Hell Bent Steel Dodge Ram Adjustable Lower Control Arms 1994-1999 User Manual

HELL BENT STEEL - INSTALLATION INSTRUCTIONS

PN: 196-1994-001 FOR 1994-1999 DODGE RAM: FRONT LOWER CONTROL ARM

Pre-Installation Warnings:

Before installing this product on your vehicle, thoroughly read and

understand these instructions and the associated warnings.

Failure to properly follow all instructions and heed all warnings may

result in major property damage and/or serious bodily injury or death.

Test drive the vehicle to verify that it does not exhibit any uncommon

sounds or vibrations.

Inspect this product and all of its associated parts. Compare

the parts to those listed in these instructions. If any parts are missing

or damaged, promptly call and notify us at 877.731.7911. Do not

substitute any part or fastener from any other source. If you desire to

return the vehicle to stock, make sure to save all the original

components.

Installation Warnings:

WARNING: ONLY A CERTIFIED MECHANIC SHOULD

INSTALL THIS PRODUCT.

The OEM manual should be used at all times as a reference guide. The

person installing t h is pr o du ct should wear saf ety gl asses and any other

personal protection items needed at all times. Failure to properly install

this product may result in serious bodily injury or death.

Maintenance Warnings:

It is your responsibility to re-torque and/or inspect the integrity of the

thread lock (where applicable) of all mounting fasteners after the first

100 miles, and every 3000 miles thereafter or after heavy use.

Failure to follow these steps could allow fasteners to come

loose and cause serious damage, bodily injury, or death.

Have your vehicle’s al ignment checked ev er y 6 mon t h s.

Use Warnings:

DRIVE SAFELY! Avoid abrupt maneuvers such as sudden sharp turns

which could cause a roll over, resulting in serious injury or death.

You are solely responsible for any and all misuse, abuse,

improper installation, and/or improper maintenance of

this product and your vehicle.

After installing this product, drive with extreme caution, particularly

until you become familiar with how the vehicle handles. Slower speeds

may be required to maintain control.

Do not engage in any conduct that would void your vehicle’s factory

warranty, such as jumping the vehicle, driving the vehicle in excess of

payload towing restri cti ons, off-road racing, rock crawling, etc. Always

wear a seat belt.

Required tools:

21mm-22mm wrench / socket 1-1/2” wrench

Torque wrench 1-7/8” wrench

Torque Settings:

14mm mounting nut/bolt: 126 ft-lb

YOU CAN VIEW THESE INSTRUCTIONS ON LINE AT

www.hellbentsteel.com

Assembly Instructions:

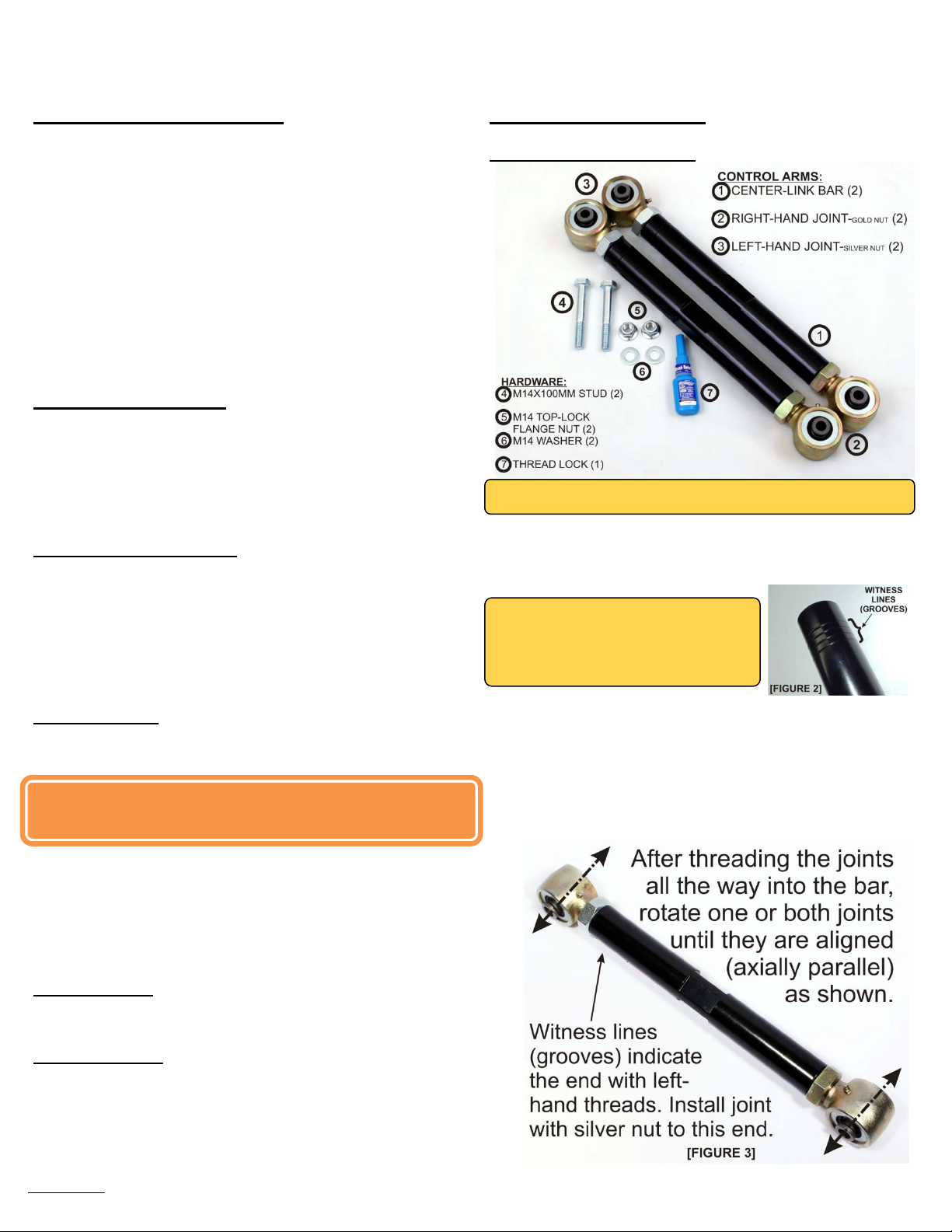

1. Unpack parts to ensure you have all components.

The kit includes the following:

NOTE: Depending on the year and model of your truck the items

may not appear the exact same as is pictured.

2. Assemble the center links and joints:

Install the nut on the joint. Thread the nut up the stem of the joint

until it reaches the bushing shoulder. Then, thread the joints all the

way into the arm, ensuring the nut stays snug at the bushing

shoulder.

