

348 (767)

Emissions

Latent heat rejection (W)

1780

3670

2750

5400

5510

10200

Sensible heat rejection (W)

1190

2450

1840

3600

3670

7100

Noise level (db (A))

< 70

Ambient climate

5–40 °C (41-104°F), 95 % relative humidity, non-condensing

Electrical connection

Protection class

IPX5

3.3

Equipment and connection data

Page 13

Description of the unit

3

Equipment and connection data

13

Connected load (kW)

10.4

20.9

15.9

30.5

31.7

60.9

Type of connection

3 N PE 400 V AC 50 Hz

Maximum line current (A)

15.6

31.0

23.6

45.0

47.0

90.0

Recommended fusing (A)

3 x 16

3 x 35

3 x 25

3 x 50

3 x 63

3 x 100

Soft water connection

Type of water

Softened tap water, cold

Carbonate hardness CaCO3

(mmol/l)

< 1.5

Chloride Cl (mg/l)

< 50

Iron Fe (mg/l)

< 0.1

Connection pressure (hPa),

(bar)

200–600, 2–6

Type of connection

R ¾", male thread

Hard water connection

Type of water

Tap water, cold

Carbonate hardness CaCO3

(mmol/l)

Maximum 4

Connection pressure (hPa),

(bar)

200–600, 2–6

Type of connection

R ¾", male thread

Wastewater connection

Type of wastewater

Dirty water, maximum 80 °C (176°F)

Connection to unit

Connection fitting, 50 mm (2in) diameter

Page 14

4

Transporting the unit

Information about transporting

14

WARNING

Risk of property damage and personnel injury from tipping equipment

a) Do not linger next to or behind raised equipment.

b) Move raised equipment carefully.

SAFETY INSTRUCTIONS

Risk of physical damage from improper transport

a) Transport the unit upright.

b) Do not tilt or stack the unit.

c) Pay attention to protruding parts when transporting the unpacked unit.

4

4.1

4.2

Transporting the unit

Information about transporting

Crossing a grate with the tray trolley

➢ Prior to transporting the unit to the installation site, ensure that:

a) The route has adequate load-bearing capacity; place rails or metal plates

underneath if necessary.

b) Wall openings are large enough. Removing the packaging reduces the

clear width required Equipment and connection data [➙ 12] .“

Transporting to the installation site

Page 15

Transporting the unit

4

Transporting to the installation site

15

SAFETY INSTRUCTIONS

Risk of physical damage from improper lifting of the unit

a) Lift size 6 and size 10 units only with the aid of wooden beams placed

underneath.

4.2.1

4.2.2

Requirement

Transporting on a pallet

a) Move the pallet truck under the pallet.

b) Raise the unit on the pallet.

Transporting the unit on a pallet

c) Move the unit to the installation site.

Transporting without a pallet

Unit sizes 6 and 10

➢ Packaging removed except for the pallet

a) Move the pallet truck under the unit from the right.

b) Place the wooden beams on the lift forks and slide under the unit.

c) Lift the unit off the pallet.

Page 16

4

Transporting the unit

Transporting to the installation site

16

Requirement

Transporting unit sizes 6 and 10 without a pallet

d) Move the unit to the installation site.

Unit size 20

➢ Packaging removed except for the pallet

a) Move the pallet truck under the guide rails of the unit from the right.

b) Lift the unit off the pallet.

Transporting unit size 20 without a pallet

c) Move the unit to the installation site.

Page 17

Transporting the unit

4

Unpacking the unit

17

DANGER

Risk of fatal injury from falling load

a) Do not linger under a suspended load.

b) Cordon off the hazard area according to regulations.

SAFETY INSTRUCTIONS

Risk of physical damage from tightened lifting straps

a) Always lift the unit with lifting straps and a spreader bar.

WARNING

Risk of injury from sharp edges

Wear protective gloves.

NOTICE

When unpacking the unit, inspect it for transport damage. Do not install

damaged units or put into service. Enter the information from the

nameplate into the commissioning report.

