Page 1

8200 Compressor

Installation, Operation and Service

-

TI CR

C

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

Instructions

8040353

Rev. 101 (11/2001)

View our inventory

HELIX TECHNOLOGY CORPORATION

http://www.helixtechnology.com

Page 2

The inform ation in this docu m en t is believed to be accu rate and reliable. However,

Helix Technology Corporation, cannot acce pt any fi na ncial or other responsibili ties th at ma y

result from the use of this information. No warranties are granted or extended by this document.

Helix Technology Corporation reserves the right to change any or all

information cont ai ne d herein without prior wri tten notice. Revisions may be issued at the time of

such changes and/or de le ti ons.

Any duplication of this manual or any of its par ts without expressed written pe rmission from

Helix Technology Corporation is strictly prohibited.

Any correspondenc e regarding this docume nt should be forwarded to:

Helix Technology Corporation

Mansfield Corpora te Center

Nine Hampshire Street

Mansfield, Massachu s et ts 02048-9171 U.S.A.

Telephone: (508 ) 337-5000

FAX: (508) 337-5464

The following H e li x Technology Corporat io n tra demarks and service ma rks m ay appear in this

document:

Conductron™

Cryogenerator

GOLDLink

Helix

RetroEase

®

®

®

ThinLine™

Convectron

®

Cryo-Torr

Granville-Phillips™

Micro-Ion

RetroFast

TurboPlus

®

®

Cryodyne

CTI-Cryogenics

GUTS

®

®

®

Mini-Ion™

Stabil-1

Vacuum Assurance

®

®

®

Cryogen

FastRegen™

Helix Technology . . Your

Vacuum Connection

On-Board

®

SM

Stabil-Ion

®

SM

®

®

All other tradem a rks or registered tradema rks are the property of th eir respective hol ders.

Copyright© 2001 Heli x Technology Corpora tion Printed in U.S.A.

Page 3

8200 Compressor

Section 1 - Introduction

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Installation, Operation and Servicing Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Section 2 - Inspection

Packaging of the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

The Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Section 3 - Installation

Compressor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Preparing the Compressor Input-Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Cooling Water Requirements (Water-Cooled Compressors Only) . . . . . . . . . 3-3

Cooling Water: General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Cooling Water: Flow and Pressure Requirements . . . . . . . . . . . . . . . . . . . . . . 3-4

Cooling Water: Temperature Rise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Final Preparation of Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Connecting the Compressor to the Cold Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Table of Contents

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

Section 4 - Maintenance Procedures

Scheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Removing the Compressor Adsorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Installing the Compressor Adsorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Unscheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Suggested Unscheduled Maintenance Equipment . . . . . . . . . . . . . . . . . . . . . . . 4-3

Adding Helium Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Helium Circuit Decontamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Appendix A - Customer Support Information

Appendix B - Troubleshooting Procedures

Appendix C - Electrical Schematics for 8200 Compressor

Appendix D - Components in the Electrical Control Module of the 8200 Compressor

P/N 8040353 iii

Page 4

-

C

8200 Compressor

TI CR

HELIX TECHNOLOGY CORPORATION

Table of Contents (continued)

Appendix E - Flow Diagrams for 8200 Air-Coo led and Water-Cooled Compressors

Figures

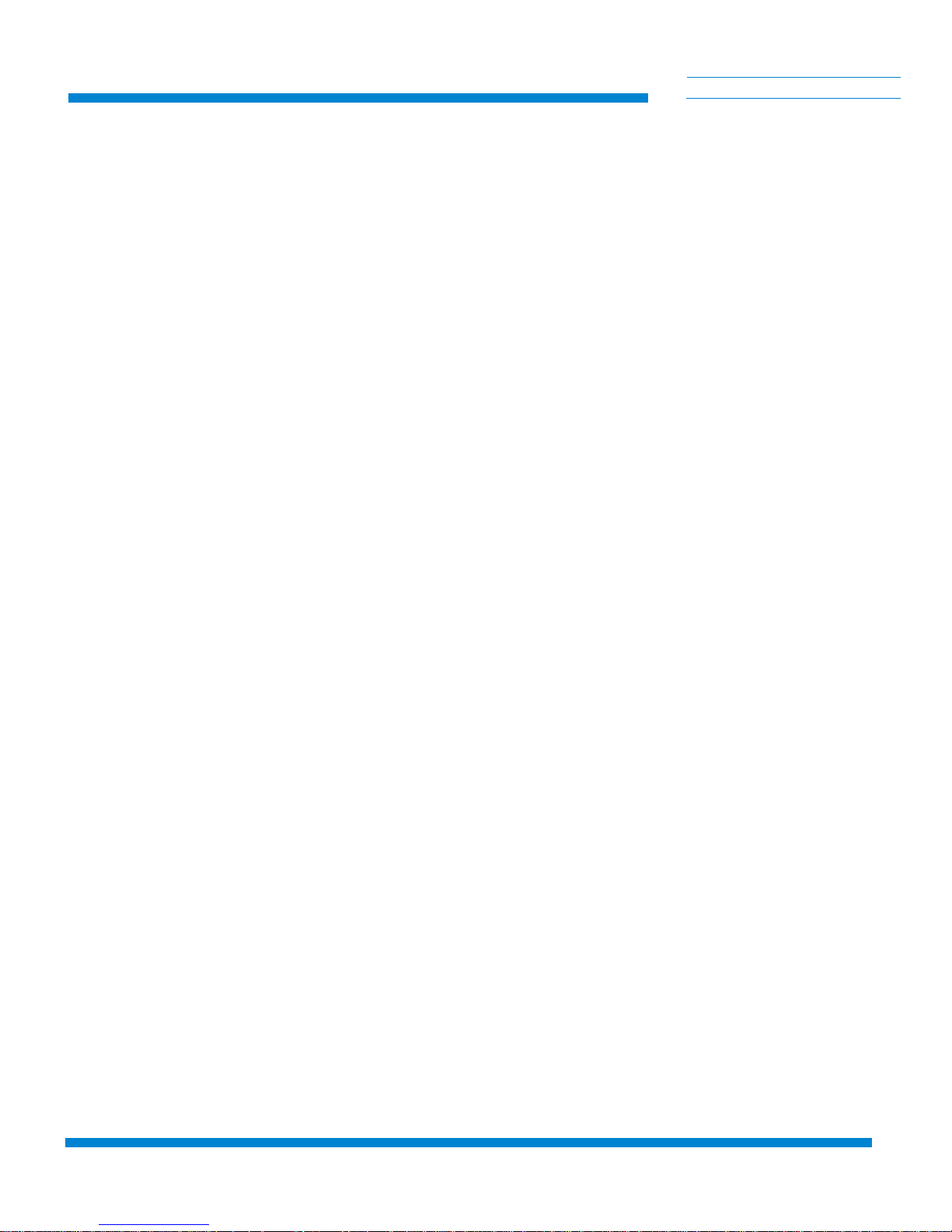

Figure 1-1: Air and Water Cooled 8200 Compressor Dimensions . . . . . . . . . . 1-2

