Henkel Loctite, MMD System 1000 Machine Manual

Henkel Corporation

MMD System 1000

Machine Manual

SAFETY

• Always wear safety glasses when operating.

• 100-PSI maximum inlet air pressure. Use a known

regulated dry air source only.

• Hazardous Noise! Agitator air motors run at 86 dBA.

Pumps cycle is peak 75 dBA. Always wear hearing

protection.

• The installation of the SYSTEM 1000 should include a

system air disconnect accessible by the operator.

• Read all material manufacturer’s product information. Always

follow material manufacturers specific recommendations

regarding dispensing even if they may differ from these

general instructions.

• Keep the MSDS accessible to the work area as it lists

valuable emergency information.

• Consult local, state and federal laws before disposing of

mixers or material.

• Do not operate if any of the SYSTEM 1000

components are missing or damaged.

• Danger Labels: Indicate an

imminently hazardous situation, which,

if not avoided, could result in death or

serious injury.

• Warning Labels: Indicate potentially

hazardous situations which, if not

avoided could result in death or

serious injury.

• Caution Labels: Indicate an unsafe

practice that may result in moderate or

minor injury.

• Notice Labels: State a company

policy.

V

Safety Precautions

This manual provides installation, operation, and maintenance instructions for Loctite meter, mix, and dispense

machines. Read this manual before you install and operate your machine. Use your machine only as directed.

Safety Terms within our manuals

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment, and/or process. Warnings are given where failure to observe the instruction could result in injury or death

to people.

Some examples follow.

Snuff-back can be monitored with D

MODE in AUTO, but must be

adjusted with DV MODE in OPEN

Safety Labeling on our machinery

All our machines carry the following safety labels wherever necessary:

Danger Labels

•

injury.

Warning Labels

•

injury.

Caution Labels

•

Notice Labels

•

DANGER

DO NOT OPERATE THIS

MACHINE WITH

GUARD(S) DETACHED

Caution

indicate an imminently hazardous situation, which, if not avoided, could result in death or serious

indicate potentially hazardous situations which, if not avoided, could result in death or serious

indicate an unsafe practice that may result in moderate or minor injury.

state a company policy. Some examples are:

CAUTION

WEAR EAR

PROTECTION

WARNING

UNPLUG MACHINE

BEFORE OPENING

ENCLOSURE

Make sure EMERGENCY STOP is

locked in before manually aligning

the ratio block to the ratio beam

CAUTION

WEAR EYE

PROTECTION

WARNING

PROVIDED AT MACHINE

SUPPLY TERMINALS

NOTICE

OVERCURRENT

PROTECTION

.

Table of Contents

WARRANTY.................................................................................................................................................1

SYSTEM 1000 GENERAL DESCRIPTION ..............................................................................................2

DIAGRAMS OF COMMON VALVES AND PARTS...............................................................................3

MACHINE FEATURES...............................................................................................................................5

REASSEMBLY AND INSTALLATION....................................................................................................6

ADJUSTING THE SHOT SIZE .................................................................................................................. 7

LOADING THE MACHINE WITH MATERIALS ..................................................................................8

PRIMING THE MATERIAL VALVES .....................................................................................................9

PHASING THE PUMPS ............................................................................................................................10

RATIO CHECK..........................................................................................................................................11

RATIO ADJUSTMENT ............................................................................................................................. 12

DAILY OPERATION.................................................................................................................................13

SHUTDOWN...............................................................................................................................................14

PISTON REPLACEMENT........................................................................................................................15

PERIODIC MAINTENANCE ...................................................................................................................16

TROUBLESHOOTING .............................................................................................................................17

ADDITIONAL INFORMATION ..............................................................................................................21

PUMP REBUILD......................................................................................................................................A-1

