.

BD0053V0004EN0316S0

460 985-69 / 03.16

Operating Instructions

en

CSC-Tool

Inhaltsverzeichnis CSC-Tool

Table of Contents

1 Safety Precautions......................................................................... 3

1.1 General Safety Precautions ...........................................................3

1.2 Safety Precautions for the CSC-Tool..............................................3

1.3 Safety Precautions – Risk of Injury ................................................4

1.4 Safety Precautions – Laser............................................................4

2 Product Description ....................................................................... 5

2.1 Intended Use.................................................................................5

2.2 Delivery Contents..........................................................................5

2.3 Tool Description............................................................................7

3 Working with the CSC-Tool.......................................................14

3.1 Precondition for the Use of the CSC-Tool.....................................14

3.2 Placing the CSC Panel in Front of the Vehicle ..............................14

3.3 Placing the CSC Panel Centred in Front of the Vehicle .................17

3.4 Placing the CSC Panel Parallel to the Vehicle ..............................21

3.5 Adjusting the Height of the Reference Panel ...............................25

4 General Information.....................................................................28

4.1 Care and Maintenance.................................................................28

4.2 Disposal......................................................................................28

4.3 Technical Data for Laser Module .................................................29

2

CSC-Tool Safety Precautions

General Safety Precautions

1 Safety Precautions

1.1 General Safety Precautions

• The CSC-Tool is exclusively intended for use on a vehicle.

It is a precondition for the use of the CSC-Tool that the

user has knowledge of automotive technology and is

therefore aware of the sources of danger and risks in the

repair shop and on motor vehicles.

• All notes given in the individual sections of the operating

instructions apply. In principle it is required to follow the

steps and safety precautions stated below.

• Furthermore, pay attention to all general instructions

from labour inspectorates, trade associations and vehicle

manufacturers as well as all laws, legal ordinances and

instructions which have to be commonly obeyed by a

repair shop.

1.2 Safety Precautions for the CSC-Tool

In order to avoid incorrect handling and injury to the user or

destruction of the CSC-Tool arising from this, pay attention to

the following:

• Only assemble the CSC-Tool according to the assembly

instructions.

• Protect the CSC-Tool from long periods of exposure to

solar radiation.

• Protect the CSC-Tool from water (it is not waterproof).

• Protect the CSC-Tool from strong impacts (do not drop).

• Regularly service the CSC-Tool.

3

Safety Precautions CSC-Tool

Safety Precautions – Risk of Injury

1.3 Safety Precautions – Risk of Injury

When working on the vehicle, there is a risk of injury through

inadvertent rolling of the vehicle. Therefore regard the

following:

• The park position should also be engaged in automatic

vehicles.

• Protect vehicle against rolling away.

1.4 Safety Precautions – Laser

There is a risk of injury through dazzling the eyes when

working with the laser. Therefore regard the following:

• Do not direct the laser beam towards persons, doors or

windows.

• Never look directly into the laser beam.

• Ensure proper room illumination.

• Avoid trip hazards.

• Secure mechanical parts from falling over or becoming

loose.

4

CSC-Tool Product Description

Intended Use

2 Product Description

2.1 Intended Use

The Camera & Sensor Calibration Tool (CSC-Tool) is a system for

calibrating driver assist systems suitable for all makes and models.

Optional modules enable brand-specific adjustments of all kinds of

systems. Therefore, in connection with a diagnostic tool from Hella

Gutmann you are able to calibrate e.g. the front camera for the lane

departure warning system, the radar sensor for the ACC (Adaptive Cruise

Control) or the camera for adaptive headlights.

The CSC-Tool can be exclusively operated in combination with a Hella

Gutmann diagnostic tool. Diagnostic tools from other manufacturers will

not be supported.

