Page 1

Frying

Page 2

50 Years Of

Frying Excellence

While the foodservice industry continues to evolve

and consumer tastes expand, one thing hasn’t changed

— customers will continue to be drawn to delicious,

golden fried foods to satisfy their cravings. For your

operation to fully capitalize on this enduring demand,

you need a foodservice partner you can trust.

Henny Penny has built a reputation for supplying the

industry’s premier fryers on a ve-decade commitment

to o ering you the highest quality equipment and an

unsurpassed level of service. We patented the rst

commercial pressure fryer in 1957, and since that time,

we’ve drawn on experience and innovation to master

the art of preparing perfectly fried foods. rough

years of proven performance and client satisfaction,

Henny Penny has grown into a global company o ering

a comprehensive range of foodservice solutions.

Yet our foundation and deepest expertise remains in

frying applications. Whatever the size and scope of

your operation, Henny Penny o ers a variety of

pressure and open fryers — all backed by our full

support — to help you meet your biggest challenges:

■

Increased food quality

■

Reduced operating costs

■

More e cient labor management

Page 3

Market Outlook

Page 4

Quality

Rectangular fry pots on our fryers promote random

tumbling and turbulent action for more evenly

products and more satisfi ed customers.

Cold zones below the heating units reduce

cracklings and greatly improve shortening quality

and food fl avor.

Integrated cooking rack system on specifi c models

lets you quickly and easily move food from breading

station to fryer to holding cabinet with minimal

food handling.

High-effi ciency heating units with quick heat recovery

and various melt modes keep shortening from

breaking down too quickly and being absorbed by

food, enabling you to cook larger volumes without

sacrifi cing quality or consistency.

