Henderson EVOLVE POCKET DOOR PRO Fitting Instructions Manual

KIT AND DOOR SPECIFICATION

Kit Short Code

Max. Door Height

Max. Door Width

Door Thickness Range

Max. Door Weight

EVOPRO1/***

1981mm (78”)

610mm (24”)

28 – 44mm

80kg

EVOPRO2/***

1981mm (78”)

686mm (27”)

28 – 44mm

80kg

EVOPRO3/***

1981mm (78”)

762mm (30”)

28 – 44mm

80kg

EVOPRO4/***

1981mm (78”)

838mm (33”)

28 – 44mm

80kg

EVOPRO6/***

2040mm (80”)

826mm (32.5”)

28 – 44mm

80kg

EVOPRO7/***

2040mm (80”)

726mm (28.5”)

28 – 44mm

80kg

EVOPRO10/***

2315mm (91”)

930mm (36.5”)

28 – 44mm

80kg

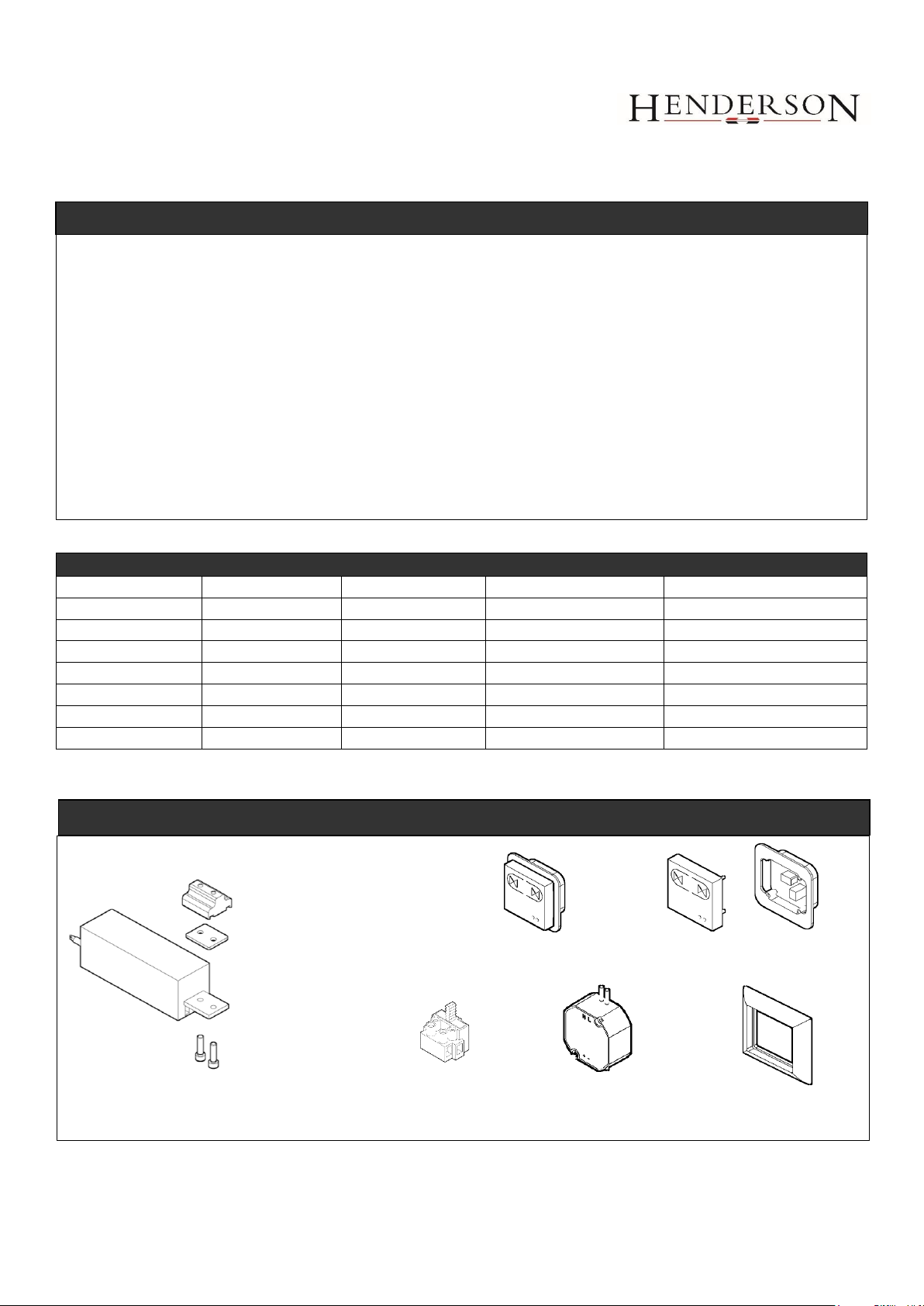

2 x Socket Surround

ELECTRICAL COMPONENTS

1 x Motor Connector

Block

1 x Motor Spacer

Plate

1 x Motor

2 x M6x25 Socket

Head Screw

1 x Wall Control

Socket

1 x Wall Socket &

1 x Cover Plate

1 x 24V Transformer

About this document

This document addresses qualified personnel only. The mounting must be done by technically educated, trained and qualified

personnel. Electrical wirings have to be completed by suitably qualified specialists.

These instructions describe how to install the track and sliding door hardware. For installation of the drive motor, switches or

sensors - please refer to the operating instructions for the Evolve Motor and Wiring Instructions.

The manufacturer’s specification must be respected in especially maximum weight restriction of door leaf. Any other use of

this product is considered inappropriate use.

It is not guaranteed that this product will work in conjunction with fittings, motors or other electronic devices supplied by other

manufacturers.

The appliance is only to be used with the power supply unit provided.

Before you commence work, please read through these instructions. Please store these instructions in a safe place and pass

them on to any future owners. Damage resulting from non-compliance with these instructions and safety instructions will void

the warranty. PC Henderson nor the motor unit manufacturer will assume liability for any consequential damage.

ABOUT THIS DOCUMENT

EVOLVE POCKET

DOOR PRO

Fitting Instructions

1 x Fused

Connector

*** For full short code replace with required finished wall thickness size – 120 or 125 (mm)

Note: If installing a liner kit with this kit please refer to Pocket Door Pro Liner Kit fitting instructions – this should be installed last.

