Versie 11.10 DIG.EN

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

This manual is for the BOXER/ MARLIN/ FALCON/ POLAR series. The general instructions apply to the models in this category.

Henkelman B.V. cannot be held responsible for any damage caused by deviating machine specifications.

This manual has been established with care. Henkelman B.V. does not accept liability for errors in this manual and/or

consequences of misinterpretation of the instructions.

Henkelman B.V. is not liable for damages and/or problems that arise from using spare parts that are not supplied by Henkelman

B.V.

Henkelman B.V. reserves the right to change specifications and/or spare parts without prior notification.

All rights reserved. No part of this publication may be reproduced by photocopy, printing or in any other way without prior consent

from Henkelman B.V.

LIABILITY

1. We exclude all liability as far as it is not provided for by law.

2. Our liability shall never exceed the total amount of the order in question.

3. Barring the generally applicable legal rules of public order and good faith we are not liable to pay for any damage of any sort

whatsoever, directly or indirectly, including business losses, to movable or immovable property, or to persons, either at the

opposing party as at third parties.

4. We are in any case not liable for damages arising from or cause by the use of the product supplied or by the unsuitability of

it for the goal for which the other party purchased it.

WARRANTY

Subject to the following limitations, the warranty period for products supplied by Henkelman is at least 12 months, as of the date

indicated on the purchase document. This warranty is limited to manufacturing and machining defects and does therefore not

cover breakdowns involving any part of the product that is exposed to any form of wear and tear. Normal wear and tear that can

be expected with the use of this product is therefore hereby excluded.

1.

Henkelman’s responsibility is limited to replacing parts found to be defective; we shall not acknowledge claims for any other

kind of damage or costs.

2.

The warranty does not apply if the defect is the result of incorrect or negligent use, or maintenance that is contrary to the

instructions given in this manual.

3.

The warranty lapses if repairs or modifications on the product have been carried out by third parties.

4.

Defects due to damage or accidents deriving from outside factors are excluded from the warranty.

5.

If we replace parts in compliance with the obligations of this warranty then the replaced parts become our property.

6.

If the other party does not, not sufficiently, or not in an acceptable period of time, fulfils the obligations to the agreement

between the parties, we are not obliged to provide this warranty as long as the situation is occurring.

The stipulations of the warranty and liability are part of the general terms and conditions of sales, which we can send to you if

requested.

Version 11.10 DIG.EN 2

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

INTRODUCTION / LIABILITY /

2

CONTENTS INSTRUCTION MANUAL

……….…………………………………………………………..

3

MACHINE REGISTRATION

……….…………………………………

………………………..

4

!!!! …..

5

!!!!

7 WARNING LABELS

……….…………………………………………………………..

8

IMPORTANT MACHINE PARTS

……….………………

…………………………………………..

9 START

OG BRUK AV PRODUKTET

……….…………………………………………………………..

11

ON/OFF (AV/

PÅ

) BRYTER

+ N

ØDBRYTER

11

S

tandBy funksjon

11

Start maskinen

11

Standard

b

ruk.

Steg for steg

12

MASKINENS

BETJENINGS

PANEL

……….…………………………………………………………..

13

B

etjeningspanel

14

F

orklaring av punkter på betjeningspanel

15

I

nstillinger av programsykluser

(manuel)

16

I

nstillinger av programsykluser (automatisk)

17

Programmodus/

Andre

modus 19

Brogramsykluser

19

PROGRA

MMER

ING ……….…………………………………………………………..

20

Manual programm

e

ring 20

Automatic programm

ering 21

MAC

HINE MAINTENANCE

……….…………………………………………………………..

23

General

23

Important before and during maintenance

23

Standard maintenance schedule

24

Vacuum pump maintenance

24

Seal system maintenance

27

Silicone holder and lid gasket maintenance

29

List of maintenance parts

30

TECHNICAL SPECIFICATIONS

……….…………………………………………………………..

32 ELECTRICAL DIAGRAMS

……….…………………………………………………………..

33 ERRORS CODES

……….…………………………………………………………..

36 PNEUMATIC DIAGRAMS

……….…………………………………………………………..

37

PROBLEM SOLVING

……….…………………………………………………………..

38

FACTORY SETTINGS CONTROL

……….…………………………………………………………..

40

SPECIAL APPLICATIONS

……….…………………………………………………………..

41

Machine with gas flush system

41

Packaging liquid products

41

Externa

l vacuuming of food containers

42

EEC DECLARATION OF CONFIRMITY

...

…………………………………………………………………

43

MAINTENANCE SCHEDULE / NOTES

……….…………………………………………………………..

44 REMOVAL FRONT PANEL

……….…………………………………………………………..

45

CONTENT USER MANUAL

GUARANTEE

…….……………………………………………………………..

IMPORTANT FOR INSTALLATION – READ THIS FIRST

IMPORTANT FOR USE – READ THIS FIRST

………………………………………………………

……………………………………………..

Version 11.10 DIG.EN 3

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

PRIOR TO STARTING TO USE THE MACHINE,

Register the machine using the following data. This information is necessary if the supplier or Henkelman BV is contacted

concerning questions or references about the specific machine.

DATA ON MACHINE TAG

Relevant data for answering questions can be found on the machine tag. The machine tag is located at the rear of the machine.

Note down the following data:

CONTROL PANEL DATA

When starting the machine, two codes appear on the display consecutively, before the control switches to user mode. The first

code indicates the software version of the control software and the second code indicates the active options. Please write down

the codes below:

MACHINE REGISTRATION TO BE COMPLETED BY THE USER

1. MACHINE TYPE

2. MACHINE NUMBER (MACHINE NO.)

3. VOLTAGE (TENSION)

4. CODE 1

5. CODE 2

Version 11.10 DIG.EN 4

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

IMPORTANT FOR INSTALLATION!!! READ THIS FIRST!!!

GENERAL

First read this manual carefully before the machine is put into operation.

This manual contains relevant information and instructions for starting up, maintenance and applications.

If problems arise with the machine that could have been avoided by referring to this manual then the guarantee expires.

Henkelman BV wishes the customer lots of pleasure for an extended period from the purchase of the machine. If there are

any problems or questions then the customer can always approach the supplier or Henkelman BV.

ENVIRONMENT

The machine must be moved or transported in an upright position. The machine may NOT be tilted as this can cause damage

to the pump.

Place the machine on a flat, level floor. This is essential for problem free operation of the machine.

Enough space must be left around the machine for good ventilation. The space must be at least 5 centimetres.

The ambient temperature in which the machine is operated must be between 10 0C and 30 0C. When operating the machine

in other ambient temperatures the user must contact the supplier or Henkelman BV for advice.

NEVER place the machine directly next to a heat source or a steaming device (for example a combi-steamer, dishwasher or

stove)

POWER / EARTH

Check that the voltage stated on the machine tag is the same as the mains voltage.

Check the direction in which the pump is running when the machine is connected to a three phase power source.

Always connect the machine correctly to an earthed socket to avoid danger for fire or electrical shocks (earth connection is

green/yellow).

The power cable must always be free and nothing may be placed on it.

Replace the power cable immediately if damaged.

Always disconnect the power if there are problems with the machine or during maintenance, prior to starting work on the

machine.

If the machine is stationary for long periods then the power should always be disconnected.

Version 11.10 DIG.EN 5

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

VACUUM PUMP

Check before starting the machine if there is oil in the pump (see page 23). NEVER start the machine without oil in the pump.

Use the right type of oil for the pump (see page 24).

After moving and/or transporting the machine, always first check the oil level before re-starting operation.

When starting the machine for the first time or after a lengthy idle period, first run the conditioning program before operating

the machine (see page 22).

Always change the oil before a long period of inactivity of the machine and make sure the pump is clean and free of moisture.

CONNECTING THE GAS FLUSH SYSTEM (if applicable

NEVER use flammable gasses or gas mixtures containing too much oxygen. There is a danger of explosion when using the

aforementioned gasses. Accidents and/or damage caused by using abovementioned gasses void all liability on the part of

Henkelman BV as well as the guarantee.

The gas bottles must always be correctly secured. If the gas flush function and/or the machine is not in use then the main

cock of the gas bottle must always be closed.

The pressure of the pressure reducing valve on the gas bottle may NEVER be set to more than 1 atmosphere/ATO. A higher

pressure may damage the machine.

The diameter of the hose nipple connector for the gas bottle is 6 mm (BOXER and MARLIN 42/42 XL), 13 mm (POLAR 2-85

and 2-95), and 8 mm for other machines. The connector is at the rear of the machine.

For more information about the use of gas bottles, please consult an authorised gas supplier

CONNECTING COMPRESSED AIR FOR EXTERNAL SEALING PRESSURE (if applicable

The pressure from the compressor may NEVER be set to more than 1 atmosphere/ATO. A higher pressure may damage the

machine.

Only dry compressed air may be used for the external seal pressure.

The diameter of the hose nipple connector the compressor is 6 mm (rear machine)

For more information about the use of compressed air, please consult an authorised gas supplier

)

)

Version 11.10 DIG.EN 6

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

IMPORTANT FOR OPERATION !!! READ THIS FIRST !!!

GENERAL

Never pack products that can be damaged during or after vacuum packaging. Live oats may never be vacuumed.

Refer to this manual if in doubt as to the operation and/or functioning of the machine. If the manual does not offer a solution

consult the supplier or Henkelman BV.

The guarantee and/or liability expires if damage is caused by repairs and/or changes made by you. In the case of

malfunctions contact the supplier or Henkelman BV.

In the case of malfunctions always stop the machine and remove the power cable from the wall socket.

GENERAL MAINTENANCE

It is essential that the machine is serviced regularly to guarantee operation and to keep the machine in optimal condition. The

maintenance schedule is clearly defined on page 22. The guarantee automatically expires due to overdue or sloppy

maintenance.

Always remove the power cable from the wall socket for maintenance work; the machine must be completely disconnected.

If there are doubts about the maintenance activities or if the machine fails to work correctly always contact the supplier or

Henkelman BV.

TRANSPARENT LID (if applicable)

Never locate the machine near a heat source. This can cause damage to the lid (cracks).

Never place hot, sharp, or heavy objects on the lid. These can cause damage to the lid (cracks) in the long run.

Always clean the lid with solvent-free cleaning agents. Solvents can damage the lid.

Check at least once a week if there are cracks in the lid. If cracks are visible in the lid then the machine must IMMEDIATELY

be turned off and not used again until the lid has been replaced. Continuing to work with a cracked lid can cause the lid to

implode. All guarantees and/or liability expire in the case of accidents and/or damage caused by working with a cracked lid.

Replace the transparent lid every 4 years as a precautionary measure as a standard maintenance interval.

Version 11.10 DIG.EN 7

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

VACUUM PUMP

Regularly check the level and quality of the oil in the pump. If there is too little oil or the quality of the oil is bad (turbid), replace

or top up the oil before operating the machine (see page 23). Let the pump conditioning program run at least one full cycle

before replacing the oil (see page 22).