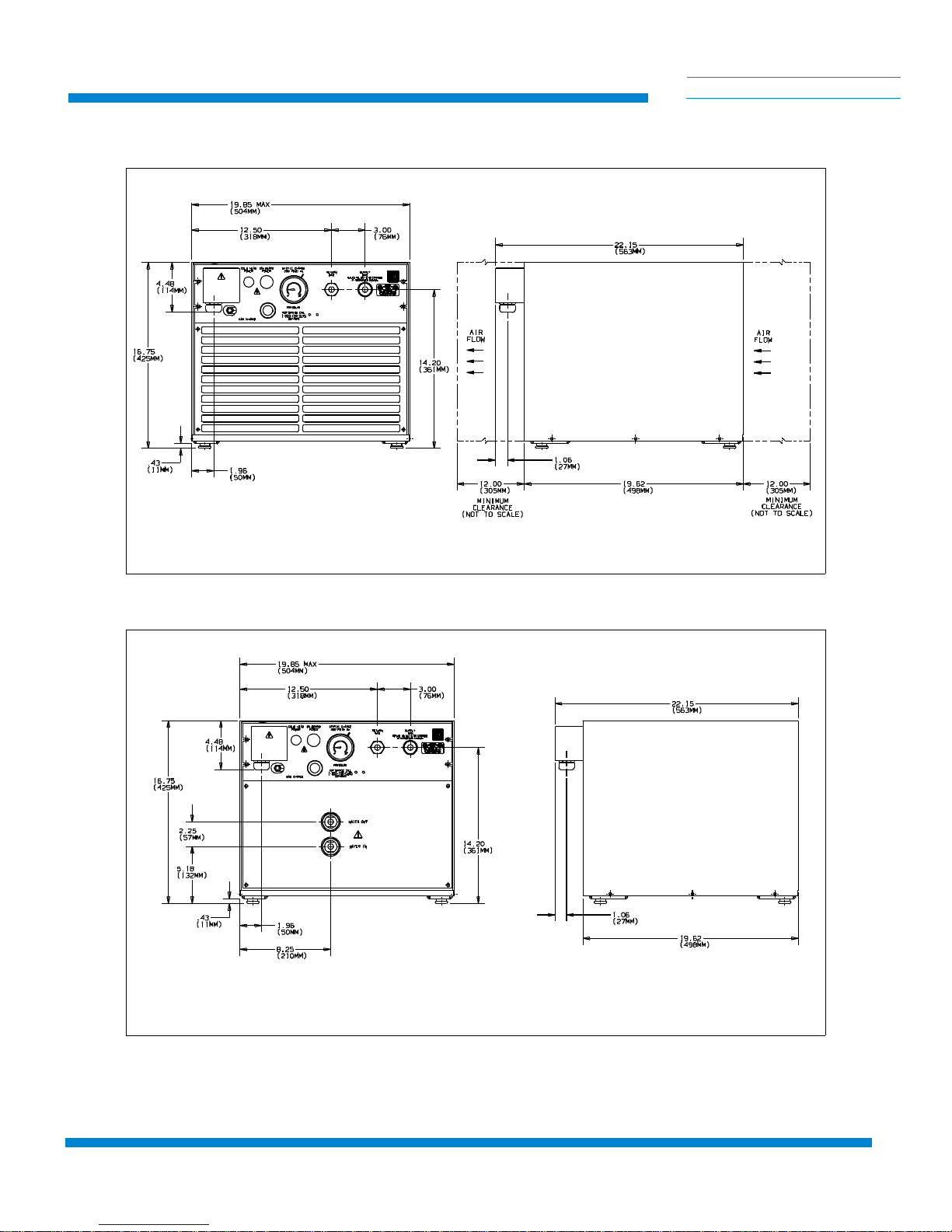

Figure 1-2: Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Figure 3-1: Electrical Terminal Enclosure with Cover in Place . . . . . . . . . . . . 3-2

Figure 3-2: Assembly of Conductors to Terminal Block . . . . . . . . . . . . . . . . . 3-3

Figur e 3-3: 8200 Co m pressor Cooling Wat er Flow and Pressure Requireme nts 3-5

Figure 3-4: 8200 Compressor Water Discharge Temperature Increase (°F) . . . 3-6

Figure 3-5: Typical 8200 Compressor Installation . . . . . . . . . . . . . . . . . . . . . . 3-9

Y

OG

ENIC

S

Figure 4-1: Disconnecting/Connectin g th e A dso rber Self-Sealing Coupling . . 4-2

Figure 4-2: Removing the Adsorber from the Compressor . . . . . . . . . . . . . . . . 4-2

Figure C-1: 8200 Compressor Electrical Schematic P/N 8032563P001

Rev. 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Figure C-2: 8200 Compressor Electrical Schematic P/N 8032564P001 Rev. D C-3

Figure D-1: Components in the Electrical Control Chassis of the

8200 Compressor Three-Phase Scott-T Configuration . . . . . . . . . . D- 1

Figure D-2: Components in the Electrical Control Chassis of the

8200 Compressor - Single-Phase RC Configuration . . . . . . . . . . . D-2

Figure E-1: Flow Diagram of the 8200 (Air-Cooled) Compre ssor . . . . . . . . . . E-2

Figure E-2: Flow Diagram of the 8200 (Water-Cooled) Compressor . . . . . . . . E-3

Tables

Table 1-1: Power Requirements (Steady-State Conditions) . . . . . . . . . . . . . . . 1-4

Table 1-2: General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 3-1: Voltage Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Table A-1: CTI-C RY OGENICS Produc t Cu stom er Support Centers . . . . . . . . A-2

Table B-1: Compressor Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . B-1

iv P/N 8040353

Page 5

8200 Compressor

General

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

Section 1 - Introduction

The manual provides instructions for installing, operating and servicing the

8200 Compressor. This compressor is available in two versions: air-cooled,

P/N 8032549G001/ G 002 and water cooled , P/N 803255G001/G002.

If you are installing or ope rating a Cryo-Torr or On-Board System you

should also have av ailable the appro priate cryopump or re frigerator.

When you purchase a system, you will receive two m anuals necessary for

system installation, plus a l oose- leaf binder with index ta b separators,

allowing you to co mpile a complete inde xe d system notebook.

S

Installation, Operation and Servicing Instructions

Installation, Opera tion and Servicing Instruct ion s for your 8200

Compressor provide ea sil y ac c essi ble inf orm a ti on. All perso nne l wi th

installation, operation, and servicing responsibilities should become

familiar with the content s of these instruct ions to ensure high quality, safe,

reliable performance.

P/N 8040353 1-1

Page 6

Introduction

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

Air Cooled

Figure 1-1: Air and Water Cooled 8200 Compressor Dimensions

1-2 P/N 8040353

Water Cooled

Page 7

8200 Compressor

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

1

3

2

Rear View - Air Cooled

6 7

5

4

8

9

10

11

12

Rear View - Water Cooled

13

14

15

16

Front View - Air and W ater Cooled

1. Compressor Input Power Block

2. Cold Head Power Receptacle

3. On-Board Power Receptacle

4. Helium Gas Fitting and Charge Valve

5. Helium Supply Pressure Gauge

6. Helium Gas Return Connector

7. Helium Gas Supply Connector

8. Rear Panel

9. Rear Grill

Figure 1-2: Component Locations

17

18

LEGEND

10. Cooling Water Output

11. Cooling Water Input

12. Rear Plate

13. 50/60 Hz Frequency Selector Switch

14. 208/220 Voltage Range Selector

Switch

15. Resettable Circuit Breakers

16. Compressor ON/OFF Switch

17. Front Panel

18. Front Grill

P/N 8040353 1-3

Page 8

Introduction

C

HELIX TECHNOLOGY CORPORATION

Table 1-1: Power Requirements (Steady-State Conditions)

-

TI CR

Y

OG

ENIC

S

Part Number Cooling Phase Hz

8032549G001 Air

Air

8032549G002 Air

Air

8032550G001 Water

Water

8032550G002 Water

Water

Table 1-2: General Sp ecification s

Specification Description

We ig ht 140 lbs (63.5 kg) approx im a te

3

3

1

1

3

3

1

1

50

60

50

60

50

60

50

60

Operating Voltage

Range

180-220

198-250

180-220

198-250

180-220

198-250

180-220

198-250

Nominal

Operating

Current

10A

10A

10A

10A

8.5A

8.5A

8.5A

8.5A

Weight

(shipping)

Power

consumption

Compressor input-power

cable

(customer-supplied)

Helium pressure Static: 245-255 psig (1688-1757 kPa) at 70 to 80°F (21 to

Ambient op er ating

temperature range

145 lbs (70.5 kg) approx im a te

2.0 kw, nominal operating(water), 2.1 kw nom inal operating

(air)

Recommended type SO-4 conduct or, 600V, neopre ne jacket

and 14-gauge wire.