1

Screw B

4.2 x 25 Self tapping

8 x in EVOPRO 1, 2, 3, 4, 6, 7

24 x in EVOPRO10

Screw c

No 8 x 1” Woodscrew

18 x in EVOPRO 1-7

24 x in EVOPRO 10

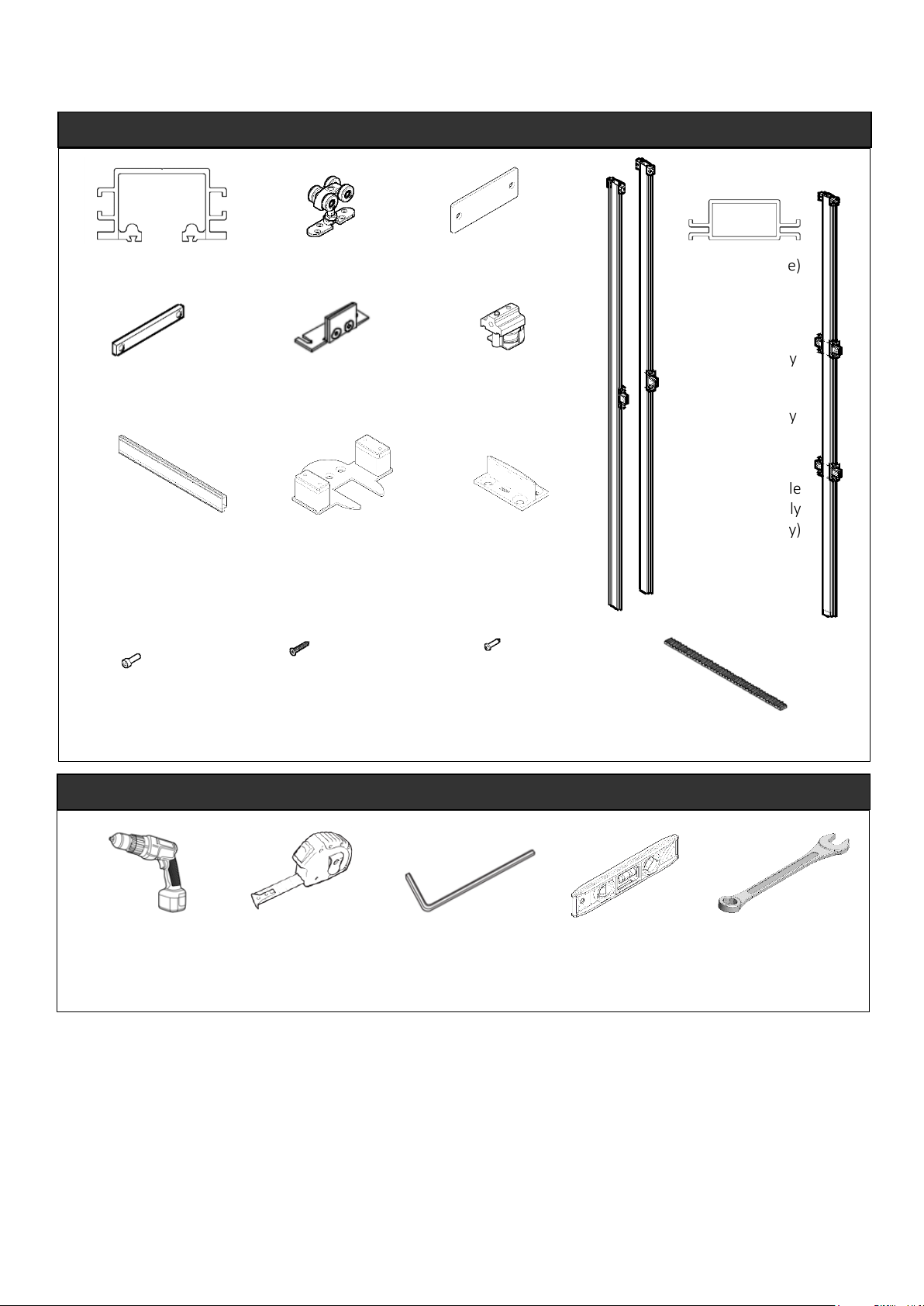

KIT CONTENTS

1 x Header Track

2 x Hangers

4 x Fixing Plates

1 x SS Belt Clamp

1 x Toothed Belt Length

Noggin

2 x 395mm in EVOPRO1 & 2

2 x 545mm in EVOPRO3, 4, 6, 7

4 X 545mm in EVOPRO10

4 X 295mm EVOPRO10

Floor/Wall Bracket

2 x in EVOPRO1, 2, 3, 4, 6, 7

4 x in EVOPRO10

8 x Screw A

M6x20 Cap Head

Screws

Drill

With magnetic posi head driver

Tape Measure

5mm Allen Key

Spirit Level

6mm & 13mm Spanner

TOOLS REQUIRED

4 x 2.5mm spacer plate

125mm finished wall thickness

version only

Floor

Guide

102N

(Upright profile)

2 x Left Hand

Upright Assembly

2 x Right Hand

Upright Assembly

2 x Double

Upright Assembly

(EVOPRO10 only)

