Vacuum Packaging Machine

Marlin, Falcon, Polar

User Manual

Art No. 0895111

Original Instructions for Use

©

Henkelman 2017-2018

• The machine is not suitable for the packaging of toxic, corrosive, irritant or potentially

explosive materials.

• All persons responsible for the operation of this machine must at least fully read and

understand the chapters about the operation and safety provided in these operating

instructions.

• All persons responsible for the assembly, installation, maintenance and/or repairs must

fully read and understand these operating instructions.

• The user is at all times responsible for the interpretation and use of this manual.

Contact the owner or the manager in case of questions or doubts about the correct

interpretation.

• This manual should be kept near the machine and should be within reach for its users.

• All major maintenance work, modifications to the machine and observations must be

kept in a logbook; see Logbook on page 75.

• Modifications to the installation/machine are not allowed without the prior written

consent of the supplier. Such modifications will invalidate the ETL Certification.

• For specific maintenance work not included in this manual, please contact the supplier.

• Comply with the safety requirements as set out in Safety at all times.

• The correct operation and safety of the system can only be guaranteed if the

recommended maintenance is performed on time and properly.

• Illustrations shown may differ from your machine.

Copyright © Henkelman BV / Henkelman Inc. 2017-2018

Henkelman BV / Henkelman Inc. reserves the right to change specifications and/or spare parts without prior notice.

The content of this user manual may also be changed without prior notice.

For information about settings, maintenance and repairs not provided for in this user manual, please contact the technical department of your supplier.

Henkelman BV / Henkelman Inc. accepts no liability for damage and/or problems arising from the use of spare parts not supplied by Henkelman BV /

Henkelman Inc..

This user manual has been compiled with all possible care. Henkelman BV / Henkelman Inc. assumes no responsibility for any errors in this manual and/or

the consequences of an erroneous interpretation of the instructions.

All rights reserved. No part of this publication may be reproduced, stored in computerised databases, or made public, in any form or by any means, either

electronic, mechanical, through photocopying, recording or otherwise, without the prior written consent of Henkelman BV / Henkelman Inc.. This also

applies to the associated drawings and diagrams.

Contents

List of Figures................................................................................................................................. 6

1 Preamble....................................................................................................................................... 7

2 Safety.............................................................................................................................................8

2.1 List of the Symbols Used in this Manual............................................................................... 8

2.2 Pictograms on the Machine................................................................................................... 8

2.3 General Warnings.................................................................................................................. 9

2.4 Warnings During Use...........................................................................................................10

2.5 Warnings for Operating Personnel.......................................................................................11

3 Introduction.................................................................................................................................12

4 Description of the Machine.......................................................................................................13

4.1 Overview of the Main Components......................................................................................13

4.2 Description of the Packaging Process/Machine Functions.................................................. 14

4.2.1 Packaging Process/Machine Functions........................................................................14

4.2.2 General Functions........................................................................................................18

4.3 Sealing System.................................................................................................................... 19

4.4 Vacuum Pump......................................................................................................................20

4.5 Electrical Installation.............................................................................................................20

5 Installation...................................................................................................................................23

5.1 Transportation and Installation............................................................................................. 23

5.2 Connecting the Machine...................................................................................................... 23

5.3 Prior to the First Use........................................................................................................... 24

6 Operation.....................................................................................................................................26

6.1 Operating Elements of the 10-Programme Control System.................................................26

6.2 Operating Elements of the Advanced Control System (ACS)..............................................27

6.2.1 Changing the ACS Settings......................................................................................... 28

6.2.2 Importing/Exporting Data..............................................................................................31

6.2.3 Data Log ID..................................................................................................................31

6.2.3.1 Setting and Using the Data Log ID...................................................................... 31

6.2.3.2 Exporting Data Log.............................................................................................. 32

6.3 Starting the Machine............................................................................................................33

6.4 Starting the Packaging Cycle...............................................................................................33

6.5 Proceeding to the Next Step in the Cycle........................................................................... 33

6.6 Terminating a Programme....................................................................................................34

6.7 Changing the Programme Settings......................................................................................34

6.7.1 10-Programme Control System....................................................................................34

6.7.1.1 Vacuum.................................................................................................................34

6.7.1.2 Vacuum (automatic)..............................................................................................35

6.7.1.3 Vacuum+ (optional)...............................................................................................35

Contents 3

6.7.1.4 Gas (optional).......................................................................................................35

6.7.1.5 Gas+ (optional).....................................................................................................36

6.7.1.6 Liquid Control (optional)....................................................................................... 36

6.7.1.7 Liquid Control+ (optional)..................................................................................... 37

6.7.1.8 Red Meat (optional)..............................................................................................37

6.7.1.9 Multi-Cycle Vacuum (optional)..............................................................................37

6.7.1.10 Seal.....................................................................................................................38

6.7.1.11 Soft-Air (optional for the Falcon)........................................................................ 38

6.7.1.12 External Vacuum (optional)................................................................................ 39

6.7.1.13 Sleeper Option....................................................................................................39

6.7.2 Advanced Control System (ACS).................................................................................40

6.7.2.1 Programming the ACS Control Using the PC...................................................... 41

6.7.2.2 Functions.............................................................................................................. 41

6.7.2.3 Vacuum.................................................................................................................41

6.7.2.4 Vacuum (automatic)..............................................................................................42

6.7.2.5 Vacuum+ (optional)...............................................................................................42

6.7.2.6 Gas (optional).......................................................................................................42

6.7.2.7 Gas+ (optional).....................................................................................................43

6.7.2.8 Liquid Control (optional)....................................................................................... 43

6.7.2.9 Liquid Control+ (optional)..................................................................................... 44

6.7.2.10 Red Meat (optional)............................................................................................44

6.7.2.11 Sequential Vacuum (optional).............................................................................44

6.7.2.12 Marinating (optional)...........................................................................................45

6.7.2.13 Tenderising (optional)......................................................................................... 45

6.7.2.14 Seal.....................................................................................................................46

6.7.2.15 Soft-Air (optional for the Falcon)........................................................................ 46

6.7.2.16 External Vacuum (optional)................................................................................ 47

6.7.2.17 Sleeper Option....................................................................................................47

6.7.2.18 Dealer Information.............................................................................................. 47

6.8 Guideline for Function Values.............................................................................................. 48

6.9 Printer (ACS only)................................................................................................................50

6.9.1 Connecting a Printer.................................................................................................... 50

6.9.2 Creating a Label...........................................................................................................51

6.10 Automatic lid (optional on Polar 2-85 and 2-95)................................................................ 51

6.10.1 Operating the automatic lid........................................................................................ 53

6.10.2 Restarting the automatic lid after an emergency....................................................... 53

7 Maintenance................................................................................................................................54