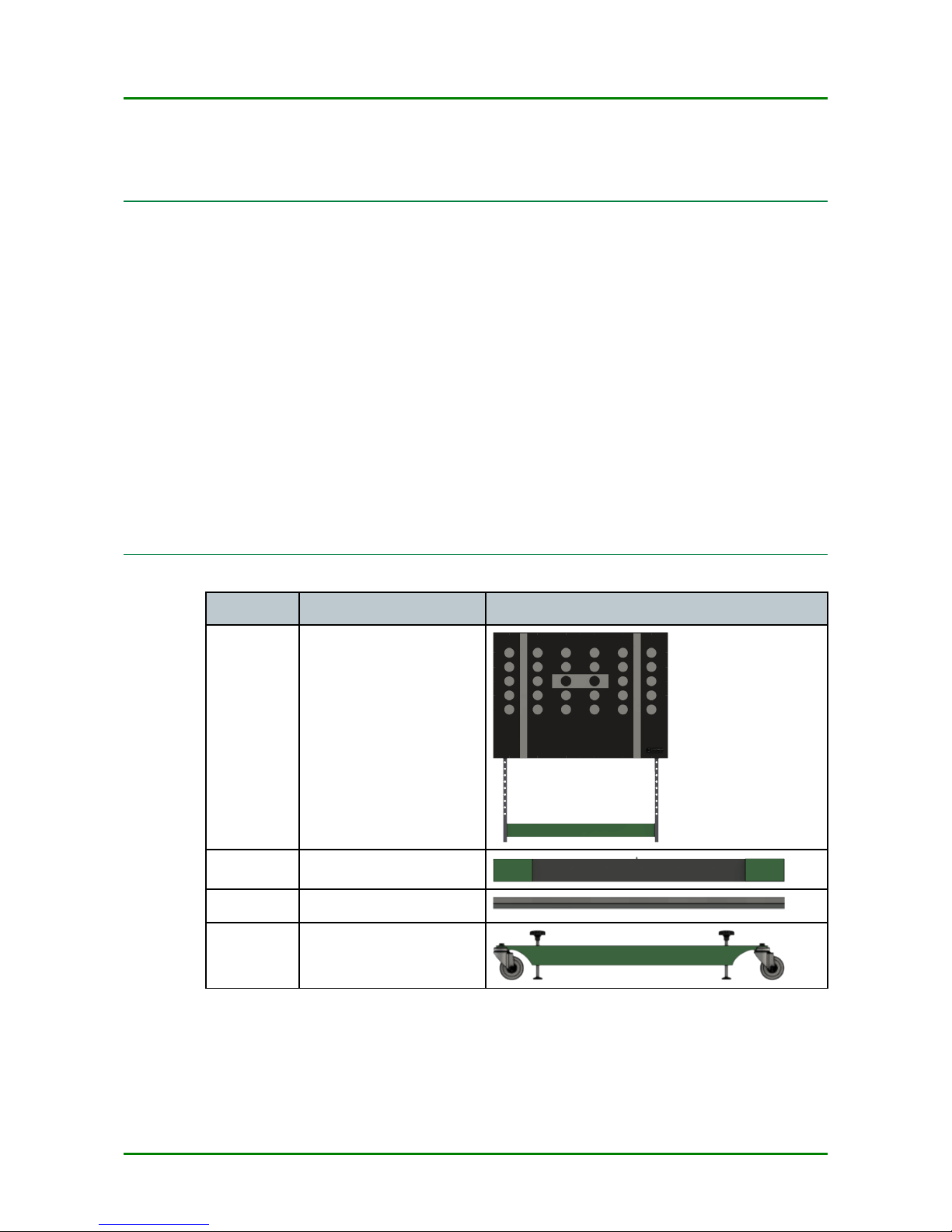

2.2 Delivery Contents

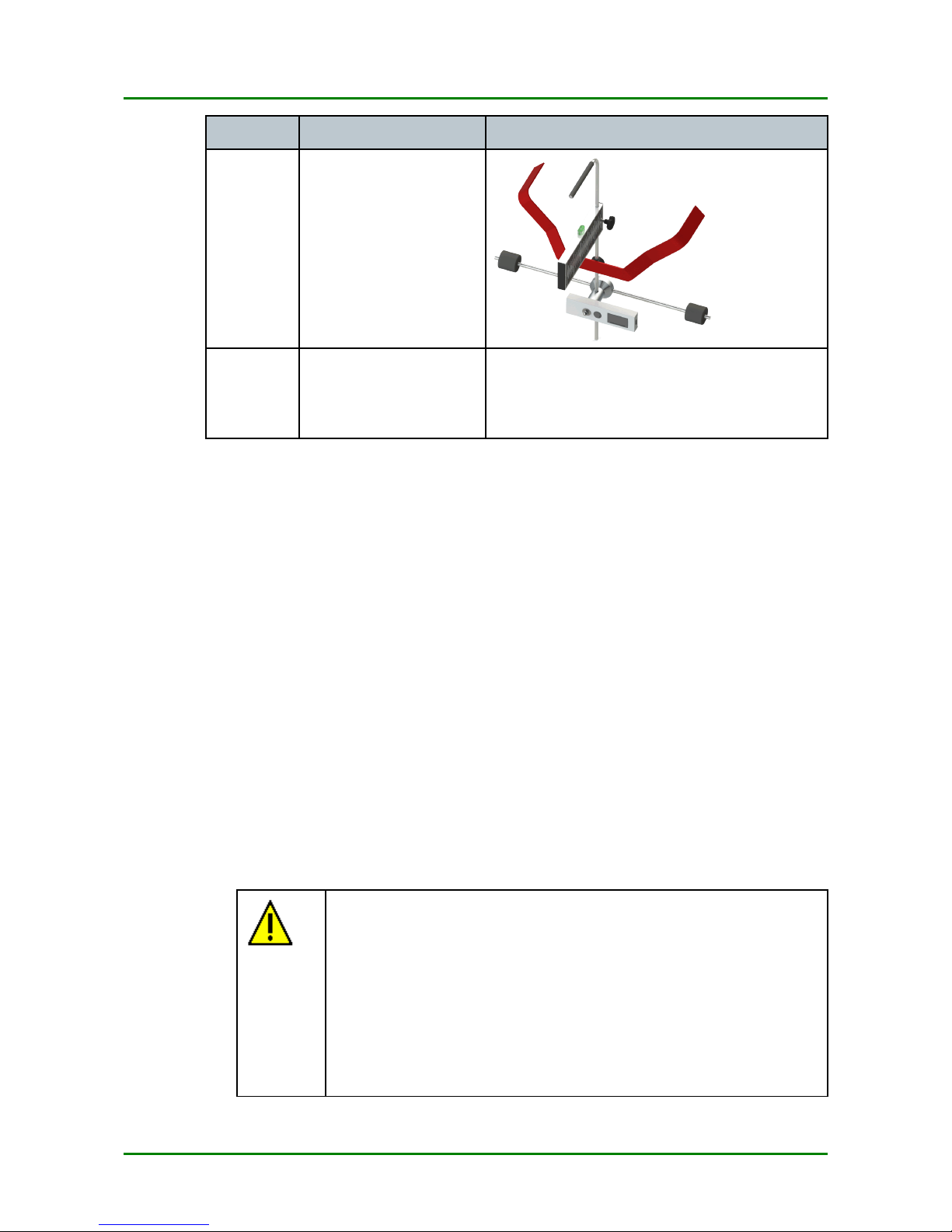

Pieces Designation

1

CSC Panel

1

Cross member

1

Dipstick

2 Base support on

caster wheels

5

Product Description CSC-Tool

Delivery Contents

Pieces Designation

2

HD-10 EasyTouch

incl. wall mount

1

Operating and

installation

instructions

2.2.1 Checking Delivery Contents

Please check the delivery contents upon receiving your tool so that

complaints can be issued immediately regarding potential damage or

missing parts.

Proceed as follows to check the delivery contents:

1. Check the package delivered to ensure that it is not damaged.

Should you identify any damage to the package, then open the package

in the presence of the delivery service and check the CSC-Tool for

hidden damage. Any transport damage to the package supplied and

damage to the CSC-Tool shall be registered in a damage report by the

delivery service.

2. Open the package supplied and check for completeness based on the

delivery slip.

CAUTION

Risk of injury due to heavy tool

The tool may drop down and cause injuries during

unloading.

Always unload the tool with the aid of a second person.

Use suitable aids as necessary.

6

CSC-Tool Product Description

Tool Description

3. Remove the CSC-Tool from the packaging.

4. Check the CSC-Tool for damage and completeness.

2.3 Tool Description

2.3.1 CSC Panel

7

Product Description CSC-Tool

Tool Description

8

CSC-Tool Product Description

Tool Description

Designation

1

Reference panel

Here you will need different reference panels depending on

the car manufacturer. These are optionally available.

2

Mirror cover/scale of cross member

Here you can check whether the CSC Panel is placed centred

in front of the vehicle.

3

Mirror of cross member

This is used to reflect the laser beam onto the scale of the

HD-10 EasyTouch.

4

Cross member

5

Adjustment screws of the base support

Use the adjustment screws to balance the level gauge of the

base support.

6

Level gauge

Use the level gauge to check whether the base support is

exactly horizontal.

7

Set screw on reference panel

Use the set screw to fix the reference panel at the

appropriate height.

8

Handle

Use this handle to move the reference panel upwards or

downwards.

9

Dipstick with set screw

Here you can read the height of the reference panel.

10

Color marking

Here you can check the nominal height of the reference panel

indicated in the diagnostic tool.

9

Product Description CSC-Tool