1 x Clamp and Pulley

Wheel

2

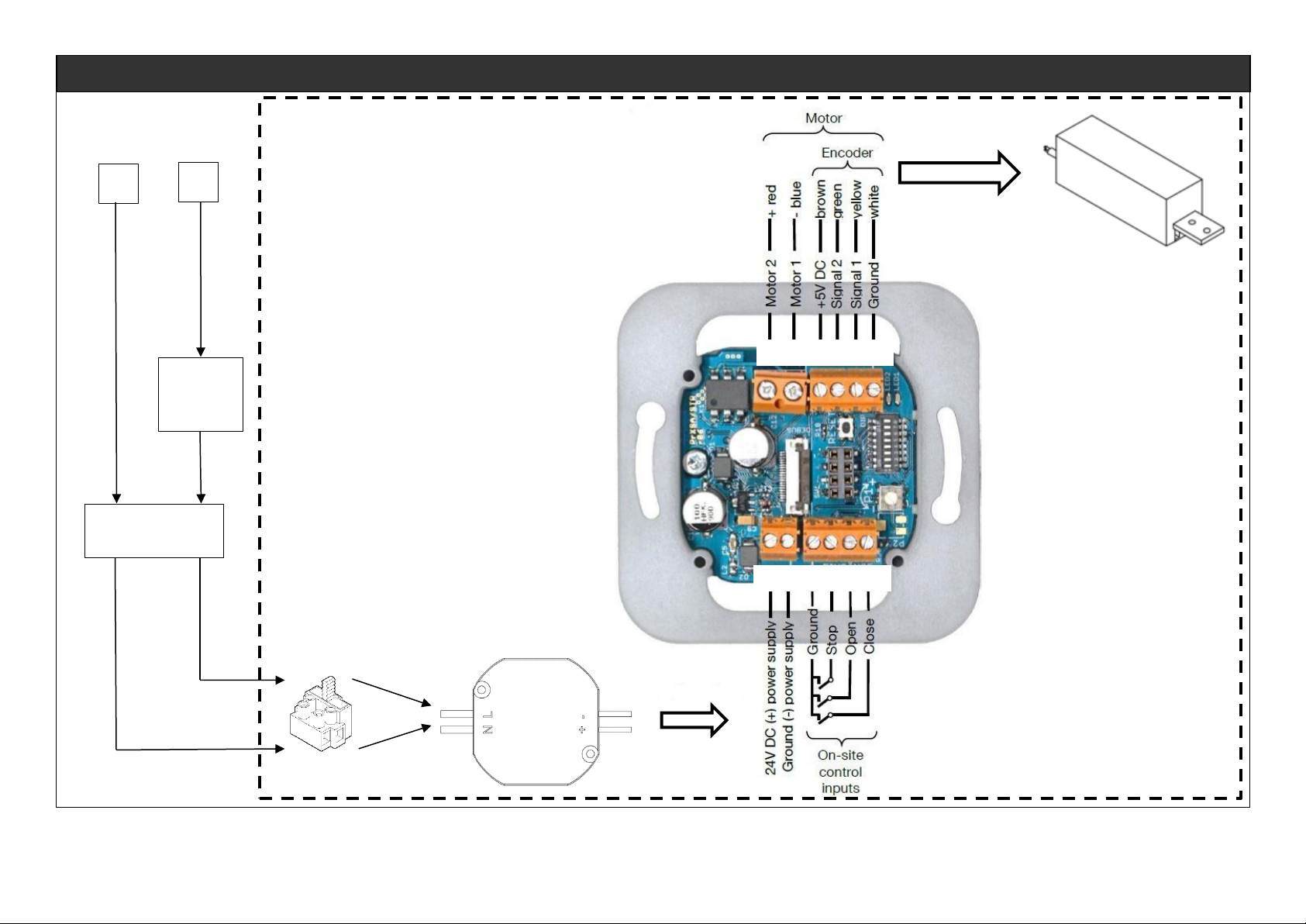

WIRING DIAGRAM OVERVIEW

All pole mains

switch (on site)

10A

(on site)

L

N

Fused Connector

Power Supply 24 V DC

Motor Unit

Electrical content supplied by PCH

b a 82 86 85 1

2 1 1 15 21 29

3

For detailed operation and programming instructions please consult separate Evolve Motor and Wiring Instructions

supplied.

