Henkel 97612 User Manual

Operating Manual

Bedienungsanleitung

Air Filtertrolley

Luftfiltertrolley

97612

2

English...................................................................................................................... 4-14

Deutsch .................................................................................................................. 15-26

2

Contents

1 Please observe the following......................................................................................4

1.1 Emphasized Sections....................................................................................................4

1.2 Items Supplied...............................................................................................................4

1.3 For Your Safety.............................................................................................................. 5

1.4 Field of Application (Intended Usage)............................................................................ 5

2 Description...................................................................................................................6

2.1 Theory of Operation.......................................................................................................6

2.2 Displays, Operating Elements and Connections............................................................7

3 Technical Data ............................................................................................................. 8

4 Installation....................................................................................................................9

4.1 Environmental and Operating Conditions...................................................................... 9

4.2 Connecting the Unit.......................................................................................................9

4.3 Connecting the Suction Hose ........................................................................................9

4.4 Connecting the Suction Arm........................................................................................ 10

5 Operation....................................................................................................................11

6 Cleaning and Maintenance........................................................................................11

6.1 General Instructions..................................................................................................... 11

6.2 Changing the Filter ...................................................................................................... 11

7 Troubleshooting ........................................................................................................12

8 Annex..........................................................................................................................13

8.1 Accessories and Spare Parts ...................................................................................... 13

8.2 Declaration of EC Conformity ......................................................................................13

8.3 Warranty (excluding Germany).................................................................................... 14

3

1 Please observe the following

For safe and successful operation of the unit, read these instructions completely. If the

instructions are not observed, the manufacturer can assume no responsibility.

Be sure to retain this manual for future reference.

Refer to the technical data sheet for the LOCTITE-product used at www.loctite.com

contact your local technical department.

or

1.1 Emphasized Sections

Warning!

Refers to safety regulations and requires safety measures that protect the operator or

other persons from injury or danger to life.

Caution!

Emphasizes what must be done or avoided so that the unit or other property is not

damaged.

The numbers printed in bold in the text refer to the corresponding position numbers in

Notice

Gives recommendations for better handling of the unit during operation or adjustment as

well as for service activities.

the illustration on page 7.

• The point emphasizes an instruction step.

Instruction steps in the illustrations are

indicated with arrows.

When several instruction steps are

indicated in an illustration, the shading of

the arrow has the following meaning:

Black arrow = 1

Grey arrow = 2

White arrow = 3

1.2 Items Supplied

1 Filtertrolley

1 Power Cord

1 Operating Manual

As a result of technical development, the illustrations and descriptions in this operating

manual can deviate from the actual unit delivered.

st

step

nd

step

rd

step

4

1 Please observe the following

1.3 For Your Safety

Damage to the power cord or the housing can result in contact with live electrical

parts.

Check the power cord and the unit before each use.

If the power cord or the unit is damaged, do not operate!

Replace a damaged power cord with a new one.

Do not remove, by-pass or disable any safety device! It can result in damage to

the unit and is therefore prohibited!

Never use the Filtertrolley without the filter!

Unplug the Filtertrolley after use, before cleaning, maintaining and before every

repair and replacement of parts.

Neither use the Filtertrolley for vacuum cleaning nor for exhausting of liquid

media or flammable substances!

The Filtertrolley must not be used for the suction of gasses, steams and dusts in

explosive concentrations!

Always carry out disposal of worn out filter according to valid regulations for

waste!

If liquids or flammable substances are inadvertently exhausted by this device,

instantly switch off the machine.

Switch off and unplug the device at any break.

Instantly switch off the device in case of danger.

Use only original substitute and spare parts.

Filtered air must not be led back to workplaces if the unit is used for filtering

carcinogenic substances.

1.4 Field of Application (Intended Usage)

The Filtertrolley is an essential device for health and the environment protection at

bonding workplaces.

It is a robust device for the mobile and stationary workshop and industrial use. It is

suitable for exhausting and filtering gases, vapors and malodors in the workplaces.

