Page 1

Rotor Span: 20.75 in [528mm]

Height: 8.125 in [206 mm]

Length: 23 in [584mm]

Weight:16 oz [454g]

Motor: 380 Brushed Motor

Radio: 5-Channel FM with 3 Micro Servos,

Receiver, ESC, and Gyro

INSTRUCTION MANUAL

IMPORTANT PRECAUTIONS

WARNING!! Read the entire instruction sheet included with this battery and charger. Failure to follow all

instructions could cause permanent damage to the battery, charger or its surroundings, and cause bodily harm!

• Only use a LiPo approved charger. NEVER use a NiCd/

NiMH peak charger!

• Do not attempt to use this charger with NiCd or NiMH

battery packs.

• Never charge in excess of 4.20V per cell.

• Only charge through the “charge” lead. Never charge

through the “discharge” lead.

• Use only the supplied AC wall adapter to power the charger.

• If the battery should become damaged, discard the battery.

Do not attempt to use a damaged battery.

• Do not leave the charger unattended while charging.

Disconnect the battery and remove input power from the

charger immediately if either becomes hot! However, It is

normal for the charger to get warm.

• Disconnect the battery from the charger and carefully move

the battery to a fi reproof location if the battery begins to

swell or smoke!

• Never charge at currents greater than 1C.

• Always charge in a fi reproof location.

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION.

IT CONTAINS IMPORTANT INSTRUCTIONS AND WARNINGS

CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

• Never trickle charge.

• Never allow the battery temperature to exceed 150° F

[65° C].

• Never disassemble or modify pack wiring in any way or

puncture cells.

• Never discharge below 2.5V per cell.

• Do not allow water, moisture or foreign objects into

the charger.

• Do not block the air intake holes, which could cause the

charger to overheat.

• Do not place the charger or any battery on a fl ammable

surface or near a combustible material while in use.

• Do not charge on a carpet, cluttered workbench, paper,

plastic, vinyl, leather, wood, and inside an R/C model.

• Never charge inside a full sized vehicle.

• Always disconnect the battery from the charger and the

power supply from the charger when not in use.

• Do not attempt to charge a battery if it is swollen or hot.

• ALWAYS KEEP OUT OF REACH OF CHILDREN.

Champaign, Illinois

(217) 398-8970

helihotline@hobbico.com

Page 2

TABLE OF CONTENTS

AMA

INTRODUCTION ............................................................... 2

AMA .................................................................................. 2

SAFETY PRECAUTIONS .................................................2

ITEMS REQUIRED ............................................................ 3

KIT INSPECTION .............................................................. 3

WARRANTY ...................................................................... 3

KIT CONTENTS ................................................................ 4

LIPO BATTERY AND CHARGER ..................................... 4

ASSEMBLY INSTRUCTIONS ........................................... 5

GET THE MODEL READY TO FLY ................................... 7

PREFLIGHT ...................................................................... 8

AMA SAFETY CODE ........................................................ 8

CONTROLS ...................................................................... 9

FLYING ............................................................................ 11

MAINTENANCE & REPAIR ............................................ 12

OPTIONAL UPGRADE ................................................... 15

ORDERING PARTS ........................................................ 18

EXPLODED VIEW ........................................................... 19

PARTS IMAGES .............................................................. 20

OPTIONAL PARTS ......................................................... 22

INTRODUCTION

We urge you to join the AMA (Academy of Model Aeronautics)

and a local R/C club. The AMA is the governing body of model

aviation and membership is required to fl y at AMA clubs.

Though joining the AMA provides many benefi ts, one of the

primary reasons to join is liability protection. Coverage is not

limited to fl ying at contests or on the club fi eld. It even applies

to fl ying at public demonstrations and air shows. Failure to

comply with the Safety Code (excerpts printed in the back of

the manual) may endanger insurance coverage. Additionally,

training programs and instructors are available at AMA club

sites to help you get started the right way. There are over

2,500 AMA chartered clubs across the country. Contact the

AMA at the address or toll-free phone number below.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

Tele: (800) 435-9262

Fax (765) 741-0057

Or via the Internet at:

IMPORTANT!!! Two of the most important things you can do

to preserve the radio controlled aircraft hobby are to avoid

fl ying near full-scale aircraft and avoid fl ying near or over

groups of people.

www.modelaircraft.org

Thank you for purchasing the Heli-Max AXE™ CP V3 RTF

Helicopter. We are certain you will get many hours of

enjoyment out of this model. If you should have any questions

or concerns please feel free to contact us at:

helihotline@hobbico.com.

For the latest technical updates or manual corrections

to the AXE CP V3 RTF visit the Heli-Max web site at

www.helimax-rc.com. Open the “Helicopters” link, and

then select the AXE CP V3 RTF. If there is new technical

information or changes to this model a “tech notice” box will

appear in the upper left corner of the page.

CAUTION: Be aware that the AXE CP V3 RTF operates

on the same frequency band as larger R/C models. If fl ying

your AXE CP V3 RTF within fi ve miles of an R/C site, there

is a real possibility that you could be operating your model

on the same frequency (channel) as another R/C pilot.

If this happens, a crash will result–with the person fl ying

the more expensive model suffering the greater loss (and

having greater potential for property damage or injury).

The best thing to do is to join an R/C club and fl y at the

site where frequency control measures will be in effect. If

you insist on fl ying elsewhere, always be aware of your

proximity to R/C fl ying sites.

SAFETY PRECAUTIONS

Failure to follow these safety precautions may result in

severe injury to yourself and others.

• Keep your face and body as well as all spectators away

from the plane of rotation of the rotors whenever the battery

is connected.

• Keep these items away from the rotors: loose clothing, shirt

sleeves, ties, scarfs, long hair or loose objects such as

pencils or screwdrivers that may fall out of shirt or jacket

pockets into the rotors.

• The spinning blades of a model helicopter can cause

serious injury. When choosing a fl ying site for your AXE

CP V3 RTF, stay clear of buildings, trees and power lines.

AVOID fl ying in or near crowded areas. DO NOT fl y close to

people, children or pets. Maintain a safe pilot-to-helicopter

distance while fl ying.

1. Your AXE CP V3 RTF should not be considered a toy, but

rather a sophisticated, working model that functions very

much like a full-size helicopter. Because of its performance

capabilities, the AXE CP V3 RTF, if not assembled and

operated correctly, could possibly cause injury to yourself or

spectators and damage to property.

2

Page 3

2. You must assemble the model according to the instructions.

Do not alter or modify the model, as doing so may result in

an unsafe or unfl yable model. In a few cases the instructions

may differ slightly from the photos. In those instances the

written instructions should be considered as correct.

3. You must correctly install all R/C and other components

so that the model operates correctly on the ground and in

the air.

4. You must check the operation of the model before every

fl ight to insure that all equipment is operating and that the

model has remained structurally sound. Be sure to check

linkages or other connectors often and replace them if they

show any signs of wear or fatigue.

5. If you are not an experienced pilot or have not fl own

this type of model before, we recommend that you get the

assistance of an experienced pilot in your R/C club for

your fi rst fl ights. If you’re not a member of a club, your local

hobby shop has information about clubs in your area whose

membership includes experienced pilots.

We, as the manufacturer, provide you with a top quality,

thoroughly tested helicopter and instructions, but

ultimately the quality and fl yability of your fi nished model

depends on how you build it; therefore, we cannot in any

way guarantee the performance of your completed model,

and no representations are expressed or implied as to the

performance or safety of your completed model.

WARRANTY

Heli-Max™ guarantees this kit to be free from defects in both

material and workmanship at the date of purchase. This

warranty does not cover any component parts damaged by

use or modifi cation. In no case shall Heli-Max’s liability

exceed the original cost of the purchased kit. Further,

Heli-Max reserves the right to change or modify this warranty

without notice.

In that Heli-Max has no control over the fi nal assembly

or material used for fi nal assembly, no liability shall be

assumed nor accepted for any damage resulting from the

use by the user of the fi nal user-assembled product. By the

act of using the user-assembled product, the user accepts

all resulting liability.

If the buyer is not prepared to accept the liability

associated with the use of this product, the buyer is

advised to return this kit immediately in new and unused

condition to the place of purchase.