7.1 Maintenance Schedule.........................................................................................................54

7.2 Cleaning the Machine.......................................................................................................... 55

7.3 Running the Pump Cleaning Programme............................................................................ 55

7.4 Removing Oil, Replacing Oil Filter, Refilling Oil...................................................................55

7.5 Replacing the Oil Exhaust Filter.......................................................................................... 56

7.5.1 Pump 76 m3/2684 cf/h - 360 m3/12713 cf/h................................................................ 57

7.6 Replacing the Sealing Wire................................................................................................. 57

7.7 Replacing the Silicone Rubber of the Silicone Holders....................................................... 59

7.8 Replacing the Lid Gasket.....................................................................................................60

Contents 4

7.9 Inspecting the Lid Springs................................................................................................... 61

8 Troubleshooting......................................................................................................................... 62

9 Disposal.......................................................................................................................................64

10 Appendices............................................................................................................................... 65

10.1 Technical Data....................................................................................................................65

10.1.1 Technical Data Marlin.................................................................................................65

10.1.2 Technical Data Falcon................................................................................................ 66

10.1.3 Technical Data Polar.................................................................................................. 68

10.2 Example Programmes........................................................................................................72

10.3 Logbook..............................................................................................................................75

10.4 EC Declaration of Conformity............................................................................................ 77

10.5 Replacing a Printer Roll..................................................................................................... 78

10.6 Aligning the Printer.............................................................................................................79

Contents 5

List of Figures

Figure 1: Overview of the Main Components................................................................................. 13

Figure 2: Overview of the Sealing System (Including Sealing Cylinder).........................................19

Figure 3: Overview of the Sealing System (Including Seal Bag).................................................... 19