Install per Figure C-1, El ec trical Schematic di agram, ensuring

compliance with all national, state and local sta ndards.

27°C)

Supply: nominal opera ti on: 270-290 psig (1860-200 0 kPa ) at

operating tempe ra ture.

50 to 100°F (10 to 38°C)

1-4 P/N 8040353

Page 9

8200 Compressor

Adsorber service schedule Replace ever y 12 m onths.

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Table 1-2: General Sp ecification s

Specification Description

Interface Cold head power receptacle: Mates with plug on cold head

power cable.

On-Board power re ce pt acle: Mates with plug on cold-he ad

power cable.

Compressor input-power terminal block enclosure: Mates with

input power cable, fabricated by customer or available from

CTI-CRYOGENICS.

Gas-supply connect or: 1/2-inch self-seali ng coupling

Gas-return connec to r: 1/ 2-i nch self-sealing coupl ing

Y

OG

ENIC

S

Cooling water requi re-

ments (water cooled only)

100°F (38°C) maxim um disc ha rge temp era ture

Refer to Figures 3-5 and 3-6 for parameters.

P/N 8040353 1-5

Page 10

8200 Compressor

Packaging of the S ystem

The Compressor

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

Section 2 - Inspection

A High-Vacuum Pump or Refrigerator System is packaged in separate

cartons for each maj or c omponent. An Instal la ti on, Op e ration, and

Servicing Manual i s inc lud ed in the carton for the com ponent packaged in

that carton.

On receipt, remove the 8200 Compre ssor from it s sh ip pin g carton and

inspect the compressor for evidence o f d amage as describ ed in this Section.

1. Unpack and remove the compressor from its shi ppi ng c art on.

S

2. Check the carton contents. It shou ld contain:

a. 8200 Compresso r (ai r cooled or water cooled).

b. Compressor Manua l P/N 8040353.

3. After unpacking, inspect the compressor for evidence of damage as

follows:

a. Inspect the compre ssor overall exterior for da ma ge .

b. Report damage to the shipp er a t on ce.

c. Retain shipping cart ons for st orage or return shipment.

When installing your system, CTI recomm en ds th at as you unpack a

component, you pe rform an inspection and the nec essary ta sks for syst em

installation for the component according to the manual included with the

component. Fina l system installation and operat ion will be performed

following proce dure s in t he hi gh-vacuum pump or re fri ge rator manual.

4. Check the helium pressure gauge. The gauge should indicate 250 psig

(1725 kPa) minimum at 70° F. If additional gas pressure is requ ired,

follow the instructions in Adding Helium Gas.

P/N 8040353 2-1

Page 11

8200 Compressor

Section 3 - Installation

Compressor Installation

Installation of your compressor requires no special tools other than those

supplied in the Installation and Scheduled Maintenance Tool Kit.

Preparing the Compressor Input-Pow er Cable

To supply input power to the 8200 compressor requires the fabrication of a

600-volt power cable that has an SO-4 conductor, 600-volt rating neoprene

jacket and 1 4-gauge or 2.3 mm

2

wire. Proceed as follows:

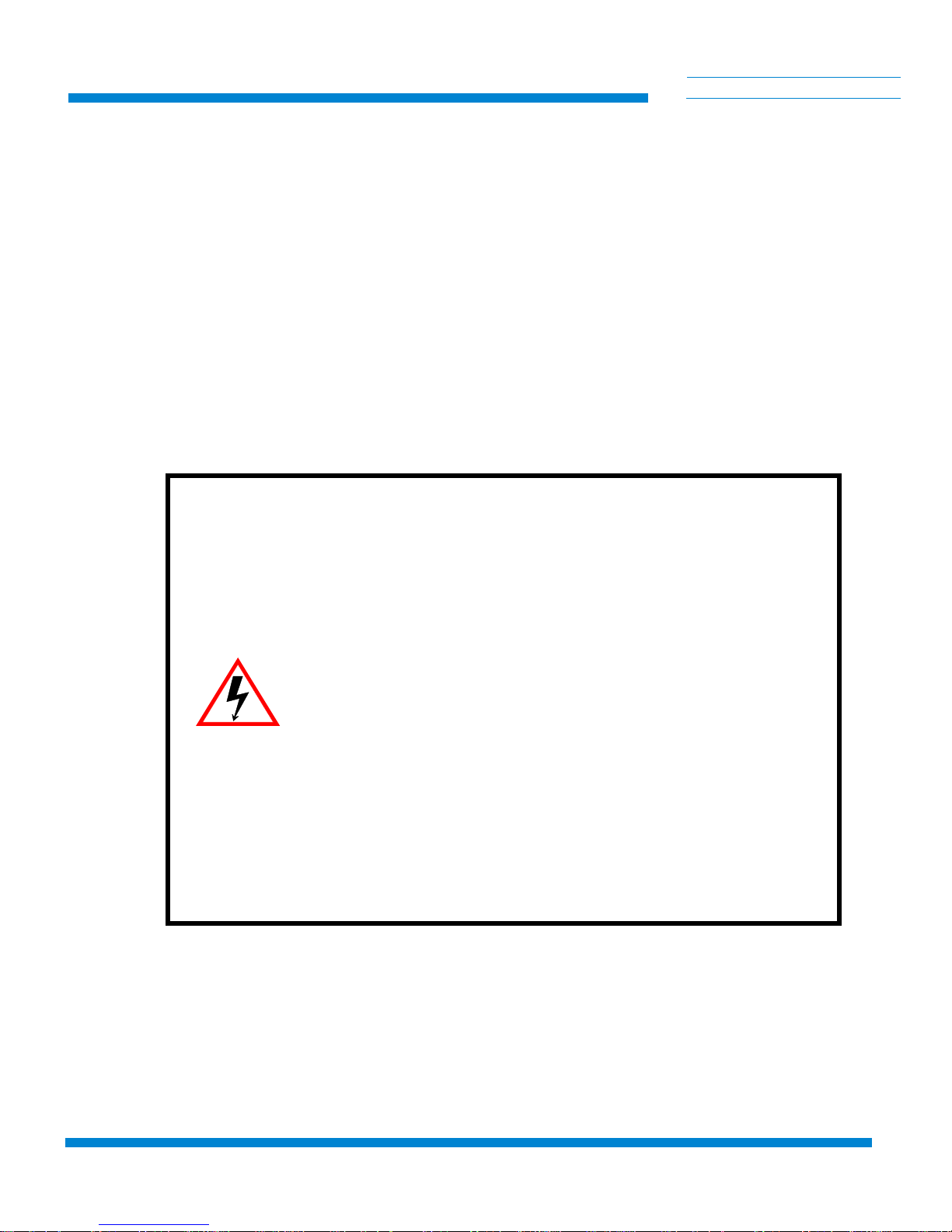

WARNING

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

Do not conne ct the compres s or to the power source at this time. All of

the preparation must be completed and all panels reinstalled before electrically connecting the compressor.

