Hendrickson OPTIMAAX Service Instructions Manual

TABLE OF CONTENTS

OPTIMAAX® Lift Axle System

Air Controller Module for

Freightliner Vehicles

SUBJECT: Service Instructions

LIT NO: 17730-310

DATE: July 2018 REVISION: A

Section 1 Introduction ......................2

Section 2 Product Description ...............2

Section 3 Important Safety Notice ............4

Section 4 Denitions .......................8

Section 5 Parts List .........................9

Section 6 Air Controller Module ............ 10

Section 7 Wiring Diagram ................. 11

Section 8 Preventive Maintenance .......... 12

Section 9 Air Controller Manifold Diagram ... 13

Section 10 Vehicle Air Plumbing Diagram .... 15

Section 11 System Operation ............... 16

Section 12 Diagnostic Tool Software ......... 17

Section 13 Troubleshooting Guide ........... 21

Electronic Components ............. 21

Fault Codes ...................... 23

OPTIMAAX® Lift Axle System Air Controller Module for Freightliner

SECTION 1

Introduction

This publication is intended to acquaint and assist maintenance personnel in the preventive

maintenance, service, repair and rebuild of the air controller module for Hendrickson’s OPTIMAAX

Lift Axle System for Freightliner vehicles.

NOTE Use only Hendrickson genuine parts for servicing this system.

Alteration of the OPTIMAAX system air controller module is not permitted.

It is important to read and understand the entire Technical Procedure publication prior to installation or performing any maintenance, service, repair, or rebuild of this product. The information

in this publication contains parts lists, safety information, product specifications, features, proper

maintenance, service, repair and rebuild instructions for the OPTIMAAX system air controller.

Hendrickson reserves the right to make changes and improvements to its products and publications

at any time. Contact Hendrickson Truck Tech Services for information on the latest version of this

manual at 1-866-755-5968 (toll-free U.S. and Canada), 1-630-910-2800 (outside U.S. and

Canada) or e-mail: truckparts@hendrickson-intl.com.

SECTION 2

Product Description

Hendrickson’s OPTIMAAX system is a 6 × 2 solution to help fleets save fuel cost, tire wear and

weight with comparable handling to 6 × 4 tandem axle configurations. Operating as a liftable

axle in the forward tandem position, this system provides versatility for fleets with variable loads.

The OPTIMAAX system air controller monitors air pressure in the drive axle suspension, and calculates axle load based on air pressure levels. When load reaches a set threshold (programmed by

Hendrickson, where the limiting factor is typically steer axle load) the OPTIMAAX lift axle automatically deploys. The OPTIMAAX system air controller module includes the air controller manifold,

electronic control unit (ECU), and the wiring harness (supplied by Freightliner).

Proprietary program logic controls lift axle movement, load transfer and braking functions.

■

Fully automated controls — Eliminates driver intervention versus conventional 6x2 manual

control systems. Automates axle lowering and lifting by sensing load capacities.

■

Optimized traction and handling — Lifted axle position provides increased traction by

increasing drive axle load. Improved traction when backing under trailers in soft soil or wet

conditions versus traditional 6 x 2 configuration. Maintains vehicle handling characteristics by

keeping the drive axle behind the fifth wheel.

®

Introduction 2 17730-310

OPTIMAAX® Lift Axle System Air Controller Module for Freightliner

FIGURE 2-1 Air Controller Manifold

FIGURE 2-2 Electronic Control Unit (ECU)

FIGURE 2-3 Air Controller Wiring Harness (Supplied by Freightliner)

Freightliner Part No. A06-95715

HARN-AXLE-LIFT, CHAS, HDR

Freightliner Part No. A06-95709

HARN-AXLE-LIFT, DASH, HDR, P4

17730-310 3 Product Description

OPTIMAAX® Lift Axle System Air Controller Module for Freightliner

SECTION 3

Important Safety Notice

Proper maintenance, service, and repair is important for the reliable operation of the suspension.

The procedures recommended by Hendrickson and described in this technical publication are

methods of performing such maintenance, service and repair.

This technical publication should be read carefully to help prevent personal injury and to assure

that proper methods are used. Improper maintenance, service or repair may damage the vehicle,

cause personal injury, render it unsafe in operation, or void manufacturer’s warranty.

