Page 1

QSR Solutions

Page 2

Setting The Pace

With nearly half of today’s restaurant meals being served in Quick-Service

Restaurants, QSRs account for one of the largest market segments in the

foodservice industry. As a QSR operator, you face the same challenges

as other foodservice professionals, but o en on an even larger scale. We

understand your unique high-volume/high-speed competitive environment

makes for some of the most demanding operational conditions in any

foodservice category. You need equipment that helps you:

■

At Henny Penny, we’ve built our reputation for quality and reliability

on decades of working with both independent restaurateurs and some

of the largest QSR franchises in the world. No matter the size of your

operation, Henny Penny and our distributors o er you the highest quality

products and unmatched market expertise. With the exibility of in-house

manufacturing and the largest worldwide network of service technicians,

we’re well equipped for resolving any issues that may arise. is global

commitment to problem solving makes Henny Penny your trusted

foodservice expert — around the world and in any language.

Ensure food quality

■

Manage time and labor more e ciently

■

Increase pro tability

■

O er extensive menu choices

Superior Food Quality Starts

With Superior Equipment

Because QSR consumers have such a wide variety of choices, you know just

how important outstanding food quality is when it comes to di erentiating

your QSR in the marketplace. Henny Penny brings you all the tools to

Page 3

prepare consistent, great-tasting products, so you can distinguish yourself

from competitors and build repeat business from customers who learn

to expect a great value from your establishment. We also understand the

importance of food safety in your business, as a single bad experience can

damage consumer perceptions drastically. at’s why at Henny Penny,

everything we build is designed to deliver the highest levels of food quality,

safety and consistency in order to ensure your customers’ satisfaction.

An Investment In Your Success

When it comes to investing in your QSR’s success, the long-term impact of

purchasing new equipment goes well beyond the initial cost. Considerations

such as the durability of your equipment to handle the heavy loads

associated with a quick-serve operation and the versatility to test the appeal

of new menu items are vital. Likewise, concerns such as equipment upkeep,

energy e ciency and reducing wasted product have a direct bearing on

raising your pro tability and keeping operational costs low. No one better

understands all of these economic intricacies, or does more to provide a

wealth of solutions, than Henny Penny.

Helping You Work Smarter

While labor is an essential component to any QSR operation, it can also

be one of the biggest challenges you face. In a market segment where high

employee turnover is a stark reality, Henny Penny equipment is designed to

ease the impact of a constantly changing workforce. Engineered to be easy to

operate and easy to clean, our equipment requires minimal supervision and

training. is means increased productivity and reduced labor costs, while

maintaining the quality and consistency of your nished product.