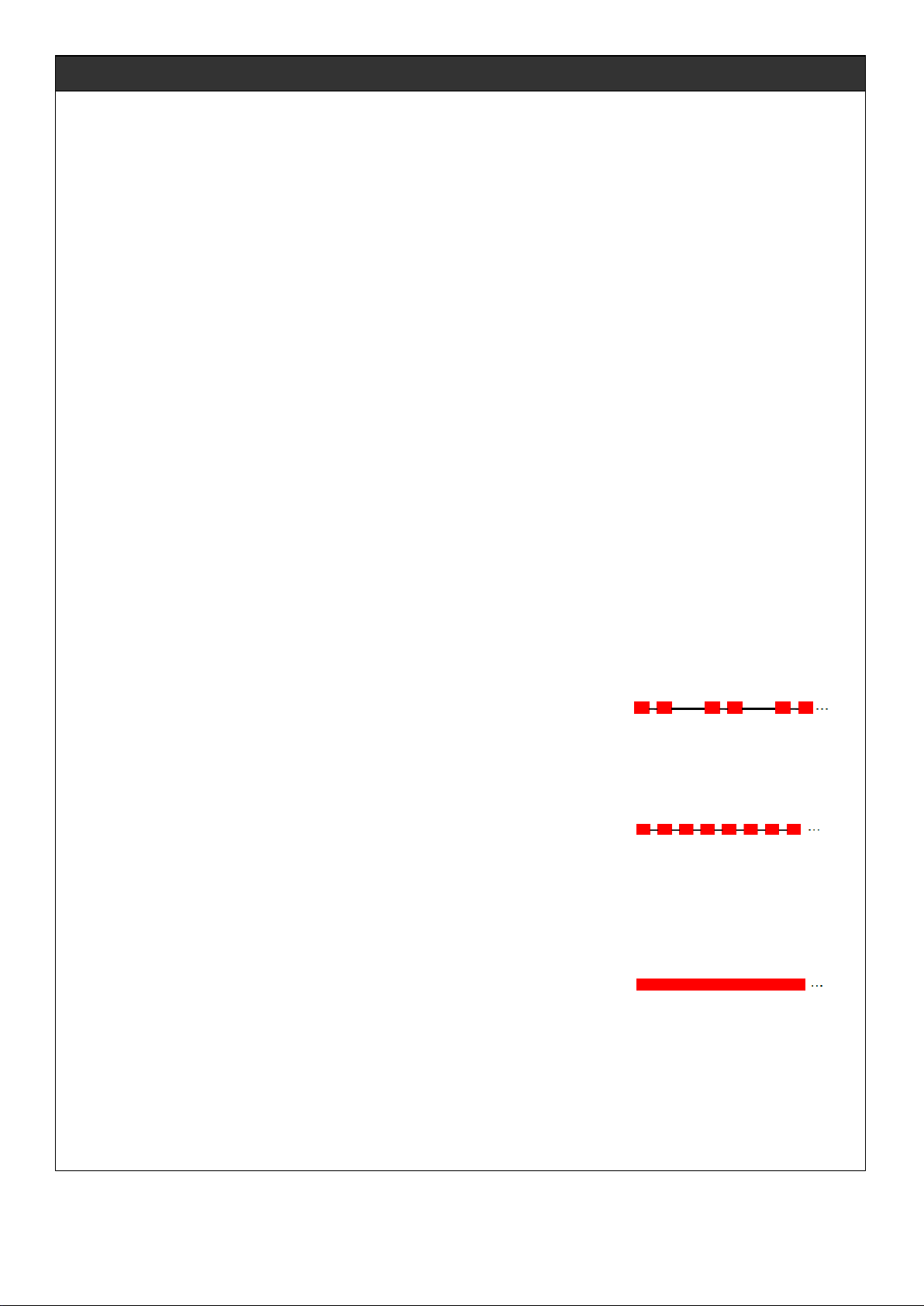

1. Operation Mode Semi-Automatic/Automatic

When semi-automatic mode is set the drive will not close automatically - the potentiometer is without function.