Use the right type of oil for the pump when replacing or filling up (see page 24).

Use the conditioning program at least once a week to enhance correct and long-lasting pump operation (see page 22).

USE OF GAS FLUSH SYSTEM (if applicable)

NEVER use flammable gasses or gas mixtures containing too much oxygen. Use thereof can cause risk of explosions.

Accidents and/or damage caused by using abovementioned gasses voids all liability on the part of Henkelman BV as well as

the guarantee.

The gas bottles must always be correctly secured. If the gassing function and/or the machine is not in use then the main cock

of the gas bottle must always be closed.

The pressure of the pressure reducing valve on the gas bottle may NEVER be set to more than 1 atmosphere/ATO. A higher

pressure may damage the machine.

For more information about the use of gas bottles, consult an authorised gas supplier

WARNING SIGNS ON THE MACHINE!!!

ONLY use the prescribed power supply voltage.

Insert the plug firmly into the mains wall socket.

Always connect the machine to an earthed wall socket

Always remove the plug during maintenance or when the machine is not in use for extended periods.

NEVER use flammable gasses or gas mixtures containing too much oxygen. Use thereof can cause risk of

explosions

Accidents and/or damage caused by using abovementioned gasses void(s) all liability on the part of

Henkelman BV as well as the guarantee.

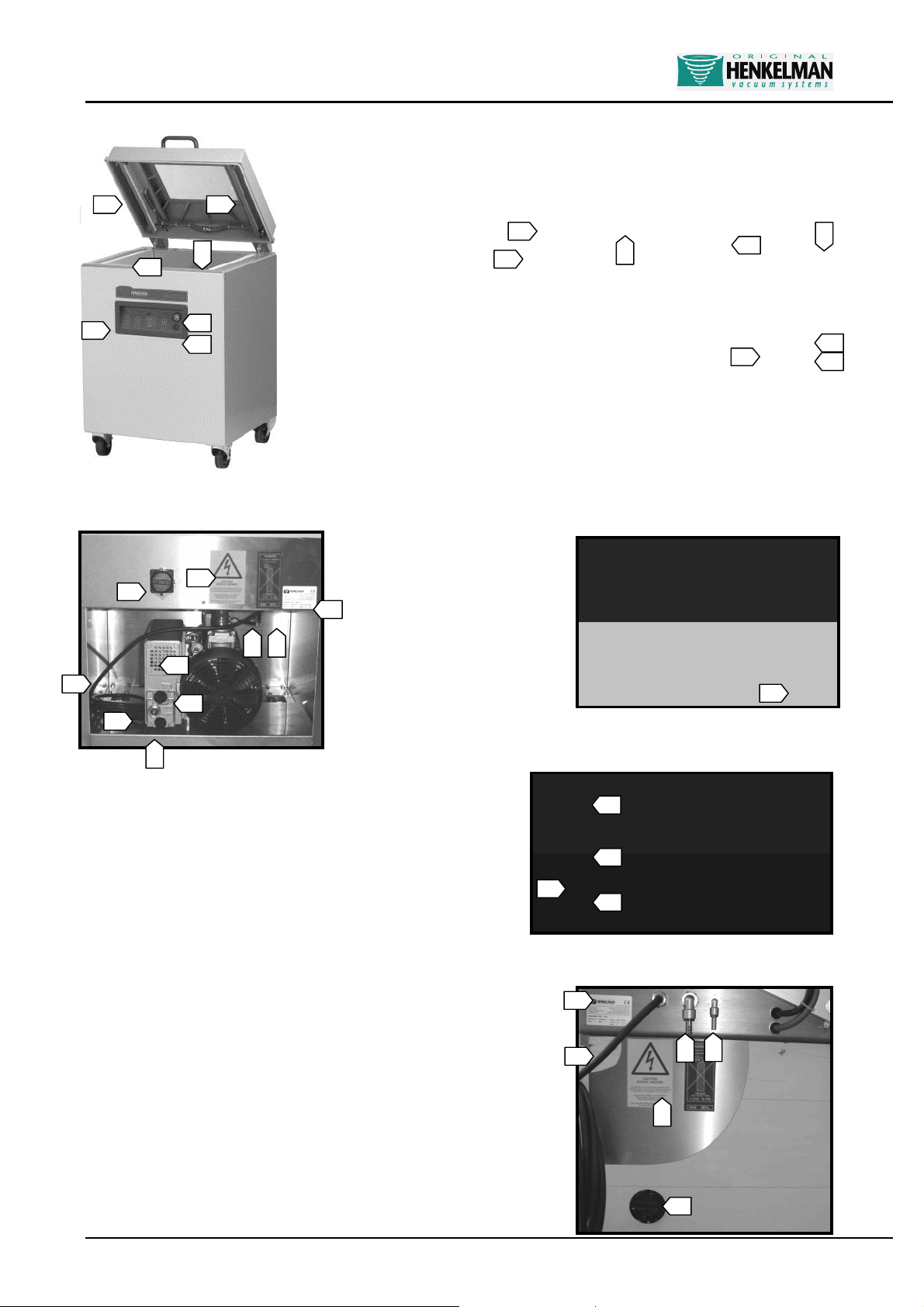

IMPORTANT MACHINE PARTS

Version 11.10 DIG.EN 8

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

POLAR SERIES

BOXER SERIES

MARLIN SERIES

Side view BOXER machines

Vacuum chamber

Rear view BOXER machines

Rear view MARLIN machines

1 2 4 5 6 7 8 1 3 11 12 13

1 2 5 6

7 8 9 14 15 16 18 10 11 12 13 14 17 18 1. Sealing bar(s) in vacuum chamber

FALCON SERIES

Version 11.10 DIG.EN 9

2. Silicone holder(s)

)

3. Gas flush nozzles (if applicable

4. Lid rubber in lid for hermetic seal

5. Gas springs for opening lid after machine cycle

6. Vacuum / Ventilation opening

7. Control panel

8. Vacuum pressure meter

9. ON/OFF Switch

10. Master switch (only MARLIN series)

11. Oil drain plug

12. Oil fill plug

13. Oil inspection window

14. Power cable

15. Fuse holder with fuse

16. Gas bottle connector (if applicable) caution max 1 Bar

17. Machine tag

18. Warning stickers

Appearance of parts and machines can deviate from illustrations

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

1. Sealing bar(s) in lids

Rear view

FALCON series and POLAR single chamber models

Side POLAR double chambers after opening side of housing

Rear view POLAR double chambers

Inside lid POLAR series

1 1 2 4 5 6 8 9 10 10 11 11 12 12 13 13 14 15 16 17 18 7 9 14 15 16 17 18 6 7 8 2 5 1 4 1 2 3 4 5 6 7 8

2. Silicone holder(s) on holders in vacuum chamber

3. Gas flush nozzles mounted on silicone holders (if applicable)

4. Lid rubber in lid for hermetic seal

5. Vacuum / Decompression / Suction pipe

6. Control panel

7. ON/OFF switch

8. Vacuum pressure meter

9. Master switch

10. Oil drain plug/elbow

11. Oil filler cap

12. Oil inspection window

13. Oil spray filter housing

14. Power cable

15. Gas bottle connector (if applicable) caution max 1 Bar

16. Seal pressure connector (if applicable) caution max 1 Bar

17. Machine tag

18. Warning stickers

Appearance of parts and machines can deviate from illustrations

Version 11.10 DIG.EN 10

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

START OG BRUK AV MASKINEN

AV/PÅ bryter Hovedbryter

AV/PÅ bryteren bukes til å skru på før bruk og av etter bruk.

ADVARSEL- AV/PÅ bryteren skrur ikke av all spenning på maskinen. På BOXER serien og alle andre 1fas modeller er det

nødvendig å trekke ut støpselet før maskinen er fullstendig strømløs. På MARLIN, FALCON, POLAR seriene og alle 3 fas

maskiner er det nødvendig å skru av hovedbryter før maskinen er helt strømløs. Vær sikker på at maskinen er helt strømløs når

det utføres service og vedlikehold.

BOXER serien

Når maskinen er skrudd på (med AV/PÅ bryteren ), kjører pumpa kun undrer vakumerings syklusen.

MARLIN / FALCON / POLAR seriene

Når maskinen er skrudd på (med AV/PÅ bryteren ), kjører pumpa kontinuerlig. 3 fas pumpene trenger lengre oppvarming av ved

å skru de av og på har negativ innvirkning på levetiden. Hvis maskinen er skrudd på men er ikke i bruk, vil pumpa skru seg av

automatisk etter 10 minutter. Dette for å unngå overoppheting av olja, og redusere unødvendig forurensing fra eksos filtrene.

Denne funksjonen kalles Sleeper function

SLEEPER FUNCTION

På modellene Marlin, Falcon og Polar er Sleeper Function alltid aktivert. Dette betyr at hvis maskinen er skrudd på men ikke i

bruk, stoppe pumpa automatisk etter 10 minutter. Ved å stenge lokket starter prosessen og pumpa samtidig. Kontakt din

leverandør for nærmere informasjon om Sleeper Function.

OPPSTART AV MASKINEN

Etter at maskinen er tilkoblet og eventuelt hovedbryter er satt på 1, kan maskinen settes på amed AV/PÅ bryteren. Når maskinen

starter vises 2 koder i displayet før kontroll panelet settes i drift modus.

Den første koden indikerer modellen på maskinen. Den andre koden viser kontrollens software

versjon. Noter ned begge disse koder på side 4 siden de er viktige for din leverandør eller Henkeman BV

når du har spørsmål eller om det oppstår et problem.

Etter at maskinen har skiftet til driftsmodus er den klar til bruk. Hvis maskinen er ny eller har vært ute av

drift en lengre periode, anbefaler vi å kjøre vedlikeholdsprogrammet for pumpa (15 minutter) for å varme

opp og rense pumpa. For instruksjon vedlikeholdsprogrammet for pumpa, se side 22

Etter at maskinen har kommet i driftsmodus kan de hende at [ OIL ] vises i displayet. Dette betyr at

driftstids telleren er aktivert og antall driftstimer som er satt er overskredet. Driftstidstelleren er

forhåndsinnstilt, men kan endres av bruker for å benyttes til en påminnelse om regelmessige vedlikeholds

aktiviteter. Når [ OIL ] vises kan maskinen fremdeles brukes som vanlig men vi anbefaler å skifte olje og

resette denne advarsel funksjonen.

Kontakt din leverandør for mer informasjon om hvordan endre driftstidtelleren..

STEGVIS BRUKSANVISNING FOR MASKINEN

1.

Skru på maskinen med AV/PÅ bryteren. Varm opp pumpa med Condition programmet hvis maskinen har vært ute av bruk

en tid (instruksjon på,side 22).

Version 11.10 DIG.EN 11

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

FALCON / POLAR series

2.

