Page 1

BASIC INFORMATION

One of the most important factors in determining the way a

helicopter handles is the rotor head speed. Once you find a

rotor head speed you like, it is desirable to maintain that rotor

head speed at all times, during all maneuvers. However, there

are many outside factors affecting rotor

head speed such as

flight speed,

acceleration/deceleration, control inputs (rotor head

loading), wind, etc. The rotor head is constantly acted upon by

these and other forces which affect rotor head speed. Overrevving and overloading of the rotor head during maneuvers

results in decreased performance. During the time that the rotor

head has unloaded and rotor speed has increased, the

machine will become jumpy or too responsive. During the time

that the rotor head is overloaded and rotor head speed has

decreased, the machine will become sluggish and less

responsive. This never ending transition causes the pilot to wait

for the helicopter before giving the next control input. This

problem can be minimized with pitch and throttle curves, but it

is not possible to totally eliminate it—until now. The Rotor Head

Speed Governor operates the throttle servo to maintain a

constant rotor head speed at all times. This decreases the

amount of collective stick movements you must make, allowing

you to concentrate more on the other controls!

It is possible to select two rotor head speeds with the Governor.

Typically, a lower RPM is selected for hovering while a higher

RPM is selected for aerobatics. This can be done in flight by

adjusting a dial or flipping the rpm select switch on your

transmitter.

OPERATION

The governor is connected between the throttle servo and the

receiver (the same way a gyro is connected between the rudder

servo and the receiver). Three magnets are mounted to the

main gear in your helicopter. When spinning (at the same rpm

as the rotor head), the magnets pass by a sensor connected to

the CSU (constant speed unit—the little black box). The sensor

reads the rpm of the main gear and sends a signal through the

CSU to the throttle servo, which modulates the throttle servo as

required. The governor will operate between 900 rpm to 2,200

rpm. The pilot determines rotor speed by settings he programs

into the transmitter.

Please note that your governor will not:

❏ 1. Hold rotor head speed when your engine is not

correctly set

up (needle valve settings, exhaust system, etc.).

❏

2. Reach the full 2,200 rpm if your engine does not have

enough power.

DECIDE HOW YOU WILL TURN ON AND ADJUST

THE GOVERNOR

Now you know what the Rotor Speed Governor can do, but how

are you going to turn it on and adjust your rotor head rpm while

you are flying? Following are three methods we suggest for

using your governor.

Method A

Use a two position switch to switch between a lower rotor head

speed (for hovering) and a higher rotor head speed (for

aerobatics). This means that in addition to flipping the switch for

your different pitch curves (Normal, Idle up 1, Idle up 2), you

will also have to flip the rotor head speed switch to access your

other rotor head rpm. For example, when you go from your

normal pitch curve for hovering to your idle up 1 pitch curve for

aerobatics, in addition to flipping your idle up 1 switch, you will

also have to flip the governor switch to activate your higher

rotor head speed. The way you adjust the RPM for each switch

position (your two rpm ranges) is to change the ATV’s for both

ends of the switch. This means you can vary the rpm only on

either side of your “middle” rpm which will be around 1,400 rpm

(1478 rpm to be exact). In other words, the two rpm you can set

are only above 1,400 rpm (when your switch is in one position)

and below 1,400 rpm (when your switch is in the other

position). You cannot have rotor head speeds of say, 1,600 rpm

and 2,000 rpm because they are both on the same side of the

ATV range.

Method B

Use an adjustable dial or slider to change your rotor head

speed. This allows infinite adjustment of your rotor head speed

(between 900 and 2,200 rpm) in any of your pitch curves, at

any time. But, you will have to manually adjust the dial while

you are flying. This might be a good method for starting out

while you get the feel for how your governor operates. With this

method, you can also turn the governor off at any time (instead

of when your throttle stick drops below a preset point when you

land, as in method A). For example, once you have established

a hover and set your hover rpm with the dial, use the dial to

increase your head speed when you go into your aerobatic

pitch curve. Similarly, when you switch back into your hover

pitch curve, adjust the dial to lower your head speed.

