Henny Penny FPDE615.615, FPDE615.216, FPDE115.615, FPDE115.621, FPDE121.615 Installation Manual

...

Model

FPDE615.615

Installation

Manual

FM 05-253 • 23/08/2018

Read the operating manual prior to commissioning

FPDE615.216

FPDE621.615

FPDE621.621

FPDE115.615

FPDE115.621

FPDE121.615

FPDE121.621

FlexFusion® ELECTRIC

PLATINUM COMBI TEAM

PLATINUM

FUSION

FLEX

FM05-253

en-US

%&&'(

)*)+,

-*%!

#$.

/"01

,/"01!

#$.

/"01"1"1

,/"01"1

222)&(&)

! 3

Directory of contents

3Installation instructions

1Introduction......................................................................... 5

1.1About this manual ............................................................................ 5

1.1.1Explanation of signs .................................................................................. 6

1.2Staff qualification ............................................................................. 7

1.3Use of the unit................................................................................... 7

1.4Warranty............................................................................................ 7

2Safety information.............................................................. 8

3Description of the unit ..................................................... 10

3.1Overview of the unit ....................................................................... 10

3.2Equipment and connection data................................................... 10

4Transporting the unit ....................................................... 15

4.1Transporting the unit to the installation site ............................... 15

4.2Unpacking the unit ......................................................................... 15

5Setting up the unit............................................................ 17

5.1Minimum clearances ...................................................................... 17

5.2Lifting the unit off the pallet .......................................................... 18

5.3Placing the unit on the equipment legs........................................ 19

5.4Aligning the unit ............................................................................. 19

6Connecting the unit.......................................................... 20

6.1Opening and closing the housing................................................. 20

6.1.1Removing and attaching side wall........................................................... 20

6.2Making the power connection....................................................... 21

6.2.1Matching the unit to the connection voltage ............................................ 23

6.2.2Connecting the power connection cable ................................................. 25

6.2.3Connecting the power optimisation system............................................. 26

6.2.4Connecting to the potential equalisation circuit ....................................... 27

6.3Connecting the kitchen management system ............................. 27

6.4Making the basic control setting................................................... 29

6.4.1Changing the basic control setting .......................................................... 29

6.5Making the water connection ........................................................ 30

6.5.1Connecting the tap water connection line ............................................... 30

6.5.2Connecting softened tap water to both connections ............................... 31

6.6Making the wastewater connection .............................................. 32

6.6.1Connecting the wastewater line to a permanent connection................... 32

6.7Making the exhaust air connection .............................................. 33

6.7.1Connecting the exhaust air line ............................................................... 34

7Checking operation.......................................................... 35

7.1Checking the controls.................................................................... 35

7.2Checking the monitoring of the cooking zone door ................... 35

FM05-253

Directory of contents

4 Installation instructions

7.3Heating the unit up and rinsing it out........................................... 36

8Putting the unit into service ............................................ 37

8.1Filling out the Commissioning report........................................... 37

FM05-253

Introduction

5Installation instructions

1 Introduction

1.1 About this manual

The instruction manual is part of the unit and contains information on

safe installation of the unit.

Observe and adhere to the following instructions:

• Read the instruction manual in its entirety prior to installation.

• Make the instruction manual available to the installer at the

operating site at all times.

• Preserve the installation manual throughout the service life of the

unit.

• Insert any supplements from the manufacturer.

• Pass on the installation manual to any subsequent operator of the

unit.

Target group The target group for the installation manual is trained technical

personnel that is familiar with installing and operating the unit.

Figures All figures in this manual are intended as examples. Discrepancies

between these and the actual unit can arise.