Fyll vakumposen med produktet. Velg riktig posestørrelse. Posen må enkelt passé rundt produktet men bør ikke være for

stor. Vær sikker på at alle hygienekrav er ivaretatt undrer denne operasjonen. Pakkemateriale, produktet og hender må

være rene og tørre hvis mulig.

3.

Plasser vakumposen i kammeret. Den åpne enden må plasseres over sveisekinna.

Posen på ikke komme utenfor kammeret. Havis produkteter mye lavere enn høyden på

sveiseskinna brukes de sorte innleggsplatene som følger med maskinen. Dette

forenkler prosessen og reduserer syklus tiden.

4.

Vakum posen må plasseres over sveiseskinna (BOXER og MARLIN) eller silikon

holderen (FALCOM og POLAR) uten bretter.

5.

Med gass flush system må åpningen av posen trekkes over gass dysene (se

illustrasjon.

6.

Flere vakumposer kan plasseres over sveiseskinna /silikonholder hvis

sveiseskinna/silkonholder er lengre enn vakum posen. Vakum posene må ikke legges oppå hverandre på skinna/holderen.

Hvis det er flere skinner/holdere kan alle skinner /holdere benyttes i den samme syklusen.

7.

Bruk [PROG] bryteren til å velge ønsket program. Se side 18 vedrørende instruksjon for programmering.

8.

Steng lokket og maskinen kjører automatisk hele syklusen med alle aktiverte funksjoner.

Lokketåpnes automatisk etter at den siste funksjonen ”utlufting” er fullført.

9.

If necessary the cycle can be partially or fully interrupted by pressing the [VACUUM STOP] key or the [STOP] key.

Om nødvendig kan syklusen delvis eller helt avbrytes ved å trykke på [VACUUM STOP] bryteren eller [STOP] bryteren.

[VACUUM STOP] bryteren avbryter den aktive funksjonen (vakum, gass flush, forseiling eller soft- air utlufting) og går

autimatisk videre til neste funksjon.

[STOP] bryteren avbryter hele syklusen og går direkte til utlufting.

10.

Etter at syklusen er fullført kan det pakkede produktet eller produktene tas ut av maskinen.

11.

Hvis maskinen er utstyrt med et cut-off sealing system, kan den overflødige delen rives av.

SIKKERHET og PRODUKT BESKYTTELSE

Pakke prosessen kan helt eller delvis avbrytes hele tiden

Stopp aktiv funksjon, trykk på [VACUUM STOP] bryteren

Stopp hele syklusen, trykk på [STOP] bryteren

OPTIMALT og EFFEKTIVT PAKKE RESULTAT

Bruk vakumposer av god kvaliset og riktig størrelse

Maximum 75% produkt fylling I vakum posen

Plasser vakum posen fritt over sveiseskinna/silikonholderen (benytt riktig antall innleggsplater i kammeret)

Trekk vakum posene langt nok over gass dysene (for gass flush) slik at ikke gass går tapt og posen ikke flytter seg

ved gass flushing

Version 11.10 DIG.EN 12

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

Betjeningspanel

Generell informasjon

Det digitale betjeningspanelet er inkludert med 9 ferdige program som individuelt kan endres i de forskjellige verdier

(for å vacuumpakke forskjellige produkter). Program 0 kan ikke bli brukt for testing eller service. Et programsyklus

er et komplett program av flere funksjoner som maskinen går gjennom under vacuumpakking av et produkt.

Betjeningspanelet er utformet med en betjeningsmodus og en programmodus.

Betjeningsdelen blir brukt under utførende av valg av programnummer med ønsket programsyklus.

Programdelen blir brukt til å bytte verdier innenfor programmene.

Betjeningspanelet er også for automatisk feilsøking under service/vedlikehold av pumpen og et 2 stegs nøkkel for en

fullstendig avbrudd eller funksjonsavbrudd. Det har også innebygget flere service-/vedlikeholdsprogram.

Digital tidsur

Alle aktive funksjoner kan tidsuropereres. Det vil si at vakuumfunksjonen, gassfunksjonen (hvis installert) og “softair” funksjonen kan innstilles i sekunder opp til 99 sekunder. Sveisefunksjonen kan innstilles i 0,1 sekunder og

maksimum 6,0 sekunder.

Følerkontroll

Verdiene i vacuumfunksjonen og gassfunksjonen (hvis installert) kan velges som en prosentandel av vacuumet. Dette

er prosentandel av trykket i vacuumkammeret relatert til trykket utenfor på 1 ATO (0%).

Den maksimale vacuumprosenten som kan settes er 99 %.

Den laveste vacuumprosenten ved bruk av gass er 30 % under trykk i relasjon til 1 ATO. Det betyr at

vacuumkammeret er pumpet opp til 30 % under sammenlignet med 1 ATO. Dette er ofte uttrykt som 70 % er pumpet

med gass (99 % - 30 % = 70 %).

“Soft air” funksjonen kan også tidsuropereres i sekunder (maksimum 99 sekunder). Sveisefunksjonen kan

tidsuropereres med 0,1 sekunders intervall (maksimum 6,0 sekunder).

VACUUM PLUS funksjonen er alltid standard med digital føler kontrollerbar. VACUUM PLUS funksjonen er en

tidsoperert tilleggs-vacuumfunksjon som kan innstilles med ekstra tid for å oppnå 99 % verdi av vacuumfunksjonen

(kan kun brukes hvis 99 % er innstilt for vacuumfunksjonen. Denne funksjonen krever ekstra vacuumtid for å unngå

å få små luftmengder i vacuumpakkingen.

Hurtig-stopp H20 betjening

Prinsippet for hurtig-stopp H20 funksjonen er et veldig sensitivt følersystem. Hvis H20 vises i displayet indikerer

dette at funksjonen er aktiv. Denne muligheten kan aktiveres i hvert individuelt program.

Den øverste grensen for vacuumprosenten som kan settes er 99 %. Den spesielle sensitive føleren H20 er i stand til å

føle øyeblikket for når fuktigheten i produktet begynner å evaporere (koke). I dette øyeblikk vil det sensitive

følersystemet avbryte og gå til neste trinn/fase og på den måten unngå at produktet tørker ut, taper vekt eller koke ut

vacuumposen som da vil forurense sveisestedet med et resultat at fuktighet ender opp i vacuumpumpen og tilslutt gir

et optimalt vacuumresultat uten bruk av unødvendig tid.

Hurtig-stopp H20 føleren er standard i H20 PLUSS funksjonen. H20 PLUS er tidsuroperert funksjon som muliggjør

ekstra tid etter oppnådd 99 % verdi av vacuumfunksjonen. Tidsinnstilingen for H20 PLUS funksjonen

0,1 sekunders intervall opp til maksimum 5,0 sekunder.

Version 11.10 DIG.EN 13

kan settes med

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

Betjeningspanel

1. Lite display. Viser aktivt program eller programmodus

2. Stort display. Viser aktuell verdi på funksjon mens programmet

utføres eller innstilt verdi i det spesifikke programmet

3. PROG 0-9 tast Valg av lagrede programmer/programmodus

4. REPOG tast Bytter mellom betjeningsmodus til programmodus (for å

innstilling av verdier) og vice versa. Etter å ha innstilt nye funksjonsverdi(er)

innenfor programmet i programmodus, må denne tasten alltid brukes for å lagre den

nye verdien i maskinens hukommelse.

5. Funksjonstast Med den velges funksjon innenfor valgte program og

programmodus. Valgt funksjon indikeres ved at pilotlampen er tent foran

programmet (under det store displayet).

6. Programtilstand Start tilstandsprogrammet for vacuumpumpen (tar ca. 15

minutter). For programinnstillinger se side 22.

7. Pilotlampe- En tent pilotlampe i front av funksjonsbeskrivelsen indikerer

funksjon at funksjonen er aktiv igjennom programsyklusen eller at funksjonen er valgt under

utføringen av programmodus.

NB!

VACUUM PLUS vises under programsykluset (hvis aktivtert). Pilotlampen vil fortsatt lyse

Display under funksjon og programmodus:

Hvis VACUUM PLUS tidsstyrt er aktivert under valgt program vil et lysende punkt vises i

Det finnes i tillegg en tidsuroperert vacuumfunksjon tilgjengelig med digital følerkontroll

med navnet VACUUM PLUS. Denne funksjonen er ikke vist på betjeningspanelet.

VACUUM PLUSfunksjonen kan kun aktiveres hvis standard vacuumfunksjon er innstilt på

99 %.

etter at man oppnår 99 % og under tidsinnstillingen for VACUUM PLUS. Under VACUM

PLUS vacuumsyklusen et lysende punkt vil vises i nedre høyre hjørne av det store displayet.

nedre høyre hjørne av det store displayet under funksjon og programmodus. Hvis funksjonen

er valgt ved å bruke “Funksjonstasten” vil pilotlampen til venstre for VACUUM tennes to

ganger og vacuumprosenten og VACUUM PLUS tiden vil vises konstant i displayet.

Hvis maskinen er utstyrt med integrert gasstilsetningsmulighet og funksjonen er aktiv valgt

program (No) vil et punkt nederst til høyre i det lille displayet lyse opp.

Version 11.10 DIG.EN 14

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

Vacuummeterskala

Vacuum i prosent (%)

0 0

0,2 20 0,3 30 0,4 40 0,5 50

0,6 60 0,7 70 0,8 80 0,9 90

- 1,0 99+

8. + /VACUUM STOP

(fungere under drift) Bryter den aktive funksjonen under programsyklusen. Syklusen fortsetter da

øyeblikkelig med neste funksjon.

(Funksjon i programmodus) Øker verdien av den valgte funksjon innenfor valgte program i

programmodus.

9. - / STOP

(funksjon under syklus) Stopper programsyklusen øyeblikkelig og går over til ventilasjonsyklusen.

(Funksjon i programmodus) Senker verdien av den valgte funksjon innenfor valgt program i

programmodus.

10. Vacuummeter Viser trykket i vacuum-kammeret. Se tabell nedenfor for samsvaret mellom

vacuummeteret og prosentandel vacuum.

11. ON/OFF Hovedstrømbryter. Brukes for å sette maskinen på før bruk og for å slå

maskinen av etter bruk. Ved ON settes alle funksjonene i maskinen i drift.

ADVARSEL. Når maskinen er i OFF modus er strømmen ikke koblet fra

maskinen (hukommelse). For å få maskinen strømløs må man koble fra

stikkontakt.

NÅR MASKINEN ER SLÅTT PÅ (ON)

Når maskinen er slått på går maskinen over til operativmodus etter å ha vist 2

START-koder i displayet. NB! Vær vennlig og noter ned de 2 START-kodene i denne

bruksanvisningen side 4 (teknisk informasjon og DATA-platen). Operativmodus er

standard på betjeningspanelet når man skal vacuumere produkter. Modifisering av verdier

kan ikke utføres under operativmodus.

Med PROG tasten og valgbrytere kan man velge verdier innenfor de forskjellig

programmer som vises. Hvis maskinen er klar for vacuumpakking (og produktet ligger

allerede i kammeret) er det bar å velge program (PROG tasten) og lukke lokket. Programsyklusen starter

da automatisk og går igjennom de valgte funksjonene i programmet.