cooked

Page 5

Food Quality

That Sets You Apart

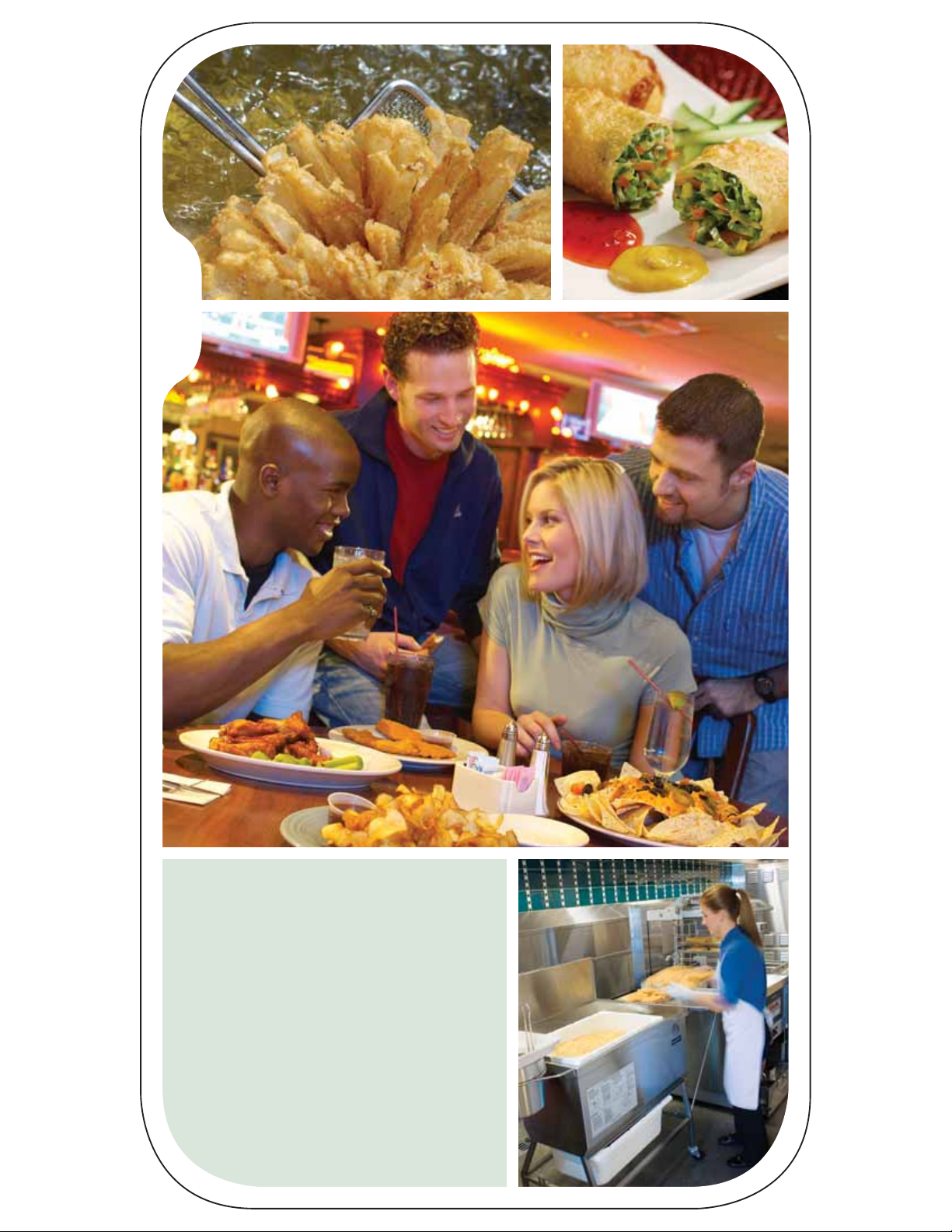

As a mature product category, fried foods are

widely available to every consumer. is means

that in order to carve out and defend a pro table

niche in the marketplace, food quality is essential.

For instance, while a potential customer can

get French fries anywhere, many will go out

of their way for those they perceive as the best

tasting and best value. Henny Penny open fryers

ensure that customer favorites like French fries,

onion rings and fried seafood are all prepared

crisp and delicious. And our industry-leading

pressure fryers allow for faster cooking at lower

temperatures, sealing in the moisture and natural

avor of entrees like fried chicken for

an unbeatably appetizing menu.

Henny Penny has devoted

more time and energy to

the re nement of our frying

technology than any other

foodservice manufacturer, so

you can be con dent in your

food’s quality, c o n s istency,

and lasting customer appeal.

PFE-500 electric pressure

fryer

and the PFG-600 gas

version

with Computron 8000™

controls. Also available with

electro-mechanical controls.

Page 6

OFG-321 gas open fryer

with attached FDS-200 fryer

dump station and FS-100

shortening shuttle.

Simplifi ed Labor Solutions

When it comes to the success of your

foodservice operation, you rely on your

workforce as much as your equipment.

A large part of Henny Penny’s

commitment to helping you prepare the

best-looking,

making sure that our pressure and open

fryers are designed for the greatest ease

of operation. is means you’ll spend

less time training new employees, and

you can have more con dence in your

menu’s consistent quality. We’ve also

made equipment upkeep and cleaning

faster and easier by making features

like built-in ltration systems standard.

Henny Penny frying systems ensure

simple interaction between workers and

equipment for improved productivity

and greater labor savings.

best-tasting products, is

OFG-391 gas or OFE-291

electric high-volume open

fryer with built-in fi ltration

and counter-balanced

lid lift system.

OFG-341 gas or OFE-341

high-volume, shallowvat open fryer.

Page 7

Programmable computer

controls coupled with a

quality timer simplify the frying

process, making training

and operation easier while

protecting the look and fl avor

of your fi nished product.

Built-in shortening fi ltration in less than four minutes

streamlines the process and reduces associated

labor costs as well as worker frustration, making

your downtime almost negligible.

Henny Penny’s shortening shuttle makes

shortening disposal safer and more effi cient by

helping you transfer used shortening out of the

fryer and easily remove it.

Labor

The Auto Lift option on our open fryers lowers

and raises loads automatically, improving both

consistency and effi ciency. This can be invaluable

in foodservice operations where employees

are often in charge of both food preparation and

waiting on customers.

Page 8

Integration of strategically placed cold zones,

condensation traps, built-in fi ltration, and advanced

heating units that better regulate temperature all

help to extend shortening life and lower the costs

of shortening replacement and disposal.

By using a higher grade of steel and

stringent quality control standards,

fryers have greater durability and are guaranteed

by a 7-year fry pot warranty as well as a 2-year

warranty on all other parts.

