Hellenbrand ProMate-1 User Manual

Owner’s Manual

Manufactured by:

HELLENBRAND, INC.

404 Moravian Valley Road • PO Box 187

Waunakee, Wisconsin 53597

Phone: 608-849-3050 • Fax 608-849-7398

Web: www.hellenbrand.com • Email: info@hellenbrand.com

©2002,2003,2004

This owner’s manual is designed to assist owners and installers with the operation, maintenance and installation of your new water

softener. It is our sincere hope that this manual is clear, concise and helpful to both owner and installer. We have included detailed

instructions on general operating conditions, pre-installation and installation instructions, start-up, and timer and meter programming.

We have included a troubleshooting guide, service instructions and parts diagrams to assist you.

Owners will appreciate the simplified, illustrated format for operation, programming and troubleshooting. In the event that you

need professional assistance for servicing your water softener, please contact the dealer who installed this system.

TABLE OF CONTENTS

Frequently Asked Questions ..................................................................................................................................................................2

Job Specification Sheet............................................................................................................................................................... Page 3

Soft Water B a s i c s ...................................................................................................................................................................................4

Operating Conditions ..............................................................................................................................................................................4

Pre-Installation Check List .....................................................................................................................................................................5

Installat i o n I n s t r u c t i o n s ...........................................................................................................................................................................6

Programming .................................................................................................................................................................................... 7-11

Water Softener Disinfection .................................................................................................................................................................12

Water Softener Draining Procedure.....................................................................................................................................................12

Trouble Shooting ............................................................................................................................................................................ 13-14

Parts Diagrams ............................................................................................................................................................................... 15-20

Specifications ................................................................................................................................................................................. 21-23

Warranty ...............................................................................................................................................................................................24

FREQUENTLY ASKED QUESTIONS

1. Do I still use the same amount of soap in the dishwasher and clothes washer and showers now that I have a water

softener? No, the Water Quality Association states soft water can save up to 55% on detergent use. Start with using half the

amount of detergent previously used, this can be adjusted up or down based on preference. Soft water helps fabrics last longer,

because hardness minerals combined with soap can make fabric fibers brittle.

2. What is the health impact of drinking soft water? The sodium added to water by a softening is a non-issue most of the time,

even for people on a sodium-restricted diet. One could soften up to 75 grains per gallon water with sodium chloride and still be

well with the US Food and Drug Administration’s labeling of a “Low Sodium” beverage. People on a sodium-restricted diet should

consult their physician.

3. Should I use soft water for my plants? Some plants may be sensitive to even minute amounts of sodium. Suggest using hard

water for watering plants, often a kitchen cold faucet is plumbed for hard water or the outside faucets are usually plumbed for hard

water. If not, you can place your softener on bypass and fill water containers at the closest sink. Water from a reverse osmosis

system can always be used to water plants.

4. Will water spots disappear now that I have soft water? Water spots caused by hardness scale will disappear with a function-

ing water softener. However, other natural minerals dissolved in the water in high enough concentrations may cause spotting.

These mineral spots will be much easier to wipe away compared to hardness spotting.

5. Will soft water cause my water or ice cubes to look or taste different? Most people can tell the difference in taste between

hard and soft water, it is a personal preference. Ice cubes will appear the same, they may look cloudy due to air in water or

dissolved minerals, and this will not change because now they are made with softened water. A reverse osmosis drinking water

system will provide clearer ice cubes.

Dealer Name _________________________________________ Phone ________________________________________

Address ______________________________________________________________________________________________

_____________________________________________________________________________________________

2

JOB SPECIFICATION SHEET

MODEL NO. ___________________________________________________________________________________________

*WATER TEST AT TIME OF INSTALLATION

_______ Hardness CaCo

_______ Iron (ppm) ______ Other______________________

_______ pH ______ Other______________________

*SIZING INFORMATION

All Water is Softened Except:

_______ Rear Hose Bib _______ Front Hose Bib _______ Kitchen Cold_______ Toilets _______ All Cold

_______ Other _________________________________________________________________________________________

The average family uses 75 gallons per person daily for all water uses in the home, about 50 gallons per person daily if soft water

is not supplied to the toilets, and about 30 gallons per person daily if only hot water is softened.

