Helo HNS–M2 User And Installation Manual

STEAM GENERATOR -- CONTROL PANEL

HNS – M2 -- Midi 2 / On Off push button

For home and professional use

314 SHS 99-3 A

User and installation manual HNS–M2

Contents

Specifications 3

Controls and accessories 3

Selecting the steam generator output for the steam room 3

General 4

Installation principle 5

Steam generator couplings 5

Electrical connections 7

Heating elements 7

Switch diagram 8

Steam generator 2 grade control 8

Steam generator maintenance procedures 9

Cleaning the steam room 10

Steam generator in professional use 10

Usage of steam generator HNS – M2 11

On/Off push button 12

Error messages 12

Installing control panel, push button and sensor 13

Troubleshooting 14

Troubleshooting table 14

ROHS 17

User and installation manual HNS-M2

2

Specifications

Operating voltage 230 V–240 V 1N~/2~, (3.4 kW – 7.7 kW)

230 V 3~, (3.4 kW–14 kW)

400 V–415 V 3N~ (3.4 kW–14 kW)

Output options 3.4 / 4.7 / 6.0 / 7.7 / 9.5 / 12.0 / 14.0 kW

Enclosure class IP 20

Installation Floor / wall

Water tank material Aisi 304, stainless steel

Water tank pipes Aisi 314, acid-resistant stainless steel

Steamer dimensions 520 x 380 x 160 mm

Weight when empty about 11 kg

Easy to use

Floor or wall installation

Digital control panel Midi 2 (operating time can be set between 0–23 hours)

On/Off push button (alternative method of control, operating time fixed 30 min)

The installation of the control centre and On/Off push button in the steam room is allowed

Easy maintenance

Changeable resistors (3 pcs), of which 1 is fitted with a heat fuse.

Fill cap for chalk remover (citric acid) has been placed on the upper part of the steam generator.

Components easily replaceable, circuit board, heating elements, surface sensor.

Controls and accessories

Control panel Midi (0043256)

On/Off push button (0043211)

Sensor (0043210)

Scent pump, (Essence kit 0038130)

Scent pump canister 20 l (0038132)

Automatic flush and rinse cycle. (Automatic drain valve 4310130)

Steam nozzles (3.4–6.0 kW 1pc, 7.7–9.5 kW 2 pcs, 12–14 kW 3 pcs) (7819604)

Light adapter (0043214)

