Hendrickson PRIMAAX EX, PRIMAAX Technical Procedures

TABLE OF CONTENTS

PRIMAAX® EX / PRIMAAX® for

Volvo Vehicles

SUBJECT: Service Instructions

LIT NO: 17730-254

DATE: March 2012 REVISION: B

Section 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . 2

Section 2 Product Description . . . . . . . . . . . . . . . . . 2

Section 3 Important Safety Notice . . . . . . . . . . . . . . 4

Section 4 Special Tools . . . . . . . . . . . . . . . . . . . . . . . 9

Section 5 Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . 12

PRIMAAX EX . . . . . . . . . . . . . . . . . . . . . . . . .12

PRIMAAX . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Section 6 Preventive Maintenance. . . . . . . . . . . . .16

Areas of Inspection . . . . . . . . . . . . . . . . . . .16

Hendrickson Recommended

Preventive Maintenance Intervals . . . . . . . .16

Component Inspection . . . . . . . . . . . . . . . . 18

U-bolt Fasteners . . . . . . . . . . . . . . . . . . . . . 19

Transverse Torque Rods . . . . . . . . . . . . . . . .20

Longitudinal Torque Rods . . . . . . . . . . . . . . 20

Shock Absorber . . . . . . . . . . . . . . . . . . . . . . 21

Air Fitting Inspection . . . . . . . . . . . . . . . . . . 22

Section 8 Component Replacement . . . . . . . . . . . 29

Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Height Control Valve . . . . . . . . . . . . . . . . . . 29

Air Spring . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Shock Absorber . . . . . . . . . . . . . . . . . . . . . . 31

Transverse Torque Rod . . . . . . . . . . . . . . . . . 32

Longitudinal Torque Rod . . . . . . . . . . . . . . . 32

Longitudinal Torque Rod Bushing . . . . . . . . . 33

Support Beam Assembly and Cross Tube . . . 34

U-beam Assembly . . . . . . . . . . . . . . . . . . . . 35

D-pin Bushing . . . . . . . . . . . . . . . . . . . . . . . 38

QUIK-ALIGN Pivot Bushing . . . . . . . . . . . . . . 43

Top Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Bottom Cap and Axle Spacer . . . . . . . . . . . . 47

Axle Stops . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Frame Hanger . . . . . . . . . . . . . . . . . . . . . . 50

Section 9 Torque Speci cations . . . . . . . . . . . . . . . 54

PRIMAAX EX . . . . . . . . . . . . . . . . . . . . . . . . . 54

PRIMAAX . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Section 7 Alignment & Adjustments . . . . . . . . . . . 23

Ride Height Adjustment . . . . . . . . . . . . . . . . 23

Lateral Alignment . . . . . . . . . . . . . . . . . . . . 23

Axle Pinion Angle . . . . . . . . . . . . . . . . . . . .24

Drive Axle Alignment Inspection Procedure

(Scrub Angle) . . . . . . . . . . . . . . . . . . . . . . . 24

Alignment Adjustment Instructions . . . . . . . 26

Pinion Angle Adjustment . . . . . . . . . . . . . . . 28

Section 10 Troubleshooting Guide . . . . . . . . . . . . . . 58

PRIMAAX® EX / PRIMAAX® for Volvo Vehicles

SECTION 1

Introduction

This publication is intended to acquaint and assist maintenance personnel in the preventive

maintenance, service, repair and rebuild of the PRIMAAX® EX / PRIMAAX® suspension systems

as installed on applicable Volvo Vehicles.

NOTE Use only Genuine

It is important to read and understand the entire Technical Procedure publication prior to performing any maintenance, service, repair, or rebuild of this product. The information in this

publication contains parts lists, safety information, product specifications, features, proper maintenance, service, repair and rebuild instructions for the PRIMAAXEX / PRIMAAX Suspensions for

Volvo vehicles.

Hendrickson reserves the right to make changes and improvements to its products and

publications at any time. Contact Hendrickson Tech Services for information on the latest version of this manual at 1-866-755-5968 (toll-free U.S. and Canada), 630-910-2800 (outside U.S.

and Canada) or e-mail: techservices@hendrickson-intl.com.

The latest revision of this publication is also available online at

www.hendrickson-intl.com

SECTION 2

Product Description

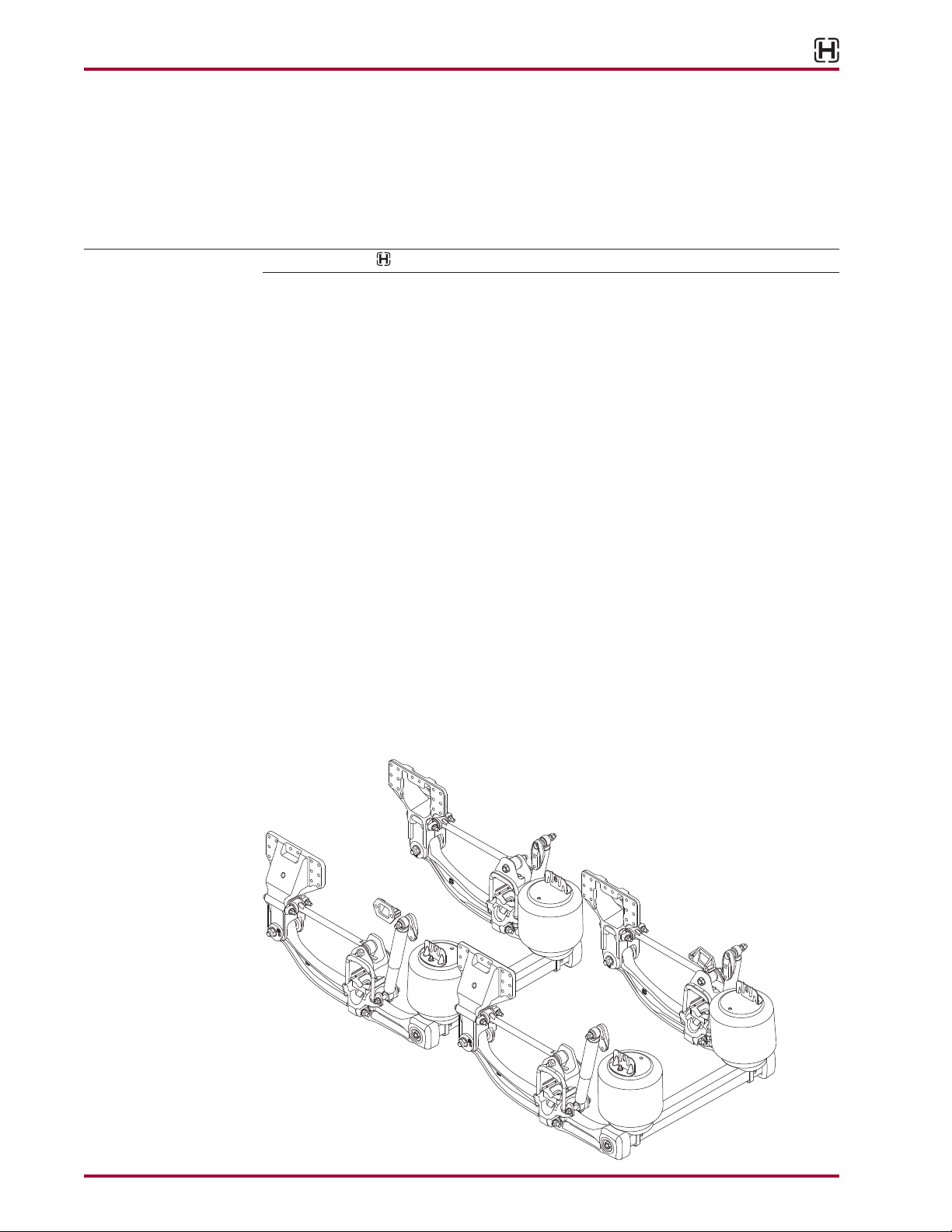

PRIMAAX EX is intended for vocational and heavy-haul vehicle applications including, but

not limited to: truck, tractor, dump, mixer, refuse, logging, platform, fire/rescue, specialty

and vehicles equipped with outriggers as approved by Hendrickson and vehicle manufacturer — contact Hendrickson or vehicle manufacturer for specific application approval and

additional information.

Hendrickson parts for servicing this suspension system.

Introduction 2 17730-254

PRIMAAX® EX / PRIMAAX® for Volvo Vehicles

■

Genuine Hendrickson torque rods — Optimized configuration helps improve handling and

roll stiffness for expanded applications.

■

QUIK-ALIGN® — Allows for easy axle alignment without shims. Reduces maintenance time

and helps extend tire life.

■

Air springs — Large volume, low frequency design for premium ride quality. Advanced

design air springs lift and support the load with less air pressure.

■

Structural beams / cross beams — Cast structural beams form a solid connection with

the square cross brace to form a rigid torsion and stabilizer system. Redesigned structural

beams utilize premium materials and are proven in some of the most challenging environments. Integrated beam end cap allows for a maintenance-free connection with the cross

beam for increased uptime. Robust rubber bushings improve service life and eliminate

lubrication requirements.

■

Heavy-duty shock absorbers — Positioned and tuned for optimum damping characteristics.

■

Axle connections — D-pin axle connection decreases torsional axle stress for reduced maintenance and increased joint integrity. Integrated axle stop contact pads reduce axle stress.

PRIMAAX EX SPECIFICATIONS FOR VOLVO VEHICLES

Capacity 46,000 lbs. 69,000 lbs.

Axle Configuration Tandem Tridem

1

Site Travel Rating

Axle Travel

Ground Clearance 9.25" 9.25"

Lift Axles Approved Approved

Ride Heights

Engine Torque Restrictions None None

Axle Spacing 52" - 72.5" 108"

60,000 lbs. 90,000 lbs.

2

7.0", 7.5" 7.0", 7.5"

3

8.5", 10" 8.5", 10"

1. Operators using vehicles equipped with liftable push or tag axles must not exceed published ratings. Ratings are

limited to no more than five percent of vehicle operation at a speed not to exceed five mph. Liftable pusher or tag

axles should be raised (or unloaded) to improve vehicle maneuverability in off-road use or when vehicle is empty.

Site travel ratings are consistent with specifications and must not be exceeded.

2. Axle travel may be limited by vehicle manufacturer; axle stop settings may restrict suspension’s articulation.

3. For different ride height options, please contact Hendrickson, your vehicle manufacturer or authorized vehicle

dealer for further information.

U.S. and foreign patents granted and/or pending.

17730-254 3 Product Description

PRIMAAX® EX / PRIMAAX® for Volvo Vehicles

SECTION 3

Important Safety Notice

Proper maintenance, service and repair are important to the reliable operation of the suspension. The procedures recommended by Hendrickson and described in this technical publication

are methods of performing such maintenance, service and repair.

The warnings and cautions should be read carefully to help prevent personal injury and to

assure that proper methods are used. Improper maintenance, service or repair may damage

the vehicle, cause personal injury, render the vehicle unsafe in operation, or void manufacturer’s

warranty.

Failure to follow the safety precautions in this manual can result in personal injury and/or property damage. Carefully read and understand all safety related information within this publication,

on all decals and all such materials provided by the vehicle manufacturer before conducting any

maintenance, service or repair.

