HENDRICKSON MAXX22T Installation Manual

Technical

Procedure

TRAILER SUSPENSION SYSTEMS

AIR DISC BRAKE (ADB)

SUBJECT: Hub and Rotor Assembly

Caliper Mounting Procedures

LIT NO: T71004

DATE: September 2023 REVISION: G

ROTOR TO HUB ASSEMBLY

Not all hub and rotor assemblies are the same. Refer to

the applicable procedure listed in this section.

NOTE: The hub and rotor assembly must be installed

before mounting the ADB caliper.

NOTICE: Thoroughly inspect rotor condition

before reuse. For details, refer to

T72009

Maintenance

IMPORTANT: Hendrickson does not recommend

reusing fasteners.

CAUTION: DO NOT lift an ADB caliper assembly

by the brake pad retainer bracket.

Other relative literature may include:

LIT NO. DESCRIPTION

T12007 General Safety Precautions & Information for

Technical Procedures

T72009 MAXX22T Installation & Maintenance Procedures

T82006 Recommended Stud Replacement Procedures

TOOLS REQUIRED

The following tools may be required during the

performance of some maintenance procedures:

TOOL WHERE USED TORQUE

Torque Wrench 10

to 250 ft-Ib

15/16 inch socket Outboard Mounted Rotor 5/8 inch

24mm socket or

15/16 inch socket

13mm socket Bendix Splined Disc Rotor

15/16 inch socket ConMet Flat Rotor and Hub

MAXX22T™ Installation &

or rotor manufacturer.

