Hellenbrand Iron Storm 10, Iron Storm 12, Iron Storm 13 User Manual

STO

RM

ProMate-6.0 Iron Curtain Storm Series

404 Moravian Valley Road • Waunakee, Wisconsin 53597

www.hellenbrand.com • info@hellenbrand.com

Consumer’s Filter Manual

p/n 111701 Rev. B

Updated 10/30/17

© 2017

Manufactured by:

HELLENBRAND, INC.

This owner’s manual is designed to assist owners and

of your new water lter. It is our sincere hope that this manual is clear, concise and helpful. Detailed instructions

on general operating conditions, pre-installation and installation instructions, start-up, and meter programming are

included. We have included a troubleshooting guide, service instructions and parts diagrams to assist future needs.

In the event that you need professional assistance for servicing your water lter, please contact the dealer

who installed this system.

installers with the operation, maintenance and installation

TABLE OF CONTENTS

General Specications..............................................................................................................................................3

Pre-Installation Check List ........................................................................................................................................ 4

Bypass Valve Operation ...........................................................................................................................................4

Startup Instructions...................................................................................................................................................5

Operating Conditions ................................................................................................................................................ 5

Specications ...........................................................................................................................................................5

Programming ............................................................................................................................................................6

Displays/Settings ......................................................................................................................................................6

Set Time of Day ........................................................................................................................................................7

Trouble Shooting ......................................................................................................................................................8

Ozone Trouble Shooting ...........................................................................................................................................8

Parts Diagrams & Installation Fittings..................................................................................................................9-13

Recommended Annual Maintenance...................................................................................................................... 14

Air Regen Specications ........................................................................................................................................15

Warranty .................................................................................................................................................................16

Dealer Name __________________________________________________ Phone _______________________________

Address _______________________________________________________ Email ________________________________

____________________________________________________________________________________________

2

GENERAL SPECIFICATIONS

OPERATING PRESSURES

Minimum/Maximum ................................................................................................................ Minimum 25 psi

Optimum Range 40-65 psi

Maximum 100 psi

OPERATING TEMPERATURES

Minimum/Maximum ................................................................................................................ 40º - 110º F

METER

Accuracy ................................................................................................................................±5%

Flow Rate Range ...................................................................................................................0.25 - 27 GPM

Gallon Range .........................................................................................................................20 - 50,000

DIMENSIONS

Drain Line ............................................................................................................................... 3/4” or 1” NPT

Ozone Check Valve ................................................................................................................3/8” Poly Tube

ELECTRICAL CURRENT DRAW AND VOLTAGE .............................................................................. 2.0A/120V

NOTE: Operating outside of the optimum pressure range may affect system function. Contact your Hellenbrand

support team for information.

3

PRE-INSTALLATION CHECK LIST

(All electrical & plumbing should be done in accordance to all local codes)

Storm is limited to indoor installations

Water Pressure: A minimum of 25 pounds of water pressure

(psi) is required for regeneration. Maximum pressure 100 psi.

Water Quality: On rural water supplies there is often a problem

with sand or sediment in the water. (This problem occasionally

occurs in public water supplies.) Sand and sediment may plug

the lter, restricting the ow through the media bed. Note: Well

and/or pump problems affecting the operation of the lter and

repairs are not covered under the warranty.

Electrical: A continuous 110 volt/60 cycle current supply is

required. Make certain the current supply is uninterrupted and

cannot be turned off with another switch. All electrical connections must be connected per local codes. Surge protection is

recommended with all electrical controls.