WARRANTY

PROPRIETARY EQUIPMENT AND COMPONENTS

MANUFACTURED BY SELLER

The warranties contained herein are not made in regard to auxiliary equipment and components (see Section below). Unless

otherwise specifically stated in writing, warranties are limited to the following: All proprietary goods designed, manufactured and

sold by Seller are guaranteed against defective workmanship or material for a period of three (3) years after date of shipment

from the factory, provided the goods were operated under the condition for which they were sold. This warranty does not cover

seals or components that are out of specification due to normal wear and tear or improper maintenance of the equipment. All

claims pursuant to the warranties must be made within such three (3) year period. If Buyer claims the goods are defective

within the three (3) year period, Buyer shall notify Seller immediately, in writing. Seller may inspect, by authorized agent, the

defective claim or issue shipping instructions for return of the goods to its factory. Seller shall have the option, at its sole

discretion, if the goods are found to be defective, to correct the defect or defects by repair or replacement or refund the

purchase price. Seller's obligation, with respect to such goods, shall be limited to the replacement or repair F.O.B. Seller's

facility, or refund of the purchase price, and in no event shall Seller be liable for consequential or special damages, or for

transportation installation, adjustment or other expenses which may arise in connection with such goods. The liability of Seller

arising out of supplying said goods and services, or their use, whether on warranties or otherwise, shall not in any case exceed

the cost of the equipment and parts involved, and upon the expiration of said three (3) years, all such liabilities shall terminate.

Seller assumes no liability for damages or expenses of any character, including those arising out of the installation, use or

resale of such goods. No representation or other affirmation of fact not set forth herein, including, but not limited to, statements

regarding capacity, or suitability for use, or performance of the goods, shall be deemed to be a warranty or representation by

Seller for any purpose, nor give rise to any liability or obligation of Seller whatsoever. NO WARRANTY OR GUARANTEE,

EXPRESSED OR IMPLIED, INCLUDING ANY WARRANTY AS TO MERCHANTABILITY OR FITNESS FOR ANY PURPOSE,

IS MADE, EXCEPT AS SPECIFICALLY PROVIDED IN THIS AGREEMENT.

AUXILIARY EQUIPMENT AND COMPONENTS

NOT MANUFACTURED BY SELLER

To the extent that auxiliary equipment and components of other manufacturers (e.g. logic control hardware, valves, transfer

pumps, motors, etc.) are included as part of the machine or system it is understood that these products which are not

manufactured by Seller are subject to the original manufacturer’s warranty policy. FURTHER, SELLER MAKES NO

WARRANTIES OR GUARANTEES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTIES AS TO MERCHANTABILITY

OR FITNESS FOR ANY PURPOSE AND ASSUMES NO LIABILITIES WITH RESPECT TO AUXILIARY EQUIPMENT AND

COMPONENTS WHICH ARE MANUFACTURED BY OTHERS.

SYSTEM 1000 General Description

The SYSTEM 1000 meter, mix, and dispense machine is a ratio proportioning pump designed

specifically to meter two liquids or pastes in a precise ratio. The volumetric positive displacement

piston pump referred to as the Posiload pump is a unique development in the course of pump

design, and because of the ability to interchange pump metering tubes from 10 mm to 55 mm in

0.001 mm increments, allows the selection of many fixed ratios.

The Posiload pump can be used for transfer of precise ratios, metering to a hand held or fixed head

mixer, or injection of the metered materials through a mixer into open or closed molds.

The complete system is totally enclosed and mixing of the liquids only takes place at the final

stage of the equipment within the mixing chamber. Flushing is achieved by an air and solvent

purge system or with one material component with a secondary component bypass.

It is recommended that this manual be read thoroughly by all personnel charged with the

responsibility of operating, maintaining, or cleaning the equipment.

CAUTION

Due to the precise nature of the SYSTEM 1000, we recommend consulting

Henkel’s technical service department

@ (800) LOCTITE before making any major adjustments.

