Page 1

9600 (High Voltage) Compressor Installation,

Operation, and Maintenance Instructions

©2007 Helix Technology Corporation Pub. No. 8040437, Rev. 104, 06/12/2007 ECO No.18068 Printed in USA

HELIX TECHNOLOGY CORPORATION

http://www.helixtechnology.com

Page 2

Page 3

The information in this document is believed to be accurate and reliable. However,

Helix Technology Corporation, cannot accept any financial or other responsibilities that may

result from the use of this information. No warranties are granted or extended by this

document.

Helix Technology Corporation reserves the right to change any or all information contained

herein without prior written notice. Revisions may be issued at the time of such changes

and/or deletions.

Any duplication of this manual or any of its parts without expressed written permission from

Helix Technology Corporation is strictly prohibited.

Any correspondence regarding this document should be forwarded to:

Helix Technology Corporation

Mansfield Corporate Center

Nine Hampshire Street

Mansfield, Massachusetts 02048-9171 U.S.A.

Telephone: (508) 337-5000

FAX: (508) 337-5464

The following Helix Technology Corporation trademarks and service marks may appear in

this document:

Conductron

Cryogenerator

GOLDLink

®

®

®

Helix Technology..

Your Vacuum Connection

On-Board

Stabil-Ion

Vacuum Assurance

®

®

SM

Convectron

Cryo-Torr

Granville-Phillips

Micro-Ion

SM

RetroEase

ThinLine™

®

®

®

®

®

Cryodyne

CTI-Cryogenics

GUTS

Mini-Convectron

RetroFast

TurboPlus

®

®

®

®

®

®

Cryogem

FastRegen™

Helix

Mini-Ion™

Stabil-1

TrueBlue

®

®

®

SM

All other trademarks or registered trademarks are the property of their respective holders.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 iii

Page 4

Page 5

Table of Contents

Table of Contents

Figures

Tables

Safety Conventions

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-1

Signal Word Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-1

Safety Shape Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-2

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-2

Section 1 - 9600 Compressor Description

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Compressor Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

CTI-CRYOGENICS Helium Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Cooling Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Component Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

System Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Elapsed Time Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Control Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Power ON Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Gas Charge Flared Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Helium Pressure Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Power Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Return Gas Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Cooling Water IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Cooling Water OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Cryopump Electrical Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Compressor Remote Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Supply Gas Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 v

Page 6

Multiple On-Board Cryopump Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Multiple Cryo-Torr Cryopump Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Section 2 - Unpacking and Inspection

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Shipping Carton Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Removal from Shipping Carton . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Compressor Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Helium "OFF" Condition Pressure Verification . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Shipping Carton Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Section 3 - Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Supply and Return Water Line Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Hard Water Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Flexible Water Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Phase Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Connecting/Disconnecting Helium Flex Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Connecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Disconnecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Single On-Board Cryopump Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Multiple On-Board Cryopump Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Helium Line Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Power Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Multiple Cryo-Torr Cryopump Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Helium Line Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Power Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Section 4 - Operation

Adjusting System Helium Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

"OFF" Condition Helium System Pressure Verification . . . . . . . . . . . . . . . . . . . . . 4-1

Compressor Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Replacement of Helium Circuit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Section 5 - Maintenance

Scheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Suggested Maintenance Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Adsorber Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Adjusting System Helium Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

vi Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 7

Reducing Helium Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Increasing Helium Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Adding Helium . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Appendix A - Customer Support Information

Customer Support Center Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Guaranteed Up-Time Support (GUTS®) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

E-mail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Appendix B - Flow Diagram

Appendix C - Troubleshooting Procedures

Troubleshooting the Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Technical Inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Appendix D - Schematic

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Index

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 vii

Page 8

viii Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 9

Figures

Figure 1-1: 9600 Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Figure 1-2: 9600 Compressor Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Figure 1-3: Water Flow Rate versus Pressure Drop . . . . . . . . . . . . . . . . . . . . . 1-6

Figure 1-4: 9600 Compressor Rear View Component Locations. . . . . . . . . . . 1-8

Figure 1-5: 9600 Compressor Connected to Multiple On-Board Cryopumps 1-12

Figure 1-6: 9600 Compressor Connected to Multiple Cryo-Torr Cryopumps 1-13

Figure 3-1:9600 Compressor Installation Flowchart . . . . . . . . . . . . . . . . . . . . 3-2

Figure 3-2: 9600 Compressor Circuit Breaker Terminals (Cover Removed) . 3-5

Figure 3-3:Connecting/Disconnecting Helium Flex Line Couplings. . . . . . . . 3-8

Figure 3-4: Single On-Board Cryopump Connections . . . . . . . . . . . . . . . . . . . 3-9

Figure 3-5: Single Cryo-Torr Cryopump Installation. . . . . . . . . . . . . . . . . . . 3-10

Figure 3-6: Recommended Multiple On-Board Cryopump or Waterpump Installation

(Splitter Box located at Process Tool) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Figure 3-7: Alternative Multiple On-Board Cryopump or Waterpump Installation

(Splitter Box located at Compressor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Figure 3-8: Multiple Cryo-Torr Cryopump Installation . . . . . . . . . . . . . . . . . 3-15

Figure 3-9: Multiple Cryo-Torr Cryopump Installation . . . . . . . . . . . . . . . . . 3-16

Figure 5-1: Disconnecting Self Sealing Couplings. . . . . . . . . . . . . . . . . . . . . . 5-2

Figure 5-2: Adsorber Location in 9600 Compressor (Rear Panel Removed). . 5-4

Figure 5-3: Helium Pressure Control Components. . . . . . . . . . . . . . . . . . . . . . 5-5

Figure B-1: 9600 Compressor Flow Diagram P/N 8135001 Rev. A . . . . . . . . B-2

Figure D-1: 9600 High Voltage Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ix

Page 10

x Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 11

Tables

Table 1-1:Compressor Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 1-2:Electrical Input Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 1-3:Cooling Water Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 1-4:General Compressor Operating Specifications . . . . . . . . . . . . . 1-7

Table 1-5:Cryopump Electrical Outlet Pin Assignments . . . . . . . . . . . . . 1-11

Table 1-6:Compressor Remote Connector Pin Assignments . . . . . . . . . . 1-11

Table 4-1:9600 Compressor Helium ("OFF" Condition) Charge. . . . . . . . 4-1

Table 5-1:Suggested Maintenance Equipment . . . . . . . . . . . . . . . . . . . . . . 5-1

Table C-1:Compressor Troubleshooting Procedures . . . . . . . . . . . . . . . . . C-2

Table D-1:Basic Control Assembly Legend. . . . . . . . . . . . . . . . . . . . . . . . D-1

Table D-2:On-Board/Cryo Electrical Module P/N 8135127G002 Legend D-2

Table D-3:On-Board Output Module P/N 8135148G001 Legend . . . . . . . D-3

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 xi

Page 12

xii Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 13

Safety Conventions

Introduction

Follow all safety precautions during installation, normal operation, and when

servicing CTI-Cryogenics products.

This chapter explains the safety conventions used throughout this manual.

CTI-Cryogenics uses a specific format for cautions and warnings, which includes

standard signal words and safety shapes.

See also the Customer Support appendix or call your local Customer Support

Center for assistance.

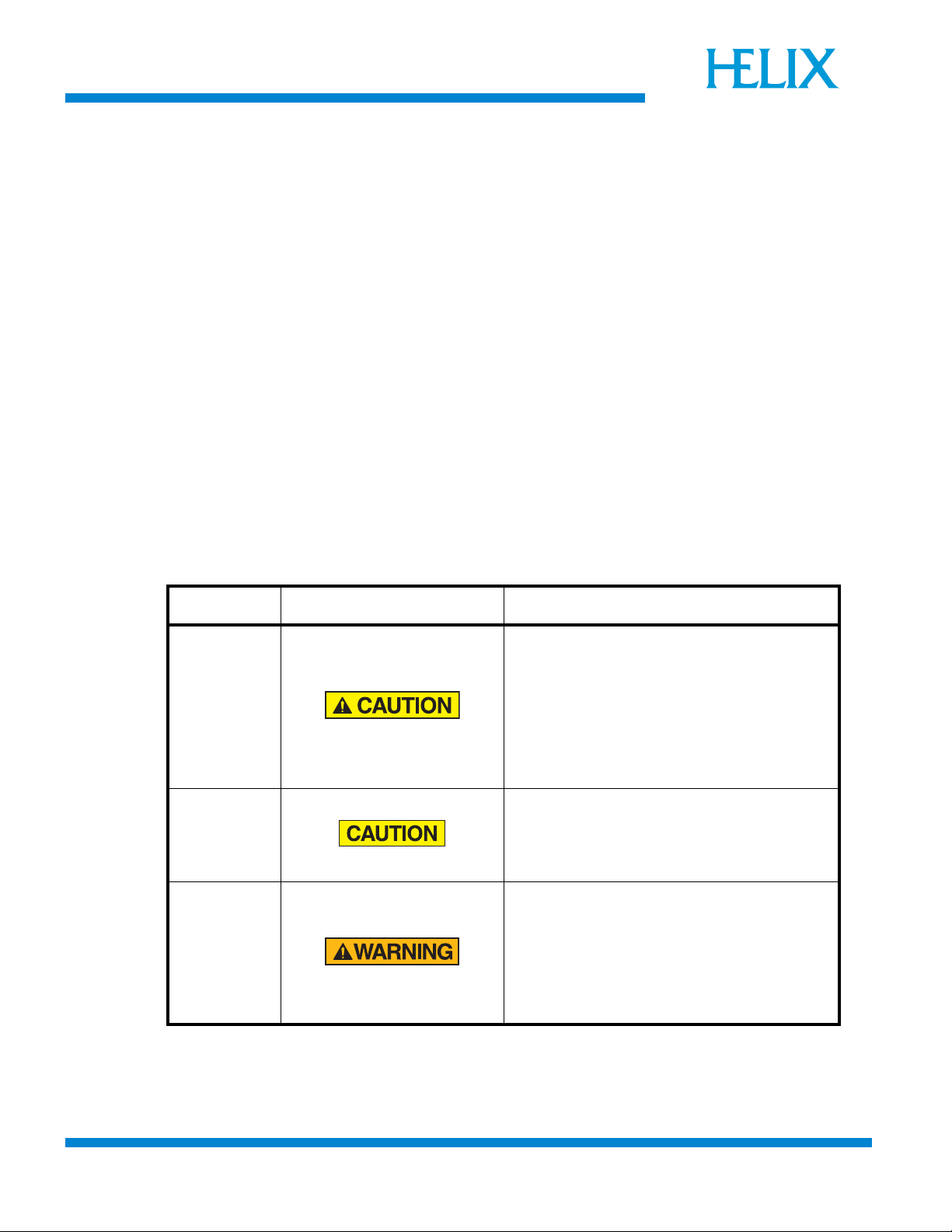

Signal Word Descriptions

All cautions and warnings contain signal words, which call attention to safety

messages and designate the degree of hazard seriousness. The following table

shows the signal words and their meanings that may be used in this document.