Your Market Challenges

Page 4

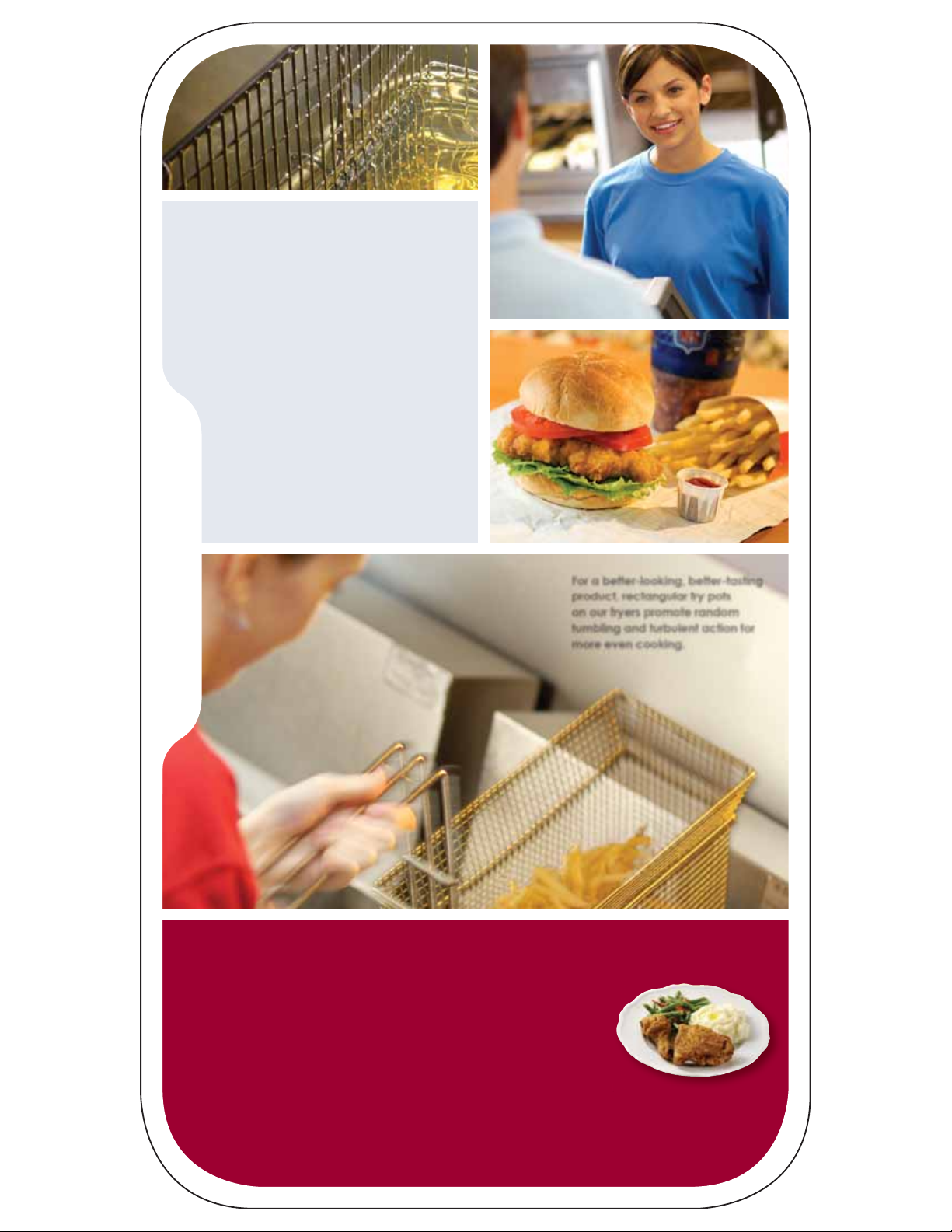

Built-in fi ltration in less than four minutes makes

the process faster and safer, reducing labor costs

as well as worker frustration and making your

downtime almost negligible. Unlike other fryers,

this feature is standard on all Henny Penny open

and pressure fryers.

Proven shortening management technology,

including built-in fi ltration and strategically

engineered placement of burners and cold

zones protect the fl avor of your food, extend

the life of your shortening and reduce costs.

The Auto Lift option on our open fryers

lowers and raises loads automatically,

improving both consistency and effi ciency.

This can be invaluable for QSRs, where

employees are often in charge of both food

preparation and waiting on customers.

For a better-looking, better-tasting

product, rectangular fry pots

on our fryers promote random

tumbling and turbulent action for

more even cooking.

Open and Pressure Fryers

Breadings, Seasonings and Breading Systems

When it comes to the avor of your fried and roasted foods, nothing is

as important as the breadings, seasonings and marinades you use.

at’s why the in-house chefs at our Food Quality Institute have

developed over twenty exclusive recipes to satisfy the entire spectrum

of customer taste preferences — we can even customize recipes for the

local palate of your customers. Whichever options you choose, you can

be con dent that Henny Penny breadings and seasonings will consistently deliver the best in

color, texture and avor. And with our hand breading stations and automatic breaders, you

can streamline the breading process depending on your volume and workforce.

Page 5

Open and

Pressure Fryers

Regardless of how consumer tastes change,

there will always be a demand for delicious fried

foods. From preparing timeless favorites like

fried chicken and French fries, to other menu

options such as tenderloins, onion rings and

zucchini, Henny Penny fryers allow you to make

the entrees and side items that many customers

crave from their Supermarket deli. Henny Penny

pioneered the rst commercial pressure fryer

in 1957, so you can rest assured knowing we’ve

spent 50 years perfecting the art of crisp, moist,

delicious fried foods with the most trusted

premium fryers on the market.

