Henkel Structural Bonding Solutions User Manual

Structural Bonding

Solutions

2

Since the original development of a unique anaerobic

technology, Loctite®products have become vital components

in many of the machines and products that are at the core of

everyday life. Loctite

®

products are used in markets as diverse

as electronics, automotive, aerospace, biomedical and many

manufacturing industries.

With the addition of Loctite

®

Hysol®Epoxies to its product

family, Henkel offers a broad range of unique adhesives

which together with the company's commitment to quality

and service, makes Henkel the single source for a diverse

technology portfolio of industry-leading adhesives.

The Loctite

®

Hysol®range comprises one and two component

epoxies that offer improved clarity, less odour, better flow,

higher strength and greater durability than competitive

products. They are approved and specified by engineers and

designers worldwide for a wide range of bonding applications,

from aerospace to the electronics industry, from maintenance

to original equipment manufacturers. Close attention to

environmental issues means they can be shipped and used in

markets worldwide without compromising performance.

The strength of the Loctite

®

Hysol®product range is in its

ability to bond the broadest possible variety of substrates

including metals, glass, ceramic, wood and most plastics.

They cure rapidly at room or elevated temperatures and are

ideal for automated production processes to replace welding

and riveting with a corrosion free, reduced stress joint.

Henkel offers much more than outstanding products, it

provides solutions to many of industry’s biggest challenges.

Whether it is by reducing assembly costs, providing design and

application assistance or increasing the reliability of a process,

Henkel is dedicated to earning and keeping the trust of its

customers.

The Loctite®brand, part of the Henkel portfolio since

1997, is renowned for the excellence of its adhesives and

sealants. For more than fifty years it has been providing

solutions across the whole spectrum of adhesive technologies

and manufacturing processes.

With products and expertise in almost every segment of industry,

Henkel engineers and chemists know the importance of understanding both

the full scope of manufacturing processes as well as the complex challenges of very

specific needs. These needs are met with a deep chemical knowledge that enables Henkel to respond with

the most innovative solutions.