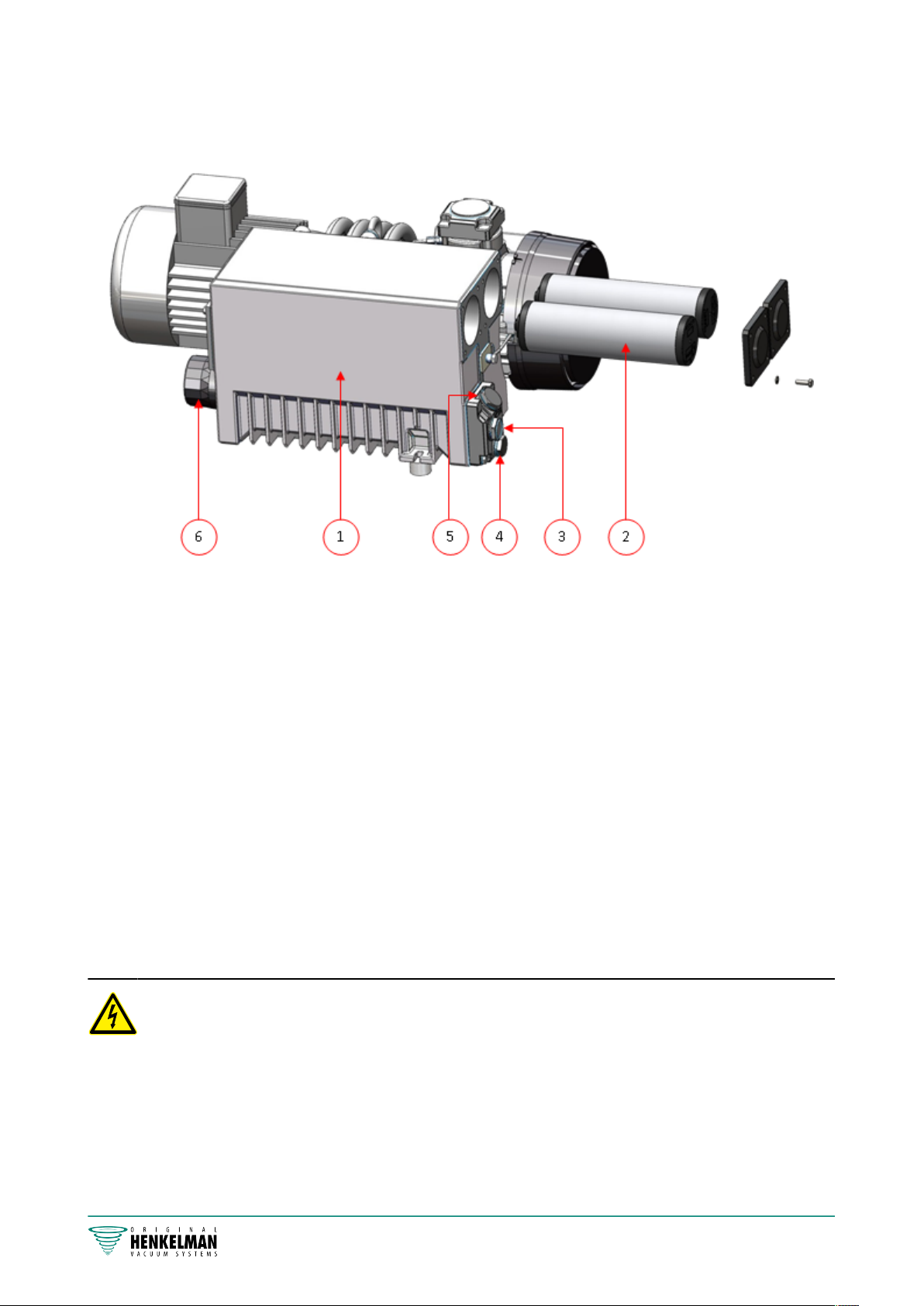

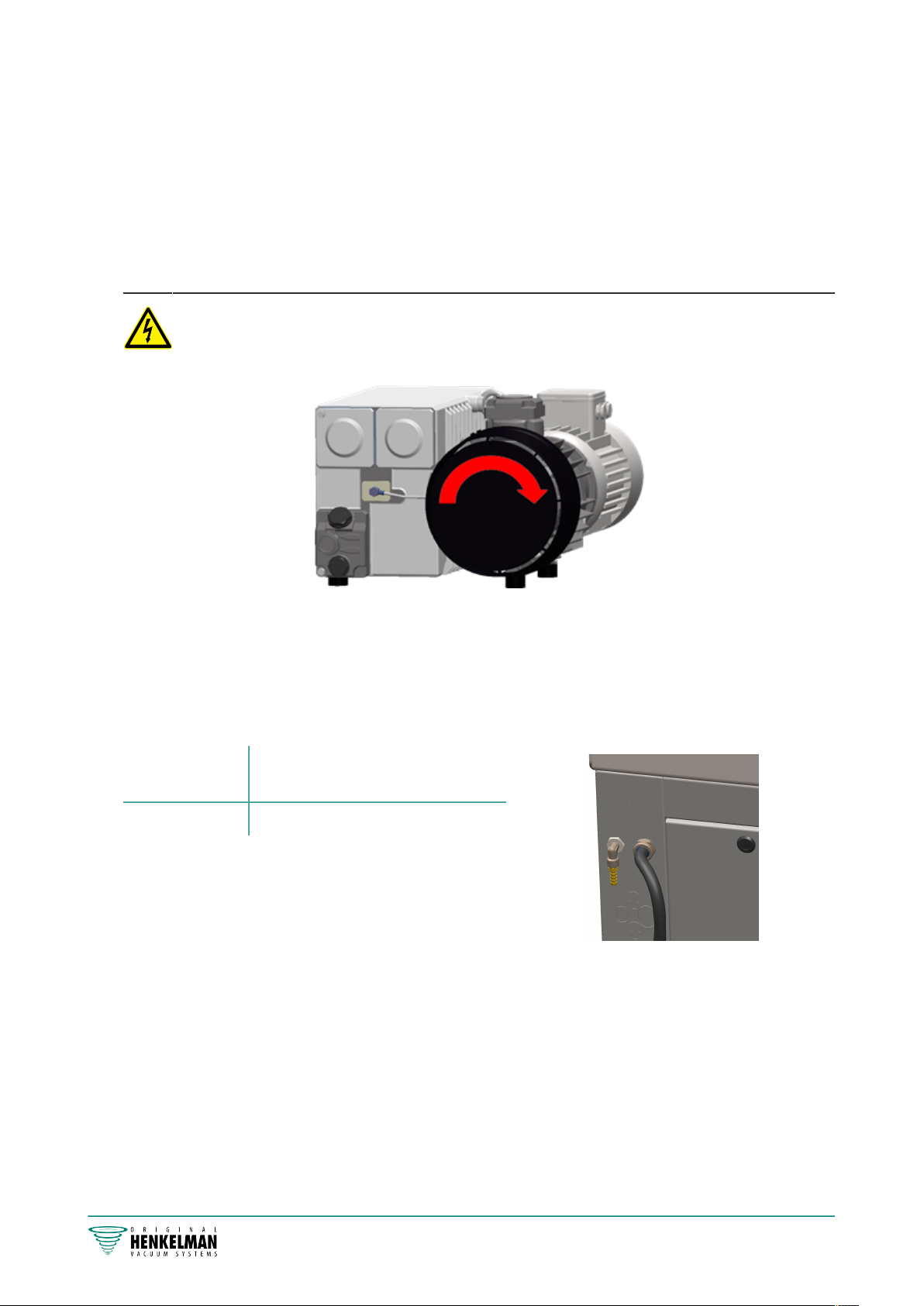

Figure 4: Overview of the Pump (75 m3/h / 2780 cf/h)...................................................................20

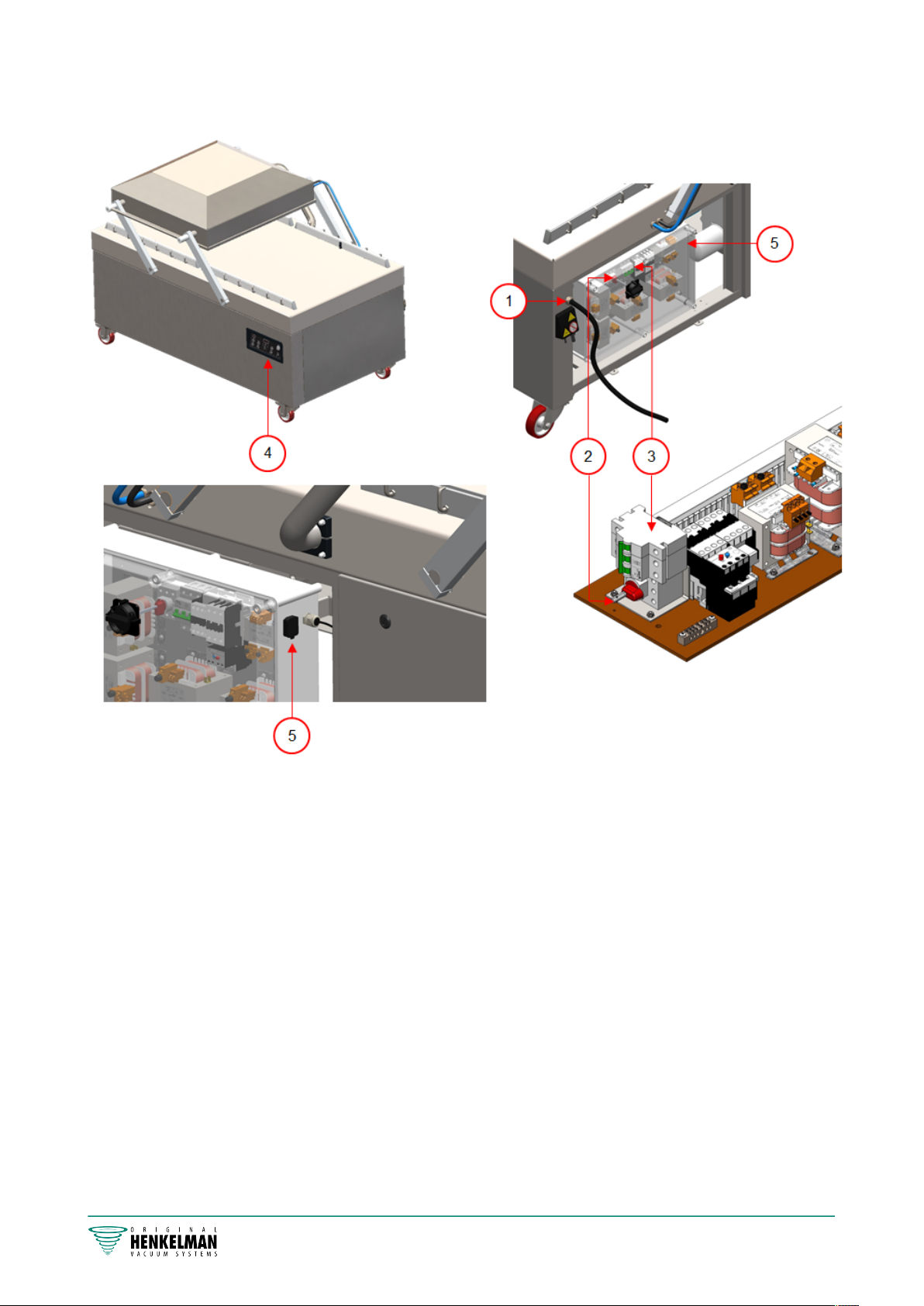

Figure 5: Overview of the Electrical Installation..............................................................................21