_______ Daily Water Usage (Gallons/Person)

x _______ Family Size (Number of people in family)

= _______ Total Gallons Per Day

x _______ Grains Per Gallon of Hardness

(Note: Add 3 grains per gallon of hardness for each ppm iron for total compensated hardness)

= _______ Total Grains Per Day

*INSTALLATION DATE __________________________________________________________________________________

*SERIAL NUMBER _____________________________________________________________________________________

(gpg) ______ Other______________________

3

NOTES ______________________________________________________________________________________________

______________________________________________________________________________________________________

3

SOFT WATER BASICS

Hardness

Excess amounts of calcium and magnesium in water produce

hardness. A water softener removes the majority of calcium

and magnesium to produce softened water.

Hardness is measured in terms of grains. (This grain

weight is derived from the average weight of a dry grain of

wheat.) When your water is tested the grain hardness is

calculated and expressed as grains per gallon (gpg). This

calculation, as well as the number of people in your household

will help determine what type and size of water softener will

most efficiently soften your water.

Your water softener contains an ion exchange

media (sometimes called resin) which removes the hardness

from water as it flows through the softener tank. Eventually so

much hardness collects on the exchange media that the softener can no longer soften water. At this point it is considered

"exhausted". Regeneration is now necessary.

Regeneration

To regenerate the exchange media, it must be rinsed with a

brine (salt) solution. This removes the hardness from the exchange media and replaces it with sodium. The exchange media

is then ready to remove hardness from water. The hardness

minerals and excess brine solution are rinsed down the drain.

During the regeneration cycle the softener is also

backwashed. This reversing of the normal flow of water serves

to remove sediment which may have accumulated during the

softening process due to the filtering action of the exchange

media. Backwashing also loosens and fluffs up the bed of

exchange media to insure that during regeneration the brine

solution will come into contact with all the media.

