Page 1

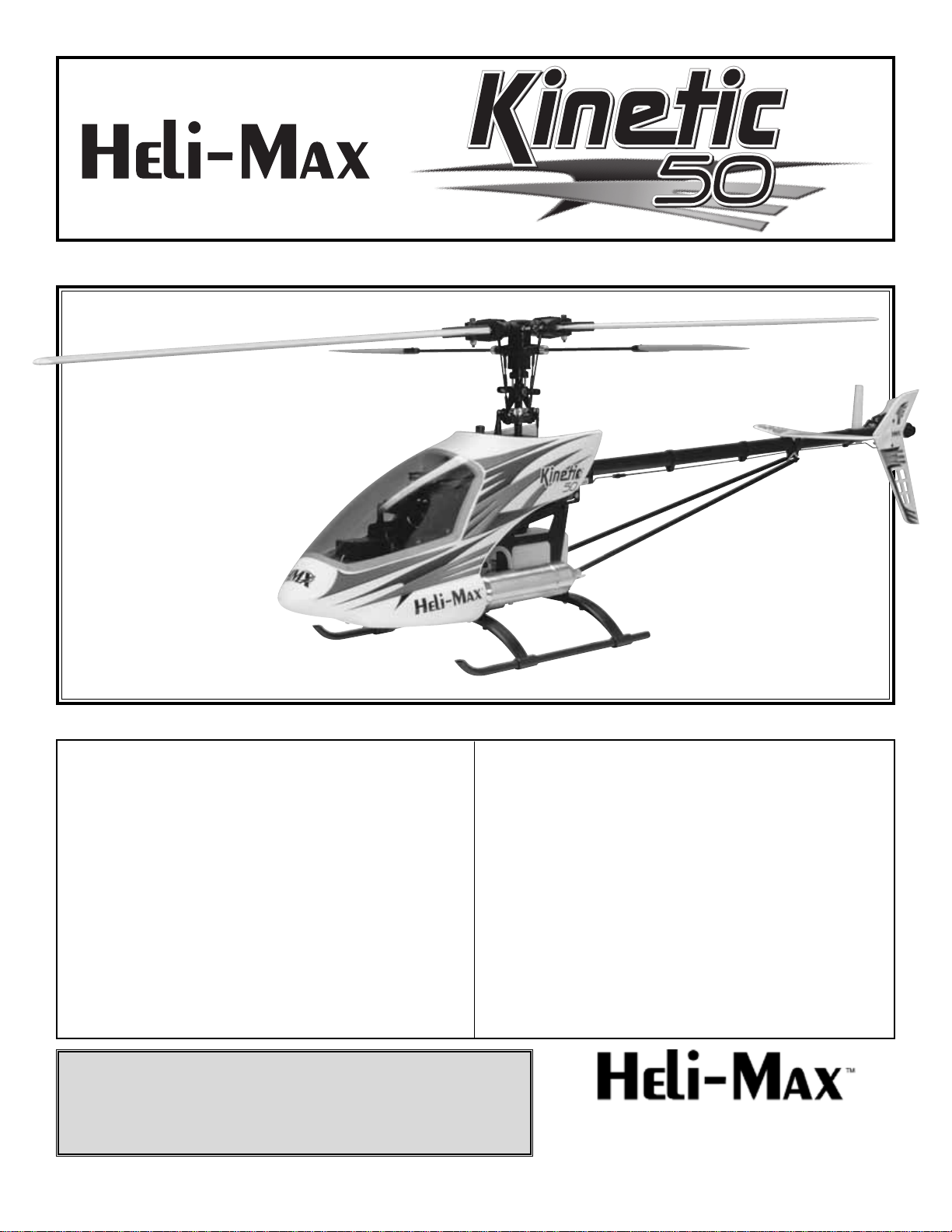

READ THROUGH THIS INSTRUCTION MANUAL

FIRST. IT CONTAINS IMPORTANT INSTRUCTIONS

AND WARNINGS CONCERNING THE ASSEMBLY

AND USE OF THIS MODEL.

HMXZ7013 for HMXE0250 V1.1Entire Contents © Copyright 2007

Champaign, Illinois

(217) 398-8970, Extension 6

E-mail: helihotline@hobbico.com

INSTRUCTION MANUAL

TM

Heli-Max™guarantees this kit to be free from defects in both

materials and workmanship at the date of purchase. This

warranty does not cover any component parts damaged by use

or modification.In no case shall Heli-Max’s liability exceed the

original cost of the purchased kit. Fur ther, Heli-Max reserves

the right to change or modify this warranty without notice.

In that Heli-Max has no control over the final assembly or material

used for final assembly, no liability shall be assumed nor accepted

for any damage resulting from the use by the user of the final

user-assembled product. By the act of using the user-assembled

product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated

with the use of this product, the buyer is advised to return

this kit immediately in new and unused condition to the place

of purchase.

To make a warranty claim, send the defective part or item to

Hobby Services at this address.

Hobby Services

3002 N. Apollo Dr., Suite 1

Champaign, IL 61822

USA

Include a letter stating your name, return shipping address, as

much contact information as possible (daytime telephone

number, f ax number, e-mail address), a detailed description of the

problem and a photocopy of the purchase receipt.Upon receipt of

the package the problem will be evaluated as quickly as possible.

WARRANTY

Rotor Span: 52.75 in [1340mm]

Weight: 7.5 lb [3402g]

Length: 47 in [1194mm]

Height: 15.25 in [387mm]

Engine: .46-.51 cu in [7.5-8cc] 2-Stroke

Gear Ratio: 9.1:1 (Main)

5:1 (Tail)

TM

Page 2

2

INTRODUCTION ..............................................................2

SAFETY PRECAUTIONS ................................................3

DECISIONS YOU MUST MAKE........................................4

ADDITIONAL ITEMS REQUIRED ....................................4

Required Hardware ..........................................................4

Field Equipment ................................................................4

Optional Supplies and Tools..............................................4

IMPORTANT BUILDING NOTES......................................5

KIT INSPECTION..............................................................5

KIT CONTENTS................................................................5

ASSEMBLY INSTRUCTIONS ..........................................6

Lower Frame and Tank......................................................6

Engine ..............................................................................6

Upper Frame and Servo Frame Installation ......................8

Main Rotor Head Assembly and Installation ....................9

Tail Boom and Gearbox Assembly..................................11

Tail Blades ......................................................................12

Horizontal and Ver tical Fins ............................................12

Tail Boom Suppor ts ........................................................13

Landing Gear ..................................................................14

Gyro Mount and Tail Rotor Servo Mount ........................14

Horizontal Fin Alignment ................................................15

EQUIPMENT INSTALLATION ........................................15

Servos and Power Switch................................................15

Battery, Receiver and Gyro ............................................16

Receiver Antenna............................................................17

Receiver Channel Assignment Table ..............................17

Connecting the Servos to the Receiver ..........................17

RADIO SETUP (FUTABA: 6EXH,7CH,9CH)..................18

Setup Quick Reference ..................................................18

Transmitter Preparation ..................................................18

Reset Model Memory......................................................18

Set Modulation Type........................................................19

Model Name....................................................................19

Exponential......................................................................19

Servo Reversing..............................................................20

End Point Adjustments....................................................21

Sub-Trim ..........................................................................21

Fail Safe ..........................................................................21

Gyro Function..................................................................21

Throttle Cut......................................................................22

Hover and Throttle Trims ................................................22

Hi-Lo Pitch Trims ............................................................22

Throttle Curve..................................................................22

Pitch Curve......................................................................23

Intermediate and Basic Aerobatic Curves ......................23

Advanced 3D and Aerobatic Curves ..............................23

SERVO SETUP AND LINKAGES ..................................24

Forward/Aft Cyclic Setup ................................................24

Left/Right Cyclic Setup....................................................24

Collective Pitch Setup......................................................25

Throttle Setup..................................................................26

Tail Rotor Ser vo ..............................................................26

Gyro Setup ......................................................................27

HEAD AND LINKAGES..................................................27

Install Main Rotor Head Linkages ..................................27

Main Blades ....................................................................27

Blade Balancing ..............................................................28

Pitch Curves....................................................................29

FINAL ASSEMBLY ........................................................30

Fuel Lines........................................................................30

Muffler Installation ..........................................................30

Body ................................................................................30

Decals..............................................................................31

PREPARE FOR FLIGHT ................................................32

Check the Control Directions ..........................................32

Range Check ..................................................................34

Balance the Model (C.G.)................................................34

PREFLIGHT ....................................................................34

Identify Your Model ..........................................................34

Charge the Batteries ......................................................34

AMA SAFETY CODE (Excerpts) ..................................34

FLYING............................................................................35

Training Gear ..................................................................36

Flying Conditions ............................................................36

Before Each Flight ..........................................................36

Starting the Model ..........................................................36

Adjust Blade Tracking......................................................36

Takeoff ............................................................................37

Hovering..........................................................................37

Landing............................................................................37

Basic Maneuvers ............................................................37

Aerobatics........................................................................37

PARTS LIST....................................................................38

Ordering Parts ................................................................38

Exploded Views ..............................................................39

Thank you for purchasing the Heli-Max™Kinetic™.50. We

are certain you will get many hours of enjoyment out of this

model.If you should ha v e an y questions or concerns please

feel free to contact us at:

helihotline@hobbico.com

For the latest technical updates or manual corrections to the

Kinetic .50 visit the Heli-Max web site at:

www.helimax-rc.com

Open the “Helicopters” link, and then select the Kinetic .50. If

there is new technical information or changes to this model a

“tech notice”bo x will appear in the upper left corner of the page.

INTRODUCTION

TABLE OF CONTENTS

Page 3

3

For any helicopter to perform to its full potential, it must be

equipped with all the right gear (servos, batteries, receiver , etc).

While other brands of equipment can be used, the equipment

we recommend has the advantage of being extensively tested

and proven effective. If you assemble this model according to

this manual and use the recommended equipment, you should

get top performance from your Kinetic .50.

We urge you to join the AMA (Academy of Model Aeronautics)

and a local R/C club.The AMA is the governing body of model

aviation and membership is required to fly at AMA clubs.

Though joining the AMA provides many benefits, one of the

primary reasons to join is liability protection. Coverage is not

limited to flying at contests or on the club field. It even applies

to flying at public demonstrations and air shows. Failure to

comply with the Safety Code (excerpts printed in the back of

the manual) may endanger insurance coverage. Additionally,

training programs and instructors are available at AMA club

sites to help you get started the right way .There are over 2,500

AMA chartered clubs across the countr y.Contact the AMA at

the address or toll-free phone number below.

Failure to follow these safety precautions may result in

severe injury to yourself and others.

• Keep your face and body as well as all spectators away

from the plane of rotation of the rotors.

• Keep these items away from the rotors: loose clothing

(includes ties, scarfs and shirt sleeves), long hair, and

loose objects (such as pencils, screwdrivers) which can f all

from shirt or jacket pockets.

• The spinning blades of a model helicopter can cause

serious injury. Main rotor blades are consumable items,

please inspect blades before flight.

• When choosing a flying site for your Kinetic .50, stay clear

of buildings, trees and power lines.

• AVOID flying in or near crowded areas. DO NOT fly close

to other people, children or pets.

• Maintain a safe pilot-to-helicopter distance while flying.

• Your Kinetic .50 should not be considered a toy, but rather

a sophisticated, working model that functions very much

like a full-size helicopter. Because of its performance

capabilities, the Kinetic .50, if not assembled and operated

correctly, could possibly cause serious injury to you or

spectators and damage to property.

• You must assemble the model according to the

instructions. Do not alter or modify the model, as doing

so may result in an unsafe or unflyable model. In a few

cases the instructions may differ slightly from the photos.

In those instances, the written instructions should be

considered as correct.

• You must take time to build properly, true and strong.

• You must use an R/C radio system that is in first-class

condition and a correctly sized engine and components

throughout the building process.