FM05-253

Introduction

6 Installation instructions

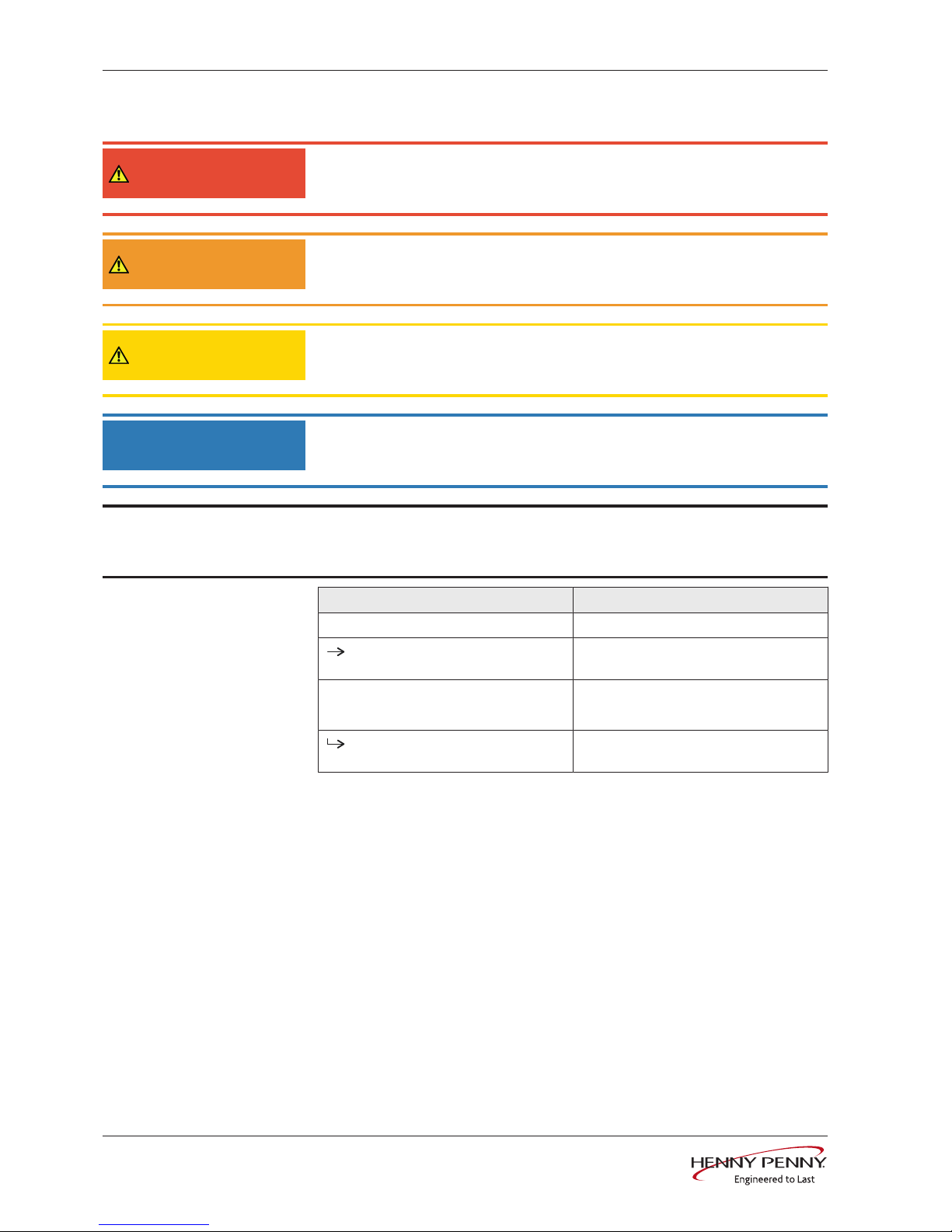

1.1.1 Explanation of signs

DANGER

Imminent threat of danger

Failure to comply will lead to death or very severe injuries.

WARNING

Possible threat of danger

Failure to comply can lead to death or very severe injuries.

CAUTION

Dangerous situation

Failure to comply can lead to slight or moderately severe injuries.

NOTICE

Property damage

Failure to comply can cause physical damage.

INFORMATION

Information

Notes for better understanding and operation of the unit.

Symbol / sign Meaning

• Listing of information.

Action steps, which can be performed in

any sequence.

1.

2.

Action steps, which must be performed

in the specified sequence.

Result of an action performed or

additional information about it.