Term Example Definition

CAUTION

CAUTION

WARNING

A signal word accompanied by a safety shape

that indicates a potentially hazardous situation

or unsafe practice.

If not avoided, the action may result in minor

or moderate personal injury or equipment

damage. A CAUTION is highlighted in

yellow.

A signal word that indicates a situation or

unsafe practice, which if not avoided may

result in equipment damage. A CAUTION is

highlighted in yellow.

A signal word accompanied by a safety shape

that indicates indicates a potentially hazardous

situation.

If not avoided, the action may result in serious

injury or death. A WARNING is highlighted

in orange.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 S-1

Page 14

Safety Shape Descriptions

Safety Shape Descriptions

Example Term Shape Definition

All cautions and warnings contain safety shapes, which have specific safety

meanings. The following table shows some of the safety shapes used in this

document and their meanings.

References

General Warning

High Voltage Indicates a high voltage hazard.

Hot Surface

For more information about safety standards, see the following documents:

Indicates a general hazard. Details about this

hazard appear in the safety notice explanation.

Indicates a surface is hot enough to cause

discomfort or a burn.

• ISO 7010: 2003(E), Graphic symbols - Safety colours and safety

signs - Safety signs used in workplaces and public areas

• ISO 3864-1: 2002(E), Graphic symbols - Safety colours and safety

signs - Part 1: Design principles for safety signs in workplaces and

public areas

S-2 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 15

Section 1 - 9600 Compressor Description

General

This manual provides the information required to install, operate, and

maintain the CTI-CRYOGENICS 9600 Compressor .

NOTE: All personnel with installation, operation, and maintenance

responsibilities should become familiar with the contents of both the 9600

Compressor Installation, Operation, Maintenance, and appropriate

cryopump manuals to ensure safe, high quality, and reliable system

performance.

CAUTION

Refer to “Appendix A - Customer Support Information” to contact the

local Customer Support Center for information on connecting 9600

Compressors to a manifold with other CTI-CRYOGENICS

compressors.

Compressor Configurations

The 9600 Compressor supports either On-Board or Cryo-Torr Cryopumps.

For multiple cryopump installations, an On-Board Splitter Box or CryoTorr Interface can be used for cold head power distribution that reduces

total cable requirements as shown in Figure 1-5 and Figure 1-6.

System Documentation

The manuals for a system cover two basic components: the cryopump and

the Compressor. A manual is shipped with each system component to

provide information for installation and operation of that component. A

loose-leaf binder with index tab separators is also provided so you can

compile a complete set of tabulated manuals.

CTI-CRYOGENICS Helium Refrigeration System

The operation of CTI-CRYOGENICS’ cryopumps is based upon a closed

loop helium expansion cycle. The system is made up of two major

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 1-1

Page 16

CTI-CRYOGENICS Helium Refrigeration System

components: the cryopump, which contains the cold head, and the helium

Compressor which compresses the helium gas.

Refrigeration is produced in the cryopump cold head through periodic

expansion of high pressure helium in a regenerative process. The high

pressure helium is provided by the Compressor. Low pressure helium

returning from the cold head is compressed into the necessary high

pressure to be returned to the cold head. The energy required to compress

the helium is rejected as heat through the cooling water.

High pressure room temperature helium is transferred to the cold head

through the supply lines. After expansion, low pressure helium is returned

to the Compressor (at or near room temperature) to repeat the cycle in a

closed loop fashion. Large separation distances can be accommodated

between the Compressor and the cryopump.

In the Compressor, helium is compressed using a highly reliable oil

lubricated commercial Compressor. Helium purification takes place via

several stages of oil removal. The final stage of purification is performed

with a replaceable adsorber cartridge. In order to maintain peak efficiency,

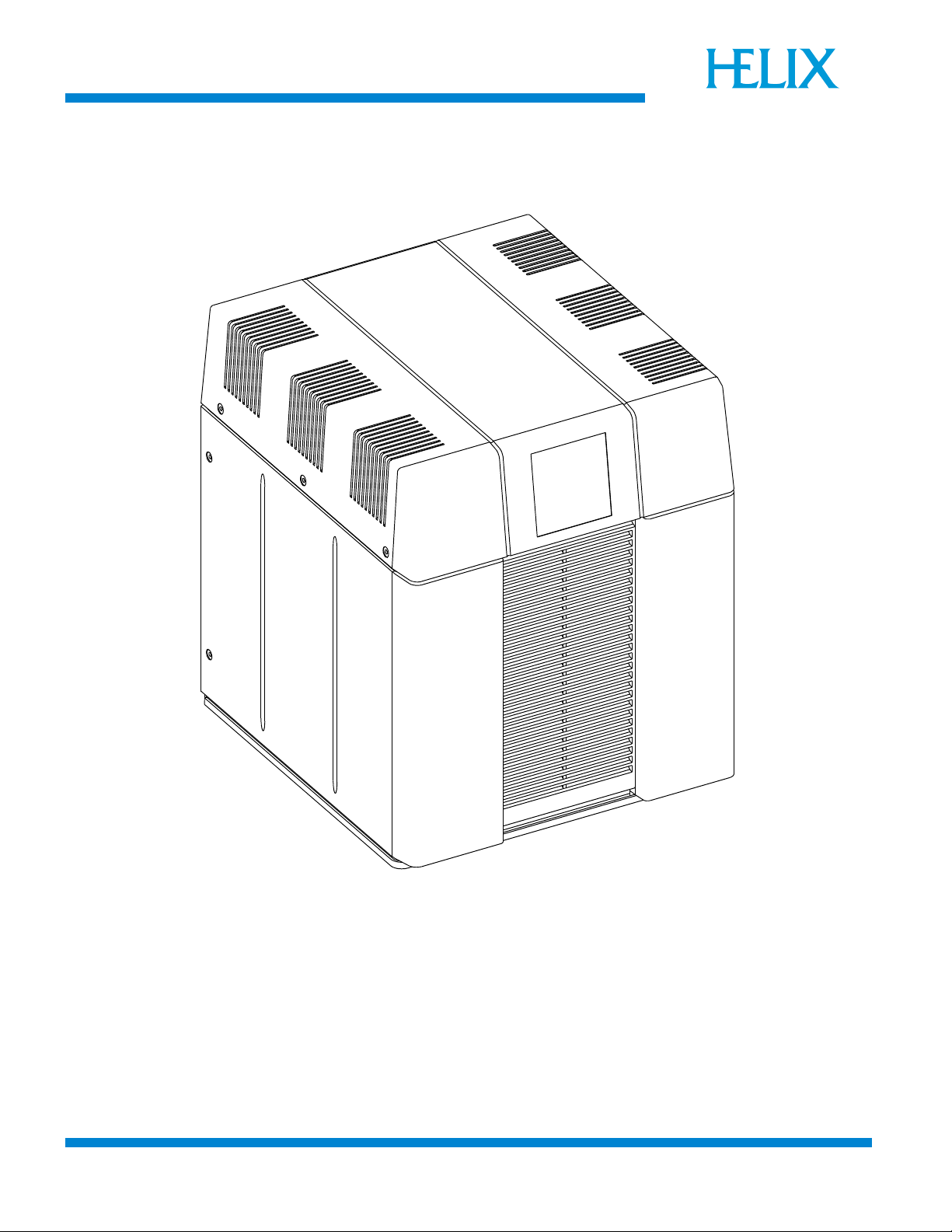

the adsorber must be replaced every three years. The 9600 Compressor is

shown in Figure 1-1.