Figure 6: Direction of Rotation of the Vacuum Pump..................................................................... 24

Figure 7: Hose connection for compressed air...............................................................................24

Figure 8: Control Panel of the 10-Programme Control System...................................................... 26

Figure 9: Control Panel of the Advanced Control System (ACS)....................................................27

Figure 10: Possible Display Modes.................................................................................................28

Figure 11: Possible Display Modes.................................................................................................28

Figure 12: Overview of the Menus..................................................................................................30

Figure 13: Example of an Exported Data Log................................................................................32

Figure 14: External Vacuum Adapter Set (10-Programme Control System)................................... 39

Figure 15: Screenshot of the navigation mode and the operating buttons of the ACS....................40

Figure 16: External Vacuum Adapter Set (ACS)............................................................................ 47

Figure 17: Vapour Pressure Curve of Water.................................................................................. 50

Figure 18: Foot switch.....................................................................................................................52

Figure 19: Emergency stop.............................................................................................................52

Figure 20: Safety bumper................................................................................................................52

Figure 21: Reset button.................................................................................................................. 53

Figure 22: Automatic lid switch....................................................................................................... 53

Figure 23: Replacing the Oil Exhaust Filter (Pump 76 m3/2684 cf/h - 360 m3/12713 cf/h)............ 57

Figure 24: Removing the Sealing Bar (Plastic Lid).........................................................................58

Figure 25: Removing the Sealing Bar (Metal Lid).......................................................................... 58

Figure 26: Replacing the Sealing Wire........................................................................................... 58

Figure 27: Replacing the Silicone Rubber of the Silicone Holders................................................. 59

Figure 28: Replacing the Lid Gasket.............................................................................................. 60

Figure 29: Replacing the Printer Roll............................................................................................. 78

Figure 30: Aligning the Printer........................................................................................................ 79

Figure 31: Printing the First Label.................................................................................................. 79

List of Figures 6

1 Preamble

This is the manual for your Henkelman vacuum packaging machine. This manual is intended for

anyone who works with or services the machine.

This manual contains information and instructions for installation, operation and maintenance

of the machine. We recommend that you carefully read this manual before use and follow the

procedures and instructions strictly. This will ensure that you get the best out of the machine and

prevents possible accidents and serious injury.

Preamble 7

2 Safety

Your vacuum packaging machine has been carefully designed and expertly built to be operated

safely. This is corroborated by the ETL Certification and the EC Declaration of Conformity.

However, there are always dangers and safety risks that cannot be eliminated. These dangers

and risks are the result of the use functions of the machine and operation of the machine by the

user. This section discusses safety instructions and precautions, how they will be pointed out to

you and the requirements the user must meet. It is essential that you are well aware of these safety

instructions and requirements and observe them at all times!

2.1 List of the Symbols Used in this Manual

For all operations in which the safety of the operator and/or technician is at stake and where

caution should be exercised, the following symbols are used.

This symbol provides insight or offers tips to help facilitate certain actions.

This symbol warns for dangerous situations that may lead to damage to the machine or

personal injury.

This symbol warns for high voltage.

2.2 Pictograms on the Machine

Pictograms and warnings have been fitted on the machine to warn users of the possible risks.

Warning sign 'Hazardous voltage'

• Is located on the back of the machine

Caution sign ‘Electric shock’

• Is located on the back of the machine

Safety 8

Caution sign ‘Hot surface’

• Is located on the housing of the machine

Warning sign ‘Gas Connection’ (optional)

Forbidden to connect oxygen

• Is located on the back of the machine

Warning sign ‘Gas Connection’ (optional)

Maximum allowed gas pressure of the gas flush system

• Is located on the back of the machine

Warning sign ‘Seal Pressure Connector’ (optional)

Maximum allowed gas pressure of the gas flush system

• Is located on the back of the machine

Machine plate

• Is located on the back of the machine

Regularly check whether the pictograms and markings are still clearly recognisable and

legible. Replace them if this is not the case.

2.3 General Warnings

• All persons responsible for the operation of this machine must at least fully read and

understand the chapters Safety and Operation on page 26.

• Failure to follow the safety instructions may result in serious injury.

• Never pack products that can be damaged by vacuum.

• Never vacuum live animals.

• Warranty, liability and/or ETL certification is void if any damage is caused by repairs and/

or modifications that are not authorised by the supplier or any of its distributors.

• In case of malfunction, contact the supplier.

Safety 9

• High pressure cleaning is not allowed. This may cause damage to the electronics and

other components.

• Prevent water from entering the ventilation inlet of the chamber or the exhaust of the

pump. This causes irreversible damage to the pump.

• The work space around the machine must be safe. The owner of the machine must take

the necessary precautions to operate the machine safely.

• It is forbidden to start the machine in an explosive environment.

• The machine has been designed in such a way that production is safe under normal

ambient conditions.

• The owner of the machine must ensure that the instructions in this manual are actually

complied with.

• The available safety devices may not be removed.

• The correct operation and safety of the system can only be guaranteed if the

recommended maintenance is performed on time and properly.

• If work must be carried out on the machine, it must be disconnected and blocked from

the power supply and, if applicable, from the air and gas supply.

• Only a technical expert may perform work on the electrical installation.

• Internal procedures and monitoring must be in place to ensure that all relevant power

supplies are disconnected.

• The machine may not be used during cleaning, inspection, repair or maintenance and

must be disconnected from the power supply by disconnecting the plug and/or using the

main switch.

• Never perform welding work on the machine without first disconnecting the cable

connection to the electrical components.

• Never use the power supply of the control unit to connect other machines.

• All electrical connections must be connected to the terminal strips according to the

wiring diagram.

2.4 Warnings During Use

• Before starting the machine, make sure no work is being performed on the installation

and that the machine is ready for use.

• The machine may not be operated by unauthorised persons. This should be monitored

by the machine operator(s).

• Immediately contact the service technician of your technical department or dealer if

something does not seem right, such as unusual vibrations or unusual noise.

• Components of the sealing system can become very hot. Contact with these

components may cause injuries.

• Improper use, such as switching off the machine while it is creating a vacuum, is

strongly discouraged. Such actions may cause oil leaking back to the vacuum chamber.

Safety 10

2.5 Warnings for Operating Personnel

• Operating personnel must be 18 years or older.

• Only authorised persons are allowed to perform work on or with the machine.

• Personnel may only perform work for which it was trained. This applies to both

maintenance and normal use.

• The machine may only be operated by trained personnel.

• Operating personnel must be familiar with all circumstances, so quick and effective

action can be taken in case of an emergency.

• If an operator notices errors or risks or disagrees with safety measures, he or she

should report this to the owner or manager.

• Safety shoes are mandatory.

• Appropriate work clothing is mandatory.