Used with sockets listed in this

table

ange nuts Figure 1

Flanged Mounted Hub and

U-Shaped Rotor M16mm screws

or 5/8 inch screws Figure 3

Assembly M8mm screws Figure 5

Assembly 5/8 inch ange nuts

Figure 6

Table 1: Tools Required

N/A

220 ft-Ib

220 ft-Ib

22 ft-Ib

200 ft-Ib

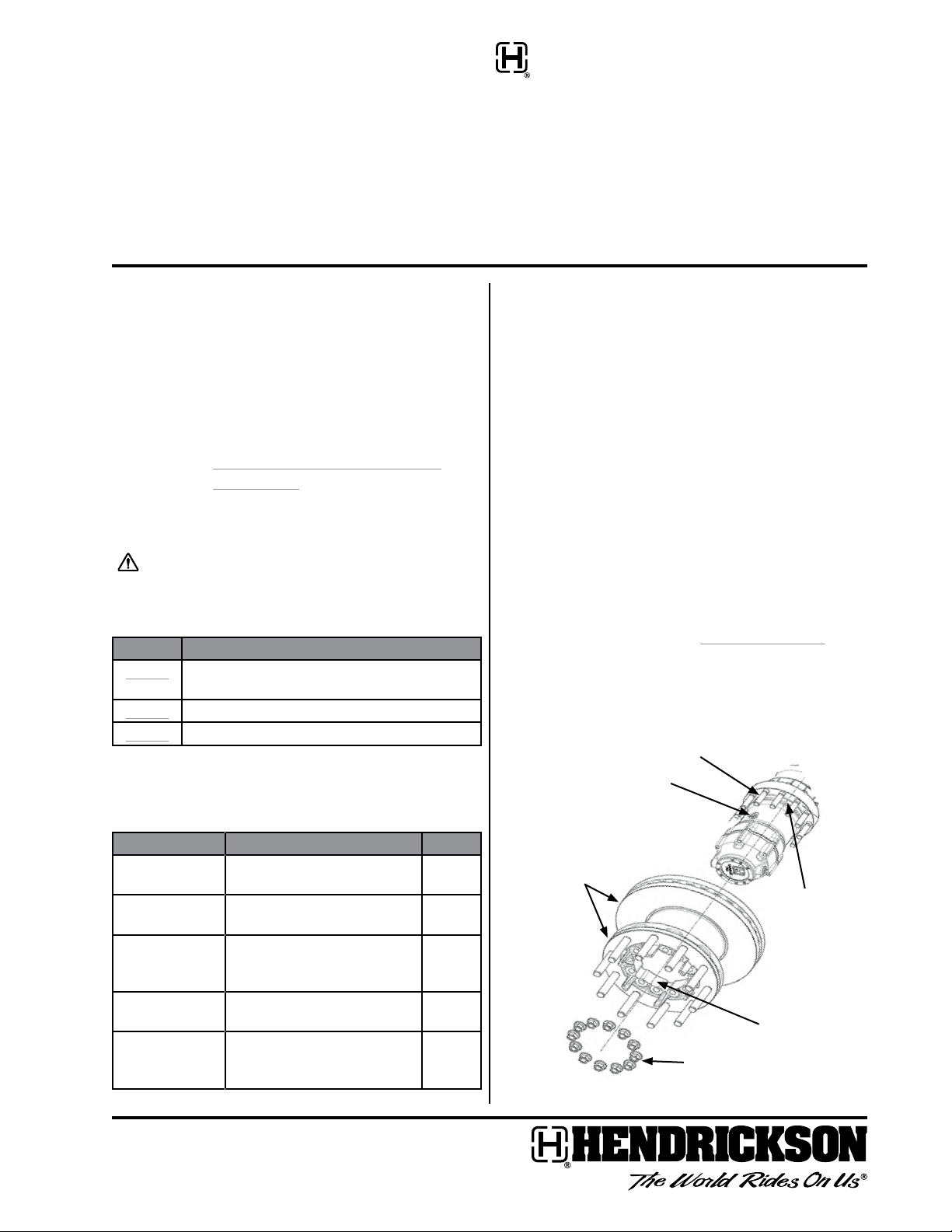

OUTBOARD MOUNTED ROTOR

1. Ensure both hub and rotor mounting surfaces are

free of loose dirt, corrosion, grease, and debris.

NOTE: Applying a light lm of lube to the rotor ange

ID may help ease sliding the rotor ange ID

over the hub rotor pilot.

2. With hub mounted on the axle, slide the new rotor

assembly onto the hub until the rotor ange ID

engages the hub rotor pilot (Figure 1).

NOTE: Ensure the hub ll port (Figure 1) is not directly

under a wheel stud.

3. Install the 12 ange nuts and hand tighten.

4. Once all the nuts are hand tightened, properly

constrain assembly and tighten the ange nuts,

in the sequence shown in Figure 2 on page 2, to

220±10 ft. Ibs. (300±10Nm) of torque.

IMPORTANT: DO NOT APPLY anti-seize compound or

additional lubricant to fastener threads.

Wheel studs (x12)