Unit must be wired by an authorized electrician in accordance with the

national Electri ca l Code, ANSI/NFPA 70-1987, as well as the local

codes. This shall include installation of a readily accessible disconnect

device into the fix ed wiring supplying power.

An insulated ear th ing cond uctor that is identica l in size, ins ulation material and thickness to the ea rth and unearth branch circuit supply conductors, except that it is green w ith or w i tho ut one or more yellow stripes is

to be installed as part of the branch circuit which supplies the unit or system. The earth ing conductor descri bed is to be connected to the earth at

the service equipm e nt, or supplied by a separatel y de rived system at the

supply transforme r or ge ne rator.

1. Prepare the input power cable by te rminating each of the four

conductors with a #10 ring terminal. Foll ow th e te rm inal

manufacturer’s instructions to insure proper crimping.

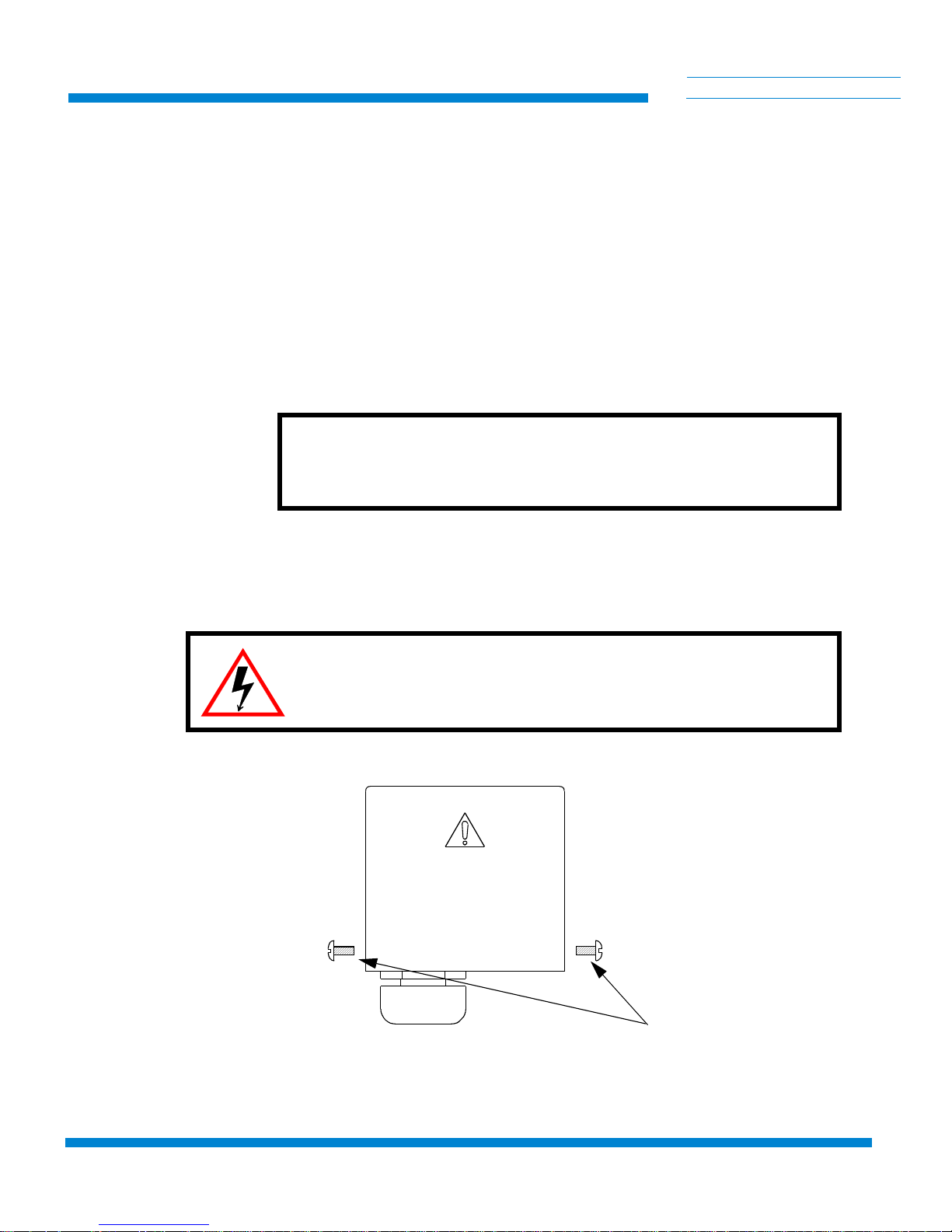

2. Disas s emble the elect r i cal terminal enc l o s ur e cover, mounted on

the compressor rear panel, as shown in Figure 3-1. Remove the two

screws securing the cover and lift it off.

3. If necessary, back off strain relief screws.

P/N 8040353 3-1

Page 12

Installation

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

4. Thread input power cable end up through the strain relief i nto the

enclosure.

5. Attach the power conductors onto the appropriate terminals of the

termin al block.

a. For three-phase hookups, attach the three power leads to ter-

minals X, Y and Z.

b. For single-phase hookups, attach the two power leads to ter-

minals X and Y. DO NOT USE TERMINAL Z.

6. Tighten all terminals to 18-22 in.-lbs. torque.

7. Tighten down screws on strain relief.

Y

OG

CAUTION

Ensure that strain relief is tightened down on the outer insulation of the

input power cable and that the cable does not slide.

ENIC

S

8. Remount the te rm i n al enclosure cover and se cure with two screws .

9. Refer to Final Preparation of Compressor for correct phasing

checkout pr ocedure.

WARNING

Insure that the grou nd wire is returned to a suitable ground in a noninterrupting manner.

Figure 3-1: Electrical Terminal Enclosure with Cover in Place

3-2 P/N 8040353

Cover Scre ws

Page 13

8200 Compressor

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

(not used for single phase)

X

Ground Screw

Power Cable

Z

Y

OG

ENIC

S

Figure 3-2: Assembly of Conductors to Ter mi nal Block

Cooling Water Requirements (Water-Cooled Compressors Only)

If flexible water hose connections are used, install the barbed fittings

supplied with the compressor on the input and output connections:

1. Apply a light coating of st andard plumbing threa d sea la nt on

the barbed fitting threads .

2. Tighten fittings on 1/2-inch FPT input and 1/2-inch FPT output connections. DO NOT OVERTIGHTEN.

3. Connect flexibl e hoses to th e fi ttings and secure with hose clamps.

If har d pipin g is d esi red, inst all the wat er li nes direct ly on to t he co mpres sor

1/2-inch FPT input and output conne ctions. DO NOT OVERTIGHTEN.

CAUTION

Check water connections for leaks.

P/N 8040353 3-3

Page 14

Installation

Cooling Water: General Considerations

NOTE: Adjust your water flow to maintain an op tim um di scharge water

temperature of 85°F with a minimum input pressure of 2 psig. For detailed

water requirements, see below .

1. Cooling water must meet flow and pressure req ui rem ents as

indicated in the following subsections.

2. Cooling water having a pH value of 6.0 to 8.0 and a calcium - c arbonate concentration of less than 75 ppm, the quality of ty pic al

municipal drinking water, is acceptable. If th e cooling water has a

pH value lower than 6.0 or a calcium - carbonate conce ntration

higher than 75 ppm , wate r conditioning may be required.

3. To conserve water, the coolin g wat er should be shut off when the

compressor is not running.