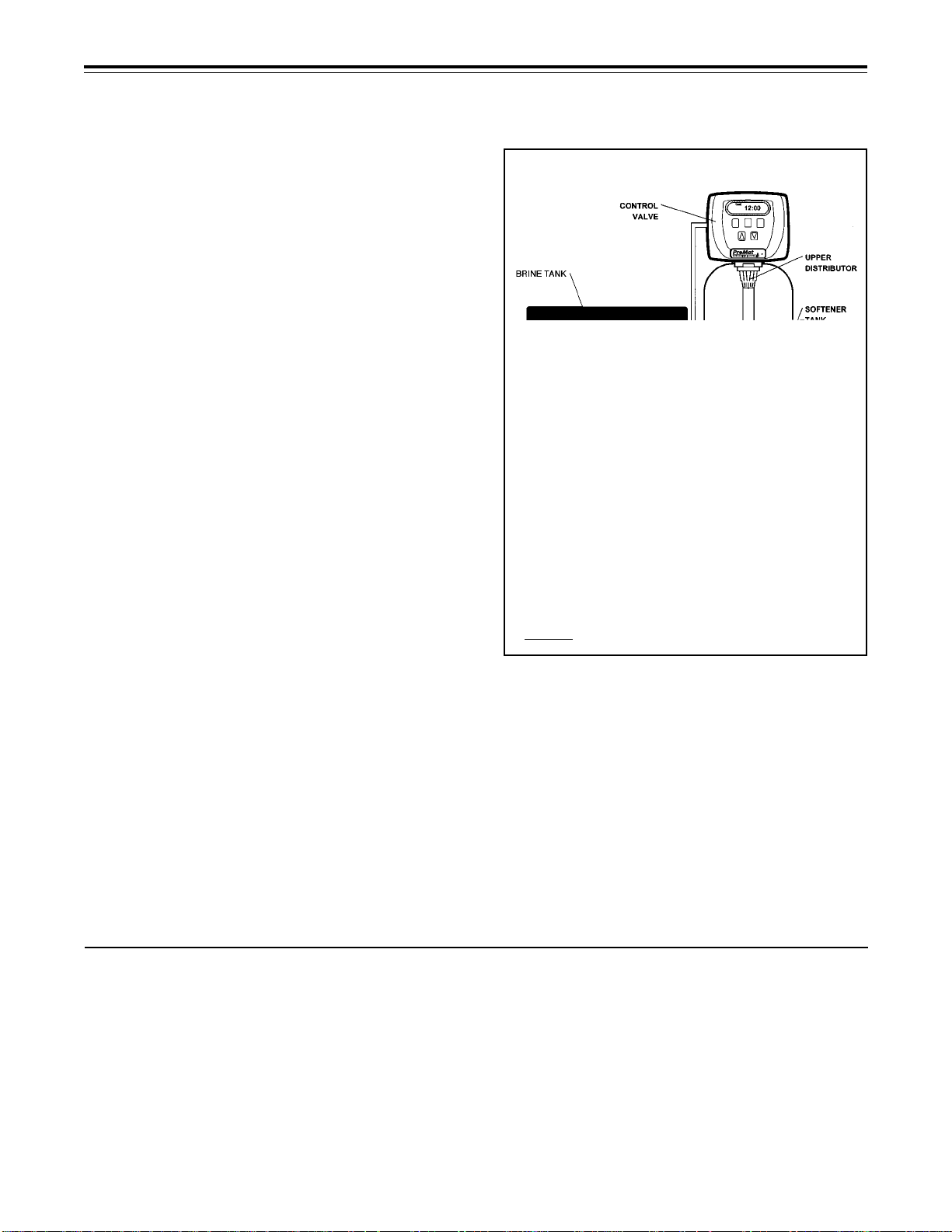

Figure 1

Maintenance of Your Softener

Salt: Salt to a softener is what gasoline is to a car. Not only must a softener have salt, but it should be the proper type to insure

efficient recharging of the unit. Ask your dealer what type of salt may best suit your needs. Always have an adequate supply of salt on

hand. Check the salt level of your brine tank every couple of weeks initially to determine how much salt you use - this will depend on

how much water you use. As a rule of thumb, with 20 gpg hard water, about a 1/2 lb. of salt per person per day is used. In other words,

a family of four uses 60 lbs. of salt a month. If your household does not use much water, do not fill your salt keeper over 1/2 full, salt

bridging may occur in the brine tank. This may result in hard water due to ineffective regeneration. Fill the tank approximately threefourths full, with a minimum of 12” of salt. DO NOT USE Block Salt when the ProMate control is programmed with a brine tank prefill.

Block salt does not dissolve quick enough to provide a good regeneration.

Cleaning Salt Keeper: Salt keeper may require periodic cleaning. Inspect the salt keeper at least once a year for buildup of

insoluble materials. It is recommended to periodically clean the salt keeper no matter what kind of salt you are using. See page 9,

miscellaneous #3 for details on cleaning.

REMEMBER: Salt is the fuel to run your water softener. Buy the best clean salt available.

OPERATING CONDITIONS

Your water conditioner has been designed to adequately

handle up to 100 grains per gallon of hardness that might be

encountered as well as up to 2 ppm of Ferrous Bicarbonate

Iron. This is iron that is dissolved in an oxygen-free water supply.

It is not visible to the eye in a freshly drawn sample because the

water appears clear. But upon standing in contact with air, the

ferrous iron will become oxidized to the ferric state and start to

precipitate as a reddish brown floc. It can then be seen and if

allowed to remain in the supply will cause discolored water. In

order for your conditioner to remove the iron, air (oxygen) must

be kept from coming in contact with water until after it has been

passed through the water conditioner. In some cases, additional

equipment may be required to treat water supplies having

special characteristics, such as: ferric hydroxide iron, iron bacteria, low pH, taste and odors, etc. If any question should exist,

contact your dealer.

This water softener is not intended to be used for treating

water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after treatment.

4

PRE-INSTALLATION CHECK LIST

(All electrical & plumbing should be done in accordance to all local codes)

Water Pressure: A minimum of 20 pounds of water pressure

(psi) is required for regeneration. Maximum 120 psi.