Method C

Use your pitch curve switch (Normal, Idle up 1, Idle up 2) to

access your pitch curves and simultaneously activate

corresponding rotor head rpm preset by the governor. This

requires a computer radio with programmable mixing where

you can alter the center point of the channel that determines

your rotor head rpm (to preset the rpm for each of your

conditions—Normal, Idle up 1, Idle up 2). Use the “offset”

mixing type instead of linear mixing type.

Rotor Head Speed Governor

INSTRUCTIONS

Congratulations and thank you for purchasing the Heli-Max

Rotor Head Speed Governor. The Governor is ideal for

expert aerobatic pilots who demand a constant rotor head

speed in order to maximize their helicopter’s performance,

and for novice pilots who wish to simplify pre-flight setup

(actually, experts can realize the benefits of simplified setup

too!) In other words, the Rotor Head Speed Governor is for

everybody!

Page 2

Before you test and install your governor, if possible, you

should test fly and set up your helicopter to perform the way

you like.

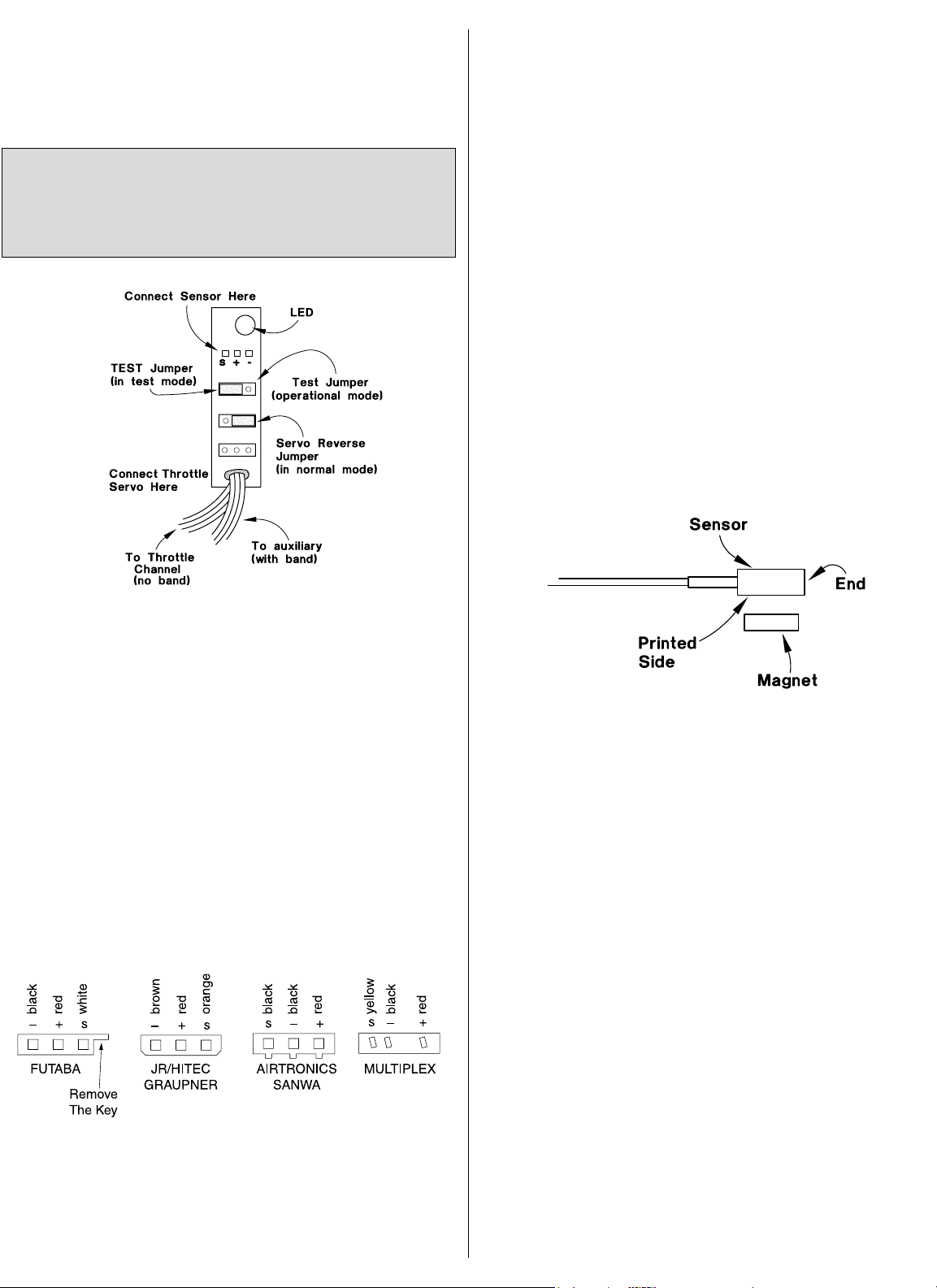

HOOKUP THE GOVERNOR

Your governor comes equipped with Futaba®brand “J” style

connectors. If you own a Futaba radio system, proceed to step

1 below. If you own another brand of radio, you may have to

modify the connectors on your governor. See the diagram

below for proper polarities for major radio brand connectors.

Usually, all that is required is to carefully remove the key on the

connectors on the governor with a utility knife so they will fit into

the slot on your receiver. If you’ve modified your connectors,

make certain the wiring order on your governor connectors

and the servo connectors is the same as the wiring order on

the Futaba connector.

Study the diagram carefully. The positive (+) wire is the center,

the negative (-) wire is on the side opposite of the key on the

connector and signal (S) is on the side of the connector nearest

the key. WARNING! Failure to match polarities on any

connector

may damage your gyro and will void your warranty.

❏

1. Connect your throttle servo to the bottom output of the

governor.

❏

2. Determine whether you will use a dial to vary your rotor

rpm or a two position switch to switch between a preset high

and low rpm. Connect the lead with a band from the governor

to the channel on your receiver that is operated by the switch or

dial you selected to control rotor rpm (usually Auxiliary 1).