Tool Description

2.3.2 HD-10 EasyTouch

Designation

1

Handle

This handle makes it easier to carry the HD-10 EasyTouch.

2

Scale of the HD-10 EasyTouch

Here you can check whether the CSC Panel is placed parallel

to the vehicle.

10

CSC-Tool Product Description

Tool Description

Designation

3

Set screw on scale

Use this set screw to adjust and fix the scale.

4

Attachment bracket for automobile

Use this attachment bracket to attach the HD-10 EasyTouch

to the tyre.

5

Shaft with cross connector

6

Set screw on shaft with cross connector

Use this set screw to adjust the height of the shaft with cross

connector.

7

Laser module

The actual value can be projected onto the scale of the cross

member of the CSC Panel with the help of the laser.

8

Protective cylinder set

This protects the wheel rim from damage.

9

Level gauge

Use the level gauge to check whether the HD-10 EasyTouch

is placed horizontally.

2.3.3 Laser Module

11

Product Description CSC-Tool

Tool Description

Designation

1

Output of the laser beam/laser beam

Output for laser beam.

Use the laser beam to read the actual value at the scales of

the cross member and at the HD-10 EasyTouch.

2

Mounting bolt

Use this to adjust and secure the laser module.

3

Switch

Switch the laser on and off.

4 Battery compartment cover

2 type AA batteries can be inserted into the battery

compartment.

2.3.4 Replacing the Batteries

Replacing the Type AA Batteries

Proceed as follows to replace the batteries:

1. Switch off the laser beam (1) with the switch (3).

2. Remove the battery compartment cover (4), tilting it from the bottom

side towards the top.

12

CSC-Tool Product Description

Tool Description

3. Remove the batteries individually.

NOTE

Pay attention to correct installation direction/polarity

4. Reassembly in reverse order

13

Working with the CSC-Tool CSC-Tool

Precondition for the Use of the CSC-Tool

3 Working with the CSC-Tool

The following steps are necessary to work with the CSC-Tool:

1. Place the CSC Panel in front of the vehicle.

2. Place the CSC Panel centred in front of the vehicle.

3. Place the CSC Panel parallel to the vehicle.

4. Adjust the height of the reference panel.

The individual steps are described below.

3.1 Precondition for the Use of the CSC-Tool

Regard the following in order to use the CSC-Tool:

• Vehicle system is working properly.

• No trouble codes stored in ECU memories.

• Possible vehicle-specific preparations done.

• Rear axle track properly adjusted.