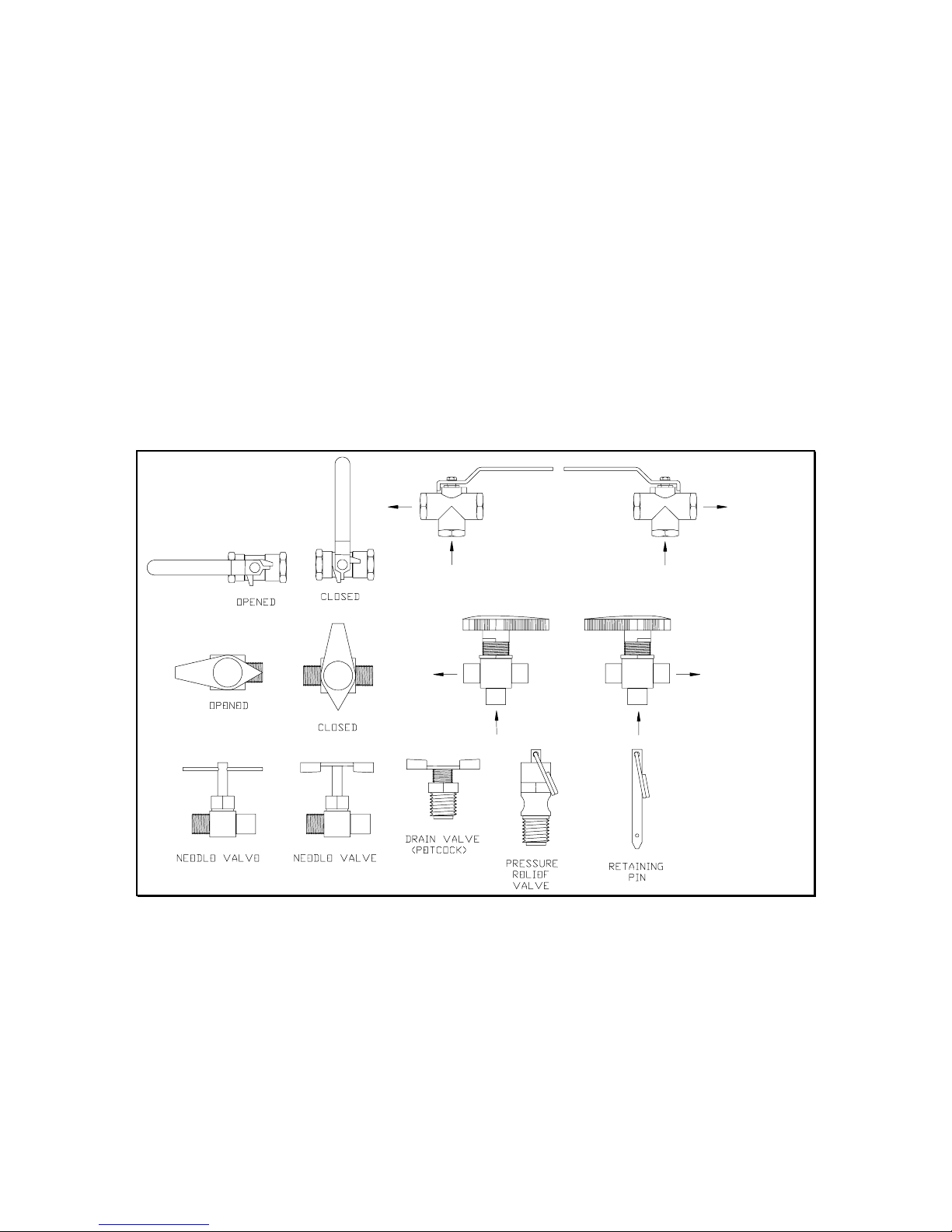

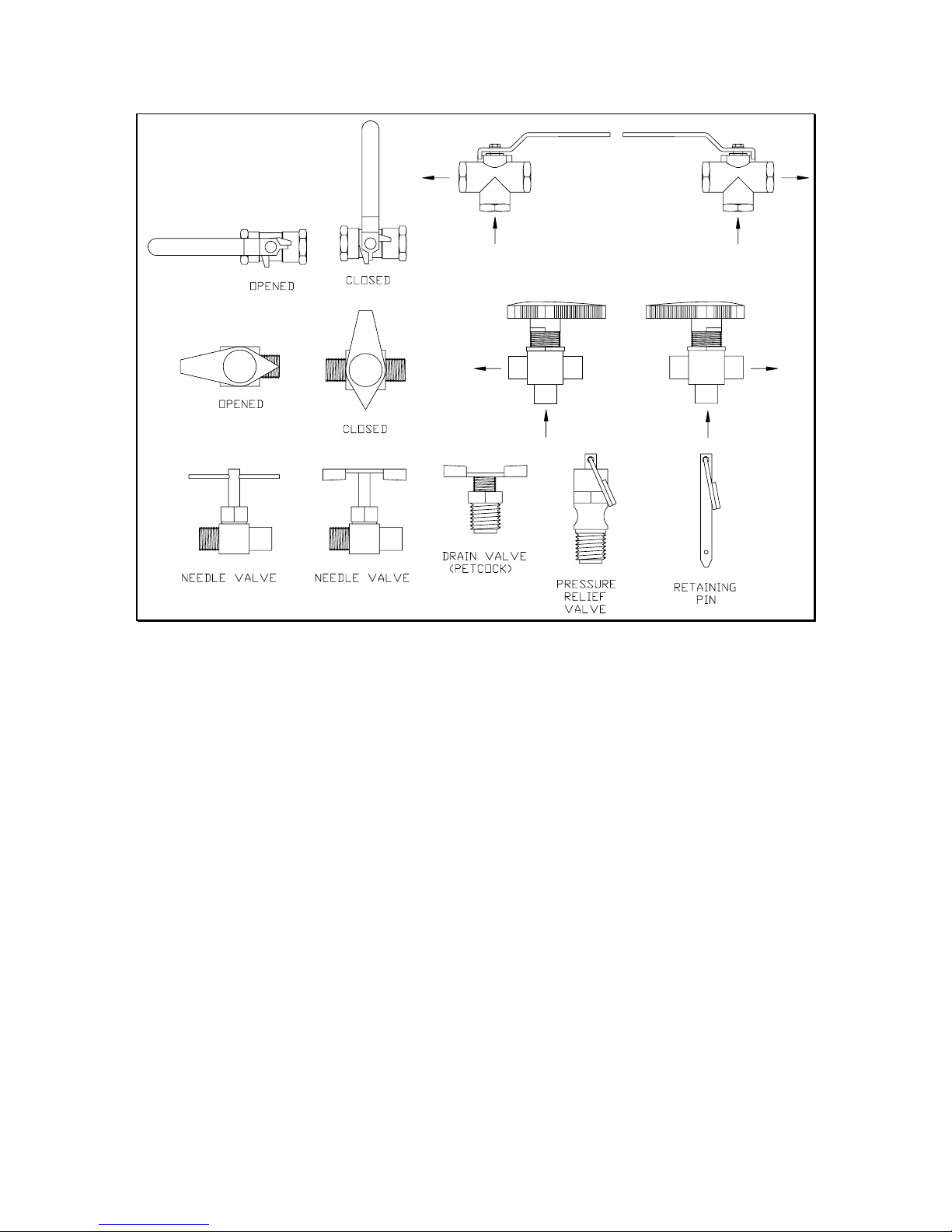

Diagrams of Common Valves and Parts

The below diagrams depict common 2-way and 3-way ball valves and the handle styles are likely

to be encountered on this machine. Also, shown in the following diagrams are miscellaneous parts

likely to be used by this machine. These diagrams are for reference only and may not show all

types and styles of ball valves and other parts.

The 2-way ball valves are shown in the OPENED and CLOSED positions. The 3-way ball valves

are shown in both flow direction conditions (see arrows). In some cases, a 3-way ball valve may

be adjusted to a NEUTRAL position, 90 degrees from the positions shown below. These

NEUTRAL positions may or may not stop flow through the valves and should not be used as

operating positions unless specified elsewhere in this manual. In some cases this machine may

contain a 3-way diverted ball valve which will appear identical to the 3-way ball valves shown

below. In the case of a diverted ball valve, the handle only turns 90 degrees (not 180 degrees) and

there is no NEUTRAL position.

3

Figure 1-Common Ball Valves

4

Figure 2-Common Valves and Parts Cont.

Loading...

Loading...