Existing Plumbing: Condition of existing plumbing must be

free from lime and iron build-up. Piping that is built-up heavily

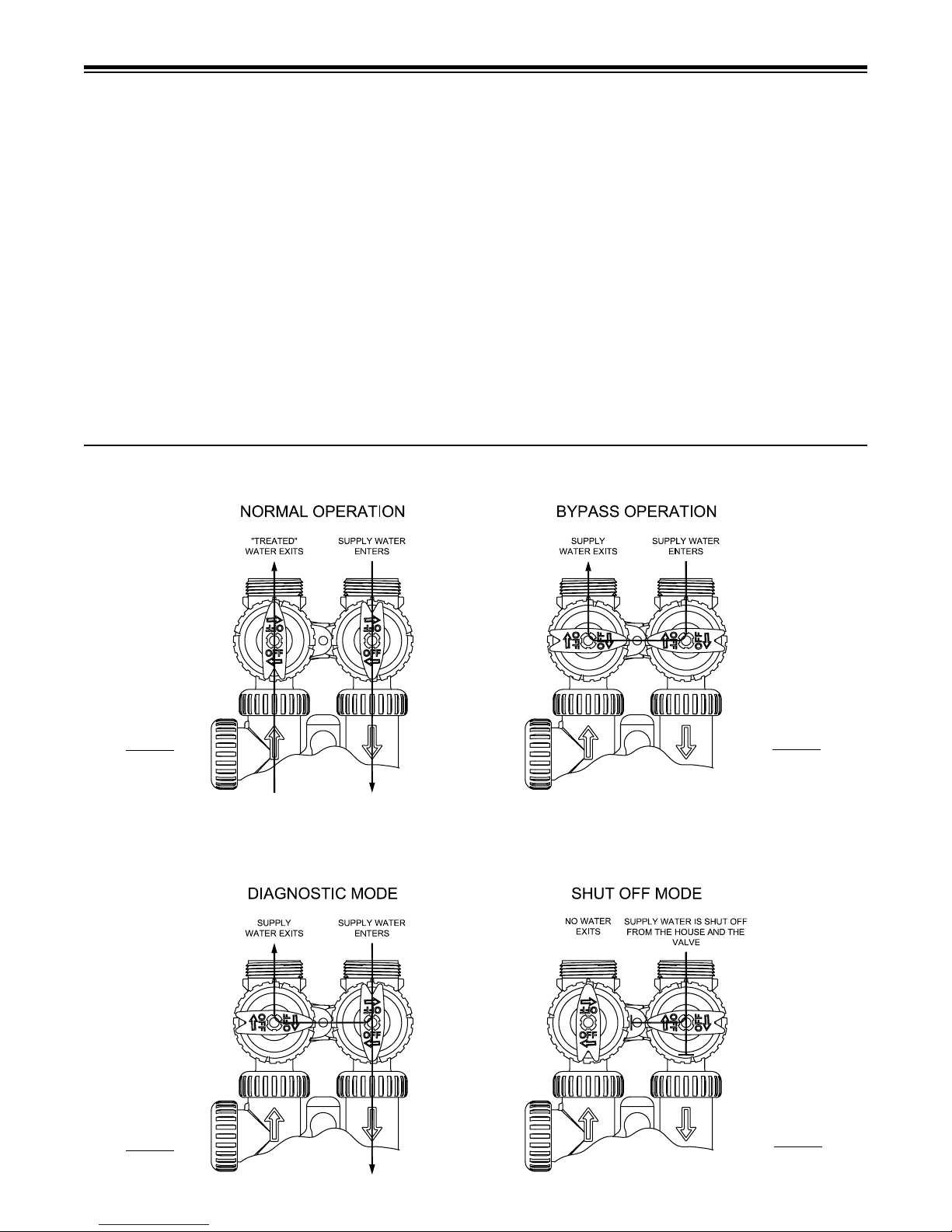

BYPASS VALVE OPERATION

Softening - Filtering

with lime and/or iron must be replaced. If piping is blocked with

iron, additional equipment may be needed ahead of the lter to

correct the problem.

Drain Line: The lter should be located close to a drain. Avoid

overhead drain lines if possible to prevent back pressure. Overhead drains are not to exceed 8 feet above the oor and no more

than 20 feet in length. The pipe size for the drain line should be

a minimum of 3/4”. Backwash ow rates in excess of 10 gpm

or length in excess of 20’ require 1” drain line.

Bypass Valves: Always provide for the installation of a bypass

valve.