Version 11.10 DIG.EN 15

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

Beskrivelse av programsyklus med digital tidsinnstilling

1. Velg programnummer med PROG tasten og det lille displayet.

Hvis det valgte program er med aktiv gasstilsetning vil en punkt nederst i høyre hjørne i det lille

displayet lyse opp.

2. Lukk igjen lokket

3. Vacuum funksjon Maskinen starter å vacuumere kammeret.

Pilotlampen foran VACUUM lyser.

Det store displayet: Tidsnedtelling starter etter innstilt tid (maksimum

99 sekunder). Vacuummeteret øker moturs.

4. Gasstilsetning Med en gang vacuumeringen er ferdig vil gasstilsetningen starte.

(hvis installert) Pilotlampen foran GAS vil lyse opp

Det store displayet: Tidsnedtelling starter som innstilt (maksimum 99

| sekunder). Vacuummeteret minker medurs.

5. Gas flush Plus I det øyeblikket gasstilsetning er ferdig er det mulig å legge til

(hvis aktivert) tid for tillegg av gass. Med denne muligheten kan man tilsette mer

gass mens sveisefunksjonen avsluttes.

6. Sveising Når vacuumfunksjonen eller gasstilsetningsfunksjonen (hvis

installert) er ferdig vil sveisefunksjonen starte med sveising av

vacuumposen.

Pilotlampen foran SEAL vil da lyse opp.

Det store displayet: Tidsnedtelling med 0,1 sekund starter etter innstilt

tid (maksimum 6.0 sekunder).

Vacuummeteret vil bli uforandret.

7. Soft-air ventilasjon Når sveisefunksjonen er over vil soft-air funksjonen starte sakte

(hvis installert) med å slippe luft inn i vacuumkammeret.

Pilotlampen foran SOFT AIR vil lyse opp.

Det store displayet: Tidsnedtelling starter som innstilt

(maksimum 99 sekunder). Vacuummeteret minker medurs.

8. Ventilering Etter endt sveise- og Soft-air funksjon (hvis installert) starter

ventilasjon av kammeret til 1 ATO og lokket åpner seg.

Alle pilotlampene foran funksjonene er slukket.

Det store displayet: streker går opp og ned til lokket er helt åpent.

Vacuummeteret går tilbake til 0 og lokket åpnes automatisk.

9. Produktet er nå ferdig vacuumert og kan tas ut/flyttes.

Version 11.10 DIG.EN 16

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

Beskrivelse av programsyklus med digital føler kontrollert

1. Velg programnummer med PROG tasten og det lille displayet.

Hvis det valgte program er med aktiv gasstilsetning vil en punkt nederst i høyre hjørne i det lille displayet lyse opp.

Hvis det valgte program er med aktiv VACUUM PLUS vil en punkt nederst i høyre hjørne i det store displayet lyse

opp.

2. Lukk igjen lokket

3. Vacuum funksjon

Maskinen starter å vacuumere kammeret.

Pilotlampen foran VACUUM lyser.

Det store displayet: Nedtelling av prosent vacuum starter etter innstilt % (maksimum 99 %).

Vacuummeteret øker moturs

4. VACUUM Plus.

(hvis installert) Pilotlampen foran VACUUM lyser opp.

99 %.

Maskinen fortsetter å vacuumere etter oppnådd 99 %.

Det store displayet: Tidsnedtelling starter etter innstilt tid (maksimum 99 sekunder) og

punktet nede i høyre hjørne lyser opp.

Vacuummeteret øker moturs veldig sakte (nesten umerkelig).

Bemerk: Kan kun installeres med vacuumfunksjonen når verdien er satt til maksimum

5. Gasstilsetning

(hvis installert) Pilotlampen foran GAS vil lyse opp.

Med en gang vacuumeringen er ferdig vil gasstilsetningen starte.

Det store displayet: Nedtelling av prosent vacuum som innstilt (minimum 30 %).

Vacuummeteret minker moturs

6. Gas flush Plus

(hvis aktivert) Med denne muligheten kan man tilsette mer gass mens sveisefunksjonen avsluttes.

I det øyeblikket gasstilsetning er ferdig er det mulig å legge til tid for tillegg av gass.

7. Sveising

(hvis installert) starte med sveising av vacuumposen.

Når vacuumfunksjonen eller gasstilsetningsfunksjonen er ferdig vil sveisefunksjonen

Pilotlampen foran SEAL vil da lyse opp.

Det store displayet: Tidsnedtelling pr. sekund starter etter innstilt tid (maksimum 6.0 sekunder).

Vacuummeteret vil bli uforandret.

8. Soft-air ventilasjon

i vacuumkammeret.

Pilotlampen foran SOFT AIR vil lyse opp.

Det store displayet: Tidsnedtelling pr. sekund starter som innstilt (maksimum 99 sekunder).

Vacuummeteret minker medurs

9. Ventilering

1 ATO og lokket åpner seg.

Alle pilotlampene foran funksjonene er slukket.

Det store displayet: streker går opp og ned til lokket er helt åpent.

Vacuummeteret går tilbake til 0 og lokket åpnes automatisk.

Etter endt sveise- og Soft-air funksjon (hvis installert) starter ventilasjon av kammeret til

Når sveisefunksjonen er over vil soft-air funksjonen starte sakte med å slippe luft inn

10. Produktet er nå ferdig vacuumert og kan tas ut/flyttes.

Version 11.10 DIG.EN 17

.

.

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

Beskrivelse av programsyklus med digital Quick Stop H20 kontrollert

1. Velg programnummer med PROG tasten og det lille displayet.

Fundamentet for Quick Stop H20 funksjonen er et meget følsomt kontrollsystem. Tilvalget kan aktiveres til hvert

program ved at H20 vises i displayet og som indikerer at funksjonen er aktiv. For å aktivere Quick Stop H20 kontrollen,

trykk på REPROG tasten, programnummer vil blinke. Trykk så på Programvalg tasten og H20 vil vises i

displayet.Trykk igjen på REPROG tasten for å gå tilbake til driftsmodus. Programnummeret vil ikke lenger blinke som

indikerer at maskinen er klar til bruk.

2. Lukk igjen lokket

3. Vacuum funksjon

Det store displayet: H20 vil vises

Vacuummeteret øker moturs.

4. VACUUM Plus

oppnådd.

Pilotlampen foran VACUUM lyser opp.

Det store displayet: Tidsnedtelling pr. sekund starter etter innstilt tid (maksimum 5 sekunder)

og punktet nede i høyre hjørne lyser opp.

Vacuummeteret øker moturs veldig sakte (nesten umerkelig).

5. Gasstilsetning

(hvis installert) Pilotlampen foran GAS vil lyse opp

Det store displayet: Nedtelling av prosent vacuum som innstilt (minimum 30 %).

Vacuummeteret minker moturs

6. Gas flush Plus

(hvis aktivert) tid for tillegg av gass. Med denne muligheten kan man tilsette mer gass mens

sveisefunksjonen avsluttes.

7. Sveising

installert) er ferdig vil sveisefunksjonen starte med sveising av vacuumposen.

Pilotlampen foran SEAL vil da lyse opp.

Det store displayet: Tidsnedtelling pr. sekund starter etter innstilt tid (maksimum 6.0

8. Soft-air ventilasjon

med å slippe luft inn i vacuumkammeret.

Pilotlampen foran SOFT AIR vil lyse opp.

Det store displayet: Tidsnedtelling pr. sekund starter som innstilt (maksimum 99 sekunder).

.

9. Ventilering

1 ATO og lokket åpner seg.

Alle pilotlampene foran funksjonene er slukket.

Det store displayet: streker går opp og ned til lokket er helt åpent.

Vacuummeteret går tilbake til 0 og lokket åpnes automatisk.

10. Produktet er nå ferdig vacuumert og kan tas ut/flyttes.

Version 11.10 DIG.EN 18

Maskinen starter å vacuumere kammeret.

Pilotlampen foran VACUUM lyser.

Maskinen fortsetter å vacuumere til H20 punktet er oppnådd eller at 99 % er (hvis installert)

Med en gang vacuumeringen er ferdig vil gasstilsetningen starte.

I det øyeblikket gasstilsetning er ferdig er det mulig å legge til

Når vacuumfunksjonen eller gasstilsetningsfunksjonen (hvis

sekunder).Vacuummeteret vil bli uforandret.

Når sveisefunksjonen er over vil soft-air funksjonen starte sakte

Vacuummeteret minker medurs

Etter endt sveise- og Soft-air funksjon (hvis installert) starter ventilasjon av kammeret til

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

PROGRAMMODUS

Programmodusene er brukt til å bytte funksjonsverdier innenfor programmer. Se side 4-6 med

instruksjoner for programmeringen.

ANDRE MODUS

Betjeningspanelet kan også benyttes for service. Programmet som er tilpasset dette er for pumpen og

tidsur/nedtellingsfunksjon som er de mest brukte i dette programmet.

Betjening av timetelleren

(Driftstidstelleren)

En av servicefunksjonene er timetelleren som automatisk gir beskjed om når man trenger service. Denne

registrerer hvor mange timer pumpen er operativ (pr.10 timer). MERK! Boxer serien har en pumpe som

ikke er aktiv hele tiden. I det øyeblikk innstilt tid er nådd vil beskjeden OIL vises i displayet (se side 11

i den kombinerte engelske og norske anvisningen). Maskinen kan fortsatt brukes som vanlig, men

varslingen vil stadig vises i displayet. Bestill service uten å vente.

Fabrikkens standardinnstilling for dette programmet OFF (slått av). Følgende steg kan benyttes for å

aktivere Driftstidstelleren eller nullstille denne.

Trykk på tasten FUNCTION SELECT for minst 3 skunder. Etter 3 sekunder vil

driftstidstelleren vise antall 10 timer som vacuumpakkemaskinen har vært i drift. Antallet vil vises i

2 sekunder. Etter 2 sekunder vil det originale innstilte timer vises (pr. 10 timer). Når

driftstimetelleren er slått av (ikke i bruk) vil brukte timer ikke vises ( i stedet vil det vises beskjeden

OFF) etter at tasten er trykket inn for 3 sekunder.

Den originale innstillingen av kan modifiseres ved å bruke tasten + og – (mellom 0 og 990 timer).

Hvis man stiller inn på 0 vil displayet neste gang automatisk vise OFF etter trykk for minst 3

sekunder.

Den nye innstillingen vil lagres ved å trykke på REPROG tasten. Den virkelige driftstiden vil da bli

satt til null.

Etter trykk på tasten REPROG vil betjeningspanelet bytte over til normal driftsmodus.

Version 11.10 DIG.EN 19

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

A.

Velg ønsket program med tasten PROG 0

-

9 for å stille inn verdier.

B.

Trykk på tas

ten REPROG for å komme inn i programmodusen.

C.