To make a warranty claim, send the defective part or item to

Hobby Services at this address.

Hobby Services

3002 N. Apollo Dr., Suite 1

Champaign, IL 61822

USA

Remember: Take your time and follow the instructions to

build a safe and enjoyable model.

ITEMS REQUIRED

❏ Eight “AA” Alkaline Batteries for the Transmitter

KIT INSPECTION

Before starting assembly, take an inventory of the AXE CP

V3 RTF to make sure it is complete, and inspect the parts

to make sure they are of acceptable quality. If any parts

are missing or are not of acceptable quality, or if you need

assistance with assembly, contact Product Support. When

reporting defective or missing parts, use the part names

exactly as they are written in the Kit Contents list.

Heli-Max Product Support:

3002 N. Apollo Drive, Suite 1

Champaign, IL 61822

Telephone: (217) 398-8970, ext. 5

Fax: (217) 398-7721

E-mail: helihotline@hobbico.com

Include a letter stating your name, return shipping address,

as much contact information as possible (daytime telephone

number, fax number, e-mail address), a detailed description

of the problem and a photocopy of the purchase receipt.

Upon receipt of the package the problem will be evaluated

as quickly as possible.

3

Page 4

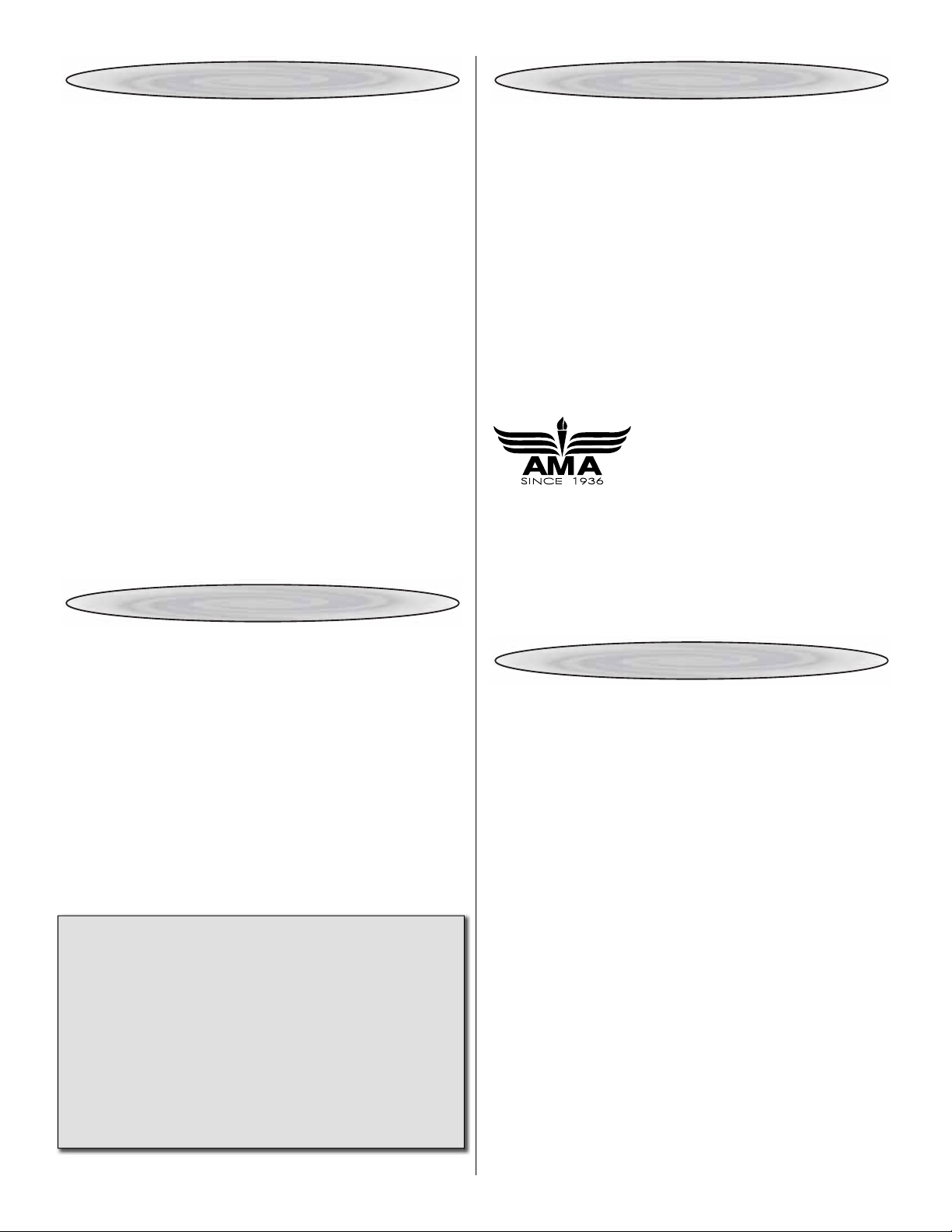

KIT CONTENTS

2

1

6

1. Transmitter

2. Main Rotor Blades

3. Body

4. Helicopter

5. Charger

6. LiPo Battery

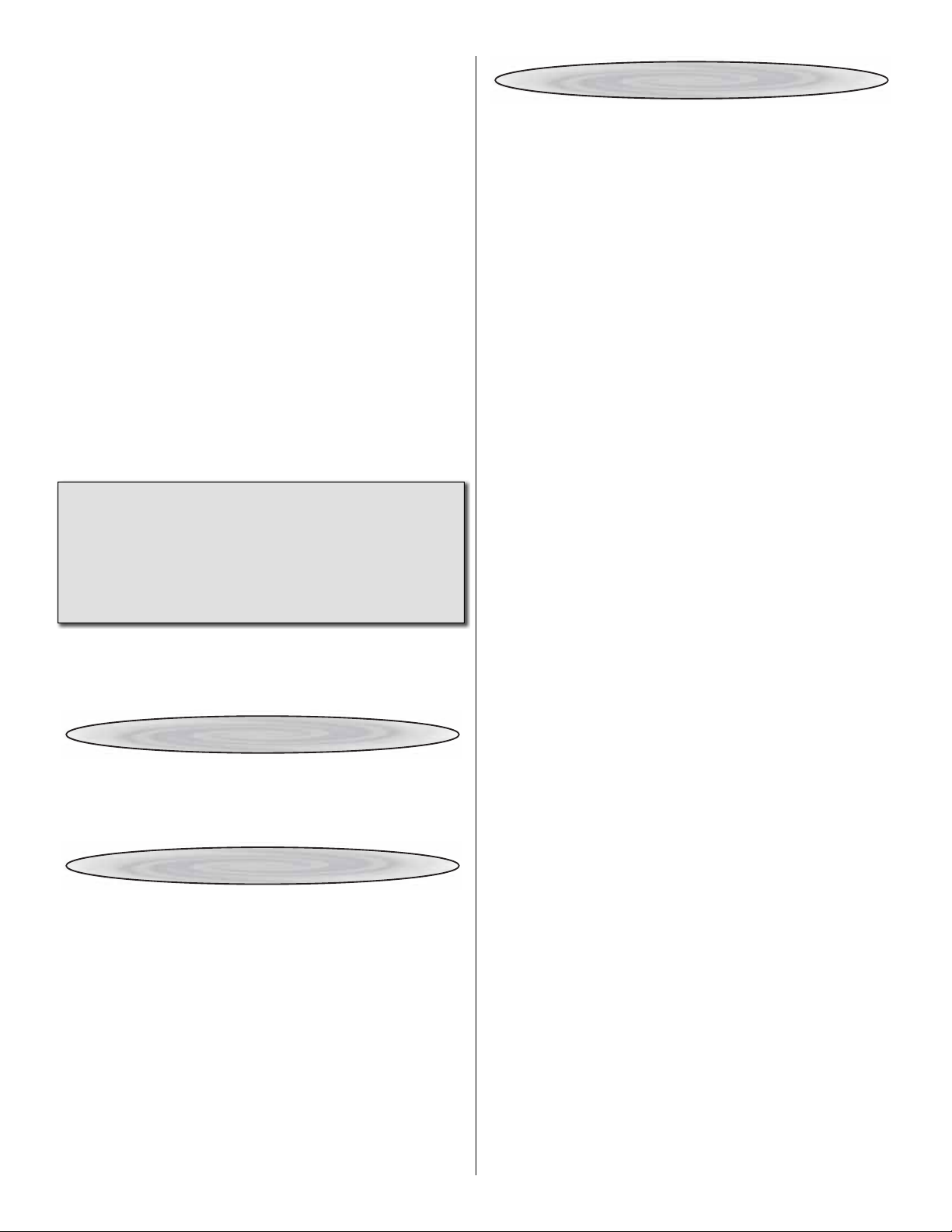

BATTERY & CHARGER

HMXP1004 3S LiPo CHARGER SPECIFICATIONS

4

8

5

3

7

7. Training Gear (Carbon

Rods, Fittings, Foam Balls)