1-2 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 17

0

0

R

6

9

O

S

0

R

ES

0

6

R

O

9

S

P

S

M

E

R

CO

P

M

O

C

Figure 1-1: 9600 Compressor

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 1-3

Page 18

Specifications

Specifications

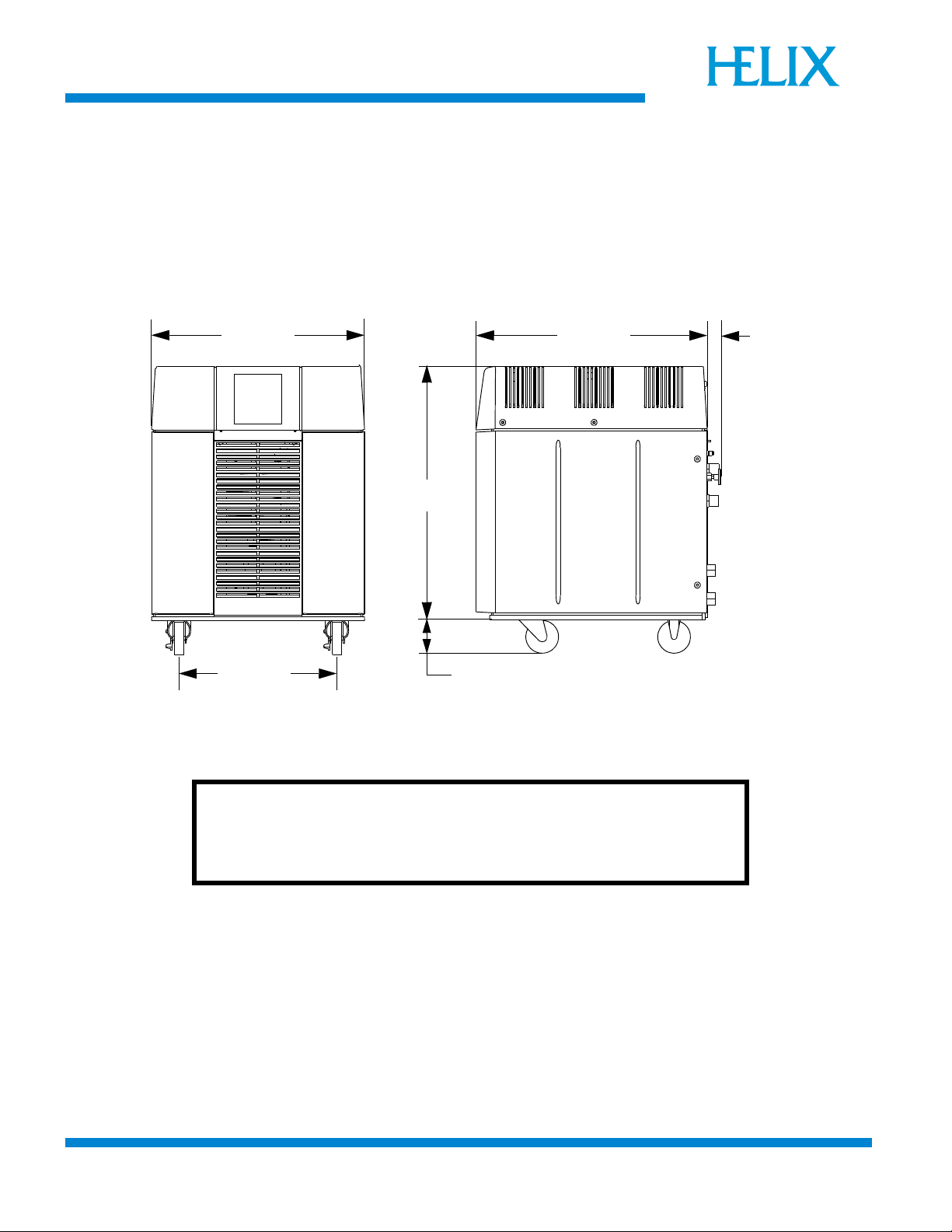

Dimensions

The dimensions of the Compressor are shown in Figure 1-2.

19.52 in.

(496 mm)

14.4 in.

(366 mm)

21.50 in.

(546 mm)

23.36 in.

(593 mm)

3.18 in.

(81 mm)

Figure 1-2: 9600 Compressor Dimensions

1.28

(32mm)

CAUTION

Do not place a weight greater than 75 lbs. (34Kg) on top of the

Compressor.

1-4 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 19

Weight

Electrical

The weight of the Compressor is listed in Table 1-1.

Table 1-1: Compressor Weight

Weight lbs./kg

267/121kg

The electrical specifications of the Compressor are listed in Table 1-2.

Table 1-2: Electrical Input Specifications

Parameter Value

Operating Voltage Range/Frequency 342-457V/50 Hz

342-506V/60 Hz

Phase 3

Nominal Input Power 5.5 KW/60 Hz

5KW/50 Hz

Nominal Power Factor 0.85

Rated FL/LR* Current 8/40

Minimum Electrical Service 15 Amps

*FL/LR = Full Load/Locked Rotor

Cooling Water

The water used to cool the Compressor must meet the specifications shown

in Table 1-3 for proper system operation.

Table 1-3: Cooling Water Specifications

Parameter Value

Maximum Inlet Temperature 90°F (32°C)

Minimum Inlet Temperature 50°F (10°C)

Flow Rate 2.75 ±1.25 gpm (10.4 ± 4.7 lpm)

NOTE: Water conditioning may be required for ap plications not meetin g these requirements.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 1-5

Page 20

Specifications

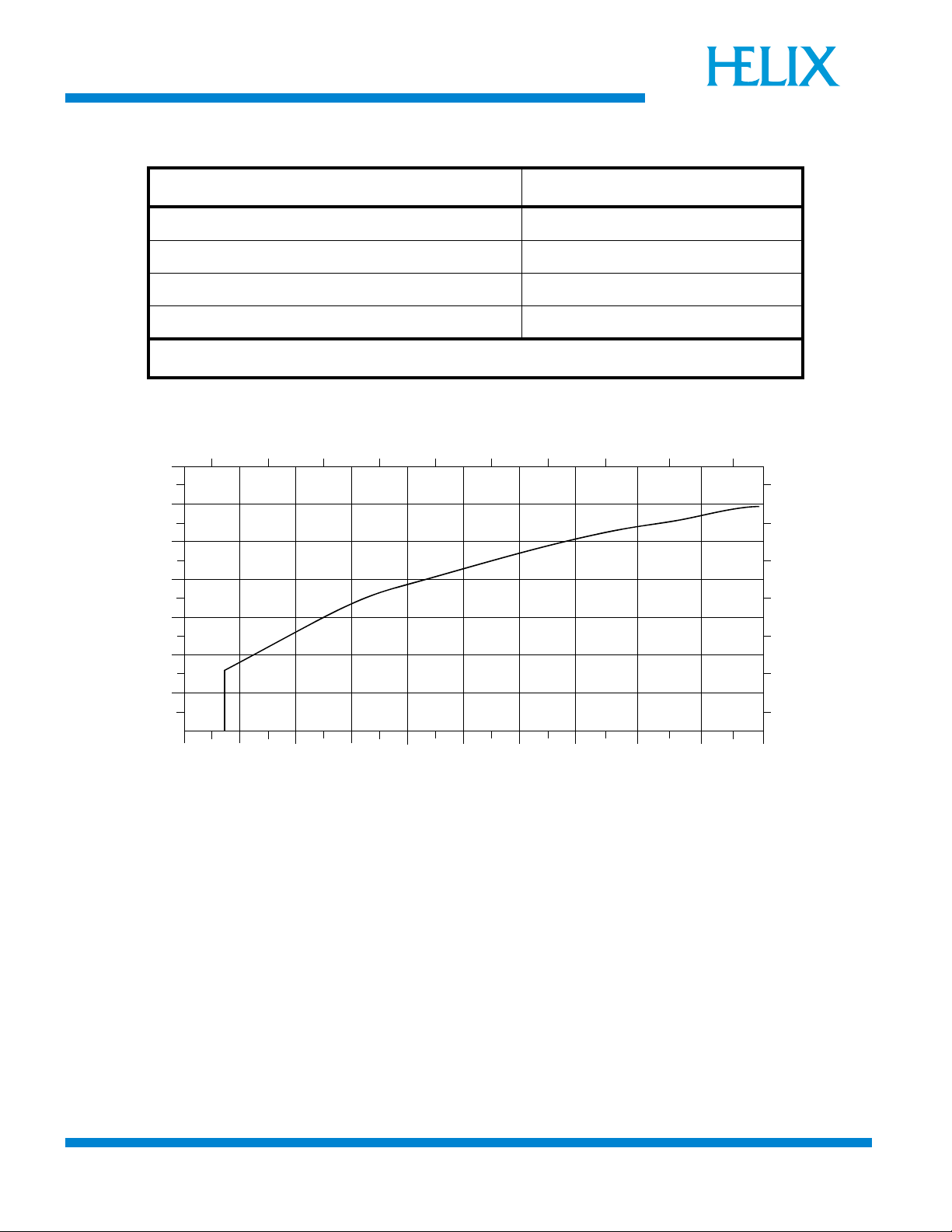

Table 1-3: Cooling Water Specifications (Continued)

Parameter Value

Pressure Drop (inlet-to-outlet)

See Figure 1-3

Maximum Inlet Pressure 100 psi (6.9 bars)

Alkalinity 6.0 - 8.0 pH

Calcium Carbonate < 75 ppm

NOTE: Water conditioning may be required for ap plications not meetin g these requirements.

WATER PRESSURE DROP (Bars)

.07 .49

.21

.35

.63

4.00

3.50

E

N

I

L

3.00

2.50

2.00

1.50

WATER FLOW RATE (GPM)

AC

C

EPT

E

P

O

E

BL

A

G

N

I

T

A

R

.77

15.2

13.3

11.40

9.50

7.60

5.70

WATER FLOW RATE (LPM)

1.00

0.50

1

NOTE: Figure 1-3 defines the water flow rate through the Compressor as a function of the pressure drop from

water inlet to water outlet. You must provide the correct pressure drop in your water supply system to ensure that

3

5

WATER PRESSURE DROP (PSID)

7

9

3.80

1.90

11

-

Figure 1-3: Water Flow Rate versus Pressure Drop

General

The information in Table 1-4 provides general Compressor operating

specifications.