■

EXPLANATION OF SIGNAL WORDS

Hazard “Signal Words” (Danger • Warning • Caution) appear in various locations throughout

this publication. Information accented by one of these signal words must be observed to help

minimize the risk of personal injury to service personnel, or possibility of improper service methods which may damage the vehicle or render it unsafe.

This is the safety alert symbol. It is used to alert you to potential personal injury haz-

ards. Obey all safety messages that follow this symbol to avoid possible injury or

death.

The following definitions indicate the use of these signal words as they appear throughout the

publication.

INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, WILL RESULT IN

SERIOUS INJURY OR DEATH.

INDICATES A POTENTIAL HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, CAN RESULT IN SERIOUS

INJURY OR DEATH.

INDICATES A POTENTIAL HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, MAY RESULT IN MINOR

OR MODERATE INJURY, OR PROPERTY DAMAGE.

NOTE An operating procedure, practice condition, etc. which is essential to emphasize.

SERVICE HINT A helpful suggestion, which will make the servicing being performed a little easier and/or

faster.

Also note that particular service operations may require the use of special tools designed for

specific purposes. These special tools can be found in the Special Tools Section of this publication.

The torque symbol alerts you to tighten fasteners to a specified torque value. Refer to Torque

Specifications Section of this publication.

Important Safety Notice 4 17730-254

■

SAFETY PRECAUTIONS

FASTENERS

DISCARD USED FASTENERS. ALWAYS USE NEW FASTENERS TO COMPLETE A REPAIR. FAILURE TO

DO SO COULD RESULT IN FAILURE OF THE PART OR MATING PARTS, LOSS OF VEHICLE CONTROL,

PERSONAL INJURY, OR PROPERTY DAMAGE.

LOOSE OR OVER TORQUED FASTENERS CAN CAUSE COMPONENT DAMAGE, LOSS OF VEHICLE

CONTROL, PROPERTY DAMAGE, OR SEVERE PERSONAL INJURY. MAINTAIN CORRECT TORQUE

VALUE AT ALL TIMES. CHECK TORQUE VALUES ON A REGULAR BASIS AS SPECIFIED, USING A

TORQUE WRENCH THAT IS REGULARLY CALIBRATED. TORQUE VALUES SPECIFIED IN THIS TECHNICAL

PUBLICATION ARE FOR HENDRICKSON SUPPLIED FASTENERS ONLY. IF NON HENDRICKSON

FASTENERS ARE USED, FOLLOW TORQUE SPECIFICATION LISTED IN THE VEHICLE MANUFACTURER’S

SERVICE MANUAL.

QUIK-ALIGN FASTENERS

DISCARD USED QUIK-ALIGN FASTENERS. ALWAYS USE NEW QUIK-ALIGN FASTENERS TO COMPLETE A

REPAIR. FAILURE TO DO SO COULD RESULT IN FAILURE OF THE PART, OR MATING COMPONENTS, LOSS

OF VEHICLE CONTROL, PERSONAL INJURY, OR PROPERTY DAMAGE.

DO NOT ASSEMBLE QUIK-ALIGN JOINT WITHOUT THE PROPER FASTENERS. USE ONLY H-COATED

FASTENERS TO SUSTAIN PROPER CLAMP FORCE. FAILURE TO DO SO CAN CAUSE LOSS OF VEHICLE

CONTROL, PROPERTY DAMAGE OR PERSONAL INJURY AND VOID WARRANTY. ENSURE THAT THE

QUIK-ALIGN FASTENER’S TORQUE VALUES ARE SUSTAINED AS RECOMMENDED IN THE TORQUE

SPECIFICATIONS SECTION OF THIS PUBLICATION. FAILURE TO DO SO CAN CAUSE LOSS OF VEHICLE

CONTROL RESULTING IN PERSONAL INJURY OR PROPERTY DAMAGE.

PRIMAAX® EX / PRIMAAX® for Volvo Vehicles

LOAD CAPACITY

ADHERE TO THE PUBLISHED CAPACITY RATINGS FOR THE SUSPENSION. ADD-ON AXLE ATTACHMENTS

AND OTHER LOAD TRANSFERRING DEVICES CAN INCREASE THE SUSPENSION LOAD ABOVE ITS

RATED AND APPROVED CAPACITIES, WHICH CAN RESULT IN COMPONENT DAMAGE AND LOSS OF

VEHICLE CONTROL, POSSIBLY CAUSING PERSONAL INJURY OR PROPERTY DAMAGE.

MODIFYING COMPONENTS

DO NOT MODIFY OR REWORK PARTS WITHOUT AUTHORIZATION FROM HENDRICKSON. DO NOT

SUBSTITUTE REPLACEMENT COMPONENTS NOT AUTHORIZED BY HENDRICKSON. USE OF MODIFIED,

REWORKED, SUBSTITUTE OR REPLACEMENT PARTS NOT AUTHORIZED BY HENDRICKSON MAY

NOT MEET HENDRICKSON’S SPECIFICATIONS, AND CAN RESULT IN FAILURE OF THE PART, LOSS

OF VEHICLE CONTROL, POSSIBLE PERSONAL INJURY OR PROPERTY DAMAGE, AND WILL VOID

WARRANTY. USE ONLY HENDRICKSON AUTHORIZED REPLACEMENT PARTS.

TORCH/WELDING

DO NOT USE A CUTTING TORCH TO REMOVE ANY FASTENERS. THE USE OF HEAT ON SUSPENSION

COMPONENTS WILL ADVERSELY AFFECT THE STRENGTH OF THESE PARTS. A COMPONENT

DAMAGED IN THIS MANNER CAN RESULT IN THE LOSS OF VEHICLE CONTROL AND POSSIBLE

PERSONAL INJURY OR PROPERTY DAMAGE.

EXERCISE EXTREME CARE WHEN HANDLING OR PERFORMING MAINTENANCE IN THE AREA OF

THE SUPPORT BEAM. DO NOT CONNECT ARC WELDING GROUND LINE TO THE SUPPORT BEAM.

DO NOT STRIKE AN ARC WITH THE ELECTRODE ON THE SUPPORT BEAM. DO NOT USE HEAT NEAR

THE SUPPORT BEAM ASSEMBLY. DO NOT NICK OR GOUGE THE SUPPORT BEAM. SUCH IMPROPER

ACTIONS CAN DAMAGE THE SUPPORT BEAM ASSEMBLY AND CAUSE LOSS OF VEHICLE CONTROL

AND POSSIBLE PERSONAL INJURY OR PROPERTY DAMAGE.

17730-254 5 Important Safety Notice

PRIMAAX® EX / PRIMAAX® for Volvo Vehicles

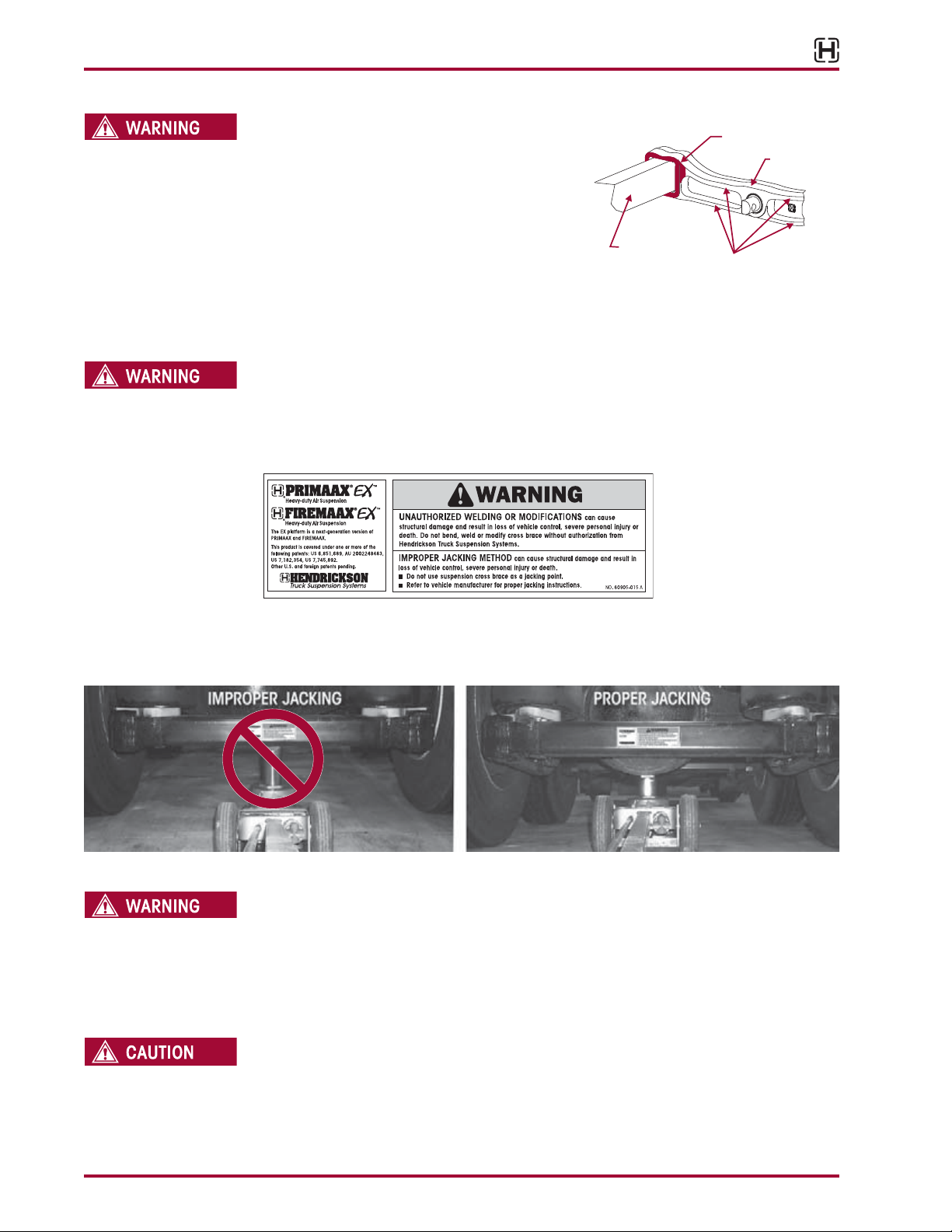

CROSS TUBE, SUPPORT BEAM AND U-BEAM ASSEMBLY FIGURE 3-1

WHEN SEPARATING THE U-BEAM ASSEMBLY, PROTECT

THE CROSS TUBE BY PLACING A PIECE OF PLYWOOD

AGAINST OR CARDBOARD AROUND THE CROSS

TUBE. CAREFULLY DISLODGE THE CROSS TUBE

FROM THE SUPPORT BEAM WITH A LONG HANDLED

SLEDGE HAMMER BY APPLYING BLUNT FORCE ON

THE SUPPORT BEAM DIRECTLY IN FRONT OF THE

INBOARD TOP CORNER JOINT. ALL BLUNT FORCE

MUST BE APPLIED FLUSH TO THE THICKEST PART OF THE SUPPORT BEAM. FAILURE TO STRIKE THE

SUPPORT BEAM SQUARELY MAY RESULT IN COMPONENT DAMAGE, PREMATURE FAILURE AND VOID

WARRANTY, SEE FIGURE 3-1.