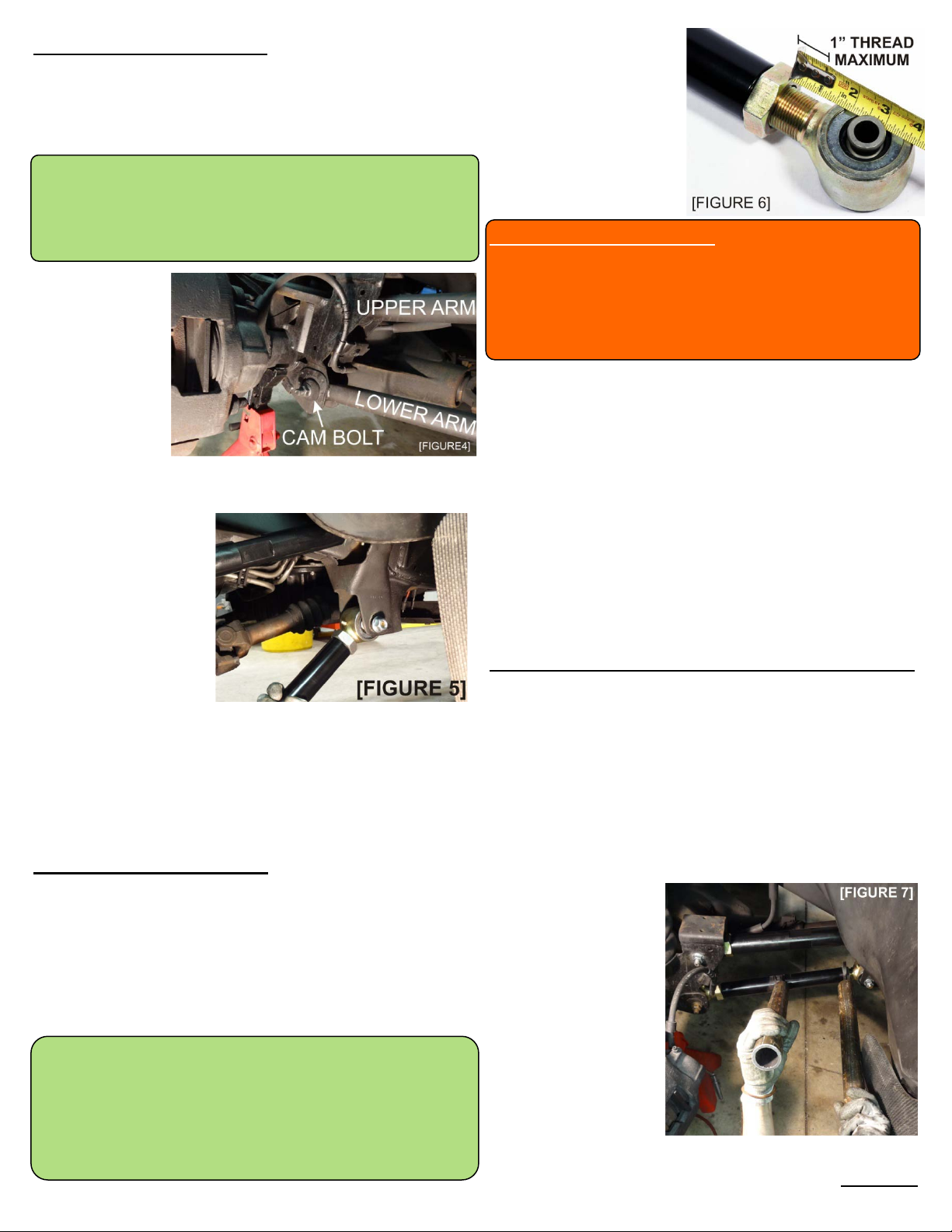

NOTE: The witness line(s)* on the center

links indicate the end of the bar with lefthanded threads. *Depending on the year

and model of your truck, there will be 1,

2, 3, or 4 grooves. [FIGURE 2]

Install the joints with the left hand threads (silver nuts) on the

witness line end of the bars. Then install the joints with the right

hand threads (gold nuts) on the non-witness line end of the bars.

Repeat for all 4 joints. This process will make the arms as short as

possible. At this point the joints are probably not aligned properly.

Rotate one or both joints until they are aligned, making the arm look

like [FIGURE 3]. This will make the Hell Bent Steel arms

approximately the length of the OEM stock arms.

196-1994-1001

07/12

Control Arm Installation:

1. Park your vehicle on level ground. Block the rear tires of the

vehicle so the vehic le is st able and cannot roll. Safely lift the front of

the vehicle and support the axel with jack stands. Place jack stands

securely on both the driver and the passenger sides of the axel.

Remove the wheels from both sides.

NOTE: The front bolt of the lower control arm is a cam bolt which will

need to be retained or replaced by the Hell Bent Steel Cam Bolt

Eliminator (CBE) Kit. If you are replacing your stock cam bolts with

the HBS CBE Kit, skip step 2 and refer to the instructions included in

the kit.