Caution: Water temperature is not to exceed 110°F; the lter

cannot be subject to freezing conditions, or to a vacuum due to

loss of pressure (such as a water main break).

Figure 1

Figure 3

Figure 2

Figure 4

4

Start Up Instructions

For optimal results, allow the lter media to soak for a

minimum of 12 hours prior to install. This

tain the manufacturer’s specied

1. Complete all plumbing connections; inlet, outlet and drain

line.

2. Place bypass valve in bypass position. Turn on main

water supply and open a cold ltered faucet to ush piping

of any air and/or foreign material. Run until water is clear.

3. Open inlet valve slowly on bypass until it is in fully open

service position. Let water run to drain until

unit into 120V outlet and remove cover and plug transformer connection into 4-prong connection

labeled power. Valve will return to service position once

this connection is made.

4. Let media soak for 15 minutes before proceeding.

ltration properties.

helps to main-

clear. Plug

on circuit board

Operating Conditions

pH — The pH level of the inuent water must be 7.0 or higher

for iron oxidation reaction to proceed per the engineering

specications.*

Iron — This system is rated for 6.0 ppm of ferrous (clear water)

and/or ferric (red water) iron.*

Hydrogen Sulde — Sometimes referred to as "rotten egg" odor.

This system is rated for 5.0 ppm hydrogen sulde. Hydrogen

sulde levels vary depending on barometric pressure.*

Manganese — Limit 1.0 ppm; amounts present over 1.0 ppm may

gradually prevent iron removal. Note: For optimum manganese

reduction, pH should be greater than 8.5.*

Organic Matter (Tannins) – The presence of organic matter such

as tannins will prevent the oxidation process of converting the

dissolved element, such as iron or manganese, to a nonsoluble

precipitate or solid substance. In other words, organics can tie

up the iron preventing ltration. The presence of organics such

as tannins above 0.5 ppm voids any claims for this system

to perform as stated above. In some applications, tannin

levels below 0.5 ppm or the presence of other organics may

hinder the operation of this system.*

5. Initiate backwash by holding “REGEN” button down until

piston movement is heard.

6. Let backwash continue until cycle is done. When “RINSE”

is displayed, push the REGEN button again to move into

the SERVICE position. Let the system settle for 5 minutes.

7. Repeat the backwash and settle steps (5&6) for a total of

three times.

NOTE: It takes several backwash cycles before all the media

nes are removed. Elimination of the 12 hour soak procedure

may result in more backwash cycles required to remove the

media nes.

Failure to follow proper start-up may result in

equipment malfunction not covered by warranty.

Total Dissolved Solids (TDS) — While TDS does not directly

affect iron removal, it is a good indicator of potential interference.

Most waters have TDS less than 500 and generally present no

problems to iron reduction. If any ion becomes excessive, it may

cause failure of iron removal. A TDS more than 500 ppm voids

any claims for this system to perform as stated above.*

*For application parameters outside the specied operation

conditions or additional information regarding the listed

items, contact your dealer.

Do not install on chlorinated water supplies - harmful byproducts may be formed with ozone.

This unit is not intended to aid in the mitigation of microorganisms and is not duly registered as a pesticidal device.

The Storm ozone lter must not be used on bacteriologically unsafe water supplies, such as those with with

positive Coliform or E Coli bacteria tests.

Small amounts of hardness (0.5-2 gpg) may occur initially

when lters installed on soft water.