• You must correctly install all R/C and other components so

that the model operates correctly on the ground and in the air .

• You must check the operation of the model before every

flight to insure that all equipment is operating and that the

model has remained structurally sound. Be sure to check

linkages or other connectors often and replace them if they

show any signs of wear or fatigue.

• If you are not an experienced pilot or have not flown this

type of model before, we recommend that you get the

assistance of an experienced pilot in your R/C club for y our

first flights. If you’re not a member of a club, your local

hobby shop has information about clubs in your area

whose membership includes experienced pilots.

SAFETY PRECAUTIONS

Two of the most important things you can do to

preserve the radio controlled aircraft hobby are to

avoid flying near full-scale aircraft and avoid flying

near or over groups of people.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

Tele: (800) 435-9262

Fax (765) 741-0057

Or via the Internet at:

http://www.modelaircraft.org

AMA

CAUTION: Be aware that the Kinetic .50 is

operated on the same frequency band as most R/C

models. If flying your helicopter within five miles of an

R/C site, there is a real possibility that you could be

operating your model on the same frequency (channel)

as another R/C pilot. If this happens, a crash will

result—with the person flying the more expensive

model suffering the greater loss (and having greater

potential for property damage or injury). The best thing

to do is to join an R/C club and fly at the site where

frequency control measures will be in effect.If you insist

on flying elsewhere, always be aware of your proximity

to R/C flying sites.

Page 4

4

Remember: Take your time and follow the instructions

to build a safe and enjoyable model.

This is a partial list of items required to finish the Kinetic .50

that may require planning or decision making before starting

to build. Order numbers are provided in parentheses.

The Kinetic .50 requires five servos.The cyclics, throttle and

collective require a minimum of 42 oz/in for basic aerobatics.

A Hi-Speed and Hi-Torque tail servo such as the (FUTM0224)

Futaba®DS9254 is highly recommended to obtain the best

performance from the gyro.

A 6-channel transmitter is required to fly the Kinetic .50.

Modern computer radios make adjustments considerably

easier and are highly recommended. Plus the features on

the radios today make 3D maneuvers possible.

Transmitter/Receiver Recommendations:

• Budget: Futaba 6EXH FM w/4 S3151 Servo (FUTK58**)

• Mid-Range: Futaba 7CHF FM w/4 S3151 Servos (FUTJ73**)

• High-End: Futaba 9CHPS PCM Synthesized (FUTK9205)

Recommended Cyclic,Throttle and Collective Servos:

• Budget: Futaba S3001 (FUTM0029)

• Mid-Range: Futaba Digital S3151 (FUTM0310)

• High-End: Futaba Digital S9252 (FUTM0222)

Recommended Gyro and Tail Servo:

• Budget: Futaba GY240 (FUTM0809) and

S3151 Servo (FUTM0310)

• Mid-Range: Futaba GY401 w/S9254 Servo (FUTM0808)

• High-End: Futaba GY611 w/S9256 Servo (FUTM0825)

Recommended Receiver Batteries:

A 4-cell, 4.8 volt (2000mAh minimum) NIMH/NICAD battery

pack is recommended for the Kinetic .50

• Hydrimax™4.8volt 2000mah Flat Battery (HCAM6321)

• Hydrimax 4.8volt 3600mah Flat Battery (HCAM6333)

• Hydrimax 4.8volt 4200mah Flat Battery (HCAM6335)

REQUIRED HARDWARE AND ACCESSORIES

This is the list of hardware and accessories required to finish

the Kinetic .50. Order numbers are provided in parentheses.

❏ O.S.

®

50 SX-H Ringed Hyper (OSMG1951)

❏ Tor pedo Muffler .46-.50 (CEHG3033)

❏ Great Planes

®

Pro Thread Locker (GPMR6060)

❏ Great Planes 1" x 3' Double Sided Tape (GPMQ4442)

❏ Great Planes 3' Silicone Fuel Tubing (GPMR4131)

❏ Great Planes Fuel Filter (GPMQ4150)

❏ O.S.Remote Glow Plug Adapter (OSMG2401)

❏ Heli-Max .30 – .50 Size Blade Holder (GPMQ4150)

FIELD EQUIPMENT

❏ Heli-Max One-Way Start Shaft (HMXP2050)

❏ Hobbico

®

Glow Plug Wrench (HCAP2550)

❏ Hobbico Ultra-Tote

™

Field Box Complete Combo

(HCAP5105) (Includes the following items):

• Filling Station Can Fittings Set (GPMP4155)

• 12V Charger Torqmaster™Battery (HCAP0200)

• Deluxe Power Panel II (HCAP0302)

• Torqmaster 12V 7A Batter y (HCAP0800)

• 5' Recoil Fuel Tubing (HCAP2200)

• Panel-Ready Locking Glow Plug Clip (HCAP2502)

• Panel-Ready Top Fueler™6/12 V olt (HCAP3107)

• Torqmaster 90 12V Star ter (HCAP3200)

• Ultra-Tote Field Box (HCAP5020)

OPTIONAL SUPPLIES AND TOOLS

❏ O.S.Crankshaft Clamp .32-.46 (OSMR1004)

❏ DuraTrax

®

Phillips Screwdriver (DTXR0181)

❏ DuraTrax Slotted Screwdriver (DTXR0177)

❏ Hobbico Needle Nose Pliers (HCAR0625)

❏ Hobbico Curved Scissors (HCAR0667)

❏ Heli-Max Ball Link Pliers (HMXR4858)

❏ Heli-Max Pitch Gauge (HMXR4850)

❏ Heli-Max Blade Balancer (HMXR4855)

❏ DuraTrax 5.5mm Nut Driver (DTXR0212)

ADDITIONAL ITEMS REQUIRED

DECISIONS YOU MUST MAKE

We, as the manufacturer, provide you with a

top quality, thoroughly tested ARF and instructions,

but ultimately the quality and flyability of your finished

model depends on how you build it; therefore, we

cannot in any way guar antee the performance of your

completed model, and no representations are

expressed or implied as to the performance or safety

of your completed model.

Page 5

5

• There are two types of threaded fasteners used in this kit:

Self-T apping Screwsare designated by a diameter and

a length and are intended to thread into plastic.

This is a 3mm x 10mm Self-Tapping

Machine screws are designated by a diameter and

threads per mm/inch. This type of screw is referred to as

Socket Head Cap Screw (SHCS) through out this man ual.

This is a 3mm x 10mm SHCS

• Thread Locker: Model engines generate a lot of vibration

and cause screws to work loose.Thread Locker (GPMR6060)

should be used on all machine screws when they are

threaded into a pre-tapped hole in metal. Generally blue

thread locker is removable and should be used in all cases.

Please keep in mind only a small amount of thread locker is

needed to retain the bolt. Please check preassembled

components for thread locking compound.

• Ball Links: If you look closely at the

plastic ball links used on this helicopter

you will notice the holes on each side of

the link are different sizes.The side with

the smaller hole also has writing on it as shown above.

When you snap the link on, make sure the writing is to

the outside. If you accidentally snap the small side on

first, the ball link may crack. If the ball link does not pivot

freely once snapped on, you can use a small pair of pliers

to lightly squeeze the link and help loosen it up.

• When you see the term

test fit

in the instructions, it means

that you should first position the part on the assembly to

verify it fits properly. Once you are sure, then proceed with

the instructions or assembly.

• Photos and sketches are placed before the step they

refer to .Frequently you can study photos in following steps

to get another view of the same parts.

Before starting to build, take an inventory of the model to

make sure it is complete, and inspect the parts to make sure

they are of acceptable quality. If any parts are missing or are

not of acceptable quality, or if you need assistance with

assembly, contact Product Support.When reporting defective

or missing parts, use the part names exactly as they are

written in the Kit Contents list.

Heli-Max Product Support:

3002 N. Apollo Drive, Suite 1,

Champaign, IL 61822

Telephone: (217) 398-8970, ext.6,

Fax:(217) 398-7721

E-mail: helihotline@hobbico.com

Bag 1: Head Parts and Paddles

Bag 2: Main Mechanics

Bag 3: Clutch System and Fan

Bag 4: Links, Gyro and Tail Servo Mounts

Bag 5: Fin Set

Bag 6: Landing Gear Set

Bag 7: Main Blades

Bag 8:Tail Boom

Bag 9: Servo Tray Set

Bag 10: Lower Frames, Fuel Tank, Fan Shroud

Bag 11: Canopy

KIT CONTENTS

KIT INSPECTIONIMPORTANT BUILDING NOTES

H

e

l

iM

a

x

Page 6

6

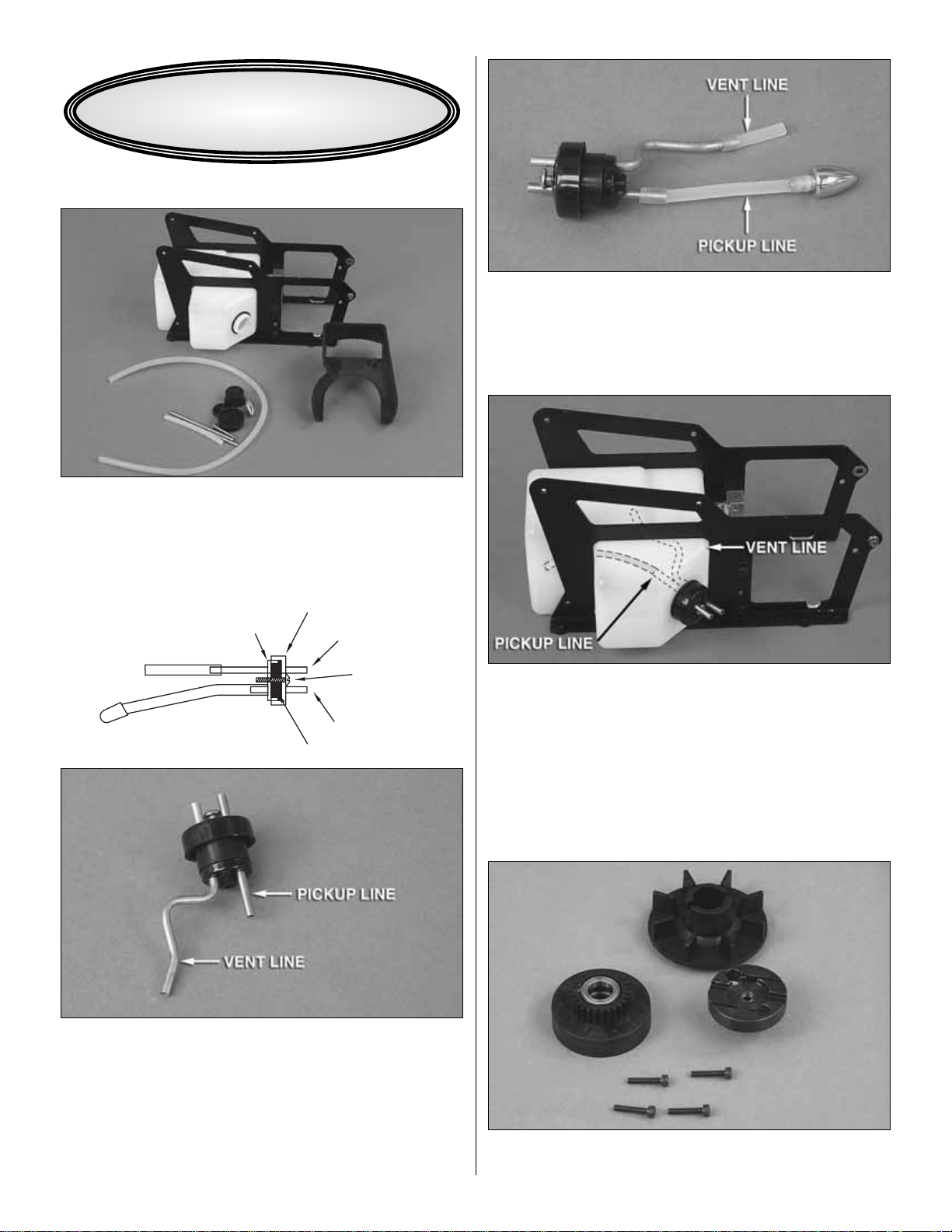

LOWER FRAME AND TANK

Bag 10 Contents: Main Frame Assembly (Engine Mount

and Fuel Tank Installed), Fuel Stopper, Brass Tubing,

Silicone Fuel Line, and Stopper Screw, Lower Fan Shroud.