Advanced Solutions

4

5

6

8

10

12

14

16

17

21

3

Complete Product List

including ordering information

Convenient Packaging

Detailed information about pack sizes

Loctite®Dispensing Equipment

Select the compatible dispensing solution

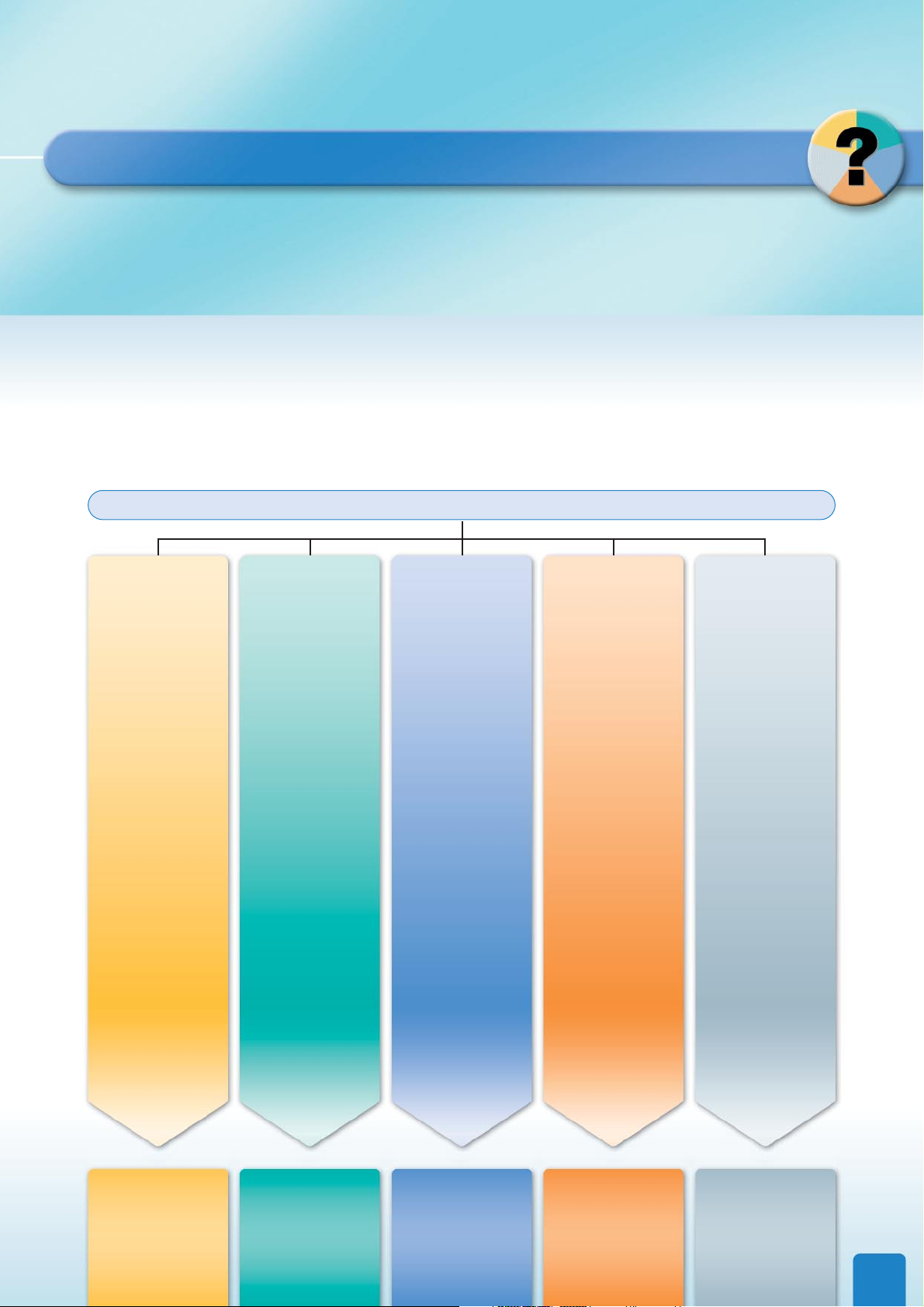

Making the Right Choice

This comprehensive guide is designed to make it easy for you to select the right Loctite®Hysol®Epoxy adhesive

for a variety of applications. Simply select suitable adhesives for bonding particular substrates and compare the

characteristics of different products using the technical data. Choose the compatible dispensing equipment for

your pack size and see the product list for ordering information.