4.2.3

4.3

Transporting by lifting and lowering

a) Guide the lifting straps under the pallet and attach them to the spreader

bar.

b) Brace the unit to prevent tipping.

c) Carefully lift the unit onto the pallet.

Unpacking the unit

a) Remove the packaging.

b) Pull the protective film off the unit.

c) Remove the packaging material from the cooking zone completely.

d) Lift the unit off the pallet and place in position.

e) Clean the unit

see the "Cleaning and maintaining the unit" chapter in the

operating instructions.

f) Separate and dispose of the packaging material.

Page 18

5

Setting up the unit

Lifting the unit off the pallet

18

WARNING

Risk of burns from spraying hot fat

a) Set up deep fat fryers outside the range of the hand shower.

CAUTION

Risk of crushing from improper setup

a) Protect the unit and work area during setup and alignment.

WARNING

Risk of fire from failure to observe applicable regional fire prevention

regulations

a) Observe applicable regional fire prevention regulations.

SAFETY INSTRUCTIONS

Risk of physical damage from overheating of the unit

a) Do not set up the unit close to heat sources.

CAUTION

Risk of property damage and personnel injury from tipping equipment

a) Do not linger next to or behind raised equipment.

b) Move raised equipment carefully.

SAFETY INSTRUCTIONS

Risk of physical damage from lifting the unit incorrectly

a) Place the forks of the lift truck next to the waste trap.

5

5.1

Requirement

Setting up the unit

Lifting the unit off the pallet

➢ Unit unpacked

➢ Protective film removed

➢ Unit cleaned

Page 19

Setting up the unit

5

Setting up the unit on the equipment legs

19

5.2

Requirement

5.3

Requirement

Lifting the unit off the pallet

a) Slide the forks of the pallet truck under the unit and to the right of the

waste trap.

b) Lift the unit off the pallet.

Setting up the unit on the equipment legs

➢ The floor must carry the weight of the unit

a) Lift the unit with the pallet truck.

b) Move the unit to the installation site.

c) Place the unit on the floor.

d) Set up the unit in accordance with the planning drawing Planning

drawing .

Setting up the unit on a work surface

➢ The base frame must carry the weight of the unit

➢ Base frame levelled

➢ Base frame set up in accordance with the planning drawing Planning

drawing

a) Lift the unit.

Page 20

5

Setting up the unit

Aligning the unit

20

a

Lift fork

d

Stud bolt

b

Waste trap on the unit

e

Equipment leg

c

Base frame

f

Unit

WARNING

Risk of burns from missing stickers

a) Attach stickers if the upper insertion rails are higher than 1.60 m (63in).

5.4

Setting up the unit on a work surface

b) Place the unit over the stud bolts on the work surface.

Attach warning sign regarding insertion height

a) Clean the adhesion surface for the sticker.

b) Attach the sticker to the cooking zone door at a height of 1.6 m (63in).

Aligning the unit

Page 21

Setting up the unit

5

Aligning the unit

21

NOTICE

The tray trolley is needed to align a floor-standing unit.

Prepare the tray trolley.

5.4.1

Requirement

5.4.2

➢ Base frame levelled

a) Place a spirit level on the unit.

b) Screw the equipment legs in or out to level the unit.

Aligning floor-standing units

a) Screw the equipment legs in or out to align the unit.

b) Open the cooking zone door.

Aligning countertop units

Aligning the unit with the tray trolley

Page 22

5

Setting up the unit

Minimum clearances

22

a

Tray trolley

d

Equipment leg

b

Distance between roller and

support rail

e

Roller

c

Support rail

a

Ceiling

b

Baking oven

c

Deep fat fryer

5.5

c) Place the tray trolley against the support rails.

d) Screw the equipment legs in or out until the rollers are 1 to 5 mm above

the support rails.

e) Retract the tray trolley.

f) Level the support rails.

g) Push the tray trolley against the unit until it stops.

h) Remove the push handle.

i) Close the cooking zone door.

⇨ The unit is aligned correctly.