1-6 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 21

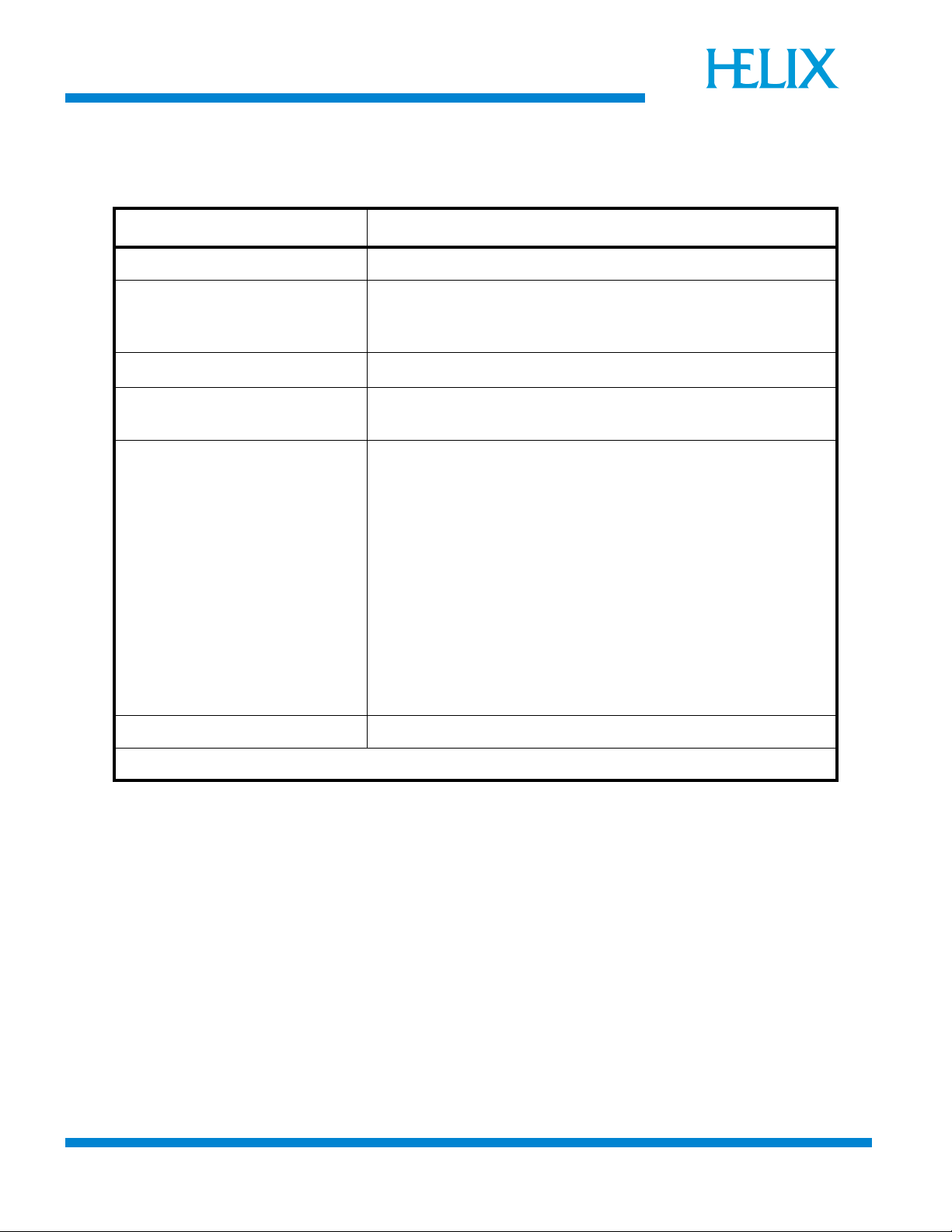

Table 1-4: General Compressor Operating Specifications

Specification Values

Part Number 8135901G001

Input Power Cable

(Customer Supplied)

Nominal Helium Pressure

Ambient Operating Tem-

perature Range

Interface

Gas Supply Connector

Gas Return Connector

Remote Control Receptacle

Adsorber Service Schedule 3 Years

600 VAC

12 Gauge, 3 conductor wire with ground

Must conform to local electrical codes

Refer to

50 - 100º F (10 - 38º C)

Cryopump Power Receptacles: mates with the

CTI-CRYOGENICS supplied cryopump power cable for single

pump use.

Mates with remote junction box power cable for multiple cryopump use.

1/2 in. Aeroquip self-sealing coupling

1/2 in. Aeroquip self-sealing coupling

24VAC, 2.7A inductive mates with P5 connector Type

MS3106A*

Table 4-1

* Supplied by CTI-CRYOGENICS

NOTE: The 9600 Compressor is designed for continuous operation and

should remain ON when the cryopumps are in a regeneration cycle.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 1-7

Page 22

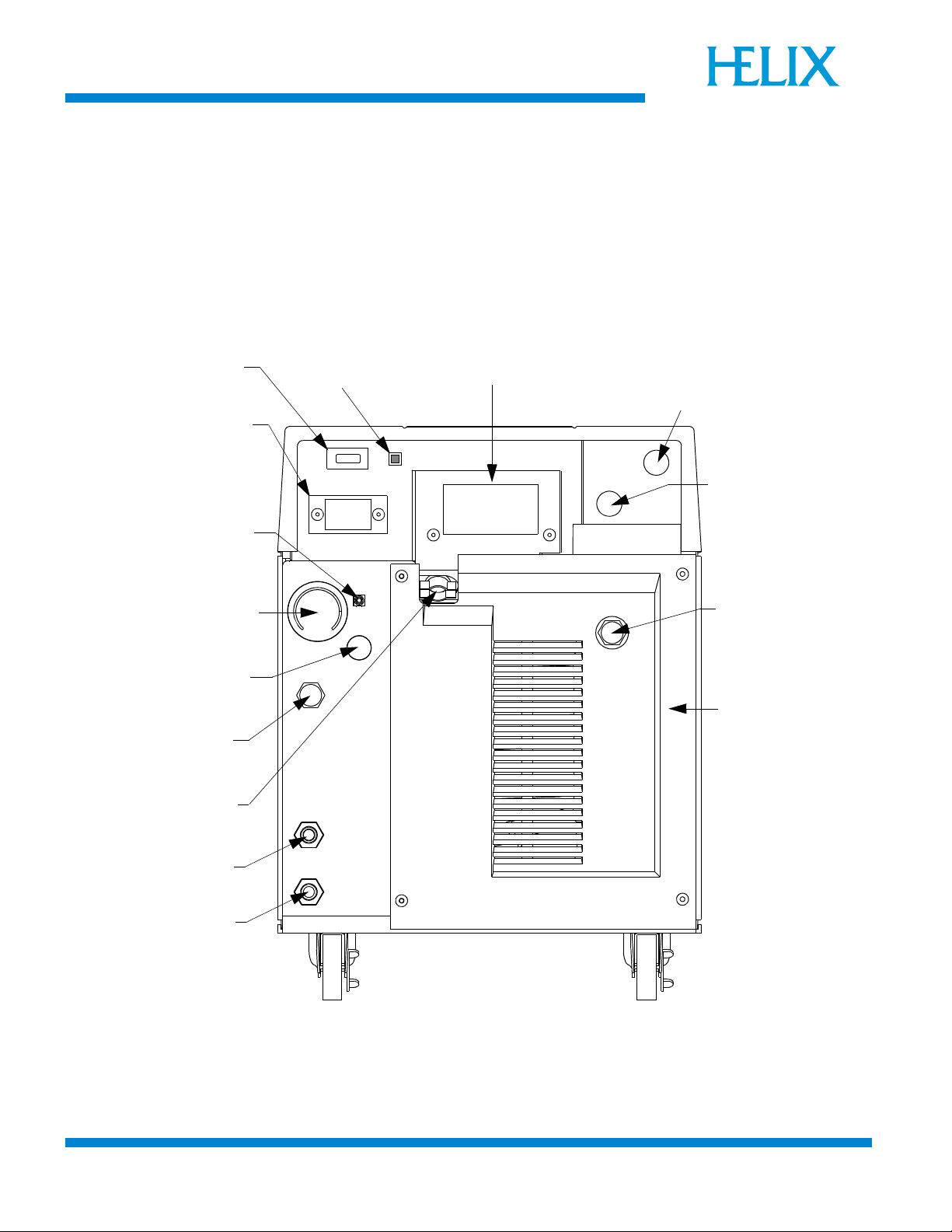

Component Description

Component Description

The components of the 9600 Compressor that are accessible from the rear

panel are shown in Figure 1-4 and described in the following paragraphs.

Elapsed Time

Meter

Control Circuit

Breaker

Gas Charge

Flared Fitting

Helium

Pressure Gauge

Gas Charge

Control Valve

Return Gas

Coupling

Power Inlet

Power ON

Indicator

System Circuit

Breaker

Cryopump Electrical Outlet

Compressor

Remote

Connector

Supply Gas

Coupling

Rear Panel

Cooling Water

IN

Cooling Water

OUT

Figure 1-4: 9600 Compressor Rear View Component Locations

1-8 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 23

System Circuit Breaker

The System Circuit Breaker protects main input power to the Compressor

pump and module. The circuit breaker positions are labeled ON (1), which

is in the UP position, and OFF (0), which is in the DOWN position.

NOTE: The phase monitor in the Compr essor will cause the system cir cuit

breaker to open when input power phases are incorrect.

Elapsed Time Meter

The Elapsed Time Meter records the number of Compressor operating

hours. Since the meter is digital, it is not illuminated unless the system

circuit breaker is in the ON position and power is connected to the

Compressor. The Elapsed Time Meter maintains the correct accumulated

operating hours while system power is turned OFF.

NOTE: The meter cannot be reset.

Control Circuit Breaker

The Control Circuit Breaker provides current overload protection for all

internal components of the Compressor except the Compressor motor. The

Compressor motor is protected by a separate overload protector. The

Control Circuit Breaker opens automatically and must be reset manually.

Power ON Indicator

The Power On Indicator illuminates when the system circuit breaker is

placed in the ON position. The Compressor pump is energized when the

power indicator is illuminated and the elapsed time meter records system

operation time.

Gas Charge Flared Fitting

The Gas Charge Flared Fitting is used to connect a 99.999% pure helium

supply to the Compressor when helium charging is required. The fitting has

a 45º flare and 7/16 in. x 20 threads/inch. Refer to “Section 5 -

Maintenance” for information on adding helium to the Compressor.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 1-9

Page 24

Component Description

Helium Pressure Gauge

Power Inlet

Return Gas Coupling

The Helium Pressure Gauge indicates system ("OFF" Condition) helium

charge pressure when the Compressor and cryopumps are OFF and

Compressor suction or inlet pressure when the Compressor is ON. Refer to

Table 4-1 for the appropriate ("OFF" Condition) helium charge pressure.