Application Selector Guide

to meet your individual requirements

Loctite®Hysol

®

High temperature epoxies

Loctite®Hysol

®

Toughened epoxies

Loctite®Hysol

®

Five-minute epoxies

Loctite®Hysol

®

General purpose epoxies

Loctite®Hysol

®

Metal-filled epoxies

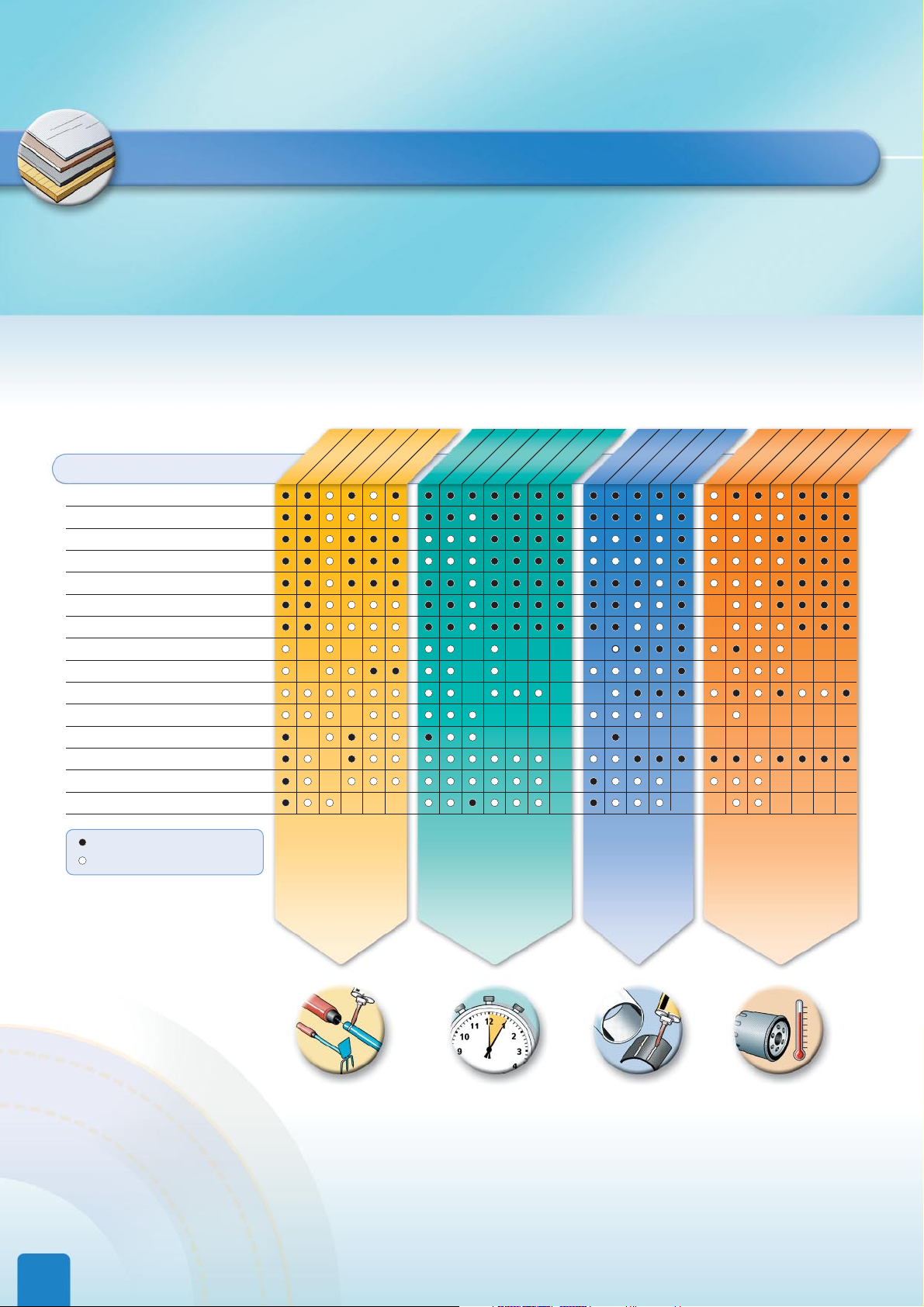

Substrate Selector Guide

for an initial product recommendation

3421 A&B

3423 A&B

9481 A&B

9483 A&B

9484 A&B

9489 A&B

3430 A&B

9455 A&B

3422 A&B

9450 A&B

3450 A&B

3455 A&B

3463 A&B

3425 A&B

9466 A&B

9461 A&B

9464 A&B

9514

9496 A&B

9497 A&B

9492 A&B

9535

9509

9502

9514

4

6 8 10 12

Steel

Stainless steel

Zinc dichromate steel

Hot dipped galvanised steel

Aluminium

Copper

Brass

Thermoplastics

Thermoset plastics

GRP / SMC composites

Rubbers

Glass

Ceramic

Masonry

Wood

Loctite®Hysol

®

Five-minute

epoxies

Toughened

epoxies

High temperature

epoxies

Substrate Selector Guide

Loctite®Hysol®Epoxy adhesives bond a wide range of substrates.

Please refer to the chart below to select the best adhesive for your application. Each adhesive is colour coded to its product group.

Refer to the following pages for product description and typical properties of the recommended adhesive.

General purpose

epoxies

Page Page Page Page

Highly recommended

Recommended

• Thermoplastics:

ABS, Acrylic, PA, PC, PVC, SAN

• Thermoset plastics:

DAP, Epoxy, Phenolic, Polyester

• Rubbers:

Butyl, EPDM, Natural, Neoprene,

Nitrile, SBR

Henkel recommends that the selected product for your specific application is evaluated to determine suitability. If you require additional

information or advice, Henkel has technical personnel trained to provide on site design and engineering support, application testing, validation

and integration of dispensing and cure systems.

