Hellenbrand TNT User Manual

TNT SERIES

WATER CONDITIONERS

For Commercial & Industrial Applications

Apartment Buildings

Boiler Water Treatment

Car Washes

Commercial Buildings

Condominiums

Factories

Hospitals

Laundries

Mobile Home Parks

Motels and Hotels

Nursing and Rest Homes

Ofce Buildings

Restaurants

Schools

Hellenbrand Means

Quality and Reliability

Since 1967, Hellenbrand Water Conditioners, Inc. has provided water solutions to the water treatment industry in the

U.S. and around the world. We have developed a complete line of high quality products. An excellent example of this,

is the Hellenbrand TNT Series Conditioners.

TNT Series Conditioners use a anged top-mounted or optional side-mounted adapter, three-inch NPT inlet and outlet

solid brass control valve with a motor-driven, time-tested, hydraulically-balanced piston with a seal and spacer concept

to pilot service ow not dependent on water pressure. No diaphragms to rupture or false transfer. It will provide up to

170 gpm hard water by-pass during regeneration, or you may have the optional “no hard water by-pass piston” for twin

or multiple systems. These high service ow rates, the simplied alternating and multiple lockout systems, eliminate the

need for diaphragms, solenoids and stagers. The ve cycle TNT controller is available with either downow (co-current)

or upow (counter-current) brining, with easy adjustable cycle times. The TNT Series offers you a choice of mechanical

or microprocessor controlled meter demand systems, with two-inch or three-inch meter turbines. All systems are factory-wired and tested electrically to assure easy installation and correct operation.