❏ 1. Slide the short brass tubing through the front cap. Slide

the rubber fuel tank stopper over the brass tubing from the

back side.Install the rear cap. Insert the long pre-bent piece of

brass tubing through the rear cap and through the rubber

stopper.Leave 1/2" [12.7mm] of brass tubing protruding from

the front of the cap.Install the 4mm self-tapping screw through

the front cap and into the rear cap (Start the screw into the

cap.Do not tighten until it has been installed into the fuel tank).

❏ 2. Cut the clunk line to a length of 60mm and slide it onto

the short brass tubing.Slide the fuel tubing ov er the clunk.Cut

a piece of the larger silicone tubing to 30mm with an angled

cut as shown above. Install on the vent line. Hint: Use a

marker to identify the pickup line later.

❏ 3. Rotate the vent line against the pickup line to make it

easier to install. Slide the fuel line assembly into the fuel

tank and align the vent line with the top of the tank (if you

find it difficult to see inside the tank, hold it up to a bright

light).Tighten the 4mm fuel tank stopper screw until you feel

it begin to compress. Do not overtighten this as you may

strip the rear cap.

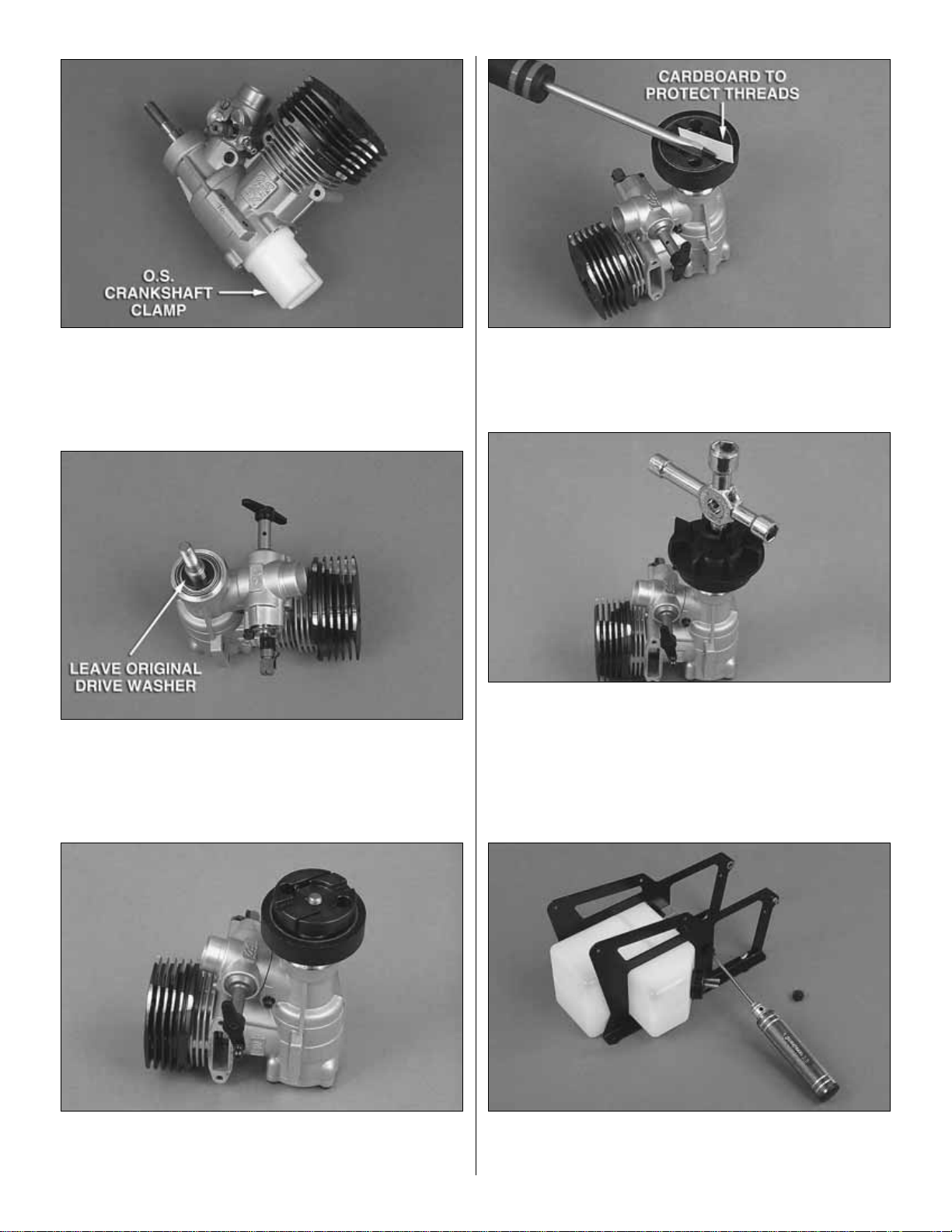

ENGINE

Bag 3 Contents: Clutch Bell, Fan, Clutch, Engine Mount

From Bag 10: Screws (3x16mm Socket Head Cap Screw)

AS VIEWED FROM THE TOP

REAR CAP

FRONT CAP

VENT

4mm SCREW

FUEL PICKUP LINE

RUBBER STOPPER

ASSEMBLY INSTRUCTIONS

Page 7

7

Note: You will need to lock the crankshaft while tightening

the clutch and nut.We recommend using a O.S.Crankshaft

Clamp .32-.46 (OSMR1004) as shown above.

❏ 1.Remove the n ut from the end of the engine’s crankshaft

but leave the large flat washer resting against the front ball

bearing. The large washer (10x16mm) included in the kit is

only used if your engine did not include one.

❏ 2. Slide the clutch bell onto the stepped end of the clutch

and test fit the assembly on the engine. Once you verify

everything threads on properly, remove the clutch and bell.

❏ 3. Apply thread lock to the crankshaft of the engine and

thread the clutch onto the engine. Use a thick piece of

cardboard to protect the crankshaft and tighten the clutch

using a screwdriver as shown in the picture above.

❏ 4. Install the fan on the engine. Make sure the key on the

bottom of the fan lines up with the slots in the clutch. Place

the 6.5x13mm washer on the crankshaft, apply some thread

lock to the crankshaft threads and install the original

crankshaft nut.Using a crankshaft clamp and a 7/16" [11mm]

wrench, tighten the nut down against the fan. Re-install the

engine’s backplate.

❏ 5.Using a 2.5mm hex driver remove the two engine mount

bolts from the right side of the frame. Remove the right side

frame and fuel tank for now.

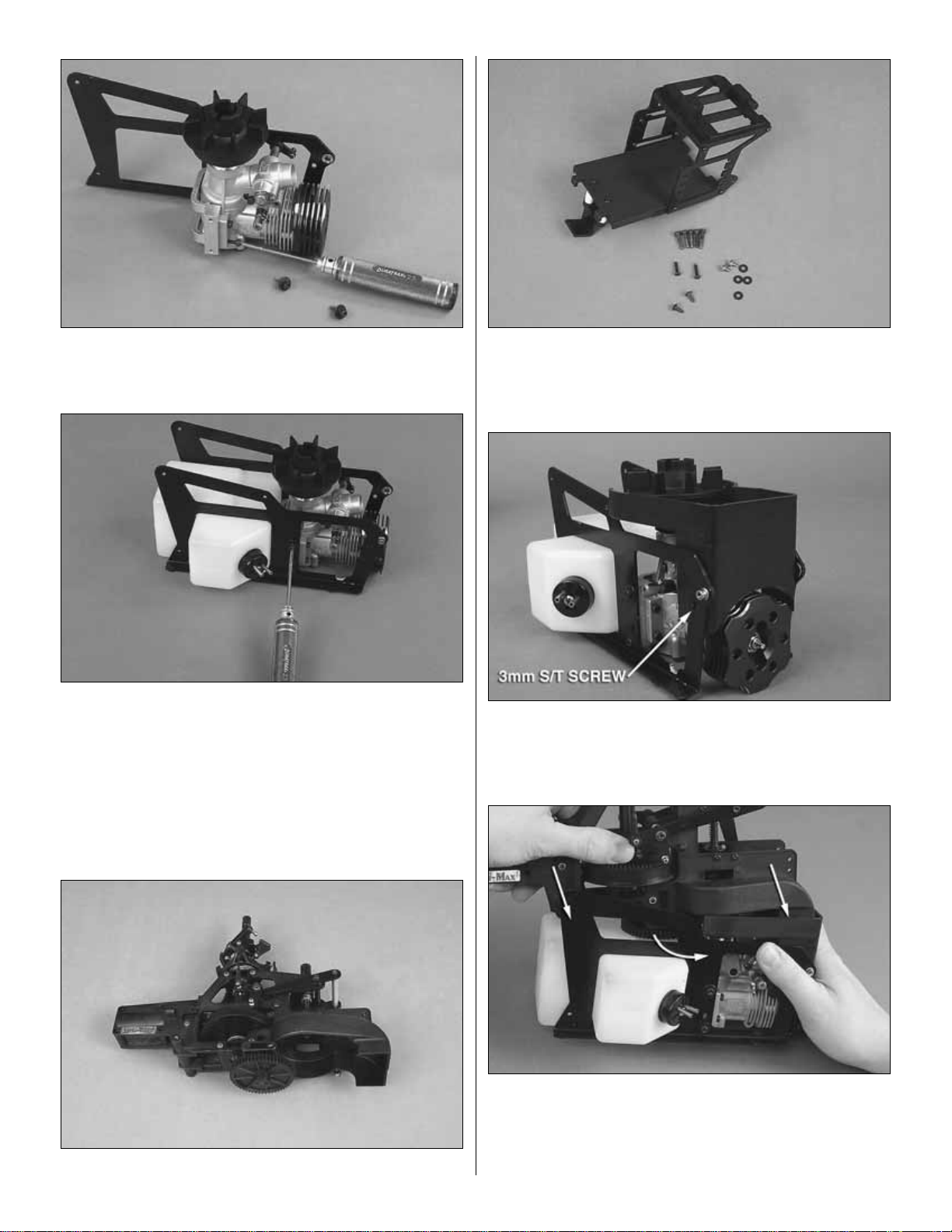

Page 8

❏ 6. Install the engine onto the mount using thread locker

and the four 3x16mm screws provided.

❏ 7.Install the right side frame using the 3x12mm screws and

large washers (use thread lock). Before tightening the bolts

place the frames on a flat surface to ensure they are parallel.

Tighten the bolts. Check the left side engine mount bolts

(factory-assembled) for thread locker and apply if necessary.

UPPER FRAME AND SERVO FRAME INSTALLATION

Bag 2 Contents: Assembled Main Mechanics

Bag 9 Contents: Servo Tray Set, 3x12mm Cap Screw (4),

3x8mm Self-Tapping Screw (2), 3x8mm Mashine Screw (2),

3x8x1mm Flat Washer (4), 3x12mm Self-Tapping Screw

❏ 1. Slide the lower fan shroud over the engine as shown in

the picture above and install the 3mm self-tapping screw as

shown. Repeat on the opposite side.

❏ 2. Slide the rear portion of the upper frame into the lower

frame. Align the upper and lower fan shroud and slide the

upper frame forward while pressing downward. The clutch

bell and pinion must clear the main gear before the upper

frame will slide down into its proper location.

8

Page 9

9

❏ 3. Apply thread locker to one 3x12mm socket head cap

screw. Install the screw and washer as shown above.

Repeat on the opposite side of the frame.