CAUTION

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

If cooling water belo w 45° F (7° C) i s all ow e d to run through the

compressor while th e co mp re sso r is not ope ra ting, the compressor oil

will change viscosity and thicken, causing the co mpressor to overheat

and shut off at startup. In this event, repeatedly restart the compressor

and allow it to run unti l it ha s shu t off several time s. T he oil

temperature will rise and thereby allow continuous compressor

operation.

4. Drain and purge water from the compressor before shipping it back

to the factory or subject in g it to fre ez in g conditions. Purge water

from the compressor by blowi ng compressed air, regulated to 30 to

40 psig (200 to 275 kPa) into the compressor output connection and

allowing water to exit from the water in put conn ection.

Cooling Water: Flow and Pressure Requirements

CAUTION

If your water supply pressure falls below 2 psig due to back pressure,

the compressor wil l ov erheat and shut down.

Use the two graphs in Figure 3-3, to determine the minimum acceptable

cooling water sup ply p ressure at different flow rates a nd te m pe r at ure s .

3-4 P/N 8040353

Page 15

8200 Compressor

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Find the minimum pressure :

1. Determine the temperature variation of the cooling water.

Allow a ±10°F to th e pr esent water te mperature if a var iation

cannot be ascerta ine d. Plo t th e high and low temperat ures on

the verti cal axis o f th e lower graph.

The example describes cooling water that varies between 40°F and70°F.

2. Determine th e opt im um water flow rate by drawing a horiz ont al

line from the upper temperature variation figure on the lower graph

to the upp er curve of the a llowable op er ating range indicat ed by

cross-hatching. Draw a line from this intersecting point straight

down to the horizontal axis to find the optim a l fl ow rat e.

The example shows a solid arrow extending from 70°F and intersecting the

allowable operating range. Dashed arr ow s pointing downward indicate a

water flow rate of 0.5 gallons per minute.

Y

OG

ENIC

S

3. Determine the cooling water supply pressure drop by drawing a line

straight up from the flow rate in the lower graph to the upper graph.

At the point at whi ch t his l ine int e rsects the upper graph, d ra w a

line leftward to the verti ca l axi s and find the water supply pressure

drop.

The example shows dashed arrows extending from the lower to the upper

graph. On th e upper graph the dashed arrow s int ersect the gr aph curve at

approx imately 2.5 psig.

Figure 3-3: 8200 Compresso r Cooling Water Flow and Pressure Requirements

P/N 8040353 3-5

Page 16

Installation

Cooling Water: Temperature Ri s e

The temper ature o f the c oolin g water as it le aves th e compr essor s hould

not exceed 1 00° F.

Use the grap h in Figure 3-4 to determine the rise in cooling wat e r

temperatur e as it pa sses th r oug h th e co mpressor . Th is information is

provided for plant engineering pe rsonnel to determine cool in g w at e r

requirements.

Find the temperature rise:

1. Draw a vertic al line upward from the horizontal axis of the

graph at the water flo w rat e de te rm ined from the previous

section, until it hits th e graph curve.

CAUTION

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

The exampl e s ho w s dashed arrows po in ting upward to th e graph curve

from 0.50 gpm on the water flow rate axis.

2. At the point which the dashed arrows intersect the graph curve,

draw a straigh t line to the left to obtain the increase in output wate r

temperature.

The example sh ows a temperature increase of 20°F.

Figure 3-4: 82 00 C ompressor Water Discharge Te mperature Increase (°F)

3-6 P/N 8040353

Page 17

8200 Compressor

Final Preparation of Compressor

1. Using a voltmeter, measure the phase-to-phase voltage from the

power source. Compare this voltage to the following table and

position the voltage range selector s w itch to the “208V” or

“220V” position as requ ire d. A lso, set the fre quency selector

switch to the 50 Hz or 60 H z position, as appropriat e. S ee

Figure 1-2 for location of selector switches.

Table 3- 1: Voltage Specifications

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

Operating Voltage Range

60 Hz 50 Hz

198-212 180-212 208V

213-250 213-220 220V

2. Ensure that water is turned on fo r the w ater-coole d compressor.

3. Set the compressor ON/OFF switch (3) to OFF. Connect the inputpower cable to the power source Refer to Table 1-1, for electrical

power requirem ents.

4. Turn the compresso r switch to the ON posi ti on and allow the co m pressor to run for 15 minutes to stabilize the oil circuit. Make sure

that the compressor fan operates freely in the air-cooled comp r es sor.

5. Switch off the compre sso r and disconnect the inpu t-power cable.

6. Install the compressor in its permanent location on a level surfac e.

Air cooled units mu st have a mini mum cleara nce of 12 inch es at the

front and back for adequate airflow.

Voltage

Adjustment Swit ch

S1 Position

Connecting the Compressor to the Cold Head

Make the connecti ons between the cryop ump and compresso r. See Figure

3-5.

1. Remove dust plugs and caps from the supply fittings and return

lines, compressor, and cold head. Che ck all fitti ngs.

2. Connect the heli um-gas return line from th e gas-return connec tor

on the rear of the compressor to the gas-return connector on the

cold head.

P/N 8040353 3-7

Page 18

Installation

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

3. Connect the heli um -ga s suppl y li ne fr om the ga s- supply connector

on the rear of the compressor to the gas-supply connector on the

cold head.

4. Attach the supply and return line identification decals (CTI-supplied) to their respectiv e c onnecting piping ends.

5. Verify prope r hel iu m suppl y sta tic pre ssure by c onfirming that the

helium pressure gaug e re ads 245-250 psig (1690-1 725 kPa), in an

ambient tempe ra ture range of 60 to 100°F (16 to 38°C).

Y

OG

WARNING

ENIC

S

!

Do not operate the 8200 Com pr essor un le ss a Cry opump or Waterpump

is connected to the system.

If the indicated pre ssure is higher than 250 psig (1725 kPa), reduce the

pressure as follows:

a. Remove the flare ca p from the gas charge fitting located on

the rear of the co m p ressor.

b. Open the gas charge valve very slowly. Allow a slight

amount of helium gas to escape until the helium pressure

gauge reads 250 psig (1725 kPa).

c. Close the gas charge valve an d reinstall the flare cap.

If the indicated pressure is lower than 245 psig (1690 kPa), add helium gas

as described in Adding Helium Gas.

6. Make the following electrical connections.

WARNING

The compressor ON/OFF power switch on the front of the compressor

must be in the OFF position before making any and all electrical connections.

a. Connect the cold head power cable to the rear panel of the

b. Connect the co mpressor input power cab le to t he power

c. Turn on compressor.

d. Your system is now ready for operation .

3-8 P/N 8040353

compressor and the other end to the electrical power connector on the hig h-va cuum pump cold head.

source.

Page 19

8200 Compressor

User’s

Vacuum

Chamber

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

Roughing Pump

Air Pressure (60-80 psi)

Nitrogen (40-80 psi)

On-Board

Cryopump

Helium Supply Line

Helium Return Line

On-Board Power Cable

Figure 3-5: Typical 8200 Compressor Installation

P/N 8040353 3-9

Page 20

8200 Compressor

Section 4 - Maintenance Procedures

Scheduled Maintenance

Removing the Compressor Adsorber

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

WARNING

Always disconnect the compressor from all source s of el ectrical power

before performing any maintenance procedures.

The only scheduled maintenance re qui red on the 8200 Comp ressor is

replacement of the compressor adsorber (P/N 8080255K001) every 12

months.

ENIC

S

1. Shut down the compressor.

2. Disconnect the compressor input power cable from its electrical

power source .