CROSS TUBE

IMPROPER JACKING METHODS CAN CAUSE STRUCTURAL DAMAGE (SEE SAFETY DECAL, FIGURE

3-2) AND RESULT IN LOSS OF VEHICLE CONTROL, SEVERE PERSONAL INJURY OR DEATH AND WILL

VOID HENDRICKSON’S WARRANTY.

FIGURE 3-2

Cross Brace

REPLACE ANY SAFETY

DECALS THAT ARE FADED,

TORN, MISSING, ILLEGIBLE,

OR OTHERWISE DAMAGED.

CONTACT HENDRICKSON

TO ORDER REPLACEMENT

LABELS.

Target Area

Support Beam

Do not strike the

Support Beam Flanges

■

DO NOT USE THE SUSPENSION CROSS TUBE AS A JACKING POINT, SEE FIGURE 3-3.

■

REFER TO VEHICLE MANUFACTURER FOR PROPER JACKING INSTRUCTIONS, SEE FIGURE 3-4.

FIGURE 3-3 FIGURE 3-4

SHOCK ABSORBERS

THE SHOCK ABSORBERS ARE THE REBOUND TRAVEL STOPS FOR THE SUSPENSION. ANYTIME THE

AXLE ON A PRIMAAX EX / PRIMAAX SUSPENSION IS SUSPENDED IT IS MANDATORY THAT THE

SHOCK ABSORBERS REMAIN CONNECTED. FAILURE TO DO SO CAN CAUSE THE AIR SPRINGS TO

SEPARATE FROM THE PISTON AND RESULT IN PREMATURE AIR SPRING FAILURE. REPLACEMENT OF

SHOCK ABSORBERS WITH NON-HENDRICKSON PARTS CAN ALTER THE REBOUND TRAVEL OF THE

SUSPENSION.

THE UPPER SHOCK BOLT MUST BE INDEXED INTO THE RECESSED HEX BORE OF THE UPPER SHOCK

MOUNTING BRACKET FOR PROPER FASTENER INSTALLATION. FAILURE TO DO SO CAN CAUSE THE

SHOCK FASTENERS TO BECOME LOOSE AND CAUSE PREMATURE COMPONENT DAMAGE.

Important Safety Notice 6 17730-254

TRANSVERSE TORQUE RODS

PRIMAAX EX / PRIMAAX SUSPENSIONS INCORPORATE TRANSVERSE RODS FOR VEHICLE STABILITY. IF

THESE COMPONENTS ARE DISCONNECTED OR ARE NON-FUNCTIONAL, THE VEHICLE SHOULD NOT

BE OPERATED. FAILURE TO DO SO CAN RESULT IN ADVERSE VEHICLE HANDLING, LOSS OF VEHICLE

CONTROL, POSSIBLE TIRE CONTACT WITH THE FRAME, PREMATURE COMPONENT DAMAGE, OR

SEVERE PERSONAL INJURY.

PRIMAAX® EX / PRIMAAX® for Volvo Vehicles

PRIOR TO AND DURING DEFLATION AND INFLATION OF THE AIR SUSPENSION SYSTEM, ENSURE ALL

AIR SPRING INFLATION

AIR SPRING LOWER MOUNTING STUDS

AIR SPRING PRESSURE RETENTION

AIR SPRING INFLATION AND DEFLATION

PRIOR TO DISASSEMBLY OF THE SUSPENSION, AIR SPRING ASSEMBLIES MUST BE DEFLATED.

UNRESTRICTED AIR SPRING ASSEMBLIES CAN VIOLENTLY SHIFT. DO NOT INFLATE AIR SPRING

ASSEMBLIES WHEN THEY ARE UNRESTRICTED. AIR SPRING ASSEMBLIES MUST BE RESTRICTED

BY SUSPENSION OR OTHER ADEQUATE STRUCTURE. DO NOT INFLATE BEYOND PRESSURES

RECOMMENDED BY AIR SPRING MANUFACTURER, CONTACT HENDRICKSON TECHNICAL SERVICES

FOR DETAILS. IMPROPER USE OR OVER INFLATION MAY CAUSE AIR SPRING ASSEMBLIES TO BURST,

CAUSING PROPERTY DAMAGE AND/OR SEVERE PERSONAL INJURY.

PERSONNEL AND EQUIPMENT ARE CLEAR FROM UNDER THE VEHICLE AND AROUND THE SERVICE

AREA, FAILURE TO DO SO CAN CAUSE SERIOUS PERSONAL INJURY, DEATH, OR PROPERTY DAMAGE.

INFLATE THE SUSPENSION SLOWLY AND MAKE SURE THAT THE RUBBER BLADDER OF THE AIR

SPRING INFLATES UNIFORMLY AND IS NOT BINDING. FAILURE TO DO SO CAN CAUSE DAMAGE TO

THE UPPER AIR SPRING MOUNTING BRACKET AND VOID WARRANTY.

IF THE AIR SPRING IS BEING REMOVED, IT IS MANDATORY TO LUBRICATE THE LOWER AIR SPRING

FASTENERS WITH PENETRATING OIL AND REMOVE WITH HAND TOOLS TO PREVENT DAMAGE TO THE

LOWER AIR SPRING MOUNTING STUD. FAILURE TO DO SO CAN CAUSE COMPONENT DAMAGE AND

VOID WARRANTY.

SOME VEHICLE APPLICATIONS, SUCH AS VEHICLES EQUIPPED WITH OUTRIGGERS, RETAIN SOME

PRESSURE IN THE AIR SPRINGS AT ALL TIMES. PRIOR TO PERFORMING ANY MAINTENANCE, SERVICE,

OR REPAIR OF THE SUSPENSION, VERIFY EACH AIR SPRING IS COMPLETELY DEFLATED. FAILURE TO

DO SO COULD RESULT IN SERIOUS PROPERTY DAMAGE AND/OR SEVERE PERSONAL INJURY.

FAILURE TO PRESS THE AIR SPRING AGAINST THE UNDERSIDE OF THE FRAME WHILE TIGHTENING

THE UPPER AIR SPRING BRACKET CAN RESULT IN COMPONENT DAMAGE AND PERSONAL INJURY

OR PROPERTY DAMAGE.

WORK SITE DUMPING

WHEN THE TRUCK/TRAILER BODY/BOOM/AND OR ATTACHMENT IS LIFTED IT IS MANDATORY TO

COMPLETELY EXHAUST THE AIR FROM THE REAR SUSPENSION SYSTEM TO HELP PROVIDE STABILITY

WHEN LIFTED. FAILURE TO DO SO CAN RESULT IN LOSS OF VEHICLE CONTROL, ROLL-OVER,

OR VEHICLE INSTABILITY, POSSIBLY CAUSING SEVERE PERSONAL INJURY, PROPERTY DAMAGE,

OR DEATH. FIRST RAISE ANY AUXILIARY AXLES AND THEN EXHAUST ALL PRESSURE FROM REAR

TRACTOR / TRAILER AND TRUCK AIR SUSPENSION SYSTEMS PRIOR TO RAISING THE BODY / BOOM

OR ATTACHMENTS. FOLLOW THE VEHICLE MANUFACTURER’S OPERATING INSTRUCTIONS FOR

MAINTAINING PROPER STABILITY.

PERSONAL PROTECTIVE EQUIPMENT

ALWAYS WEAR PROPER EYE PROTECTION AND OTHER REQUIRED PERSONAL PROTECTIVE

EQUIPMENT TO HELP PREVENT PERSONAL INJURY WHEN PERFORMING VEHICLE MAINTENANCE,

REPAIR OR SERVICE.

17730-254 7 Important Safety Notice

PRIMAAX® EX / PRIMAAX® for Volvo Vehicles

PROCEDURES AND TOOLS

A TECHNICIAN USING A SERVICE PROCEDURE OR TOOL WHICH HAS NOT BEEN RECOMMENDED

BY HENDRICKSON MUST FIRST SATISFY HIMSELF THAT NEITHER HIS SAFETY NOR THE VEHICLE’S

SAFETY WILL BE JEOPARDIZED BY THE METHOD OR TOOL SELECTED. INDIVIDUALS DEVIATING IN

ANY MANNER FROM THE INSTRUCTIONS PROVIDED WILL ASSUME ALL RISKS OF CONSEQUENTIAL

PERSONAL INJURY OR DAMAGE TO EQUIPMENT INVOLVED.

PARTS CLEANING

SOLVENT CLEANERS CAN BE FLAMMABLE, POISONOUS, AND CAUSE BURNS. TO HELP AVOID

SERIOUS PERSONAL INJURY, CAREFULLY FOLLOW THE MANUFACTURER’S PRODUCT INSTRUCTIONS

AND GUIDELINES AND THE FOLLOWING PROCEDURES:

1. WEAR PROPER EYE PROTECTION.

2. WEAR CLOTHING THAT PROTECTS YOUR SKIN.

3. WORK IN A WELL-VENTILATED AREA.

4. DO NOT USE GASOLINE OR SOLVENTS THAT CONTAIN GASOLINE. GASOLINE CAN EXPLODE.

5. HOT SOLUTION TANKS OR ALKALINE SOLUTIONS MUST BE USED CORRECTLY. FOLLOW THE

MANUFACTURER’S RECOMMENDED INSTRUCTIONS AND GUIDELINES CAREFULLY TO HELP

PREVENT PERSONAL ACCIDENT OR INJURY.

DO NOT USE HOT SOLUTION TANKS OR WATER AND ALKALINE SOLUTIONS TO CLEAN GROUND OR

POLISHED PARTS. DOING SO WILL CAUSE DAMAGE TO THE PARTS AND VOID WARRANTY.