When the automatic mode is set the drive closes automatically.

2. Dead Man’s Control

When dead man’s control is activated the drive will lonely operate, as long as an input is applied. Switch 1 is inactive

when dead man’s control is selected.

3. Push & Go

With push & go enabled the drive starts to move, as soon as the door is pushed manually.

4. Reaction on Obstruction

When reverse is set the drive stops and starts to move in the opposite direction as soon as an obstruction is

detected. If this isn’t set it will stop until a new command is given. This is only possible in semi-automatic mode.

5. Closing Speed

By default the closing speed is slower than the opening speed. The closing speed can be set as fast as the opening

speed, by setting this switch to ON>

6. Maximum Door Speed

The maximum speed has to be set via these switches

Maximum speed is dependent on the door weight according to DIN EN 18650

Weight of door is up to 80kg - maximum speed is 20cm/s

Weight of door is up to 80kg - maximum speed is 23cm/s

Weight of door IS up to 80kg - maximum speed is 26cm/s

When no switch is activated, the slowest speed is set (20cm/s)

When more than one switch is activated, a reduced speed is set (12 cm/s)

PERFORM RESET

1. Switch Power Supply On

Control device in delivery status or after power cut

Red LED blinks continuously twice with a short break of 1.5sec

2. Press RESET for About 2 Seconds

Red LED blinks continuously

3. Check Driving Direction of Motor with Control Keys

When pressing OPEN, door has to open and when pressing CLOSE, door has to close

When driving direction is wrong - swap motor cables (terminals MA and MB), check driving direction again.

4. Move Door in Middle Position by Pressing and Holding the Control Keys

5. Press RESET for About 2 Seconds

Red LED lights up permanently

Green LED lights up during motor activity

Door moves in the open position

Door moves in the closed position

Door moves in the open position

LED’s go out

CHECK FUNCTIONALITY

1. Test, if the door shows desired behavior

2. In case of malfunction check electrical connections and configurations

for electrical connection refer to chapter 5.3 of the Evolve Motor and Wiring Instructions supplied

for configuration refer to chapter 6.1 of the Evolve Motor and Wiring Instructions supplied