Minimum clearances

FlexFusion minimum clearances

The following clearances from walls, ceilings or other equipment must be

provided when setting up the unit:

▪ Left, right and behind: at least 50 mm (2in).

▪ If possible at the left, 500 mm (20in) for service work

Page 23

Setting up the unit

5

Minimum clearances

23

▪ If possible at the left, 800 mm (31in) for parking the trolley tray

▪ At the left, 500 mm (20in) to heat sources (baking ovens) so that the

cooling air for the unit is not heated.

▪ Left and right, one length of the hand shower so that no water can be

sprayed into the hot deep fat fryer.

▪ To ceilings, at least 500 mm (20in). There must be no water, gas or

electric lines in the ceiling above the unit.

Page 24

6

Connecting the unit

Opening and closing the housing

24

DANGER

Risk of electric shock

a) Prior to working on the unit, ensure that the unit has been disconnected

from the mains.

b) Do not operate the unit with the housing open.

WARNING

Risk of injury from sharp edges

a) Wear protective gloves.

SAFETY INSTRUCTIONS

Risk of physical damage from damage to the lines

a) Remove and attach housing components carefully.

6

6.1

6.1.1

Connecting the unit

Opening and closing the housing

Removing and attaching the side panel

Removing the side panel

a) Unscrew the bolts on the bottom of the side panel.

b) Pull the bottom of the side panel forward.

Removing and attaching the side panel

c) Remove the side panel.

Page 25

Connecting the unit

6

Opening and closing the housing

25

SAFETY INSTRUCTIONS

Risk of physical damage from squeezing the lines

When attaching the side panel, make sure that no lines are squeezed.

SAFETY INSTRUCTIONS

Risk of physical damage from a loose side panel

a) The side panel must be in contact with the unit on all sides.

Attaching the side panel

a) Insert the top edge of the side panel.

a) Carefully push the bottom of the side panel inward.

b) Secure the bottom of the side panel with bolts.

c) Check that the side panel is in contact with the unit on all sides.

Page 26

6

Connecting the unit

Making the electrical connection

26

Unit size

6.15

6.21

10.15

10.21

20.15

20.21

Electricity network type

3PE / AC 50/60Hz , 3NPE / AC 50/60Hz

Voltage (V)

200

Connected load (kW)

9.7

16.3

14.7

25.5

29.4

50.9

Fusing (A)

35

50

50

80

100

180

Voltage (V)

208

Connected load (kW)

10.2

17.4

15.7

27.3

31.4

54.6

Fusing (A)

35

50

50

80

100

180

Voltage (V)

230

Connected load (kW)

12.6

21.4

19.3

33.6

38.6

67

Fusing (A)

35

63

63

100

125

180

Voltage (V)

240

Connected load (kW)

13.7

23.3

21

36.5

42

72.9

Fusing (A)

35

63

63

100

125

180

Voltage (V)

380

Connected load (kW)

9.4

18.9

14.4

27.6

28.7

55

Fusing (A)

16

35

25

50

50

100

Voltage (V)

400

6.2

6.2.1

Making the electrical connection

▪ Ensure that only licensed electricians connect the unit.

▪ Note the information on the nameplate.

▪ Observe applicable regional regulations of the electrical utility.

Connected loads for various connection

voltages

Page 27

Connecting the unit

6

Making the electrical connection

27

Connected load (kW)

10.4

20.9

15.9

30.5

31.7

60.9

Fusing (A)

16

35

25

50

50

100

Voltage (V)

415

Connected load (kW)

11.2

22.5

17.1

32.8

34.1

65.5

Fusing (A)

16

35

25

50

50

100

Voltage (V)

440

Connected load (kW)

10.4

20.9

15.8

30.5

31.5

60.9

Fusing (A)

16

35

25

50

50

100

Voltage (V)

480

Connected load (kW)

12.3

20.9

18.9

32.6

37.6

65.1

Fusing (A)

16

35

25

50

50

100

6.2.2

Electric power cable

Residual-current protective

device

Connecting to the electric mains

An electric power cable of the type HO7RN-F must be used to connect the

unit to the electric mains.