Some pilots with advanced computer radios may choose to use

their programmable mixing and flight conditions to mix preset

rotor rpm with their pitch curves (Idle up 1, Idle up 2). When

different pitch curves are switched on (Idle up 1, Idle up 2), the

preset rotor rpm will be selected without having to adjust an

additional dial or switch.

❏

3. Connect the lead from the governor without the band to

the throttle servo output on your receiver.

❏

4. Connect the governor’s sensor lead to the top output of

the governor.

SET UP AND TEST PROGRAM

Determine The Active Side Of The Magnets

❏

1. Place the test jumper in the test mode on the governor

(refer to the previous diagram).

❏

2. Turn on your transmitter, then your receiver.

❏

3. Place one of the magnets on your workbench. Pass the

sensor over the magnet within a distance of 2mm or less. Note

that the printed side of the sensor, not the end, reads the magnet.

❏ A. If the LED on the governor glows, use a felt tip pen to

mark

the upward facing side of the magnet as “active” (mark an “A”).

❏

B. If the LED on the governor does not glow, flip the magnet

over and try again. When the LED glows mark that side of the

magnet as active.

❏

4. Determine and mark the active side of the remaining two

magnets.

Now you’re ready to begin the setup and test program.

Set Up Your Transmitter

❏

1. If your radio has a “hovering throttle trim” (an adjustable

trim operated by a dial that is used to adjust throttle position at

hover only), deactivate or inhibit the trim. This is not to be

confused with your regular throttle trim.

❏

2. Turn your ATV’s at both ends of your throttle servo to

100% (when instructed to do so, you will have to adjust your

throttle linkage mechanically because the ATV’s must be set at

100% for your governor to operate correctly).

Do not mount the governor in your helicopter until instructed

to do so. We recommend setting the governor up on the

bench before you mount it in your helicopter. This will make it

easier to perform the test procedures and give you a better

understanding of how the governor works.

2

Page 3

Set Up And Test The Governor

❏

1. If you haven’t already done so, turn off your Tx and Rx.

Now, turn on your Tx, then the Rx.

❏

2A. If you are using an adjustable dial on your transmitter to

adjust the rotor rpm, turn the dial to the position where the rpm

will be minimum (counter clockwise).