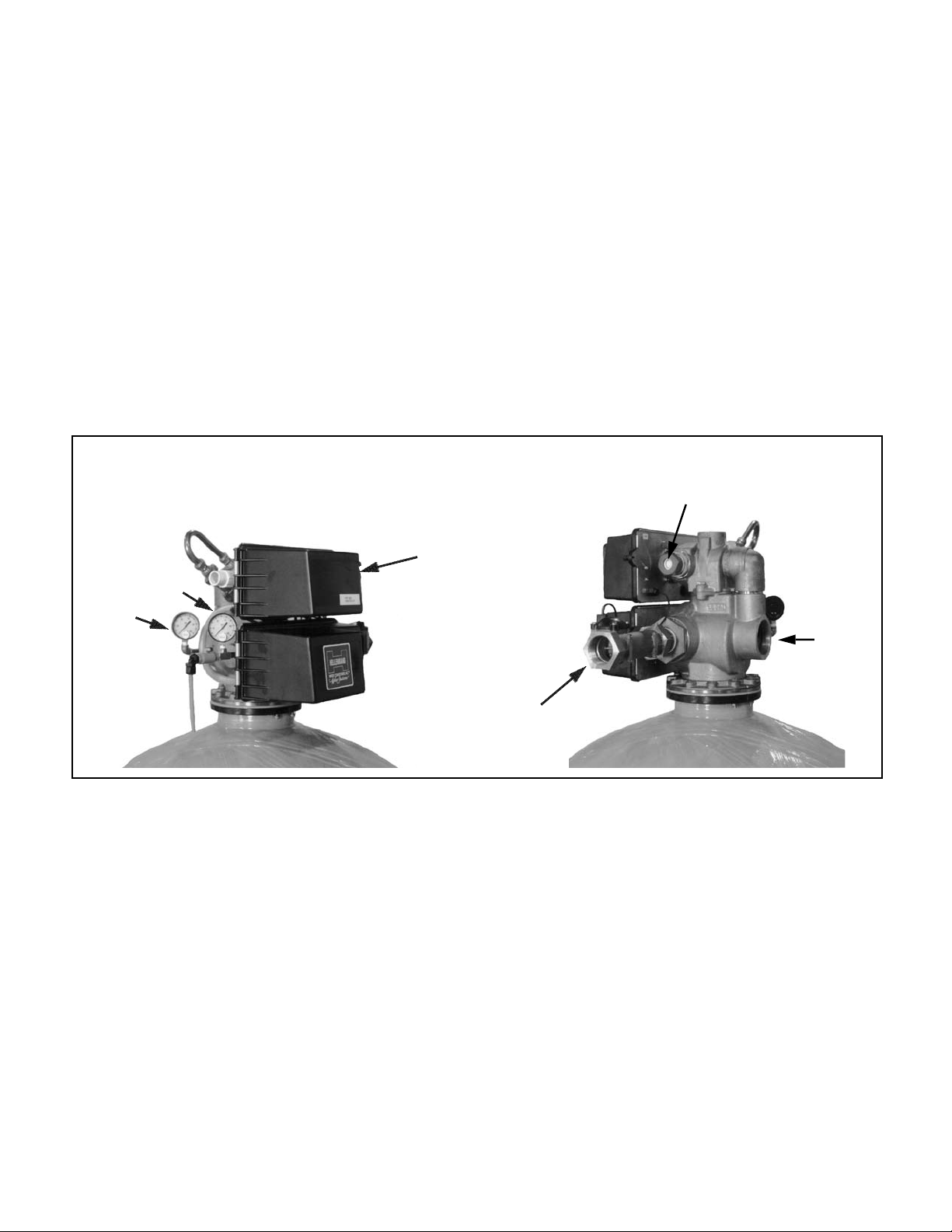

FRONT VIEW

Optional Inlet & Outlet Pressure Gauges & Soft Water

Test Port

Controller

Outlet

Inlet

Optional Factory Installed Vacuum

Breaker

Optional

2” Meter Outlet

BACK VIEW

TNT Series Control Valve -Three Inch Inlet/Outlet

1. Stainless Steel Backplate will not rust or corrode.

2. Factory provided Drain Line Flow Control maintains

accurate backwash rates.

3. Three-Inch NPT Inlet & Outlet Connections.

4. Solid Brass Valve assures durability and long life.

5. Hydraulically-balanced Piston, Seal, and Spacers.

Lower service piston is available with or without hard

water by-pass. Non-sticking Teon-coated Piston al-

lows foreign particles to pass through without damaging

the unit.

6. Upper Piston pilots the regeneration steps of backwash,

brine and slow rinse, fast rinse, and brine tank rell.

7. Separate “Time-ll” Brining with accurate ow controls

allows automatic brine tank rell. Brine Tank Rell

Rates are easily adjustable on the cycle programmer. No need to worry about adjusting oat valves or

repositioning brine plugs for salt measurements.

8. Heavy-duty Drive Motor receives signal from timer

to efciently direct water ow during regeneration.

Piston shifts smoothly and quietly regardless of water

pressure.

9. Lower Heavy-duty Drive Motor receives signal from

upper drive motor to direct the service piston into position. Piston shifts smoothly and quietly regardless of

water pressure.

10. TNT Series Timer provides fully automatic, dependable timing for regeneration. The Cycle Programmer

regulates all regeneration cycles which are easily

adjustable. For manual regeneration start, simply turn

the service indicator clockwise.

Inlet

TN2 Standard System Design Options

(for more specic information on the various system designs, contact your local Hellenbrand representative or go to: www.hellenbrand.com

1. Single Tank Systems - XT Controller

• Time Clock

• XT Controller Electronic Meter Demand

Twin, Tri-Plex & Four-Plex Systems - 3200NXT Controller

2.

Parallel Operation

• 2-4 Units

• Individual Meters

• Single or Individual Brine Systems

Alternating Operation

• 2-4 Units

• Twin Systems - One Meter or Two Meters

• Tri-Plex & Four-Plex Systems - Individual Meters

• Single or Individual Brine Systems

3200NXT Electronic Controller

The 3200NXT Network Controller uses on-board communications capabilities to link multiple valves (via off-the shelf CAT3,

CAT5, or better cables) for a variety of multiple system types as

described above.

Program Features:

• 2x16 character backlit LCD display

• Networks up to four units

• Auxiliary inputs and outputs

- Remote signal start input

- Remote lockout input

- Programmable relay output/chemical pump output

• Easy installation with plug-in wiring harnesses

• Front panel diagnostics button

- Flow rate

- Peak ow rate

- Totalizer

- Hours between last two regenerations.

- Hours since last regeneration

- Adjustable volume remaining

- Valve position

3. Twin, Tri-Plex & Four-Plex Demand Recall Progressive

Systems - 3214NXT Controller

• 2-4 Units

• Individual Meters

• Single or Individual Brine Systems

Three programming levels

• User mode

• Master programming

• Diagnostics mode

Note: The 3214NXT Demand Flow Network Controller is

used for demand recall applications.

3214NXT Demand Flow Network Controller

The 3214NXT Demand Flow Network Controller can be pro-

grammed to bring multiple units to the service position and back

to standby based on system demand ow. The 3214NXZT Demand Flow Network Controller used on-board communication

capabilities to link multiple valves via standard CAT3, CAT5, or

better communication cables.

Program Features:

• Network two to four valves

• Simple, on-site network programming

• Easy installation with plug-in wiring harnesses

• Shift key allows digit selecting in programming

• 2x16 character LCD backlit display

(letter or digit codes not needed)

• Valve, piston, and cam type default storage

• User and master programming modes

• Diagnostic mode:

- Current ow rate

- Peak ow rate (can be reset)

- Totalizer (can be reset)

- Hours between last two regenerations

- Hours since last regeneration

- Volume remaining (adjustable)

- Valve addresses

Three programming levels

• User mode

• Master programming

• Diagnostics mode

Mechanical or Electronic Meter/Turbine Options:

Size Flow Ranges Accuracy

1.5” CC Meter 0.5 – 60 GPM +5%

2” CC Meter 1.5 - 150 GPM +5%

Loading...

Loading...