The Loctite

®

Hysol®range is part of an extensive range of high-performance adhesives and sealants designed for industrial use. This includes

anaerobic, cyanoacrylate, light curing and specialised silicone adhesives. For more information on the complete range of Loctite

®

products

please contact Henkel or visit the web site at www.loctite.com.

for an initial product recommendation

6 8 10 12 14

5

Your application?

General

purpose

epoxies

Five-minute

epoxies

Toughened

epoxies

High

temperature

epoxies

Metal-filled

epoxies

Application Selector Guide

to meet your individual requirements

Loctite®Hysol®Epoxy adhesives for a variety of applications

General purpose epoxies are suitable for a wide range of general and flexible bonding applications. Five-minute epoxies are fast curing

and ideal for multi-purpose use or metal repair where a rapid cure is required. Toughened epoxies offer exceptional strength and impact

resistance, while High temperature epoxies are designed for use up to 180 °C. For the repair of worn or damaged parts, Metal-filled

epoxies provide the perfect solution. The range also includes ultra clear products for bonding transparent substrates, adhesives with an

extended working life for large areas as well as paste adhesives for gap filling and vertical applications.

• Multi purpose

adhesives for

general bonding

applications?

• Ultra clear

adhesives for

transparent

bond lines?

• Flexible

adhesives for

low stress

bonding of

plastics and

dissimilar

substrates?

• Rapid cure for a

fast fixture time?

• Ultra clear

adhesives for

fast transparent

bonding?

• Emergency repair

of metal parts

like pipes and

tanks?

• Highest shear

and peel

strength?

• Excellent impact

resistance?

• Adhesives for

bonding high

performance

composites like

GRP and CFRP?

• Resistance to

high operating

temperatures?

• One component

heat curing?

• High thermal

conductivity?

• Rebuild and

restore worn and

damaged metal

parts?

• Repair metal

pipes and

castings?

• Form moulds,

tools, fixtures

and models?

• Reduce sliding

wear on moving

parts?