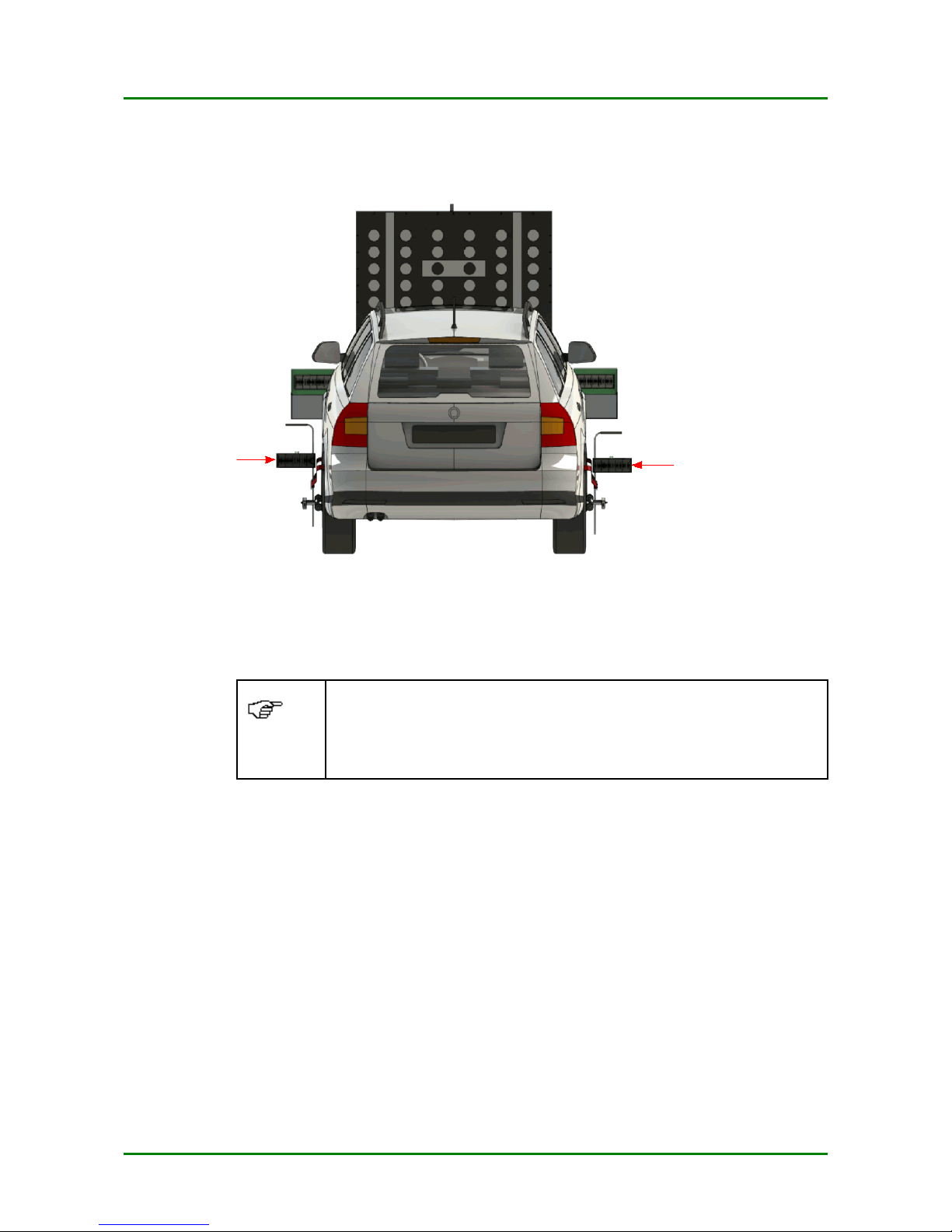

3.2 Placing the CSC Panel in Front of the Vehicle

Proceed as follows to place the CSC Panel in front of the vehicle:

1. Connect the diagnostic tool to the vehicle (see user manual).

2. Select >Diagnostics< in the main menu.

3. Select the system to be calibrated, e.g. front camera or ACC under

>Basic setting<.

A window with information and instructions appears.