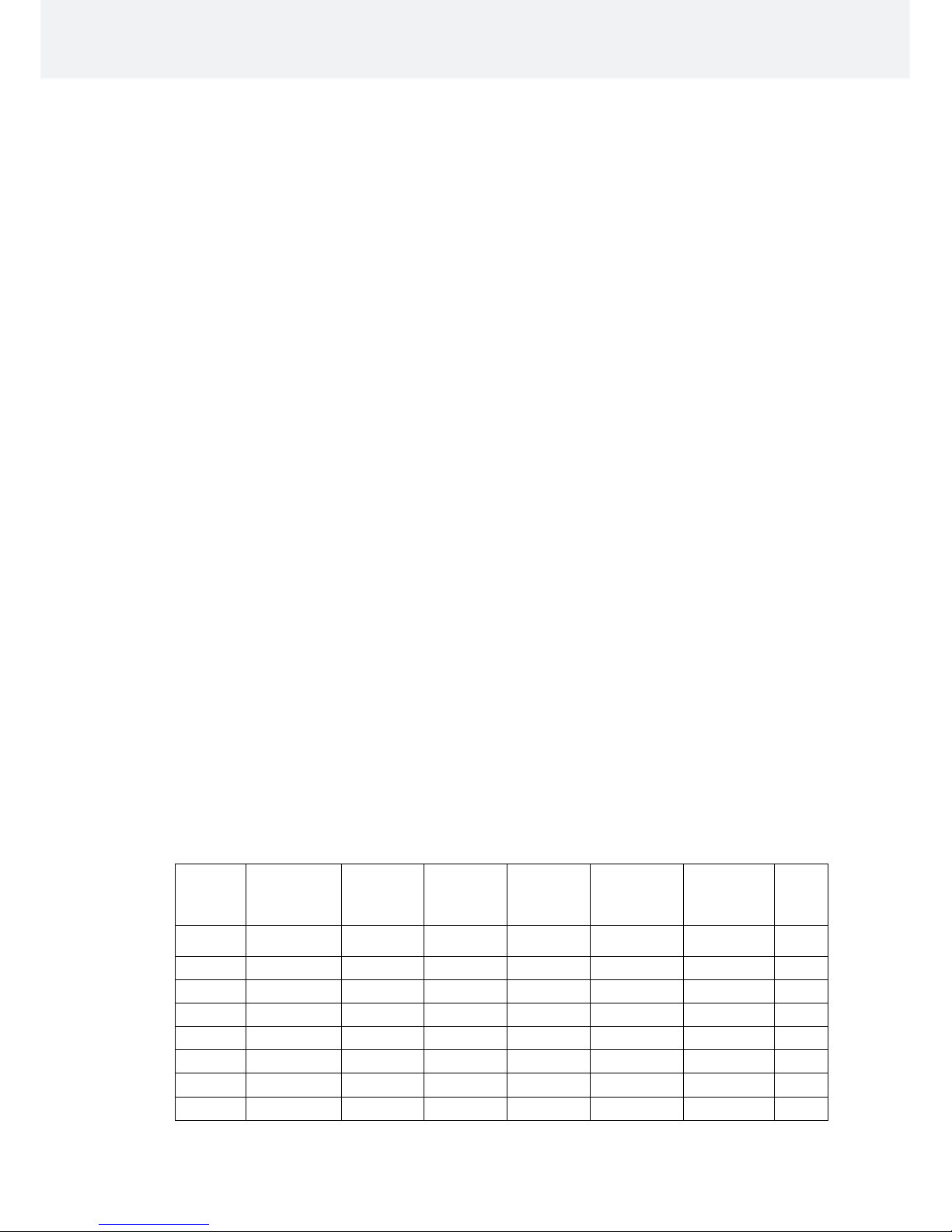

Selecting the steam generator output for the steam room

You can estimate the power requirement using the formula below.

Volume (m

3

) x K1 x K2 = Power requirement (kW)

Forced ventilation K1 = 0.75

No ventilation K1 = 0.52

Acrylic wall K2 = 1.00

Light wall: board + tile K2 = 1.25

Heavy wall: stone, concrete + tile K2 = 1.50

Very heavy wall: stone, concrete + tile K2 = 2.00

In heavy built steam rooms, it is recommended to use e.g. electric heating cable for warming the seats,

walls and floors.

Output Light struc-

ture, acrylic,

tempered

glass

Light board

wall + tile

Heavy wall,

concrete,

stone

Steam

kg / h

kW No A/C Air condi-

tioned

No A/C Air condi-

tioned

No A/C Air condi-

tioned

3,4 2 – 7 m³ 2 – 6 m³ 2 – 6 m³ 2 – 5 m³ 2 – 5 m³ 2 – 4 m³ 5

4,7 3 – 8 m³ 3 – 7 m³ 3 – 7 m³ 2 – 6 m³ 2 – 6 m³ 2 – 5 m³ 6

6,0 4 – 13 m³ 4 – 9 m³ 4 – 8 m³ 3 – 7 m³ 3 – 7 m³ 3 – 6 m³ 8

7,7 6 – 15 m³ 6 – 11 m³ 6 – 10 m³ 5 – 9 m³ 5 – 9 m³ 4 – 8 m³ 10

9,5 9 – 17 m³ 9 – 13 m³ 9 – 14 m³ 8 – 13 m³ 7 – 11 m 6 – 9 m 13

12,0 12 – 24 m³ 11 – 18 m³ 11 – 20 m³ 9 – 16 m³ 9 – 16 m³ 8 – 12 m³ 16

14,0 18 – 30 m³ 14 – 22 m³ 14 – 24 m³ 12 – 18 m³ 11 – 17 m³ 10 – 14 m³ 19

Table for selecting a steam generator based on the steam room volume and wall materials.

User and installation manual HNS–M2

3

General

HNS-M2 steam generators are only intended for use in heating spa facilities. Using steam generators in other areas

than steam rooms can damage the building's structure.

The manufacturer is not responsible for damages caused if the unit has been used incorrectly or in a manner for

which the unit was not designed for.

Water and steam pipe connections must be made prior to connecting the unit into the mains.

Due care and attention must be taken when making the connections. Proper sealing must be ensured for all

extensions. A good extension must have at least taped over threaded connections, but it is recommended that

connections are soldered.

Ventilation

It is not normally necessary to arrange ventilation for steam saunas that are used for less than two hours. steam

rooms that are used for more than two hours at a time need ventilation for functional and hygienic reasons. The

ventilation recommendation is 10 to 20 m

3

per person per hour.

If there is an empty space above the ceiling of the steam room, it must not be completely sealed off. Make at least

one ventilation hole (100 mm x 100 mm) into the empty space, on the same wall with the door.

The Supply air valve may be a hole in the bottom part of the wall with the door or a gap under the door.

The Exhaust valve is placed in the ceiling or on a wall near the ceiling as far from the supply air valve as possible,

however not above the door or the seats. The exhaust valve is connected to an air conditioning channel going

outside

Forced ventilation. If natural ventilation is not adequate (e.g. negative pressure in the room where the fresh air is

taken from), the steam room must be equipped with forced ventilation. Its output must be equivalent of 10 to20 m³ of

ventilation per person per hour.

Testing the water before using the steam generator.

The test packet that comes with the steamer includes test slips, which can be used for testing the water hardness

number as follows:

Dip the test slip in water for about 1 second, take it out and shake off the excess water. After a minute, compare the

colour code appearing on the test slip with the code key in the packet.

Test result: < 3° dH, Very soft water.

> 4° dH, Soft water, Installing the decalcification device recommended

> 7° dH, Medium-hard water, Install decalcification device and retest the water hardness.