Important Safety Notice 8 17730-254

PRIMAAX® EX / PRIMAAX® for Volvo Vehicles

SECTION 4

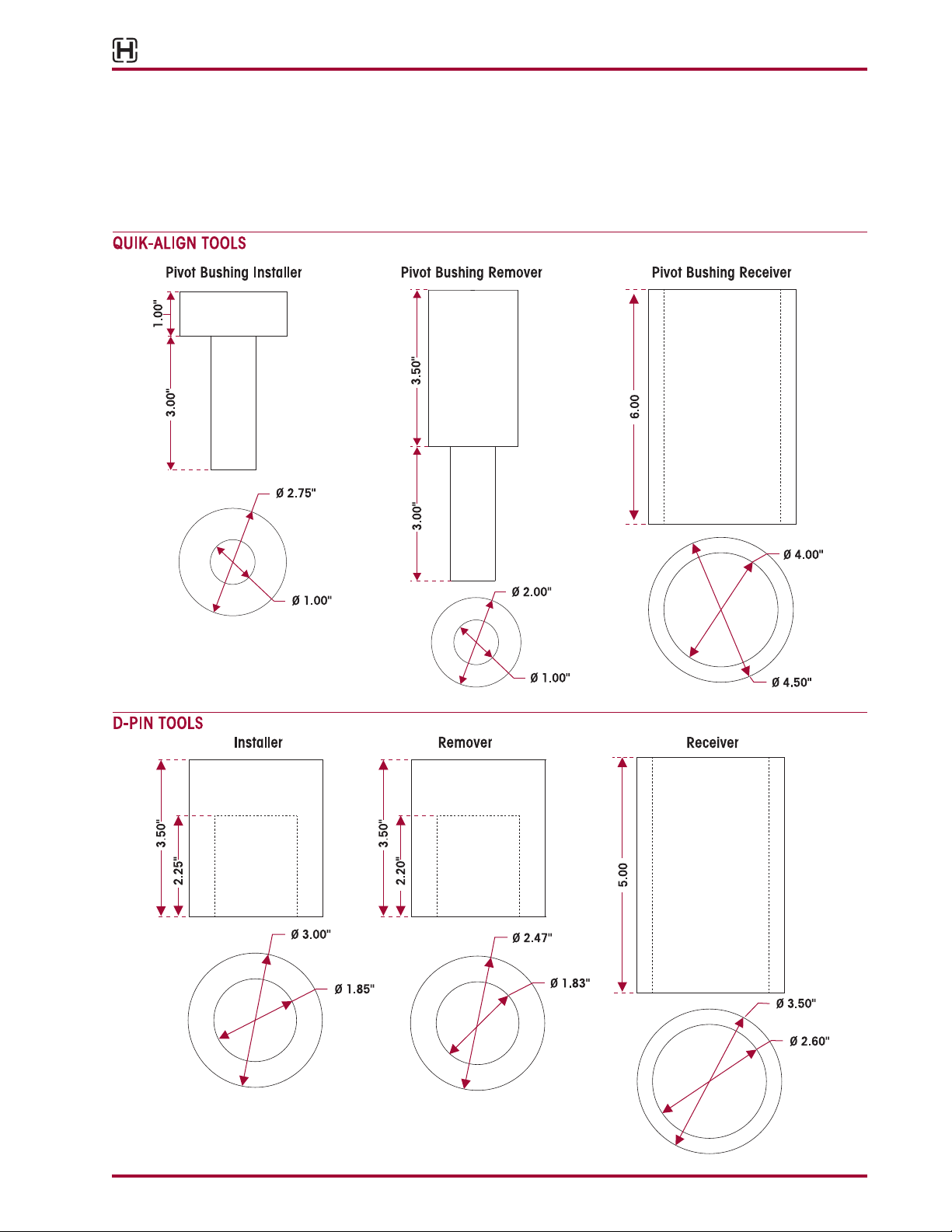

Special Tools

These shop made tools are designed to install and remove pivot bushing and D-Pin bushing. Bushing tools are made from

cold rolled steel or equivalent. Drawings are for reference only. Hendrickson does not supply these tools.

17730-254 9 Special Tools

PRIMAAX® EX / PRIMAAX® for Volvo Vehicles

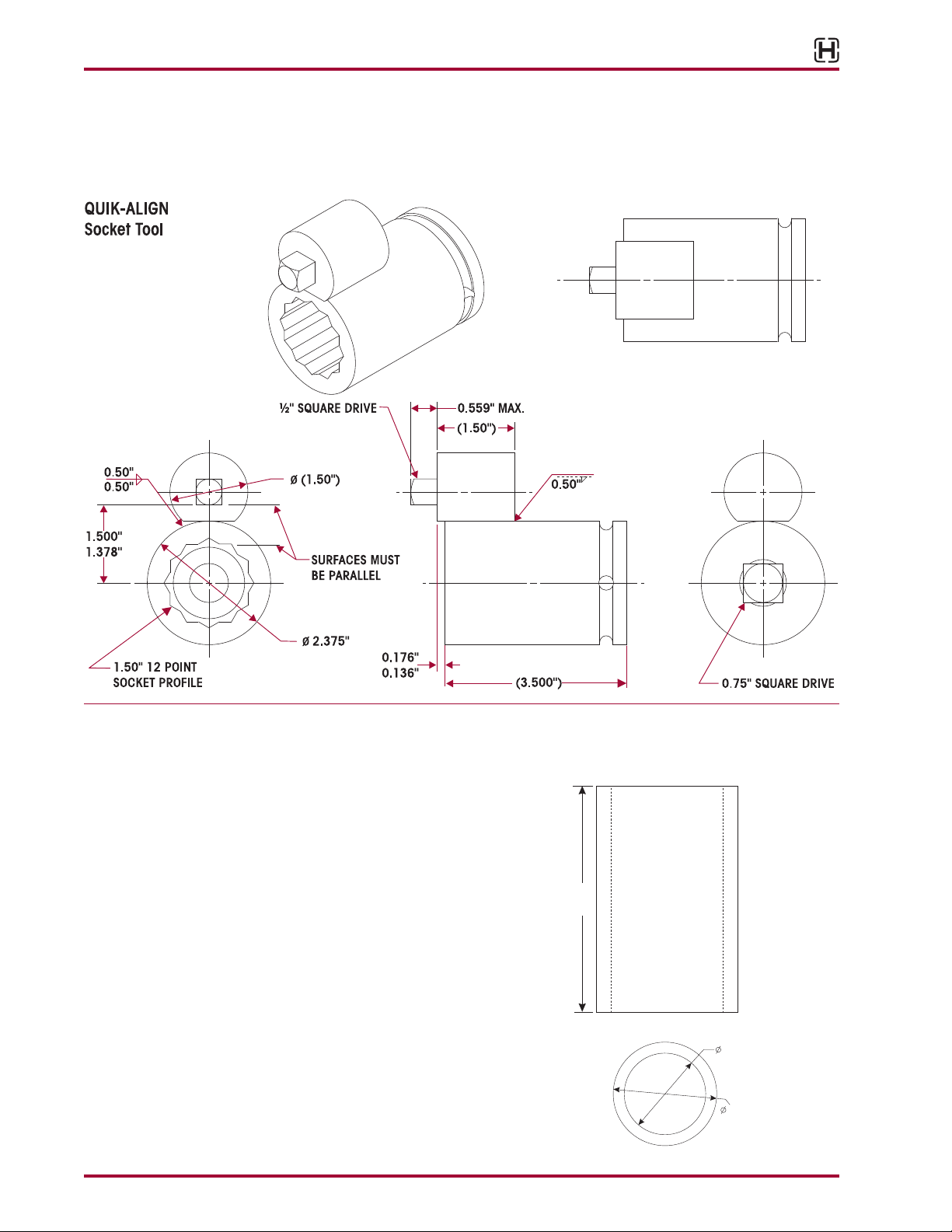

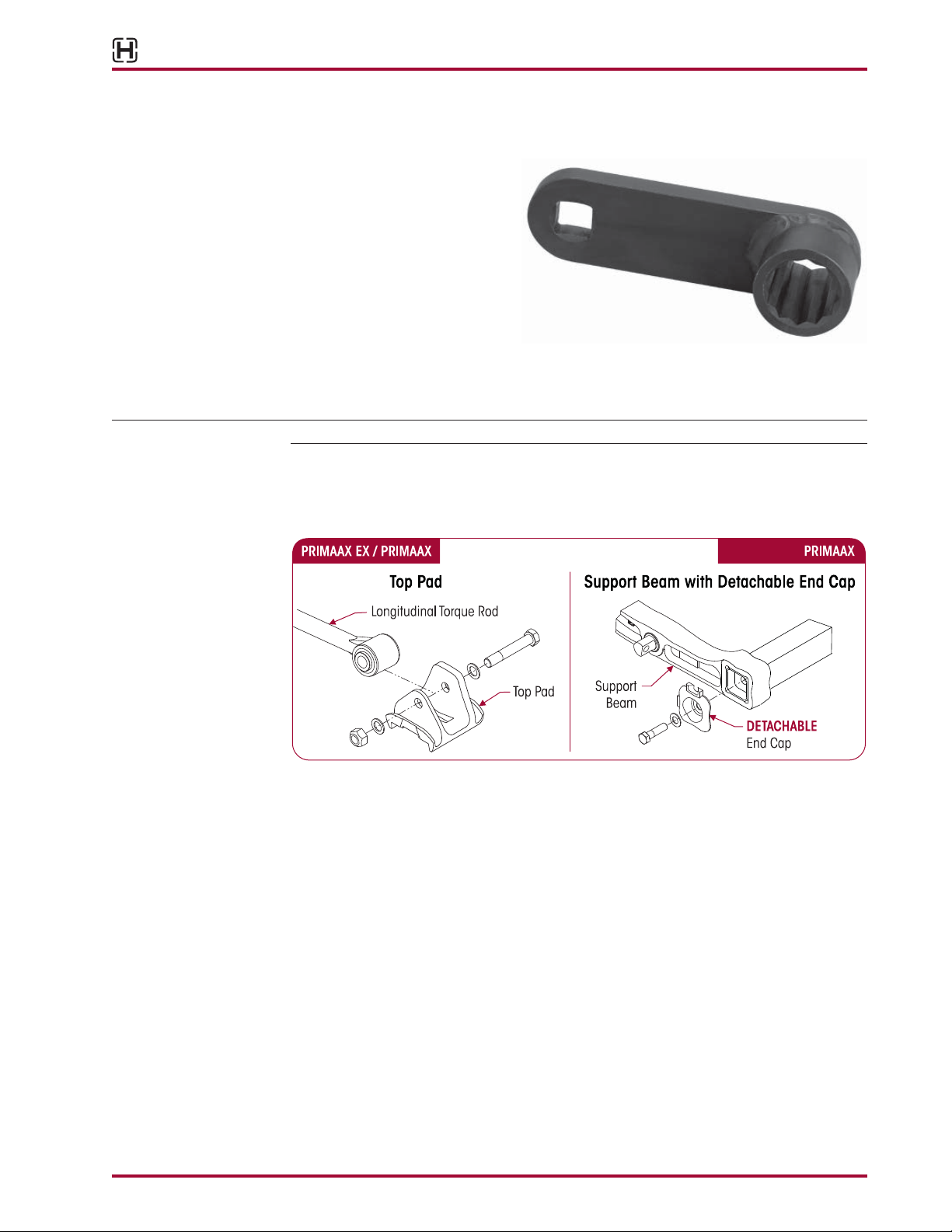

QUIK-ALIGN SOCKET TOOL

Hendrickson PRIMAAXEX QUIK-ALIGN Socket Tool is available from the Owatonna Tool Corporation (Owatonna Tool No. 1767,

website: www.otctools.com) or a shop made tool can be made from the drawing shown. Hendrickson does not supply QUIK-ALIGN

tooling. Material: Optional per customer discretion, Grade 80 or better case harden per SAE requirements.

TORQUE ROD BUSHING

This shop made tool is designed for the torque rod bushing. Bushing tools

are made from cold rolled steel or equivalent. Drawing is for reference only,

Hendrickson does not supply this tool.