Failure to follow the safety precautions in this manual can result in personal injury and / or property damage. Carefully read and understand all safety related information within this publication,

on all decals and in all such materials provided by the vehicle manufacturer before conducting

any maintenance, service or repair.

■

EXPLANATION OF SIGNAL WORDS

Hazard “Signal Words” (Danger-Warning-Caution) appear in various locations throughout this

publication. Information accented by one of these signal words must be observed to help minimize the risk of personal injury to service personnel, or possibility of improper service methods

which may damage the vehicle or render it unsafe.

This is the safety alert symbol. It is used to alert you to potential personal injury haz-

ards. Obey all safety messages that follow this symbol to avoid possible

injury or death.

Additional Notes or Service Hints are utilized to emphasize areas of procedural importance and

provide suggestions for ease of repair. The following definitions indicate the use of these signal

words as they appear throughout the publication.

INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, WILL RESULT IN SERIOUS

INJURY OR DEATH.

INDICATES A POTENTIAL HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, COULD RESULT IN SERIOUS

INJURY OR DEATH.

INDICATES A POTENTIAL HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, MAY RESULT IN MINOR OR

MODERATE INJURY, OR PROPERTY DAMAGE.

NOTE An operating procedure, practice condition, etc. which is essential to emphasize.

SERVICE HINT A helpful suggestion that will make the servicing being performed a little easier and / or faster.

Also note that particular service operations may require the use of special tools designed for

specific purposes. These special tools can be found in the Special Tools Section of this publication.

The torque symbol alerts you to tighten fasteners to a specified torque value. Refer to Torque

Specifications Section of this publication.

The warnings and cautions should be read carefully to help prevent personal injury and to assure

that proper methods are used. Improper maintenance, service or repair may damage the vehicle,

cause personal injury, render the vehicle unsafe in operation, or void manufacturer’s warranty.

Important Safety Notice 4 17730-310

OPTIMAAX® Lift Axle System Air Controller Module for Freightliner

■

SAFETY PRECAUTIONS

NOTE REPLACE ANY SAFETY DECALS THAT ARE FADED, TORN, MISSING, ILLEGIBLE, OR OTHERWISE

DAMAGED. CONTACT HENDRICKSON TO ORDER REPLACEMENT LABELS.