The Power Inlet is used to connect your power cable to the Compressor.

Refer to “Section 3 - Installation” for information on power cable

installation.

The Return Gas Coupling returns the helium, which has been cycled

through the cryopump, back to the Compressor. Refer to “CTI-

CRYOGENICS Helium Refrigeration System” in this section for more

information.

Cooling Water IN

The Cooling Water IN connector provides water to the Compressor from

your facility to cool the Compressor during operation. The connector

thread size is a 1/2 in. female pipe thread. The water must meet the

specifications outlined in Table 1-3. Refer to “Section 3 - Installation” for

more information on cooling water connections.

Cooling Water OUT

The Cooling Water OUT connector returns the water that has been used to

cool the Compressor to your facility. The connector thread size is a 1/2 in.

female pipe thread. Refer to “Section 3 - Installation” for more information

on cooling water connections.

Cryopump Electrical Outlet

The Cryopump Electrical Outlet provides power to a single On-Board or

Cryo-Torr Cryopump, an On-Board Splitter Box, or a Cryo-Torr Interface.

The Compressor requires the use of an On-Board Splitter Box or Cryo-T orr

Interface for multiple cryopump system connections. Refer to T able 1-5 for

connector pin identification. Refer to “Multiple On-Board Cryopump

Connections” or “Multiple Cryo-Torr Cryopump Connections” in this

1-10 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 25

section for more information.

Table 1-5: Cryopump Electrical Outlet Pin Assignments

Identifier Function

A and B Heater Power - 208 VAC nominal

C Center tap for D and E

D and E 24 VCT @ 4.6 Amps

F-G and G-H Cold Head Voltage Output 130-160 VAC @ 4.5 Amps

J Chassis Ground

K Not Used

Compressor Remote Connector

The Compressor Remote Connector is a 14 pin connector that can be used

in conjunction with the On-Board setpoint relays, relays in the Cryo-Torr

Interface, or a signal from the vacuum system to turn the Compressor ON

or OFF. Refer to Table 1-6 for connector pin identification. Switching

contacts must be rated at 24VAC, 2.7A inductive.

NOTE: The Compr essor is shipped with a mating plug which must remain

installed in the Compressor Remote Connector to ensure Compressor

operation when the Compressor remote feature is not being used.

Table 1-6: Compressor Remote Connector Pin Assignments

Identifier Function

D and E Compressor Remote Control

F, G, I, J Answer Back

A,B,C,H,K,L,M,N Open

Supply Gas Coupling

The Supply Gas Coupling provides a connection for high pressure

compressed helium to the cryopump cold head. Refer to “CTI-

CRYOGENICS Helium Refrigeration System” in this section for more

information.

Make = ON, Break = OFF

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 1-11

Page 26

Multiple On-Board Cryopump Connections

Multiple On-Board Cryopump Connections

The On-Board Splitter Box permits the connection of multiple On-Board

Cryopumps or Waterpumps to one 9600 Compressor as shown in Figure 1-

5. Refer to “Section 3 - Installation” for more information on connecting

single or multiple On-Board Cryopumps or Waterpumps to the

Compressor.

WATER

SUPPLY

REMOTE

POWER

RETURN

On-Board

Splitter

Box

On-Board Cryopump

Power Cable

Figure 1-5: 9600 Compressor Connected to Multiple On-Board Cryopumps

NOTE: Your installation (number of pumps per compressor) will vary

based upon the On-Board Cryopumps or Waterpumps used. Refer to

“Appendix A - Customer Support Information” to consult your local CTI-

CRYOGENICS Customer Support Center for information on specific

compressor/pump applications.

1-12 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 27

Multiple Cryo-Torr Cryopump Connections

The Cryo-Torr Interface permits the connection of multiple Cryo-Torr

Cryopumps to one Compressor as shown in Figure 1-6.

Refer to “Section 3 - Installation” for more information on connecting

single or multiple Cryo-Torr Cryopumps to the Compressor.

SUPPLY

RETURN

Cryo-Torr

Interface

Remote

WATER

POWER

Cryopump Electrical Input

User Remote

(from vacuum system)

Figure 1-6: 9600 Compressor Connected to Multiple Cryo-Torr Cryopumps

NOTE: Your installation (number of pumps per compressor) will vary

based upon the Cryo-Torr Cryopump models used. Refer to “Appendix A -

Customer Support Information” to consult your local CTI-CRYOGENICS

Customer Support Center for information on specific compressor/

cryopump applications.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 1-13

Page 28

Multiple Cryo-Torr Cryopump Connections

1-14 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 29

Section 2 - Unpacking and Inspection

Introduction

The 9600 Compressor is shipped in a shipping carton incorporating a ramp

system which makes removing the Compressor from the carton safe and

easy.

Shipping Carton Inspection

Inspect the exterior of the shipping carton for visible signs of damage

before opening the shipping carton. Report any damage to the shipping

company at once.

Removal from Shipping Carton

1. Cut the two straps on the exterior of the shipping pallet.

2. Lift the cardboard carton straight up and remove it from the

pallet.

3. Cut the tape which holds the ramp in the vertical position.

4. Swing the ramp down until the end touches the floor.

5. Remove any excess shipping material from around the Compressor .

Maintain control over the movement of the Compressor

as it rolls down the ramp. Injury to personnel may result if the Compressor

is allowed to roll freely down the ramp.

CAUTION

Maintain control over the movement of the Compressor as it rolls

down the ramp. Damage to the Compressor may result if the

Compressor is allowed to roll freely down the ramp.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 2-1

Page 30

Compressor Inspection

Compressor Inspection

Compressor

Helium "OFF" Condition Pressure Verification

6. Carefully roll the Compressor down the ramp and onto the floor.

Inspect the Compressor for visible signs of damage as indicated in the

following paragraphs.

Inspect the exterior of the Compressor for visible signs of damage,

evidence of an oil leak, and check the Helium Pressure Gauge for proper

helium pressure. Report any damage to the shipping company at once.

Refer to “Section 4 - Operation” for more information on the ("OFF"

Condition) helium charge pressure of the 9600 Compressor.

Shipping Carton Contents

The shipping carton should contain the following items:

• Compressor

• Two barbed fittings for flexible water lines

• Installation, Operation, and Maintenance manual

• Compressor remote start connector and strain relief

2-2 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 31

Introduction

Section 3 - Installation

Section 3 provides you with the information required to install the 9600

Compressor and connect it to single or multiple On-Board or Cryo-Torr

Cryopump configurations.

Figure 3-1 highlights the major tasks for Compressor installation and refers

to the appropriate installation procedures in this section.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 3-1

Page 32

Introduction

START

Supply and Return Water

Line Connections

(page 3-3)

Electrical Connections

(page 3-4)

Phase Check

(page 3-6)

Connect/Disconnect Helium

Flexlines (page 3-7)

Single Cryopump

Connections (page 3-8)

Single or Multiple

Cryopump

Installation?

Multiple Cryopump

Connections (page 3-11)

See

“Section 4 - Operation”

END

Figure 3-1: 9600 Compressor Installation Flowchart

3-2 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 33

Supply and Return Water Line Connections

NOTE: The water used for cooling the Compressor must meet the

specifications outlined in “Section 1 - 9600 Compressor Description”.

Hard Water Lines

1. Apply a light coating of standard plumbing thread sealant to the

hard line pipe threads.

2. Install the Supply hard line into the INPUT connection on the rear

panel of the Compressor. Tighten the fitting by hand.

3. Install the Return hard line into the OUTPUT connection on the

rear panel of the Compressor. Tighten the fitting by hand.

CAUTION

Do not overtighten the ferrules. Damage to the input and output

connector threads may occur.

4. Using a wrench, tighten the fittings.

5. Allow water to flow and check for leaks at the rear of the

Compressor.

Flexible Water Lines

1. Apply a light coating of standard plumbing thread sealant to the

barbed fitting threads.

2. Install the barbed fittings into the INPUT and OUTPUT

connections on the rear panel of the Compressor.

Do not overtighten the barbed fittings. Damage to the INPUT and

OUTPUT connector threads may occur.

3. Using a wrench, tighten the barbed fittings.

4. Connect the Supply flexible water line to the INPUT barbed fitting

and secure with a hose clamp.

5. Connect the Return flexible water line to the OUTPUT barbed

fitting and secure with a hose clamp.

CAUTION

6. Allow water to flow and check for leaks at the rear of the

Compressor.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 3-3

Page 34

Electrical Connections

Electrical Connections

Follow all local high voltage safety precautions when performing this

procedure to reduce the possibility of electrical shock. Make sure all

electrical power is OFF before proceeding with this procedure.

The following procedures provide information for making all three phase

(180 - 250 VAC) electrical connections to the Compressor.

Power Cable Preparation

WARNING

CAUTION

The cable used for making the Compressor power cable must be 10

gauge, 3 conductor cable with ground rated at 600 VAC.

1. Cut a 10 AWG (6.00 mm2), 3 conductor cable with ground to

an appropriate length.

2. Strip the cable jacket back 4 in. (101.6 mm).

3. Strip the insulation back 3/8 in. (9.3 mm) on each individual

conductor.

4. Install a #10 ring tongue terminal on the end of each conductor

using the appropriate size double crimping tool.

5. Remove the rear panel as shown in Figure 3-2.

6. Remove the circuit breaker terminal cover as shown in Figure 3-2.

7. Install the cable into the Compressor through the cable strain relief.

8. Remove the 10-32 nut and install the grounding wire on the ground

stud. Install the nut and tighten to 18 in.-lbs (0.21m-kg).

NOTE: Use a slotted screwdriver which is capable of holding a screw

when performing steps 9 and 10.

9. Remove the screws from the Compressor circuit breaker terminals

X, Y, and Z as shown in Figure 3-2.

