Hell Bent Steel 2006-2012 Dodge Ram 1500 4X4,4WD 2.5 Leveling User Manual

HELL BENT STEEL, INC - INSTALLATION INSTRUCTIONS

FRONT LEVELING SYSTEM FOR DODGE RAM 1500 2008.5-2010 4X4

P/N : 120-200-001, 120-250-001, 125-200-001, & 125-250-001

These instructions are available with larger color photos on our website at www.hellbentsteel.com

IMPORTANT NOTES:

Please read before beginning installation. OEM Manual should be used

as a reference.

It is highly recommended that a certified mechanic perform this

installation.

Read and understand all the instructions before beginning

installation.

Use Locktite® on all bolts associated with this installation.

Torque Specifications:

Shock Absorber-to-Lower Arm Nut and Bolt………….………….…..….. 155 ft-lbs

Stabilizer Bar-to-Link Nut ……..…………………………………………….……. 75 ft-lbs

Tie-Rod End Nut ……….……………………………………………………………. 45 ft-lbs

Upper Ball Joint Nut …………………..……………………………..……………… 50 ft-lbs

Upper Strut Mounting Nuts ……………………………………………………….. 45 ft-lbs

Wheel Lug Nut ………………………………………………………….……… 120-150 ft-lbs

If you desire to return the vehicle to stock, make sure to save all the

stock components.

WARNING: IT IS HIGHLY RECOMMENDED THAT A

CERTIFIED MECHANIC PERFORM

IMPORTANT CUSTOMER INFORMATION:

This vehicle’s reaction and handling characteristics may differ from that

of standard cars and/or trucks. Modifications to improve off road

performance may raise the vehicle’s intended center of gravity.

Extreme caution must be utilized when encountering driving conditions

that may cause vehicle imbalance or loss of control. DRIVE SAFELY!

Avoid abrupt maneuvers, such as sharp turns, which could cause a roll

over, resulting in serious injury or death.

It is the customer’s responsibility to make sure a re-torque is

performed on all hardware associated with this suspension system

after the first 100 miles. It is also the customer’s responsibility to do a

complete re-torque after every 1000 miles or after every off road use.

After the original installation, it is recommended to have the alignment

checked by a certified alignment technician that is experienced with

lifted vehicles. Also the alignment should be checked every 6 months

to ensure proper tracking, proper wear on tires and front-end

components. The responsibility for abuse, improper installation, or

improper suspension maintenance is solely that of the customer.

It is the responsibility of the customer or the mechanic to wear safety

glasses at all times when working with air tools.

BEFORE BEGINNING, Please read all of the instructions

carefully. Before installation begins, drive the vehicle and inspect it

to make sure that there are not any uncommon sounds or frame

damage.

Front End Installation:

1. To begin installation, block the rear

tires of the vehicle so that the vehicle is

stable and can’t roll backwards. Safely lift

the front of the vehicle so that the front

wheels are off the ground. Support the

frame with jack stands. Place jack stands

on both the driver

and the passenger sides of the vehicle.

Next remove the wheels from both sides.

THIS INSTALLATION.

NOTICE:

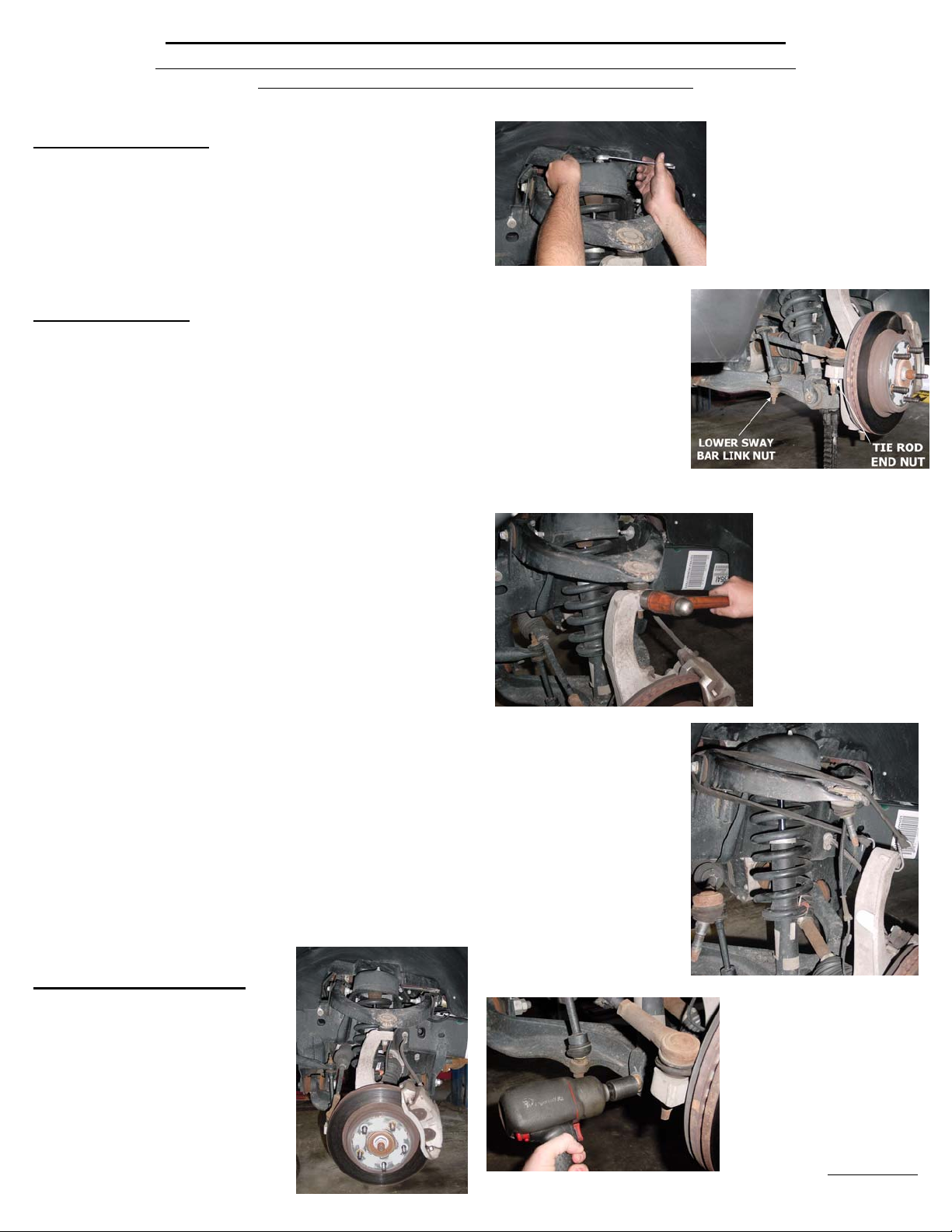

2. Break loose the 3 upper strut

mount nuts with a 15-mm wrench

or socket. Remove the back two

nuts completely. Loosen but do

not remove the front nut.

3. Remove the lower sway bar

link from the bottom of the

control arm with an 18 mm

deep socket. Disconnect the

tie rod end nut with a 21 mm

socket. Using a ball peen

hammer or impact tool, hit the

steering knuckle (not the tie

rod) until the tie rod pops out.

If you use a tie rod pickle fork,

be careful not to cut the tie rod

boot. A severed tie rod boot will allow dirt and moisture to damage the

tie rod end.

5. Support the knuckle with a

bungee cord or safety wire so

not to overextend the CV axel

or stretch the brake hydraulic

hose.

6. Next remove the struts

lower bolt. Using a 24 mm

wrench, hold the nut and

remove the bolt with a 21 mm

socket. Now remove the third

nut from the upper strut

mount.

4. Remove the upper

ball joint nut with a 21

mm

socket. Use a

hammer to strike

the side of the

steering knuckle

until the upper control

arm pops out.

7. Pulling outward on the strut

assembly, you should be able

to clear the upper strut tower

and remove the strut

assembly.

120-000-1001

06/10

***PLEASE NOTICE***

In March of 2008 Dodge made a change to the strut of the Dodge Ram

1500 4X4 strut cap. Dodge deci ded to omit a 1/8” plate that was th ere in

the earlier models. See photos below.

Shown in Figures 1 and 2, is the 2006-Feb 2008 strut cap design.

FIG 1 FIG 2

Figure 3 shows the post March 2008 strut cap.

FIG 3

**Notice the absence of the plate over the rubber bushing.**

If your truck was manufactured after 2008 you should have received plates

with your kit. Please notice this upon install. If your truck does NOT have

the plate attached, use the 1/8” thick plate provided with the HBS spacers.

Place the plate on the strut cap BEFORE you fasten the spacer to the cap

as shown in Figures 4, 5, and 6. This must be done in order to secure

the rubber bushing in the strut cap.

FIG 6

FIG 4 FIG 5

*** If you have a 2006-2007 and your truck does NOT have the

plate attached, do NOT install the kit and please contact us at the

number above so that we can send you the plates needed***

8. Place the Hell Bent Steel

strut extension on the top of

the strut, hold the part up to

start the factory nuts onto the

factory studs.

* NOTE: Use the factory

nuts with the factory

studs*

9. Run down the factory nuts

snug with 15 mm end wrench.

Torque to OEM specs.

10. Place strut back into upper

strut mount. Tighten provided

nuts snug with wrench or

ratchet (after install, you will

torque to OEM specs).

Because of the shape of the HBS spacer, you will need

to rotate the strut assembly 180º

11. Use a pry bar and/or floor jack to position the lower control arm

and the strut assembly to reinstall the lower mounting bolt. Torque to

OEM specs.

12. Place a jack under

the lower control arm.

Raise the lower control

arm to reattach the ball

joint. A pry bar may be

used to hold the upper

control arm into

position. Torque the

ball joint nut to OEM

specs. Reattach the tie

rod end and torque to

OEM specs.

13. Repeat procedure on opposite side.

14. Reattach the sway bar. Torque to OEM specs.

15. Reattach the front wheels. Torque to OEM specs

16. Lower vehicle to ground and torque strut mounts to OEM specs.

17. HAVE THE VEHICLE ALIGNED. A certified alignment technician

that is experienced with lifted vehicles is recommended to perform the

alignment. Realignment is necessary to allow the suspension to settle to

its desired ride height (the wheels will be toed-in which will cause

excessive wear on your tires and the nose will sit higher than it should.)

**Adjust your head lights if necessary.**

PLEASE NOTE:

The 1-3/8" thick spacer gives you a total lift of 2.5". This is

due to the fact that when you extend the strut by 1-3/8" the

strut will be rotated to a slightly steeper angle. It is the

combination of extending the strut and the change in angle

that gives the total lift. For the same reason, the spacer in

the 2" kit measures 1-1/4".

If you have any questions please call our Tech Support toll

free at 1.877.731.7911

These instructions are available

in full color on our website www.hellbentsteel.com

120-000-1001

06/10

Loading...

Loading...