Water Quality: On rural water supplies there is often a problem

with sand or sediment in the water. (This problem occasionally

occurs in public water supplies.) If the water is not filtered

before being softened, the sand and sediment will plug up the

water softener restricting the flow through the resin bed. This

problem often requires rebedding of the mineral tank. Note:

Well and/or pump problems affecting the operation of the

softener are repairs that are not covered under warranty. To

prevent these unnecessary, and expensive repairs that are not

covered under warranty, we recommend the installation of an

in-line filter system ahead of softener installations.

Electrical: A continuous 110 volt 60 cycle current supply is

required.

cannot be turned off with another switch. All electrical connections

must be connected per local codes.

recommended with all electric controls.

Existing Plumbing: Condition of existing plumbing must be

Make certain the current supply is uninterrupted and

Surge protection is

free from lime and iron build-up. Piping that is built-up heavily

with lime and/or iron must be replaced. If piping is blocked with

iron, additional equipment must be installed ahead of the water

conditioner to correct the problem.

Drain Line: The conditioner should be located close to a drain.

Avoid overhead drain lines if possible to prevent back pressure

on the brine injector. Overhead drains are not to exceed 8 feet

above the floor and no more than 20 feet in length. The pipe

size for the drain line should be a minimum of 3/4”. Backwash

flow rates in excess of 7 gpm or length in excess of 20’ require

1” drain line.

Bypass Valves: Always provide for the installation of a bypass valve.

Softening: It is recommended that the conditioner be installed

to soften both the hot and cold water supply. A separate hard

water faucet may be plumbed for drinking purposes if you

desire. Outside faucets should be left on hard water.

Caution: Water temperature is not to exceed 110°F; the

conditioner cannot be subject to freezing conditions, or to a

vacuum due to loss of pressure (such as a water main break).