3-4 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 35

See Detail A

Circuit Breaker

Terminal Cover

Y

Z

Rear Panel

X

Three Phase Power

Detail A

Figure 3-2: 9600 Compressor Circuit Breaker Terminals (Cover Removed)

NOTE: The phase order in which the conductor terminal lugs are

connected to circuit breaker terminals X, Y, and Z will be determined

during the Phase Check Procedure.

NOTE: For installation where one of the three phase legs is at or near

ground potential, connect that leg to terminal Y on the Compressor as

shown in Figure 3-2.

10. Install the conductor terminal lugs to the circuit breaker terminals

X, Y, and Z as shown in Figure 3-2.

11. Torque the screws to 12 in.-lbs (0.14m-kg).

12. Allow enough cable to stay in the electrical enclosure to prevent

strain on the electrical connections and tighten the screws on the

cable strain relief.

13. Install the power source end of the power cable according to the

local electrical codes.

14. Install the circuit breaker terminal cover.

15. Proceed with Phase Check.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 3-5

Page 36

Phase Check

WARNING

Follow all high voltage safety precautions when performing this

procedure to prevent the possibility of electrical shock.

1. Make sure power is applied to compressor circuit as described

in Table 1-2.

NOTE: The cir cuit breaker will trip immediately during step 2 if the power

phase connections are not correct.

2. Turn the Compressor circuit breaker to the ON position. If the

circuit breaker trips, refer to step 3. If the circuit breaker does not

trip, refer to step 4.

3. If the circuit breaker trips, perform the following steps:

a. Turn the Compressor circuit breaker to the OFF position.

b. Disconnect the power cord from the power source.

c. Remove the circuit breaker terminal cover.

d. Reverse the wiring order of Compressor circuit breaker

terminals X and Y.

e. Torque the circuit breaker terminal screws to 12 in.-lbs.

f. Install the circuit breaker terminal cover.

g. Repeat steps 1- 2 of this procedure.

4. Install the rear panel.

5. Proceed with appropriate cryopump connections.

3-6 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 37

Connecting/Disconnecting Helium Flex Lines

CAUTION

Make sure the helium flex lines are connected and disconnected from

the 9600 Compressor using the following procedure and as shown in

Figure 3-3. Failure to follow this procedure could damage connector

O-ring seals or cause a helium circuit leak.

Connecting

1. Remove all dust plugs and caps from the Gas Supply and

Return lines, and the Compressor and cryopump Supply and

Return connectors. Check for the presence of a flat gasket in

the male connector, and no gasket in the female connector.

2. Connect the Gas Return line to the GAS RETURN connector on the

rear of the Compressor and then to the GAS RETURN connector

on the cryopump. Using two wrenches as shown in Figure 3-3,

tighten the connector.

3. Connect the Gas Supply line to the GAS SUPPLY connector on the

rear of the Compressor and then to the GAS SUPPLY connector on

the cryopump. Using two wrenches as shown in Figure 3-3, tighten

the connector.

Disconnecting

4. Attach the Supply and Return line identification labels to each end

of the appropriate lines.

1. Using two wrenches as shown in Figure 3-3, disconnect the two

self sealing coupling connectors quickly to minimize helium

leakage.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 3-7

Page 38

Single On-Board Cryopump Connections

This 1 1/8 (or 1) in. wrench

holds the coupling in a stationary position.

HOLD WITH 1 1/8 INCH WRENCH

TURN WITH 1 3/16 INCH WRENCH

TO LOOSEN

Figure 3-3: Connecting/Disconnecting Helium Flex Line Couplings

This 1 3/16 in. wrench

is used to turn the self

sealing coupling connector.

TO TIGHTEN

TURN WITH 1 3/16 INCH WRENCH

HOLD WITH 1 INCH WRENCH

Single On-Board Cryopump Connections

CAUTION

Make sure the Compressor power is OFF before making any

connections to the rear panel.

1. Connect the Supply and Return lines to the 9600 Compressor as

described in “Connecting/Disconnecting Helium Flex Lines” in

this section.

2. Connect one end of the Cryopump cold head cable to the

CRYOPUMP ELECTRICAL OUTLET on the rear panel of the

Compressor as shown in Figure 3-4.

3. Connect the opposite end of the cold head cable to the cryopump

3-8 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 39

cold head cable connector.

SUPPLY

RETURN

REMOTE

On-Board Cryopump

Power Cable

WATER

POWER

Figure 3-4: Single On-Board Cryopump Connections

CAUTION

Make sure the Compressor power is OFF before making any

connections to the rear panel.

1. Connect the Supply and Return lines to the 9600 Compressor as

described in “Connecting/Disconnecting Helium Flex Lines” in

this section.

2. Connect one end of the Cryopump cold head cable to the

CRYOPUMP ELECTRICAL OUTLET on the rear panel of the

Compressor as shown in Figure 3-5. Connect the opposite end of

the cold head cable to the cryopump cold head cable connector as

shown in Figure 3-5.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 3-9

Page 40

Single On-Board Cryopump Connections

SUPPLY

RETURN

REMOTE

Cryo-Torr

Power Cable

WATER

POWER

Figure 3-5: Single Cryo-Torr Cryopump Installation

3-10 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 41

Multiple On-Board Cryopump Connections

CAUTION

Make sure the Compressor power is OFF before making any

connections to the rear panel.

Helium Line Connections

CAUTION

The use of several compressors on a single manifold feeding a

common supply header and a common return header requires special

precautions. Contact CTI-CRYOGENICS for a review of the intended

installation and for specific technical instructions.

The use of a 9600 compressor on a manifold with other

CTI-CRYOGENICS compressor models requires a reduction of the

helium charge pressure to 200 - 210 psig charge pressure to avoid

helium safety valves from inadvertently venting. Refer to “Section 4 -

Operation” and “Section 5 - Maintenance” for more information.

1. Connect the Supply and Return lines to the 9600 Compressor as

described in “Connecting/Disconnecting Helium Flex Lines” in

this section.

2. Connect the Gas Return Line to the customer supplied helium

manifold and then to the GAS RETURN connector on the

On-Board Cryopump.

3. Connect the Gas Supply Line to the customer supplied helium

manifold and then to the GAS SUPPLY connector on the On-Board

Cryopump.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 3-11

Page 42

Multiple On-Board Cryopump Connections

Power Cable Connections

1. Connect the On-Board Splitter Box power cable between the

CRYOPUMP ELECTRICAL OUTLET on the rear panel of the

Compressor and the On-Board Splitter Box power connector as

shown in Figure 3-6.

2. Connect the On-Board Cryopump or Waterpump power cables to

the CRYOPUMP 1, 2, or 3 connectors on the On-Board Splitter

Box and the respective cryopumps as shown in Figure 3-6.

NOTE: Your installation (number of pumps per compressor) will vary

based upon the On-Board Cryopump models used. Refer to “Appendix A -

Customer Support Information” to consult your local CTI-CRYOGENICS

Customer Support Center for information on specific compressor/pump

applications.

NOTE: The On-Board Splitter Box can be installed at the process tool

containing the pumps as shown in Figure 3-6, or on the rear of the

Compressor as shown in Figure 3-7. CTI-CRYOGENICS recommends that

the On-Board Splitter box be installed near the pr ocess tool to r educe cable

requirements.

WATER

SUPPLY

POWER

NOTE:

RETURN

REMOTE

On-Board Power Cable

On-Board

Splitter Box

Figure 3-6: Recommended Multiple On-Board Cryopump or Waterpump Installation

3-12 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 43

SUPPLY

RETURN

REMOTE

On-Board Power Cables

On-Board

WATER

POWER

Splitter Box

(Splitter Box located at Process Tool)

Figure 3-7: Alternative Multiple On-Board Cryopump or W aterpump Installation

(Splitter Box located at Compressor)

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 3-13

Page 44

Multiple Cryo-Torr Cryopump Connections

Multiple Cryo-Torr Cryopump Connections

CAUTION

Make sure the Compressor power is OFF before making any

connections to the rear panel.

Helium Line Connections

CAUTION

The use of several compressors on a single manifold feeding a

common supply header and a common return header requires special

precautions. Contact CTI-CRYOGENICS for a review of the intended

installation and for specific technical instructions.

The use of a 9600 compressor on a manifold with other

CTI-CRYOGENICS compressor models requires a reduction of the

helium charge pressure to 200 - 210 psig charge pressure to avoid

helium safety valves from inadvertently venting. Refer to “Section 4 -

Operation” and “Section 5 - Maintenance” for more information.

1. Connect the Supply and Return lines to the 9600 Compressor as

described in “Connecting/Disconnecting Helium Flex Lines” in

this section.

2. Connect the Gas Return Line to the customer supplied helium

manifold and then to the Gas Return connector on the Cryo-Torr

Cryopump.

3. Connect the Gas Supply Line to the customer supplied helium

manifold and then to the Gas Supply connector on the Cryo-Torr

Cryopump.

Power Cable Connections

1. Connect the Cryo-Torr power cable between the CRYOPUMP

ELECTRICAL OUTLET on the rear panel of the Compressor

and the CRYOPUMP ELECTRICAL INPUT on the Cryo-Torr

Interface as shown in Figure 3-8 or Figure 3-9.

2. Connect the Cryo-Torr Power Cables between the CRYOPUMP 1,

3-14 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 45

SUPPLY

2, or 3 connectors on the Cryo-Torr Interface and the respective

Cryo-Torr Cryopumps as shown in Figure 3-8 or Figure 3-9.

3. Connect the User Remote cable to the Cryo-T orr Interface as shown

in Figure 3-8 or Figure 3-9.

4. Connect the Remote cable between the Cryo-Torr Interface and the

Compressor as shown in Figure 3-8 or Figure 3-9.

NOTE: Your installation may vary based upon the Cryo-Torr Cryopump

models used. Refer to “Appendix A - Customer Support Information” to

consult your local CTI-CRYOGENICS Customer Support Center for

information on specific compressor/cryopump applications.