8. DVD

GPMP0401 BATTERY SPECIFICATIONS

Input voltage: 12V DC

Battery types, # cells: 3 lithium-polymer cells

connected in Series (11.1V LiPo)

Charge current: 500mAh maximum

Charge termination: Voltage detection

Minimum battery capacity: 500mAh

Status indicator: two LEDs

Input connectors: polarized DC power jack

for DC input

Output connectors: one balance plug

Case size: 1.8 x 1 x 2.6 in

[45 x 25 x 66mm]

Weight: 1.3 oz [41g]

Capacity: 950mAh

Number of Cells in Series: 3

Rated Voltage: 11.1V

Max. Charge Voltage: 12.6V

Min. Discharge Voltage: 7.5V

Ma ximum Recommended

Charge Current: 950mA

Co ntinuous Discharge

Current: 14.25A (15C)

Pack Dimensions: 2.6 x 1.5 x 0.9 in

[66 x 37 x 22mm]

Weight: 2.9 oz [83g]

4

Page 5

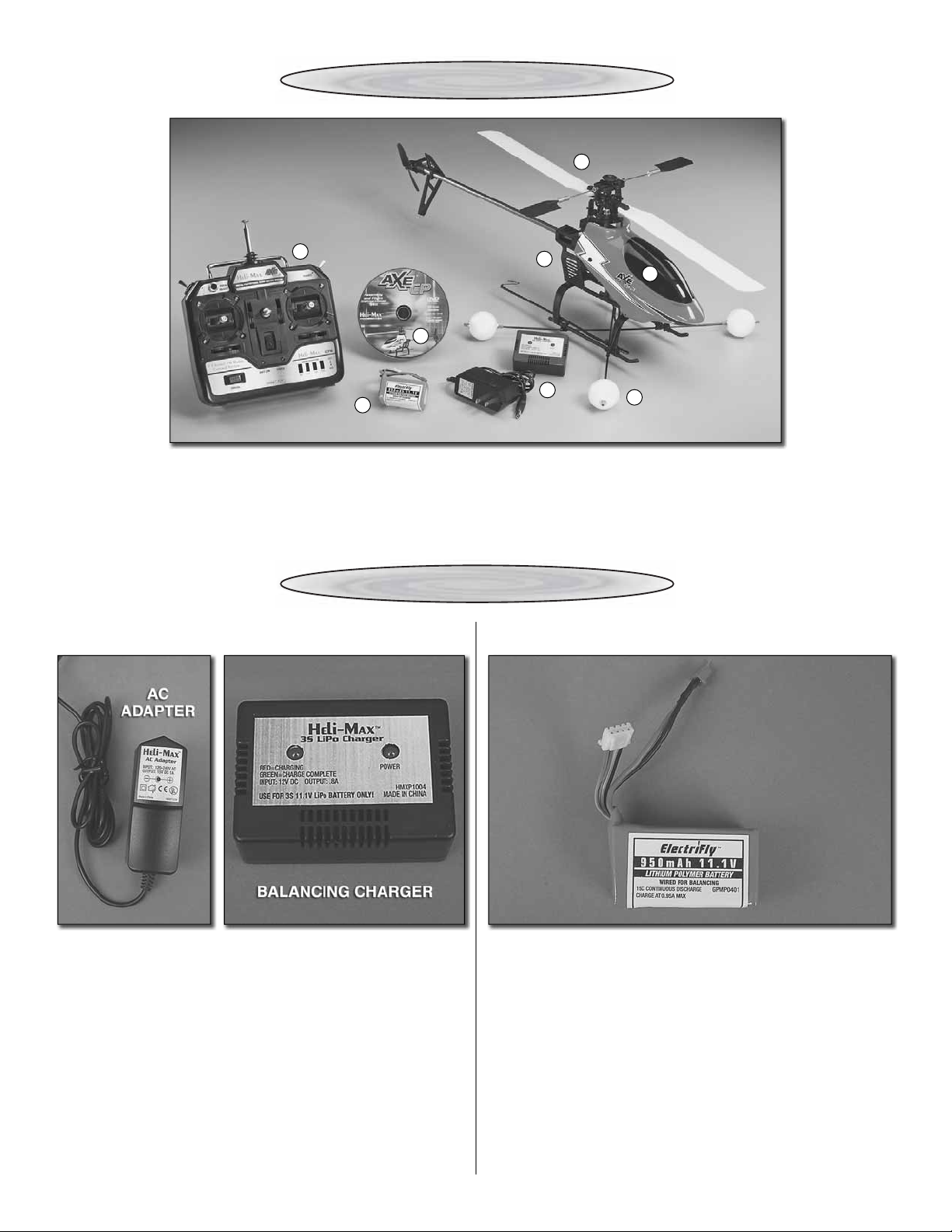

ASSEMBLY INSTRUCTIONS

INSTALL BATTERIES IN THE TRANSMITTER

CHARGING THE FLIGHT BATTERY

IMPORTANT!! Always remove the LiPo battery pack

from the helicopter and charge the battery in a location

that is fi reproof. Never leave the battery unattended

while being charged! If the battery becomes hot, starts

to smoke or begins to swell immediately disconnect the

battery from the charger and carefully move the battery

to a fi reproof location!

❏ 1. Remove the battery cover from the back of the transmitter.

Remove the battery box and install eight “AA” batteries in the

transmitter. Check the polarity of each battery before replacing

the battery cover.

❏ 2. Turn on the transmitter using the power switch as shown

above. Check the LEDs on the front of the transmitter. Only

the Green LED should be on. If the Red LED is on or fl ashing,

then the batteries need replacing.

❏ 1. Connect the input power plug from the AC Wall adapter

to the charger. The power light should now be bright red and

the charger indicator light should be off.

❏ 2. Always use the charge and balance connector on the

battery when charging. Do not use the discharge connector

to charge the battery!

❏ 3. Connect the battery to the balance connector on the

charger. The charge indicator light will turn to red, indicating

5

Page 6

that the battery is being charged. If the charger indicator

light turns to green immediately, then the battery is already

fully charged.

❏ 4. When the battery is fully charged, the charge indicator

light will turn GREEN. Remove the battery from the charger at

this time and disconnect the charger from its power source.

❏ 5. Charging time depends on the amount of charge

remaining in the battery. The charge process may take as long

as 2 hours and 30 minutes with a fully discharged battery.