Page 6

Combi-Ovens

When it comes to expanding the capabilities

and revenue opportunities of your QSR,

no single piece of equipment can match

the versatility of combi-ovens. Using both

moist heat and dry heat, separately and in

combination, a combi-oven can

replace your need for a traditional

grill, steamer and convection

oven, and help you make the

most of limited oor space. What

sets Henny Penny’s SmartCombi™ apart

from others on the market is our Advanced

Steam Technology.™ is patented technology

utilizes an integrated heat exchanger to heat

water before it ows onto a fan wheel where

a specialized rim and high rotation speed

split the water into tiny droplets that quickly

evaporate throughout the cooking chamber.

Henny Penny’s quality design and construction

means a combi-oven that delivers better food

quality at a lower cost of ownership. And with

the optional Crosswise Plus pans, you can

increase SmartCombi™ capacity by 50 percent

without sacri cing taste.

Page 7

Programmable controls and an integrated temperature

probe make

regardless of your experience with the technology.

the SmartCombi™ simple to master,

Henny Penny’s WaveClean

our SmartCombi

supervision. Simply load a cleaning cartridge and

push a button.

Unmatched fl exibility means frozen entrees,

side dishes, appetizers and even baked goods

are all prepared perfectly, and the added

convenience of being able to cook multiple

different items at the same time leads to

increased effi ciency and faster prep times.

™

ovens automatically, requiring no

™

system thoroughly cleans

Ovens

™

SmartCombi

Page 8

Easily removable stainless steel parts and optional

®

Tefl on

coating make Henny Penny rotisseries easy

to clean and keep maintenance to a minimum,

saving both time and labor.

Programmable controls allow you to customize

your settings for superior taste and consistency

regardless of operator.

Patented THERMA-VEC

combines infrared heating with gentle cross-fl ow

convection for uniform browning and a moist,

evenly cooked fi nished product.

Cook a full load of chickens in a shorter amount

of time, giving you the ability to prepare more

meals in less time.

®

even heat process

Rotisseries

Page 9

Rotisseries

Available in a variety of sizes, rotisseries

give you yet another option for expanding

your QSR’s menu and driving consumer

sales with products that o er a unique

visual appeal. While best known for

cooking mouth-watering, golden chicken,

a rotisserie is also great for preparing items

such as kebabs, ribs, roasts and pastries.

Page 10

Holding Cabinets

e ability to cook in volume and serve on

demand is critical to any QSR operation.

Henny Penny understands just how important

holding cabinets are to this process and to your

bottom line, that’s why we manufacture a wide

variety of cabinets with an impressive range

of features. From modular countertop drawer

units to full-size oor models, our heated

and humidi ed holding cabinets o er fully

insulated doors and cabinet walls, thermostat-

controlled heat, circulating air ow and

self-closing doors. All of which helps keep

your food warm and ready-to-serve for

exceptionally long periods of time.

Page 11

Full and half-size holding cabinets

are available with standard or

multiple count-down timer (CDT)

controls, stainless steel or tempered

glass doors, and as solid back or

pass-through units.

Accessories

In addition to the major

equipment required to

build your QSR operation,

Henny Penny also o ers all

of the additional accessories

you may need to keep your

business running smoothly.

From integrated racking

systems, heated portable

dump stations and shortening

shuttles for more e cient

handling, to incidentals

such as potato cutters,

decorative carryout cartons

and a full line of cleaning

supplies, Henny Penny has

everything you need.

Accessories

SmartHold

pan heat, fans and ventilation in

a closed loop control to maintain

precise humidity levels from 10 to 90

percent, allowing you to create the

perfect holding environment.

®

technology links water

Holding Cabinets

Page 12

Pressure Fryers

Open Fryers

Rotisseries

SmartCombi

™

Ovens

Holding Cabinets

Heated Display Cases

Blast Chillers/Freezers

Island and Express Merchandisers

Breading Systems

Breadings, Seasonings and Supplies

Technical Service and Training

To learn more about Henny Penny’s

comprehensive products, programs and services,

contact your nearest Henny Penny distributor.

P.O. Box 60

1 937 456.8400

80 0 417.84 17

FM03 -672 Litho in U. S.A. © 20 07 Henny Penny Corp oration, Pr inted 12-06

Tefl on

■

www.hennypenny.com

Eaton, Ohio 45320

■

FAX 1 937 456.8434

Toll-free in USA:

■

FAX 800 417.8434

®

is a regi stered tradem ark of DuPont

®

Loading...

Loading...