Velg ønsket funksjon for programmet med å trykke på FUNCTION SELECT

D.

Digital Tids Controll

E.

F.

Trykk på tasten REPROG etter innstilling av relevante funksjoner for så å

PROGRAMMERING

Verdifunksjonen i valgte programnummer kan alltid endres enten manuelt eller med automatisk

programmering. For enhet, område eller begrensninger av verdifunksjon henviser vi til forrige kapittel.

10 programmer kan velges (fra 0 til 9). Program 0 kan ikke benyttes av bruker. Dette programmet er for

service. Kun autoriserte personer kan benytte (endre verdier) dette programmet (trykke REPROG tasten for

minst 5 sekunder). Etter valg av program 0 må man bytte til PROGRAM MODE.

MANUELL PROGRAMMERING (oppstart med maskinen PÅ og med lokket åpent)

Programnummeret vises i det lille displayet.

Programnummeret begynner nå å blinke i det lille displayet.

tasten. Pilotlampen vil lyse opp for valgte funksjon.

OBS! Under SEAL (sveising) mulighet 1-2 Cut-Off seal

Under valgmulighet 1-2 cut-off seal vil pilotlampen lyse opp to ganger.

Første gangen for innstilling av sveisetid og andre gangen for innstilling av

kuttetiden.

OBS! Valgmulighet Digital Sensor Control and Quick Stop H20 Control.

Under valgmulighet sensor control, pilotlampen foran VACUUM vil lyse

opp to ganger. Første gangen er for Vacuum funksjonen (vacuum

prosenten) og andre gangen for Vacuum Plus funksjonen (med tid). Se side

8 og 9 i den engelske bruksanvisningen.

Innstill ønsket verdi ved å trykke på + og – tasten

Digital sensor Control og Quick Stop H20 Control

Still inn ønsket verdi prosent av vacuum eller ønsket tid for valgt funksjon

ved å trykke på + og – tasten.

OBS!

Verdiene vil vises i det store displayet.

Funksjonen VACUUM PLUS (sensor control), Gasstilsetning og Soft-Air kan

slås av i programmet hvis ønskelig. For å slå av trykk på – tasten inntil OFF

vises i det store displayet.

Gjenta steg C og D for innstilling av andre verdier.

lagre disse i programmet. Maskinen går da tilbake til normal drift og den

kan brukes til vacuumering. De nye innstilte verdier er nå standardverdier

inntil de blir endret på nytt.

Version 11.10 DIG.EN 20

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

A.

Velg ønsket program med tasten PROG 0

-

9 for å stille inn verdier.

B.

Trykk på tasten REPROG for å komme inn i

programmodusen.

C.

VACUUM funksjon

D.

VA

CUUM PLUS funksjon

E.

GASSTILSETNINGS funksjonen

(ikke standard/kan fås som tillegg)

F. S

VEISING OG SOFT

-

AIR funksjonene. Begge muligheter kan kun stilles inn manuelt

AUTOMATISK PROGRAMMERING (oppstart med maskinen PÅ og med lokket åpent)

Programnummeret vises i det lille displayet.

Programnummeret begynner nå å blinke i det lille displayet.

Lukk lokket. Maskinen starter automatisk

Digital Tidskontroll

Tiden øker. Så snart som Vacuummeteret når -1 trykk så på STOP

VACUUM-tasten. Automatisk vil maskin-syklusen bytte til følgende funksjon:

Bemerk Digital Tids-kontroll

La vacuumfunksjonen gå for 2 til 4 sekunder etter at -1 er oppnådd på

vacuummeteret slik at mulig små rester av luft også er trukket ut.

Digital Sensor Control

Den prosentuelle andel vacuum øker. Så snart som verdien 99 % er oppnådd

trykk på STOP VACUUM tasten. Automatisk vil maskin-syklusen bytte til

følgende funksjon: (NB! Hvis full vacuumering ikke er ønsket trykk på STOP

VACUUM tasten når ønsket verdi er oppnådd).

Digital Sensor Control + Quick Stop H20 Control

Tiden øker. Trykk på STOP VACUUM tasten når ønsket tid oppnås.

Da bytter maskinen automatisk til følgende funksjon.

(NB! VACUUM PLUS funksjonen kan kun deaktiveres med OFF tasten ved

manuell programmering. VACUUM PLUS funksjonen kan kun brukes når

VACUUM funksjonen er blitt innstilt på 99 %).

Digital Tids-drift

Tiden øker. Trykk på STOP VACUUM så snart vacuummeteret oppnår ønsket

undertrykk. Maskinsyklusen vil da automatisk bytte til følgende funksjon

Digital Føler-kontroll

Den prosentuelle andel vacuum øker. Trykk på VACUUM STOP tasten i det

øyeblikk maskinen nå ønsket verdi. Maskinsyklusen vil da automatisk til

neste funksjon. (NB! Det anbefalte minimale undertrykket er 0,5 bar eller 50

% vacuum. Det minste undertrykket som kan innstilles er 0,3 bar eller 30 %.

GAS FLUSH/gasstilsetning funksjonen er kun mulig å deaktivere med OFF

tasten ved manuell programmering).

Etter at syklusene er innstilt vil de automatisk bli lagret.

Version 11.10 DIG.EN 21

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

VÆR SPESIELT OPPMERKSOM PÅ FØLGENDE VED PROGRAMMERING

For DIGITAL SENSOR CONTROL (Digital Føler Kontroll)

Verdiene som blir programmert ved gasstilsetningsfunksjonen er den endelige vacuumprosenten i

vacuumkammeret etter gasstilsetningen.

Eksempel: Vacuum funksjonen er satt til 99 % og gasstilsetningen er satt til 60 %. Det betyr at etter

vacuum funksjonen vil vacuumkammeret få gasstilsetning til det oppnås 60 % vacuum og 40 % (39 %)

gass i vacuumkammeret.

For automatisk programmering

Vær sikker på at alle funksjoner er aktivert i det valgte programmet. Aktivert betyr at funksjonen i

programmet er tildelt en verdi. Hvis verdien er OFF betyr det at verdien ikke er aktivert og vil ikke bli

inkludert i det automatiske programsykluset.

For maskiner med gasstilsetningsfunksjonen

Hvis man programmerer et program med aktiv gasstilssetning vil dette indikeres ved at et punkt nede i høre

hjørne av det lille displayet vil lyse opp når man velger et program med denne modusen.

For maskiner med tillegg av Sensor Control (digital Føler Kontroll)

Hvis et program er satt opp med aktiv VACUUM PLUS funksjonen vil dette indikeres ved at et punkt nede

i de høyre hjørne i det store displayet lyse opp når man velger program med denne modusen.

Hvis funksjonsverdien er OFF er det kun mulig å aktivere denne ved manuell programmering.

Version 11.10 DIG.EN 22

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

MACHINE MAINTENANCE

GENERAL

A regular and complete maintenance is required for long usage of the machine, to avoid malfunctioning and to achieve an optimal

packaging result. If the machine is used intensively (more than 5 hours per day), we recommend professional servicing every 6

months. For normal use of the machine, complete servicing once a year should be sufficient (depending on location, environment

and products).

However, there are small maintenance activities that must be carried out regularly. These maintenance activities can be done by

the user. The following page contains an overview of these activities.

IMPORTANT BEFORE AND DURING MAINTENANCE

The machine must always be completely voltage free before any maintenance is carried out on it. Remove the plug from the

wall socket or put the master switch in the O position.

If the machine is not functioning properly or if it produces strange noises, turn it off immediately with the ON/OFF switch and

contact the supplier or Henkelman BV.

If the machine is equipped with a gas flush system then always close the main crane during standard maintenance activities.

Always note that the pressure on the pressure reducing valve on the gas bottle is never higher than 1 atmosphere/ATO

before, during and after the maintenance activities. A higher pressure may cause irreparable damage to the machine. NEVER

use flammable gasses or gas mixtures containing oxygen.

When cleaning transparent lids (if applicable), NEVER use cleaning agents containing solvents. Check at least once a week if

there are cracks in the lid. In case of cracks, turn off the machine immediately and contact the supplier or Henkelman BV.

High pressure cleaning is not permitted for cleaning the machine. High pressure cleaning can cause considerable damage to

electronic and other parts of the machine.

Water may never be permitted to enter either the extraction nozzle of the chamber or the blow-off opening of the pump. This

would cause irreparable damage to the pump.

Larger services must always be carried out by an authorised supplier.

The BOXER serie machines are designed for a maximum of 5 hours operation per day. Other machines are designed for a

maximum of 8 hours per day. The supplier or Henkelman BV cannot be held responsible for any malfunctions or defects if

these operation time limits are clearly exceeded without consultation.

The machine must be moved or transported in an upright position. The machine may NOT be tilted as it can cause damage to

the pump.

The supplier or Henkelman BV cannot be held responsible for any malfunctions or defects if the maintenance instructions in

this manual are not followed.

Contact the supplier or Henkelman BV if there are any doubts or questions about maintenance or malfunctions.

Version 11.10 DIG.EN 23

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

Daily

Clean the vacuum chamber, lid, and housing after use with a damp cloth.

Weekly

Check the oil level and replace or fill up oil when

the oil is turbid or the oil level is too

Every Six Months

Replace oil at least once every 6 months.

Yearly

Inspect the oil exhaust filter for saturation. If saturated, repl

ace the filter. For

Four

-

yearly

Replace transparent lid and the lid’s gas springs (if applicable)

STANDARD MAINTENANCE SCHEDULE FOR THE MACHINE

Make sure that no cleaning agents containing solvents are used.

Make sure that no high pressure cleaner is used.

low. For instructions, see page 23.

Activate the conditioning program for the pump at least once a week.

Inspect the sealing bar for damage. Replace Teflon tape/sealing wire if the seal quality

is no longer sufficient or if the Teflon tape/sealing wire is no longer tight and straight on

the sealing bar. For instructions, see page 26.

Inspect the lid gasket and replace it when the gasket is damaged or stretched. For

instructions, see page 27.

Inspect the transparent lid (if applicable). When cracks are visible, turn off the machine

immediately and contact the supplier or Henkelman BV.

instructions, see page 24.

Contact the supplier for a professional service

Replace membranes seal cylinder (if applicable)

VACUUM PUMP MAINTENANCE

It is very important to regularly service the pump to ensure extended and correct operation. The following activities are essential

for correct maintenance. If the machine is used regularly then it is advisable to have the pump fully inspected at least once a year

by the supplier to ensure extended and problem free operation. Contact the supplier or Henkelman BV for more advice and

information.

Conditioning Program

key [conditioning program], and close the lid. The program runs automatically. During the program the large display will display

moving lines.

The program can be interrupted at any time using the [STOP] key. It is however important for the sake of good maintenance that

the program completes a full 15 minute cycle and therefore advisable only to interrupt the cycle for something urgent.

It is also advisable to run the program before using the machine for the first time, after the machine has been stationary for a

lengthy period of time, and especially prior to changing oil.