Repeat initial operation, if necessary

3. Initial operation is completed when function is correct

WIRING WALL MOUNTED SOCKET - OVERVIEW

5

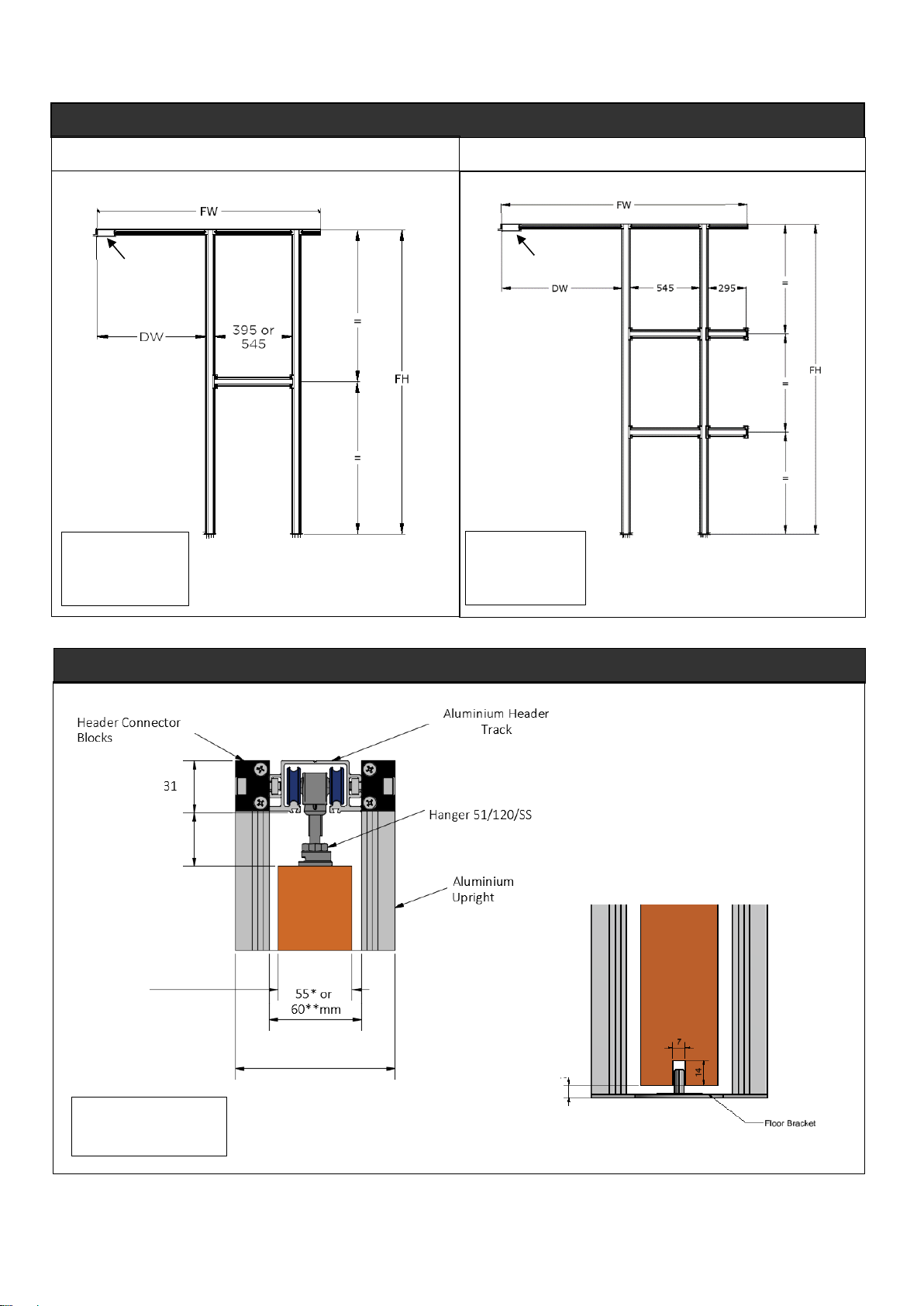

EVOLVE POCKET DOOR PRO KIT CONFIGURATION

EVO PRO 1, 2, 3, 4, 6 & 7

EVO PRO 10

NOTE

DW = door width

FW = frame width

FH = frame height

EVOLVE POCKET DOOR PRO HEADER & FOOTER DETAIL

NOTE

DW = door width

FW = frame width

FH = frame height

NOTE

*When using 120mm kit

** When using 125mm kit

32mm

Door Thickness

35 – 44mm

95* or 100**mm

MOTOR

ASSEMBLY

MOTOR

ASSEMBLY

5

5

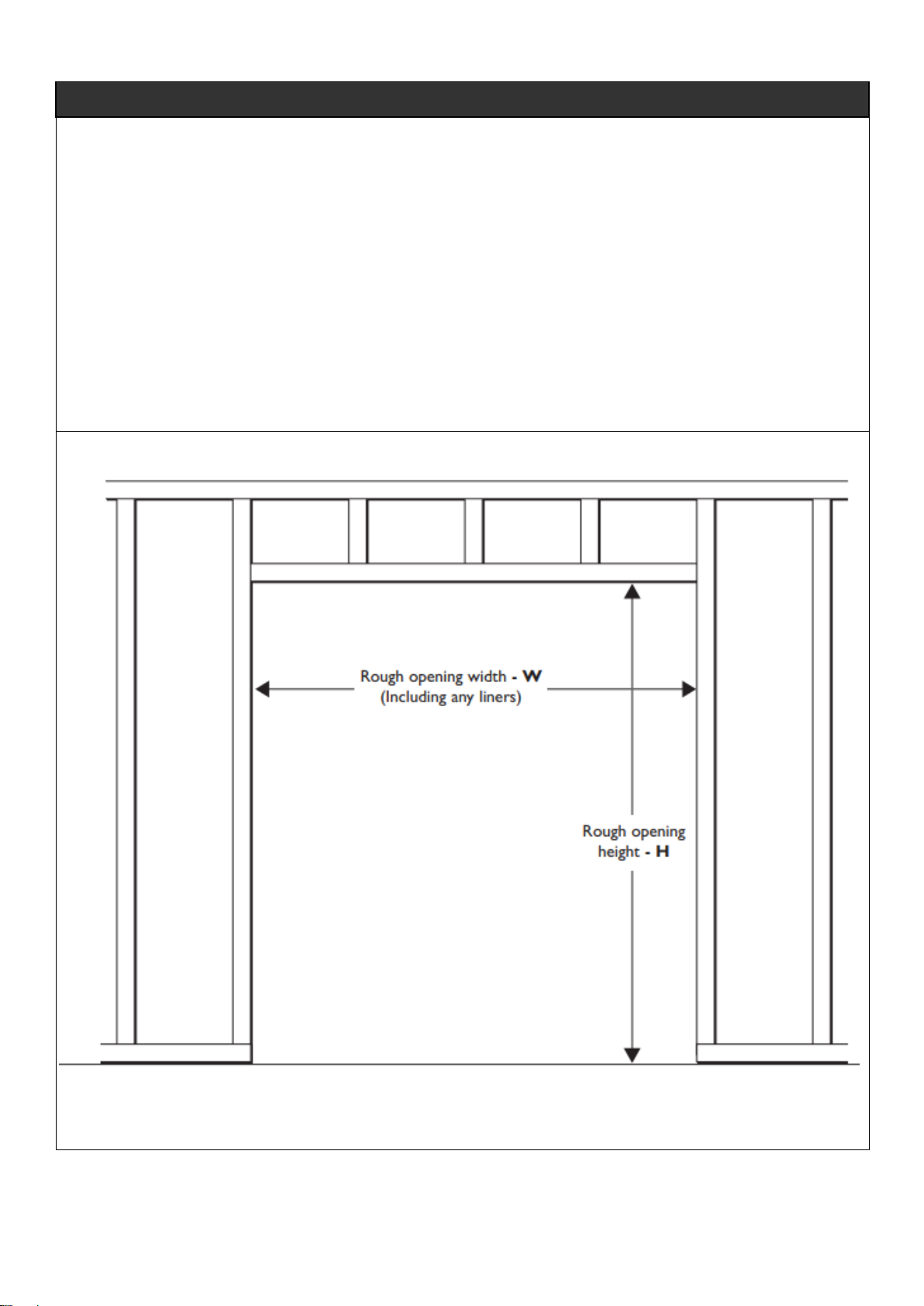

STEP 1: Prepare the rough opening

How to calculate the opening width required

Opening width in mm = (door width x 2) + 30mm (or 62mm if using with self-closing mechanism)

Opening height in mm = door height + 70mm

Note: 70mm allows for: door floor clearance (range 7 - 20mm) + top of door to bottom of track (range 19 - 32mm)

+ track height (31mm)

Finished Wall Thickness

Stud wall can be 95mm or 100mm plus plasterboard (2 x 12.5mm) e.g.

95mm cavity + 12.5mm plasterboard either side= 120mm finished wall thickness

100mm cavity + 12.5mm plasterboard either side = 125mm finished wall thickness

STEP BY STEP INSTRUCTIONS

6

Loading...

Loading...