FM05-253

Introduction

7Installation instructions

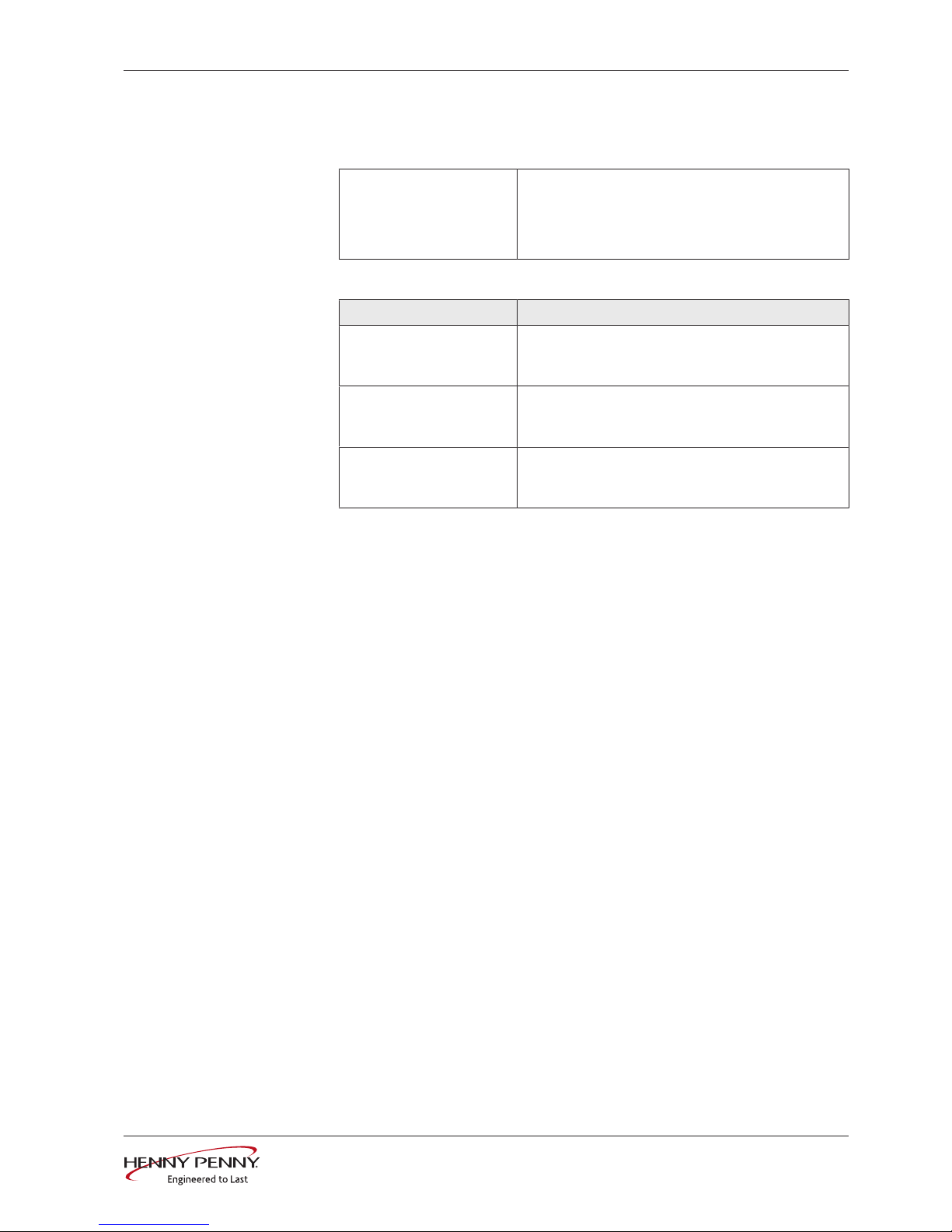

1.2 Staff qualification

Explanation of qualification

Skilled staff • Skilled staff are those, who due to their profes-

sional training, knowledge and experience as well

as their knowledge of the relevant standards can

assess the tasks given to them and recognize any

possible dangers.

Type of activity Qualification

Power connection • Electrician

• Specific professional training

• Employee of the specialist company concerned

Water connection • Plumber

• Specific professional training

• Employee of the specialist company concerned

Wastewater connection • Wastewater specialist

• Specific professional training

• Employee of the specialist company concerned

1.3 Use of the unit

This unit is intended to be used solely for commercial purposes,

particularly in commercial kitchens.

1.4 Warranty

The warranty is void and safety is no longer assured in the event of:

• Improper conversion or technical modifications of the unit,

• Improper use,

• Incorrect startup, operation or maintenance of the unit,

• Problems resulting from failure to observe these instructions.

FM05-253

Safety information

8 Installation instructions

2 Safety information

The unit complies with applicable safety standards. Residual risks

associated with operation or risks resulting from incorrect operation

cannot be ruled out and are mentioned specifically in the safety

instructions and warnings.

The installer must be familiar with regional regulations and observe

them.

The installer must observe the safety instructions in these mounting

instructions and in the "Safety information" chapter of the operating

instructions.

Ensuring conformity with

standards

Observe applicable international, European and national laws,

regulations, standards and directives for the unit when transporting,

setting up and connecting it.

Improper installation Risk of property damage and personal injury from improper

installation

• Install the unit only as specified in these installation instructions.

• Do not add anything to the unit or modify the unit.

• Use only original spare parts.

Transportation and storage Risk of personal injury and property damage from improper

transportation and improper storage

• Store the unit in a dry, frost-free environment.

• Observe the safety regulations for the lifting gear used.

• Attach the unit to the lifting gear securely during transport and

setup, and prevent it from dropping.

• Transport the unit in an upright position, do not tilt or stack.

• Pay attention to protruding parts when transporting the unit

without packaging.

Fire prevention Risk of fire from combustible surfaces

• Observe general fire prevention regulations.

Organisational measures Risk of property damage and personal injury from lack of

organizational measures

• Identify hazard areas when transporting, setting up and

connecting the unit.

• Prior to starting the installation work, notify any operators present

about the procedure.

• Prior to starting the installation work, discuss how to behave in an

emergency.

• Use equipment and protective gear suitable for the activity.

• Brace housing components to prevent them from falling over and

dropping.

FM05-253

Safety information

9Installation instructions

Setup Risk of property damage and personal injury from improper

setup

• Ensure that the installation area has adequate load-bearing

capacity.

• Wear safety shoes and protective gloves.

Electrical connection Risk of fire from improper connection

• Observe applicable regional regulations of the electrical utility.

• Ensure that only electricians licensed by the electric utility connect

the unit.

• Ensure that the electrical system is earthed by a protective

earthing conductor.

• Note the information on the nameplate.

Risk of electric shock from live components.

• Prior to working on the electrical system, switch off the unit,

disconnect the electrical system from the mains and prevent

power from being switched on again. Check to ensure absence of

voltage.

• Use only insulated tools.

Unit on casters Risk of a line breaking if subjected to high tensile load

• Secure the unit with a chain as a strain relief for the power

connection at the installation site so that no tensile load is applied

to the power connection if the unit is moved.

Commissioning Risk of property damage and personal injury from improper

commissioning

• Read the operating instructions prior to commissioning. Observe

the safety instructions in this installation manual and in the "Safety

information" chapter of the operating instructions.

• Put the unit into service only after a successful function test

following assembly.

• Put the unit into service only after it has reached room

temperature.

• Observe the units during operation.