TORQUE ROD

Bushing Receiver

5.00

2.00"

2.50"

Special Tools 10 17730-254

PRIMAAX® EX / PRIMAAX® for Volvo Vehicles

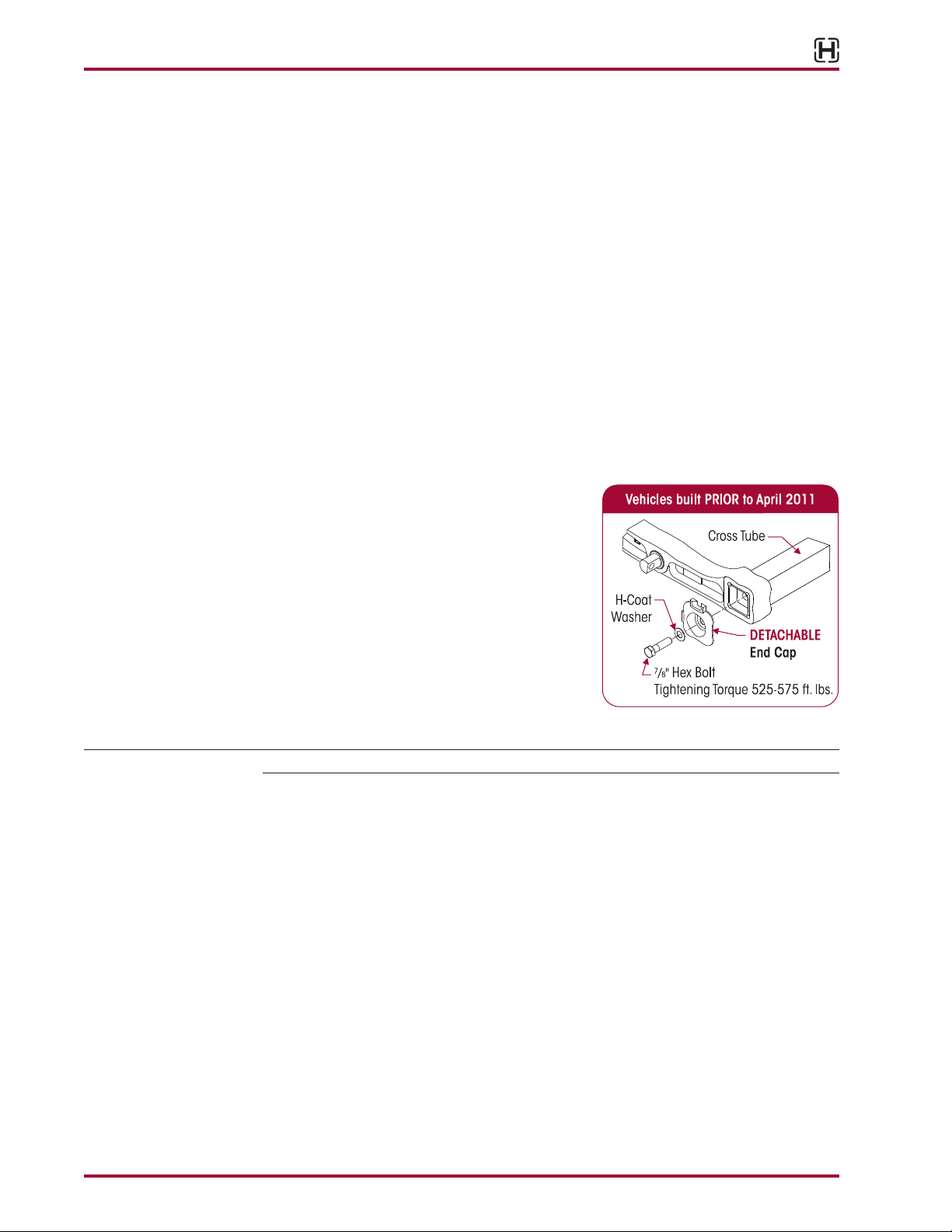

PRIMAAX EX / PRIMAAX QUICK WRENCH

FIGURE 4-1 OTC TOOL NO. 1768

Owatonna Tool Company (OTC)

manufactures a Hendrickson

approved tool (OTC Tool Number

1768) for use on PRIMAAXEX /

PRIMAAX suspensions. Contact

OTC for more information at

800-533-6127.

■

Used to tighten to torque the

longitudinal torque rod top

pad bolts and cross tube end cap bolts (if equipped).

■

Reduces maintenance time by eliminating the need to remove the tires to gain access to

the detachable end cap bolt.

NOTE Due to some vehicle configurations and/or tire sizes wheel removal may be required.

■

Use the OTC Quick Wrench tool with Hendrickson PRIMAAXEX / PRIMAAX suspension longitudinal torque rod to top pad configuration illustrated in Figure 4-2 and with PRIMAAX

suspensions detachable end cap, see Figure 4-3.

FIGURE 4-2 FIGURE 4-3

Any questions regarding the OTC Quick Wrench tooling applications contact

Hendrickson Tech Services

■

E-mail: techservices@hendrickson-intl.com

■

Telephone: 866-755-5968

17730-254 11 Special Tools

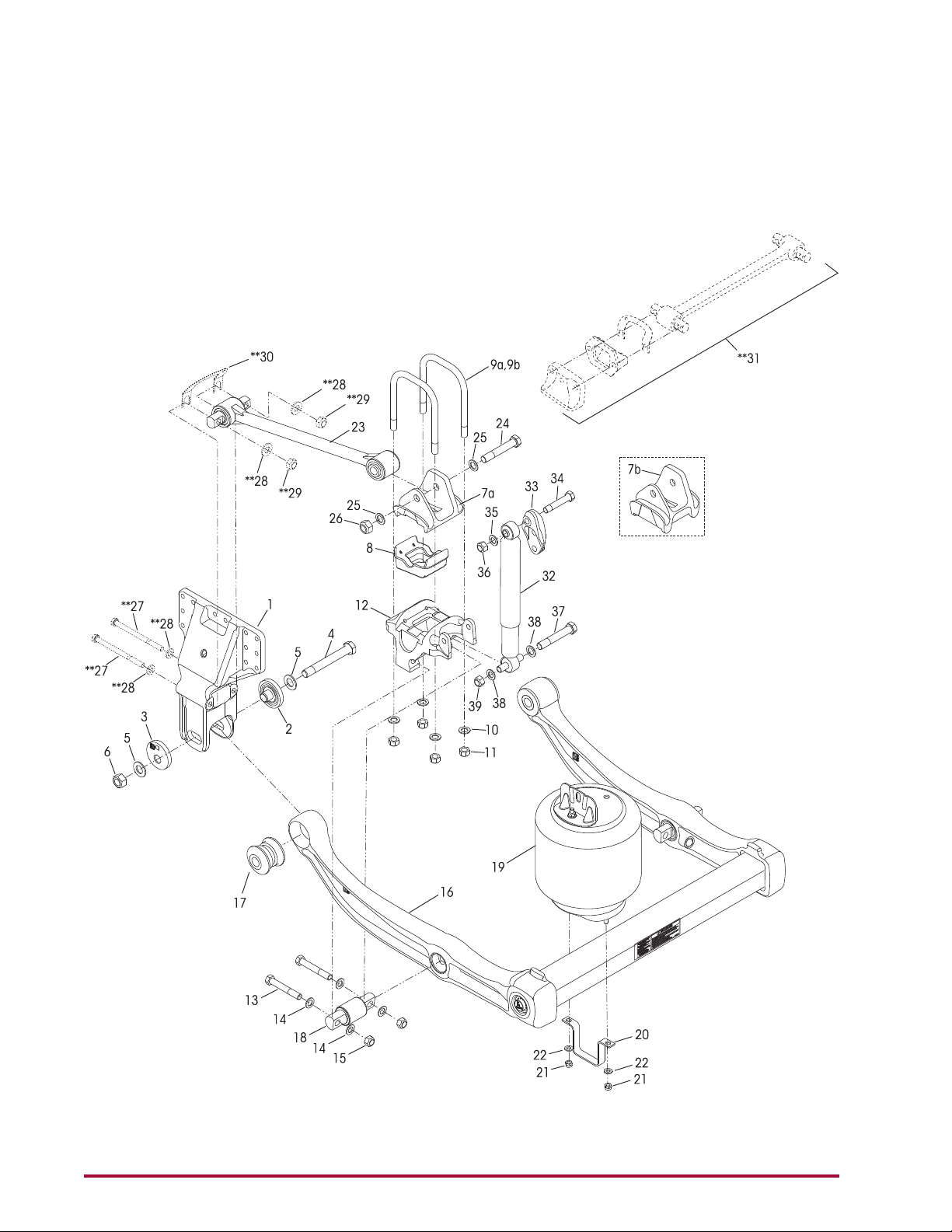

SECTION 5

Parts Lists

PRIMAAX EX

Parts Lists 12 17730-254

PRIMAAX® EX for Volvo Vehicles

KEY NO. PART NO. DESCRIPTION NO.REQ. KEY NO. PART NO. DESCRIPTION NO.REQ.

1 67222-000 Frame Hanger 4

60632-021 QUIK-ALIGN Collar Service Kit, Axle Set,

Includes Key Nos. 2-6

60632-020 QUIK-ALIGN Pivot Bushing Service Kit,

One Axle, Includes Key Nos. 2-6, 17

60632-019 QUIK-ALIGN Collar Service Kit,

Per Wheel End, Includes Key Nos. 2-6

60632-018 QUIK-ALIGN Fasteners Service Kit,

Per Wheel End, Includes Key Nos. 4-6

2 64633-000 QUIK-ALIGN Concentric Collar 4

3 64632-000 QUIK-ALIGN Eccentric Collar 4

4 68217-000 1.0"-14 UNF-2A H-Coat 7.5" Hex Bolt 4

5 68232-000 1.0" H-Coat Flat Washer 8

6 68218-000 1.0"-14 UNF-2B H-Coat Locknut 4

7 Top Pad 4

a 60877-001 8.5" Ride Height

b 65641-000 10" Ride Height

8 65139-003 Axle Spacer, 8.5" Ride Height (if equipped) 4

U-bolt Service Kit, One Wheel End,

48718-125 8.5" Ride Height, Includes Key Nos. 9a,10-11

48718-126 10" Ride Height, Includes Key Nos. 9b,10-11

9 U-bolt 8

a 59367-004 ¾" Square 10.375"

b 59367-009 ¾" Square 10.0"

10 22962-001 ¾" Flat Washer 16

11 49685-000 ¾"-16 UNF U-bolt Locknut 16

12 60556-XXX Bottom Cap, See pinion angle chart below 4

34013-107 D-Pin Service Kit, One Wheel End,

Includes Key Nos. 13-15, 18

13 21867-036 ¾"-16 UNF 5.0" Bolt 8

14 22962-001 ¾" Flat Washer 16

15 30191-000 ¾"-16 UNF Locknut 8

16 ***U-beam Assembly, See chart below

Includes Key Nos. 17-18

67249-003 Rear 1

67249-004 Front 1

17 58648-000 QUIK-ALIGN Pivot Bushing 4

18 60383-000 D-Pin Bushing 4

60961-230 Air Spring Assembly Service Kit,

19 67043-002 Air Spring Assembly 4

20 60911-002 Lower Air Spring Mounting Bracket 4

21 17700-010 ½"-13 UNC Locknut 8

22 22962-014 ½" Flat Washer 8

23 67274-XXX Longitudinal Torque Rod Assembly, See pinion 4

58821-012 Longitudinal Torque Rod Rear Bolt

24 30418-009

25 22962-034 7⁄8" Flat Washer 8

26 29248-000 7⁄8"-14 UNF-2B Locknut 4

27 **M16 x 2 6G Bolt 8

28 **M16 Washer 16

29 **M16 x 2 6H Locknut 8

30 **Shim (may or may not required) As req.