Page Page Page Page Page

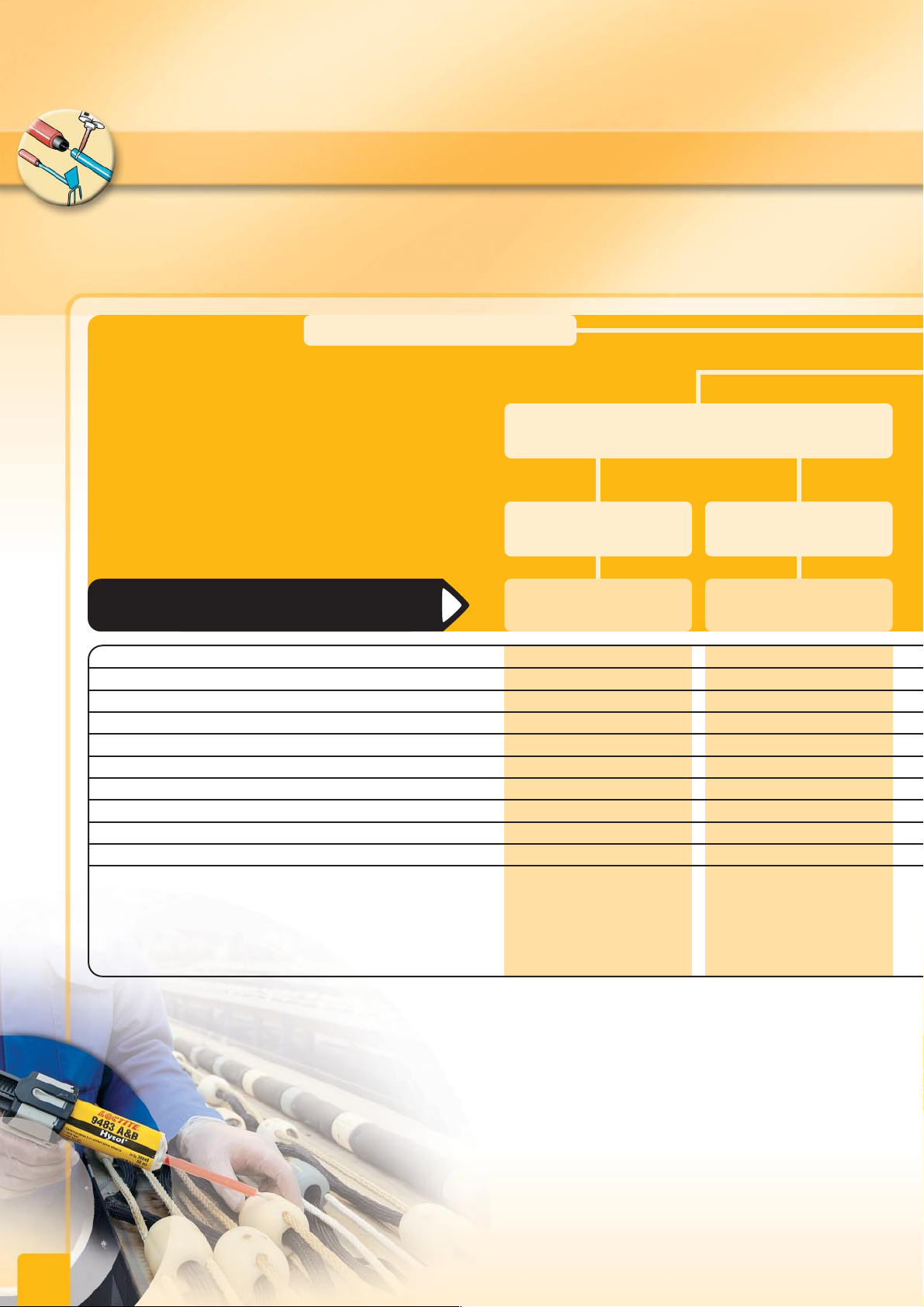

6

Solution

Description 2K-Epoxy 2K-Epoxy

Mix ratio by volume (A:B) 1:1 1:1

Mix ratio by weight (A:B) 100 : 90 100 : 70

Working life 180min. 70 min.

Fixture time 240 min. 180 min.

Colour Clear amber Grey

Viscosity 40 Pa.s 300Pa.s

Shear strength (GBMS) 23 N/mm

2

17 N/mm

2

Peel strength (GBMS) 2.5 N/mm 2.7 N/mm

Operating temperature -55°C to 120°C -55°C to 120°C

Pack sizes 50 ml dual cartridge 50 ml dual cartridge

200 ml dual cartridge 200 ml dual cartridge

400 ml dual cartridge 400 ml dual cartridge

1 kg tubs 1 kg tubs

20 kg pails 20 kg pails

3421 A&B 3423 A&B

Your application

General bonding

Medium viscosity Non-sag paste

Loctite

®

Hysol®3421 A&B

• Medium viscosity

• Extended working life

• Excellent humidity resistance

Loctite

®

Hysol®3421 A&B is a

general purpose, 2K-Epoxy

adhesive for bonding large

surfaces which require a long

open time. Ideal for bonding

metals, plastics and most other

surfaces which will be subjected

to high humidity environments.

Loctite®Hysol®3423 A&B

• Non-sag paste

• Medium working life

• Excellent chemical resistance

Loctite

®

Hysol®3423 A&B is a

general purpose, 2K-Epoxy

adhesive, suitable for gap filling

and vertical applications. Ideal

for bonding metal components.