FM05-253

Description of the unit

10 Installation instructions

3 Description of the unit

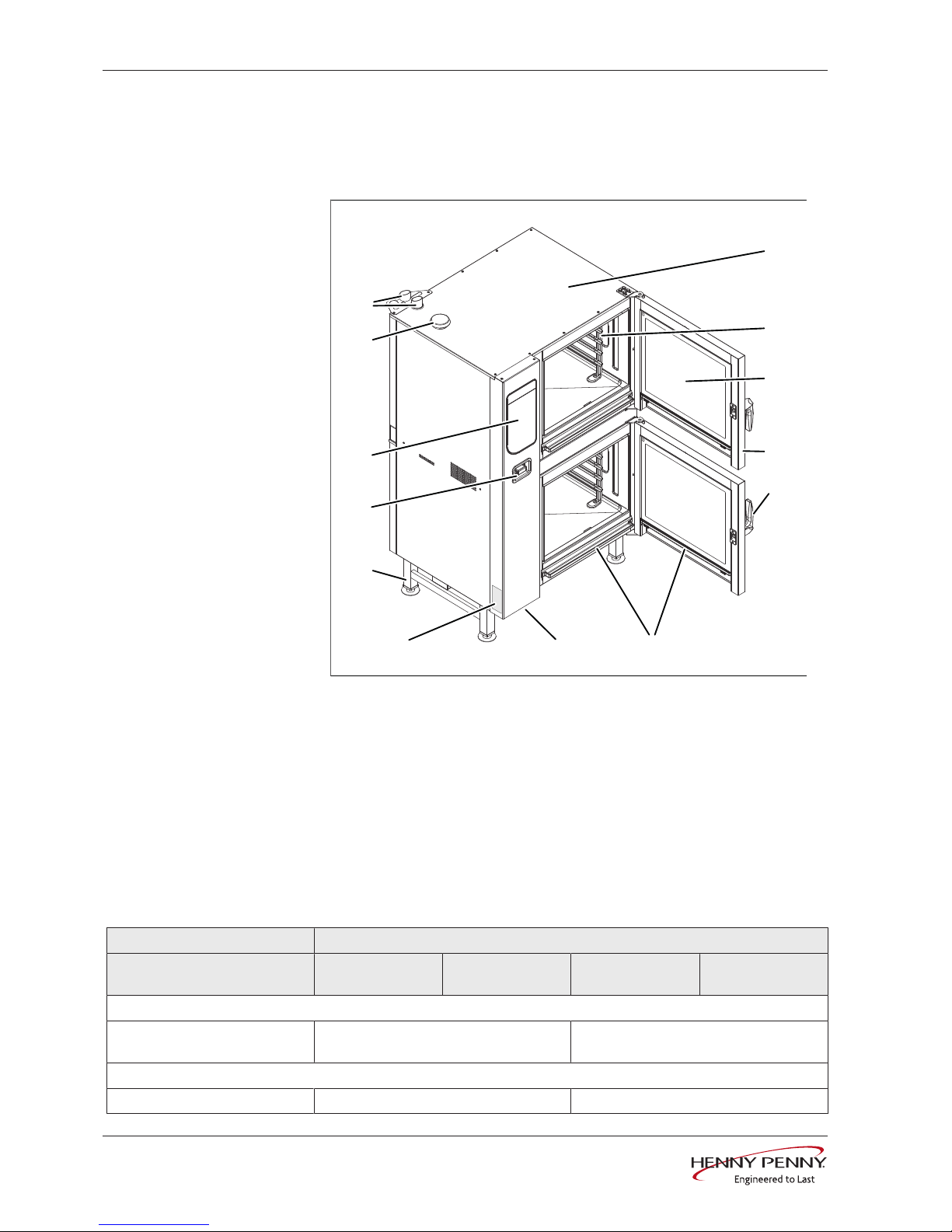

3.1 Overview of the unit

a

j

i

h

g

f

e

d

c

b

m

l

k

Image: Floor-standing unit

a Housing h Nameplate

b Support rack i Equipment leg

c Insulated window j Hand shower

d Cooking zone door k Control unit

e Door handle l Air inlet

f Steam drain channel m Steam outlet

g USB port (covered)