❏

2B. If you are using a two position switch to select between a

high and a low rpm, flip the switch to the position that will be

used for the lower of the two rpm.

❏

3. Pass the sensor over one of the magnets three times. The

LED on the governor will glow each time. If the LED does not

glow, you have your magnet upside down. Flip the magnet

over, reset your radio, and return to step 1.

❏

4. Pass the sensor over the magnet a 4th time. The throttle

servo should move the carburetor to “idle” position. If the

throttle servo moves to full throttle, reverse the direction of your

servo using the reverse jumper on the governor. Turn your Rx

switch off, move the reverse jumper to the servo reverse

position, then reset the governor by turning it back on and

passing the sensor over the magnet 4 times. On the 4th time

the throttle servo should move to idle.

❏

5. Pass the sensor over the magnet a 5th time. The throttle

servo will move the carburetor to full throttle.

❏

6. Pass the sensor over the magnet a 6th time. The throttle

servo will move the carburetor to engine off.

❏

7. Repeating steps 1 through 6 as many times as necessary,

adjust your throttle linkage (do not use your ATV’s) so your

carburetor is fully open and fully closed when the governor

moves the throttle servo after passing the sensor over the

magnet the 5th and 6th time.

❏

8A. If you are using a dial to adjust the rpm, turn the dial to

its maximum position.

❏

8B. If you are using a switch to select a high and low rpm,

flip the switch to the position that will provide the higher of the

two rpm.

❏

9. Pass the sensor over the magnet a 7th time. If the LED

glows, reverse the channel in your transmitter that operates the

dial or switch you are using to adjust the rpm, then reset the

governor. When you get to step 9 and the LED flashes, go to

the next step.

❏

10A. If you are using a dial to adjust the rpm, turn the dial to

its minimum position.

❏

10B. If you are using a switch to switch between high and

low rpm, flip the switch to the position that will provide the low

rpm. The LED will glow.

❏

11. Turn the dial or your rpm select switch to the high rpm

setting. The LED will go out. At this point the governor is

activated and will maintain constant rotor rpm.

❏

12. Turn the dial or your rpm select switch to the low rpm

setting. The LED will glow. Now the governor is deactivated.

❏

13A. If you are using a dial, slowly increase the dial until the

LED goes out. At the point when the LED goes out, the

governor is activated. From this point on, rotor rpm will increase

as you turn up the dial.

❏

13B. Decrease the ATV on the side of the rpm select switch

that controls the lower of the two rpm positions until the LED

goes out. Note the ATV percentage. At this point the governor is

active and is set at the lowest possible rpm you can use

(900 rpm).

❏

14A. Slowly decrease the dial until the LED glows. The

governor is now inactive.

❏

14B. Slowly increase the same ATV you adjusted in step

13B until the LED glows. The governor is now inactive. When

it’s time to fly your helicopter and set the hovering rpm, set your

helicopter on the ground and adjust the ATV until you reach the

rpm you desire.

❏

15. Move your throttle stick to full throttle. Pass the sensor

over the magnet an 8th time. The LED should flash.

❏

16. Move the throttle stick to idle. The LED will glow. Now

the governor is inactive.

❏

17. Move the throttle stick back to full throttle. While you do

this, note the position of the throttle stick when the LED goes

off. This is the point at which the governor “turns on” and

cannot be adjusted.

❏

18. Now that the governor is set up, activate your other pitch

curves (Idle up 1, Idle up 2). Lower the throttle stick. Make sure

the LED remains off so the governor will not turn off when you

lower the throttle stick while performing aerobatics (or hovering

inverted).

❏

19. If the LED remains off, your governor is set up correctly

and you are finished. If the LED glows when you lower the

throttle stick while you are in your aerobatic pitch curves (Idle

up 1, Idle up 2), raise your throttle curves so the LED remains

off. Now you are finished setting up the governor.

You must adjust your linkage mechanically because the

throttle servo receives its signal from the governor, not your

transmitter. This is a fail safe feature. Do not use your ATV’s

to adjust the throttle lever settings.

In the flow chart, whenever you see the term “Reset your

governor,” it means you should turn off your receiver, return

to step 1 and follow the flow chart until you return to the step

that instructed you to reset your governor.