❏ 4. Apply thread locker to one 3x14mm socket head cap

screw .Install the screw and washer as shown above.Repeat

on the opposite side of the frame.

❏ 5. Slide the servo frame in-between the lower frames and

onto the upper frames. Install a 3x12mm self-tapping screw

into the top of the frame as shown above. Repeat for the

opposite side.

❏ 6. Install the silver 3x6mm silver Phillips screw into the

lower part of the servo frame as shown above. Remove the

two bellcrank to swash linkages and verify they are 51mm

long. Go ahead and re-install the linkages now.

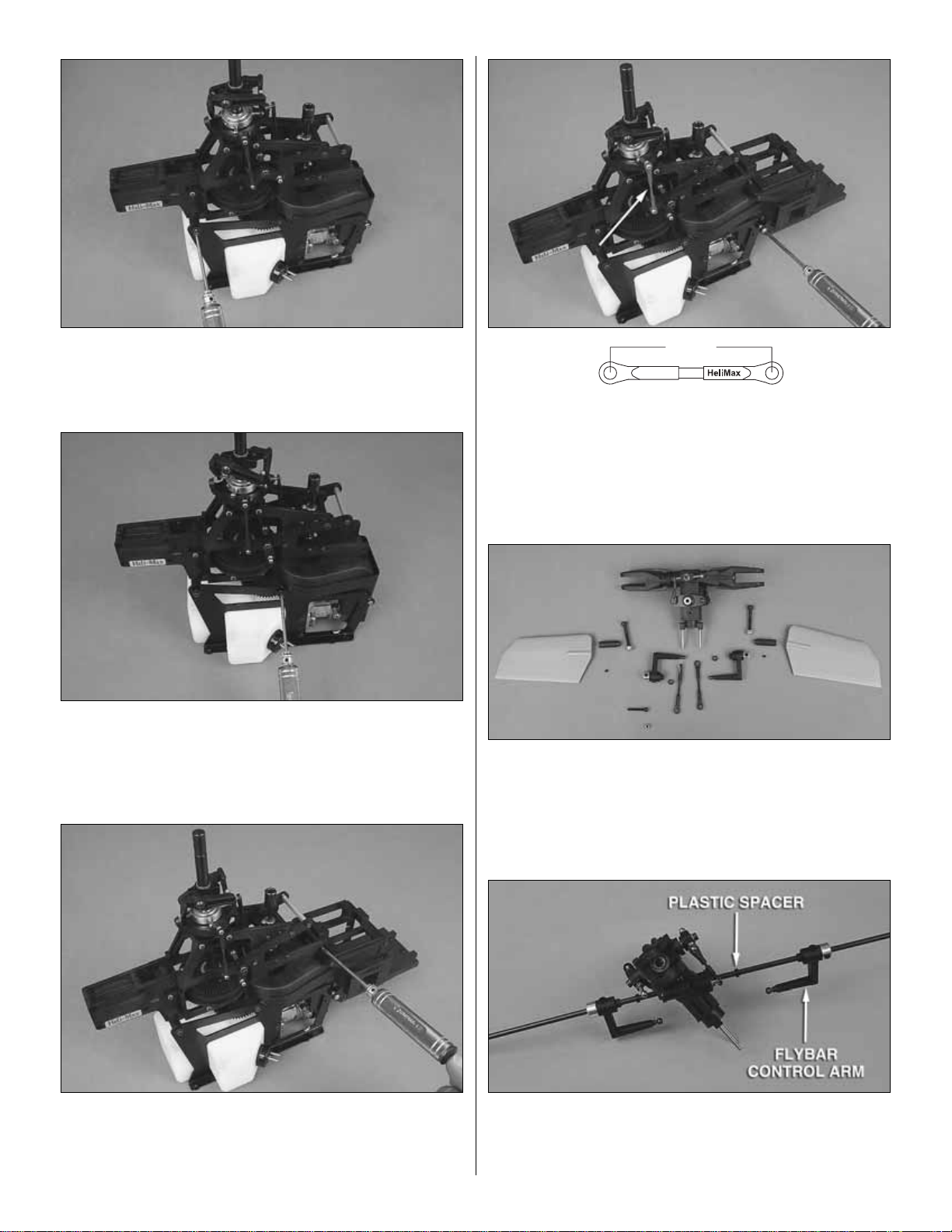

MAIN ROTOR HEAD ASSEMBLY AND INSTALLATION

Bag 1 Contents: Flybar Control Arm [4x6x2.5mm Plastic

Spacer (2), Washout-Flybar Pushrod (2), Flybar Control

Arm (2), 5x4mm Set Screw], Flybar Paddles [Flybar Weights

(2), 3x3mm Set Screws (2), Flybar Paddles .50 Sized (2)],

Main Head Assembly, 4x30mm Cap Screw (2), 4mm

Locknut (2), 3x20mm Cap Screw, 3mm Locknut

❏ 1. Slide the 4mm flybar (found in tail boom bag 8) through

the flybar carrier bearings and slide a plastic bushing on from

each side.Next slide the control arms onto the flybar as shown

in the picture above.(The set screws will face upwards.)

51mm

(Sketch not to scale)

Page 10

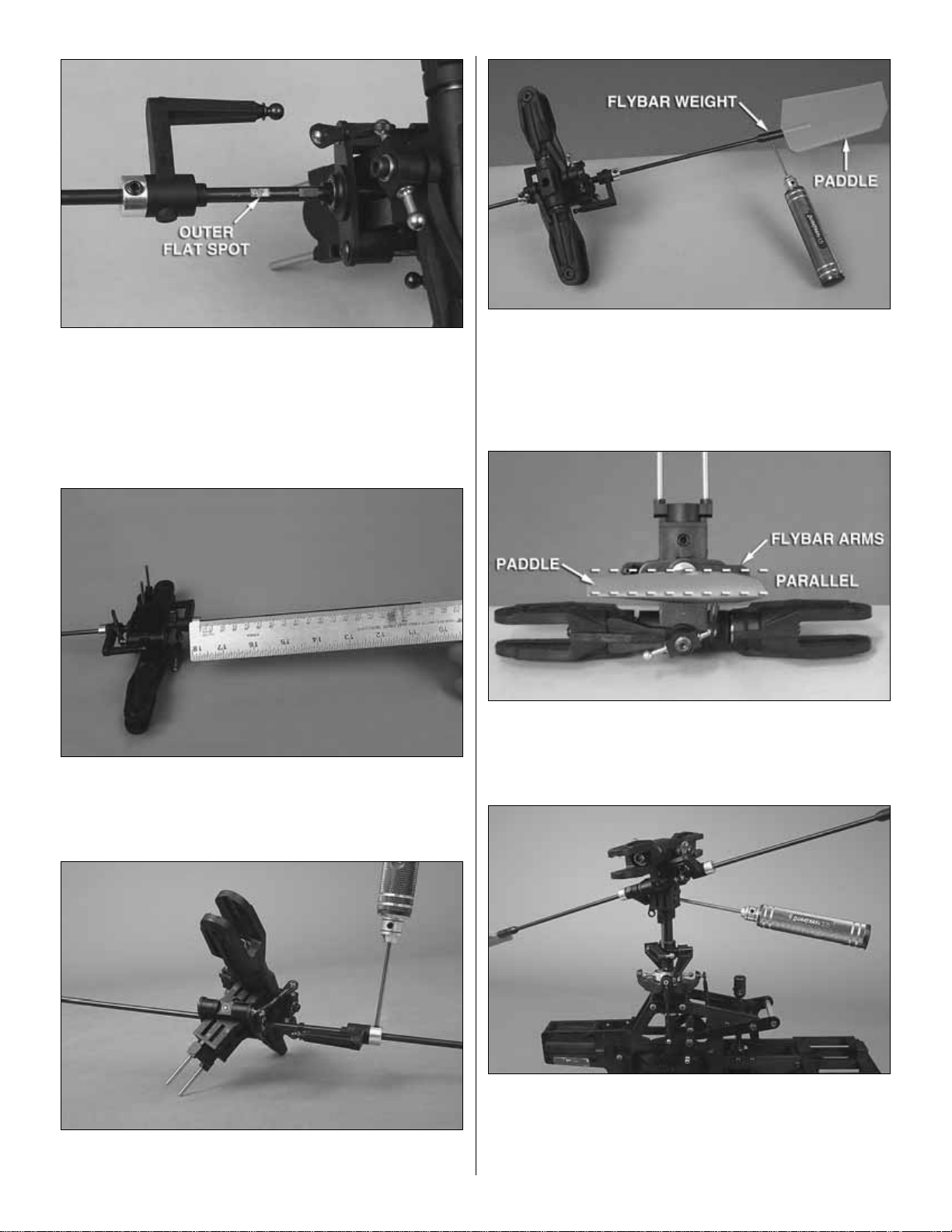

❏ 2.Remo v e the set screws from the flybar arms and align the

hole with the flat spot on the flybar. Apply a small amount of

thread locker to each of the set screws and re-install.Only lightly

tighten them at this time as the flybar needs to be centered.

❏ 3. Using a ruler, center the flybar as shown above. The

measurement should be approximately 181mm for each side .

❏ 4. Once the flybar is centered, tighten the flybar arm

set screws.

❏ 5. Install the two 3x3mm set screws into the flybar

weights. Slide the weights onto the flybar with the beveled

end facing inward. Thread the paddles onto the flybar at

least 1" [25.4mm]. Measure from the outside of the flybar

arm to the beginning of the paddle. Make sure both paddles

are the same distance out and facing forward as shown.

❏ 6. Align the paddle with the flybar control arms as shown

above. The paddles and arms must be parallel. Slide the

flybar weights all the way out against the paddles and tighten

the set screws.

❏ 7. Slide the head onto the main shaft and align the bolt hole

in the head block with the hole in the main shaft.To help align

the two holes, insert a 2.0mm hex driver into the hole.Insert the

3x16mm SHCS through the head block and main shaft.Place a

3mm nylon lock nut on the opposite side and tighten the bolt.

10

Page 11

11

❏ 8.Chec k the two linkages and v erify they are 42mm.Install

the two linkages onto the flybar control arm and the washout

arm as shown above.Temporarily install the 4mm main blade

bolts into the blade grips.Do not tighten at this time.