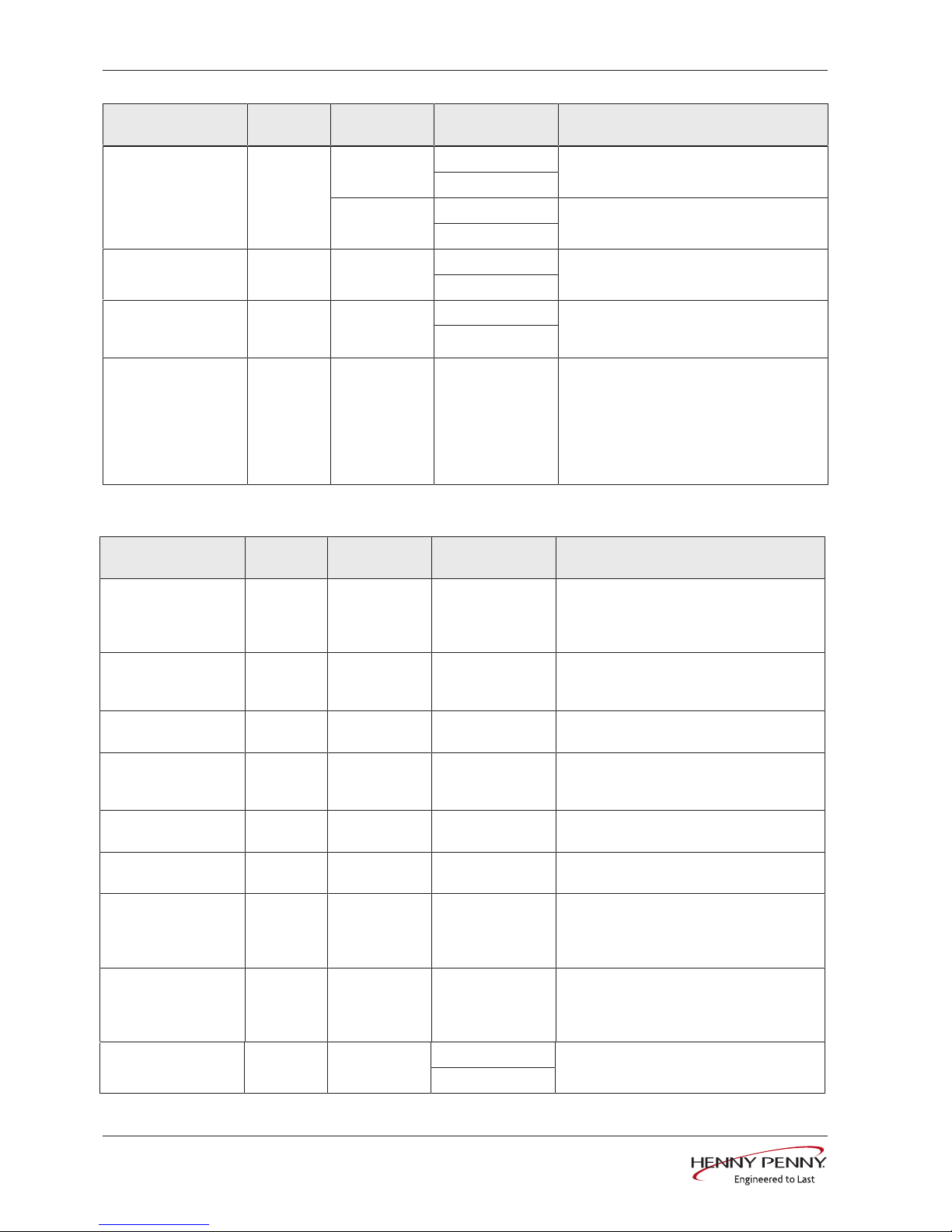

3.2 Equipment and connection data

Model FPED

Size 615-615

615-621

621-621

621-615

115-615

115-621

121-615

121-621

Dimensions

Unit Length x Width x Height

(mm(in))

997 (39,25) x 799 (31,46) x1700 (66,93) 997 (39,25) x 799 (31,46) x1900 (74,80)

Weight

Unit (kg (lb)) 253 (557,77) 291 (641,55)