INSTALL THE BATTERY

INSTALL MAIN ROTOR BLADES

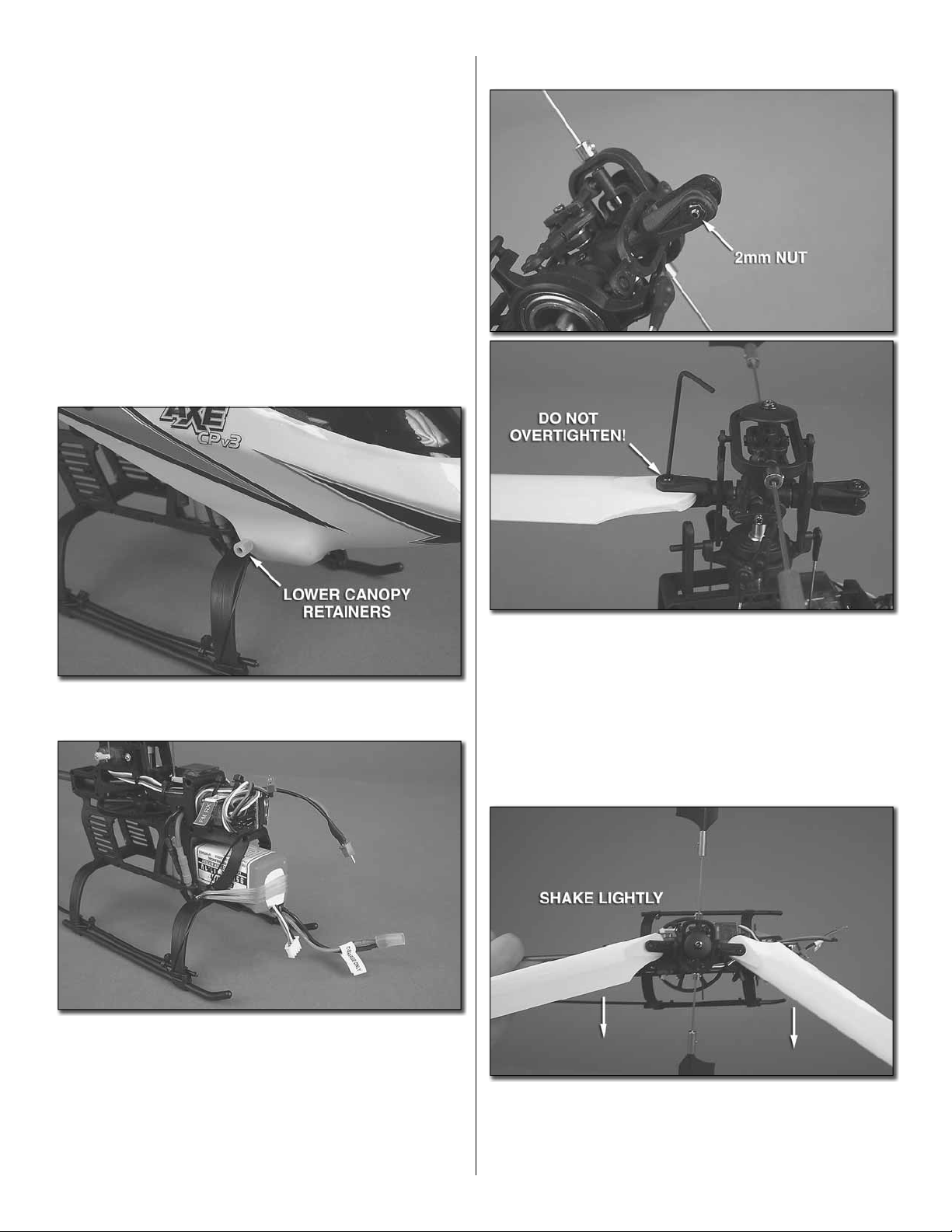

❏ 1. Remove the lower canopy retainers from the lower

canopy mount.

❏ 2. Remove the canopy by sliding the canopy grommets

off of the carbon rods. Slide the battery into the front of the

battery tray as shown above. Use three rubber bands to hold

the battery into the tray.

❏ Please make note of the 2mm nut used on the bottom of

each blade grip. When removing the blade bolt, press upward

on the nut to ensure it remains in the grip. Remove the blade

grip bolts using the 1.5mm hex wrench. Slide a blade into

the blade grip and re-install the 2 x 12mm socket head cap

screw. Repeat for the other blade.

BLADE TENSION TEST

❏ To test the blade tension, hold the helicopter up sideways.

The blades should support themselves until the helicopter

is shaken slightly; then they will fall as shown in the picture

above. The blades should be fairly loose but it is critical that

both blades are the same tension.

666

Page 7

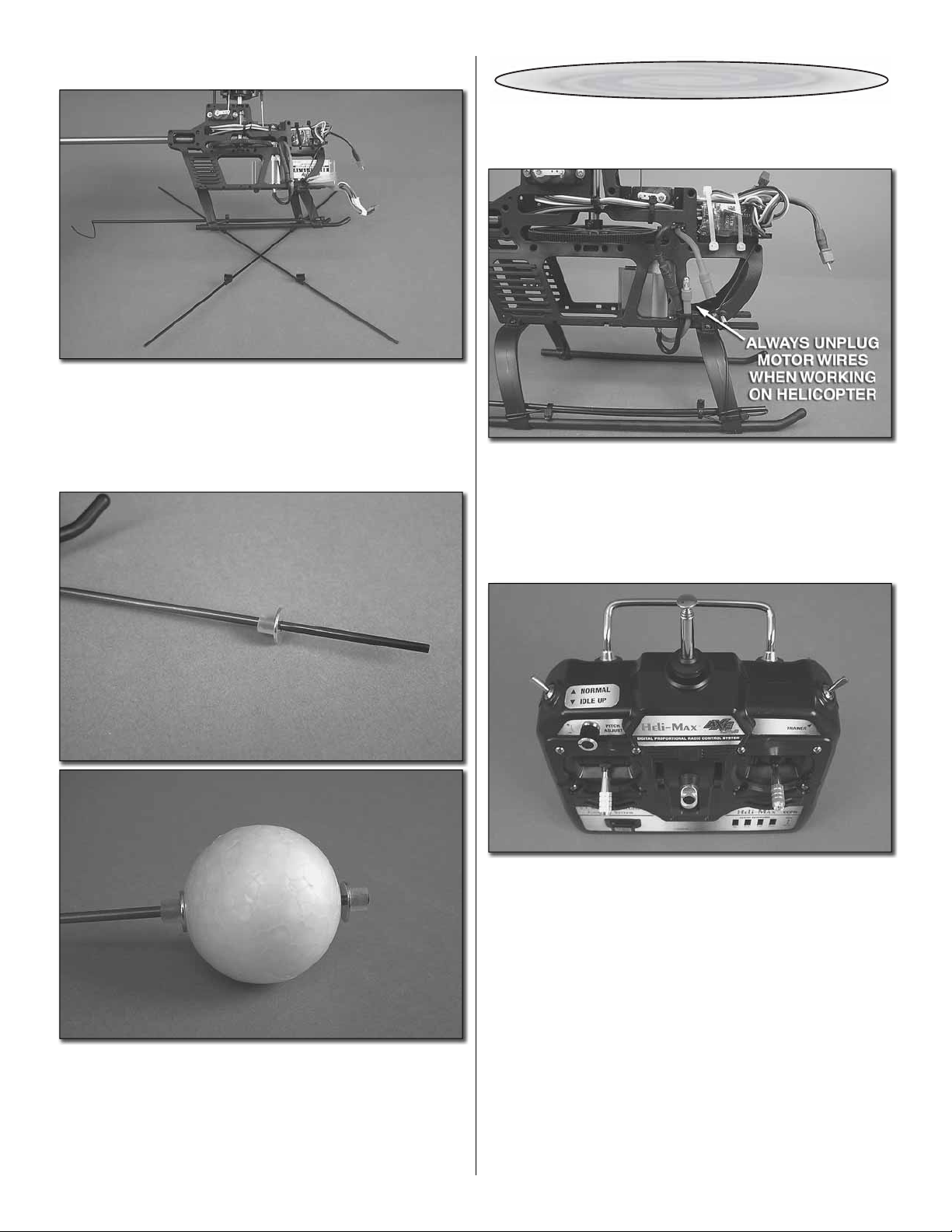

ASSEMBLE TRAINING GEAR

❏ 1. Snap the four plastic fi ttings onto the landing gear

as shown. Slide the carbon rods through the underside of

the fi ttings.

GET THE MODEL READY TO FLY

ELECTRIC MOTOR WARNING

Electric-powered models are very dangerous. Please remove

the pinion gear or unplug the motor while working on the

model. If your helicopter uses an electric tail motor, make

sure it is unplugged as well.

❏ 2. Cut the supplied silicone tubing into eight 1/8" [3mm]

pieces. Please keep in mind that carbon rods are dangerous

to handle and splinter easily. Using pliers, carefully slide

the silicone tubing onto the carbon rod approximately 4"

[102mm]. Now install a foam ball followed by a washer. Using

pliers, install the last piece of fuel tubing. Repeat this step for

the other three balls.