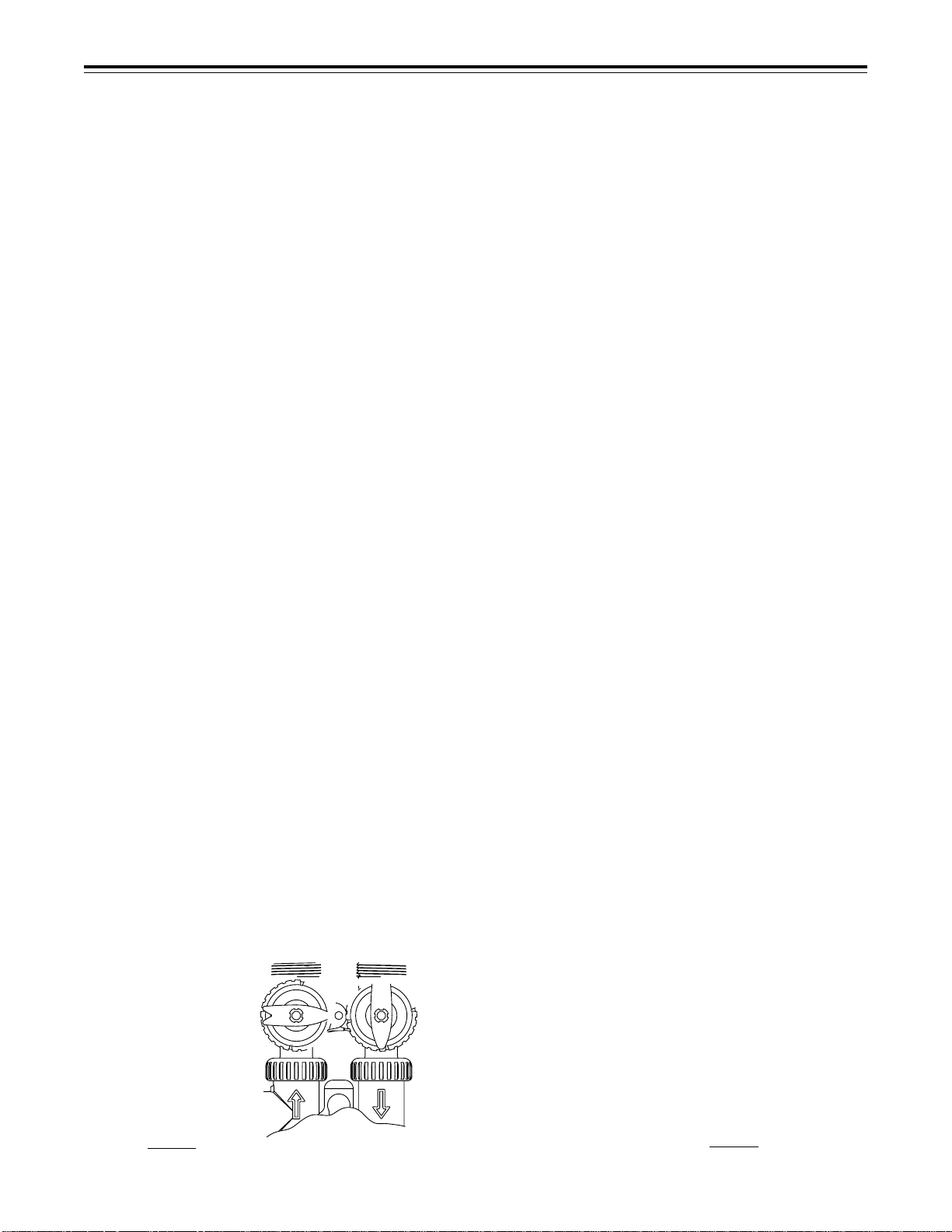

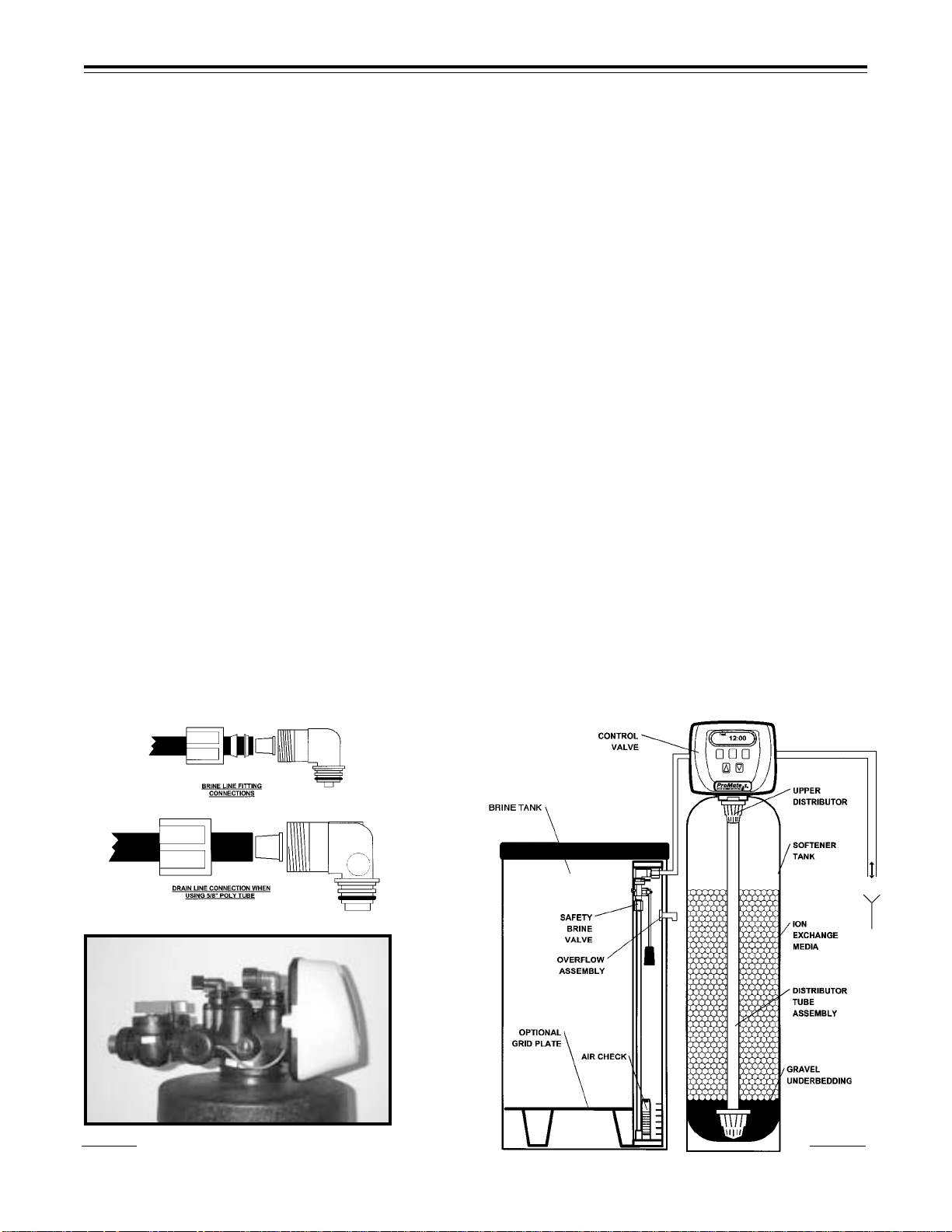

Figure 4

Figure 5

5

INSTALLATION INSTRUCTIONS

(All electrical & plumbing should be done in accordance to all local codes)

• Do not use vaseline, oils, other hydrocarbon lubricants or

spray silicone anywhere. A silicon lubricant may be used on

black o-rings but is not necessary. Avoid any type of

lubricants, including silicone, on red or clear lip seals.

• Do not use pipe dope or other sealants on threads. Only

teflon tape may be used on threads. Teflon tape is not

necessary on the nut connection or caps because of o-ring

seals.

• The pipe size for the drain line should be a minimum of 3/4”.

Backwash flow rates in excess of 7 gpm or length in excess

of 20’ require 1” drain line.

1. Place the conditioner where you want to install it, making

sure it is on a clean, level and firm base.

2. Do all necessary plumbing (inlet to inlet, outlet to outlet and

drain line to drain). The control valve, fittings and/or bypass

are designed to accommodate minor plumbing

misalignments but are not designed to support the weight of

a system or the plumbing.

3. When assembling the installation fitting package (inlet and

outlet), connect the fitting to the plumbing system first and

then attach the nut, split ring and o-ring. Heat from soldering

or solvent cements may damage the nut, split ring or o-ring.

Solder joints should be cool and solvent cements should be

set before installing the nut, split ring and o-ring. Avoid

getting primer and solvent cement on any part of the o-rings,

split rings, bypass valve or control valve.

4. A jumper ground wire should be installed between the

inlet and outlet pipe whenever the metallic continuity of

a water distribution piping system is interrupted. Install grounding strap on metal pipes.

5. The drain connection may be made using either 5/8” polytube

(See figure 6a, page 5) or a 3/4” female adapter. If

soldering, joints near the drain must be done prior to

