Henkel 3609TM User Manual

Technical Data Sheet

LOCTITE®3609™

March-2008

PRODUCT DESCRIPTION

LOCTITE®3609™ provides the following product

characteristics:

Technology Epoxy

Chemical Type Epoxy

Appearance (uncured) Dark, red viscous gel

LMS

Components One component - requires no mixing

Cure Heat cure

Application Surface mount adhesive

Key Substrates SMD components to PCB

Other Application Areas Small parts bonding

Dispense Method Syringe

Dispense Speed Medium 15,000 -25,000 dots/h

Wet Strength High

LOCTITE®3609™ is designed for the bonding of surface

mounted devices to printed circuit boards prior to wave

soldering. Particularly suited for applications where medium to

high dispense speeds, high dot profile, high wet strength and

good electrical characteristics are required. LOCTITE®3609™

has been used successfully in lead free processes with water

and alcohol based fluxes under conditions outlined in the

Environmental Resistance section.

TYPICAL PROPERTIES OF UNCURED MATERIAL

Specific Gravity @ 25 °C 1.2

Particle Size, µm <150

Flash Point - See MSDS

Yield Point, 25 °C, Pa

Cone & Plate Rheometer:

Haake PK 100, M10/PK 1 2° Cone

Casson Viscosity @ 25 °C, Pa∙s

Cone & Plate Rheometer:

Haake PK 100, M10/PK 1 2° Cone

250 to 700

0.16 to 2.0

LMS

VISCOSITY VS. TEMPERATURE

The following graph shows a typical temperature-viscosity

curve as measured using a Haake rotoviscometer PK100,

M10/PK1 2° Cone system at a shear rate of 2 s

-1

which is

representative of the shear rate in the dispense nozzle.

Increased cabin or nozzle temperature in the 30°C to 35°C

range may aid dispense performance at higher dispense

speeds.