The unit can be connected to a residual-current protective device. The

residual-current protective device must incorporate a residual-current

protective switch of type B (RCD Type B) in order to detect AC fault currents,

pulsating DC currents and continuous DC currents.

RCD switch type B circuit symbol

Page 28

6

Connecting the unit

Making the electrical connection

28

SAFETY INSTRUCTIONS

Risk of property damage and personal injury from improper installation

a) In the case of a permanent electrical connection, install an all-phase

disconnect switch before the unit.

SAFETY INSTRUCTIONS

Risk of property damage and personal injury from improper installation

a) The plug-in connection must be readily accessible.

A, B, C, D

Power optimizing

system

PE

Protective earth

13, 14

Floating contact

X1

Mains connection

L1, L2, L3

Phases

X2

Power optimizing system

connection

N

Neutral conductor

Permanent connection

Plug-in connection

6.2.3

Install an all-phase disconnect switch if the unit will be connected

permanently to the electric mains.

If the unit will be connected to the electric mains by a plug, use a plug and

socket that comply with IEC 60309. The socket must be readily accessible

so that the unit can be disconnected from the electric mains at any time.

Connecting the electric power cable to the unit

Electrical connection terminal diagram in the unit

Page 29

Connecting the unit

6

Making the electrical connection

29

Model

Length mm (in)

6.15, 6.21

1000 (39)

10.15, 10.21

1200 (47)

20.15, 20.21

720 (28)

a

Connection terminals

c

Electric power cable

b

Cable tie

d

Cable gland

Requirement

Length of connection cable in the unit

Connecting the electric power cable

➢ Electrical connection to the unit matches the information on the

nameplate

➢ Housing open

➢ Electric power cable sufficiently long

a) Insert the electric power cable into the unit through the cable gland.

b) Connect the electric power cable in accordance with the terminal

diagram.

c) Secure the electric power cable to the unit with cable ties.

d) Tighten the cable gland securely to provide strain relief.

Page 30

6

Connecting the unit

Connecting the power optimizing system

30

Type of network

Ethernet

Cabling

In accordance with EN 50173

Cable quality

4-twin, shrouded patch cable

Cat-6 S/FTP

Connection to the unit

Shrouded RJ45 plug

Cable length in the unit

As per electric power cable

6.3

Requirement

6.4

Connecting the power optimizing system

The unit can be connected to a power optimizing system. The line length in

the unit corresponds to the length of the electric power cable.

➢ Unit disconnected from the electric mains

➢ Left side panel removed

a) Pull the connection cable into the unit through the opening next to the

entry for the electric power cable.

b) Bring the connection cable to the connection terminals.

c) Attach the connection cable in accordance with the terminal diagram.

d) Secure the connection cable with cable ties.

e) Enter the power optimizing system in the basic settings.

Connecting the unit to the network

The units can be connected to an Ethernet network with a RJ45 plug.

Requirements for network connection

Page 31

Connecting the unit

6

Connecting the unit to the network

31

a

RJ45 socket

d

Cable tie

b

RJ45 plug

e

Feed-through in the base of the

unit

c

Network cable

f

Ferrite rings

Requirements

Connecting the network cable

➢ Unit is disconnected from the electric mains

➢ Side panel is removed

a) Pull the network cable alongside the electrical connection into the unit.

b) Lead the network cable through the two ferrite rings with one turn each.

c) Connect the network cable to the unit with the RJ45 plug.

d) Put the unit into service and under basic setting enter the network

address or select DHCP.

Page 32

6

Connecting the unit

Basic settings

32

a

Start menu for FlexFusion

ChefsTouch

d

Key for “Unit functions”

b

Key for

FlexFusion Help

e

Key for “Back”

c

Language selection

Basic setting

No.

Standard

value

Setting range

Explanation

Actual voltage

1

Enter the local, mean voltage

between the outer cables.

Date / Time

2 dd mm yyyy/

hh mm

6.5

Requirements

Basic settings

Start menu for FlexFusion ChefsTouch

By entering the password "2100", the basic settings for the installation can

be displayed and changed.