LIFT AXLE RAPID AUTOMATIC MOVEMENT

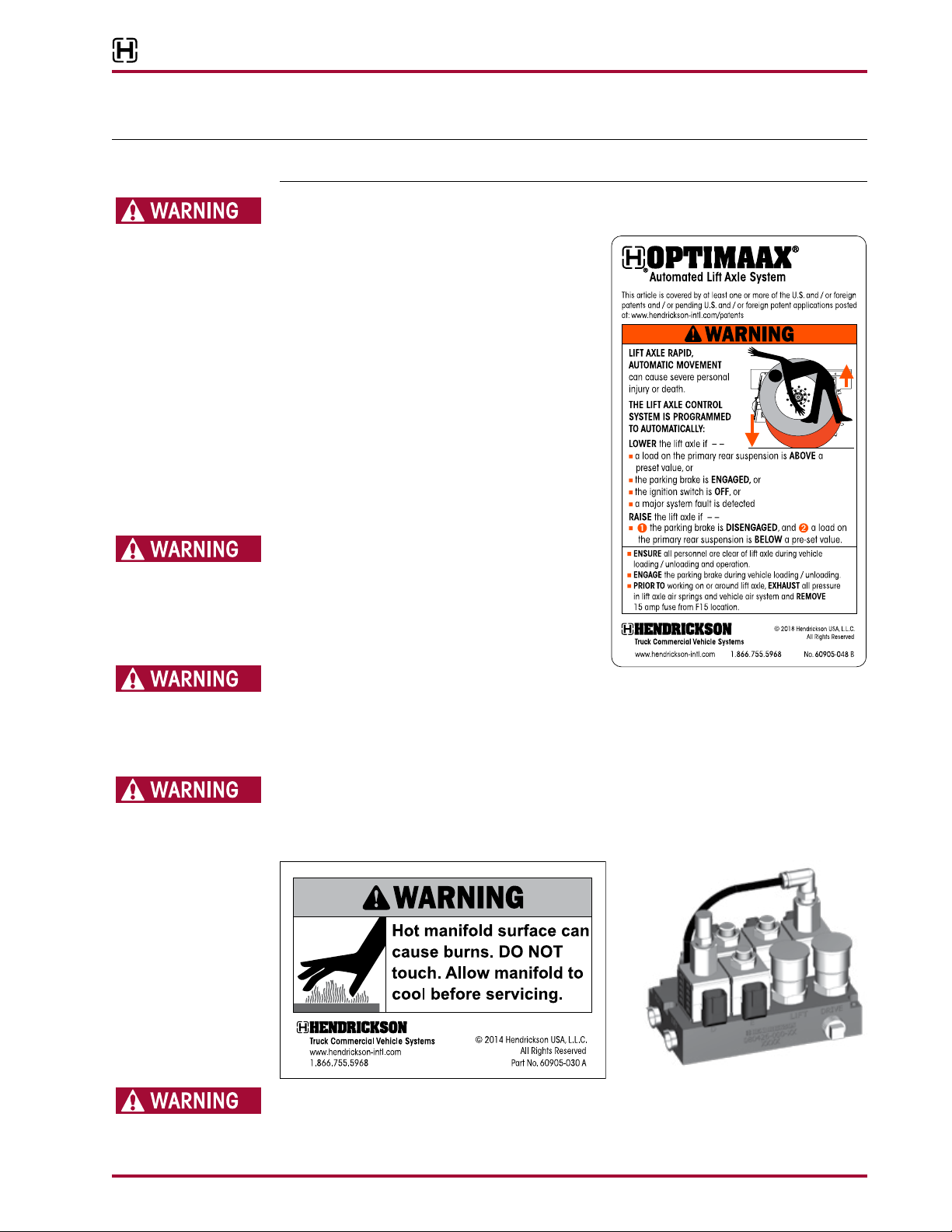

FIGURE 3-1 Product / Safety Decal 60905-048

LIFT AXLE RAPID, AUTOMATIC MOVEMENT CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH.

THE LIFT AXLE CONTROL SYSTEM IS PROGRAMMED TO

AUTOMATICALLY:

LOWER THE LIFT AXLE IF –

■

A LOAD ON THE PRIMARY REAR SUSPENSION

IS ABOVE A PRESET VALUE, OR

■

THE PARKING BRAKE IS ENGAGED, OR

■

THE IGNITION SWITCH IS OFF, OR

■

A MAJOR SYSTEM FAULT IS DETECTED

RAISE THE LIFT AXLE IF –

■

1) THE PARKING BRAKE IS DISENGAGED,

AND 2) A LOAD ON THE PRIMARY REAR

SUSPENSION IS BELOW A PRE-SET VALUE.

LIFT AXLE LOADING / UNLOADING

■

ENSURE ALL PERSONNEL ARE CLEAR OF LIFT AXLE

DURING VEHICLE LOADING / UNLOADING AND

OPERATION.

■

ENGAGE THE PARKING BRAKE DURING VEHICLE

LOADING / UNLOADING.

PRIOR TO SERVICE

■

EXHAUST ALL PRESSURE IN LIFT AXLE AIR SPRINGS AND VEHICLE AIR SYSTEM BEFORE WORKING

ON OR AROUND LIFT AXLE.

■

REMOVE 15 AMP FUSE FROM F15 LOCATION, REFER TO THE SYSTEM OPERATION SECTION OF

THIS PUBLICATION.