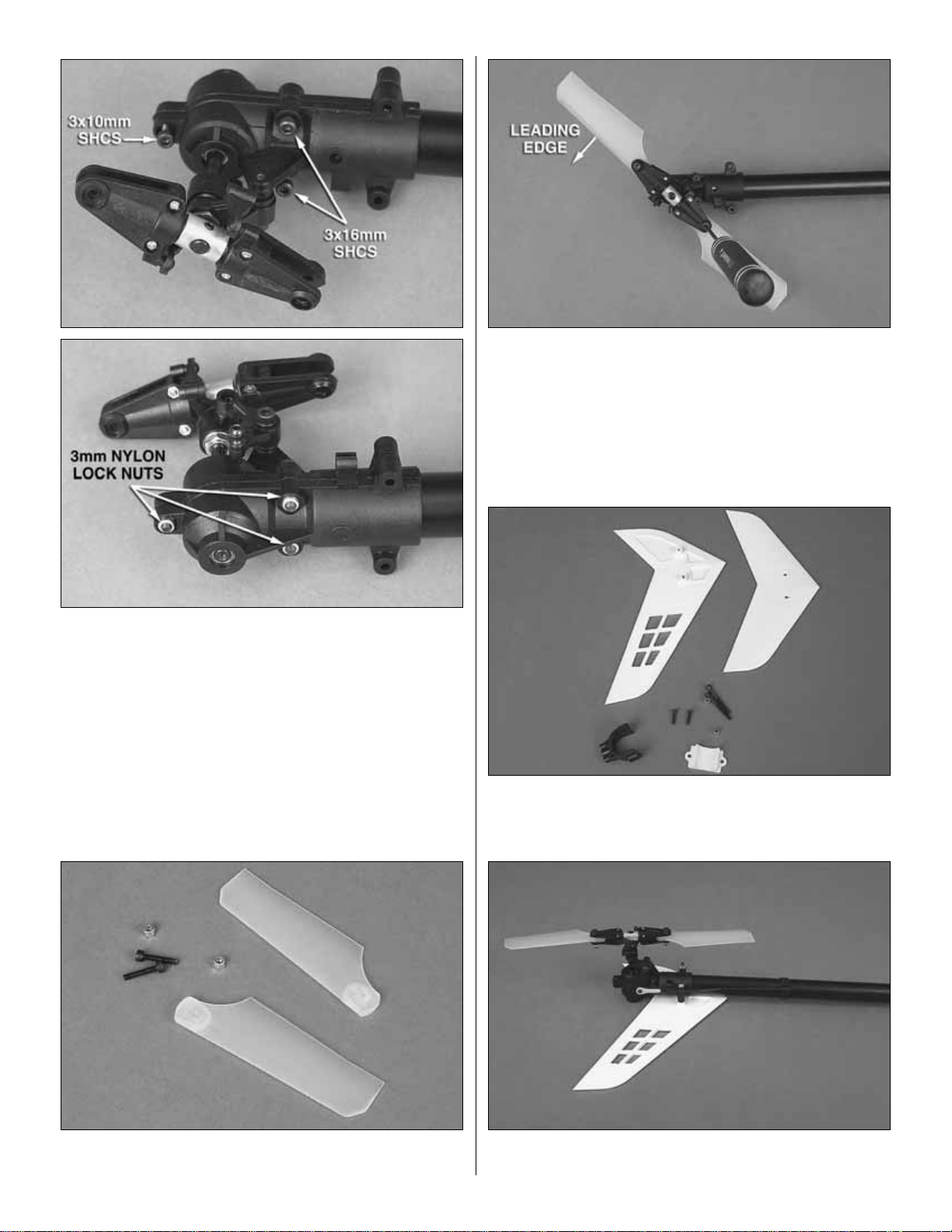

TAIL BOOM AND GEARBOX ASSEMBLY

Bag 8 Contents: Tail Boom, Tail Boom Supports, Tail Rotor

Pushrod, Antenna Tube

Bag 8-1 Contents: Torque Tube

Bag 8-2 Contents: 3x16mm SHCS, 3x10mm SHCS, 3mm

Nylon Lock Nuts

❏ 1.Insert the torque tube into the tail boom. If the O-rings

do not slide easily, apply a small amount of dishwashing

soap to the O-rings.

❏ 2. Remove the left side of the tail rotor gearbox and insert

the right side into the boom as shown above. Please notice

there are two holes on one end of the tail boom.This is the end

where the tail gearbox attaches.Make sure the alignment tab

molded in the tail rotor gearbox halves line up with the hole in

the tail boom. Install the left side of the tail rotor gearbox.

42mm

(Sketch not to scale)

Page 12

❏ 3. Install three 3mm nylon lock nuts on the back side of

the gearbox where you just inserted the 3mm screws.

Tighten the bolts.

TAIL BLADES

Bag 5-1 Contents:

Tail Rotor Blades, 3x16mm Cap Screw

(2), M3 Locknut (2), Fiber Filled Tail Blades 85mm (2)

❏ Install the plastic tail blades as shown above using a

3x16mm SHCS and 3mm Nylon lock nuts.Tighten until the

blades will support their own weight. Both tail blades need

to be tightened equally.

HORIZONTAL AND VERTICAL FINS

Bag 5 Contents: Horizontal Tail Fin, Vertical Fin, Horizontal

Fin Mount, Horizontal Mounting Plate, 3x30mm Cap Screw,

3x11mm Self-Tapping Screw, 3mm Locknut

❏ 1. Using two 3x30mm screws and 3mm nylon lock nuts,

attach the vertical fin to the tail rotor gearbox as shown abov e.

12

Page 13

13

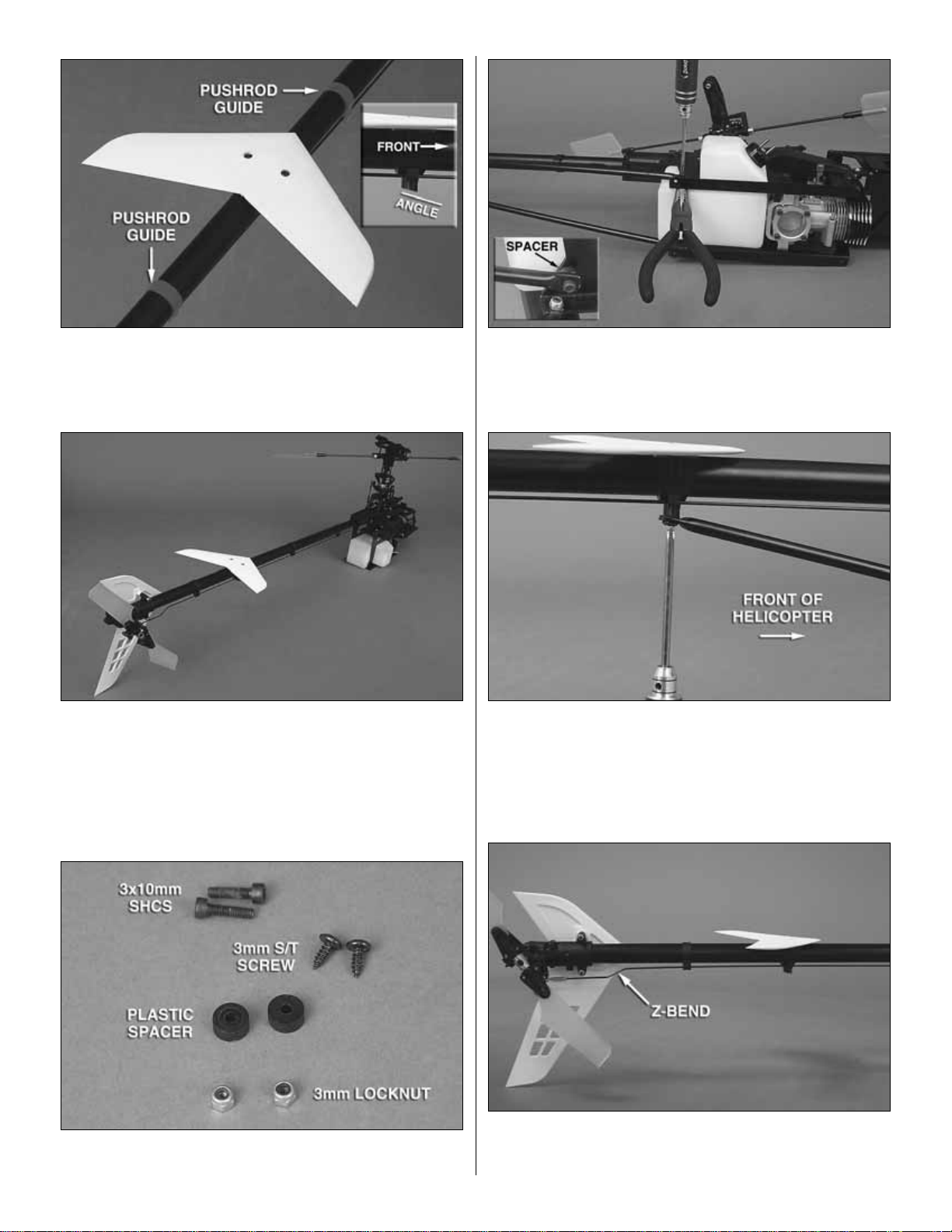

❏ 2. Install the horizontal fin clamp.Using two 3x16mm self-

tapping screws, attach the horizontal fin to the clamp .Do not

completely tighten bolts at this time as you will need to adjust

the position in a later step.

❏ 3.Slide the tail boom into the main frame as shown.It will be

necessary to turn the main rotor head while pushing forward on

the boom to help align the tail drive system.The frame screws

used to clamp the boom are installed in a later step.

TAIL BOOM SUPPORTS

Bag 8-3 Contents: 3x10mm SHCS, 3mm Self-Tapping

Screws, Plastic Spacers, 3mm Nylon Lock Nuts

❏ 1.Install the boom supports using two 3x10mm SHCS and

two 3mm nylon lock nuts .You will need a pair of small needle

nose pliers for this step.

❏ 2. Install the two 3x8mm self-tapping screws.Use a drop

of CA on the screw to prevent it from coming loose. Please

notice that the angle molded on the bottom of the fin clamp

angles down and toward the front of the helicopter.

❏ 3. Slide the tail rotor pushrod through the guides and

horizontal fin clamp.The Z-bend lines up vertically as shown in

the picture.Snap the plastic ball link onto the tail rotor bellcrank.

Page 14

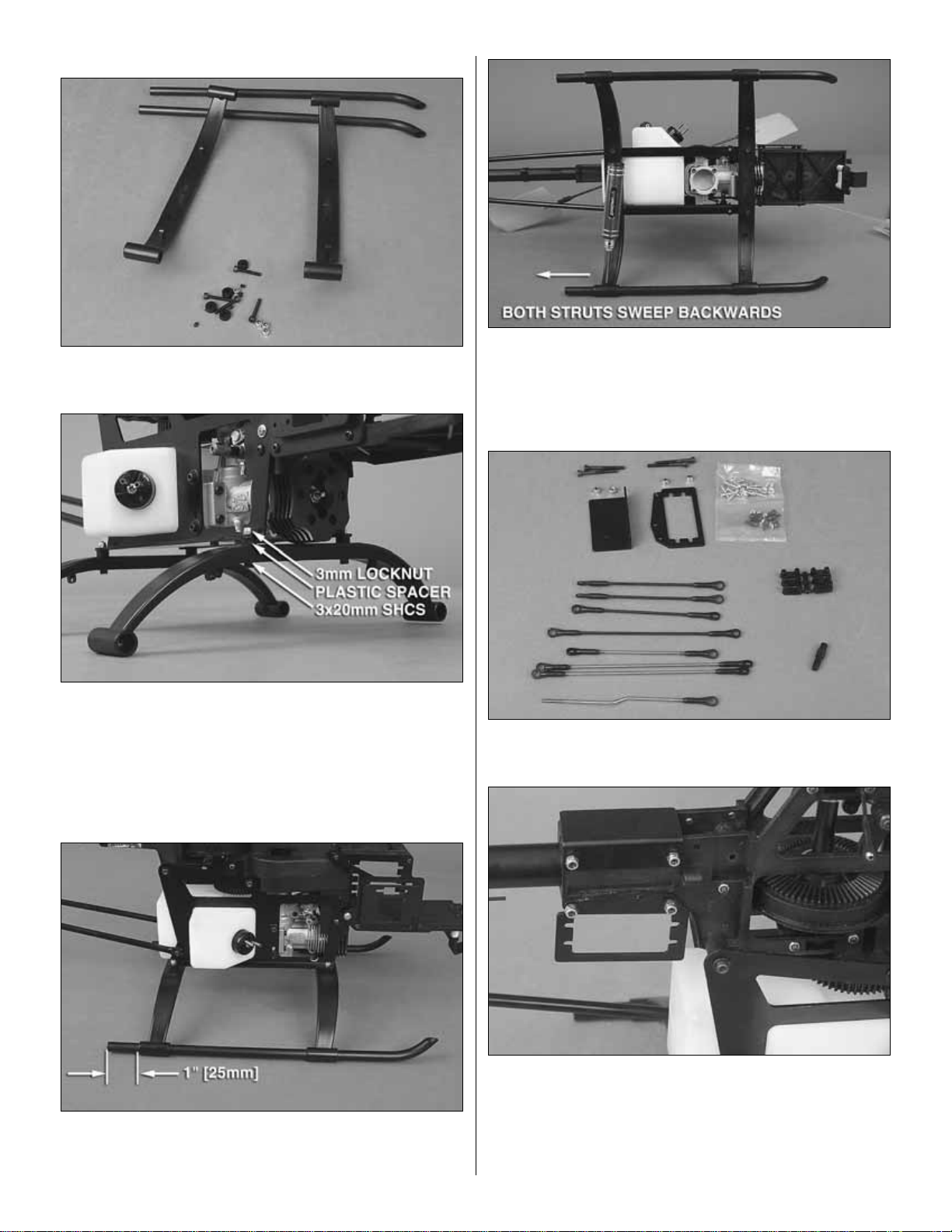

LANDING GEAR

Bag 6 Contents: 3x20mm SHCS (4), Plastic Spacers,

3mm Nylon Lock Nut (4), 3x4mm Set Screws (4)

❏ 1. Inser t a 3x20mm SHCS through the underside of the

landing gear strut. Slide a plastic spacer on the top and

insert the screw into the front frame hole. From the top,

install a 3mm nylon lock nut and tighten the bolt.Repeat for

the other side and the rear strut. If the front skid does not

clear the cylinder head on your engine, then simply mount

the front skid in the aft hole.