14

CSC-Tool Working with the CSC-Tool

Placing the CSC Panel in Front of the Vehicle

4. Regard the window with information and instructions.

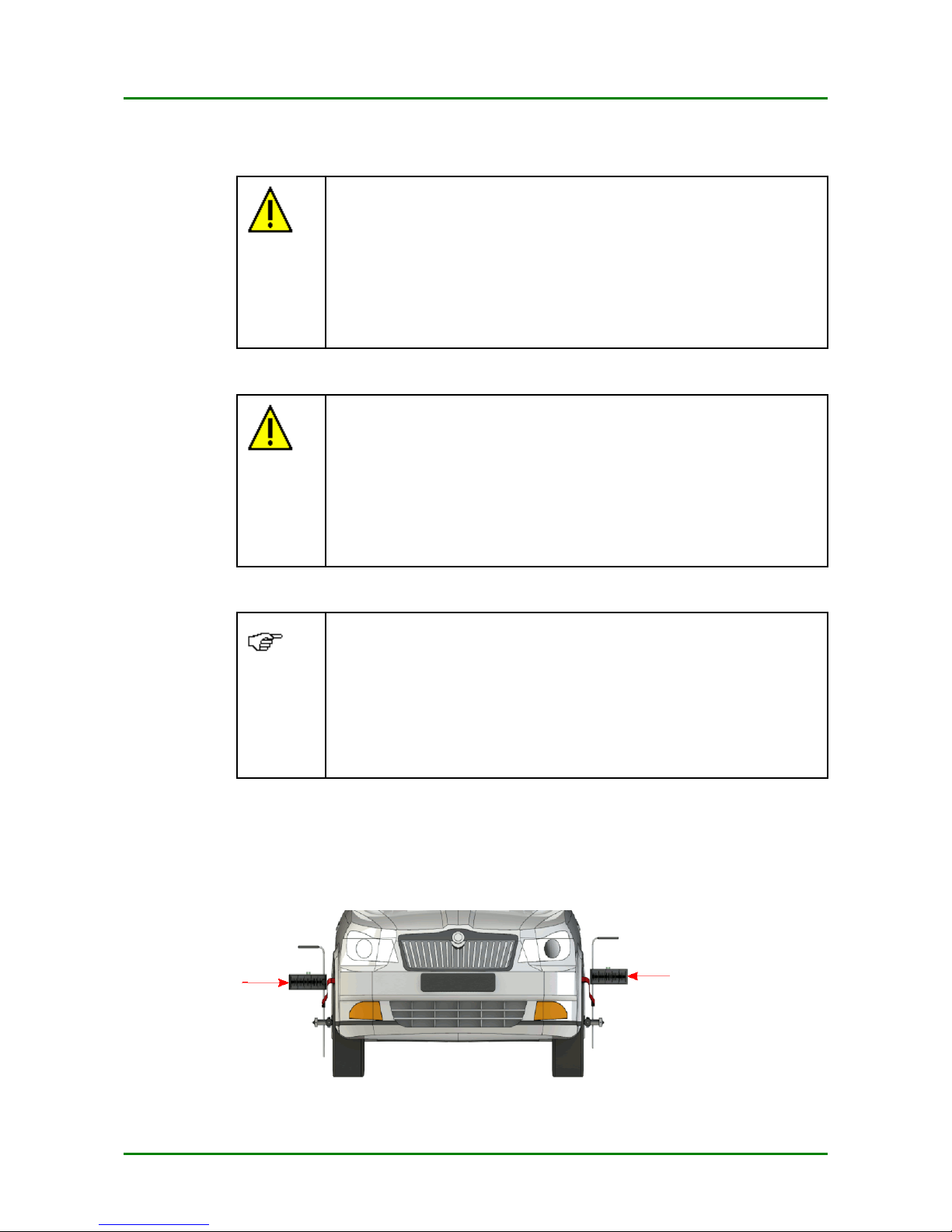

WARNING

Sharp object

Risk of injury/piercing

Using the handle, always attach the HD-10 EasyTouch to

the rim flange or tyre.

CAUTION

Scratching of surfaces

Damage to wheel rims

Always attach the protective cylinder set to the rim flange

or tyre.

NOTE

The distance between the CSC Panel and the centre of the

wheel can be measured with a yard stick (not included in

the delivery contents) only if the HD-10 EasyTouch is

attached horizontally and centred to the centre of the

wheel.

5. Install one HD-10 EasyTouch on the left and right front wheel

respectively.

15

Working with the CSC-Tool CSC-Tool

Placing the CSC Panel in Front of the Vehicle

6. On the HD-10 EasyTouch, loosen the set screw of the shaft with cross

connector (6).

Now you can adjust the height of the shaft with cross connector.