TURNING THE MODEL ON

Always turn the Transmitter on fi rst and ensure the idle up

switch is off. With the AXE CP V3 RTF sitting still, plug the

battery into the ESC. The AXE CP V3 RTF must sit still for

10 seconds so the gyro can initialize and determine center. If

the AXE CP V3 RTF is moved during this initialization, then

the gyro will not operate properly.

Always step 15 feet away from the AXE CP V3 RTF before

fl ipping any switches or operating the throttle. Do not hold

onto the model and run it up. Safety fi rst.

RANGE CHECK

Ground check the operational range of your radio before the

fi rst fl ight of the day. For safety reasons, unplug the main

motor so power cannot be applied to the main rotor blades.

With the transmitter antenna collapsed and the receiver and

7

Page 8

transmitter on, you should be able to walk at least 50 feet

away from the model and still have control. Have an assistant

stand by your model and while you work the controls, tell you

what the servos are doing. If the controls do not respond

correctly, do not fl y! Find and correct the problem fi rst. Look

for loose servo connections or broken wires, corroded wires

on old servo connectors, poor solder joints in your battery

pack or a defective cell or a damaged receiver crystal from

a previous crash.

5) I will not fl y my model unless it is identifi ed with my name

and address or AMA number, on or in the model. Note:

This does not apply to models while being fl own indoors.

7) I will not operate models with pyrotechnics (any device

that explodes, burns, or propels a projectile of any kind).

RADIO CONTROL

BALANCE THE MAIN BLADES

The AXE CP V3 RTF main rotor blades are already balanced

and ready to fl y.

PREFLIGHT

IDENTIFY YOUR MODEL

No matter if you fl y at an AMA sanctioned R/C club site or

if you fl y somewhere on your own, you should always have

your name, address, telephone number and AMA number

on or inside your model. It is required at all AMA R/C club

fl ying sites and AMA sanctioned fl ying events. Fill out the

identifi cation tag on the back cover and place it on or inside

your model.

AMA SAFETY CODE (EXCERPTS)

1) I will have completed a successful radio equipment ground

check before the fi rst fl ight of a new or repaired model.

2) I will not fl y my model aircraft in the presence of spectators

until I become a qualifi ed fl ier, unless assisted by an

experienced helper.

3) At all fl ying sites a straight or curved line(s) must be

established in front of which all fl ying takes place with the

other side for spectators. Only personnel involved with

fl ying the aircraft are allowed at or in the front of the fl ight

line. Intentional fl ying behind the fl ight line is prohibited.

4) I will operate my model using only radio control

frequencies currently allowed by the Federal

Communications Commission.

5) I will not knowingly operate my model within three

miles of any pre-existing fl ying site except in

accordance with the frequency sharing agreement

listed (in the complete AMA Safety Code).

9) Under no circumstances may a pilot or other person touch

a powered model in fl ight; nor should any part of the

model other than the landing gear, intentionally touch

the ground, except while landing.

Read and abide by the following excerpts from the Academy

of Model Aeronautics Safety Code. For the complete Safety

Code refer to Model Aviation magazine, the AMA web site or

the Code that came with your AMA license.

GENERAL

1) I will not fl y my model aircraft in sanctioned events,

air shows, or model fl ying demonstrations until it has

been proven to be airworthy by having been previously,

successfully fl ight tested.

2) I will not fl y my model aircraft higher than approximately

400 feet within 3 miles of an airport without notifying the

airport operator. I will give right-of-way and avoid fl ying

in the proximity of full-scale aircraft. Where necessary,

an observer shall be utilized to supervise fl ying to avoid

having models fl y in the proximity of full-scale aircraft.

3) Where established, I will abide by the safety rules for the

fl ying site I use, and I will not willfully and deliberately fl y my

models in a careless, reckless and/or dangerous manner.

8

Page 9

CONTROLS

Always turn the transmitter on fi rst and verify the idle up

switch is set to normal. With the AXE CP V3 sitting still, plug

the battery into the ESC. The AXE CP V3 will need to sit still

for 10 seconds so the gyro can initialize and can determine

center. If the AXE CP V3 is moved during this initialization,

then the gyro will not operate properly. Re-install the body

and your AXE CP V3 is ready for fl ying.

There is a safety built into the AXE CP V3 RTF that prevents

the motor from activating unless the collective stick has been

lowered to its lowest position. If the motor won’t run and turn

the main blades, please make sure the collective stick is all

the way down and leave it there for two seconds.

TRANSMITTER CONTROLS

Idle Up Switch: Used for forward fl ight and aerobatics. This

switch raises the main rotor RPM and also changes the lowest

position on the throttle stick to around 40% throttle. This allows

the AXE CP V3 RTF to perform aerobatics and inverted fl ight.

This can be a dangerous switch since it raises the throttle. Be

extremely careful not to hit this switch accidentally or the

motor will instantly come on to at least 40% power.

Moving the cyclic stick right will cause the helicopter to tilt

right and start moving that direction.

All controls are described with the tail pointing directly toward

you. This is the best way to start out since it keeps the control

inputs oriented in the same direction. Once you become

comfortable you can work on side-in and nose-in hovering.

Trainer System: You can use a cable to connect two transmitters

together and an instructor can take and give control back with

the release of a switch. Be careful not to hit this switch while in

fl ight as this would disable the transmitter output.

Moving the cyclic stick left will cause the helicopter to tilt left

and start moving in that direction.

Moving the cyclic stick backwards (towards you) will cause the

helicopter to tilt backwards and start moving that direction.

9

Page 10

Moving the cyclic stick forward (away from you) will cause

the helicopter to tilt forward and start moving that direction.

Moving the collective stick forward (away from you) will cause

the helicopter to climb higher.

Moving the tail rotor stick left will cause the helicopter nose

to move left (counterclockwise).

Moving the tail rotor stick right will cause the helicopter nose

to move right (clockwise).

Moving the collective stick backwards (towards you) will

cause the helicopter to descend.

10

Page 11

TRACKING THE MAIN BLADES

FLYING

TAKEOFF

During your fi rst fl ights it is important to have light winds and

a helper to keep an eye on things around you. Also, if you are

fl ying from grass, make sure it’s cut low as this will allow the

helicopter to slide around without catching. Also make sure

there are no obstacles in your fl ying area to distract you.

Slowly add power and observe the model. If you feel it needs

trimming, do so before lift off. You will fi nd that model helicopters

never allow you to return the sticks to center. Simply hold

the sticks as needed to keep a steady hover. Please don’t

fi ght the trim too much as it is a normal thing to experience,

Winds have a large effect on model helicopters. Please wait

for calmer days and slowly work into windy days.

You will notice the cyclic controls lag slightly behind your

inputs. This is perfectly normal and something you become

accustomed to. It is normal to drift around some in a hover,

until you get used to fl ying the model. The cyclic controls

on the AXE CP V3 RTF are fairly sensitive so only small

movements are necessary.

At zero pitch, bring the main rotor up to speed and observe

whether the rotational planes of the blades are the same. If

they are not, adjust one of the linkages to bring the blades

into the same plane.

Apply the two different colored stripe decals to the tips of

your main rotor blades. These decals help identify which

blade is out of track.

HOVERING

Once the helicopter is in the air simply try to keep the

helicopter in one spot. This will take some practice and wind

has a big effect on the stability of the helicopter. Be patient

and slowly progress. Trying to rush the learning process can

be costly.

LANDING

Level the helicopter into a steady hover and slowly decrease

power until the helicopter settles onto the ground.

BASIC MANEUVERS

Once you are comfortable with hovering at different

orientations and landing, it’s time to move on to more

advanced maneuvers.

Slow Pirouettes: Add a small amount of tail rotor (left or

right) and try rotating the helicopter slightly sideways and

see if you can hold it there. If you become uncomfortable

bring the tail back towards you. Once you are comfortable,

try moving the helicopter to the side and turning back. Then

fl y back to the other side in straight lines.

The training gear is a big help to beginners. They soften not

so perfect landings and help to prevent the helicopter from

tipping over. Even if you have experience fl ying a helicopter,

please consider using the supplied training gear for the fi rst

few fl ights.