400

300

200

Viscosity, Pa∙s

100

0

20 25 30 35

Temperature, °C

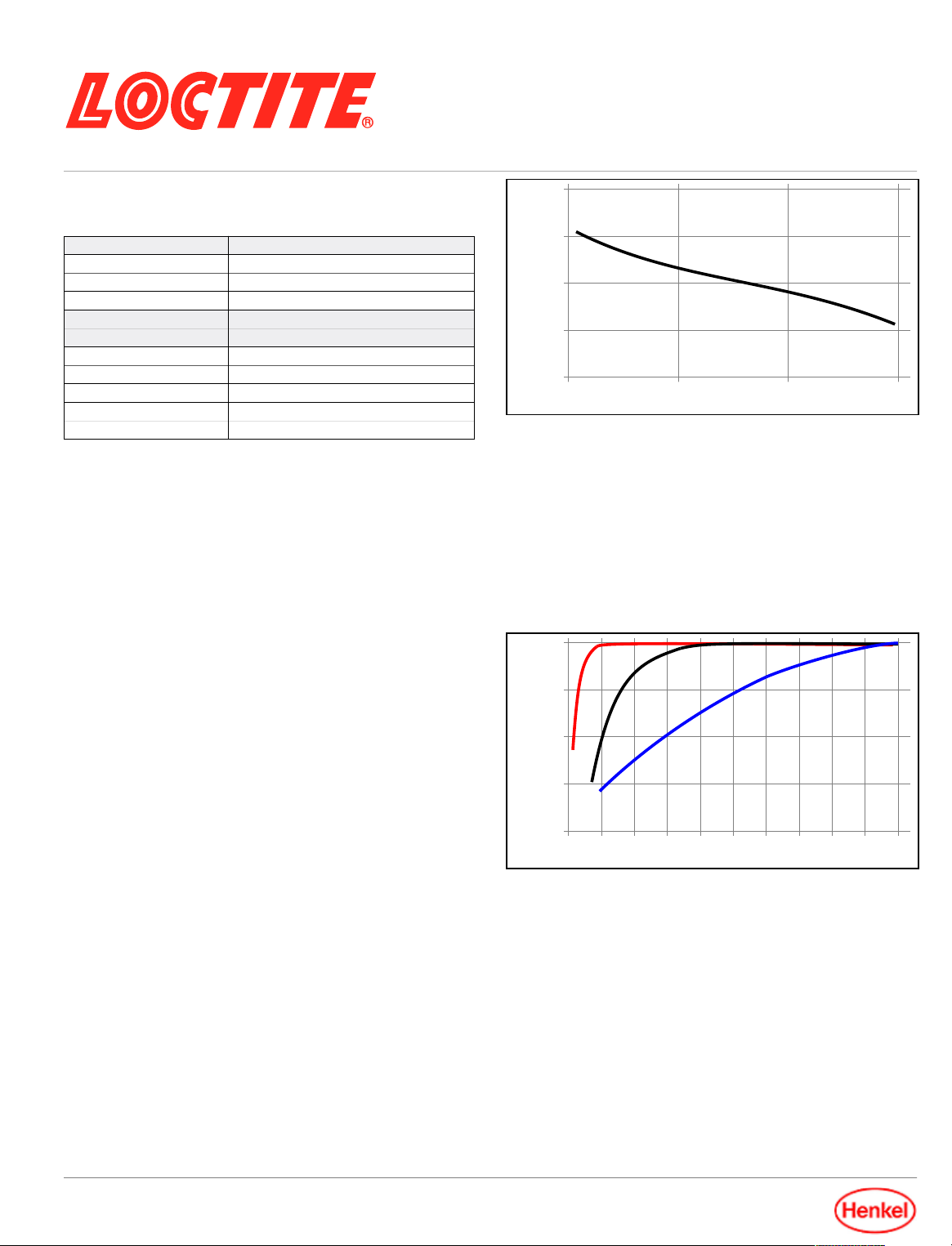

TYPICAL CURING PERFORMANCE

Recommended conditions for curing are exposure to heat

above 100 °C (typically 90-120 seconds @ 150 °C). Rate of

cure and final strength will depend on the residence time at the

cure temperature.

Cure Speed vs. Time, Temperature

The following graph shows the rate of torque strength

developed with time at different temperatures. These times are

defined from the moment the adhesive reaches cure

temperature. In practice, total oven time may be longer to allow

for heat up period. Strength is measured on 1206 capacitors @

22 °C, tested according to IPC SM817, TM-650 Method 2.4.42.

100

75

50

25

% of Full Strength

150°C

0

0 1 2 3 4 5 6 7 8 9 10

125°C

100°C

Time at Temperature, minutes

TYPICAL PROPERTIES OF CURED MATERIAL

Cured for 30 minutes @ 150 °C

Physical Properties:

Coefficient of Thermal Expansion,

ISO 11359-2, K

Coefficient of Thermal Conductivity, ISO 8302,

W/(m·K)

Glass Transition Temperature, ASTM D 4065, °C 73

Specific Heat, kJ/(kg·K) 0.3

Density, BS 5350-B1 @ 25 °C, g/cm³ 1.4

-1

145×10

0.4

-6

TDS LOCTITE®3609™, March-2008

Electrical Properties:

Surface Resistivity, IEC 60093, Ω 2×10

Volume Resistivity, IEC 60093, Ω·cm 2×10

Surface Insulation Resistance, Ω:

SN 59651:

Initial 0.1×10

Aged for 4 days @ 40 °C, 93 % RH 10×10

Aged for 21 days @ 40 °C, 93 % RH 1×10

Electrolytic Corrosion, DIN 53489 AN-1.2

Dielectric Constant / Dissipation Factor, IEC 60250:

1-kHz 3.7 / 0.009

10-kHz 3.3 / 0.03

1,000-kHz 3.2 / 0.03

10,000-kHz 3.1 / 0.03

15

15

9

9

9

TYPICAL PERFORMANCE OF CURED MATERIAL

Adhesive Properties

Cured for 10 minutes @ 110 °C

Push-off Strength:

C-1206 on bare FR4 board N ≥20

(lb) (≥4.5)

Cured for 5 minutes @ 125 °C

Pull-off Strength, Siemens norm SN59651:

C-1206 on bare FR4 board N 40 to 80

(lb) (9 to 18)

Torque Strength, IPC SM817 , TM-650 Method 2.4.42:

C-1206 on bare FR4 board N·mm 30 to 70

(in.oz) (4 to 10)

Cured for 30 minutes @ 150 °C

Lap Shear Strength, ISO 4587:

Steel (grit blasted) N/mm² ≥10

(psi) (≥1,450)

LMS

LMS

Bond strength achieved in practice will vary considerably

depending on the SMD component type, adhesive dot size

and the type, grade and degree of cure of the solder

mask/resist.

TYPICAL ENVIRONMENTAL RESISTANCE

Cured for 30 minutes @ 150 °C

Lap Shear Strength, ISO 4587:

Mild steel (grit blasted)

Hot Strength

Tested at temperature

100

75

50

25

% Initial Strength at 22 °C

0

0 25 50 75 100 125 150 175

Temperature, °C

Chemical/Solvent Resistance

Aged under conditions indicated and tested @ 22 °C.

% of initial strength

Environment °C 100 h 500 h 1000 h

Air 22 100 100 95

Air 150 85 70 70

Heat/humidity 98% RH 40 110 110 100

Resistance to Hot Solder Dip

Cured for 90 seconds @ 150 °C

Hot Solder Dip, IPC SM817, TM-650 Method 2.4.42.1, Pass/Fail:

R-1206 on bare FR4 board:

Supported 60 seconds above solder

bath @ 260°C and dipped for 10

seconds

Pass

Resistance to Process Conditions

Cured for 90 seconds @ 150 °C

Torque Strength, IPC SM817 , TM-650 Method 2.4.42, % of initial

strength retained:

C-1206 on bare FR4 board:

Aged 30 seconds preheat to 100°C

and 3 seconds @ 260°C with flux and

wave solder

100

Resistance to Lead Free Solder

LOCTITE®3609™ can be used in lead free wave solder with

both water based and alcohol based fluxes

Lead Free Solder Test Conditions

Flux Types Multicore MF200 (alcohol based) and

Wave Condition 100°C pre-heat with dual wave at 260°C

Components C1608 bonded with twin dot 0.8mm

Result No component loss in the wave

Multicore MF300 (water based)

SOD 80 bonded with single dot 1.1mm

GENERAL INFORMATION

For safe handling information on this product, consult the

Material Safety Data Sheet (MSDS).

Directions for use

1.

LOCTITE®3609™ is supplied de-aerated in a range of

ready-to-use syringes which fit straight into a variety of air

pressure/time dispensing systems commonly available.

2. After storage in a refrigerator the adhesive must be

allowed to equilibrate to room temperature before use,

typically 2 to 4 hours.

3. Avoid cross contamination with other adhesive residues

by ensuring dispense nozzels, adapters etc. are

thoroughly cleaned.

4. Do not leave dirty nozzles on dispensing equipment while

not in use or soaking in solvents for long periods of time.

5. The quantity of adhesive dispensed will depend on the

dispense pressure, time, nozzle size and temperature.

6. These parameters will vary depending on the type of

dispensing system used and should be optimised

accordingly.

7. Dispensing temperature should ideally be controlled at a

value between 30 °C to 35 °C for optimum results,

however higher dispense temperatures are possible.

8.

LOCTITE®3609™ can also be dispensed using positive

displacement pump systems.

9. The product is not recommended for dispensing by pin

Henkel Americas

+949.789.2500

Henkel Europe

+44.1442.278.000

For the most direct access to local sales and technical support visit: www.henkel.com/electronics

Henkel Asia Pacific

+86.21.2891.8000

Loading...

Loading...