➢ The unit is switched on

a) Touch the key for “Unit functions” in the main menu.

b) Enter the password “2100” with the keypad.

c) Select and set parameters in the menu.

Page 33

Connecting the unit

6

Basic settings

33

Basic setting

No.

Standard

value

Setting range

Explanation

Altitude

3 0 0 - 3

Request the altitude above

sea level from the closest

weather station. If the altitude

is unknown, enter 0 – 500 m.

▪ 0 = 0 - 500 m (0 - .31 mi)

▪ 1 = 501 – 1000 m (.31 -

.62 mi)

▪ 2 = 1001 – 1500 m (.62 -

.93 mi)

▪ 3 = > 1500 m (.93 mi)

Audio setting

4

20

0 – 180 s

Duration of the audible signal

0 = Signal off

Units

5 Metric/Imperial

Water filter

maintenance

6 Litres > 0

0 = No maintenance

message

Water quantity up to the

maintenance message

Network

7 Network address and

DHCP

Select Ethernet interface

Kitchen control

technology

Disabled/enabled

Address of port and unit can

be entered.

80% power

4

0

0 = No

1 = Yes

Yes = Power limited to 80 %

(for special applications)

Power optimizing

system

connected?

5

0

0 = No

1 = Yes

If the power optimizing

system is connected, "Yes"

must be selected in order for

the unit to heat.

Page 34

6

Connecting the unit

Making the water connection

34

6.6

6.6.1

6.6.2

Making the water connection

Information about the water connection

Installation work involving drinking water must be performed by an

authorised plumbing contractor. Observe applicable regional regulations with

regard to drinking water installations and connection data.Equipment and

connection data [➙ 12]

Connecting hard and soft water

The unit is equipped with a connection for:

▪ Soft water for generating steam

▪ Hard water for cooling, rinsing and WaveClean

Page 35

Connecting the unit

6

Making the water connection

35

SAFETY INSTRUCTIONS

Hygiene risk from contaminated drinking water

a) The connection to the drinking water supply must be equipped with a

backflow preventer.

NOTICE

Always connect hard and soft water to the unit

SAFETY INSTRUCTIONS

Risk of physical damage from the wrong water quality

a) Ensure that the water quality complies with the equipment and

connection data.

SAFETY INSTRUCTIONS

Hygiene risk from contaminated drinking water

a) The connection to the drinking water supply must be equipped with a

backflow preventer.

a

Soft water tap

e

Hard water connection fitting

b

Backflow preventer, installed

f

Hard water hose

c

Hose

g

Backflow preventer, installed

d

Soft water connection fitting

h

Hard water tap

Requirement

➢ Water quality meets specifications

➢ Backflow preventers installed

➢ Required water pressure available

Hard and soft water connection

Page 36

6

Connecting the unit

Making the water connection

36

a

Soft water tap

e

Hard water connection fitting

b

Backflow preventer

f

Dirt filter

c

Hose

g

T-piece

d

Soft water connection fitting

h

Seal

6.6.3

Requirement

➢ Pressure-resistant hoses suitable for drinking water available

a) Connect the hoses to the water taps.

b) Open the water taps and flush the hoses.

c) Insert dirt filters into the two water connection fittings.

d) Connect hoses to the unit.

e) Open the water taps and check the threaded fittings for leaks.

Connecting soft water twice

If only a soft water connection is available at the installation site, the hard

water connection fitting and the soft water connection fitting must be

connected by means of a T-piece.

Soft water connection twice

➢ Hose connected to soft water tap

a) Insert a dirt filter into the hard and soft water connection fittings.

b) Connect the T-piece with seals to the connection fittings.

c) Connect hose with seal to the T-piece.

d) Open the soft water tap and check the threaded fittings for leaks.

Page 37

Connecting the unit

6

Making the wastewater connection

37

a

Wastewater discharge from

unit

d

Wastewater system trap

b

Wastewater line

e

Pipe clamp

c

Wastewater system

f

Vacuum breaker valve

NOTICE

If a waste trap is installed in the wastewater system, a vacuum breaker

must be installed in the wastewater line.