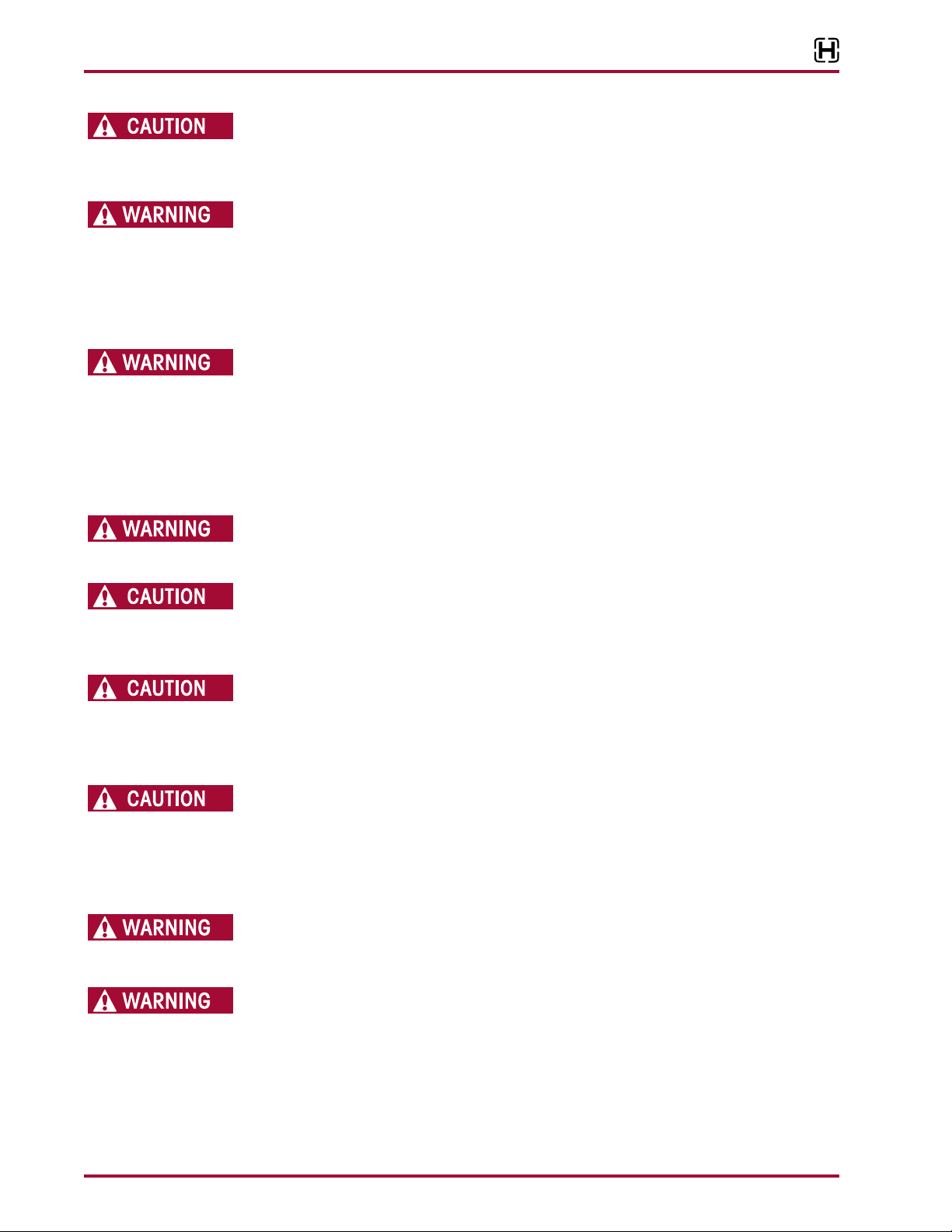

AIR CONTROLLER MANIFOLD

HOT AIR CONTROLLER MANIFOLD SURFACE CAN CAUSE BURNS. DO NOT TOUCH. ALLOW MANIFOLD TO

COOL BEFORE SERVICING, SEE FIGURES 3-2 AND 3-3.

FIGURE 3-2 FIGURE 3-3

ELECTRICAL SYSTEM

DO NOT WORK ON THE VEHICLE ELECTRICAL SYSTEM WITH THE VEHICLE POWER ON. DAMAGE TO

VEHICLE ELECTRICAL SYSTEM AND / OR UNEXPECTED AXLE MOVEMENT MAY RESULT.