31 **Transverse Rod Assembly 2

60961-106 Shock Absorber Service Kit, One Wheel End,

32 60657-007 Shock Absorber 4

33 67463-006 Shock Upper Frame Bracket 4

34 50764-010 ¾"-10 UNC 4.25" Upper Shock Bolt 4

35 22962-001 ¾" Flat Washer 4

36 49842-000 ¾"-10 UNC Locknut 4

37 32043-017 5⁄8"-11 UNC 6.0" Lower Shock Bolt 4

38 22962-004 5⁄8" Flat Washer 8

39 47764-000 5⁄8"-11 UNC-2B Locknut 4

Not Shown **Height Control Valve Assembly 1

Not Shown **Height Control Valve Linkage 1

One Wheel End, Includes Key Nos. 19-22

angle chart below, Replaces 64981-XXX

Service Kit, One Side Only,

Includes Key Nos. 24-26

7

⁄8"-14 UNF-2A 5.5" Hex Bolt 4

Includes Key Nos. 32, 34-39

NOTE: * Quantities shown are for a tandem con guration.

** Item Required, component supplied by vehicle manufacturer. Hendrickson is not responsible for components not supplied by Hendrickson, for

assistance with maintenance and rebuild instructions on these components see vehicle manufacturer.

Pinion Angle Chart

8.5'' RIDE HEIGHT 10'' RIDE HEIGHT

Pinion

Bottom Cap

Angle

(degree)

10.3 60556-100

10.7 60556-105 10.2 60556-105

11.2 60556-110 10.7 60556-110

11.6 60556-115 11.2 60556-115

12.1 60556-120 11.6 60556-120

13.4 60556-135 13.1 60556-135

Measured with Pinion QUIK-ALIGN at neutral position (12 O'Clock)

Part No.

2.9 60556-025

6 60556-060 6.1 60556-060

7.9 60556-120 550 (front) 67274-550 8.2 60556-120 550 (front) 67274-550

13 60556-130 12.6 60556-130

Longitudinal Torque Rod

Length

(mm)

530 (front) 67274-530

575 (rear) 67274-575

Part No

Pinion

Bottom Cap

Angle

(degree)

2.9 60556-025

9.8 60556-100

Part No.

Longitudinal Torque Rod

Length

(mm)

530 (front) 67274-530

570 (rear) 67274-570

Part No

***U-beam Assembly Enhancement

AFTERMARKET SERVICE KIT

NO. 69565-001, AXLE SET

CONTENTS

PART NO. DESCRIPTION QTY.

69351-000

69432-000 Tamper Resistant Cap 2

69570-000 Loctite® 277 - 10 ml Bottle 1

50104-0067⁄8"-9 UNC 4.0" Hex Bolt 2

22962-0427⁄8" H-Coat Flat Washer 2

*** In the event any service to the suspension

Sika ex 221 Polyurethane

Sealant, 300 ml Tube

requiring disassembly of a U-beam

assembly equipped with integrated end

caps, the Loctite 277, tamper resistant caps

and Sika ex 221 polyurethane sealant

must be properly installed to ensure

components function to their highest

ef ciency. The enhancement components

can be purchased individually or as an

aftermarket service kit.

1

17730-254 13 Parts Lists

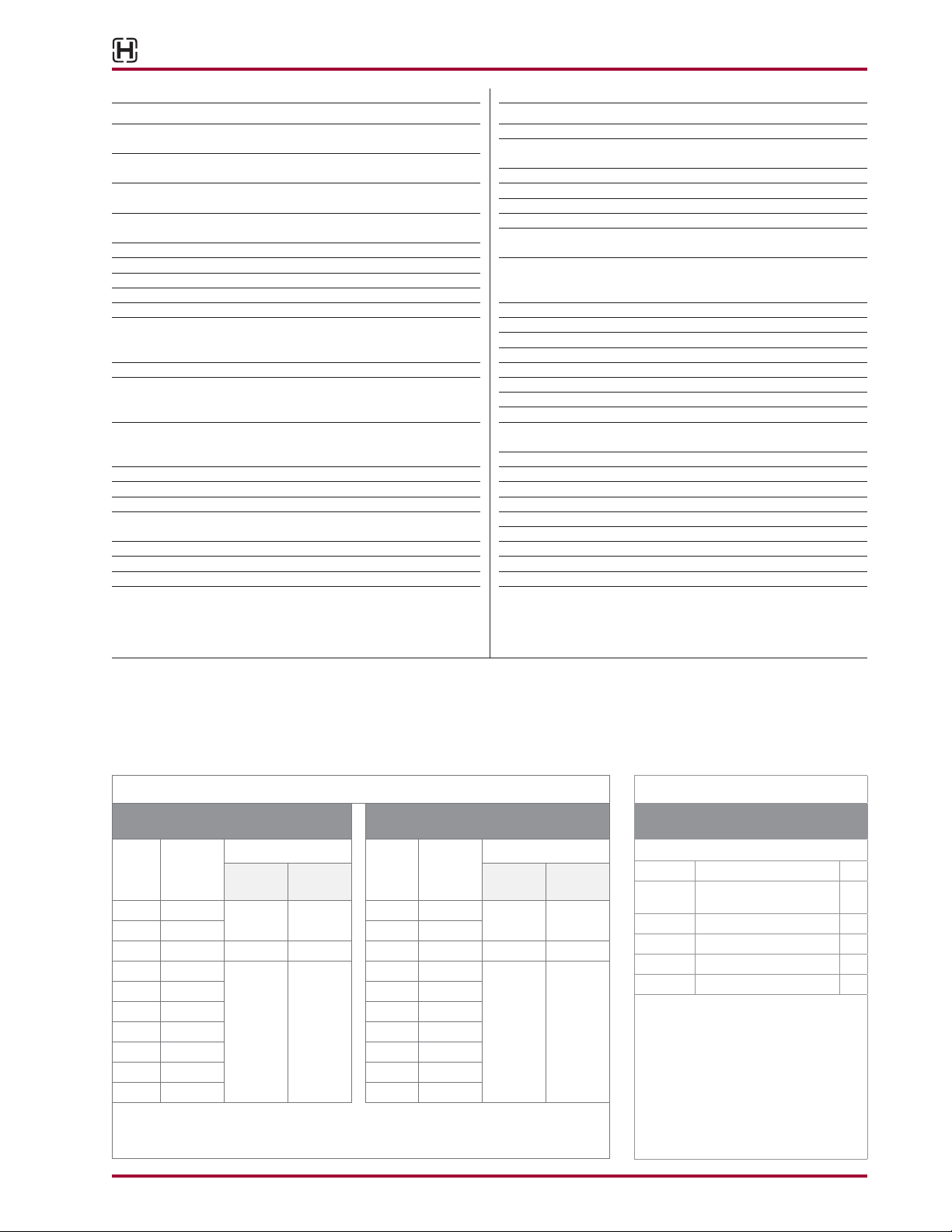

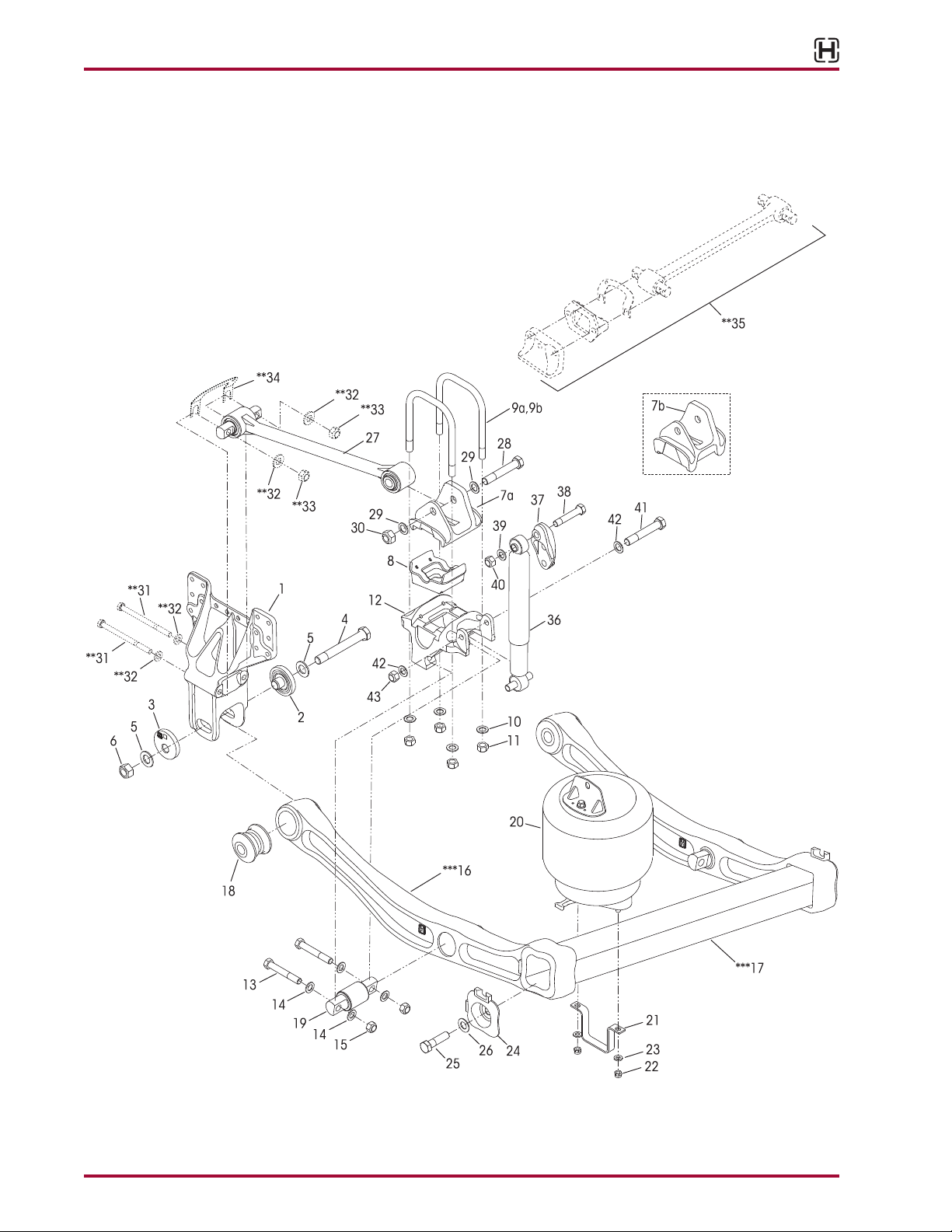

PRIMAAX® for Volvo Vehicles

PRIMAAX

Parts Lists 14 17730-254

PRIMAAX® for Volvo Vehicles

KEY NO. PART NO. DESCRIPTION NO.REQ. KEY NO. PART NO. DESCRIPTION NO.REQ.