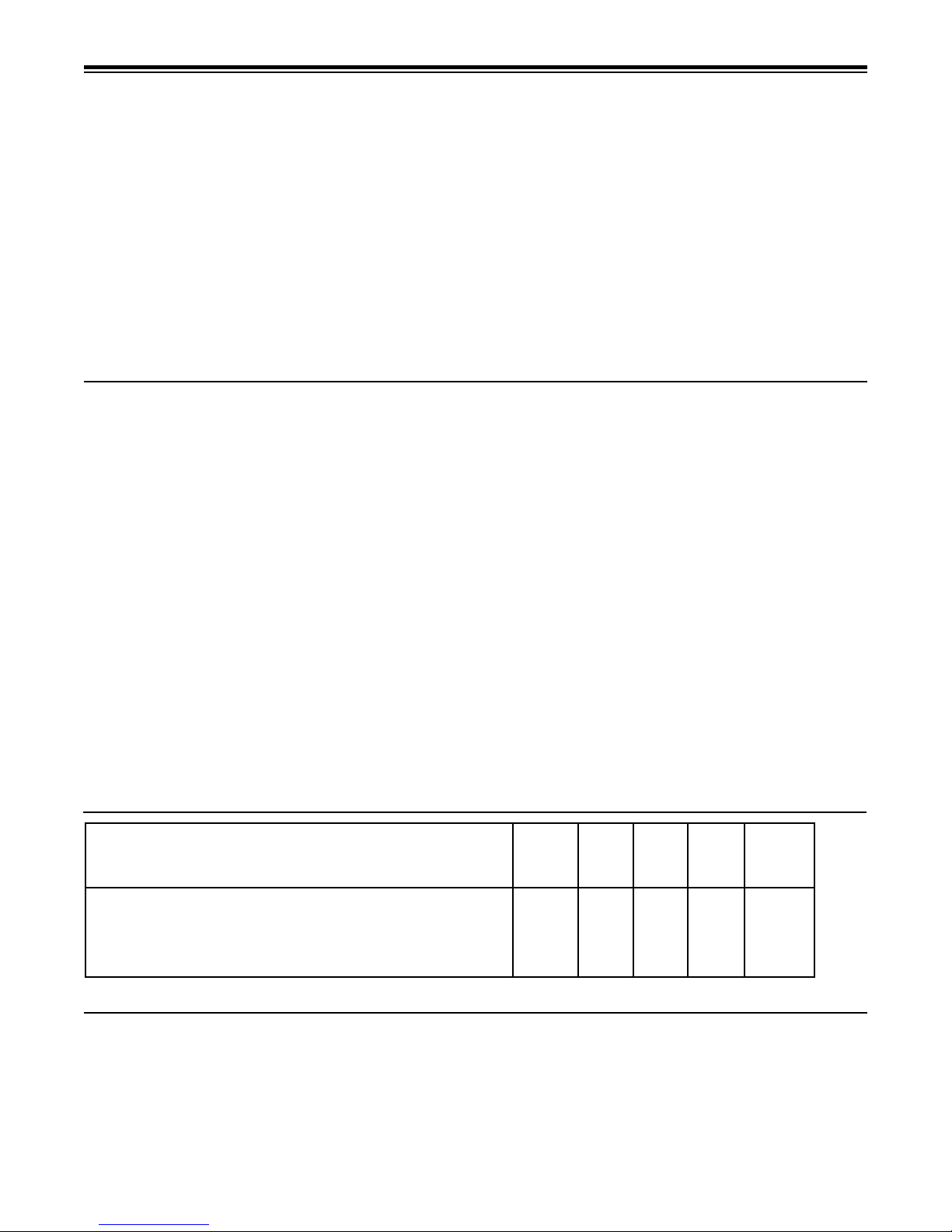

Specications

Iron Storm Models

Iron Storm-10 10"x54" 1.0 1" 4 5.3

Iron Storm-12 12"x52" 1.6 1" 6 7.5

Iron Storm-13 13"x54" 1.9 1" 7 10

(1) Water temps above 60° F will require a higher backwash rate. Consult factory.

Backwash Frequency

Iron Applications

0.3 - 2.0 ppm Iron - Every 3rd Day

2.0 - 4.0 ppm Iron - Every Other Day

4.0 - 6.0 ppm Iron - Every Day

5

Filter

Tank

Size

Media

Cu. Ft

Inlet/

Outlet

Max.

Service

Flow

GPM

(1)

Backwash

Rate

GPM

Ozone Recharge Frequency

Hydrogen Sulde Applications

0.1 - 1.0 ppm Hydrogen Sulde - 100 Gallon

1.0 - 5.0 ppm Hydrogen Sulde - 50 Gallon

Loading...

Loading...