❏ 2. Slide the landing gear skids through the struts from

the front. Leave approximately 1" [25mm] protruding from

the back.

❏ 3. Install the four 3x4mm set screws into the inside of the

struts.These are used to lock the struts to the skids. Please

be careful not to overtighten.

GYRO MOUNT AND TAIL ROTOR SERVO MOUNT

Bag 4 Contents: Tail Rotor Servo Mount, Linkage Rods,

Tail Rotor Pushrod Coupler, Servo Retainers

❏ 1. Install the gyro and servo mount using four 3x30mm

SHCS and four 3mm nylon lock nuts as shown above.Push

the boom all the way f orward into the frame while turning the

rotor head before tightening the bolts down completely.

Please make sure the boom is far enough forward to

engage the tail drive.

14

Page 15

15

❏ 2. Thread the plastic tail rotor pushrod coupler onto the

short pushrod at least 1/4" [6.4mm]. If you find the coupler

difficult to thread on you can use a hobby knife to chamfer

the ball link.

❏ 3.Thread the coupler and pushrod onto the tail pushrod

as shown.

HORIZONTAL FIN ALIGNMENT

❏ Align the horizontal fin and tighten the bolts that were left

loose earlier.

SERVOS AND POWER SWITCH

Please follow the manuf acturer’s instructions for y our servos.

Install the grommets and eyelets and remove the servo arm

screws and servo arms.

❏ 1. Use the picture above as a reference when installing

the throttle and collective servos.

❏ 2. Remove the left side servo frame by removing the five

screws as shown above.

❏ 3.Now is the best time to install the receiv er pow er s witch.

EQUIPMENT INSTALLATION

Page 16

❏ 4. The collective and throttle servos are mounted on the

inside of the frame.Slide the throttle servo into the frame as

shown above. Install a 2.6x10mm screw and use a plastic

servo nut behind the servo.Tighten the 2.6mm screw until the

grommet begins to compress. Install the other three screws

and the plastic servo nut on the opposite end of the servo.

❏ 5.Install the collective servo using f our 2.6x10mm scre ws

and two plastic servo nuts. Re-install the ser vo frame with

the five screws you removed earlier.

❏ 6.Install the forw ard/aft cyclic servo using four 2.6x10mm

screws.Note servo arm direction.

❏ 7. Install the left/right cyclic servo using four 2.6x10mm

screws.Note s e rvo ar m d i r e ct i o n .

❏ 8.Install the tail rotor servo as sho wn using four 2.6x10mm

screws and two plastic servo nuts.

BATTERY, RECEIVER AND GYRO

❏ 1.Wrap the batter y with 1/4" foam. Use electrical tape to

attach the foam to the battery. Place the battery on the front

tray and attach it with electrical tape.

❏ 2.Place a piece of 1/4" foam on top of the battery and place

the receiver on top of the foam.Wrap lightly but securely with

electrical tape, leaving room for the foam to absorb vibration.

16

Page 17

17

RECEIVER ANTENNA

❏ 1. Slide the antenna tube into the mounts on the bottom of

the landing gear. Cut two pieces of fuel tubing 1/4" [6.4mm]

long and slide onto the tube in the front and back to capture

it. Slide the receiver antenna through the tube. Use a rubber

band to attach the antenna to the horizontal fin.

❏ 2. Following the manufacturer’s instructions, install your

gyro as shown. Use zip ties or Velcro®to bundle the excess

wire and prevent it from reaching the gears.

CONNECTING THE SERV OS TO THE RECEIVER

❏ Using the table above , plug the servos into the appropriate

channels on the receiver.

RECEIVER CHANNEL ASSIGNMENTS

LEFT / RIGHT FOR/AFT

RECEIVER TYPE CYCLIC CYCLIC TAIL ROTOR GYRO GAIN COLLECTIVE THROTTLE

Futaba PPM / FM CH 1 CH 2 CH 4 CH 5 CH 6 CH 3

Futaba PCM 1024 CH 1 CH 2 CH 4 CH 5 CH 6 CH 3

Futaba PCM 2048 G3 CH 4 CH 5 CH 2 CH 3 CH 6 CH 1

Hitec CH 1 CH 2 CH 4 CH 5 CH 6 CH 3

JR CH 2 CH 3 CH 4 CH 5 CH 6 CH 1

Airtronics CH 2 CH 1 CH 4 CH 5 CH 6 CH 3

Multiplex CH 1 CH 2 CH 3 CH 6 CH 4 CH 5

Page 18

FUTABA: 6EXH – 7CH – 9CH

This manual assumes you have already read through your

transmitter operating instructions and are familiar with its

operation. The settings shown will be for a beginner;

recommendations for intermediate and 3D pilots are on

page 23. The settings provided can be used as a star ting

point for other transmitters but please verify the model is set

up correctly before flying. Settings such as the servo

reversing can vary depending on the radio manufacturer

and which servo you use.The settings shown are for Futaba

transmitters and Futaba servos.

Before setting up the servo arms and linkages, make

sure the servos are hooked up properly and rotate in the

proper direction.

TRANSMITTER PREPARATION

❏ Using the instructions provided with your r adio, select a ne w

model memory on your transmitter. Perform a reset on the

model memory to ensure that previous settings are eliminated.

WARNING: Please make absolutely sure you have

selected an empty model memory before starting.

RESET MODEL MEMORY

6EXH

7CH

9CH

❏ 1.Futaba T6EXH:Press (Select) until you see the [SWSH]

option. Verify that it is set to 1-S for swashplate type. Next

select the [MODL] menu and press the (Select) button. The

transmitter will show [REST CLR]. Now hold the (+) slider

upwards at least two seconds to execute the reset.

RADIO SETUP

18

L/R CYCLIC F/A CYCLIC THROTTLE TAIL ROTOR GYRO COLLECTIVE

EPA/ATV 110% / 110% 110% / 110% 100% / 90% 100% / 100% 100% / 100% 100% / 100%

D/R 100% 100% 100%

EXP -30% -30% -30%

Reverse (Futaba) 1 – Normal 2 – Normal 3 – Reverse 4 – Reverse 5 – Normal 6 – Normal

Servo Arm Length 10.5mm 10.5mm 13mm 17.5mm 10.5mm

Sub Trim 0 0 0 0 0 0

Trim Step* 4* -- 1 4* -- 1 4 4* -- 1

MODEL TYPE H-1

TH-CUT ACT Rate: -10% Thr: 5% SW-H

Fail Safe Low Throttle–Idle

GYRO (Head Hold) SW-E MODE - GY UP> 60% CT>60% DN>55%

HOV-THR INH - Best to use mechanical adjustments

HOV-PIT INH - Best to use mechanical adjustments

Throttle Hold ACT POS>+- 0% R-OF> INH RT>+- 0%

THROTTLE CURVE

Normal 0% 25% 50% 75% 100%

PITCH CURVE

Normal 45% / -2° 55% 65% / +4.5° 82% 100% / +10°

Hold 30% / -4° 47% 65% / +4.5° 82% 100% / +10°

SETUP QUICK REFERENCE

*After initial flights, reduce trim step to 1 for a finer adjustment.

Page 19

19

❏ 2. Futaba T7CH: Select the [PARAMETER] menu and

verify the model [TYPE>] is set to [H-1]. Position the cursor

on [RESET>EXECUTE]. Press the rotary dial and hold it for

two seconds. The screen will show [SURE?]. Press the

rotary dial again to confirm and execute the reset.

❏ 3. Futaba T9CH: Select the [PARAMETER] menu and

verify the model [TYPE>] is set to SWH1.Position the cursor

on [RESET>EXECUTE]. Press the rotary dial and hold it for

two seconds. The screen will show [SURE?]. Press the

rotary dial again to confirm and execute the reset.

SET MODULATION TYPE

6EXH

7CH

9CH

Most computer radios are capable of transmitting in FM/PPM

or PCM. Depending on your radio and receiver, you must set

the modulation type in the radio. If the modulation type is

wrong, the receiver and servos will not operate at all. If you

are having problems, this is the first thing to check.

Once the modulation type is changed, it is necessary to

power down and power up again before the change will take

effect. Futaba radios also keep the modulation type in

memory for each model. If the modulation changes from

model to model, then the transmitter must be powered down

and up again before the controls will work.

❏ Futaba T6EXH:Select the [MODL] menu and press (Select)

button twice.The screen should now show [PULS] [PPM/PCM].

Use the data and button to select the type.

❏ Futaba T7CH:Select the [PARAMETER] men u and use the

and cursor buttons to scroll down to the [MODUL>]

line. Use the rotary dial to select either [PCM] or [PPM].

❏ Futaba T9CH: Select the [PARAMETER] menu and use

the and buttons to scroll down to the [MODUL] line.

Use the rotary dial to select either [PCM] or [PPM].

MODEL NAME

6EXH

7CH

9CH

❏ Futaba T6EXH: Select the [MODL] menu and press the

(Select) button three times.Use the and data buttons

to change letters and use the (Select) button to move to the

next character.

❏ Futaba T7CH: Select the [MODEL] menu and use the

button to move down to [NAME]. Use the Rotary Dial to

change letters and the and buttons to change

positions within the name.

❏ Futaba T9CH: Select the [MODEL] menu and use the

and buttons to mov e down to [NAME].Use the Rotary

Dial to change letters and the and buttons to change

positions within the name.

EXPONENTIAL

Exponential should be used to soften the control feel around

center. Futaba radios use a “–” percentage to soften the

sensitivity.Please read your transmitter’s instruction manual

to determine if “–” or “+”e xponential should be used.Futaba

users should start out with –30% exponential on the

following controls: Forward and Aft cyclic, Left and Right

cyclic, and Tail Rotor.

Most radios allow you to set the e xponential f or low and high

rates independently; you should set both rates to the same

value in case you accidentally have the dual rate switched

on. Dual rates are not needed on the Kinetic .50. If you still

feel the model is too sensitive, increase the exponential %

until you are satisfied with the overall feel.

Page 20

6EXH

7CH

9CH

❏ Futaba T6EXH:Press the (MODE) button until the screen

shows [D/R ch1 100%]. Press the (Select) button until the

screen shows [EXPO CH1 + – 0%]. Use the button and

decrease to –30%. Flip the Dual Rate switch on the

transmitter and adjust the low/high rate also. Repeat this for

the forward/aft (CH2) and tail rotor (CH4).

❏ Futaba T7CH:Select the [D/R,EXP] menu.Press the cursor

button to move do wn to [EXP + – 0%]. Use the rotary dial

to set the value to –30%. Cursor back up to [CH> 1-AIL] and

turn the rotary dial clockwise one position. You will notice the

arrow next to AIL changes.This is the low rate setting for CH1

AIL; set it to –30%.Turn the rotary dial clockwise one position

and the display will change to [CH> 2-ELE]. Continue setting

the high and low rate exponential to –30% for forward/aft cyclic

(CH2) and tail rotor (CH3).