The conditioning program ensures that the pump is thoroughly rinsed. During the program the pump and oil

reaches operation temperature so that the oil can better absorb any moisture and contaminants and filter them.

The high temperature enables any moisture in the pump to evaporate minimising the risk for rust spots.

The program lasts 15 minutes and it is advisable to run it at least once a week. Turn on the machine, press the

Version 11.10 DIG.EN 24

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

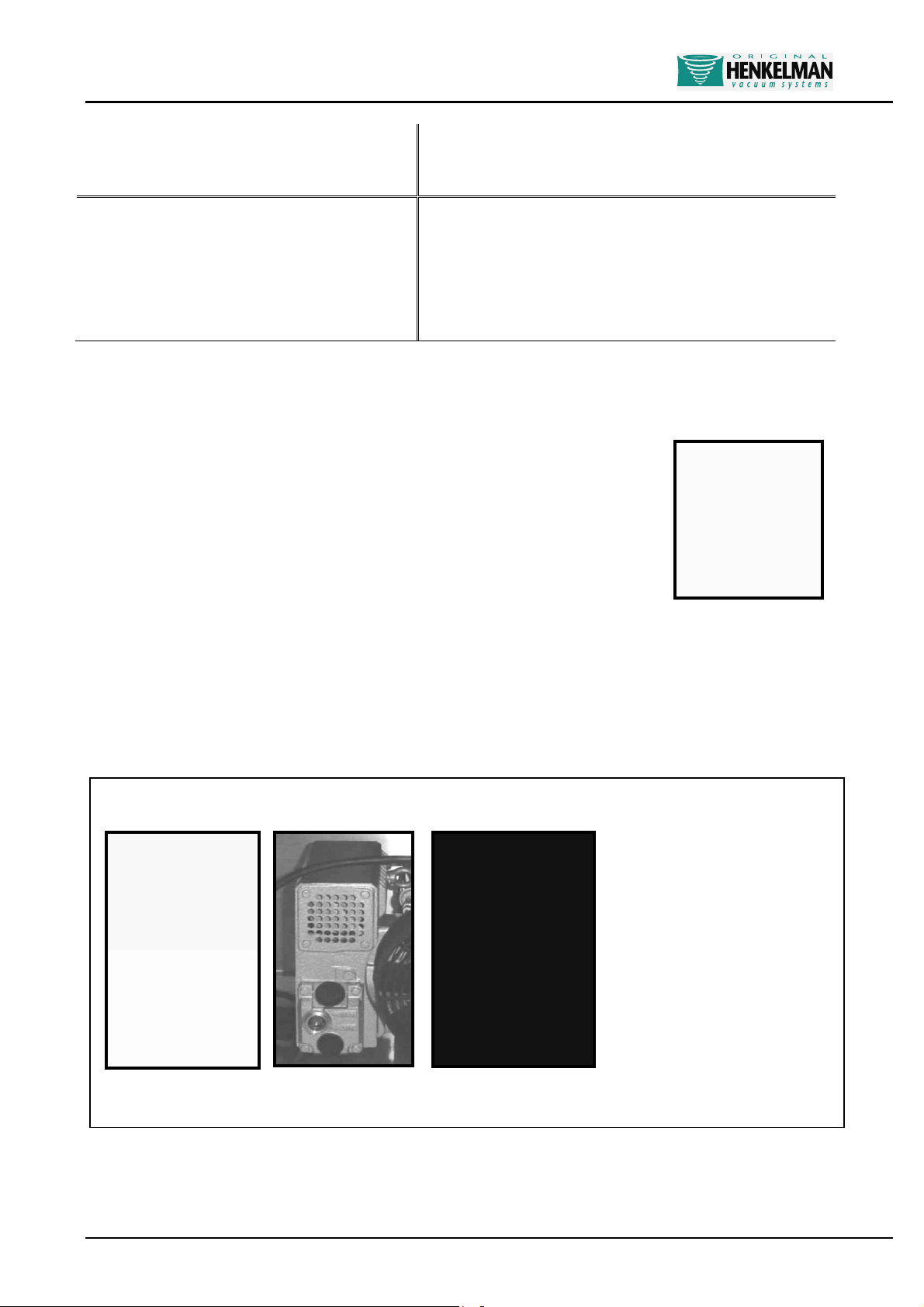

Location at rear or side of machine

Take care to use the correct type

1 2

4 1 2

3

Changing Oil / Filling Up

The oil level and oil quality must be checked at least once a week. The oil inspection window serves this purpose. Fill up the oil

level if it is too low. Replace the oil if it is turbid. Oil must be replaced at least once every 6 months.

BOXER series

MARLIN / FALCON / POLAR series

View can differ per model

Filling up oil

After draining or if the oil level has dropped, oil needs to be filled up. The oil fill plug must be removed with the correct size

spanner. The pump can now be filled with oil. Make sure that you add the correct amount (see table on page 24)

TAKE CARE to fill with small amounts at intervals. Fill the oil level to the top of the oil level indicator sticker.

TAKE CARE to replace the oil filter before adding the new oil (see page 24)

Oil types and amounts

It is important to use the correct type and quantity of oil for the pump. The wrong type or too much oil could damage the pump.

The ambient temperature where the machine is operated is also important for the type of oil. See amounts and types with related

ambient temperatures in the table on the next page.

Examples of supplier brands for the standard types of oil are Shell Vitrea, Aral Motanol GM, BP Energol CS, or Texaco Regal R+

O with related viscosity numbering. If the machine is used outside normal specifications regarding ambient temperature, contact

the supplier or Henkelman BV.

1. Oil fill plug

3

2. Oil drain plug

3. Oil inspection window

4. Oil level indicator sticker

of oil for the pump

Beware of hot oil fumes during

drainage

Draining oil

If the oil is white or turbid when checked then it must be replaced. Before draining off the oil

let the conditioning program run a full cycle. The dirt and moisture is absorbed by the oil

and the oil becomes thinner making draining easier.

After the program has ended the drainage plug can be removed.

CAUTION, when unscrewing hot oil fumes can escape. The oil now drains from the drain

hole (an oil pan must be placed underneath). For the BOXER series, when the oil has

drained, tilt the machine slightly so that all residual oil can drain off. After draining the oil

drain plug is replaced.

Version 11.10 DIG.EN 25

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

Ambient Temperature

Machine Type

Pump

Fill

ing

Standard

“Cold”

“Hot”

BOXER 42 / 42 XL

021 m

/h 0.4 Viscosity VG 32

VM 32

VS 32

MARLIN 46

040 m

/h 1.0 Viscosity VG

32

VM 32

VS 32

MARLIN 52 / 90

- FALCON 52 / 2

-

60 –

POLAR 52 / 2

-40

063 m

/h 1.0 Viscosity VG 100

VM 100

VS 100

FALCON 2

-

60 -

POLAR 2

-50

100 m

/h 2.0 Viscosity VG 100

VM 100

VS 100

POLAR 2

-75

160 m

/h 5.0 Viscosity VG 100

VM 100

VS 100

POLAR 2

-

85 / 2

-95 300 m

/h 7.0 Viscosity VG 100

VM 100

VS 100

Oil filter

Filter housings can be

160-300 m3/h

040-063-100 m3/h

Capacity

BOXER 35

Machines are supplied with standard type oil.

The capacity of models with a 063 m3/h pump and 60Hz voltage, is 2.0 litre instead of 1.0 litre.

016 m3/h 0.4 Viscosity VG 32 VM 32

(litres)

3

3

3

3

3

3

Oil Type

10 - 30

o

C

Oil Type

5 - 10

o

C

Oil Type

30 - 40

VS 32

o

C

Changing the oil filter

The pumps of all floor models have oil filters. When replacing the oil the filters must also be

replaced. The oil filter is screwed to the rear of the oil exhaust filter housing.

When replacing the oil, it is first drained off. The old filter is then screwed off and replaced by a new

one. The pump can now be filled with new oil.

For the correct type of oil filters refer to the list of maintenance parts on page 29.

Inspect and change oil exhaust filter

There are one or more oil exhaust filters in the pump which absorb and filter oil vapours. The filters will become saturated after a

period of time and need to be replaced. This is on average between 12 and 18 months. When the filters are saturated it is no

longer possible to achieve maximum vacuum.

Filter housing types

Version 11.10 DIG.EN 26

located at the side or

behind the machine

Appearance can vary

depending on the model

(multiple housings on

pump or multiple filters

in one housing)

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

OFFSEAL

Remove tensioner(s) and

Take care that the filter gasket does not

Pumps and housing can have a different appearance but the principle of replacing remains the same.

Place and tension the new filter (take

Open rear or side of

machine for pump

Change oil exhaust filter(s)

filter(s) from the housing

Take care that the correct type of filter is used for the pump type, see page 29 for the correct type of filter for the type of

SEAL SYSTEM MAINTENANCE

pump

It is advisable to have the suppler do this service.