1 65702-001 Frame Hanger 4

60632-021 QUIK-ALIGN Collar Service Kit, Axle Set,

Includes Key Nos. 2-6

60632-020 QUIK-ALIGN Pivot Bushing Service Kit,

One Axle, Includes Key Nos. 2-6, 18

60632-019 QUIK-ALIGN Collar Service Kit,

Per Wheel End, Includes Key Nos. 2-6

60632-018 QUIK-ALIGN Fasteners Service Kit,

Per Wheel End, Includes Key Nos. 4-6

2 64633-000 QUIK-ALIGN Concentric Collar 4

3 64632-000 QUIK-ALIGN Eccentric Collar 4

4 68217-000 1.0"-14 UNF-2A H-Coat 7.5" Hex Bolt 4

Replaces 64107-000

5 68232-000 1.0" H-Coat Flat Washer 8

Replaces 22962-035

6 68218-000 1.0"-14 UNF-2B H-Coat Locknut 4

Replaces 64108-000

7 Top Pad 4

a 60877-001 8.5" Ride Height

b 65641-000 10" Ride Height

8 65139-003 Axle Spacer, 8.5" Ride Height (if equipped) 4

U-bolt Service Kit, One Wheel End,

48718-125 8.5" Ride Height, Includes Key Nos. 9a,10-11

48718-126 10" Ride Height, Includes Key Nos. 9b,10-11

9 U-bolt 8

a 59367-004 ¾" Square 10.375"

b 59367-009 ¾" Square 10.0"

10 22962-001 ¾" Flat Washer 16

11 49685-000 ¾"-16 UNF U-bolt Locknut 16

12 60556-XXX Bottom Cap, See pinion angle chart on page 3 4

34013-107 D-Pin Service Kit, One Wheel End,

Includes Key Nos. 13-15, 19

13 21867-036 ¾"-16 UNF 5.0" Bolt 8

14 22962-001 ¾" Flat Washer 16

15 30191-000 ¾"-16 UNF Locknut 8

16 ***Support Beam Assembly (60831-XXX, see

replacement guide below)

17 ***Cross Tube (60912-001, see replacement

guide below)

18 58648-000 QUIK-ALIGN Pivot Bushing 4

19 60383-000 D-Pin Bushing 4

60961-062 Air Spring Assembly Service Kit,

One Wheel End, Includes Key Nos. 20-23

20 60271-002 Air Spring Assembly 4

21 60911-000 Lower Air Spring Mounting Bracket 4

22 17700-010 ½"-13 UNC Locknut 8

23 22962-014 ½" Flat Washer 8

24 60822-000 End Cap 4

25 50104-003

7

⁄8"-9 UNC 3.5" Hex Bolt 4

26 22962-034 7⁄8" Dacromet Flat Washer 4

27 67274-XXX Longitudinal Torque Rod Assembly, See pinion 4

angle chart on page 3, Replaces 64981-XXX

58821-012 Longitudinal Torque Rod Rear Bolt

Service Kit, One Wheel End,

Includes Key Nos. 28-30

28 30418-009 7⁄8"-14 UNF-2A 5.50" Hex Bolt 4

29 22962-034 7⁄8" Dacromet Flat Washer 8

30 29248-000 7⁄8"-14 UNF-2B Locknut 4

31 **M16 x 2 6G Bolt 8

32 **M16 Washer 16

33 **M16 x 2 6H Locknut 8

34 **Shim (may or may not be required) As Req

35 **Transverse Rod Assembly 2

60961-106 Shock Absorber Service Kit, One Wheel End,

Includes Key Nos. 36, 38-43

36 60657-007 Shock Absorber 4

37 67463-006 Shock Upper Frame Bracket 4

Replaces 65000-006

38 50764-010 ¾"-10 UNC 4.25" Upper Shock Bolt 4

39 22962-001 ¾" Flat Washer 4

40 49842-000 ¾"-10 UNC Locknut 4

41 32043-017 5⁄8"-11 UNC 6.0" Lower Shock Bolt 4

42 22962-004 5⁄8" Flat Washer 8

43 47764-000 5⁄8"-11 UNC-2B Locknut 4

Not Shown **Height Control Valve Assembly 1

Not Shown **Height Control Valve Linkage 1

NOTE: * Quantities shown are for a tandem con guration.

** Item Required, component supplied by Vehicle Manufacturer. Hendrickson is not responsible for components not supplied by Hendrickson, for

assistance with maintenance and rebuild instructions on these components see vehicle manufacturer.

*** No longer available for service, see replacement guide below. For more information, refer to Hendrickson Technical Bulletin SEU-0229 or contact

Hendrickson Tech Services.

SUPPORT BEAM AND CROSS TUBE ASSEMBLY REPLACEMENT GUIDE

Key No. Description Current Part No. Replacement Kit No. Comments

60831-003 (LHF)

16 Support Beam Assembly

60831-004 (RHF)

60831-001 (LHR)

60831-002 (RHR)

17 Cross Tube 60912-001

17730-254 15 Parts Lists

60961-237 (Forward)

60961-238 (Rear)

60961-237 (Forward)

60961-238 (Rear)

Requires the replacement of associated suspension parts on one axle.

Replacement Kit includes two new support

beam assemblies, one cross tube, two air

spring assemblies, air spring fasteners,

QUIK-ALIGN fasteners and D-pin fasteners.

PRIMAAX® EX / PRIMAAX® for Volvo Vehicles

SECTION 6

Preventive Maintenance

Following appropriate inspection procedures is important to help ensure the proper maintenance

and operation of the suspension system and component parts. Hendrickson recommends the

PRIMAAX® EX • PRIMAAX® heavy-duty rear suspension is inspected at pre-delivery, the first 1,000

miles of service and at the regular preventive maintenance intervals. Off-highway and severe service operating conditions require more frequent inspections than on-highway service operation.

Following appropriate inspection procedures is important to help ensure the proper maintenance and operation of the PRIMAAXEX • PRIMAAX suspension system and component parts

function to their highest efficiency.

NOTE Torque values shown in this publication apply only if Hendrickson supplied fasteners are used.

If non Hendrickson fasteners are used, follow the torque specification listed in the vehicle

manufacturer’s service manual.

AREAS OF INSPECTION

The inspection must include the following components:

➤ Air springs

• Air supply and fittings

• All fasteners

• Tire wear

➤ Clamp group

➤ Top pad

➤ U-bolt locknuts

➤ U-beam assembly

• Cross tube

• Support beam

• End cap (enhanced or

detachable)

• Frame hanger bracket

• Height control valve

➤ QUIK-ALIGN® connections

• S-cam support tube

bracket

• Shock absorbers

• Torque rods

– Transverse

– Longitudinal

➤ Signifies performance critical components.

HENDRICKSON RECOMMENDED

PREVENTIVE MAINTENANCE INTERVALS

PRE-DELIVERY INSPECTION

1. Visually inspect the suspension for proper assembly.

2. Verify the lateral alignment of the drive axles are within the vehicle manufacturer’s tolerances, contact the vehicle manufacturer for the correct lateral alignment instructions.

3. Visually inspect the overall condition of the U-beam assembly (support beam assembly,

cross tube, and integrated end cap) for any damage.

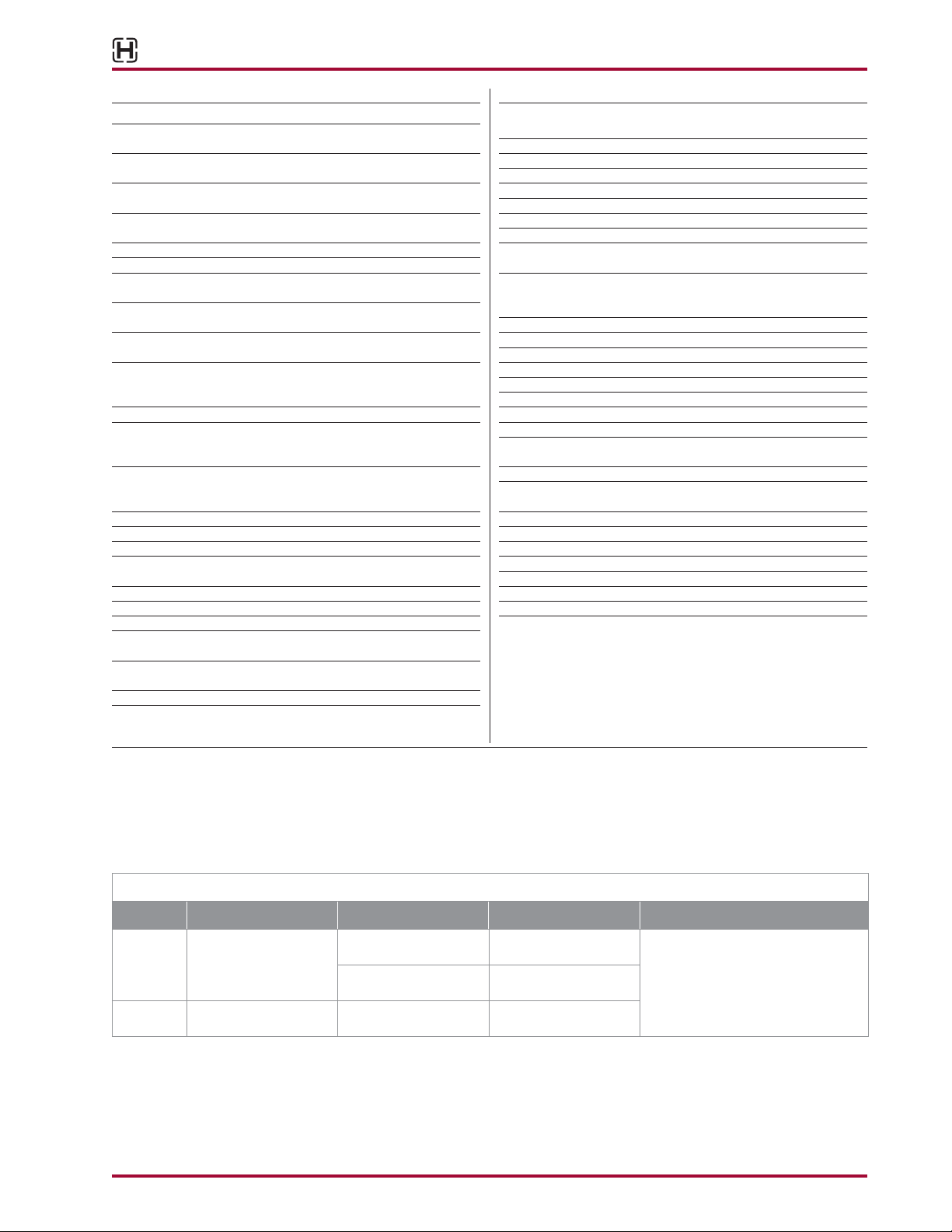

4. DO NOT RE-TORQUE the integrated end cap (vehicles built AFTER April 2011), see Figure

6-1.