Released, partly unhealthy gases and vapors, are captured by suction elements

immediately at the place of their origin and thereafter filtered with the Filtertrolley.

The clean air can be supplied back to the working premises.

Not valid for carcinogenic substances!

The Air Filtertrolley can be equipped via a Y splitter with two suction hoses for supplying

two workplaces.

The producer is not liable for any resulting damage arising from use outside the

intended use, the scope or these instructions.

5

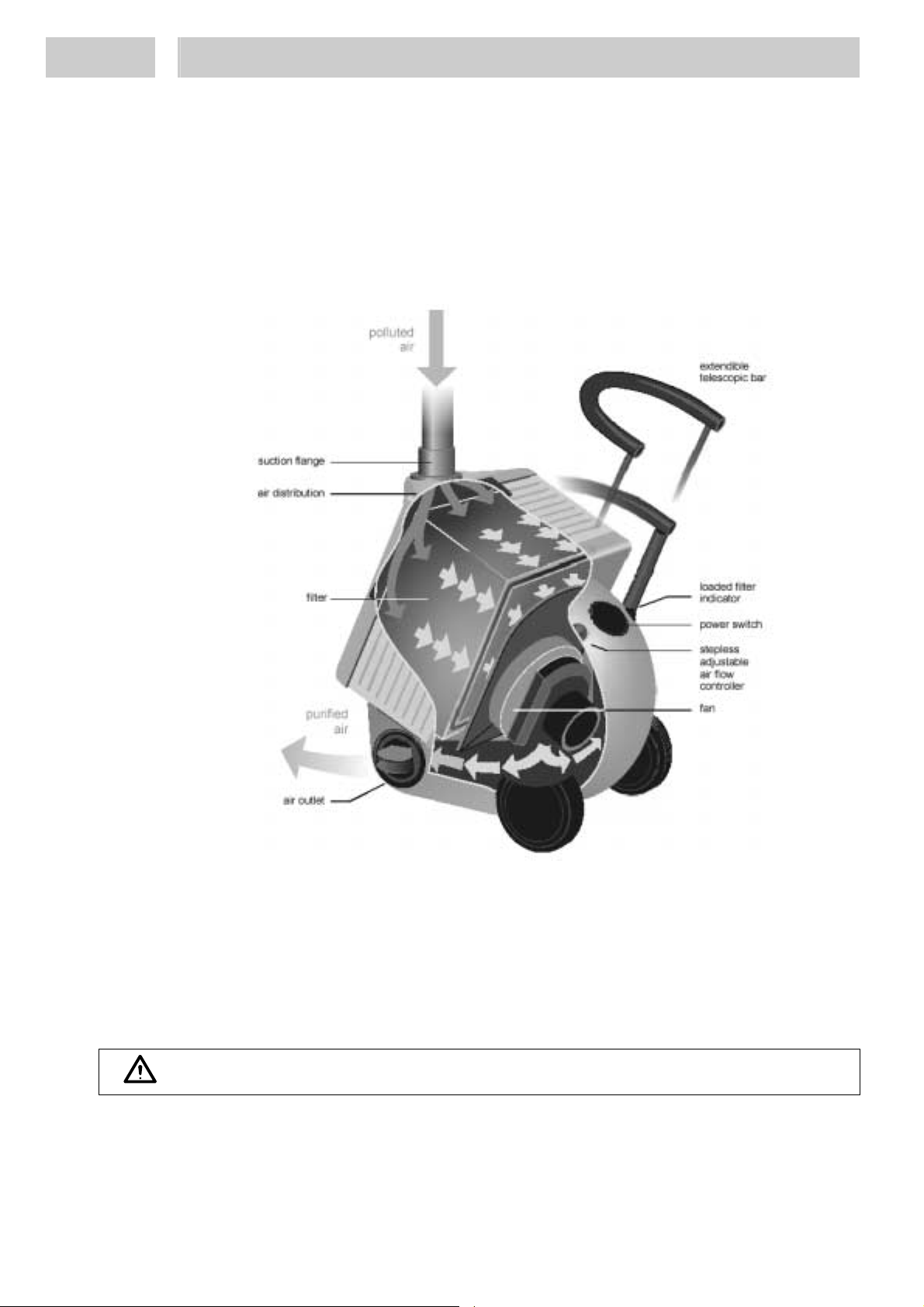

2 Description

2.1 Theory of Operation

The suction hose or the suction arm (both accessories) has to be placed near the

bonding place. The unit exhausts the polluted air and blows out the cleaned air at the air

outlet.