FM05-253

Description of the unit

11Installation instructions

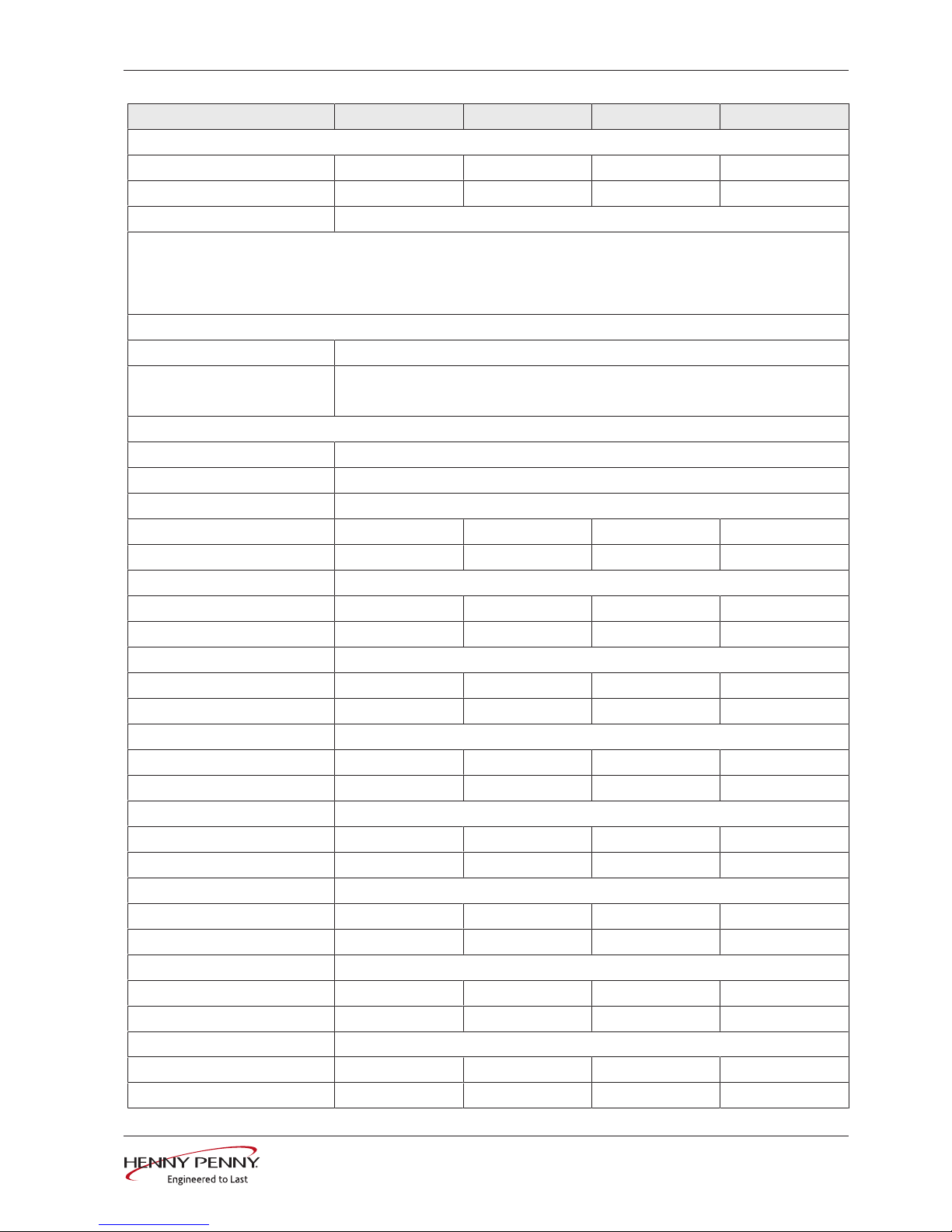

Size 615 621 115 121

Emissions

Latent heat (W) * 1780 3670 2750 5400

Sensible heat (W) 1190 2450 1840 3600

Noise level (db (A)) < 70

* The stated value is reduced by 80% when operating with a condensation hood; the sensible heat is increased by the

amount of the reduction.

The sensible and latent heat amounts are determined in Germany on the basis of VDI 2052 at a connection voltage of

400V. The applicable regional regulations may vary from this.

Operating environment

Temperature (°C (in)) 5 (42) — 40 (104)

Relative humidity (%)