Loctite® Hysol

®

General purpose epoxies

7

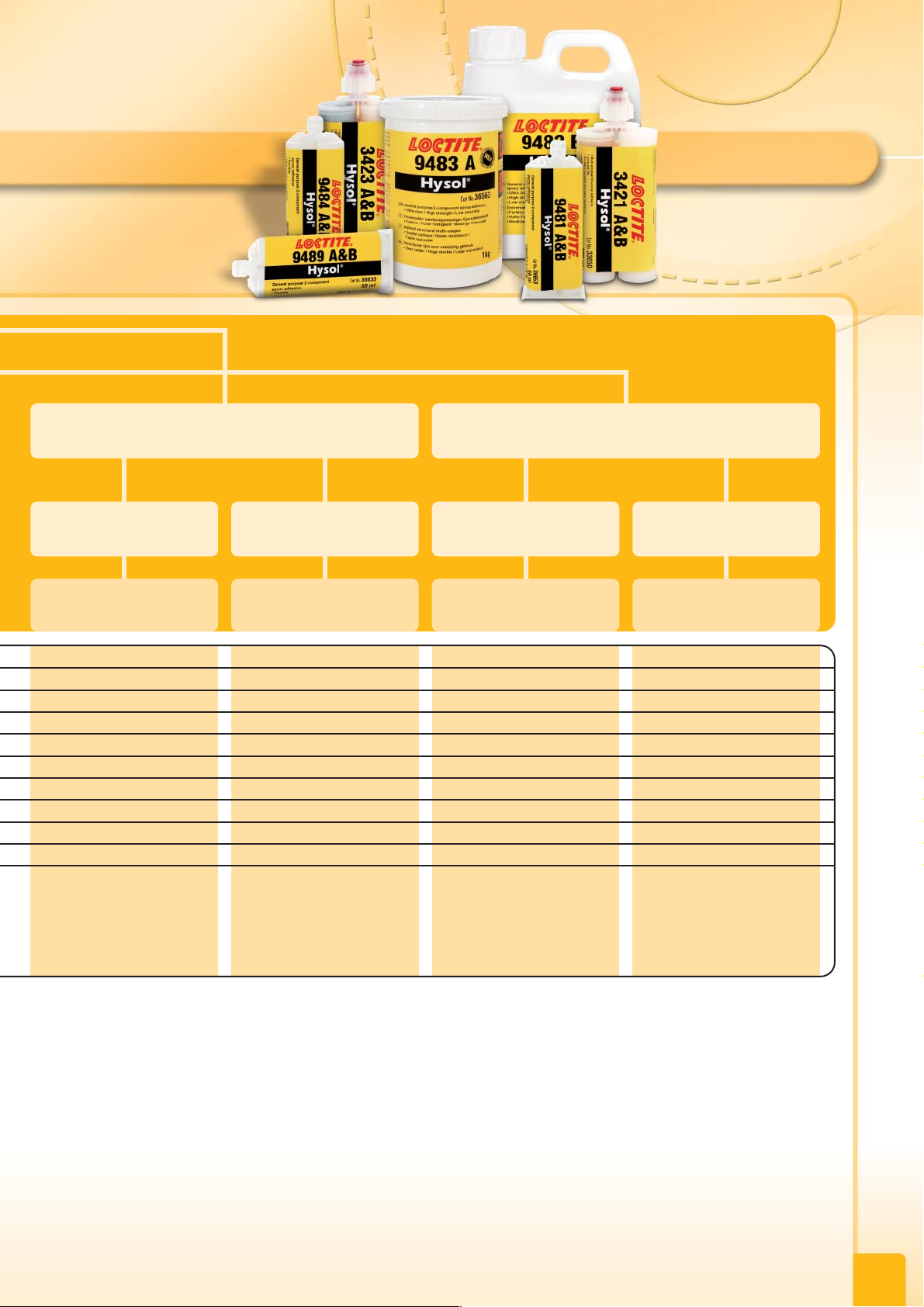

2K-Epoxy 2K-Epoxy 2K-Epoxy 2K-Epoxy

2.7:1 (2:1 cartridges) 2:1 1:1 1:1

100 : 33 100:46 100:85 100:85

60 min. 30 min. 40 min. 100 min.

300 min. 210 min. 180 min. 300 min.