You can try rotating the helicopter around 360°, which is called

a pirouette. The helicopter can drift during this maneuver

so make certain you have plenty of room when you fi rst

start practicing.

Nose-In Hovering: After pirouettes it’s time to move onto

nose-in hovering. The best bet is to wait for a calm day. Take

off and climb to 15 feet, practice half pirouettes from tail-in

to nose-in hovering, and try to lengthen the delay between

11

Page 12

transitions. This will allow you to practice nose-in and still

give you a chance to get out of trouble. As you improve you’ll

remain nose-in for longer periods of time.

MAINTENANCE & REPAIRS

Forward Flight: Now it’s time to work into basic forward

fl ight. Just take the basic hovering maneuvers listed above

and slowly fl y out farther and faster and always bring the

helicopter back after one pass. Practice controlled slow fl ight

in close as well. The more time you spend practicing here the

easier things will be later on.

AEROBATICS

So you are getting comfortable in fast forward fl ight? Well,

now it’s time to slowly progress into aerobatics. Once you are

in forward fl ight start using the idle up switch which raises

the rotor RPM for aerobatics and allows the AXE CP V3 RTF

to fl y inverted. Also, in wind it may be diffi cult to descend to

land without the idle up on.

Chandelles: Your fi rst step is chandelles. Fly straight across

in front of you and pull up to a 45° angle. Now at the top, when

the helicopter slows down to a stop, apply left or right tail

rotor to bring the nose around 180° and continue back down

the 45° angle. As you progress with the maneuver you can

pull a greater angle than 45°, but 90° would be considered

a stall turn.

Loops: Once you become comfortable with the chandelles

and stall turns it’s time to move onto the loop. The key to the

loop is to enter with plenty of speed. Start pulling aft cyclic

to enter the loop and as the model transitions to inverted at

the top of the loop pull back on the throttle (towards negative

(–) collective) this will help maintain altitude. As the model

returns back to vertical add some positive (+) collective to

maintain the speed. One of the most common mistakes made

on loops is using too much negative (–) collective at the top.

Flips: Be certain to start with plenty of altitude. From an

upright hover slowly add in full forward cyclic and as the

model approaches vertical bring the collective stick back to

center. Now as the model continues to inverted you will need

to start adding in negative (–) collective (or pull the collective

stick back towards yourself). As the model transitions back to

vertical again bring the collective stick back to the middle and

start adding in positive (+) collective as the model returns back

to upright. It’s simply a matter of timing. The most important

thing is, do not throw the sticks around as this can cause the

head speed to drop and may cause the tail to drift.

E-BOARD ADJUSTMENTS

Note: All of the e-board adjustments are pre-set and test

fl own at the factory. If you replace the e-board with a new

one or need to re-adjust it for any reason, please follow the

guidelines below. Never turn these adjustments more than

180° and only use a plastic non-conductive screwdriver to

make the adjustment.

Tip: If you need to make adjustments consider using a

felt-tip marker and place a mark on the adjusters so you

can always return them back to the factory defaults.

Left/Right Bias: Is used to obtain a balanced feel between

left and right tail rotor inputs. The adjustment is very sensitive

so only make small changes. Turn clockwise to increase the

left tail rotor bias.

Gyro Gain: Turn clockwise to increase gain. Typically too

little gyro gain causes the tail to slowly move around and

drift. With the gyro gain too high, you will notice a very fast

oscillation in the tail known as “wag.” This adjustment is not

very critical so please don’t spend a lot of time trying to get

”the best” setting possible.

Tail Rotor Trim: If the helicopter wants to drift one direction in

a stable hover then try using this adjustment. The adjustment

is very sensitive so only make small changes. Turn clockwise

to add right tail rotor trim.

Inverted Hovering: Keep in mind fl ying a helicopter inverted

is very diffi cult but can be learned. One of the main problems

is 3 out of 4 of the controls are reversed (forward/aft cyclic,

collective and tail rotor). You have to mentally reverse these

while fl ying. It will take some practice.

Take the loop you learned above and just hold the inverted

portion for short periods of time. As you become accustomed

to the reversed controls, you will extend the time inverted. It

is very diffi cult and will take some practice. Also, make sure

you have plenty of altitude for recovery if needed.

12

Page 13

SERVO SETUP

Note: The AXE CP V3 RTF is factory set-up and test fl own

so there is no need to make these adjustments unless you

have damaged or changed a servo.

Servo arms are perfectly level when the throttle stick is all

the way down in normal mode (Idle Up Off). Helicopter left

side Servo A pushrod length should be 1.77" [45mm].

SPINDLE REPLACEMENT

Servo arms are perfectly level when the throttle stick is all

the way down in normal mode (Idle Up OFF). Helicopter right

side Servo B pushrod length should be 1.26" [32mm] and

Servo C pushrod length should be 1.77" [45mm].

TAIL ROTOR REPLACEMENT

Before starting, make note of the 2mm nut used on the

bottom of each blade grip. When removing the blade bolt,

press upward on the nut to ensure it remains in the grip.

Remove the blade grip bolts using the 1.5mm hex wrench.

Then, remove the blades from the helicopter

Use two small fl at bladed screwdrivers to pry the old tail rotor

from the motor. Try to apply even pressure to both sides of

the tail rotor. When installing the new tail rotor please note

that the beveled portion of the hub goes in towards the motor.

Simply press the new propeller onto the tail motor.

Use a 1.5mm hex wrench to remove a spindle screw. Remove

the linkages from the blade grips. On the side where you

removed the spindle screw, carefully remove the blade grip

13

Page 14

by pulling outward. Remove the dampening spacer. Pull on

the other blade grip and remove the spindle and blade grip.

If the O-rings come loose, simply press them back into the

head block.

New spindle installation. Apply threadlocking compound to

one of 2mm screws. Slide the 2mm washer onto the screw

and thread it into the new spindle. Slide one of the blade grips

onto the spindle followed by one of the dampening spacers.

MAIN SHAFT REMOVAL

Use a 1.5mm hex wrench to remove the head block retaining

bolt. Using a pair of ball link pliers remove the oval links from

the swashplate. While holding onto the main gear pull upward

on the main rotor head assembly. If the head is diffi cult to

remove simply try to rotate the main rotor head back and

forth while holding onto the main gear. Please note there is a

fl at spot on the main shaft. You will not be able to rotate the

head more than a few degrees due to this.

Using a 1.5mm hex wrench, slide the blade grip and spindle

assembly through the head block. Make certain the O-rings

are properly seated and do not slide out the other side.

Place the other dampening spacer and blade grip onto the

spindle. Apply threadlocking compound to the remaining

2mm spindle screw. Slide a 2mm washer onto the screw

and install into the spindle. Using two 1.5mm hex wrenches

tighten the spindle bolts.

Use pliers to grasp the 2mm nut on the main gear. Insert

a 1.5mm hex wrench into the main gear bolt and remove

the screw.

Snap the ball links onto the blade grips and re-install the

main blades.

Insert a 1.5mm hex wrench into the main shaft collar set

screw and loosen. Insert another 1.5mm hex wrench into the

hole in the top of the main shaft. While holding onto the main

gear try pulling upwards on the main shaft. If you are having

diffi culty removing the main shaft make certain you have

loosened the set screw on the main shaft collar. If necessary

try rotating the main shaft back and forth to help pull the shaft

loose from the lower gear. If you decide to remove the main

gear please note there is a small spacer located beneath it.

14

Page 15

MAIN SHAFT INSTALLATION

OPTIONAL UPGRADE

Using the 1.5mm hex wrench and pliers to hold the nut, reinstall the lower main shaft bolt.

This section is provided to help you install the optional

Futaba

®

GY240 AVCS heading hold gyro in the Heli-Max

AXE CP V3 RTF. This section may be omitted if you do

not intend to install this gyro.