> 14° dH, Hard water, Install decalcification device and retest the water hardness.

> 21° dH, Very hard water, Install decalcification device and retest the water hardness.

See page 9 for steam generator's operation time in hours before decalcification

The steam generator must be placed away from water and moisture (dry room). The room must be well ventilated as

the unit also produces heat. The maximum temperature of the room must not exceed 35°C. Recommended minimum

free space to sides and above the steamer is 30 cm. Adequate space for maintenance should also be planned for in

the placement of the unit. There should be a drain nearby for draining the tank.

The steam generator can be installed freestanding on the floor or on the wall using wall fittings. When using wall

fittings, ensure you use appropriate fittings and screws for the type of construction material of your walls. The steam

generator weighs about 17 kg when filled with water.

When the automatic drain valve is used, it is recommended you use wall installation so an adequate angle can be

ensured for draining of water.

User and installation manual HNS–M2

4

Image of principle of installation

1700mm

Locating the control panel Generator wall mounting

Control panel is installed inside or outside the steam room, model HNS – M2.

The cable of the control panel can be extended with an equivalent cable, max 10 m.

The On/Off push button can be used for remote starting and stopping of the steam generator, the push button can be

placed inside or outside the steam room. For more detailed instructions, see page 12

Steam nozzle/nozzles are fitted approximately 200 to 400 mm from the floor underneath a bench or a seat, or onto

the wall so that the hot steam cannot burn anyone's feet. The steam nozzles are aimed towards the floor. When the

nozzles are installed, you must ensure to place them somewhere where nobody can accidentally touch them. The

steam temperature is +100 °C and it can cause injuries on contact.

If children or people with impaired reflexes use the steam room, the steam nozzle must be fitted with a protector that

prevents people from being exposed to the hot steam shower.

Sensor. The sensor is connected with the steam generator circuit board to connectors T1 and T2 which identify it

automtically.

Sensor is installed at about 1,700 mm high, preferably on the wall opposite the door. It is recommended to seal the

sensor installation hole with appropriate sealing material, so that moisture cannot enter the wall structures.

The steam room thermometer is installed at such a height that it shows the same reading as the control panel.

Steamer connections

5

2

0

380

160

Sensor

Control panel

Water connection

Power

supply

Flushing

Steam pipe

Steam room

On/off push button

User and installation manual HNS–M2

5

Water connection, ¾”

Automated electromagnetic valve

plug (HNS-M2)

Water draining ½ ”, manual

or electric valve

Lid nut

for decalcification

Steam pipe ½”

Main switch

Control panel cable

Power supply

Water and steam pipe connections

Connect the flexible ¾” water connection tube in the packaging to the water connection in the installation panel of the

unit and to the cold water piping of the building. The water pressure must be between 0.2 and 10 bars. The water

supply pipe must have a manual stop valve for stopping water supply to the unit, if the unit is not used for a prolonged

time.

Installation must follow local regulations

It is recommended to use at least 18x16 mm (steam generator’s size 3.4 kW-9.5 kW) and 22x20 mm (steam

generator’s size 12.0 kW- 14 kW) copper pipe or a silicone tube of similar type when connecting the steam pipe. The

steam pipe diameter must be the same for the whole length.

The steam pipe must be tilted upwards or downwards from the steam generator to the steam room. There MUST

NOT be any water seals or water pockets. The condensation water forming in the steam pipe must be allowed to

drain freely to the steam room or back to the generator. If a fragrance pump is connected to the generator, the pipe

must ALWAYS drain away from the steamer, so that the chemicals cannot get into the tank.

Recommended maximum length for the steam pipe is 5 metres.

It is recommended to always use additional insulation for the steam pipe, for both safety reasons and to prevent

water condensation in the pipe.

Clearance from an uninsulated steam pipe to flammable material such as wood must be at least 10 mm.

WARNING: Hot steam can cause burn injuries.

The electromagnetic valve designed for discharging water from the steam generator tank (accessory: Automatic drain

valve) is installed on the downpipe, alternatively use manual flushing valve. Connect the downpipe (copper pipe with

a minimum diameter of 16 mm) to the downpipe of the steam generator. The downpipe is led to the nearest drain

outside the steam room. The temperature of the discharge water is 90–95 C.

IMPORTANT! No stoppers (valves, taps, etc.) may be fitted on the downpipe.

Regardless of where the downpipe is led, it must fall all the way from the steam generator to the drain. To ensure

adequate fall, you may have to place the steam generator on a wall mount or on a stand.

The steamer generator’s tank should be drained after each use. This extends the life cycle of the appliance

and reduces scaling and the need for repair.

The product’s warranty will be void if the steam generator has been incorrectly installed or it has been used

in a manner other than described in the user manual.

The warranty also expressly excludes operational faults if they are caused by hard water i.e. water with high

levels of chalk, or otherwise impure water.

The steam generator must be maintained as described in the user manual.

User and installation manual HNS–M2

6

Loading...

Loading...