connecting the drain line flow control fitting. Leave at least

6” between the drain line control fitting and solder joints

when soldering pipes that are connected on the drain line

control fitting. Failure to do this could cause interior damage

to the drain line flow control fitting.

6. The brine refill flow control assembly is installed in an easy

to access refill elbow located on top of the control valve. The

refill flow control assembly is attached to the control valve

with a locking clip. The locking clip allows the elbow to

rotate 270 degrees so the outlet can be orientated towards

the saltkeeper.

7. Connect the brine line found in the brine tank to the brine

connection on the control valve. The control valve has a

standard refill elbow which a 3/8” flexible tube can be

connected, see figure 6a, page 5. (An optional elbow can

be ordered which accommodates a 1/2” flexible tube for a

high regenerant draw rate situation). Both elbows use the

same refill flow control and retainer. Do not connect the

other end of the brine line to the safety brine valve in the

brine tank at this time. Make sure the floor is clean beneath

the salt tank and that it is level and smooth.

8. A 1/2” (inside diameter) gravity drain line may be connected

to the overflow fitting on the side of the brine tank. This

overflow is in case of a malfunction in the brine shut off. If

the unit is installed where water may flow in the event of an

overflow and cause water damage, connect a length of

flexible tubing and run to a drain below the level of the

overflow. (Do not connect the tubing to the drain line on

the control valve. Do not run tubing above overflow

height at any point.)

6

Figure 6a

1”

Drain

Connection

Brine Line

Connecton

Figure 6b

PROGRAMMING

Initial Start Up

The initial start up will probably be done by the technician

installing the softener system. If not, the following instructions

will step you through the process.