17730-310 5 Important Safety Notice

OPTIMAAX® Lift Axle System Air Controller Module for Freightliner

WIRING HARNESS

ENSURE THERE IS SUFFICIENT FREE MOVEMENT IN AIR CONTROLLER WIRING HARNESS TO PREVENT

WIRES AND CONNECTIONS FROM BEING UNDER TENSION DURING INSTALLATION. FAILURE TO DO SO

MAY DAMAGE OR FRAY THE CABLES.

SYSTEM INSTALLATION

IT IS THE RESPONSIBILITY OF THE INSTALLER OF THE AIR CONTROLLER MODULE AND OTHER OPTIMAAX

SYSTEM COMPONENTS TO ENSURE PROPER INSTALLATION. ANY INSTALLATION DEVIATIONS MUST

BE APPROVED, IN WRITING, BY HENDRICKSON’S PRODUCT ENGINEERING DEPARTMENT. ANNUAL

INSPECTION OF SYSTEM PRESSURE SENSORS IS REQUIRED TO CHECK FOR PROPER LOADING ON

DRIVE AXLE AND STEER AXLE. FAILURE TO COMPLY WITH ANY OF THE ABOVE WILL VOID APPLICABLE

WARRANTIES.

AIR SPRING INFLATION AND DEFLATION

PRIOR TO DISASSEMBLY OF THE SUSPENSION, AIR SPRING ASSEMBLIES MUST BE DEFLATED.

UNRESTRICTED AIR SPRING ASSEMBLIES CAN VIOLENTLY SHIFT. DO NOT INFLATE AIR SPRING

ASSEMBLIES WHEN THEY ARE UNRESTRICTED. AIR SPRING ASSEMBLIES MUST BE RESTRICTED

BY SUSPENSION OR OTHER ADEQUATE STRUCTURE. DO NOT INFLATE BEYOND PRESSURES

RECOMMENDED BY AIR SPRING MANUFACTURER, CONTACT HENDRICKSON TECHNICAL SERVICES

FOR DETAILS. IMPROPER USE OR OVER INFLATION MAY CAUSE AIR SPRING ASSEMBLIES TO BURST,

CAUSING PROPERTY DAMAGE AND / OR SEVERE PERSONAL INJURY.

PRIOR TO AND DURING DEFLATION AND INFLATION OF THE AIR SUSPENSION SYSTEM, ENSURE ALL

PERSONNEL AND EQUIPMENT ARE CLEAR FROM UNDER THE VEHICLE AND AROUND THE SERVICE

AREA, FAILURE TO DO SO CAN CAUSE SERIOUS PERSONAL INJURY, DEATH, OR PROPERTY DAMAGE.

AIR SPRING INFLATION

INFLATE THE SUSPENSION SLOWLY AND MAKE SURE THE RUBBER BLADDER OF THE AIR SPRING

INFLATES UNIFORMLY AND IS NOT BINDING. FAILURE TO DO SO CAN CAUSE DAMAGE TO THE AIR

SPRING AND / OR MOUNTING BRACKETS AND VOID WARRANTY.

AIR SPRING LOWER MOUNTING STUDS

IF THE AIR SPRING IS BEING REMOVED FOR AN ALTERNATE REPAIR, IT IS MANDATORY TO LUBRICATE THE

LOWER AIR SPRING FASTENERS WITH PENETRATING OIL AND REMOVE WITH HAND TOOLS TO PREVENT

DAMAGE TO THE LOWER AIR SPRING MOUNTING STUD. FAILURE TO DO SO CAN CAUSE COMPONENT

DAMAGE AND VOID WARRANTY.

PROCEDURES AND TOOLS

A MECHANIC USING A SERVICE PROCEDURE OR TOOL WHICH HAS NOT BEEN RECOMMENDED BY

HENDRICKSON MUST FIRST SATISFY HIMSELF THAT NEITHER HIS SAFETY NOR THE VEHICLE’S SAFETY

WILL BE JEOPARDIZED BY THE METHOD OR TOOL SELECTED. INDIVIDUALS DEVIATING IN ANY MANNER

FROM THE INSTRUCTIONS PROVIDED ASSUME ALL RISKS OF POTENTIAL PERSONAL INJURY OR

DAMAGE TO EQUIPMENT INVOLVED.