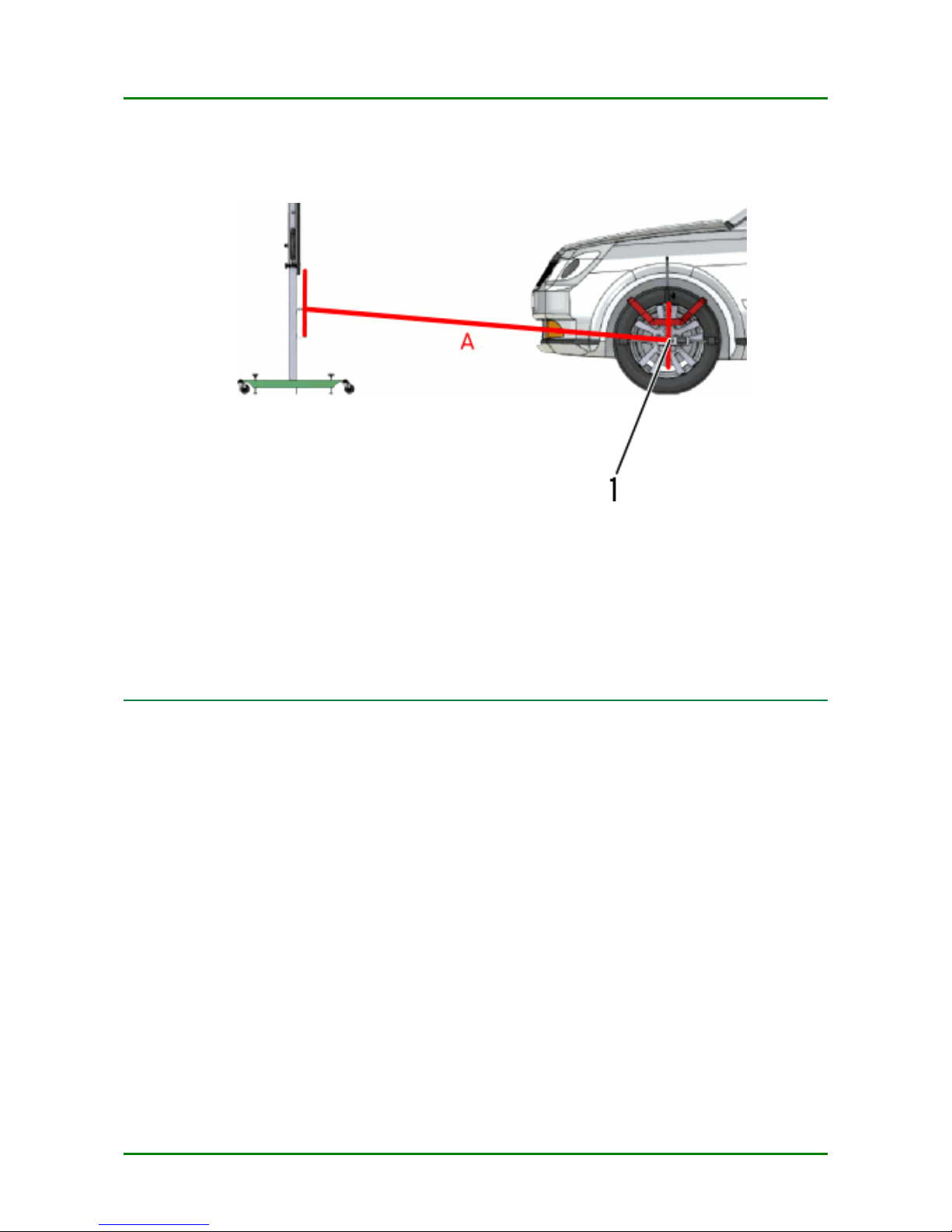

7. Align the shaft with cross connector (5) to the wheel centre 1.

8. Align the scales of the HD-10 EasyTouch at a right angle.

9. Use a yard stick (not included in the delivery contents) to measure

from the centre of the wheel 1 to the rear edge (see marking) of the

cross member (4).

16

CSC-Tool Working with the CSC-Tool

Placing the CSC Panel Centred in Front of the Vehicle

10. Place the CSC Panel with the distance A, indicated in the diagnostic

tool, to the centre of the wheel 1.

11. Perform steps 6 to 10 for the second HD-10 EasyTouch.

Now the CSC Panel is placed correctly in front of the vehicle.