5. Check all other fasteners for proper torque with special attention to the following suspension connections:

■

QUIK-ALIGN fasteners, see Figure 6-2.

■

Torque rod to top pad fasteners, see Figure 6-2.

■

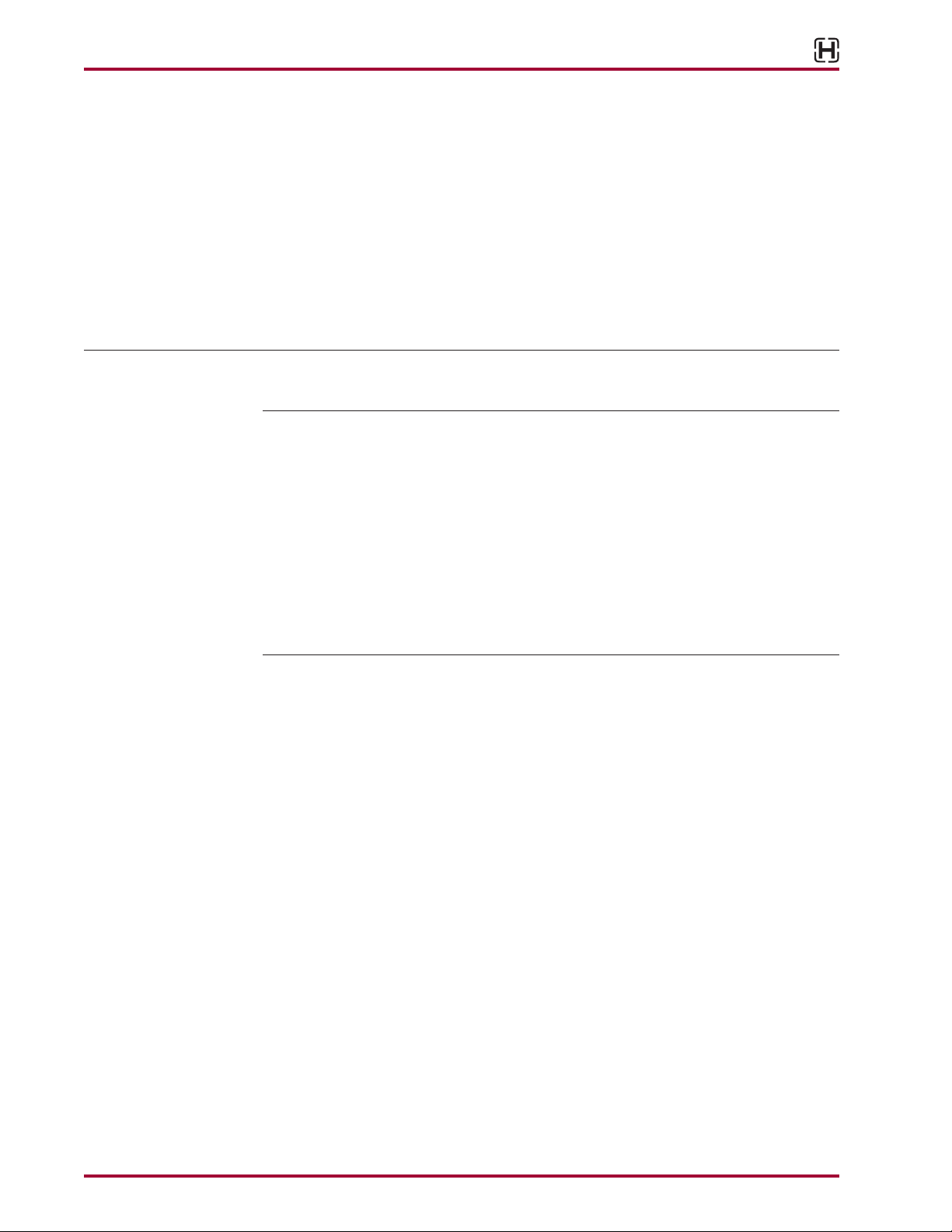

Clamp group fasteners (U-bolts), see Figure 6-3.

6. Verify the ride height is within specification. Ride height is measured from the bottom of the

frame rail to the centerline of the axle.

Preventive Maintenance 16 17730-254

PRIMAAX® EX / PRIMAAX® for Volvo Vehicles

FIGURE 6-1 FIGURE 6-2

INSPECTION AT 1,000 MILES

1. Visually inspect suspension components with special attention to air springs and U-beam

assembly (support beam assembly, cross tube, and integrated end cap). Check for:

■

Proper suspension function

■

Any signs of unusual movement, loose or missing components

■

Any signs of abrasive or adverse contact with other components

■

Any damaged, bent or cracked parts

2. Check all fasteners for proper torque with special attention to the following suspension

connections.

■

QUIK-ALIGN fasteners, see Figure 6-2.

■

Torque rod to top pad fasteners, see Figure 6-2.

■

Clamp group fasteners (U-bolts), see Figure 6-3.

FIGURE 6-3

17730-254 17 Preventive Maintenance

PRIMAAX® EX / PRIMAAX® for Volvo Vehicles

PREVENTIVE MAINTENANCE – PRIMAAX EX • PRIMAAX

■

Off highway and severe service – Every 25,000 miles or six months, whichever comes first

■

100% On-highway – Every 50,000 miles or 12 months, whichever comes first

1. Visually inspect suspension components with special attention to air springs and U-beam

Assembly (support beam assembly, cross tube, and integrated or detachable end cap).

Check for:

■

Proper suspension function

■

Any signs of unusual movement, loose or missing components

■

Any signs of abrasive or adverse contact with other components

■

Any damaged, bent or cracked parts

2. Check all fasteners for proper torque with special attention to the following suspension

connections.

■

QUIK-ALIGN fasteners, see Figure 6-2.

■

Torque rod to top pad fasteners, see Figure 6-2.

■

Clamp group fasteners (U-bolts), see Figure 6-3.

FIGURE 6-4

■

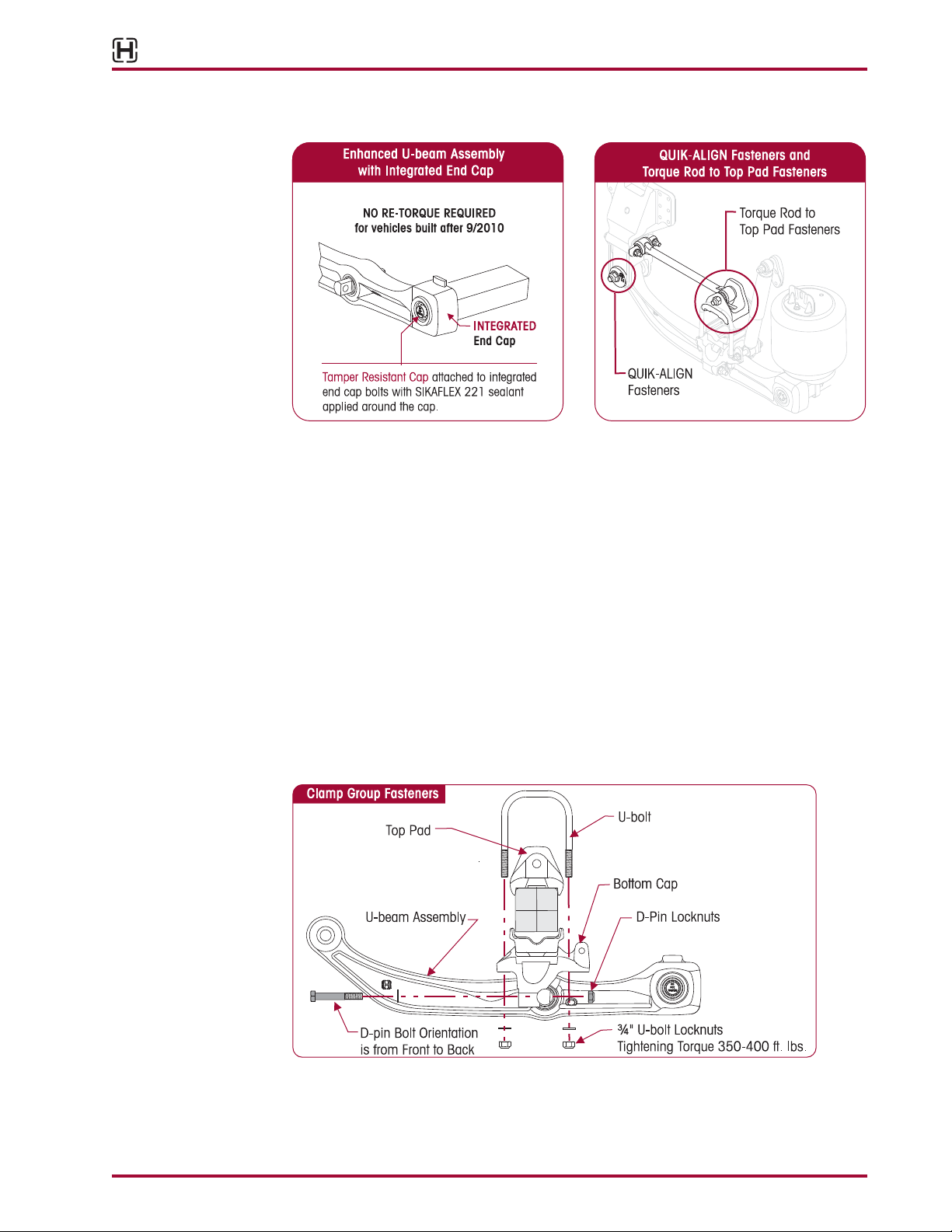

Check detachable end cap connection fasteners on PRIMAAX vehicles (built PRIOR to

April 2011), see Figure 6-4.

3. Verify the ride height is within specification.

Ride height is measured from the bottom of the

frame rail to the centerline of the axle.

4. Verify that the lateral alignment of the drive axle

is within the vehicle manufacturer’s tolerances,

contact the vehicle manufacturer for the correct

lateral alignment instructions.

COMPONENT INSPECTION

IMPORTANT NOTE Replace all worn or damaged parts.

■

Air spring — Visually inspect the outer surface of the air spring for chafing, uneven wear,

cracks or any signs of component damage. Ensure that the upper bead plate is tight against

the underside of the frame. Check for any lateral slippage at the lower air spring bracket.

An 1⁄8" of slippage in either direction is acceptable. Verify all mounting hardware have the

proper torque values maintained. See Torque Specification Section of this publication for

recommended torque requirements.

■

Air supply (Pneumatic components) — The air supply to the system plays a large role in

the air springs’ performance. Inspect, clean and replace, if necessary, any support products

to the air springs, valves, regulators and air lines. See Air Fitting Inspection in this section if

an air leak is suspected.

■

Clamp group — Visually inspect for any loose or damaged fasteners. Verify the U-bolt

locknuts have the proper torque values maintained. See the U-bolt Locknuts in this section.

■

End cap (if equipped) — Visually inspect the end cap connection for signs of movement

or damage. Verify the support beam / cross tube connection bolts have the proper torque

values maintained. See Torque Specification Section of this publication for recommended

torque requirements.

Preventive Maintenance 18 17730-254

Loading...

Loading...