1. Complete all plumbing connections: inlet, outlet, drain

line and brine line. Do not add salt at this time.

2. Place the bypass valve in the bypass position. (See

figure 3 page 4) Turn on the main water supply. Open

a cold soft water faucet to flush the piping of any air

and/or foreign material. Run until the water is clear.

3. Manually add 6 inches of water to the brine tank.

4. Now plug the transformer into a 110-volt receptacle.

(Be certain the outlet is uninterrupted.) Within 5

seconds the control will automatically align itself into

the softening mode and the display will flash 12:00 (am).

(Figure 7, page 6).

5. Set the time of day. (figure 8, page 7)

6. Push REGEN button and hold it down for 3 seconds.

The system will advance to the “First” position. (Note:

Depending on how the system is programmed it could

read backwash, rinse, brine or fill). Keep pushing

REGEN button until “Rinse” shows in the lower right

hand corner of display. Slowly place the by-pass into

the “diagnostic mode” (see fig 4, page 5). Run water

to the drain until it runs clear. Return the by-pass valve

to the by-pass position (fig 3, page 5). Push REGEN

button until “Time” appears in upper left hand corner

of display.

7. Once again, push REGEN button and hold down for 3

seconds. Keep pushing REGEN button until “Backwash” appears. Slowly place the by-pass valve into

the “Diagnostic Mode” 1/2 way. Allow water to slowly

fill the mineral tank. When a solid stream of water

starts coming out of the drain line, open the by-pass

inlet valve all the way and allow to run out the drain

until water clears. Then slowly place the by-pass into

the “normal operation” mode by opening the outlet

side of by-pass valve, figure 2, page 4.