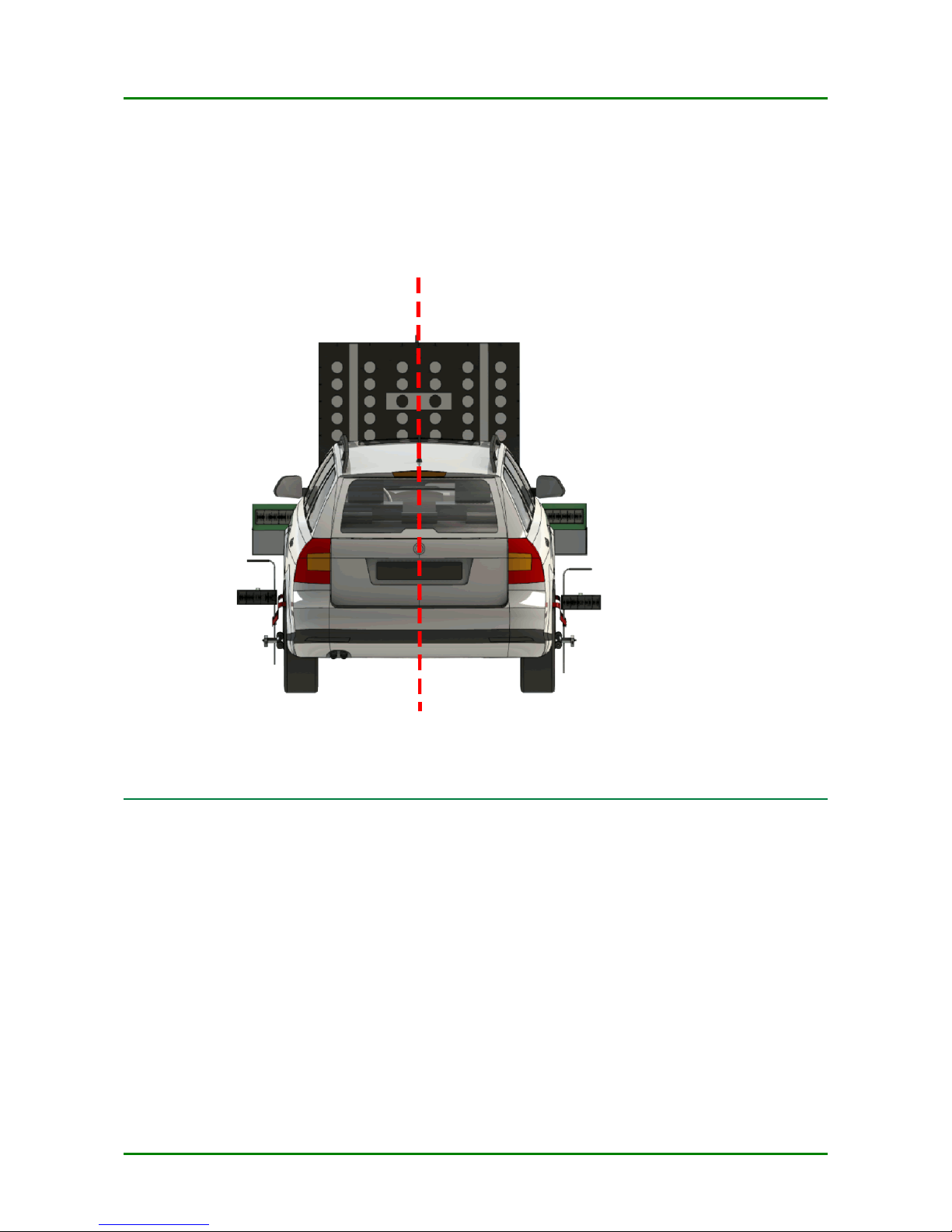

3.3 Placing the CSC Panel Centred in Front of the Vehicle

Proceed as follows to place the CSC Panel centred in front of the vehicle:

17

Working with the CSC-Tool CSC-Tool

Placing the CSC Panel Centred in Front of the Vehicle

1. Attach one HD-10 EasyTouch on the left and right rear wheel

respectively.

2. Align the scales of the HD-10 EasyTouch at a right angle.

NOTE!

Ensure that the level bubbles of both HD-10 EasyTouch

devices are centred.

18

CSC-Tool Working with the CSC-Tool

Placing the CSC Panel Centred in Front of the Vehicle

3. The left and right mirror covers (2) of the cross member (4) should be

tilted upwards.

The scales of the cross member and mirrors are visible.

CAUTION

Laser radiation

Damage to/destruction of the retina

Never look directly into the laser beam.

4. Switch on the laser beam (1) of the laser module (7) with the switch

(3).

19

Working with the CSC-Tool CSC-Tool

Placing the CSC Panel Centred in Front of the Vehicle

5. Align the laser module (7) by turning the mounting bolt (2) on the scale

of the cross member (4).

The laser beam is indicated on the scale of the cross member.

20

CSC-Tool Working with the CSC-Tool

Placing the CSC Panel Parallel to the Vehicle

6. Perform steps 4 + 5 for the second laser module.

7. By moving the CSC Panel laterally, place the panel in a way that the

left and right scale of the cross member (4) show the same values.

Now the CSC Panel is placed centred in front of the vehicle.

3.4 Placing the CSC Panel Parallel to the Vehicle

Proceed as follows to place the CSC Panel parallel to the vehicle:

21

Working with the CSC-Tool CSC-Tool

Placing the CSC Panel Parallel to the Vehicle

1. Align the laser beam (1) of the laser module (7) with the mirror (3) of

the cross member (4).

The laser beam will be reflected from the mirror to the scale of the

HD-10 EasyTouch.

2. Perform step 1 with the second laser beam.

22

CSC-Tool Working with the CSC-Tool

Placing the CSC Panel Parallel to the Vehicle

3. By axially turning the CSC Panel, place the panel in a way that the left

and right scale of the HD-10 EasyTouch show the same values.

Now the CSC Panel is placed parallel to the vehicle.

23

Working with the CSC-Tool CSC-Tool

Placing the CSC Panel Parallel to the Vehicle

4. Switch off the laser beam (1) of the laser module (7) with the switch

(3).

5. Use the adjusting screws of the base support (5) to adjust the

horizontal and the vertical level gauge (6) of the cross member (4) and

CSC Panel accordingly.

The adjusting screws also prevent the CSC panel from slipping. The

CSC panel is held in place and can no longer be moved.

If the horizontal and vertical level gauges are centred and even, you

can adjust the height of the reference panel.

24

CSC-Tool Working with the CSC-Tool

Adjusting the Height of the Reference Panel

3.5 Adjusting the Height of the Reference Panel

Proceed as follows to adjust the height of the reference panel:

WARNING

Movable reference panel

Risk of injury or pinching

Use only the handle to move the reference panel.

1. Loosen the left and right set screws (7) on the back of the reference

panel (1).

2. Position the dipstick (9) on the floor.

Now you can adjust the height of the reference panel.

25

Working with the CSC-Tool CSC-Tool

Adjusting the Height of the Reference Panel

3. Use the handle (8) to move the reference panel (1) up to the height

indicated in the diagnostic tool.

4. Check the height of the reference panel (1) using the color marking

(10).

5. Tighten the left and right set screws (7).

26

CSC-Tool Working with the CSC-Tool

Adjusting the Height of the Reference Panel

6. Slightly push the dipstick (9) upwards from the floor and fix it with the

set screw of the measuring rod (9). Then it cannot be damaged when

moving the CSC Panel again.

7. Start the calibration in the diagnostic tool with

.

27

General Information CSC-Tool

Care and Maintenance

4 General Information

4.1 Care and Maintenance

• As with every tool, the CSC-Tool should also be handled with care.

• Regularly lubricate moving parts with acid-free and resin-free grease

or oil.

• Re-tighten the mounting bolts regularly.

• Regularly clean the CSC-Tool with non-aggressive cleaning agents.

• Use commercial household cleaning detergents and a moistened, soft

cleaning cloth.

• Replace damaged accessories immediately.

• Always use original spare parts.

4.2 Disposal

In compliance with directive 2002/96/EC of the European Parliament and

Council of 27 January 2003, relating to used electrical and electronic

appliances, and the national statute governing the distribution, return and

environmental disposal of electrical and electronic appliances (Waste

Electrical and electronic Equipment (WEEE) regulation) of 16 March 2005,

we are obliged to take back this device, distributed after 13 August 2005,

at the conclusion of its service life and to dispose it in accordance with the

above mentioned directives.