Refer to the flow chart to help you through the steps of

setting up your governor. The steps in the flow chart

correspond to the steps in the following instructions.

3

Page 4

Mount The Magnets And Sensor

❏

1. Determine where you will mount the magnets and sensor.

The magnets must be mounted where they will turn the same

rpm as the main rotor. We recommend you mount them to the

main gear.

❏

2. Use the template included to accurately mark your main

gear where each magnet will be positioned. Make sure you

count the same number of gradations along each 120° line so

the magnets are aligned. This is important for the sensor to

read them correctly and for balance!

❏

3. Mount the magnets in or on the main gear (with the active

side facing the sensor). They must pass within 2mm of the

sensor. You may mount the magnets to the surface of the gear

with silicone cement, epoxy or CA. For the most security, we

recommend drilling a 3/16" diameter shallow cavity or a hole all

the way through the gear to hold the magnets.

❏

4. Mount the sensor. If possible, mount it directly to the

frame of the helicopter, or fashion a mount from thin plastic or

aluminum. Mount the sensor mount to the frame of your

helicopter where the sensor will be within 2mm or less of the

magnets when they pass.

❏

5. Make certain the sensor and none of the cords can

interfere or become entangled in the mechanics of the

helicopter.

TEST FLYING

Start your engine with the throttle stick at idle and your rpm dial

or switch on the low rpm setting. The governor will not be

activated until the throttle stick reaches the required position

(noted in step 17 under Set Up And Test The Governor) and

you advance the rpm dial (or adjust the ATV if you are using a

two position switch).

When you are ready to lift off, advance the throttle to begin the

rotor head turning, then turn on the governor by adjusting the

dial (or adjusting the ATV) until the desired rotor rpm is

reached. There will be a slight delay when you change the rpm.

Important: Be certain the jumpers are secure on the governor

unit. If the servo reverse jumper becomes disconnected, the

governor will switch off.

Initially, your helicopter will feel different. But, after you get the

feel for the new setup you will wonder how you did without it!

You can get the maximum from your rotor speed governor (and

your helicopter) if you experiment with different rotor rpm. This

way, you can match your helicopter to your engine. Once you

have mastered the setup of your rotor speed governor, your

flying sessions will become more relaxed. Gone will be the

days of programming rotor blade pitch and throttle curves! This

leaves you to the most important task at hand—flying!

TECHNICAL DATA

Power supply: 3-9 Volt DC

Consumption: 7mA

Size: 2.2 x 1.4 x 0.4" (56 x 37 x 10.5mm)

Weight: 0.14 oz (4g)

Operational range: approx. 900 rpm to approx. 2,200 rpm

with included three magnets (approx. 650

rpm to approx. 1530 rpm with four

magnets)

ONE YEAR WARRANTY STATEMENT

*USA and Canada Only

Heli-Max warrants this product from defects in materials and

workmanship for a period of one year from the date of

purchase.

During that period, Heli-Max will, at its option, repair or replace

without service charge any product deemed defective due to

those causes. You will be required to provide proof of purchase

(invoice or receipt). This warranty does not cover damage

caused by abuse, misuse, alteration or accident. If there is

damage stemming from these causes within the stated

warranty period, Heli-Max will, at its option, repair or replace it

for a service charge not greater than 50% of its then current

retail list price. Be sure to include your daytime telephone

number in case we need to contact you about your repair. This

warranty gives you specific rights. You may have other rights,

which vary from state to state.

For service on your Heli-Max product, warranty or nonwarranty, send it post paid and insured to:

HOBBY SERVICES

1610 Interstate Drive

Champaign, IL 61822

Attn: Service Department

Phone: (217) 398-0007 9:00 A.M. - 5:00 P.M. Central Time M-F

E-Mail: hobbyservices@hobbico.com

We can also be reached on the internet at:

www.hobbies.net/helimax

*For warranty and service information if purchased outside the

USA or Canada, see the additional warranty information (if

applicable) or ask your retailer for more information.

Entire Contents © Copyright 1998

Printed in USAHMXZ4913 For HMXM1500

4

Loading...

Loading...