8. Press the regen button until LED display says “BRINE”.

7

➔

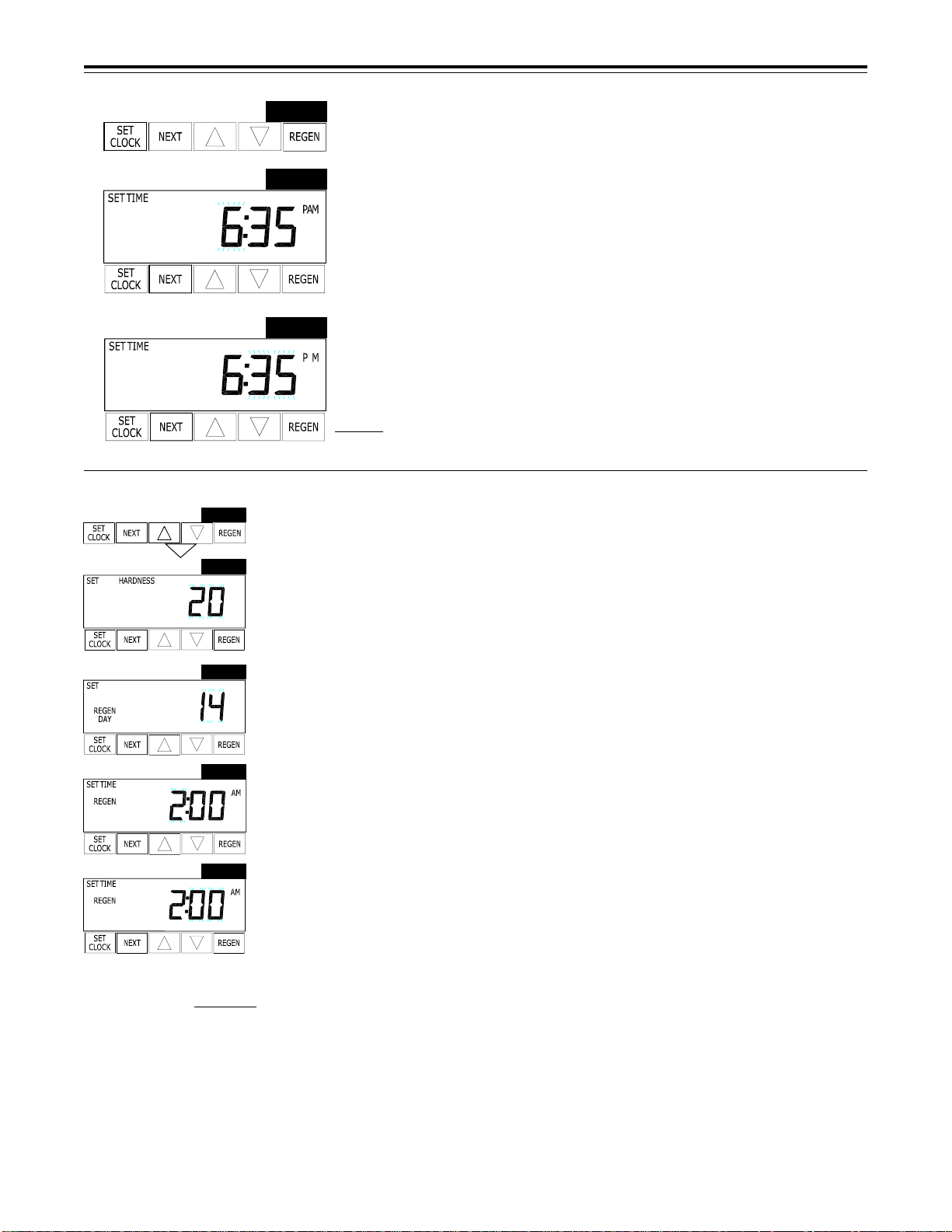

STEP 1

SET TIME OF DAY

➔

➔

➔

STEP 1

STEP 2

STEP 3

STEP 2

STEP 3

Figure 9

Step 1 - Press SET CLOCK.

Step 2 - Current Time (hour): Set the hour of the day using ▲ or ▼ buttons. AM/

PM toggles after 12. Press NEXT to go to step 3.

Step 3 - Current Time (minutes): Set the minutes of day using ▲ or ▼ buttons.

Press NEXT to exit Set Clock. Press REGEN to return to previous step.

Power Loss - If the power goes out for less than two hours, the system will

automatically reset itself. If an extended power outage occurs, the time of day

will flash on and off which indicates the time of day should be reset. The system

will remember the rest of the program settings. Do not forget to reset for daylight

savings time.

INSTALLER DISPLAYS/SETTINGS

Step 1 - Press NEXT and ▲ simultaneously for 3 seconds.

Step 2 - Hardness: Set the amount of total compensated hardness in grains (hardness as

calcium carbonate) per gallon using ▲ or ▼ buttons. The default is 20 with value ranges from 1 to

150 in 1 grain increments. Note: The grains per gallon should be increased if soluble iron needs

to be reduced. Add 3 grains of hardness for each ppm of iron present. If this display shows nA , then system is either set-up in “time clock” or “filter” modes. (See page 23). Press NEXT to go to

Step 3. Press REGEN to exit Installer Displays/Settings.

➔

➔

➔

RETURN TO

NORMAL MODE

STEP 4

STEP 5

Figure 10a

Step 3 - Day Override: This sets the number of days between regenerations. If value set to

“oFF” regeneration initiation is based solely on gallons used. If value is set as a number (allowable range from 1 to 28) a regeneration initiation will be called for on that day even if sufficient

number of gallons were not used to call for a regeneration. Set Day Override using ▲ or ▼

buttons:

• number of days between regeneration (1 to 28); or

• “oFF”

See figure 12a & b, page 10-11, for more detail on softener setup. Press NEXT to go to step 4.

Press REGEN to return to previous step.

Step 4 - Next Regeneration Time (hour): Set the hour of day for regeneration using ▲ or ▼

buttons. AM/PM toggles after 12. The default time is 2:00 a.m. This display will show “REGEN”

on 0 GAL if system is set for immediate regeneration. See table 6, page 19. Press NEXT to go to

step 5. Press REGEN to return to previous step.

Step 5 - Next Regeneration Time (minutes): Set the minutes of day for regeneration using ▲ or

▼ buttons. This display will not be shown if system is set for immediate regeneration. Press

NEXT to exit Installer Displays/Settings. Press REGEN to return to previous step.

8

Loading...

Loading...