Hellenbrand H200HF User Manual

H200 & H200HF SERIES

WATER CONDITIONERS

H200 Top Mount

H200 Side Mount

H200HF Side Mount

For Commercial & Industrial Applications

Apartment Buildings

Boiler Water Treatment

Car Washes

Commercial Buildings

Condominiums

Factories

Hospitals

Laundries

Mobile Home Parks

Motels and Hotels

Nursing and Rest Homes

Ofce Buildings

Restaurants

Schools

Hellenbrand Means Quality and Reliability

Since 1967, Hellenbrand, Inc. has provided water solutions to the water treatment industry in the

U.S. and around the world. Our growth in the water treatment industry is a direct result of providing high quality products and supporting the applications for those products with over 200+

years of industry knowledge before, during and after the sale, which has resulted in multiple applications over the years with the same customers.

H200 & H200HF Series Conditioners may either be top-mounted using a ange design or sidemounted using a side-mounted adapter, with either berglass or steel tanks. The H200 inlet/outlet opening is a two-inch FPT or 2.5” Victaulic. The H200HF "High Flow" Series uses a

side-mount design with 2.5”, 3” or 4” high ow service valves to provide higher ow rates with

minimal pressure loss. The lead free brass valve body has an NSF Approved Food Grade Electro-Deposited Epoxy Coating to protect against corrosion, both internally and externally. Utilizing

the proven technology of a piston and seal/spacer stack assembly and the powerful H200 micro-

processor you can operate up to four tanks in parallel, alternating or demand recall/stage by ow

and choose up to nine regeneration cycles in any order with a wide range of values for backwash,

brine draw, slow rinse, fast rinse, rell and service allowing you to customize the H200/H200HF

system for your particular application.

Brine Connector

Internal Meter (H200 Series Only)

Drain Connection

Inlet

Outlet

Removable

POD Display

2

The H200 / H200HF is powerful, easy to use and packed with benets

• Solid state microprocessor can control from

one to four units allowing you system add on

capabilities as your needs grow.

• Regeneration may be initiated with a time

clock, meter delayed or meter immediate.

Up to nine fully programmable cycle times, that

•

can be moved around and repeated in various

orders for your particular application needs.

• Soft water brine rell reduces build up in brine

tank from hardness and iron present in the raw

water supply.

• Easy to use user screen shows Time of Day,

Current Flow Rate, Total Gallons Processed

and Volume/Days until Regeneration.

• Solid state microprocessor has a removable

POD display allowing you to remote mount the

POD on top-mounted systems for easy access.

• Economical built-in electronic meter on H200

Series requires no extra piping.

• Economical remote mount electronic meters

are available in a wide variety of sizes for the

H200HF Series.

• Both two-inch FPT and 2.5” Victaulic Inlet/

Outlet are standard on the H200 Series.

•

Lead free brass body with NSF Approved Food

Grade Electro-Deposited Epoxy Coating to protect internally and externally against corrosion.

• Corrosion free Noryl® backplate.

• Nema 3 Enclosure

• Optional Calendar Day Override from 1-28 days.

• 24-Volt output AC adapter is safe, comes with

a 15-foot cord for easy installation.

• Reliable and proven DC drive from our family

of H-Series Systems.

• Capacitor back-up with up to 24-hour power

carry over.

• Optional System Control Board enables the

addition of a third and fourth unit to be implemented into the system design. In addition

the system board can be utilized to operate

external devices like chemical feed pumps,

booster pumps, and to lock out an R.O. system. The available two sets of normally open

& normally closed auxiliary outputs can be

activated after the start of a regeneration, after

the start of a specied regeneration cycle, on

a set number of gallons during service, on a

set number of gallons during service, on a set

number of gallons during service & regeneration mode, while in standyby & regeneration

mode with a multi-tank system, or if a unit

would be in an Error Mode.

• Motorized Alternating Valve "MAV" Provides:

• Twin Alternating for H200 Top or Side

Mount Systems.

• Provides for no Raw Water By-Pass

during regeneration for H200 Top or

Side Mount Systems.

• Provides choices of treated or non-

treated water for regeneration.

• Separate source regeneration.

Removable POD Display

2" Motorized Alternating Valve "MAV"