• All personnel must obey the safety regulations to avoid danger to themselves and

others. Always strictly follow the work instructions.

Safety 11

3 Introduction

Henkelman Inc.is a supplier of ultra-modern vacuum packaging machines. Our machines are

developed and manufactured to meet the highest standards. They combine a sleekly built and

functional design with optimal ease of use and a long service life. After mounting the plug, it is just

a matter of "plug & pack". The clever design ensures compliance with the hygiene standards at all

times.

The Marlin, Falcon and Polar series are floor models with various options suitable for a variety of

applications. These machines have several programmes and options for optimal packaging.

Introduction 12

4 Description of the Machine

This section provides an overview of the main components and functions. If detailed information is

available in this manual, you will be referred to the specific sections.

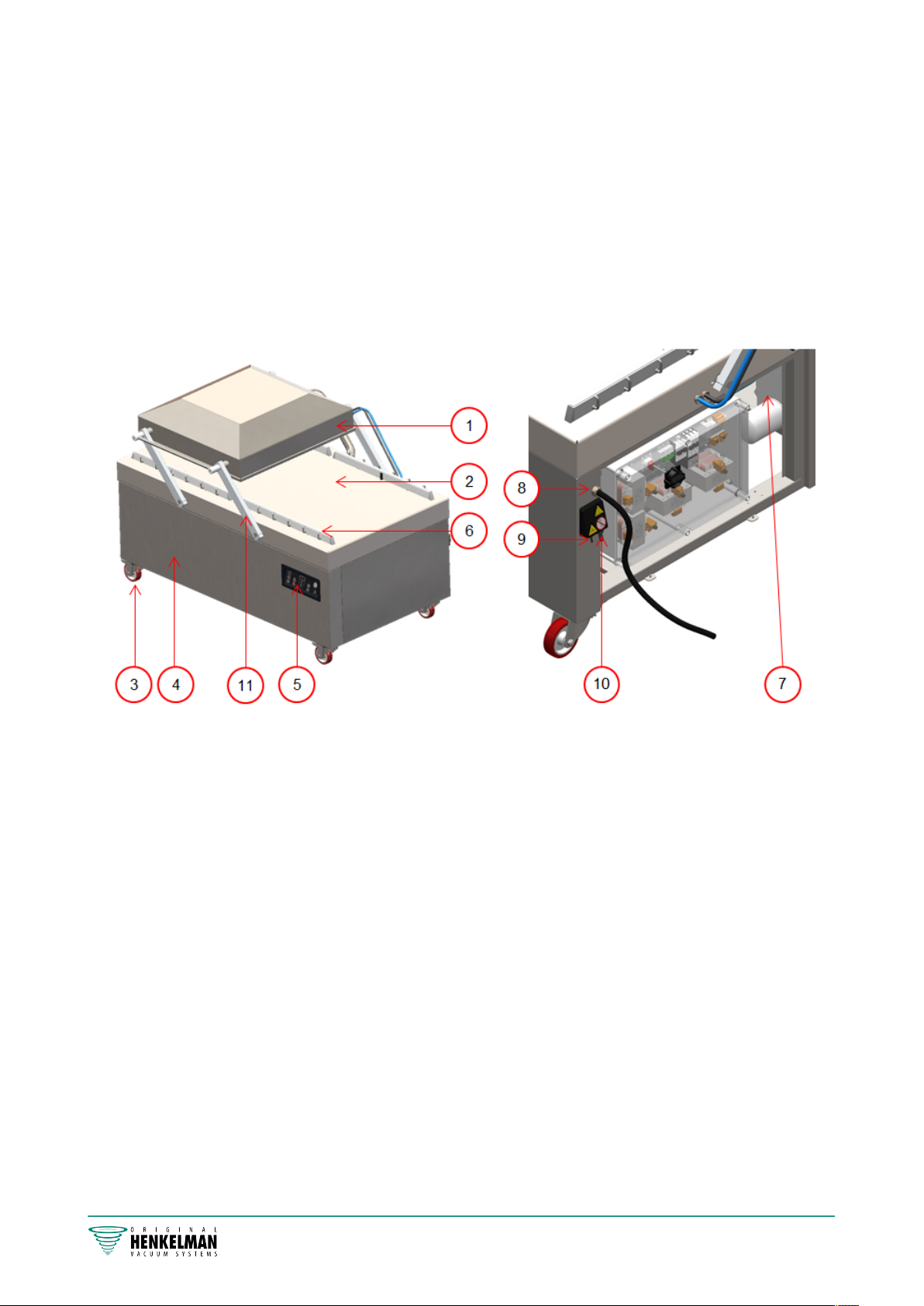

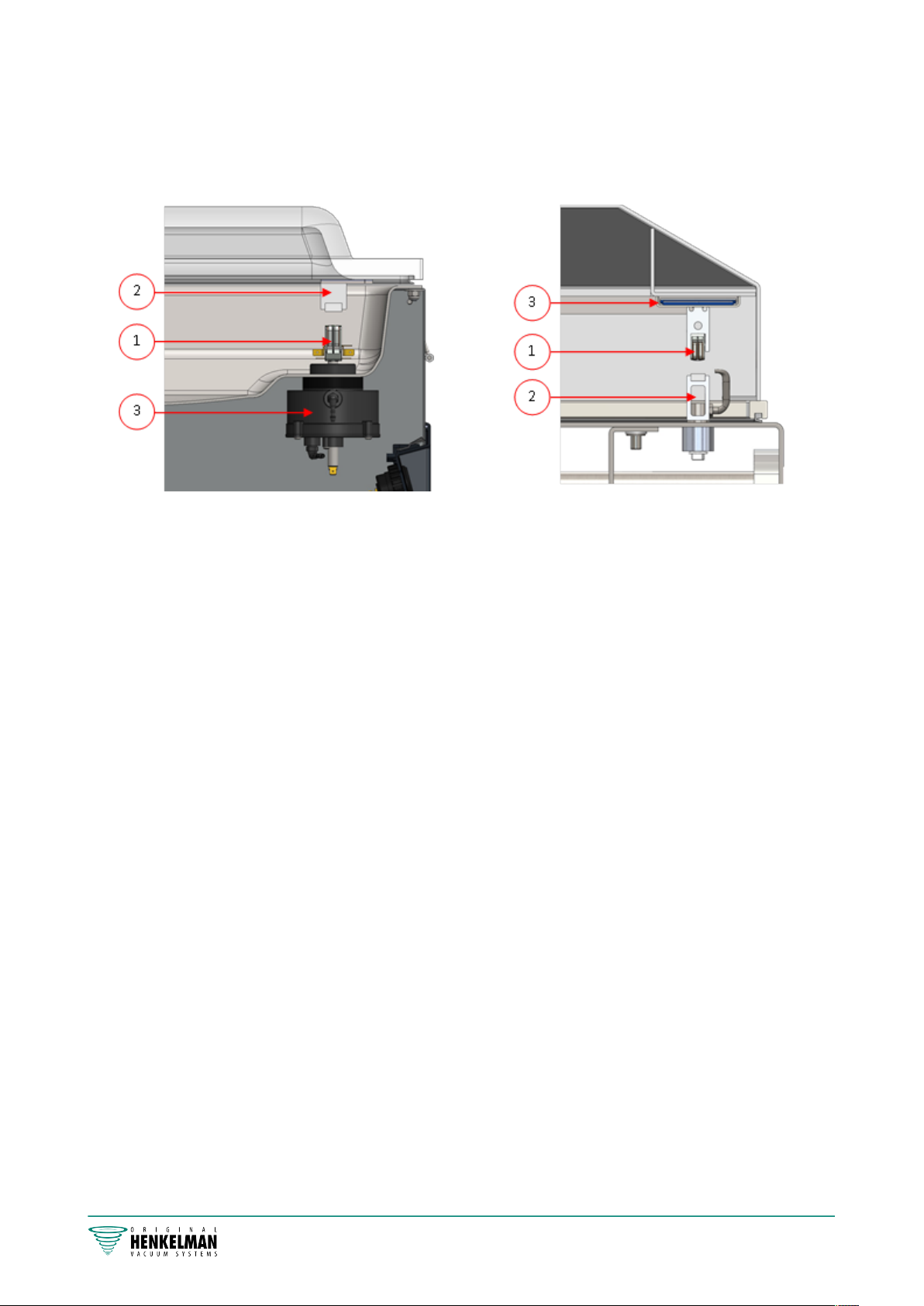

4.1 Overview of the Main Components

The figure below shows the main components of the system. The model shown may differ from

your machine.

Figure 1: Overview of the Main Components

1. Lid

The lid closes the vacuum chamber during the application of the vacuum. A rubber is mounted

in the lid to ensure proper closing. On machines with two vacuum chambers, the lid can be

moved from position 1 to position 2 manually. In these machines, the sealing bars and suction

inlet for the vacuum are included in the lid.

2. Vacuum chamber

The products to be packaged are placed on the work surface with the openings of the vacuum

bags on the sealing position. On machines with two vacuum chambers, the already packaged

product can be removed and new products can be placed on the free work surface during the

vacuuming and sealing process.

3. Castor with brake

The machines are fitted with four castors with brake. This allows for easy moving of the

machine to a different location.

4. Machine housing

The machine housing contains all the components necessary for the functioning of the

machine.

Description of the Machine 13

5. Control panel

This serves to operate the available control functions. Depending on your model, your

machine will have the 10-programme control system or the Advanced Control System (ACS).

6. Seal system

Depending on the model, one, two or three sealing bars are mounted in the vacuum chamber.

These close the vacuum bag.

7. Vacuum pump

The vacuum pump creates the vacuum.

8. Power connection and cable

This serves to connect the machine to the power supply. The machine is supplied without an

electrical plug.

9. Seal pressure connector (optional)

Where the standard model makes use of atmospheric pressure to press the seal bar onto the

vacuum bag during the sealing process, it is also possible (optional) to connect to an external

source in order to obtain a higher sealing pressure.

10. Gas flush system connector (optional)

After applying vacuum, a gas is injected into the packaging to create a modified atmosphere to

protect the shape of the product or increase the shelf life of the product.

4.2 Description of the Packaging Process/Machine Functions

This section provides an overview of the packaging process and available machine functions.

For the functions Liquid Control (and Liquid Control+), Gas (and Gas+), Seal 1-2 Cut-off

and Soft-air, specific components must be installed on your machine before they can be

enabled. Contact your supplier for more details.

See Changing the Programme Settings on page 34 for information about setting the