3. Disconnect the flex lines from the gas-return and gas-supply connectors at the rear of the compress or.

4. Remove the screws hol ding the compressor rear grille, rear panel,

front panel and cover (Figure 1-2). Front and rear panels remain in

place.

5. Use the two wrenches (supplied) to avoid loosening the body of the

coupling from its adapter.

6. Unscrew the two self-sealing coupling ha lve s qui ckly to minimize

gas leakag e as sho w n in Figure 4-1.

7. Disconnect the adso rber-i n l et self-sealing coupling as shown in

Figur e 4-1.

8. Remove the bo lts, nuts, and washers that se cure the adsorber to the

base of the compressor. Save all nuts, bolts, and washers for installing the replacement adsorber.

9. Carefully lift the adsorber inward until the outlet self-sealing coupling clears the rea r panel and remove t he adsorber as shown in

Figur e 4-2.

10. Re m ove the adsorber from the com pre ssor as shown in Figure 4-2.

P/N 8040353 4-1

Page 21

Maintenance Proc edu res

Compressor

Rear

Panel

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

This 1 1/8 in. wrench

holds the coupling in

a stationary position.

To Disconnect The Coupling

Figure 4-1: Disconnecting/Connecting the Adsorber Self-Sealing Coupling

This 1 3/16 in. w rench is used

to loosen the self sealing

coupling connector. Note the

direction of the large arrow.

This 1 1/8 in. wrench

holds the coupling in

a stationary position.

To Connect The Coupling

This 1 3/16 i n. wrench is used

to tighten the self sealing

coupling connector. Note the

direction of the large arrow.

WARNING

Depres surize the ad s orber befo r e disposing of it. Att ach the depressurization fitting (inc l ude d in the Installation and Sch eduled Maintenance

Tool Kit) to the coup li ng half at either end of the adsorber and tight en it

slowly.

Figure 4-2: Removing the Adsor b er from the Compressor

4-2 P/N 8040353

Compressor Bas e

Page 22

8200 Compressor

Installing the Compressor Adsorber

1. Install the re placement ads orber as follow s :

a. Remove the dust caps from the self-sealing coupling halves

at each end of the replacement adsorber.

b. Write insta l lation date on th e ad s or b er decal.

c. Install the replacement adsorber following the steps for

compressor adsorber removal in reverse order. Use the hard-

ware saved in step 5 above .

2. Connect the ad so rbe r to the compressor intern al pipi ng. Refer to

Figur e 4-1.

a. Check the self-se aling connector flat rubbe r gasket to make

sure that it is clean and prope rly positioned.

CAUTION

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

Make sure to hold f as t on the lef t coupling n ut while tightening the

right coupling nut, as shown in Fi gure 4-1.

b. Make the first turns by hand and then firmly seal the con-

nection using th e two wrenches until the fit tings “bottom”.

Refer to Figure 4-1, for pr ope r coupling of the self-seal in g

connection

3. Replace the cove r and the front and rear grilles and secure them

4. Ensure that the pressure gauge reads 245-250 psig (169 0-1725

kPa). If additional gas pressure is required, follow th e in stru ctions

in, Adding Helium Gas.

5. Reconnect the re turn and supply flex lines to the com pre ssor.

6. Connect the compressor input power cable to the electrical power

source.

Unscheduled Maintenance

Suggested Unscheduled Maintenance Equipment

It is advisable to keep on hand the unscheduled mai nt enance equipment

and disposable suppli es liste d be lo w.

1. Helium, 99.999% pure .

2. Pressure regulator (0-3000/0-400 psig).

3. Maintenance manifold, P/N 8080250K003*.

P/N 8040353 4-3

Page 23

Maintenance Proc edu res

4. Helium charging line terminating in a 1/4-inch female flare fitting,

P/N 7021002P001.

5. Installation and Scheduled Maintenance Tool Kit, P/N

8032040G004.

*Available from stock ; consult the factory or your sales rep resentative.

Adding Helium Gas

Use only 99.999% pure he li um gas.

If the compressor he li um pressure gauge read s 0 , decontamination is

required. Refer to dec ont amination procedu res under, Helium Circuit

Decontamination, or contact the Produc t Se rvi ce D ep art m ent.

CAUTION

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

1. A User-supplied helium cha rging l ine te rm inating in a 1/4-inch

female flare fitting, and a two-stage pressure regulator rated at

0-3000/0-400 psig is required for this operation.

2. If you need to add heliu m mo re tha n once every several mo nth s ,

check for leaks ca use d by improperly connected self-sealing connection s o r any mechanical joint within th e compres s or.

There are two conditions that r equ ire the addition of he lium gas:

1. Compressor not operat ing; helium pressure gauge rea ds 245

psig or below.

2. Compressor operati ng; helium pressure reads 270 psig , or bel ow.

To add helium gas:

1. Attach a pressure re gulator (0-3000/0-4 00 psig) and charging

line to a helium gas (99.999% pure) bottle. DO NOT OPEN

THE BOTTL E AT THIS TIME. Purge the regulator and

charging lines as instructed in steps a through e below. Do not

use helium gas that is less than 99.999% pure.

a. Open the regulator a smal l amo unt by turning th e ad justing

knob clockwi s e unt il it contacts the dia phragm, then turn

approx imately 1 /8 to 1/4 tur n more, so th at the regulator is

barely open .

b. Slowly open the bottle valve, and purge the regulator for 10

4-4 P/N 8040353

to 15 seconds. Turn the regulat or knob countercloc kwise

until the helium stop s flowing.

Page 24

8200 Compressor

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

c. Connect the charge line to the helium pre ssure regulator.

d. Remove the flare cap of the gas charge fitting on the rear of

the compressor. Loosely conn ec t th e charge line to the

charge fitting.

e. Set the helium pressure regulator to 10 to 25 psig (70- 125

kPa). Allow helium gas to flow t hrough the charging line

and around the loosened flare fitting for 30 seconds to purge

the charging line of air. Then tighten the flare nut at the end

of the charge line.

(This procedur e is required to ensure that bot h th e regulator and the

charging line w ill be purged of ai r and that the air trapped in the regulator

will not dif fus e back into the he liu m bottle . For best re sults, CT I sugg ests a

dedicated heli um bottle, regulator, and line, which are never separat ed, for

adding helium. )

2. Set the helium pressure regulator to 300 psig (2070 kPa). Depending on the compressor ope rating state, add heliu m gas:

Y

OG

ENIC

S

a. If the compressor is run ning (approximatel y 2 hours operat-

ing time) under norm a l ope ra ting conditions, slowly ope n

the helium ch arge va lve on the rear of the com pressor.

When the helium pre ssure gauge rises to 270 - 290 psig

(1860 - 2000 kPa) tightly close the ch arge va lve.

b. If the compressor is not running, slowly open the heli um

charge valve. When the helium pressure gauge rises to 245 255 psig (1688 - 1757 kPa), tightly clos e th e charge valve.

Add helium gas slowly to prevent relief valve blow-off.

3. Ensure that the helium char ge valve on the co mp re ssor is tightly

closed . S hut off the helium pr essure regulato r on t he helium bo ttle

and remove the cha rging line f rom the m al e fl are fit ti ng. Shut off

the heli um gas bottle valve . Reinstall the flare cap.

Helium Circuit Decontamination

Refer to Section 4 - Maintenance of the appropriate On-Board Cryopump

Installat ion Oper atio n, an d Main tena nce ma nua l for in fo rmat ion on helium

circuit decontaminat ion.