NOTE: The Cryo-Torr Interface can be installed at the process tool

containing the cryopumps as shown in Figure 3-8 or near the Compressor

as shown in Figure 3-9. CTI-CRYOGENICS recommends that the CryoTorr Interface be installed at the process tool to reduce cable requirements.

RETURN

Cryo-Torr

Interface

User Remote

(from vacuum system)

WATER

POWER

Remote

Cryopump Electrical Input

Figure 3-8: Multiple Cryo-Torr Cryopump Installation

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 3-15

Page 46

Multiple Cryo-Torr Cryopump Connections

SUPPLY

RETURN

Cryopump Power

Remote

Cryo-Torr

Interface

WATER

POWER

User Remote

(from vacuum system)

Figure 3-9: Multiple Cryo-Torr Cryopump Installation

3-16 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 47

Section 4 - Operation

Adjusting System Helium Pressure

Your CTI-CRYOGENICS high vacuum pump system is comprised of

several pressurized components i.e. compressor, flex lines, and cryopumps.

Each component is charged with helium before shipment. After all

cryopumps, helium lines, and manifolds are attached to the compressor, the

system ("OFF" Condition) helium charge pressure must be verified before

system operation. Once the ("OFF" Condition) helium system pressure has

been verified, the system is ready for operation. After cooldown, the

normal system operating pressure is recorded.

NOTE: The 9600 Compressor is designed for continuous operation and

should remain ON even when the cryopumps are in a regeneration cycle.

"OFF" Condition Helium System Pressure Verification

The proper system ("OFF" Condition) helium charge pressure is necessary

so that the cryopumps operate at maximum performance as well as to

assure that the compressor will operate below the maximum design motor

winding temperature which will maximize the life of the compressor

motor.

1. Make sure the Compressor and Cryopump(s) are OFF.

2. Make sure all system components are connected together as

described in “Section 3 - Installation”.

3. Allow all system components to acclimate to a temperature

between 60º F and 80º F (15.5º C - 26.6º C).

4. Read the compressor helium pressure gauge located on the

compressor rear panel as shown in Figure 1-4. Compare the gauge

reading to the appropriate 50/60 Hz line frequency value

(depending upon your system installation) indicated in Table 4-1.

Table 4-1: 9600 Compressor Helium ("OFF" Condition) Charge

Line Frequency Helium ("OFF" Condition) Charge Pressure

60 Hz 240 - 250 psig (16.5 - 17.2 bars )

50 Hz 255 - 265 psig ( 17.6 -18.3 bars )

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 4-1

Page 48

Compressor Operation

Exceeding the recommended system ("OFF" Condition) helium

charge pressure will result in the compressor and cryopump safety

relief valves opening and releasing excess helium gas.

Compressor Operation

NOTE: The use of a higher helium charge pressure for 50 HZ operation is

necessary in order to compensate for the slower speed at which the

compressor operates at 50 HZ. The ("OFF" Condition) charge level for 60

Hz remains at 240-250 PSIG.

CAUTION

5. If the ("OFF" Condition) helium charge pressure is not in the ranges

as indicated in Table 4-1, then adjust the charge pressure as

described in “Section 5 - Maintenance”.

CAUTION

While the 9600 Compressor is operating, the helium pressure gauge

indicator should never be in the red zone. If the gauge indicator is

below 65 psig, then the system must be checked for insufficient

helium or helium leaks. If the gauge indicator is above 160 psig, then

the system has been over pressurized. Refer to “Section 5 -

Maintenance” and either add or remove helium before operating the

9600 Compressor.

The system may be operated once the helium charge pressure is correct.

Perform the following steps to start the compressor:

1. Set the System Circuit Breaker to the ON (UP) position.

2. Set the Control Circuit Breaker to the ON (UP) position.

3. Close all Cryopump gate valves.

4. Refer to the On-Board Module Programming and Operation

manual or Cryo-Torr Cryopump Installation and Service

manual (that came with your cryopump) and perform the cryopump

start-up procedure.

5. Once the second stage temperature for all cryopumps is below 17K,

record the compressor pressure gauge reading as the normal system

operating pressure.

NOTE: During compressor operation, the compressor gauge reads the

pressure of the gas entering the compressor prior to it being compressed.

4-2 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 49

6. Affix a copy of the data next to the compressor gauge on each

compressor . This data is to be verified for each tool installa tion and

whenever a configuration change is made affecting the amount of

system helium gas and line volume.

The compressor pressure reading will decrease from the normal system

operating pressure during cryopump regeneration or if fewer cryopumps

are being operated. These are normal variations in the compressor pressure

reading and should not be cause for concern.

If you have concerns about system performance changing, then check the

normal system operating pressure which was determined in “Compressor

Operation” in this section. If the normal system operating pressure is not

correct, check the system for leaks.

Once the leaks have been repaired, helium must be added to return the

system to normal operating system pressure as described in “Section 5 -

Maintenance”.

Replacement of Helium Circuit Components

On occasion, it may be necessary to replace components such as

cryopumps, helium gas lines or compressors, or change the configuration

of the system. Whenever any of these conditions occur, "OFF" Condition

Helium System Pressure Verification should be performed to ensure that

("OFF" Condition) helium pressure has not changed.

CAUTION

The use of several compressors on a single manifold feeding a

common supply header and a common return header requires special

precautions. Contact CTI-CR YOGENICS for a review of the intended

installation and for specific technical instructions. The use of a 9600

compressor on a manifold with other CTI-CRYOGENICS compressor

models requires a reduction of the helium charge pressure to 200--210

psig charge pressure to avoid helium safety valves from inadvertently

venting.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 4-3

Page 50

Replacement of Helium Circuit Components

4-4 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 51

Section 5 - Maintenance

Scheduled Maintenance

Suggested Maintenance Equipment

It is recommended to have the following equipment and disposable

supplies available as listed in Table 5-1.

Table 5-1: Suggested Maintenance Equipment

Supply CTI-CRYOGENICS P/N

Helium, 99.999% pure -

Pressure regulator (0-3000/0-400 psi) Assy. 8031403

Helium charging line terminating in a 1/4-inch

female flare fitting

Lint-free gloves and cloth -

Oakite or equivalent detergent soap -

Denatured alcohol -

Refer to

“Appendix A - Customer Support Information” and contact the local Customer

Support Center to obtain the

CTI-CRYOGENICS parts listed in this table.

7021002P001

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 5-1

Page 52

Scheduled Maintenance

Adsorber Replacement

Use the following procedure to change the adsorber every three years.

1. Set the System Circuit Breaker, on the rear of the 9600

Compressor, to the OFF position.

2. Remove the 4 screws which secure the rear panel to the

Compressor and remove the rear panel.

NOTE: Use two wrenches in Step 3 to prevent loosening the body of the

coupling.

3. Using a 1-3/16 in. wrench, and a 1-1/8 in. wrench, as shown in

Figure 5-1, disconnect the two self sealing coupling connectors

quickly to minimize helium leakage.

This 1 1/8 (or 1) in. wrench

holds the coupling in a stationary position.

HOLD WITH 1 1/8 INCH WRENCH

TURN WITH 1 3/16 INCH WRENCH

TO LOOSEN

Figure 5-1: Disconnecting Self Sealing Couplings

This 1 3/16 in. wrench

is used to turn the self

sealing coupling connector.

TO TIGHTEN

TURN WITH 1 3/16 INCH WRENCH

HOLD WITH 1 INCH WRENCH

4. Using a 7/16 in. (11mm) wrench, remove the adsorber mounting

bolt as shown in Figure 5-2.

5-2 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 53

5. Move the adsorber from under the mounting tabs in the base as

shown in Figure 5-2 and remove the adsorber from the Compressor .

6. Install the replacement adsorber under the mounting tabs and

secure it into place with the bolt removed during Step 4.

7. Using two wrenches as shown in Figure 5-1, connect the two self

sealing couplings quickly to minimize helium leakage.

8. Install the Compressor rear panel.

9. Ensure that the pressure gauge reads the proper value as shown in

Table 4-1. If additional gas pressure is required, refer to “Adding

Helium” in this section. If gas pressure needs to be reduced, refer to

“Reducing Helium Pressure” in this section.

10. Record the adsorber replacement date on the label as shown in

Figure 5-2, and also note that the next adsorber replacement should

be performed every three years.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 5-3

Page 54

Scheduled Maintenance

DATE

Adsorber

Adsorber

Mounting

Bolt

Figure 5-2: Adsorber Location in 9600 Compressor (Rear Panel Removed)

5-4 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 55

Adjusting System Helium Pressure

NOTE: These pr ocedur es can be performed on a compressor that is turned

ON or OFF. However, the helium pressure gauge should be set to the

("OFF" Condition) helium charge pressure value if the compressor is

turned OFF or set to the normal system operating pressure if the

compressor is turned ON. Refer to “Section 4 - Operation” for more

information.

Reducing Helium Pressure

NOTE: You must obtain the normal system operating pressure from the

“Compressor Operation” procedure in “Section 4 - Operation” in order to

perform this procedure. If the normal system operating pressure is

unknown, then shut the compressor OFF and perform the “"OFF"

Condition Helium System Pressure Verification” procedure in “Section 4 Operation” instead.

1. Remove the flare cap from the gas charge fitting as shown in

Figure 5-3.

Gas Charge Flared Fitting

Helium

Pressure

Gauge

Gas Charge

Control Valve

Figure 5-3: Helium Pressure Control Components

2. Open the gas charge control valve very slowly to allow a slight

amount of helium to escape. Leave the valve open until the helium

pressure gauge indicates one of the following:

• To the appropriate value in Table 4-1 if the compressor is OFF and

acclimated to a temperature between 60º F and 80º F

Rear Panel

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 5-5

Page 56

Adjusting System Helium Pressure

Increasing Helium Pressure

If helium is being added more than once every several months, check

for leaks caused by improperly connected self-sealing connections or

any mechanical joint in the Compressor.