Items Needed (must be purchased separately):

(1) Futaba GY240 AVCS Gyro (FUTM0809) OR (1) Heli-

Max HM4000 Heading Lock Gyro (HMXM1012)

(1) Great Planes® ElectriFly™ C-12 Micro Brushed ESC

w/BEC (GPMM2015)

(1) W.S. Deans® Micro 2R Plug (WSDM3007)

(for C-12 ESC)

(2) Small Tie Wraps

Tools:

Solder and Soldering Iron

Wire Cutters

Installing a heading hold gyro into the Heli-Max AXE CP V3

RTF will make the model easier to fl y. The gyro will now allow

you to focus your concentration on the other controls instead

of constantly fl ying the tail.

We highly recommend using the optional Great Planes

950mAh LiPo 11.1V 3s 15C battery (GPMP0401) for the

best overall performance.

Insert a 1.5mm hex wrench into the main shaft collar set

screw. While pushing downward on the main shaft, pull

upward on the main shaft collar and tighten the set screw.

There should be no vertical movement in the main shaft

once you have completed this step.

Slide the main rotor head block back onto the main shaft.

Make certain the fl at spot inside of the head block is aligned

with the fl at spot on the main shaft. Use a 1.5mm hex wrench

to re-install the 2mm bolt head bolt.

INSTALLING THE GYRO

Use alcohol and a paper towel to remove any grease or mold

release agents on the gyro and helicopter frame. Apply the

double-sided foam mounting tape included with the gyro to

the bottom of the unit. Carefully align the gyro as shown in

the picture and mount the gyro onto the helicopter frame.

15

Page 16

Solder a Micro Deans plug onto the motor wires of the C12 ESC as shown. The negative (–) motor lead (blue wire)

connects to the male pin on the connector. This will be

connected to the tail motor in a later step.

It will be necessary to solder the E-Board and C-12 ESC to

the battery connector as shown above. If you decide to use

the Great Planes 950mAh LiPo battery (GPMP0401), we

suggest installing a Deans Ultra Male Plug onto the ESC and

E-Board to match the connector on the battery pack. The

Deans Ultra Plug will better handle the increased current

draw of more aggressive fl ight as your skill level advances.

Disconnect the tail motor plug as shown above and connect

the plug directly into the blue and white motor wires on the

C-12 ESC.

Using wire cutters, remove the Deans Micro connector from

both battery input leads on the E-Board and the C-12 ESC.

Remove 1/4" [6mm] of wire insulation from both the positive

(+) and negative (–) leads of the C-12 ESC and E-Board.

Compare the battery pack connector to the ESC connector

and verify the polarity is correct before soldering. Twist and

solder together the positive battery lead from the C-12 ESC

and the positive lead from the E-Board. Slide the supplied

heat-shrink tubing (included with the Deans Ultra Plug) over

the wires and solder them to the Deans connector. Repeat

for the negative lead. Slide the heat-shrink tubing up the wire

to the plug. Use heat to shrink the tubing.

16

Page 17

Since the E-Board provides power to the receiver and servos,

the BEC in the C-12 ESC must be disabled. Carefully lift up

the plastic tab on the C-12 ESC connector, remove the red

pin from the plug, and fold it back over the wire. Wrap a piece

of electrical tape or heat-shrink tubing around the connector

pin and wire. Plug the C-12 ESC into the GY240 gyro.

On the gyro, set the “AVCS” switch to “ON” and set the “DIR”

switch to “REV”. Set the gain to 60% using the adjustment

dial on the gyro. If necessary, adjust the gain to match your

fl ying style or desired setup. The typical range of gain is 50%

to 75%.

Review your work and verify that none of the wires can

get caught in the main rotor gear or the swashplate. The

helicopter is now ready for the test fl ight.

FLIGHT INITIALIZATION

If this is your fi rst time fl ying a heading hold gyro, be sure

to take your time and become accustomed to the new gyro

before jumping into your normal fl ying routine.

Turn on the transmitter, center the tail rotor trim tab, extend

the antenna, and verify the idle up switch is “OFF” (toward

the back of the transmitter). Connect the fl ight battery and

allow the gyro 10 seconds to initialize. The helicopter and tail

rotor stick must remain still during this process.

Remove the orange wire from the receiver and plug the

GY240 into the same position. Verify the black wire (–) on the

connector is towards the outside edge of the receiver. Now

plug the orange connector into the next available position on

the receiver (channel 5), and align it with the column of white

wires on the other connectors.

Use two tie straps to attach the gyro wires to the frame. Bundle

the wires and ESC together at the front of the helicopter.

ARMING THE TAIL ESC

The tail motor ESC must be armed before each fl ight. The

best time to do this is after you place the helicopter on the

ground before taking off.

You will hear three beeps from the tail ESC once the gyro has

initiated. Carefully apply full right tail rotor and you will hear

4 beeps. Apply full left tail rotor and you will hear another set

of beeps. The tail ESC and motor are now armed and you

are ready to fl y. If you need to pick up the helicopter, fi rmly

hold onto the main frame since the tail motor could operate

at any time. You can hold full left tail rotor on the transmitter

to prevent this from occurring.

FLYING

If the tail wants to drift slowly due to wind gusts, your gain

may be set too low. Increase the gain a small amount and

see if performance improves. If the tail has a tendency to

oscillate from left to right, your gain may be set too high.

Reduce the gain and see if performance improves.

GOOD LUCK AND GREAT FLYING!

17

Page 18

ORDERING PARTS

Replacement parts for the Heli-Max AXE CP V3 RTF are

available using the order numbers in the Parts List on page

18. The fastest, most economical service can be provided by

your hobby dealer.

To locate a hobby dealer, visit the Hobbico web site at www.

hobbico.com. Choose “Where to Buy” at the bottom of the

menu on the left side of the page. Follow the instructions

provided on the page to locate a U.S., Canadian or

International dealer.

Parts may also be ordered directly from Hobby Services by

calling (217) 398-0007, or via facsimile at (217) 398-7721,

but full retail prices and shipping and handling charges will

apply. Illinois and Nevada residents will also be charged

sales tax. If ordering via fax, include a Visa® or MasterCard®

number and expiration date for payment.

Mail parts orders and payments by personal check to:

Hobby Services

3002 N. Apollo Drive, Suite 1

Champaign, IL 61822

Be certain to specify the order number exactly as listed in

the Parts List. Payment by credit card or personal check

only; no C.O.D.

If additional assistance is required for any reason contact

Product Support by e-mail at helihotline@hobbico.com, or

by telephone at (217) 398-8970.

AXE CP V3 PARTS LIST

# Stock # .......... Description .......................... Includes

22 HMXE9563 .... DD Tail Rotor Blade ...........................1

23 HMXE9556 .... Tail Motor Screws ..............................2

24 HMXE9561 .... Tail Vertical Fin Bracket w/screws ......3

25 HMXE7301 .... Replacement Bearing Set ..................8

26 HMXE8405 .... Main Shaft Collar and Bushing ..........3

27 HMXE7627 .... Complete Linkage Set (Includes #60) ..7

28 HMXE8406 .... Main Shaft .........................................1

29 HMXE9001 .... Swashplate Assembly ........................1

31 HMXE8319 .... Bell-Hiller Mixing Arms ......................2

32 HMXE7806 .... Feathering Spindle ............................1

33 HMXE8607 .... Center Hub ........................................1

34 HMXE9058 .... Slide Block .........................................1

35 HMXE8606 .... Control Hub Screws ...........................2

36 HMXE8801 .... Seesaw ..............................................1

37 HMXE7804 .... Flybar Paddles ...................................2

38 HMXE8622 .... Head Button .......................................1

39 HMXE8813 .... Stabilizer Control Hub ........................1

40 HMXE7805 .... Flybar Weights ...................................2

41 HMXE8320 .... Bell-Hiller Weights .............................2

42 HMXE7803 .... Flybar .................................................1

43 HMXE8323 .... Bell Hiller Dampening Spacer ............4

44 HMXE8322 .... Reinforced Main Rotor Blades ...........2

45 HMXE8318 .... Bell-Hiller Main Blade Grips ...............2

46 HMXE7362 .... O-Ring Set .........................................4

47 HMXE8621 .... Head Bolt and Nut .............................2

48 HMXE7802 .... Flybar Links .......................................2

50 HMXM2005 ... Receiver.............................................1

51 HMXM2003 ... E-Board (Mixer, Gyro, ESC) ..............1

52 HMXE8002 .... Main Motor, 380 .................................1

59 HMXE8404 .... Main Rotor Gear ................................1

60 HMXE8321 .... Bell-Hiller Linkage Set .......................4

HMXE7511 .... Decal Set .............................................