parameters to the correct values.

4.2.1 Packaging Process/Machine Functions

This section describes the packaging process and the machine functions. See Operation on page

26 for the realization of the specific steps of the procedure.

Step Process phase Operation

1. Preparation The operator puts the product in a vacuum bag and places it

on the work surface with the opening on the sealing position.

2. Applying vacuum

The vacuum process is initiated by closing the lid.

Depending on the options you selected for your machine and

the product you are packaging, the following functions are

available:

Description of the Machine 14

Step Process phase Operation

Vacuum

Vacuum+

During the cycle, the air is removed from the chamber until

the set time or pressure has been reached, depending on

the selected model.

Applying vacuum until a set value is reached is only possible

if your machine is sensor-controlled (optional for 10programme control system). This value can be set in %.

The percentage indicates the depth of the vacuum. This is

in relation to an outside atmosphere of 0%. In case of the

Advanced Control System (ACS), the value is indicated in

percentages, mbar or hPa.

Vacuum+ is only available if the vacuum percentage is set to

the maximum.

The Vacuum+ option continues the vacuum process for an

additional time to allow any entrapped air to escape from the

product.

The Vacuum+ option is only available on sensor-controlled

machines.

Gas (optional)

Gas+ (optional)

Liquid Control

(optional)

After applying vacuum, a gas is injected into the package

to create a modified atmosphere to protect the shape of the

product or to increase the shelf life of the product. The value

of the gas function can be set in %, mbar or hPa or time,

depending on the control type of the machine.

The Gas+ option continues injecting gas during the closing

of the bars to increase the amount of gas in the package.

See Gas+ (optional) on page 36.

Liquid Control is only available if your machine is equipped

with the optional Liquid Control sensor.

With the Liquid Control option, the system is controlled by

a highly sensitive sensor. The sensor is able to detect the

moment that liquids from the product or the product itself

begin to evaporate (boil). At that time the system will proceed

to the next step in the process. This will prevent the product

from dehydrating, losing weight and/or the vacuum bag from

Description of the Machine 15

Step Process phase Operation

bursting, thus contaminating the seal, the chamber, and the

oil in the pump. See Liquid Control (optional) on page 36.

Liquid Control+

(optional)

Red meat (optional)

Sequential Vacuum

(optional)

Liquid Control+ is only available if your machine is equipped

with the Liquid Control option.

The Liquid Control+ function allows you to continue the

vacuum process for a certain time after the evaporation point

has been reached.

This option is especially designed for the packaging of fresh

meat. It is added to the normal vacuum function to prevent

degassing of the product during and after the sealing phase.

This degassing could create air pockets inside the package.

See Red Meat (optional) on page 37.

This function is only available on machines with the

Advanced Control System (ACS).

With sequential vacuum, you can alternate vacuum and

pause steps to allow air trapped inside a product to escape

from the core. A maximum of 5 steps can be programmed.

Multi-Cycle Vacuum

(optional)

Marinating (optional)

This function is only available on machines with a 10programme control system. See 10-Programme Control

System on page 34.