(15.5º C - 26.6º C).

• To the value previously recorded in the “Compressor Operation”

procedure in “Section 4 - Operation” if the compressor is ON.

3. Close the gas charge control valve and install the flare cap.

Use the following procedure to increase the helium pressure if the

indicated pressure is below the appropriate value as shown in Table 4-1.

CAUTION

Adding Helium

NOTE: You must obtain the normal system operating pressure from the

“Compressor Operation” procedure in “Section 4 - Operation” in order to

perform this procedure. If the normal system operating pressure is

unknown, then shut the compressor OFF and perform the “"OFF"

Condition Helium System Pressure Verification” procedure in “Section 4 Operation” instead.

This procedure ensures that both the regulator and the charging line will be

purged of air and that the air trapped in the regulator will not diffuse back

into the helium bottle. For best results, CTI-CRYOGENICS suggests a

dedicated helium bottle, regulator, and line, which are never separated, for

adding helium.

NOTE: You are required to supply the helium charging line terminating in

a 1/4-inch female flare fitting, and a two-stage pressure regulator rated at

0-3000/0-400 psig for this operation.

CAUTION

Use only 99.999% pure helium gas. Helium circuit contamination may

result if a lower quality of helium is used.

5-6 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 57

1. Attach a regulator (0-3000/0-400 psig) and charging line to a

helium bottle (99.999% pure).

NOTE: Do not open the bottle at this time.

2. Purge the regulator and charging lines as follows:

a. Open the regulator a small amount by turning the adjusting

knob clockwise until it contacts the diaphragm, then turn

approximately 1/8 to 1/4 turn more, so that the regulator is

barely open.

b. Loosely connect the charge line to the helium pressure

regulator.

c. Slowly open the bottle valve, and purge the regulator and

line for 10 to 15 seconds. Turn the regulator knob

counterclockwise until the helium stops flowing.

3. Remove the flare cap of the gas charge flared fitting on the rear of

the Compressor.

4. Loosely connect the charging line from the helium pressure

regulator to the 1/4-inch male flare fitting installed on the helium

charge valve. Purge the charge line again, as in step a, for 30

seconds, and tighten the charge line flare fitting onto the gas charge

fitting while the helium is flowing.

5. Set the helium pressure regulator to 300 psig (20.7 bars). If the

compressor is ON, proceed with step a. If the compressor is OFF,

proceed with step b.

a. Obtain the previously recorded normal system operating

pressure from the “Compressor Operation” procedure in

“Section 4 - Operation”. Open the gas charge control valve

very slowly and allow helium to flow until the compressor

gauge reading is the same as the value obtained from

“Section 4 - Operation”. Quickly close the gas charge

control valve.

b. Obtain the appropriate (50 or 60 Hz) ("OFF" Condition)

system operating pressure from Table 4-1. Open the gas

charge control valve very slowly and allow helium to flow

until the compressor gauge reading is the same as the

appropriate value in T able 4-1. Quickly close the gas char ge

control valve.

6. Ensure that the helium charge valve on the Compressor is tightly

closed. Shut off the helium pressure regulator on the helium bottle

and remove the charging line from the male flare fitting. Reinstall

the flare cap.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 5-7

Page 58

Adjusting System Helium Pressure

5-8 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 59

Appendix A - Customer Support Information

Customer Support Center Locations

To locate a Customer Support Center near you, please visit our website

www.helixtechnology.com on the world wide web and select CONTACT on

the home page.

Guaranteed Up-Time Support (GUTS®)

For 24-hour, 7-day per week Guaranteed Up-Time Support (GUTS) dial:

1 800-367-4887 - Inside the United States of America

+1 508-337-5599 - Outside the United States of America

Product Information

Please have the following information available when calling so that we

may assist you:

• Product Part Number

• Product Serial Number

• Product Application

• Specific Problem Area

• Hours of Operation

• Equipment Type

• Vacuum System Brand/Model/Date of Manufacture

For your convenience, you may also e-mail us at:

techsupport@helixtechnology.com

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 A-1

Page 60

E-mail

A-2 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 61

Appendix B - Flow Diagram

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 B-1

Page 62

A

.

v

e

R

1

0

0

5

3

1

8

N

/

P

m

a

r

g

a

i

D

w

o

l

F

r

o

s

s

e

r

p

m

o

C

0

0

6

9

:

1

B

e

r

u

g

i

F

B-2 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 63

Appendix C - Troubleshooting Procedures

Troubleshooting the Compressor

The compressor troubleshooting procedures are summarized in Table C-1.

Technical Inquiries

Please refer to “Appendix A - Customer Support Information” of this

manual for a complete list of the

CTI-CRYOGENICS’ world wide customer support centers.

CAUTION

Disconnect the compressor before performing any troubleshooting

procedures. The compressor pump is hot after operating. Wait for the

pump to cool down before working on the inside of the compressor

Do not change or modify any compressor internal wiring circuits, this

may cause failure of the compressor and cold head due to improper

phasing.

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 C-1

Page 64

Technical Inquiries

Table C-1: Compressor Troubleshooting Procedures

Problem Possible Cause Corrective Action

1) System circuit breaker

(CB1) trips immediately to

the OFF (0) position when

switched to the ON (1)

position.

2) System (CB1) and Control

Circuit (CB2) circuit breakers remain in the ON (1)

position when switched ON

but the compressor will not

run.

1) Incorrect phasing of input

power.

1) No power coming from

source.

2) Insufficient power

3) Remote control jumper plug

not in place. This will apply

only if remote circuit is not

being used.

1) Check phasing of input

power. Refer to

“Phase

Check” in “Section 3 Installation”.

1) Check source fuses, circuit

breakers, and wiring associated with the power

source. Repair as needed.

2) Verify adequate phase-tophase input voltage. Refer

to

Table 1-2.

3) Check to insure that remote

jumper plug is fully seated.

See

Figure 1-4 for loca-

tion. Refer to

“Compres-

sor Remote Connector”

in

“Section 1 - 9600

Compressor Description” for more information.

4) Improperly wired external

remote control circuit.

NOTE: Only applies if

remote control feature is

being used.

C-2 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

4) Verify correct installation of

remote control feature.

Refer to

Table 1-6.

Page 65

Table C-1: Compressor Troubleshooting Procedures (Continued)

Problem Possible Cause Corrective Action

3) System circuit breaker

(CB1) will not remain in

the ON (1) position when

switched ON. The Control

Circuit circuit breaker

(CB2) trips when excessive current is being drawn

by the cold head or 24 volt

compressor control circuits.

4) System circuit breaker

(CB1) remains in the ON

(1) position and the compressor stops after several

minutes of operation and

remains OFF (0).

1) Damaged On-Board power

cable, connectors, or drive

motor.

2) Damaged component in the

compressor power or control

circuit.

1) Thermal protective switches

are open.

2) Very cold water has caused a

restriction of oil flow through

the oil injection orifice during start-up.

1) Check for compressor operation with cryopump cable

disconnected from compressor. Refer to

“Appendix A

- Customer Support Information” to contact the Cus-

tomer Support Center if the

compressor operates

improperly.

2) Refer to

“Appendix A Customer Support Information” to contact the Cus-

tomer Support Center.

1) Check for inadequate water

cooling. Refer to

2) Recheck for proper cooling

water temperature. Refer to

Table 1-3.

Table 1-3. Restart compres-

sor repeatedly until continuous operation is achieved.

5) System circuit breaker

(CB1) trips after a period

of running.

1) Loss or degradation of power

from the source.

2) Defective motor windings.

1) Check that line voltage is

correct on all phases.

2) Check running current on all

phases.

3) Refer to

“Appendix A Customer Support Information”

Customer Support Center.

to contact the local

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 C-3

Page 66

Technical Inquiries

C-4 Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 ©2007 Helix Technology Corporation

Page 67

Introduction

Appendix D - Schematic

The schematic in Appendix D supports the 9600 (High Voltage)

Compressor CTI-CRYOGENICS P/N 8135164P002.

Table D-1: Basic Control Assembly Legend

Identifier Description

1M Compressor Motor

CB1 Main Circuit Breaker (15A)

CB2 Control Circuits Circuit Breaker (4A)

ETM Elapsed Time Meter

ETM1 Elapsed Time Meter

J15 Module Power Receptacle

J1/P1 Autoset Power Connector

J2/P2 Unload Solenoid Connector

J3/P3 Oil Solenoid Connector

J4/P4 Helium Thermal Switch

J5/P5 Water Thermal Switch

J6/P6 Compressor Contactor Coil

J7/P7 Autoset Input Connector

J8 ETM Connector

M1 Contactor 7.5 HP IEC

J9/P9 LT1 Connector

J10/P10 Control Transformer

J11 Open

J12 Module Signal Connector

J13/P13 Phase Monitor

J14 Open

©2007 Helix Technology Corporation Part Number 8040437, Revision 104, 06/12/2007, ECO Number 18068 D-1

Page 68

Introduction

Table D-1: Basic Control Assembly Legend (Continued)

Identifier Description

K2 Over Temperature Lockout Relay

LT1 Lamp, 24-28V LED Green

M1OL Relay, Overload (10-16A - set at 10A)

PM1 Phase Monitor OMRON RDR-TFY-M

PWB1 PWB Autoset

T3 Transformer Assembly Control

Table D-2: On-Board/Cryo Electrical Module P/N 8135127G002 Legend

Identifier Description

JT1 Open

JT2 Open

JT3/PT3 T2 Cold Head Supply, 2 phase

JT4/PT4 T1 Cold Head Supply, 2 phase

JT5/PT5 T2 Cold Head Transformer Output

JT6/PT6 T1 Cold Head Transformer Output

JT7/PT7 T4 Supply

JT8/PT8 T4 Low Voltage Output (23/26 VCT)

J18 Power Output

J19 Signal Output