The combination of pre-filter and activated carbon guarantees a high filtration efficiency

of unhealthy gases, vapor and fumes. The large surface area and small particle size of

the actuated carbon maximizes absorption of polluted air.

Whenever adhesive vapors are involved, life expectancy can only be estimated, as the

amount of product vapors released depends on temperature, the exposed surface area

and the length of time.

Additional contaminant loads in the air being filtered may include oil mist, cigarette

smoke, etc.

For activators and primers, calculation of service life is easy: The filter will be saturated

after extracting vapors from approx. 2.5 to 3.5 liters of solvent. However, this does not

apply for heptane, which the filter will not adsorb.

Never spray directly into the extraction tube. Minimum spray distance is 50 cm.

Risk of explosion due to super saturation!

The unit can be used for all Loctite Cleaners. Estimating when the filter will be loaded is

easy. The filter will be loaded after extracting about 2 kg of solvents. This is equivalent to

approximately 6 spray cans. Combinations of adhesives with heptane based activators

and primers - e.g. 770, 7455, 7457, etc. are an exception. In this case life expectancy is

not expected to be reduced, as heptane loading on the filter is negligible.

6

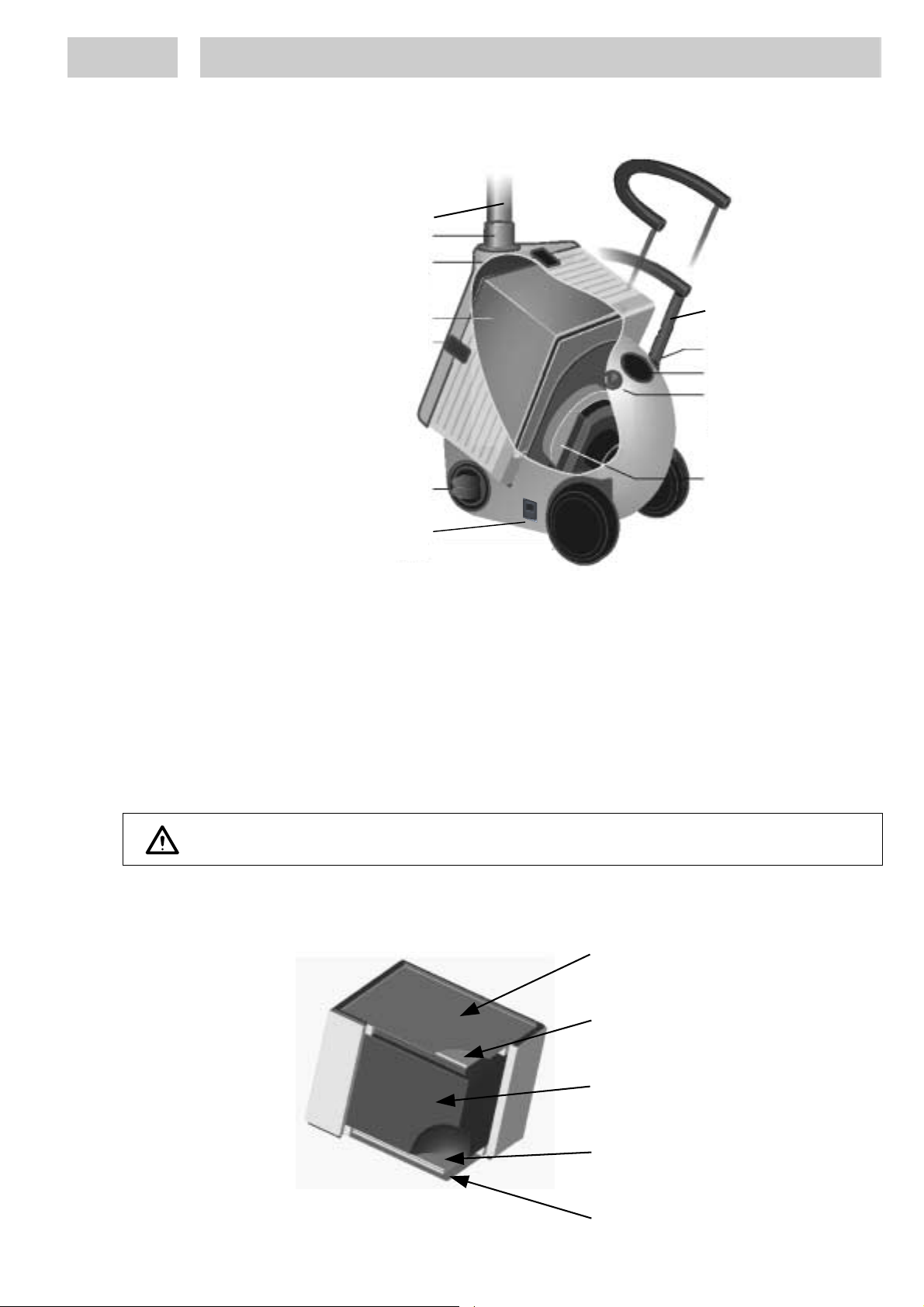

2 Description

2.2 Displays, Operating Elements and Connections

12, 13

11

10

Extendible Telescopic Bar

1

Filter Indicator for clogged filter (LED

2

two-colored)

3 Power Switch 10

Stepless Adjustable Air Flow

4

Controller

5

Fan

Power Connection with Fuse 5 A,

6

time-lag

9

8

1

2

3

4

7

5

6

7

Air Outlet

8

Snap Lock

9

Filter

Air Distribution Plate

11

12

13

Suction Flange

Suction Hose

The Suction Arm (not shown).

12 and 13 are accessories.

They have to be ordered

separately.

Do not remove, by-pass or disable any safety device! It can result in damage to the unit

and is therefore prohibited!