HMXE9552 .... Training Gear .....................................2

HMXP1004 .... 3s LiPo Balance Charger ...................1

HMXZ7006 .... Instruction Manual .............................1

# Stock # .......... Description .......................... Includes

1 HMXE7442 .... Canopy White CPv3 ..........................1

2 HMXE8819 .... Battery Rubber Bands .......................3

3 HMXE7426 .... Canopy Grommets.............................2

4 GPMP0401 .... LiPo 111v 950 MHA AXE CPv3 .........1

5 HMXE4703 .... Antenna Tube .....................................1

6 HMXE8605 .... Canopy Mounts..................................3

7 HMXE8901 .... Skids ..................................................2

8 HMXE7342 .... Screw Set ........................................40

9 HMXE8902 .... Skid Supports ....................................2

10 HMXE8407 .... Main Frame ........................................2

11 HMXM2004 ... Servo .................................................1

12 HMXE8814 .... Servo Mounting Screws .....................6

13 HMXE8818 .... Servo Arms w/screws ........................6

14 HMXE9002 .... Swashplate Stay ................................1

15 HMXE9554 .... Tail Motor Extension Wire ..................1

16 HMXE9550 .... Tail Boom ...........................................1

17 HMXE9551 .... Tail Fin Support Rod ..........................1

18 HMXE9562 .... Tail Vertical Fin ...................................1

19 HMXE8623 .... Heat Sinks .........................................2

20 HMXE9553 .... Tail Motor ...........................................1

21 HMXE9564 .... DD Tail Motor Mount ..........................1

OPTIONAL PARTS

HMXE7450 ... Carbon Fiber Vertical Fin w/Hardware

HMXE7451 ... Carbon Fiber Horizontal Fin w/Hardware

HMXE7452 ... Carbon Fiber Flybar Paddles .......................

HMXE7453 ... Carbon Fiber Tail Boom ................................

HMXE7454 ... CNC Swashplate Assembly .........................

HMXE7455 ... CNC Center Hub & Head Button ..................

HMXE7456 ... CNC Slide Block & Seesaw ..........................

HMXE7459 ... CNC Bell-Hiller Main Blade Grips ................

HMXE7657 ... CNC Flybar Carrier ......................................

18

Page 19

EXPLODED VIEW

60

60

59

DETAILED VIEW OF ROTOR HEAD

19

Page 20

LiPo Battery 1 PC

950 mAh 11.1V

Part # GPMP0401

EVPL # 4

Antenna Tube 1 PC

Part # HMXE4703

EVPL # 5

Canopy 1 PC

Part # HMXE7420

EVPL # 1

Canopy Grommets 2 PCS

Part # HMXE7426

EVPL # 3

Center Hub 1 PC

Part # HMXE8607

EVPL # 33

Servo Arms with Screws 6 PCS

Part # HMXE8818

EVPL # 13

Flybar Weights 2 PCS

Part # HMXE7805

EVPL # 41

3s LiPo Balance Charger 1 PC

Part # HMXP1004

Receiver 1 PC

Part # HMXM2005

EVPL # 50

Flybar 1 PC

Part # HMXE7803

EVPL # 42

Control Hub Pin 2 PCS

Part # HMXE8606

EVPL # 35

Flybar Links 2 PCS

Part # HMXE7802

EVPL # 48

Flybar Paddles 2 PCS

Part # HMXE7804

EVPL # 37

Canopy Mounts 3 PCS

Part # HMXE8605

EVPL # 6

Feathering Spindle 1 PC

Part # HMXE7806

EVPL # 34

Head Bolt & Nut 2 PCS

Part # HMXE8621

EVPL # 8

Head Button 1 PC

Part # HMXE8622

EVPL # 38

Main Blade Grips 2 PCS

Part # HMXE8318

EVPL # 45

Main Rotor Gear 1 PC

Part # HMXE8002

EVPL # 59

Linkage Set 5 PCS

Part # HMXE7627

EVPL # 27

Main Frame 2 PCS

Part # HMXE8407

EVPL # 10

Main Shaft Collar & Bushing 3 PCS

Part # HMXE8405

EVPL # 26

O-Ring 4 PCS

Part # HMXE7362

EVPL # 46

Main Motor, 380 1 PC

Part # HMXE8002

EVPL # 52

Main Shaft 1 PC

Part # HMXE8406

EVPL # 28

Main Rotor Blades 2 PCS

Part # HMXE8322

EVPL # 44

Main Rotor Shaft Bushing 2 PCS

Part # HMXE8403

EVPL # 43

Replacement Bearing Set 8 PCS

Part # HMXE7301

EVPL # 25

20

Page 21

Screw Set 40 PCS

Part # HMXE7342

EVPL # 8

Silicon Secture Tubes 4 PCS

Part # HMXE8701

Skids 2 PCS

Part # HMXE8901

EVPL# 7

Skid Supports 2 PCS

Part # HMXE8902

EVPL # 9

Swashplate Stay 1 PC

Part # HMXE9002

EVPL # 14

Tail Motor Extension Wire 1 PC

Part # HMXE9554

EVPL # 15

Slide Block 1 PC

Part # HMXE9058

EVPL # 27

Tail Boom 1 PC

Part # HMXE9550

EVPL # 16

Tail Motor Mount 1 PC

Part # HMXE9564

EVPL # 21

Stabilizer Control Hub 1 PC

Part # HMXE8813

EVPL # 39

Training Gear 2 PCS

Part # HMXE9552

Tail Motor Screws 2 PCS

Part # HMXE9556

EVPL # 23

Swashplate Assembly 1 SET

Part # HMXE9001

EVPL # 29

Tail Motor 1 PC

Part # HMXE9553

EVPL # 20

Tail Rotor Blade 1 PC

Part # HMXE9563

EVPL # 22

Battery Rubber Bands 3 PCS

Part # HMXE8819

EVPL # 2

Tail Vertical Fin 1 PC

Part # HMXE9562

EVPL # 18

Servo 1 PC

Part # HMXM2004

EVPL # 11

Washer Set 4 PCS

Part # HMXE9900

EVPL # 43

Seesaw 1 PC

Part # HMXE8801

EVPL # 36

Heat Sinks 2 PCS

Part # HMXE8623

EVPL # 20

Servo Mounting Screws 6 PCS

Part # HMXE8814

EVPL #12

Tail Vertical Fin Bracket 3 PCS

with Screws

Part # HMXE9561

EVPL # 24

E-Board (Mixer, Gyro, Exc) 1 PC

Part # HMXM2003

EVPL # 51

21

Page 22

OPTIONAL PARTS

CF 3D Vertical Fin w/Hardware (1 Set)

Part # HMXE7450

CF Tail Boom (1 Set)

Part # HMXE7453

CF 3D Horiz Fin w/Hardware (1 Set)

Part # HMXE7451

CNC Swashplate Assembly (1 Set)

Part # HMXE7454

CF 3D Flybar Paddles (2 Pcs)

Part # HMXE7452

CNC Center Hub & Head Button (1 Set)

Part # HMXE7455

CNC Slide Block & Seesaw (1 Set)

Part # HMXE7456

CNC Flybar Carrier (1 Set)

Part # HMXE7457

CF Main Rotor Blades (2 Pcs)

Part # HMXE7469

22

CNC Bell-Hiller (1 Set)

Part # HMXE7459

Page 23

Great Planes 11.1V, 950 mAh Axe CP V3 LiPo Battery

Part # GPMP0401

ElectriFly PolyCharge™ LiPo Charger

Part # GPMM3010

ElectriFly Triton2™ Charger

Part # GPMM3153

ElectriFly Triton™ Jr Charger

Part # GPMM3152

DuraTrax® IntelliPeak™ ICE™ Charger

Part # DTXP4170

Heli-Max HM4000 Heading Lock Gyro

Part # HMXM1012

23

Page 24

Entire Contents © Copyright 2008

HMXE07xxMNL01

Loading...

Loading...