The Multi-Cycle Vacuum option allows you to vacuum and

insert gas in steps. This provides an additional reduction in

the oxygen content.

This function is only available on machines with the

Advanced Control System (ACS).

This function is especially designed to accelerate the

marinating of a product. This programme allows definition of

up to 5 vacuuming steps with intermediate ventilation steps.

The vacuuming steps have a fixed vacuum value of 80%,

except for the last step. The last vacuuming step has an

adjustable value of up to 99.8%. This also allows setting

Description of the Machine 16

Step Process phase Operation

Vacuum+. The intermediate ventilation steps have a fixed

value of 42%. After the last step, sealing takes place.

Liquid Control: It is also possible to enable Liquid Control.

This function will then only be active during the last

vacuuming step. If, for instance, 3 vacuuming steps have

been defined, Liquid Control will be active during the third

step. Vacuum+ is also possible here; however, this would be

a Liquid Control+ setting of 0.1 sec with a maximum of 5.0

sec.

3.

Tenderising

(optional)

Sealing The sealing bars are pressed against the vacuum bag and

Seal

This function is only available on machines with the

Advanced Control System (ACS).

This feature has been designed to keep the chamber at a

pre-determined vacuum level for a certain time. This is done

to tenderise or degas the product.

During the cycle, the air is removed from the chamber until

the pre-set value has been reached. Once this value has

been reached, the chamber will remain at this vacuum level

for the pre-set time.

melt the bag closed.

During the sealing process, the material of the vacuum bag

is heated and pressed together to create a hermetic seal.

The programming of this function takes place in seconds.

Optionally, a cut-off wire is available. The purpose of the

cut-off wire is to remove the excess foil. Depending on the

selected model, the cut-off wire is controlled simultaneously

with or independent from the sealing wire (Seal 1-2 cut-off).

Soft-Air (optional for

the Falcon)

4. Decompressing The vacuum is removed from the vacuum chamber by letting

5. Opening the

vacuum chamber

This function allows air from outside to slowly enter the

chamber so the vacuum bag will shape itself slowly around

the product. This prevents sharp edges of the product from

puncturing the foil and causing leaks.

air into the chamber.

The lid opens.

Description of the Machine 17

Step Process phase Operation

6. Removing the

product

The operator can remove the packaged product from the

work surface.

4.2.2 General Functions

Function Pictogram Operation

Cleaning of the

oil pump

Menu

Printing

The pump cleaning programme ensures that the pump is

thoroughly rinsed. During the programme, the pump and

oil reach the operating temperature, so the oil and moisture

are separated and any contamination is filtered. The high

temperature causes any moisture in the pump to evaporate, thus

minimising the risk of corrosion.

This menu is available on machines with ACS control. The menu

is used to change the machine settings, such as language and

print options.

This function is available on machines with ACS control.

This function allows the creation of one or more labels per cycle,

to be put on the packaging.

External

Vacuum

Sleeper option The Sleeper option shuts down the machine after a certain time.

The following information can be printed on the label: name of

the producer, name of the product, production date, shelf life,

achieved vacuum, initials of the user, recommended storage

temperature and an information field (for example to indicate the

gas used).

This function is available as an option, depending on the type of

machine.

This function allows special food containers to be vacuumed

outside the machine.

The options to set the vacuum value are the same as for

standard vacuuming (see External Vacuum (optional) on page

39 for 10-programme control system or External Vacuum

(optional) on page 47 for ACS control).

The default setting is 10 minutes. If you wish to change this time,

please contact your supplier.

Description of the Machine 18

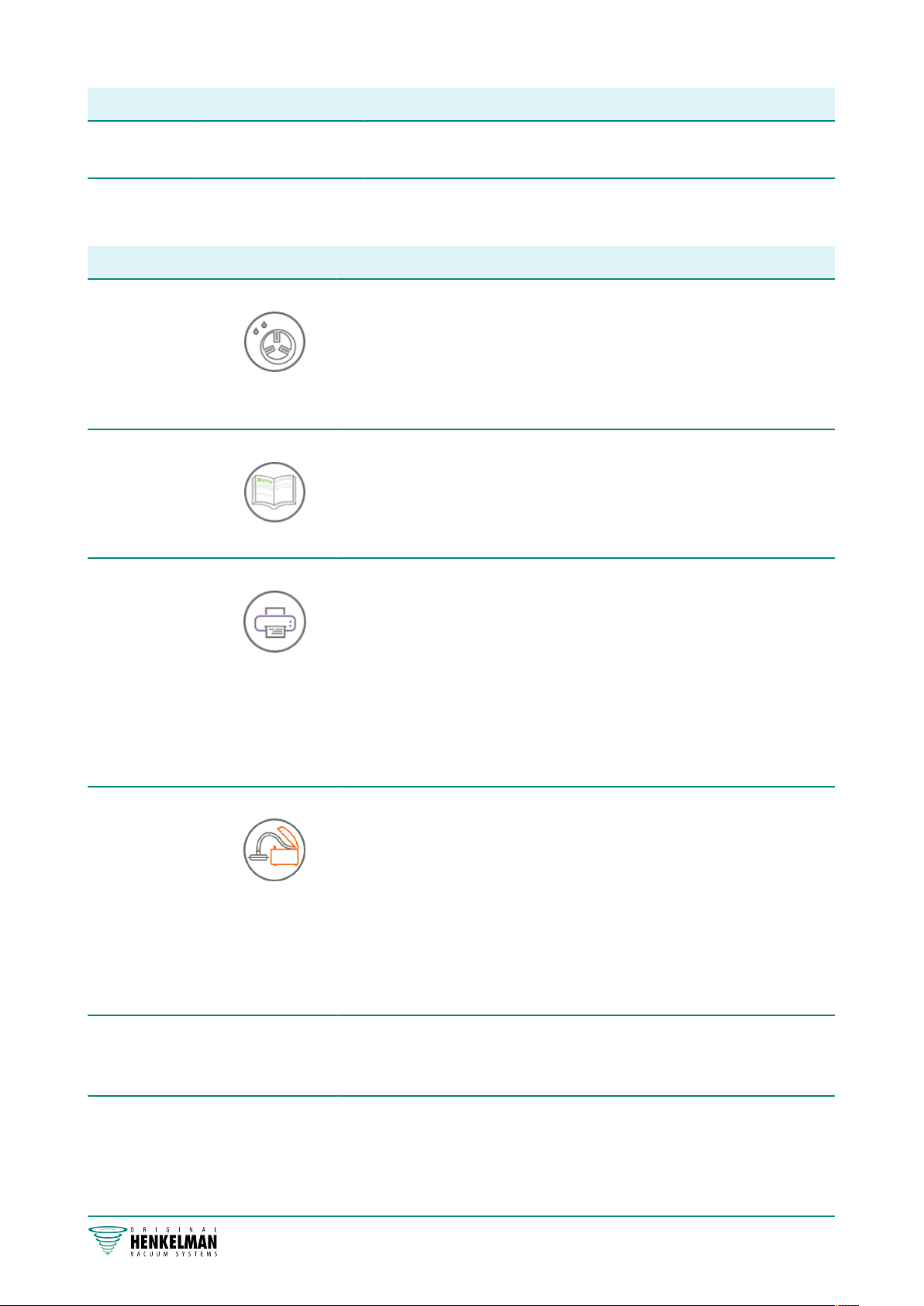

4.3 Sealing System

The sealing system closes the opening(s) of the bag to retain the vacuum and/or gas in the bag.