CAUTION

P/N 8040353 4-5

Page 25

-

C

Appendix A - Customer Support Information

TI CR

HELIX TECHNOLOGY CORPORATION

Appendix A - Customer Support Information

Introduction

Refer to Table A-1 for the nearest Customer Support Center for technical

assistance or service for CTI-CRYOGENICS products. North American

customers may call 800-FOR-GUTS (800-367-4887) 24 hours a day, seven

days a week. All other cu stom e rs mu st c al l their local Customer Supp ort

Center.

NOTE: Please contact the Customer Suppo rt Cent er in Mansf ie ld ,

Massachusetts in the Uni te d States of America by dialing 508-337-5599 if

a Customer Support office is not located in your area.

Please have the following information available when calling so that we

may assist you:

Y

OG

ENIC

S

• Product Part Number

• Product Serial Number

• Product Application

• Specifi c P roblem Area

• Hours of Operation

• Equipmen t Type

• Vacuum Syst em Brand/Model/Date of Manu fac t ure

For your convenience, you may also e-mai l us a t:

contact@helixtechnology.com

Visit us at our corporate website:

www.helixtechnology.com

A-1

Page 26

Appendix A - Customer Support Information

Table A-1: CTI-CRYOGENICS Product Customer Support Centers

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

United States and Canada

Guaranteed Uptime Support Line GUTS

Dial: 800-FOR-GUTS (800-367-4887) (within USA)

508-337-5599 (outside USA)

24 hours a day, seven days a week

Corporate Headquarters: 800-379-7224 (within USA)

508-337-5000 (outside USA)

Austin, TX: 800-324-6445 (within USA)

512-912-2800 (outside USA)

Longmont, CO: 800-776-6543 (within USA)

303-652-4400 (outside USA)

Santa Clara, CA: 800-324-6449 (within USA)

408-562-5940 (outside USA)

France, Spain, Po rtugal , Gr eece , Belgi um, North

Africa

Dial: +(33) 1-6935-2600

24 hours a day, seven days a week

®

Germany, Italy, Denmark, Switzerland, Holland,

Norway, The Netherlands

Dial: +(49) 6151-959-55

24 hours a day, seven days a week

United Kingdom, Ireland, N. Ireland, Scandinavia

Dial: +(44) 1-506-460017

24 hours a day, seven days a week

A-2

Japan

Dial: +(81) 0120-60-4887

24 hours a day, seven days a week

Taiwan

Dial: +(886) (3) 516-9022

24 hours a day, seven days a week

Austr alia, Ne w Zealand, Tasmania

Dial: +(612) 9-4810748

24 hours a day, seven days a week

India

Dial: +(91) 22-7632906

24 hours a day, seven days a week

Korea

Dial: +(82) 2-577-3181

24 hours a day, seven days a week

China

Dial +(86) 21-6279-1389

24 hours a day, seven days a week

Singapore, Malaysia, Philippines, Indonesia

Dial: +(65) 268-20 24

24 hours a day, seven days a week

Israel

Dial: +(972) 3-9247710

24 hours a day, seven days a week

Page 27

8200 Compressor

Appendix B - Troubleshooting Procedures

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

WARNING

Disconnect the compressor before performing any troubleshooting procedures.

The compressor pump is hot after operating. Wait for the pump to cool

down before working on the inside of the compressor

Table B-1: Compressor Troubleshooting Procedur es

Problem Possi ble Cause Correc t ive Action

Y

OG

ENIC

S

1) System power ON/

OFF switch (CB1) and

compressor switch (S1)

remain s in the ON posi tion when switched on

but the compressor w ill

not run. Refer to Figure

C-1 for id entification of

all electrical components

2) System power ON/

OFF switch (CB1)

remain s in the ON posi tion, but the compressor

will not run.

1) The thermal prote ct ive

switch (TS1) is closed, activating the relay-trip coil in the ON/

OFF switch (SW1).

2) Incorrect phasing at input

power.

3) Excessive current drain has

activated the series trip in the

compressor ON/OFF switch.

1) No power coming from the

power source.

2) Incorrect or disconnected

wiring within the compressor

1) T est switch (TS1) on air-cooled

compressor; test (TS1) and (T S2)

on water-cooled com pre ssor. If

continuity is foun d in any sw i tch,

contact the Product Service

Department.

2) Correc t phase sequence at

input power cable.

3) Measure and record the current

and contac t th e Product Servi ce

Department.

1) Check service fuse s, circui t

breakers , an d w iring associated

with power sour ce , a nd re pair as

needed.

2) Check the compressor against

its electrical schematic, Figure

C-1.

P/N 8040353 B-1

Page 28

Appendix B - Troubleshooting Procedures

Table B-1: Compressor Troubleshooting Procedur es

Problem Possi ble Cause Correc t ive Action

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

3) Compressor stops

after sev eral minu tes of

operation and remains

off.

1) High tempera tur e of the

compressor is caused by insufficient co ol ing water, resulting

in the opening of thermal protective switch (water -cooled

compressor only).

2) After turn-off, very cold

cooling water was left running

through the compressor. The

resulting low oil tem pe r atu r e

has caused a restriction of oil

flow through the metering orifice during startup.

3) Very cold cooling water is

circulating through the compressor. The resulting low oil

temperat ure cause s a re st ri ct ion

of oil flow through the metering

orifice during startup.

1) Confirm that cooling water to

the compressor is flowing. Confirm that proper cooling water

flow rate and pressure exist by

referring to Figure 3-3.

2) Turn on the comp re s s o r and

allow it to run until it has stopped

several times, allowing the oil

temper ature to rise and the compressor to operate continuously

for one hour minimum.

3) Rechec k for proper cooling

water temperature per, Cooling

Water Requirements (WaterCooled Compressors Only).

4) Ambient temperature is

unusually high resultin g in the

opening of the th ermal protective switch (air-c ooled compressor only).

5) Insufficient helium supply

pressure is indicated by the supply pressure gauge.

6) High tempera tur e of the

compressed heliu m in the discharge line from the compres sor pump has tripped the

thermal prot ec ti ve switc h.

7) Mechan ical seizur e.

4) Provide a free flow of air to the

compressor. Confirm a 12-inch

(30 cm) clearance at the front and

back of the compressor. Confirm

unobstr ucted and clean heat

exchanger surfaces.

5) Add helium pe r, Unscheduled

Maintenance.

6) Confirm that oil is visible in

the compressor sight glass (aircompressor only).

7) Contact the Product Service

Department.

B-2 P/N 8040353

Page 29

8200 Compressor

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Table B-1: Compressor Troubleshooting Procedur es

Problem Possi ble Cause Correc t ive Action

Y

OG

ENIC

S

4) Compressor pump

stops after several minutes of operating and

then switch es O N and

OFF at short intervals.

5) Compressor operates

but cold head motor does

not run.

1) Intermittent powe r so urc e

voltage.

1) Loose or defect ive ca ble. 1) Check cold head cable.

1) Confirm power source voltage

between 198-2 50V, 60 Hz or 180220V, 50 Hz an d re store if necessary.