❏ Futaba T9CH:Select the [*D/R,EXP] menu.Press the cursor

button to move down to [EXP + – 0%]. Use the rotary dial

to set the % to -30%.Cursor back up to [CH> 1-AIL] and turn

the rotary dial clockwise one position.You will notice the arrow

next to AIL changes.This is the low rate setting f or CH1 AIL;set

it to –30%.Turn the rotary dial clockwise one position and the

display will change to [CH> 2-ELE]. Continue setting the high

and low rate exponential to –30% for (CH4) tail rotor.

SERVO REVERSING

6EXH

7CH

9CH

WARNING:These settings are ONLY for Futaba radios using

Futaba servos.Please double-check the settings before flight

to be absolutely sure they are correct.

❏ Futaba T6EXH with Futaba Servos: Select the [REVR]

menu. Reverse channels 3-Throttle and 4-Tail Rotor.

Channels 1, 2, 5, and 6 should remain as [NORM]

❏ Futaba T7CH with Futaba Servos:Select the [REVERSE]

menu. Reverse channels 3-Throttle and 4-Tail Rotor.

Channels 1, 2, 5, and 6 should remain as [NORM]

❏ Futaba T9CH with Futaba Servos:Select the [REVERSE]

menu. Reverse channels 3-Throttle and 4-Tail Rotor.

Channels 1, 2, 5, and 6 should remain as [NORM]

20

Page 21

21

END POINT ADJUSTMENTS

6EXH

7CH

9CH

❏ Futaba T6EXH: Select the [EPA] menu and set CH1 and

CH2 to 110% (left/right and forward/aft).

❏ Futaba T7CH: Select the [EPA] menu and set CH1 and

CH2 to 110% (left/right and forward/aft).

❏ Futaba T9CH: Select the [EPA] menu and set CH1 and

CH2 to 110% (left/right and forward/aft).

SUB-TRIM

If possible, sub-trim should be avoided.Most servo arms are

designed with an odd number of splines which allows you to

rotate it 90° or 180° and change the center position of the

arm. If you cannot get the arm perfectly straight, then a

small % of sub-trim may be used but it is best to a v oid using

it. Sub-trim can decrease the available throw one direction.

FAIL-SAFE

6EXH

7CH

9CH

This function is only available for PCM receivers and cannot

be used on FM.What fail-safe provides is a set of commands

for the servos to follow if the receiver should experience

interference for more than two seconds. Please set the

throttle [FAIL SAFE] to bring the engine back to idle and

leave all other servos set to [HOLD].This will help to prevent

damage in the case of severe interference.

GYRO FUNCTION

6EXH

7CH

9CH

The gyro function is only used on gyros that have a remote

gain that plugs into the receiver. If your gyro does not have

remote gain, please follow the instructions provided with the

gyro and set it up for heading hold mode.

❏ Futaba T6EXH: Select the [GYRO] menu. Enable the

function and set the gain to +60%.

Page 22

❏ Futaba T7CH: Select the [GYRO] menu. Enable the

function and set the switch to [SW -E] (Flight Condition Switch).

Set all positions to [A 60%] which is A VCS (Heading Hold) and

60% gain.

❏ Futaba T9CH: Select the [GYRO] menu. Enable the

function and set the switch to [SW -E] (Flight Condition Switch).

Set all positions to [A 60%] which is A VCS (Heading Hold) and

60% gain.

THROTTLE CUT

7CH

9CH

❏ Futaba T7CH: Select the [TH-CUT] menu. Enable the

function and set the switch to [SW-H], using the following

settings: [RATE –10%] — [THR> 5%]

❏ Futaba T9CH: Select the [TH-CUT] menu. Enable the

function and set the switch to [SW-H], using the following

settings: [RATE–10%] — [THR>5%] — [POSI->DOWN]

HOVER AND THROTTLE TRIMS

Since the hover and throttle trims operate only in normal

flight mode, it’s best to disab le them and mak e changes with

mechanical adjustments.

HI-LO PITCH TRIMS

Set the “CONTROL” to null on both HI and LO pitch trims.

THROTTLE CURVE

6EXH

7CH

9CH

❏ Futaba T6EXH:Select the [N-TH] menu. Set Point #1 to 0%.

Press (Select) to move to the next point. Set Point #2 to 25%,

set Point #3 to 50%, Point #4 to 75% and Point #5 to 100%.

❏ Futaba T7CH: Select the [TH-CRV(N)] menu. Press the

button until you are editing Point #1. Use the rotary dial

to set it to 0%.Press the button to move to Point #2 and

set it to 25%. Set Point #3 to 50%, Point #4 to 75% and

Point #5 to 100%.

❏ Futaba T9CH: Select the [TH-CV/NOR] menu. Set Point

#1 to 0%. Press the button to move to Point #2 and set

it to 25%.Set P oint #3 to 50%, Point #4 to 75% and Point #5

to 100%.

22

Page 23

23

PITCH CURVE

6EXH

7CH

9CH

❏ Futaba T6EXH: Select the [N-PI] menu. Set Point #1 to

45%. Press (Select) to move to Point #2 and set it to 55%.

Continue to set Point #3 to 65%, Point #4 to 82% and Point

#5 to 100%.

❏ Futaba T7CH: Select the [PI-CRV(N)] menu. Press the

button until you are editing Point #1. Use the rotary dial

to set it to 45%. Press the button to move to Point #2.

Set it to 55%. Set Point #3 to 65%, Point #4 to 82% and

Point #5 to 100%.

❏ Futaba T9CH: Select the [PI-CV/NOR] menu. Set Point

#1 to 45%. Press the button to move to Point #2. Set it

to 55%. Set Point #3 to 65%, Point #4 to 82% and Point #5

to 100%.

INTERMEDIATE AND BASIC AEROBATIC CURVES

Please take the time to become accustomed to the new setup .

The increased negative collective will make the controls very

sensitive.Be aware of switches, as well.Accidentally switching

to “Idle Up 2”, for instance , automatically advances the engine

to full throttle.

ADVANCED 3D AND AEROBATIC CURVES

Once accustomed to the curves above, you can use these

curves for everything from everyday flight to advanced 3D

aerobatics.The throttle mixes help maintain rotor head speed.

If your Kinetic .50 loses head speed during maneuvers,

increase the throttle mix percentages.

THROTTLE CURVE POINT 1 POINT 2 POINT 3 POINT 4 POINT 5

Normal 0% 25% 50% 75% 100%

Idle Up 1 25% 37% 50% 75% 100%

Idle Up 2 85% 70% 60% 80% 100%

PITCH CURVE POINT 1 POINT 2 POINT 3 POINT 4 POINT 5

Normal 45% / -3° 55% 65% / +4.5° 82% 100% / +10°

Idle Up 1 35% / -4.5° 50% 65% / +4.5° 82% 100% / +10°

Idle Up 2 0% /-10° 32% 65% / +4.5° 82% 100% / +10°

Hold 30% / -5° 47% 65% / +4.5° 82% 100% / +10°

BASIC AND INTERMEDIATE AEROBATIC CURVES

THROTTLE CURVE POINT 1 POINT 2 POINT 3 POINT 4 POINT 5

Normal 0% 25% 50% 75% 100%

Idle Up 1 25% 37% 50% 75% 100%

Idle Up 2 100% 70% 50% 70% 100%

PITCH CURVE POINT 1 POINT 2 POINT 3 POINT 4 POINT 5

Normal 35% / -4.5° 42% 50% / 0° 82% 100% / +10°

Idle Up 1 35% / -4.5° 42% 50% / 0° 82% 100% / +10°

Idle Up 2 0% /-10° 25% 50% / 0° 82% 100% / +10°

Hold 20% / -7° 47% 50% / 0° 82% 100% / +10°

THROTTLE MIXES

L/R Cyclic Throttle 40% F/A Cyclic Throttle 40% T/R Throttle 40%

ADVANCED 3D AND AEROBATIC CURVES

Page 24

SERVO SETUP AND LINKAGES

Most servo arms have an odd number of splines, which

allows you to rotate it 90°, 180° or 270° to help with the

centering. All servo arms should be perpendicular to the

servos when installed in the Kinetic .50.

FORWARD/AFT CYCLIC SETUP

❏ 1. Turn on the transmitter and receiver and center the

sticks.Test fit a servo arm onto the ser vo.The arm must be

perpendicular to the servo, as shown above. (If the ar m isn’t

perfectly aligned, rotate it 90° and recheck alignment.Repeat

until 90° alignment is achieved.)

❏ 2. Remove the arm and using a pair of wire cutters, clip

off the three unused sides. Install a metal control ball into

the servo arm at 10.5mm from center (second hole out from

center on Futaba arms). Using thread locker, install the

2mm nut onto the back side of the servo arm and tighten.

❏ 3. Verify the servo arm clears the left/right cyclic servo.If

needed, trim the arm as required.

❏ 4. Install the servo arm and screw as shown above.

Locate the forward/aft cyclic linkage and verify that it is

128mm long. Install linkage as shown above.

LEFT/RIGHT CYCLIC SETUP

❏ 1. Turn on the transmitter and receiver and center the

sticks.Test fit a servo arm onto the servo.The arm must be

perpendicular to the servo, as shown.

❏ 2. Remove the arm and using a pair of wire cutters, clip

off the two unused sides. Install a metal control ball onto

both sides at 10.5mm from center (second hole out from

center on Futaba arms). Using thread locker, install the

2mm nuts onto the back side of the servo arm and tighten.

10.5mm

10.5mm

24

128mm

(Sketch not to scale)

Page 25

25

❏ 3. Install the servo arm and screw as shown above.Locate

the left/right cyclic linkages and make sure they are both

148mm long. Install the linkages and the servo arm screw.

❏ 4. Please remove the bellcrank to swashplate linkage as

shown above and verify it is 51mm long. Repeat on the

opposite side.

COLLECTIVE SERVO SETUP

❏ 1. Make sure that the transmitter and receiver are “ON”

and the sticks are centered. Put a servo arm in place,

making sure that one side is perpendicular to the servo.

❏ 2. Remove the arm and using a pair of wire cutters, clip

off the three unused sides. Install a metal control ball into

the servo arm at 10.5mm from center (second hole from

center on Futaba arms). Using thread locker, install the

2mm nut onto the back side of the ball and tighten.

❏ 3. Verify the collective pushrod is 90mm long. Install as

shown above.

❏ 4.Install the collective servo arm screw.

10.5mm

148mm

(Sketch not to scale)

90mm

(Sketch not to scale)

51mm

(Sketch not to scale)

Page 26

THROTTLE SETUP

❏ 1. Make sure that the transmitter and receiver are “ON”

and the sticks are centered.Put a servo arm in place, making

sure that one side is perpendicular to the servo.

❏ 2. Remove the arm and using a pair of wire cutters, clip

off the three unused sides. Install a metal control ball into

the servo arm at 13mm from center (third hole out from

center on Futaba arms). Using thread locker, install the

2mm nut onto the back side of the ball and tighten.

❏ 3.Ver ify the throttle pushrod is 90mm long. Install the ball

link onto the throttle arm. Make sure that the throttle arm on

the engine is straight up and down when the stick is at half

throttle.The O.S..50 SX-H Hyper has indentations on the carb.

❏ 4. Leave the other side of the linkage loose. Move the

throttle to idle and verify the throw is correct and does not bind.

Move the throttle to full and place the linkage over the control

ball. Verify that the servo is traveling the proper distance. If

necessary use the radio’s End Point Adjustments.

❏ 5.Install the servo arm screw.

TAIL ROTOR SERVO

❏ 1.With the transmitter and receiver turned on, make sure

the gyro is centered. (Use Normal mode instead of Heading

hold.) Place a servo arm onto the servo and verify the arm

is perpendicular to the servo.

❏ 2. Remove the arm and using a pair of wire cutters, clip

off the three unused sides. Install a metal control ball into

the servo arm at 17.5mm from center (fourth hole out from

center on Futaba arms). Using thread locker, install the

2mm nut onto the back side of the ball and tighten.