2. Remove lower

arm cam bolt.

NOTE: If you

intend to retain

and re-use the cam

bolt, place a line

on the washer and

frame with chalk or

marker to indicate

the position for

reinstallation later.

Remove the front OEM cam bolt. Remove rear mounting bolt. This will

release the lower arm completely.

3. Insert new lower

control arm in existing

mounts. Ensure the left-

hand threaded joint (silver

nut) is toward the rear of

the vehicle and the righthand threaded joint (gold

nut) is toward the front.

Install the rear joint first

using the new HBSprovided 14mm hardware with the washer on the bolt head and the

nut toward the outside of the vehicle. Next install front cam bolt (align

with the mark made in Step 3) or the HBS Cam Bolt Eliminator Kit.

Place the nut toward the outside of the vehicle.

4. Torque fasteners. Torque each fastener to specification.

5. Repeat steps 1 through 4 on the opposite side of the vehicle.

Control Arm Adjustment:

1. To adjust the arms: Park your vehicle on level ground. On your

new arms, rotate the center link so the arms are at their shortest

possible length. Begin rotating each arm (driver's side and passenger's

side) THE SAME NUMBER OF TURNS until the bottom of the shocks

are just forward of the top of the shock. There is no standard number

of turns that will accomplish this. Each truck may require a different

number of rotations to reach the proper position.

IMPORTANT: The number of rotations of the control arms should be

the same for both the driver's and passenger's side of the vehicle. This

is especially important if you are re-using your OEM cam bolts. If you

are replacing your cam bolts with the HBS CBE kit, your alignment

shop may adjust the rotation of each arm to achieve perfect alignment.

However, for your safety and the safety of your vehicle, have your

truck aligned immediately.

The HBS Adjustable

Control Arms have up

to 2" of adjustment

designed into them. It

is important to avoid

extending the length

beyond the designed

amount of adjustment.

UNDER NO CIRCUMSTANCES should the arms be adjusted

beyond the point where more than 1" of joint threads are

exposed! Extending the arms further can lead to critical

failure that could result in vehicle damage, personal i njury,

and even death. Any adjustment beyond 1" of exposed

threads will void all warranties.

2. Have the vehicle aligned. It is necessary to apply thread-lock

to the jam nuts of each end joint of the new control arms to ensure

the nuts maintain position over time. However, once the thread lock

cures, you should never adjust the arms without cleaning off the old

thread lock and applying a new solution. It is required that the

vehicle be aligned before applying the thread lock for this reason.

3. Apply thread-lock. Once the adjustment has been reached and

the vehicle has been properly aligned, apply thread-lock.

When applying the thread lock you will want to ensure the solution

gets onto the threads that fit inside the center link as well as the jam

nut. Make a mark across the jam nuts onto the center link. You will

use this mark to ensure you return the parts to the same location.

Loosen the jam nuts. Record the number of turns you loosen the

nuts below. Then adjust the center link out, exposing more threads,

Record the number of turns below.

Driver's side: Passenger's side:_________

Front nut: __________ Front nut:__________

Rear nut: __________ Rear nut: __________

Center link: ________ Center link: ________

Generously apply the thread lock onto the exposed threads. Return

the center link and jam nuts to their previous location. The handling

cure time for the thread lock is 10-12 minutes. You will need to

tighten the jam nuts within that time frame. Full cure time is 24

hours.

9. Tighten the jam nuts. Put 1-1/2” wrench over the flat sections

on the center link to keep

it from twisting, then

place 1-7/8” wrench onto

the nut. You will want to

ensure that the joints are

parallel within the

mounts, not twisted or

binding while you are

tightening the nuts. If

you are using wrenches

purchased from Hell Bent

Steel, do not use more

than 16-inch cheater bar

on either wrench.

196-1994-1001

07/12

Loading...

Loading...