Hub Fill port

Rotor

assembly

Hub rotor

pilot

Rotor ange ID

Figure 1: Outboard Mounted Rotor

HUB AND ROTOR ASSEMBLY CALIPER MOUNTING PROCEDURES

1

4

10

9

2

1

12

8

4

10

6

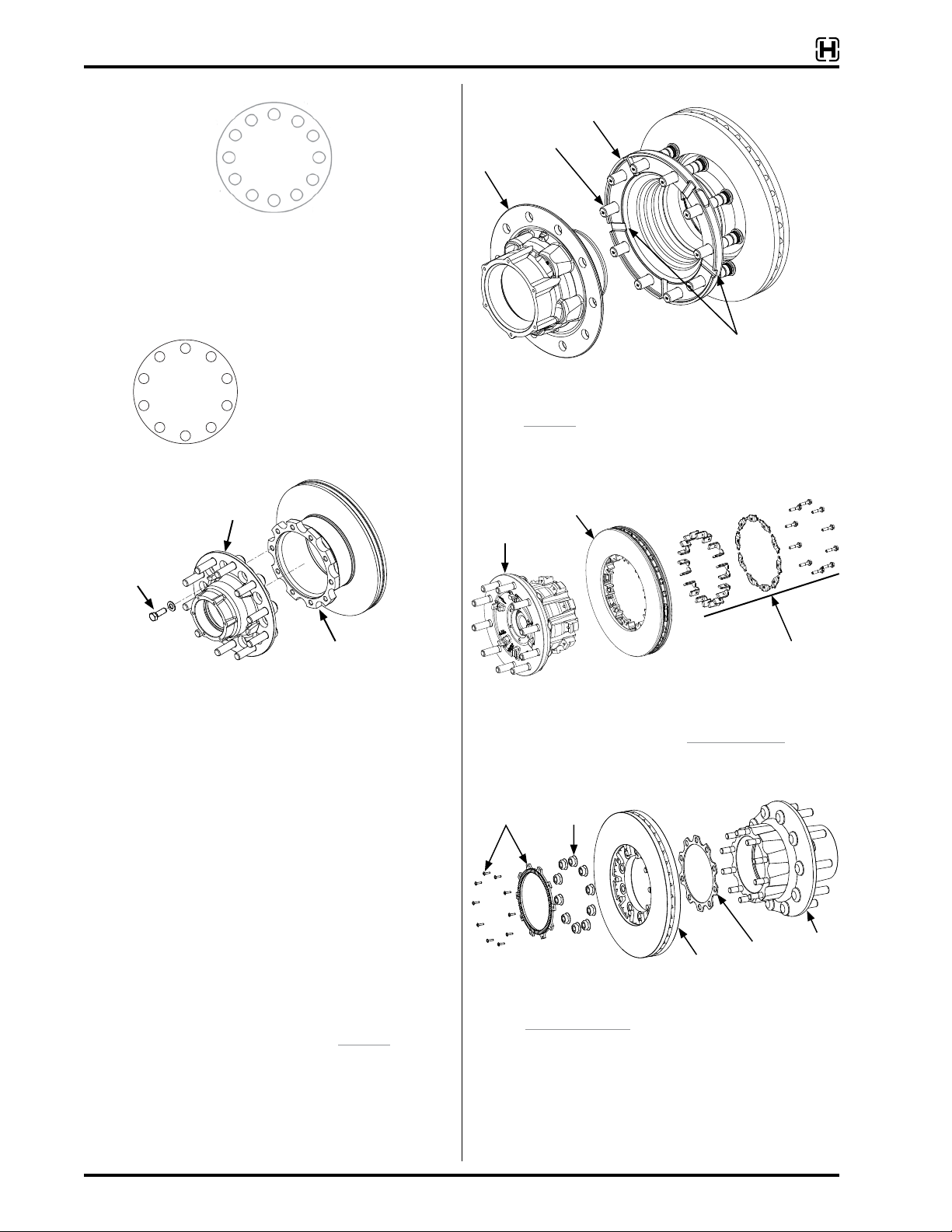

Figure 2: Outboard Mounted Rotor torque sequence

5

9

3

7

11

2

FLANGED MOUNTED HUB AND U-SHAPED

ROTOR

6

M16 or 5/8”-11

Mounting

screws x10

7

3

Rotor torque sequence

for all U-shaped rotors

58

Hub

STUD MOUNTED ROTOR

U-shaped rotor

Studs (x10)

Hub

Drain slots (x5)

Figure 4: Hendrickson stud mounted hub & U-shaped rotor assembly

Refer to T82006 for disassembly or stud replacement

procedures.

BENDIX SPLINED DISC® ROTOR ASSEMBLY

Splined Disc

Splined hub

®

rotor

Rotor

Figure 3: Flange mounted hub & U-shaped rotor assembly

Figure 5: ConMet hub & Bendix Splined Disc rotor assembly

Splined Disc

rotor hardware

1. Ensure both hub and rotor mounting surfaces are

clean and free of loose dirt, corrosion, grease, and

For rotor information, refer to the Bendix website.

debris.

2. Place the rotor onto a stable work surface with

the outboard mounting surface facing upward.

CONMET FLAT ROTOR AND HUB ASSEMBLY

Tone ring &

10 fasteners

Flanged

nuts (x10)

3. Carefully lower the hub onto the rotor until the

hub mounting pilot engages the rotor bore.

IMPORTANT: DO NOT APPLY anti-seize compound or

additional lubricant to fastener threads.

4. Align fastener holes and insert new screws and

washers.

5. Hand tighten.

6. Properly constrain assembly and tighten mounting

Figure 6: ConMet hub & at rotor assembly

Refer to ConMet website.

Flat rotor

Insulator

Hub

screws, in the sequence shown in Figure 3, to

220±10 ft. lbs. (300±10 Nm) of torque.

NOTE: Ensure the heads of the new screws are

recessed below the ange wheel mounting

surface.

2

T71004 G

Loading...

Loading...