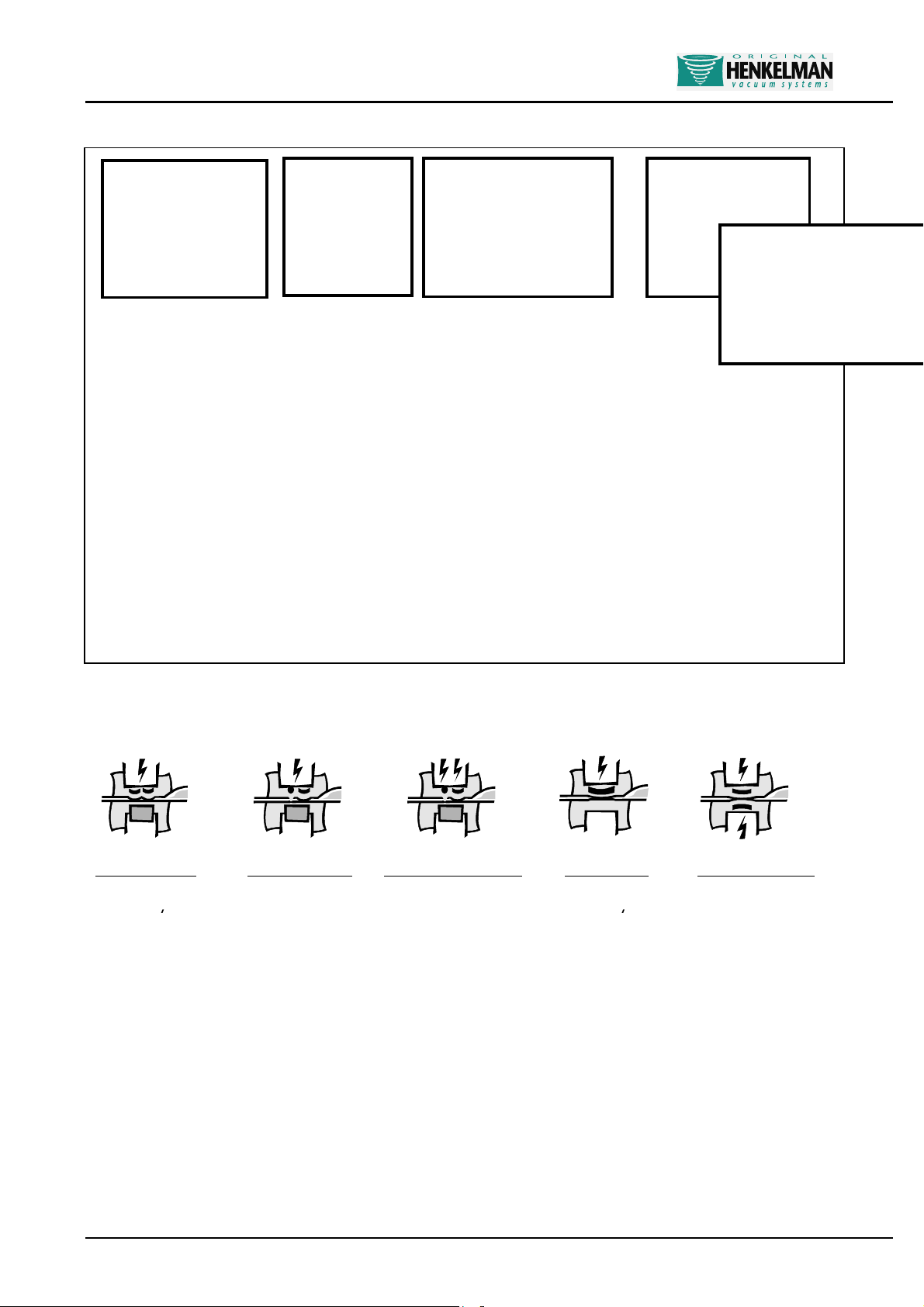

All or some of the following sealing systems are possible in the BOXER/MARLIN/FALCON/POLAR series. It is essential to know

which sealing system is applicable to the relevant machine.

DOUBLE SEAL

2 x 3,5 mm

CUT-OFFSEAL

1 x 3,5 mm seal

1 x 1,1 mm cut

Servicing the sealing bar is almost identical for all systems. The seal quality is partially dependent on the maintenance of the

sealing bar and contra-bar (silicone holder). The main maintenance activities are the daily cleaning of the sealing bar and the

silicone holder with a damp cloth and a weekly inspection of the bars with replacement of the sealing wire, teflon tape or silicone

rubber if irregularities appear on top of the bar or the seal quality is insufficient.

The average maintenance cycle of the sealing bar (teflon tape / sealing wire) is at least once every 3 months.

(This indication refers to regular use of the machine, on average 8 hours per day and packaging standard products with standard vacuum packaging materials.

No rights can be derived from this indication)

care that the gasket is correctly

positioned) in the housing

Screw the cover back onto the housing

Screw the back or side plate on the

machine

remain behind when removing the filter

1-2 CUT-

1 x 3,5 mm seal

1 x 1,1 mm cut

WIDE SEAL

1 x 8,0 mm

BI-ACTIVE SEAL

1 x 5,0 mm seal

above and below

Version 11.10 DIG.EN 27

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

Pull wires taught using a

Remove teflon tape

Unscrew and remove

Replace the teflon tape

Screw down new wires

Cut off the ends of the sealing wire and stick

Special remark bi

-

active sealing system

Replace sealing wire and teflon tape

1.

Remove the sealing bar(s) from the holders (in the chamber or lid) by releasing the click system or by

sealing wires

onto clamping plate

unscrewing the screws.

2. Remove the teflon tape from the sealing bar.

3.

The old sealing wires and cut-off wires (if applicable) can be removed by unscrewing the clamp (see

illustration) and pulling the wires from the grooves.

4. Remove the teflon tape that is attached to the top of the sealing bar and stick a new piece of teflon tape

to the bar of the same length after having degreased and cleaned the bar with a dust free cloth.

5.

Cut a new peace of sealing wire or cut-off wire to the size of the sealing beam plus about 15 cm (± 6

inches). If 2 sealing wires or an extra cut-off wire is on the sealing beam then a second sealing wire or

cut-off wire must of course be cut.

6.

Place the end of the wire or wires through the groove(s) on the side of the sealing beam and screw the

wires to the bottom.

7. Place the sealing bar top down in a vice and pull the sealing wire or wires through the other side of the

groove(s) on the sealing beam.

8.

Pull the wires tight with a pair of pliers and screw them down at the same time. Ensure that the wire

(wires) is (are) pulled taught and straight with the help of a pair of pliers before the wires are screwed

down.

9. It is handy to use a pair of adjustable pliers as a lever for optimal wire tension. Place one end of the

sealing beam in the vice and stretch the wire (wires) by pressing down the bar.

10. Cut off the extruding wire end(s) on both ends after having screwed it tight.

11. Cut a piece of teflon tape as long as the sealing bar plus about 5 cm (± 2 inches).

12.

Stick the new teflon tape straight over the new sealing wire (wires). Ensure that the teflon is straight on

the sealing bar and that the sticky part is stuck on the side. Ensure that the teflon is stuck on the bar

smoothly and without folds.

13.

Cut the teflon tape off so that the sticky part does not get stuck on the sides of the clamps but that the

teflon extends over the top of the clamps.

14.

Place the sealing bar back in the machine. Ensure that the sealing beam is properly clicked onto the

holders or that the screws are firmly screwed in.

pair of pliers and a vice

and screw the wires down

on the clamping plate.

Version 11.10 DIG.EN 28

The sealing wire must be accurately placed on the upper

and lower beams so that the sealing wires line up with

each other exactly during sealing.

See page 30

for correct parts and quantities

Teflon tape over the sealing beam without folds

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

SILICONE HOLDER AND LID GASKET MAINTENANCE

Replace the rubber silicone holder

The silicone holder must be inspected weekly for irregularities on the silicone rubber (mainly caused by burning by the sealing

wire). If irregularities appear then the silicone rubber must be replaced.

Average maintenance cycle for silicone rubber is at least once every 6 months

(This indication refers to regular use of the machine with standard products. No rights can be derived from this indication)

1.

Remove the old silicone rubber from the holder.

2.

Cut a new piece of silicone rubber the same size as the old one. The same

size is very important, too short or too long will cause problems with sealing.

3.

Place the new piece in the silicone holder. Ensure that the silicone rubber is

completely and evenly placed in the groove. It is also important that the

surface of the silicone rubber is smooth after it is in place and is shows no

signs of tension.

Replace lid gasket

The lid gasket ensures that the vacuum chamber is completely sealed during the

machine cycle. This is essential for achieving a maximum vacuum. The lid gasket wears

due to the extreme pressure differences and must be replaced regularly. Inspect the lid

gasket weekly for tears or damage.

Average maintenance cycle for lid gasket is at least once every 6 months

(This indication refers to regular use of the machine, on average 8 hours a day and with standard

products. No rights can be derived from this indication)

De length of the new lid gasket is determined by using the old gasket. If the lid rubber

is too short or too long it can cause problems closing the lid or leak.

The rubber must be placed evenly and without tension in the holder. The ends must be cut

straight and must be laid tightly against each other to avoid leakage.

Appearance may differ per

Ensure that the ends of

Version 11.10 DIG.EN 29

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

016 m

/h BOXER 35

021 m

/h BOXER 42 / 42 XL / 42 XL BA

040 m

/h MARLIN 46

063 m

/h MARLIN 52 / 90

– FALCON 52 / 2

-

60 –

POLAR 52 / 2

-40

100 m

/h FALCON 80 / 2

-

70 –

POL

AR 80 / 2

-50

160 m

/h POLAR 2

-75

300 m

/h POLAR 2

-

85 / 2

-95

BUSCH

STANDARD OIL

OIL FILTER

OIL MIST FILTER

Henkelman

Henkelman

Henkelman

016 m

/h VG 32

0439510

0.40 - - 50-60Hz 0939163 1

021 m

/h VG 32

0439510

0.40 - - 50-60Hz 0939165 1 040 m

/h VG 100

0439520

1.0 040-063-100 0939090

50-

60Hz 0939

171 1 063 m

/h –

50Hz VG 100

0439520

1.0 040-063-100 0939090

50Hz 0939

171 1 063 m

/h –

60Hz VG 100

0439520

2.0 040-063-100 0939090

60Hz

0939

170 2 100 m

/h VG 100

0439520

2.0 040-063-100 0939090

50-

60Hz 0939170 2 160 m

/h VG 100

0439520

5.0 160-300 0939091

50-

60Hz 0939175 2 300 m

/h VG 100

0439520

7.0 160-300 0939091

50-

60Hz 0939175 3

Teflon tape

46 mm wide teflon tape

0305515

length sealing

bar + 5 cm

Double Seal

2 x 3.5 mm round wire

0305000

2 wires length of sealing

bar + 15 cm

Cut-off seal

1 x 3.5 mm round wire

0305000

1 wire length of sealing

bar +

15 cm

1 x 1.1 mm round wire

0305010

1 wire length of sealing

bar + 15 cm

1-2 Cut

-

off seal

1 x 3.5 mm round wire

0305000

1 wire length of sealing

bar + 15 cm

1 x 1.1 mm round wire

0305010

1 wire length of sealing b

ar + 15 cm

Broad Seal

1 x 8.0 mm flat

wire 0305025

1 wire length of sealing b

ar + 15 cm

Bi-Active Seal

1 x 5.0 mm flat wire

0305020

1 wire length of sealing

bar + 15 cm

1 x 8.0 mm flat wire

0305025

1 wire length of sealing

bar + 15 cm

Silicone Rubber

Silicone 17 x 8

0320200

length s

ilicone holder

LIST OF SERVICE PARTS

VACUUM PUMP PARTS

BUSCH VACUUM PUMPS HENKELMAN MODELS

3

3

3

3

3

3

3

Type

3

3

3

3

3

3

3

3

SEAL SYSTEMS

PARTS

Reference

Litres Type

SPECIFICATIONS

Reference

HENKELMAN

REFERENCE

Type

Reference

QUANTITY

Amount

Bi-active Seal: Single chambers uses 2 x 5,0 mm. Double chambers 1 x 5,0 mm and 1 x 8,0 mm

Version 11.10 DIG.EN 30

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

LID GASKET

MODELS

HENKELMAN

REFERENCE

LENGTHS PER MODEL (in cm)

BOXER SERIES

0320215 BOXER 35

BOXER 42

BOXER 42 XL / BOXER 42 XL BA

MARLIN 46 / 52 / 90

FALCON SERIES

POLAR 52 / 80 / 2-40 / 2-50

0320210 MARLIN 46

MARLIN 52 / FALCON 52 / POLAR 52

MARLIN 90

FALCON 80 / POLAR 80

FALCON 2-60 / 2-70

POLAR 2-40 / 2-50

POLAR 2-75 / 2-85 / 2-95

0320212 POLAR 2-75 / 2-85 / 2-95

Lengths specified are always a little longer and must be cut to the correct length.