6.7

6.7.1

6.7.2

Requirement

Making the wastewater connection

Information about the wastewater connection

Installation work involving wastewater must be performed by an authorised

plumbing contractor. Observe the applicable regional regulations of the

sewage utility involved.

Connecting the wastewater line permanently

Connecting the wastewater line permanently

Polypropylene (PP) pipes and elbows

▪ Heat-resistant to 95 °C (203°F)

▪ Nominal diameter 50 mm (2in)

▪ Maximum pipe length 1.0 m (39in)

Page 38

6

Connecting the unit

Making the exhaust air connection

38

CAUTION

Risk of physical damage from fouling of the exhaust air ducts

a) Do not incorporate the exhaust air line directly into an exhaust air

system.

CAUTION

Risk of corrosion damage from condensate

a) Install the exhaust air line such that condensate cannot collect.

6.8

6.8.1

Requirement

a) Install wastewater line up to connection to the sewer system.

b) Secure the wastewater line with clamps.

c) Pour tap water into the wastewater trap on the unit.

Making the exhaust air connection

Information about the exhaust air connection

When setting up the unit under an exhaust hood, observe the applicable

regional regulations for ventilation systems.

Flexible aluminium hose

▪ Nominal diameter 63 mm for sizes 6 and 10

▪ Nominal diameter 76 mm for size 20

▪ Maximum length of hose 2.5 m (98in)

▪ Temperature-resistant to 180 °C (356°F)

a) Connect hose to exhaust air connection fitting.

b) Route hose to the exhaust hood with about a 3° rise.

c) Secure end of hose about 50-200 mm (2-8in) below the exhaust hood.

Page 39

Putting the unit into service

7

Filling out the commissioning report

39

General

Yes

No

Information from the nameplate entered?

SN: _____________________________ Typ: _____________________________

QN (Hi): _____________________________

E: ________________________________________________________________

Bez: ______________________________________________________________

Item-Nr.: _____________________________ (if listed)

Obvious damage to the unit?

What and where?:

______________________________________________________________________________

Unit levelled?

Elements that can tilt levelled? (for instance: pans)

Electrical connection

Yes

No

Power connection made properly?

Equipotential bonding

Power optimizing system

Floating contact

…

Electrical connections made properly?

Residual-current protective device connected immediately before this unit?

Residual-current protective device connected before this and other units?

7

7.1

Putting the unit into service

Filling out the commissioning report

Page 40

7

Putting the unit into service

Filling out the commissioning report

40

Water connection

Yes

No

Minimum connection pressure available?

Connection pressure: _______________ bar

Water connection made properly?

Lines and connections have no leaks?

Mixing battery mounted properly?

Wastewater connection

Yes

No

Wastewater connection made properly?

On-site waste trap

Vacuum breaker

Funnel discharge

Wastewater pipe dimension: ____________________ mm (in)

Exhaust air connection

Yes

No

Set up under exhaust hood?

Connected to exhaust air duct?

Exhaust air pipe dimension: ____________________ mm (in)

Exhaust air pipe length: ________________________ m (in)

Final notes

Yes

No

Was the unit put into service?

Comments:

Operator trained?

Electrical installation was provided by:

Company

Installer

City, date

Signature

Page 41

Putting the unit into service

7

Filling out the commissioning report

41

Water installation was provided by:

Company

Installer

City, date

Signature

Wastewater installation was provided by:

Company

Installer

City, date

Signature

Exhaust air connection was provided by:

Company

Installer

City, date

Signature

Operator training was provided by:

Company

Installer

City, date

Signature

Page 42

Henny Penny Corporation

P.O.Box 60

Eaton,OH 45320

1-937-456-8400

1-937-456-8402 Fax

Toll free in USA

1-800-417-8417

1-800-417-8434 Fax

www.hennypenny.com

Henny Penny Corp., Eaton, Ohio 45320, Revised 2-19-15

Loading...

Loading...