Clear Ultra clear Grey Grey

50 Pa.s 9.0 Pa.s 70 Pa.s 45 Pa.s

19 N/mm

2

23 N/mm

2

25 N/mm

2

10 N/mm

2

1.0 N/mm 1.5 N/mm 1.3 N/mm 2.0 N/mm

-55°C to 120 °C - 55 °C to 150 °C -55°C to 120°C -55 °C to 120°C

50 ml dual cartridge 50 ml dual cartridge 50 ml dual cartridge 50 ml dual cartridge

400 ml dual cartridge 400 ml dual cartridge 400 ml dual cartridge 400 ml dual cartridge

1 kg tubs 1 kg tubs 1 kg tubs 1 kg tubs

20 kg pails 20 kg pails 20 kg pails 20 kg pails

9483 A&B9481 A&B 9484 A&B 9489 A&B

Flexible bondingClear bonding

Light paste Flowable

Medium

working life

Extended

working life

Loctite

®

Hysol®9481 A&B

• Light paste

• Long working life

• Multi purpose

Loctite

®

Hysol®9481 A&B is a

general purpose, 2K-Epoxy

adhesive, suitable for a wide

variety of substrates including

metals, ceramic, glass and most

plastics. Ideal for bonding fibre

optics and printed circuit boards.

Loctite®Hysol®9483 A&B

• Flowable

• Ultra clear

• Low moisture absorption

Loctite

®

Hysol®9483 A&B is a

general purpose, 2K-Epoxy

adhesive, suitable for bonding

and potting where optical clarity

and high strength are required.

Ideal for bonding decorative

panels and displays.

Loctite®Hysol®9484 A&B

• Medium working life

• Flexible (elongation: ~ 20 %)

• High impact resistance

Loctite

®

Hysol®9484 A&B is a

general purpose, 2K-Epoxy

adhesive, suitable for low stress

and high impact resistant bonding.

Ideal for bonding dissimilar

substrates like GRP, SMC and

composite elements.

Loctite®Hysol®9489 A&B

• Extended working life

• Flexible (elongation: ~ 60 %)

• High impact resistance

Loctite

®

Hysol®9489 A&B is a

general purpose, 2K-Epoxy

adhesive, suitable for low stress

and high impact resistant bonding

of large surfaces. Ideal for bonding

dissimilar substrates like GRP, SMC

and composite elements.

Flowable

8

Toughened Flowable Medium viscosity

3422 A&B9455 A&B3430 A&B

Multi purpose

Loctite®Hysol®3430 A&B

• Medium viscosity

• Ultra clear

• Toughened

• Water resistant

Loctite

®

Hysol®3430 A&B is a

five-minute, 2K-Epoxy adhesive,

suitable for applications

requiring an optically clear bond

line. Ideal for bonding glass,

decorative panels and displays

and general DIY applications.

Loctite®Hysol®9455 A&B

• Flowable

• Ultra clear

• Flexible (elongation: ~ 80 %)

• UV resistant

Loctite

®

Hysol®9455 A&B is a

five-minute, 2K-Epoxy adhesive,

which forms a clear bondline

with good flexibility and peel

resistance. Ideal for bonding and

potting of optical components

like sensors and lenses.

Loctite®Hysol®3422 A&B

• Medium viscosity

• Fast curing

• High strength

• Water resistant

Loctite

®

Hysol®3422 A&B is a

five-minute, 2K-Epoxy adhesive,

suitable for a wide variety of

substrates including metals,

ceramic, glass and most plastics.

Loctite® Hysol

®

Five-minute epoxies

Description 2K-Epoxy 2K-Epoxy 2K-Epoxy

Mix ratio by volume (A:B) 1:1 1:1 1:1

Mix ratio by weight (A:B) 100 : 100 100 : 105 100 : 100

Working life 4 min. 3 min. 3 min.

Fixture time 12 min. 15 min. 7 min.

Colour Ultra clear Ultra clear Pale yellow

Viscosity 25 Pa.s 3.2 Pa.s 50 Pa.s

Shear strength (GBMS) 22 N/mm

2

14 N/mm

2

18 N/mm

2

Peel strength (GBMS) 1.5 N/mm 1.8 N/mm 1 N/mm

Operating temperature - 55 °C to 100 °C - 55 °C to 100 °C -55°C to 100°C

Pack sizes 24 ml twin syringe 50 ml dual cartridge 50 ml dual cartridge

50 ml dual cartridge 200 ml dual cartridge 200 ml dual cartridge

200 ml dual cartridge 1 kg jerry cans

400 ml dual cartridge 20kg pails

20 kg pails

Solution

Your application

Loading...

Loading...