Non-condensing

95

Power connection

Protection class IPX5

Type of connection 3NPE / AC 50/60 Hz, 3PE / AC 50/60 Hz

Voltage (V) 200

Connected load (kW) 10.1 16.3 14.7 25.5

Fuse (A) 3 x 35 3 x 50 3 x 50 3 x 80

Voltage (V) 208

Connected load (kW) 10.2 17.4 15.7 27.3

Fuse (A) 3 x 35 3 x 50 3 x 50 3 x 80

Voltage (V) 220

Connected load (kW) 11.6 19.7 17.7 30.8

Fuse (A) 3 x 35 3 x 63 3 x 63 3 x 100

Voltage (V) 230

Connected load (kW) 12.6 21.4 19.3 33.6

Fuse (A) 3 x 35 3 x 63 3 x 63 3 x 100

Voltage (V) 240

Connected load (kW) 13.7 23.3 21 36.5

Fuse (A) 3 x 35 3 x 63 3 x 63 3 x 100

Voltage (V) 380

Connected load (kW) 9.4 18.9 14.4 27.6

Fuse (A) 3 x 16 3 x 35 3 x 25 3 x 50

Voltage (V) 400

Connected load (kW) 10.4 20.9 15.9 30.5

Fuse (A) 3 x 16 3 x 35 3 x 25 3 x 50

Voltage (V) 415

Connected load (kW) 11.2 22.5 17.1 32.8

Fuse (A) 3 x 16 3 x 35 3 x 25 3 x 50

FM05-253

Description of the unit

12 Installation instructions

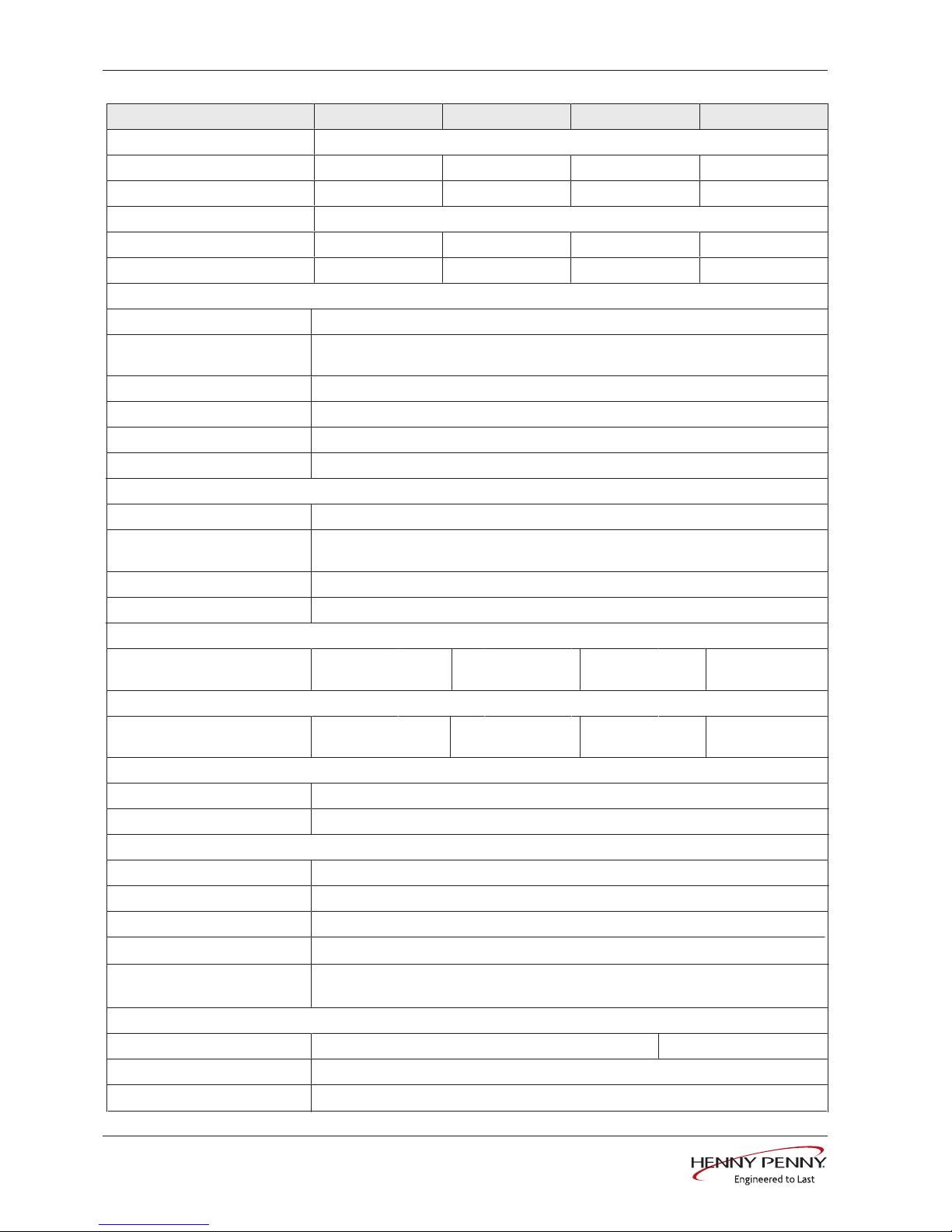

Size 615 621 115 121

Voltage (V) 440

Connected load (kW) 10.4 20.9 15.8 30.5

Fuse (A) 3 x 16 3 x 35 3 x 25 3 x 50

Voltage (V) 480

Connected load (kW) 12.3 20.9 18.9 32.6

Fuse (A) 3 x 16 3 x 35 3 x 25 3 x 50

FM05-253

Softened drinking water connection

Type of water Softened drinking water, cold

Carbonate hardness CaCO

3

(mmol/l (ppm))

< 0,9 (90 ppm)

Chloride Cl (mg/l) < 50

Iron Fe (mg/l) < 0.1

Connection pressure (kPa (psi)) 200 (29) — 600 (87)

Connection (") R 3/4

Drinking water connection

Type of water Drinking water, cold

Carbonate hardness CaCO

3

(mmol/l (ppm))

< 4 (400 ppm)

Connection pressure (kPa (psi)) 200 (29) — 600 (87)

Connection (") R 3/4

Water consumption for steaming

Softened drinking water (l/h

(gal/h))

16 (4,23) 21 (5,55) 18 (4,76) 24 (6,34)

Water consumption for combisteaming

Softened drinking water (l/h

(gal/h))

3,5 (0,92) 4,6 (1,22) 4 (1,06) 5,3 (1,4)

Water consumption for WaveClean cleaning program

Softened drinking water (l (gal)) 3 l (0,79)

Drinking water (l (gal)) 32 l (8,45)

Waste water connection

Waste water type Dirty water, maximum 80 °C (176 °F)

Connection to unit (mm (in)) 50 (1,97)

Maximum length (m (ft)) 1 (3,3) with a drop of at least 5% or 3°

Temperature-resistant to (°C(°F)) 95 (203 )

Maximum flow rate (l/min (gal/

min))

10 (2,64)

Exhaust air connection

Connection to unit (mm (in)) 53 (2,09) 73 (2,87)

Maximum length (m (ft)) 2,5 (8,2)

Temperature-resistant to (°C(°F)) 180 (356)