PERSONNEL PROTECTIVE EQUIPMENT

ALWAYS WEAR PROPER EYE PROTECTION AND OTHER REQUIRED PERSONAL PROTECTIVE EQUIPMENT

TO HELP PREVENT PERSONAL INJURY WHEN PERFORMING VEHICLE MAINTENANCE, REPAIR OR SERVICE.

MODIFYING COMPONENTS

DO NOT MODIFY OR REWORK PARTS WITHOUT AUTHORIZATION FROM HENDRICKSON. DO NOT

SUBSTITUTE REPLACEMENT COMPONENTS NOT AUTHORIZED BY HENDRICKSON. USE OF MODIFIED,

REWORKED, SUBSTITUTE OR REPLACEMENT PARTS NOT AUTHORIZED BY HENDRICKSON MAY NOT

MEET HENDRICKSON’S SPECIFICATIONS, AND CAN RESULT IN FAILURE OF THE PART, ADVERSE VEHICLE

HANDLING, POSSIBLE PERSONAL INJURY OR PROPERTY DAMAGE, AND WILL VOID ANY APPLICABLE

WARRANTIES. USE ONLY HENDRICKSON AUTHORIZED REPLACEMENT PARTS.

Important Safety Notice 6 17730-310

OPTIMAAX® Lift Axle System Air Controller Module for Freightliner

SUPPORT THE VEHICLE PRIOR TO SERVICING

PLACE THE VEHICLE ON A LEVEL FLOOR AND CHOCK THE WHEELS TO HELP PREVENT THE VEHICLE

FROM MOVING. PRIOR TO SERVICING A VEHICLE IN THE RAISED POSITION, PROPERLY SUPPORT THE

VEHICLE WITH SAFETY STANDS. DO NOT WORK AROUND OR UNDER A RAISED VEHICLE SUPPORTED

ONLY WITH FLOOR JACKS OR OTHER LIFTING DEVICES, FAILURE TO DO SO CAN CAUSE DEATH,

PERSONAL INJURY OR DAMAGE TO COMPONENTS.

IMPROPER JACKING METHOD

IMPROPER JACKING METHOD CAN CAUSE STRUCTURAL DAMAGE AND RESULT IN ADVERSE VEHICLE

HANDLING, SEVERE PERSONAL INJURY OR DEATH. DO NOT USE AXLE BEAM OUTBOARD OF AXLE

SPRING SEATS. REFER TO VEHICLE MANUFACTURER FOR PROPER JACKING INSTRUCTIONS.

SUPPORT THE LIFT AXLE PRIOR TO SERVICING

PLACE THE VEHICLE ON A LEVEL FLOOR AND CHOCK THE WHEELS TO HELP PREVENT THE VEHICLE

FROM MOVING. PRIOR TO SERVICING A LIFT AXLE IN THE RAISED POSITION, (1) PROPERLY SUPPORT

THE LIFT AXLE WITH SAFETY STANDS, AND (2) RELEASE ALL AIR PRESSURE IN THE LIFT AXLE AIR

SPRINGS AND RIDE SPRINGS. DO NOT WORK AROUND OR UNDER A RAISED LIFT AXLE SUPPORTED

ONLY WITH FLOOR JACKS OR OTHER LIFTING DEVICES, FAILURE TO DO SO CAN CAUSE DEATH,

PERSONAL INJURY OR DAMAGE TO COMPONENTS.

17730-310 7 Important Safety Notice

OPTIMAAX® Lift Axle System Air Controller Module for Freightliner

SECTION 4

Definitions

DEFINITIONS

APU

Bobtail Condition

CAN BUS

CAN Wires

Cong File

Diagnostic tool

Software

ECU

EEPROM

OBD

sSAM

USB

VPDM

Auxiliary Power Unit

A bobtail truck is a semi-truck that travels from one point to another

without a trailer.

Controller Area Network Bus

Controller Area Network Wires

License le needed to run the Diagnostic Tool Software. Controlled

by Hendrickson.

Software used to communicate with the lift axle

Electronic Control Unit

Electrically Erasable Programmable Read-only Memory

On-board Diagnostics

Single Signal-detection and Activation Module

Universal Serial Bus

Vehicle Power Distribution Module

Denitions 8 17730-310

Loading...

Loading...