Since, in the case of the present device, this relates to exclusively

commercially used equipment (B2B), it must not be handed over to a

public disposal facility.

The device can be disposed of at the following address (specifying the date

of purchase and the device number):

Hella Gutmann Solutions GmbH

Am Krebsbach 2

79241 Ihringen

GERMANY

WEEE reg. no. DE 25419042

Phone: +49 7668 9900-0

28

CSC-Tool General Information

Technical Data for Laser Module

Fax: +49 7668 9900-3999

Mail: info@hella-gutmann.com

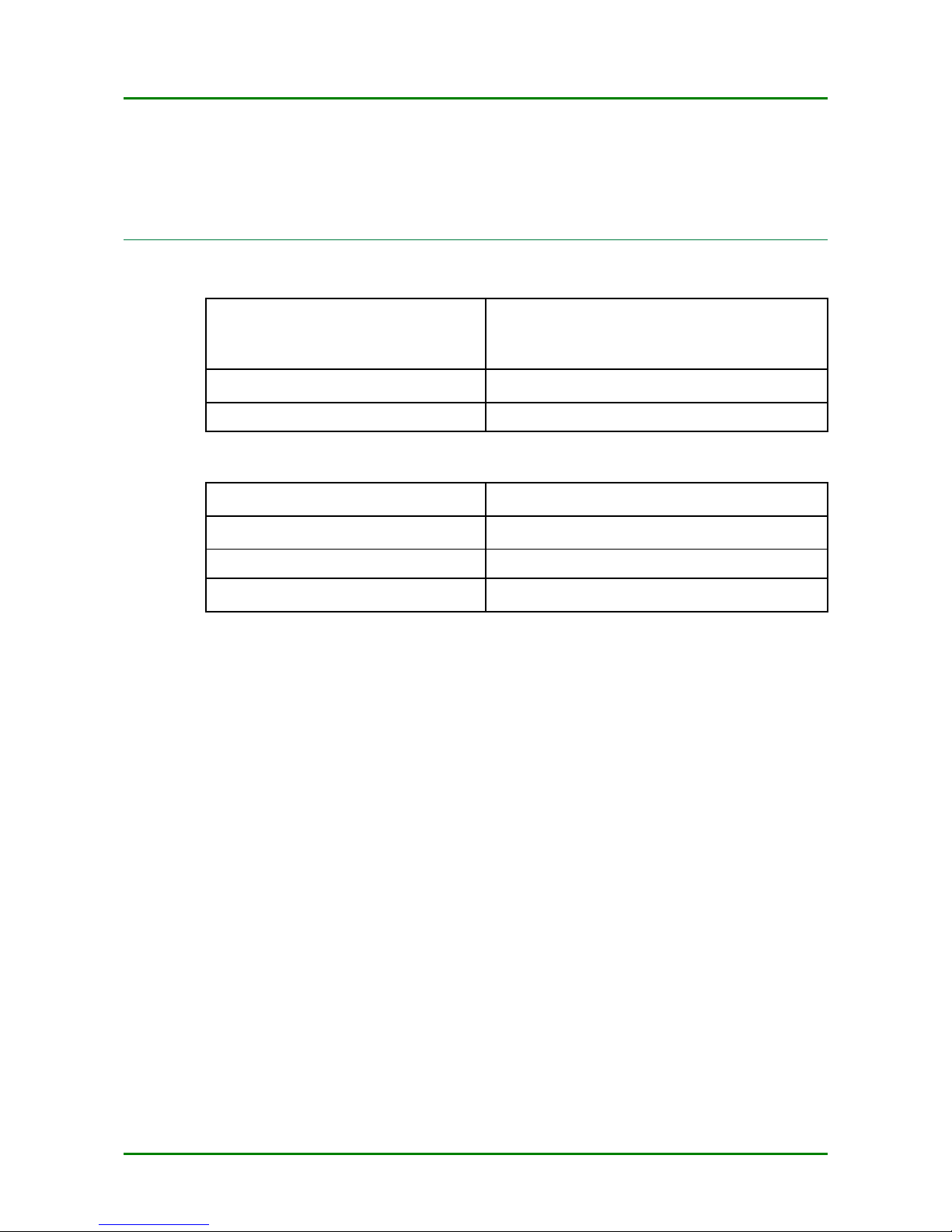

4.3 Technical Data for Laser Module

General data

Ambient temperature Recommended: 0 - 35°C

Operating range: 0 - 50°C

Supply voltage

2.7 - 3.3 V DC

Batteries 2x 1.5 V AA

Laser

Wavelength

635 nm

Output 1 mW

Class

2

Operating range 0 - 10 m

29

Notes

CSC-Tool

Notes

30

CSC-Tool

Notes

Notes

31

HELLA GUTMANN SOLUTIONS GMBH

Am Krebsbach 2

79241 Ihringen

GERMANY

Phone: +49 7668 9900–0

Fax: +49 7668 9900–3999

info@hella-gutmann.com

www.hella-gutmann.com

© 2016 HELLA GUTMANN SOLUTIONS GMBH

1 STUECK/PIECE(S)

*9XQ 460 985-691*

9XQ 460 985-691

Made in Germany

Loading...

Loading...