Filter 9

Pre-Filter Mat G2

Filter Foam

Special Activated Carbon

Filter Foam

After-Filter Mat G2

7

3 Technical Data

Power Supply 230 V AC, 50 Hz

Power Consumption 150 W

Power Protection 5 A, time-lag

Protection Class I acc. to EN 60 335

Max. Air Flow 170 m³/h

Constant Air Flow 80 m³/h at 1,400 Pa

Max. Vacuum 2,800 Pa

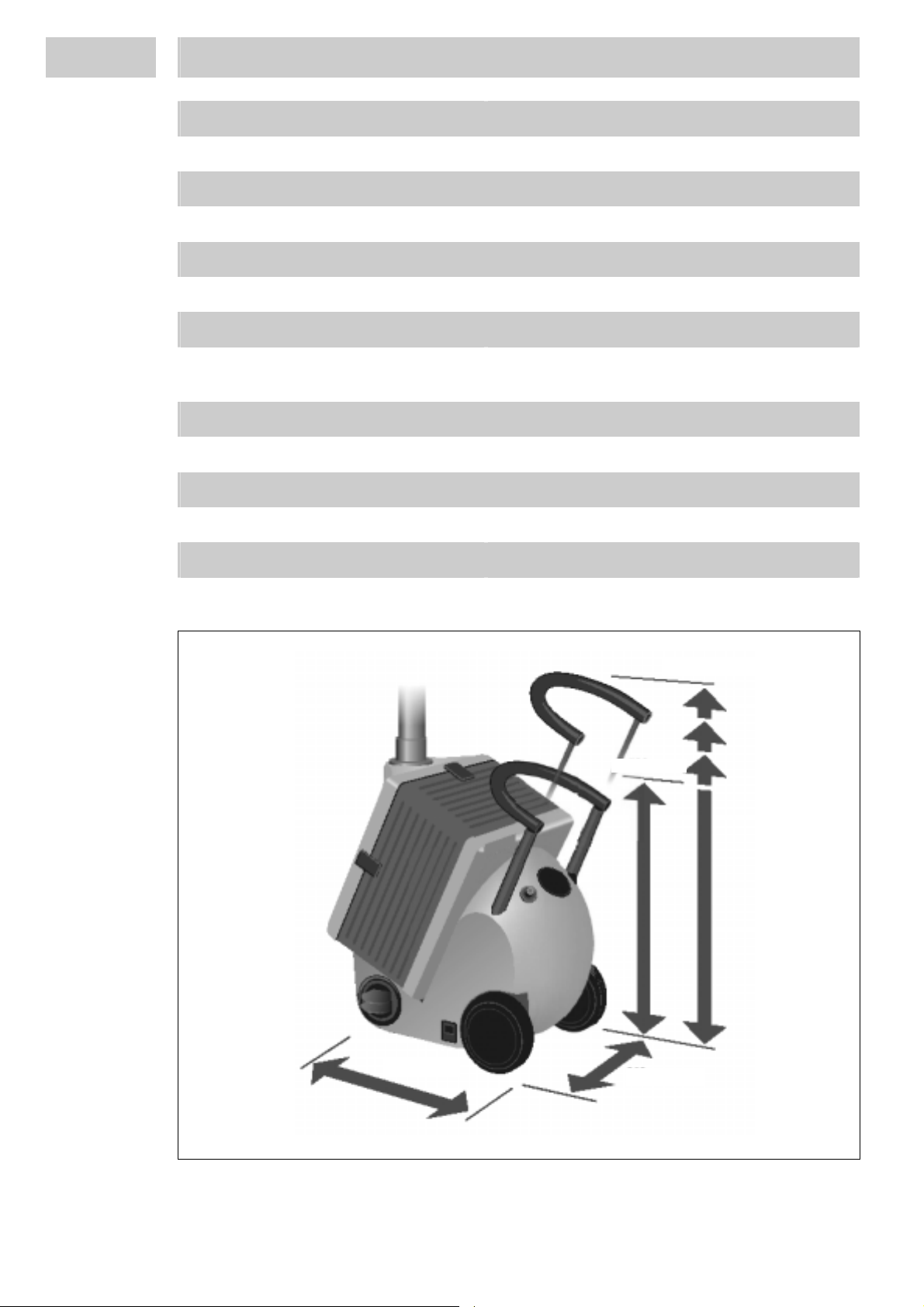

Dimensions (width x height x depth): 450 mm * 530 – ~860 mm * 340 mm

17.7” * 20.9 – ~34” * 13.4”

Ambient Operating Temperature +10°C to +45°C (50°F to 113°F)

Storage Temperature +5°C to +55°C (41°F to 131°F)

Relative Humidity for Storage Max. 50 %

Weight ~ 18 kg

Noise Level 49 dB (A)

Dimensions

Max. 860 mm

450 mm

8

340 mm

4 Installation

4.1 Environmental and Operating Conditions

– Do not operate if there is a danger of condensing humidity or condensation.

– Do not splash with water!

4.2 Connecting the Unit

• Connect power cord to the unit.

4.3 Connecting the Suction Hose

The Air Filtertrolley can be equipped via a Y splitter with two suction hoses for supplying

two workplaces. This y splitter has to be mounted before the suction hose is mounted.

The Y splitter has to be ordered separately.

•

Open the 3 snap locks.

• Mount the air distribution plate in the

same direction as the suction flange

should be pointing.

•

Close the 3 snap locks.

• Push the suction hose into the

connecting piece.

9

Loading...

Loading...