175

190

210

255

250

290

300

260 / 300

280 / 300

350 / 390 / 440

Version 11.10 DIG.EN 31

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

MODEL

VACUUM CHAMBER

LID HOUSING

DIMENSIONS

PUMP

FINAL

BOXER SERIES

35 Stainless steel

Transparent

Stainless steel

450x525x385

016 99,80%

42

Stainless steel

Transparent

Stainless steel

490x525x430

021 99,80%

42 XL

Stainless steel

Transparent

Stainless st

eel 490x610x445

021 99,80%

42 XL Bi

-

active

Stainless steel

Transparent

Stainless steel

490x610x420

021 99,80%

MARLIN SERIES

46

Stainless steel

Transparent

Stainless steel

780x660x970

040 99,98%

52

Stainless steel

Transparent

Stainless ste

el 700x690x1030

063 99,98%

90

Stainless steel

Transparent

Stainless steel

1065x480x960

063 99,98%

FALCON SERIES

52

Aluminium

Aluminium/

Sight glass

Stainless steel

700x690x1070

063 99,98%

80

Aluminium

Aluminium/

Sight glass

Stainless steel

900x820x1070

100 99,98%

2-60

Aluminium

Aluminium/

Sight glass

Stainless steel

1060x880x1070

063 99,98%

2-70

Aluminium

Aluminium/

Sight glass

Stainless steel

1260x1010x1070

100 99,98%

POLAR SERIES

52

Stainless steel

Stainless steel

Stainless

steel 700x730x1100

063 99,98%

80

Stainless steel

Stainless steel

Stainless steel

920x790x1125

100 99,98%

2-40

Stainless steel

Stainless steel

Stainless steel

1480x790x1090

063 99,98%

2-50

Stainless steel

Stainless steel

Stainless steel

1480x970x1120

100 99,98%

2-75

Stainless steel

Stainless steel

Stainless steel

1545x1150x1150

160 99,99%

2-85

Stainless steel

Stainless steel

Stainless steel

1900x1300x1150

300 99,99%

2-95

Stainless steel

Stainless steel

Stainless steel

2420x1210x1130

300 99,99%

TECHNICAL SPECIFICATIONS

WORKING PLATE

(mm)

(m

3

/h)

VACUUM

(%)

Specifications can deviate from optional models

Standard ambient temperature 05

For deviating ambient temperatures see page 24 for special oil specifications

0

C – 30 0C

Maximum use per day BOXER series 5 hours per day

Other machines: 8 hours per day

Electricity Voltage: see machine tag

Frequency: see machine tag

Power: see machine tag

Electrical connection Maximum fluctuation ± 10% of the official registered voltage

Gas bottle connector diameter BOXER series diameter 6 mm

(if applicable

) POLAR 2-85 / 2-95: diameter 13 mm

OTHER MODELS: diameter 8 mm

Maximum pressure gas bottle connector 1 ATO

(if applicable

)

External seal pressure connection diameter 6 mm

(if applicable

)

Sound level < 70 DB

Version 11.10 DIG.EN 32

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

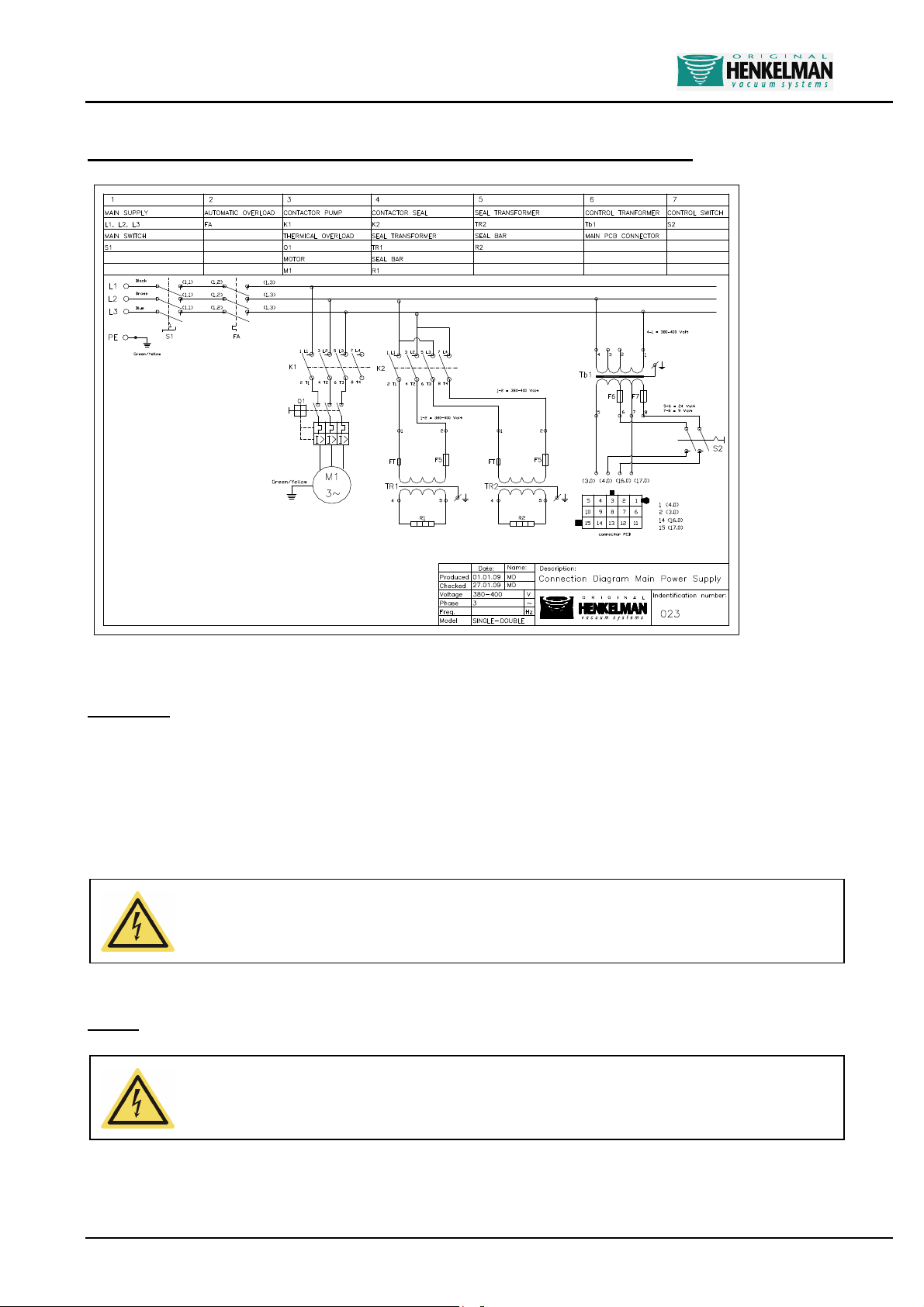

ELECTRICAL DIAGRAMS

Control Current Diagram BOXER/ TOUCAN series

Power Circuit Diagram BOXER / TOUCAN series

Diagrams are shown for standard configurations.

Version 11.10 DIG.EN 33

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

Control Current Diagram MARLIN 46/52/90 / FALCON 52/80 / POLAR 52/80

Diagrams are shown for standard configurations.

Control Current Diagram FALCON 2-60/2-70 / POLAR 2-40/2-50/2-75/2-85/2-95

Version 11.10 DIG.EN 34

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

Main Circuit Diagram MARLIN 46-52-90/FALCON 2-60/2-70 / POLAR 2-40/2-50/2-75/2-85/2-95

Diagrams are shown for standard configurations.

List of fuses

Fuses are located where the power enters the component board

Fuses are located on transformers (control and seal)

Two fuses are placed on the control circuit.

Due to different mains voltages and machine models there is a variety of fuse types that can be present in the machine. Refer to

the specifications of the relevant component for the correct types and values of fuses for replacement, or contact your supplier.

Caution, to avoid fire and/or other irreparable damage to the machine, replacement fuses must always be

of the same type with the same value as the fuses being replaced!!

Voltage

Caution, the maximum allowable voltage fluctuation is ± 10% of the official voltage stated on the machine

tag.

Version 11.10 DIG.EN 35

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

ERROR CODES

The controls are programmed with a number of error codes. These error codes are intended to give the user / dealer a clear

indication of what the possible cause might be why starting or packaging is not working as expected.

F1: This code indicates that the cycle (cover switch) will be interrupted prematurely.

Example: the cover of the machine closes after starting, but before sufficient vacuum is present to keep the cover closed the

operator lets go of the cover. The F1 code will now be shown on the display.

In a time-controlled machine, the time for gassing is set in such a way that the entire chamber is gassed and the cover opened

without sealing taking place. Here too the F1 code will immediately be shown on the display.

This message will never be shown directly after the controls are started, but during the course of the cycle.

F2: This code indicates that the sensor is not working properly.

When the controls are started, the condition of the sensor is checked. If the feedback data of the sensor are not correct, F2 is

shown on the display. This message will be shown directly after the sensor controls are started.

RP-: This message will be shown when, due to circumstances, the controls are unable to retrieve the programme values.

The word ‘circumstances’ means peak tensions or a tension drop during starting. When such a situation occurs, the print will start

with this message and go no further. Two options exist now: the machine can be switched off and on again to see if the problem

repeats itself or the reprog key can be pressed. By operating the reprog key, the controls will use the factory settings to start. The

programme values set by the client will be cancelled as a result.

This message will be shown directly after the controls are started.

If one or more of the above messages occur regularly, we advise you to contact your supplier.

Version 11.10 DIG.EN 36

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

PNEUMATIC DIAGRAMS

BOXER series / MARLIN series

FALCON series / POLAR series

Diagrams are shown for standard configurations.

Version 11.10 DIG.EN 37

BOXER / MARLIN / FALCON / POLAR SERIES USER MANUAL

PROBLEM SOLVING

PROBLEM

Machine does not

work

Machine does not

work

Control panel is on

Transparent lid does

not open

automatically

Final vacuum is

insufficient

CAUSE

· The plug is not plugged into the wall

socket.

· The main fuse is burnt.

· The circuit board fuse is burnt.

· The control transformer fuse is burnt.

· The micro switch which is activated when

the lid is closed needs adjustment or is

faulty.

·

There is an internal malfunction.

·

The gas spring is faulty

· The set vacuum time is too short.

· There is too little oil in the vacuum pump.

· The extraction hole at the back of the

vacuum chamber is partially covered by

the vacuum bag during vacuuming.

· The lid gasket is worn.

· The oil is contaminated.

·

The oil exhaust filter is saturated.

SOLUTION

·

Plug the plug into the wall socket.

· Replace the fuse (Ensure the correct

value).

· Disassemble the front panel and replace

the fuse.

· Check this and if necessary replace it.

· The micro switch must be properly

adjusted or replaced

· Consult supplier.

·

Consult the supplier.

· Extend the vacuum time.

·

Check the oil level and fill up if necessary

(Note the type and quantity).