Description of the unit

13Installation instructions

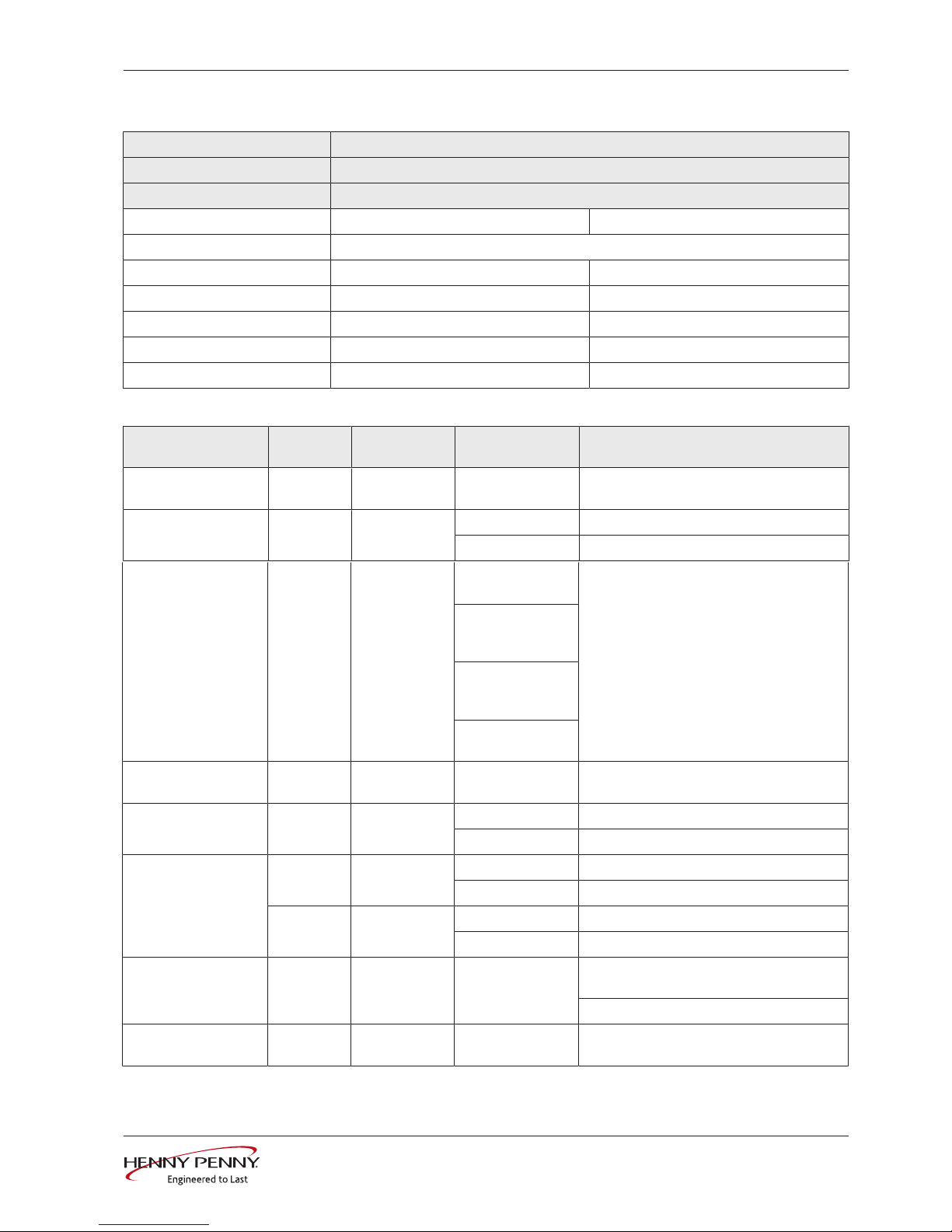

Transformer voltage

Type of connection 3NPE / AC 50/60Hz, 3PE / AC 50/60Hz

Voltage range (V) 200 — 240

Transformer T1

Marking or colour of the cores Blue Red

Voltage measured (V) Voltage at the transformer (V)

190 — 200 0 200

201 — 220 0 220

221 — 230 0 230

231 — 240 0 240

241 — 250 0 250

Basic control setting

Basic setting ParametersStandard

value

Adjustment

range

Explanation

Actual voltage 14 400 100 — 500V Set the local, mean voltage between the

line conductors.

Date/time yyyy - mm - dd Year - Month - Day

hh : mm Hour : Minute

FM05-253

ft) the closest weather station. If the altitude

is unknown, set 0—999 m (3277 ft).

1000 m (3280

ft)—1999 m

(6557 ft)

2000 m (6560

ft)—2499 m

(8197 ft)

2500 m (8200 ft)

or higher

Volume of audible

signal

33 Medium Individual Sets the volume.

Unit of temperature 1 °C °C Celsius (°C)

°F Fahrenheit (°F)

Unit of volume 34 ml (ml) Millilitre (ml)

(fl.oz.) Fluid ounce (fl.oz.)

35 Imperial

(fl.oz.)

Imperial (fl.oz.) Imperial fluid ounce

U.S. (fl.oz.) U.S. fluid ounce

Water filter

maintenance

44 0 0 — 99900 l

(26393,66 gal)

Water quantity up to the maintenance

message.

0 = No maintenance message

Network DHCP Network address

and DHCP

Select and set interface.

0—999

2

Altitude

0 - 999 m (3277

Description of the unit

14 Installation instructions

Basic setting ParametersStandard

value

Adjustment

range

Explanation

Kitchen management

system

Disabled Active Port and unit address can be set.

Disabled

Ethernet Ethernet Type of signal transmission

Serial

80% power 3 100 80 % Power can be limited to 80% (for special

applications).

100 %

Power optimisation

system

42 Off On If a power optimisation system is

connected, "On" must be selected for the

unit to heat.

Off

Settings parameters 1. Set parameters via the roller.

2. Tap the "Read" button to display the

set value.

3. Specify another value via the button

panel.

4. Press the "Write" button to save the

new value.

Basic control setting (Advanced)

FM05-253

Basic setting ParametersStandard

value

Range of

adjustment

Explanation

Preheating

temperature

Ready2Cook

4 15 0 — 30% When loaded a full charge of large masses

(roasts, loaf of bread), increase the

preheat temperature so that the oven

temperature does not drop too suddenly.

Condensation-hood

after-running time

5 60 0 – 600 s Time extension for the condensation hood,

after the cooking chamber door has been

opened

Preselected steaming

temperature

9 100 30 °C (86 °F) —

130 °C (266 °F)

Preset temperature for steaming

Preset

combisteaming

temperature

10 150 30 °C (86 °F) —

250 °C (482 °F)

Preset temperature for combisteaming

Preset hot air

temperature

11 180 30 °C (86 °F) —

300 °C (572 °F)

Preset temperature for hot air

Preset regeneration

temperature

12 130 30 °C (86 °F) —

180 °C (356 °F)

Preset temperature for regeneration

Maximum waiting

time after

Ready2Cook for T <

250 °C (482 °F)

37 120 0 — 300 min Maximum waiting time after reaching the

Ready2Cook temperature, for set value <

250 °C (482 °F)

Maximum waiting

time after

Ready2Cook for T >

250 °C (482 °F)

38 30 0 — 60 min Maximum waiting time after reaching the

Ready2Cook temperature, for set value >

250 °C (482 °F)

Time format 675 0 0 = 24 h Set the 12-h or 24-h time format

1 = 12 h

Loading...

Loading...