P/N 8040353 B-3

Page 30

8200 Compressor

Appendix C - Electrical Schematics for 8200

Compressor

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

P/N 8040353 C-1

Page 31

GRN/Y E L 1 4

M2

FAN

AIR COOLED ONLY

P5

1

3

4

0

P2

4

0

1

3

J5

J2

M1

S

R

123

444

444

123

TS2

PUMP

C

WATER C OOLED ON LY

SOL1

TS1

4

0

1

2

123

P3

0

1

2

2 2

1 1

4

J3

3

P4

2 2

3

123

1 1

J4

ON-BOARD CONNECT OR

ABCDEFGHJ

J10

123456789

123456789

J1 P1

K

10 10

44444

J11

ABCDE

ORN

VIO GRA

YEL

GRN/YEL

CRYO-TORR

0

F

YELYEL

CR1

BRN-14 BRN 14

RED

BLK

1 2 5

35UF

C1

R2

119UF

C2

K1

NONC

WHT/BL K

GRN/ YEL-14

POWER IN

Z

L3

x Y GND

L1 L2

208/230 VAC 3ph

TB1

R1

15A15A 1A

1 2 3

P1 P2 P3

CB1

SRT

PM

NO C NC

A BC

ETM

WHT/ORN

7 765 5

J/P7

WHT

WHT/RED

t

12

24

T1

188

217

WHT

C

BLK 14 BLK 14

WHT/RED

RED 14 RED 14

WHT/RED

CB3

CB2

250

WHT/BR N

WHT/OR N

66

4

5 5

J/P6

BRN BRN

WHT/BRN

8

4

3A

12

3A

RED

W/BRN

BRN

GRA

WHT/BLK/VIO

1

2

S2

50 HZ

60 HZ

2a

2b

W/BLK

WHT/BLK/VIO

ORN WHT/RED

7

7654321 1

BLK

20

t

GRA

0

10

ORN

WHT/BLK/BLU

J/P8

WHT WHT/BRN YEL

24

T2

J/P9

ORN

1

5

9

44

3 3221 1

W/YEL

W/VIO

WHT

0 WHTWHT

t

162

212

0

108

125

BLU BLK BLK

WHT/BL U

WHT/GR A

33

11

2 2

VIO

WHT/BLU

3

7

11

BLU

RT1

YEL

2

1

S1

1a

1b

2a

2b

220V

208V

19.9 - 23.5

20.5 - 21.2

21.9 - 23.5

CONTROL V OLTS

W/ORN

2

3

5

6

WHT/RE D WHT/VI O

WHT/VI O

WHT/YE L YEL

BLK

GRA

0 WHT BR N

162

212

t

t

12

217

250

188

BRN

WHT/BR N

WHT/OR N

6

55

3211

4 4

K2

WHT/O RN

13

14

0

20

0

108

125

WHT/BL U

BLU

WHT/GR A

WHT

WHT/YE L

CH VOLTS

118 - 139

208V 50 Hz

180 - 212

FREQUE NCY LINE VOLT S S1 S2

1. VOLTAGE SELECTION:

NOTES:

20.5 - 24.0

121 - 125

148 - 159

138 - 162

60 Hz

208V 60 Hz

213 - 220 220V 50 Hz

198 - 212

213 - 250 220V

50 Hz

60 Hz

Figure C-1: 8200 Comp ressor E lectr ical Schematic P/N 803 2563P001 Rev. 100

119UFSTART CAPA CITOR,

35UF

RUN CAPACI TOR,

MAIN CIRCUIT BREAKER

CB1 C1C2

CB2 CIRCUIT BREAKER, 3A

CB3 CIRCUIT BREAKER, 3A

CR1 MOTOR S TA RT RELAY

ETM METER ELAPS E D TIME

J1 COLDHEAD CONNECT OR

J2 PUMP CONNECTOR

TRANSFORMER CONNECTO R

TRANSFORMER CONNECTO R

J3 THERMOSTAT CONNECT OR

J4 SOLENOID CONNECTOR

J5 FAN CONN ECTOR

J/P6 TRANSFOR MER CONNECTOR

J/P7 TRANSFOR MER CONNECTOR

J/P8

J/P9

K1 OVERTE MPERATURE TRIP R ELAY

K2 VOLT AGE S EL ECTOR RELAY

M1 PUMP MOTO R

M2 FAN MOT OR, AI R COOL ED ONLY

PM PHASE MONI TOR

J10 ON-BOARD CONN ECT OR

J11 CRYO-TORR CONN ECTO R

R1 OVER TEMPERATURE RES ISTOR

R2 BL EED RESISTOR

RT1 CURRENT L IMITER

S1 VOL TAGE SEL ECTOR SWI TCH

S2 FR EQUENC Y SELECT OR SWIT CH

TRANSFORMER

SOL1 SOLENOIDT1T2

TRANSFORMER

TERMINAL BLOCK, INCOMING VOLTAGE

THERMOSTAT

THERMOSTAT, FOR WATER COOLED

USE TS1 AND TS2

TB1

TS1

TS2

Page 32

Figure C-2: 8200 Comp ressor Ele ctr ical Schematic P/N 803 2564P001 Rev. D

Page 33

8200 Compressor

Appendix D - Components in the Electrical

Control Mo dule of the 8200 Compr e ssor

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

1. Overtemperature Resistor R1

2. Run Capacitor, 35 µf C1

3. Start Capacitor, 119 µf C2

4. Transformer T2

5. Phase Monitor PM

6. Voltage Selector Relay K2

7. Main Circuit Breaker CB1

8. Circuit Breaker, 3A CB2

Figure D-1: Components in th e El ectrical Control Chassis of the 8200 Compressor

P/N 8040353 D-1

9. Circuit Breaker, 3A CB3

10.Voltage Selector Switch S1

11.Frequency Selector Switch S2

12.Overtemper ature Trip Relay K1

13.Transformer T1

14.Motor Start Relay CR1

15.Meter, Elapsed Time ETM

Three-Phase Scott-T Configuration

Page 34

Appendix D - Components in the Electrical Control Module of the 8200 Compressor

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

1. Coldhead Phase-Shifting ResistorR3

2. Overtemperature Resistor R1

3. Run Capacitor, 35 µf C1

4. Start Capacitor, 119 µf C2

5. Transformer T2

6. Run Capacitor, 2 µf C4

7. Run Capacitor, 6 µf C3

8. Main Circuit Breaker CB1

Figure D-2: Components in the Electrical Control Chassis of the 8200 Compressor - Single-

D-2 P/N 8040353

9. Circuit Breaker, 3A CB2

10.Circuit Breaker , 3A CB3

11 . Voltage Selector Switch S1

12.Frequency Selector Switch S2

13.Relay, Trip Relay K1

14.Transformer T1

15.Motor Start Relay CR1

16.Meter, Elapsed Time ETM

Phase RC Configuration

Page 35

8200 Compressor

Appendix E - Flow Diagrams for 8200

Air- Cooled and Water- Cooled Compressors

Compressor Gas and Oil Flows

Refer for Figure E-1 or Figu re E -2 whi le reviewing this subsection.

Helium return in g fro m th e co ld hea d en te rs th e compressor, and a small

quantity of oil is injec ted into the gas stream, thereby overcoming helium

low specific head and inability to carry heat produced during compression.

Helium is then compresse d and passed th r oug h a heat exchanger for

removal of compression -c aused heat. The helium flows t hrough a bulk oil

separator, oil-mist separator, and helium filter cartridge, where oil and

contamin ants are removed.

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

A differential pressure relief valve in the compressor limits the operating

pressure differential betw een the helium supply an d return lines, thereby

allowing compressor operating without cold head operation. When cold

head operation reaches a steady-state condition, further pressure regulation

is unnecessary.

P/N 8040353 E-1

Page 36

Appendix E - Flow Diagrams for 8200 Air-Cooled and Water-Cooled Compressors

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

Figure E-1: Flow Diagram of the 8200 (Air-Cooled) Compressor

E-2 P/N 8040353

Page 37

8200 Compressor

-

C

TI CR

HELIX TECHNOLOGY CORPORATION

Y

OG

ENIC

S

Figure E-2: Flow Diagra m of the 8200 (Water-Cooled) Comp ressor

P/N 8040353 E-3

Loading...

Loading...