Requires System Board For Operation

3

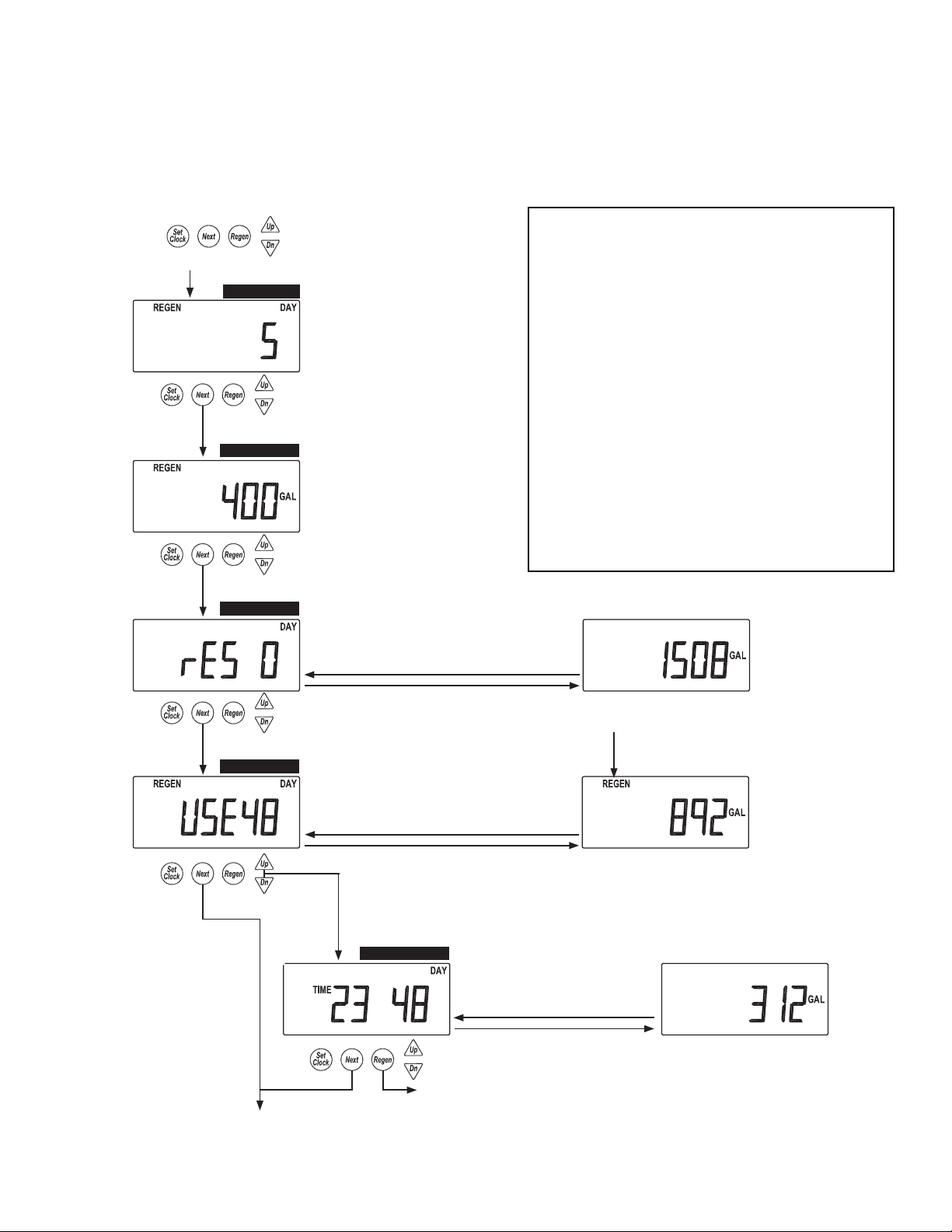

H200/H200HF Diagnostic and History Screens provide the

DIAGNOSTIC 1

Automatically Toggles

Automatically Toggles

Diagnostic 4

DIAGNOSTIC 2

DIAGNOSTIC 3

DIAGNOSTIC 4

DIAGNOSTIC 4-B

Page 20 WS2H Control Valve Manual

Diagnostic Screens

All Diagnostic History screens are resettable

with the History Reset sequence while in the

Diagnostics1 screen. Holding the Set Clock

and Regen buttons for > 3 seconds initiates a

totalizer or history reset.

Accessed by pressing UP and DOWN

simultaneously for >3 seconds.

DIAGNOSTICS 1

Days since the last regeneration.

DIAGNOSTICS 2

Gallons or Liters x1000 since the last

regeneration.

DIAGNOSTICS 3

Reserve history. This screen only appears if valve

is set to calculate Reserve in System Setup 7.

Use arrows to select a day.

0 = Today

1 = Yesterday

6 = 6 days ago (max.)

Reserve Value

DIAGNOSTICS 4

History of volume used.

Use arrows to select a day.

0 = Today

1 = Yesterday

63 = 63 days ago (max.)

REGEN will display if a

regeneration occurred that day.

Gallons Used

Simultaneously press

UP and DOWN.

DIAGNOSTICS 4-B

Hourly history of volume use. Use

the UP and DOWN arrow to select

the hours of the day from screen 4.

Volume used within the selected hour

Automatically Toggles

Returns to normal operation after 5 minutes.

water treatment operator with a wealth of information.

Diagnostic Screens

• Days since last regeneration

• Total volume treated since last regeneration

• Reserve history for the current day and

previous six-days

• Usage history by the hour for each of the

last 63 days

• Maximum ow rate and hour it occurred

• Maximum ow rate per unit by hour and

day it occurred

• Total volume through the unit since it was

installed

All Diagnostic History screens are resettable

with the History Reset sequence while in the

Diagnostics1 screen. Holding the Set Clock

and Regen buttons for >3 seconds initiates a

totalizer or history reset.

4

Loading...

Loading...