The end of the bag can optionally be cut off by the sealing bar.

Figure 2: Overview of the Sealing

System (Including Sealing Cylinder)

1. Sealing bar

The sealing bar consists of the following components:

• Sealing wires: during the sealing process, the sealing wires are heated for a certain time

causing the edges of the vacuum bag to melt together.

• Cut-off wires (optional): A cut-off wire is heated in such a way that the foil of the bag

partially melts, allowing the excess foil of the vacuum bag to be removed easily.

• Teflon tape: sealing and cut-off wires are covered with Teflon tape to prevent the bag from

sticking to the sealing bar.

Consult Replacing the Sealing Wire on page 57 for more detailed information about

maintenance.

2. Silicone holder

Opposite the sealing bar is a silicone holder which provides counter pressure on the cylinders/

seal bag (Replacing the Silicone Rubber of the Silicone Holders on page 59).

3. Sealing mechanism

The sealing bars are pressed onto the vacuum bag by bellows or cylinders.

By connecting the inlet of the bellows or cylinders with the atmospheric pressure outside, they

press the sealing bar onto the bag.

Additional sealing pressure (optional) may, depending on the model you have, be used if

additional pressure force is needed.

See Technical Data on page 65 and Connecting the Machine on page 23 for more

information.

Figure 3: Overview of the Sealing

System (Including Seal Bag)

Description of the Machine 19

4.4 Vacuum Pump

The vacuum pump creates the vacuum.

Figure 4: Overview of the Pump (75 m3/h / 2780 cf/h)

1. Vacuum pump - Creates the vacuum for the process.

2. Oil exhaust filter - Filters the air by capturing oil vapours.

3. Oil sight glass - Indicates the maximum and minimum oil levels of the vacuum pump.

4. Oil drain plug - Removing the oil drain plug allows the oil to be drained.

5. Oil filler plug - Removing the oil filler plug allows the oil to be refilled.

6. Oil filter - Filters the oil.

4.5 Electrical Installation

The electrical installation provides power for the vacuum pump, the seal system and the operation

of the machine.

See the electrical diagram for the further structure and operation of the electrical installation.

Please contact your supplier for the electrical diagram.

Only a technical expert may perform work on the electrical installation.

Description of the Machine 20

The machine consists of the following electrical components:

Figure 5: Overview of the Electrical Installation

1. Power connection and cable

This serves to connect the machine to the power supply. The machine is supplied without an

electrical plug.

2. Main switch

This switch is used to switch the machine ON and OFF.

3. Circuit breaker

Protects against overload or a short circuit. Also see Troubleshooting on page 62

4. Control panel

This serves to operate the control functions. Depending on your model, your machine will have

one of the following control options:

• Operating Elements of the 10-Programme Control System on page 26

• Operating Elements of the Advanced Control System (ACS) on page 27

Description of the Machine 21

5. USB connector (only in case of ACS control)

The USB connector is located on the side of the control box, which is located behind the rear

wall. Reaching the USB connector requires removing the rear wall.

After opening the cover of the USB connector, the machine is no longer waterproof

(IP65).

The USB connector enables the import and export of data.

Description of the Machine 22

5 Installation

Consult Technical Data on page 65 for the specifications of the machine.

Before installing the machine, carefully read the safety instructions in Safety. Failure to

follow or disregard of the safety instructions may result in serious injury.

5.1 Transportation and Installation

The machine must be moved and transported in an upright position.

The machine may not be transported using a crane. The machine may be transported with a forklift

provided it is still on the pallet packaging.

Moving the machine on wheels on uneven surfaces may lead to loss of stability of the machine.

Always move the machine slowly and carefully.

1. Place the machine on a flat, level surface. This is essential to ensure a trouble-free operation

of the machine.

Do not position machines with plastic covers in the vicinity of a heat source.

Make sure there is sufficient space (at least 19.7 in (50 cm)) around the machine to

ensure a proper ventilation.

2. Ensure the brakes of the machine are activated.

3. Verify that the machine housing is present and correctly fitted.

If the machine is provided with the optional automatic lid (Polar 2-85 and 2-95 only):

4. Remove the panel door on the right hand side of the machine and release the cable of the foot

switch.

5.2 Connecting the Machine

1. Make sure the voltage stated on the machine plate matches the mains voltage.

2. Fit the correct plug on the cable in accordance with local legislation and connection data. See

Technical Data on page 65.

3. Fit the connecting cable to the machine. See Technical Data on page 65.

4. Connect the machine to a grounded wall outlet to avoid fire or electric shock (the earth

connection is green/yellow).

The power cable must be free at all times, and nothing may be placed on it.

Installation 23

Immediately replace the power cable if damaged.

5. Check the correct direction of rotation of the three-phase model pump. See Figure 6: Direction

of Rotation of the Vacuum Pump on page 24.

Operating the machine with an incorrect direction of rotation results in damage to the pump,

in which case no vacuum can be created. After connecting the machine to a different threephase power supply, the direction of rotation should be checked again. If the direction of

rotation is incorrect, two phases in the plug must be interchanged.

Only a technical expert may perform work on the electrical installation.

Figure 6: Direction of Rotation of the Vacuum Pump

6. Optional: Connect the gas supply for the gas flush system.

7. Optional: Connect the air supply for additional sealing pressure.

If the machine is provided with the optional automatic lid (Polar 2-85 and 2-95 only):

8. Connect the hose for compressed air to the hose pillar (8 mm) at the back of the machine.

Pressure

Flow

5 bar - ≤ 10 bar / ≥ 72.5 Psi -

≥

145 Psi

≤

100 l/min.

≥

Figure 7: Hose connection

for compressed air

5.3 Prior to the First Use

1. Check the oil sight glass to see if the amount of oil in the pump is sufficient.

2. Optional: If the amount of oil in the pump is insufficient, refill it. See Removing Oil, Replacing

Oil Filter, Refilling Oil on page 55.

Installation 24

Loading...

Loading...