The combined savings from faster cook times,

more effi cient use of labor, decreased downtime,

and lower energy bills means lifecycle payback

in 1-2 years.

implementing

Henny Penny

Economy

Improved uptime no matter what conditions you work in,

thanks to full lifecycle testing in labs that can simulate any

climate or humidity. And 100 percent of equipment is tested

for operational integrity before shipping.

Page 9

OEA-322 electric

or OGA-322 gas

Auto Lift open fryer.

Even More Savings

Along with food quality and labor challenges,

we understand your foodservice operation faces

a number of other economic concerns that a ect

your bottom line. at’s why Henny Penny fryers

are built with every aspect of your business in

mind. Like all Henny Penny equipment, our

pressure and open fryers are engineered to

be longer-lasting and more energy e cient.

And with shortening costs representing

the single biggest expense associated with

frying, our various shortening management

features help you save thousands

of dollars every year. Right away

you’ll nd that the

of Henny Penny

signi cant operational savings and

a lower overall cost of ownership.

premium quality

fryers leads to

PFE-591 electric pressure fryer

and the PFG-691 gas version

with built-in fi ltration and

counter-balanced lid lift system.

Page 10

Complementary Equipment

Henny Penny also carries a full line of additional equipment

that works seamlessly alongside our pressure and open fryers.

By o ering further solutions that help you prep food for frying,

hold food for longer periods while keeping it fresh, and display

your o erings in a visually appealing manner, Henny Penny

can be a valuable and versatile foodservice partner.

Holding Cabinets

■

Henny Penny’s SmartHold® system links water

pan heat, fans and ventilation in a closed loop

control that lets you measure and maintain precise

humidity levels from 10 to 90 percent, holding

practically any type of food for exceptionally long

periods without sacri cing freshness.

■

Additional features such as fully insulated doors

and cabinet walls, thermostat controlled heat,

compatible racking system and self-closing doors

also help protect food quality, reduce wasted

product and provide for more e cient work ow.

■

From modular countertop drawer units to

full-size oor models, we o er a complete

range of sizes to choose from based on your

individual holding needs.

HHC-990 SmartHold®

full-size humidifi ed

holding cabinet

with stainless steel

doors and multiple

count-down timer

(CDT) controls.

shown

Page 11

Complementary Equipment

Merchandisers/Heated Displays

■

THERMA-VEC® technology gives precise, even heat

without hot or cold spots or fogged glass for longer

hold times, better taste and more desirable presentation.

■

Control over individual heat wells lets you hold

di erent menu items in the same merchandiser, each

under optimal temperature conditions to maximize

freshness and customer satisfaction.

■

Enhance your operation’s overall aesthetic and

match the look of your current lines with a variety of

con gurable bases and glass cover options.

Breadings, Seasonings

and Breading Systems

■

In-house chefs at our Food Quality Institute have

developed a variety of breadings, seasonings and

marinades — even o ering custom formulations to

meet the tastes of your market.

■

Quality avoring products help you consistently

produce great-tasting chicken with more visual appeal.

■

Our automatic breader is less labor intensive than

hand breading, and supports high-volume production

to meet heavy demand.

■

Customer-proven recipes and shipping within

24 hours make Henny Penny your single source

for fried food breadings and seasonings.

HMR-104

4-well heated

merchandiser.

HB-121 hand

breader and

BM-110 automatic

breading machine.

Page 12

Pressure Fryers

Open Fryers

Rotisseries

SmartCombi

™

Ovens

Holding Cabinets

Heated Display Cases

Blast Chillers/Freezers

Island and Express Merchandisers

Breading Systems

Breadings, Seasonings and Supplies

Technical Service and Training

To learn more about Henny Penny’s

comprehensive products, programs and services,

contact your nearest Henny Penny distributor.

P.O. Box 60 ■ Eaton, Ohio 45320

www.hennypenny.com

1 937 456.8400

80 0 417. 8 417

FM03 -681 Litho in U. S.A. © 20 07 Henny Penny Cor poration, Pr inted 12-06

■

FAX 1 937 456.8434

Toll-free in USA:

■

FAX 800 417.8434

Loading...

Loading...