❏ 3. Install the ser vo arm screw. Move the T/R stick to full

left.Hold the pushrod ball link ov er the control ball and v erify

the servo throw is correct. Balance the left and right throws

by adjusting the pushrod length. Make sure the pushrod

does not bind when moving either direction.Try to keep the

gyro limit near 100% by adjusting the length of the servo

arm. Your goal is to have maximum mechanical throw

without binding and have the gyro limit at 100%.

13mm

26

90mm

(Sketch not to scale)

Page 27

27

GY401 GYRO SETUP

If you are using a digital servo such as the Futaba S9254 or

S9253, the DS mode switch should be “ON”.Otherwise, set

it to “OFF”.The “DIR” should be set to “NOR” or “OFF”.

INSTALL MAIN ROTOR HEAD LINKAGES

❏ 1.Find the two pre-assembled collective linkages and v e rify

they are 102mm long.Install the linkages as shown above.

❏ 2.The short double links should have a 1mm gap betw een

the ball links as shown above.

MAIN BLADES

Warning: The blade root reinforcements must be glued to

the main blades. Please inspect the blades for damage

before assembling them.Do not exceed 1700 RPM with the

wood blades or failure may occur. Blades are considered

consumable items and should be discarded if there is any

sign of damage.

❏ 1. Position the blade as shown above and test fit the top

reinforcement on the blade.

❏ 2.T urn ov er the blade and test fit the bottom reinf orcement.

HEAD AND LINKAGES

102mm

(Sketch not to scale)

Page 28

❏ 3. Once you have verified everything fits properly, mix up

some 30-minute epoxy and apply it to the exposed wood on

the root of the blade.Install the top and bottom reinforcements

as shown above. Double check your work to verify the

reinforcements are installed properly. Install and tighten the

two 2.6mm screws into the reinforcements as shown.

❏ 4. Use a paper towel dampened with isopropyl alcohol to

remove the e xcess glue from the blade.Before the epoxy sets,

install the blades into the grips to clamp the reinforcements

down onto the blade.Once the epoxy has set, you can proceed

to the next step.

❏ 5. Using the 4mm bolts and nylon lock nuts, install the

blades into the grips as shown.

BLADE BALANCING

Note: All main blades must be balanced before use. We

recommend using the Heli-Max Blade Balancer (HMXE4855).

❏ 1. Apply the two colored stripe decals to the tips of your

main rotor blades (for use in blade tracking later on).

❏ 2. Prepare the balancer for use by rotating the brass

adjustment dial until the bubble in the vial indicates level. Make

sure that the blade balancer does not move during this process.

❏ 3. Place one blade onto the balancer with the leading

edge against the side with the level. Shift the blade on the

balancer until the bubble indicates level. The middle of the

black balancing tray is now at the C.G. of this blade. Mark

this position on the blade with a felt tip pen.

❏ 4.Line up the ends of both blades.Transfer the mark you

made on the first blade to the second blade.

28

Page 29

❏ 5.Position the second blade on the tray, with the mark at

the center.Add balancing or electrical tape to the lighter end

until the bubble indicates that both sides are level.The C.G.

of both blades is now matched. If the tape ends overlap,

make sure the overlapping end points to the

trailing

edge of

the blade.

❏ 6. Your Heli-Max Blade Balancer includes four sizes of

blade mounting plates and a nylon mounting bolt.Select the

mounting plate that best fits the holes in the blade grips.

Secure the mounting plate and two blades to the balancer

with the nylon mounting bolt.

❏ 7.Add tape to the C.G.of the lighter blade until the bubble

level indicates that the two blades balance.Using a different

tape color in this step will remind you that future

adjustments will require both balancing steps.

PITCH CURVES

❏ 1.The pitch gauge is used by setting the desired pitch on the

gauge and adjusting the blade pitch until the top (or bottom) of

the gauge is parallel with the flybar.Make sure the flybar is level

while doing this.If y ou need to make an adjustment to the pitch

of the blades, then adjust the long linkages that connect the

swashplate to the mix er arm.The goal is to have positive 10° at

full throttle/collective and negative 10° at low throttle/collective.

Then use the pitch curves within the radio to adjust the

collective pitch range.

29

PITCH CURVE POINT 1 POINT 2 POINT 3 POINT 4 POINT 5

Normal 45% / -2° 55% 65% / +4.5° 82% 100% / +10°

Hold 30% / -4° 47% 65% / +4.5° 82% 100% / +10°

PITCH CURVE SETUP

Warning: Beginners should use a maximum negative 2° collective with the throttle stick at idle. It helps to reduce the

sensitivity of the collective and prevents hard landings when the throttle is brought back to idle.Later, once you advance and

need more negative collective, simply make adjustments in the transmitter

.

Page 30

❏ 2. Tur n on the transmitter and receiver.Move the collective

stick to full throttle. Place the pitch gauge on the blade as

shown and set it to +10°.Align the top (or bottom) of the pitch

gauge with the flybar. If necessary, adjust the long linkage

between the mixer and the s w ashplate .Once the correct pitch

has been established, adjust the length of the linkage on the

opposite side to match.

❏ 3. On your transmitter, place the throttle/collective stick in

the center.Verify that the setting is around +4.5°.If the pitch is

off, adjust P oint #3 in the pitch curve on your radio .If you adjust

Point #3, adjust Points #2 and #4 to maintain a smooth curve.

❏ 4. Lower the throttle/collective stick on the transmitter to

the bottom. Verify that the setting is around –2°. Use pitch

curve Point #1 if adjustments are needed. Once you are

finished, set Point #2 to keep an even curve.

❏ 5. Repeat the pitch curve setup for the Hold function and

any other Idle Ups you may need.

FUEL LINES

❏ Cut a piece of 4" [102mm] fuel line for the carburetor

pickup line and install. Use the remaining fuel line for the

pressure line to the muffler.

MUFFLER INSTALLATION

❏ Install your muffler f ollowing the man ufacturer’ s instructions.

Mounting hardware should be included with the muffler.

BODY AND MOUNTS

❏ 1. Slide the threaded rod through the frame.Using thead

locking compound, install the body mounts as shown abov e.

FINAL ASSEMBLY

30

Page 31

31

❏ 2.T rim the front of the body as shown abo ve .Make a clean

cut by making several passes with a hobby knife. Mark the

body 5/8" [16mm] up from the back edge and 5/8" [16mm]

right. Drill 1/4" [6.4mm] holes for the rubber grommets.Install

the grommets into the body.

❏ 3. Install the front body clamp using two 3x8mm self-

tapping screws. Please note that the wider end should face

the back of the canopy.

❏ 4. Depending on your muffler, it may be necessary to cut

the body for clearance.Leave at least 1/4" [6.4mm] between

the body and muffler.Mount the body by sliding the canopy

latch onto the “L” bracket on the servo tray. Lift up the back

portion of the body and push the grommets onto the rear

body mounts.

❏ 5. Once the body is installed, trim and test fit the

windshield. When satisfied with the fit, drill 1/16" [1.5mm]

holes at the locations shown and use 2x3mm self-tapping

screw to attach the windshield. Repeat for the other side of

the body.

DECALS

❏ Clean the body thoroughly with glass cleaner to remove

any mold release left over from manuf acturing.Spraying glass

cleaner on the body before applying the decals enables you

to reposition them until they are perfectly placed. Once in

place, use a squeegee to remove the cleaner, allowing the

decals to “stick”in place.

Page 32

CHECK THE CONTROL DIRECTIONS

Turn on the transmitter and allow the gyro 5 seconds to

initialize before moving the helicopter or oper ating the sticks .If

everything has been adjusted properly the swashplate should

be level with the main frame when the sticks are centered.

Forward Cyclic

❏ Look at the helicopter from the right side. Push the right

stick forward.The swashplate should tilt forward as shown.

Aft Cyclic

❏ Pulling the right stick back should make the swashplate

tilt backwards.

Left Cyclic

❏ View the helicopter from the rear. Pushing the right stick

to the left should make the swashplate tilt to the left.

Right Cyclic

❏ Continue to view the helicopter from the rear. Pushing

the right stick to the right should make the swashplate tilt to

the right.

Ascend Collective

PREPARE FOR FLIGHT

32

Page 33

33

❏ When the left (collective) stick is pushed forward, the

swashplate should move up and the carburetor should open.

Descend Collective

❏ When the left (collective) stick is pulled backward, the

swashplate should mov e down and the carb uretor should close.

Left T ail Rotor

❏ When the left (tail rotor) stick is moved to the left, the tail

pitch slider should move to the right as shown.

Right T ail Rotor

❏ When the left (tail rotor) stick is mov ed to the right, the tail

pitch slider should move to the left as shown.

Gyro Compensation Direction

❏ Pick the helicopter up by the main shaft and rotate the nose

to the left (counterclockwise).The gyro should compensate by

moving the tail rotor pitch slider to the left (toward the tail

boom). If the pitch slider moves right instead, change the

reversing switch for the servo.

Page 34

RANGE CHECK

Ground check the range of your radio before the first flight of

the day. With the transmitter antenna collapsed and the

receiver and transmitter “ON”, you should be able to walk at

least 100 feet awa y from the model and still ha ve control.Have

an assistant stand by your model and tell you what the servos

are doing while you work the controls. If the controls do not

respond correctly , do not fly! Find and correct the prob lem first.

Look for loose servo connections or broken wires, corroded

wires on old servo connectors, poor solder joints in your

battery pack or a defective cell, or a damaged receiv er crystal

from a previous crash. Failure to follow these safety

precautions may result in severe injury to you and others.

Keep yourself and all spectators away from the plane of

rotation of the rotors. Keep these items away from the rotors:

loose clothing (shirt sleeves, ties, scarfs), long hair, or loose

objects (such as pencils or screwdrivers) that may fall out of

shirt or jacket pockets into the rotors.The spinning blades of a

model helicopter can cause serious injury.When choosing a

flying site for your model, stay clear of buildings, trees and

power lines.AVOID flying in or near crowded areas.DO NOT

fly close to people, children or pets. Maintain a safe pilot-tohelicopter distance while flying.

BALANCE THE MODEL (C.G.)

The Kinetic .50 should balance level when picked up by the

flybar with the flybar perpendicular to the tail boom. If the tail

drops, the helicopter is tail heavy and you need to add

weight to the front or if possible move equipment forward. If

the nose drops, you need to add some weight to the tail of

the helicopter or move equipment back as needed.

The C.G. on a model helicopter is not as critical as it is on

model airplanes, but can cause some trim problems as you

learn to fly .If nose weight is needed, consider using a larger

capacity battery.

At this stage, the model should be in ready-to-fly condition.

IDENTIFY Y OUR MODEL

Whether you fly at an AMA sanctioned R/C club site or

somewhere on your own, y ou should alwa ys hav e y our name,

address, telephone number and AMA number on or inside

your model.It is required at all AMA R/C club flying sites and

AMA sanctioned flying events .Fill out the identification tag on

page 38 and place it on or inside your model.

CHARGE THE BA TTERIES

Follow the battery charging instructions that came with your

radio control system. You should always charge your

transmitter and receiver batteries the night before y ou go flying,

and at other times recommended by the radio manufacturer.

Read and abide by the following e xcerpts from the Academy

of Model Aeronautics Safety Code.For the complete Safety

Code, refer to

Model Aviation

magazine, the AMA web site

or the Code that came with your AMA license.

GENERAL

1) I will not fly my model aircraft in sanctioned events, air

shows, or model flying demonstrations until it has been

proven to be airworthy by having been previously,

successfully flight tested.

2) I will not fly my model aircraft higher than approximately

400 feet within 3 miles of an airport without notifying the

airpor t operator. I will give right-of-way and avoid flying in

the proximity of full-scale aircraft. Where necessar y, an

observer shall be utilized to supervise flying to avoid

having models fly in the proximity of full-scale aircraft.

3) Where established, I will abide by the safety rules for the

flying site I use, and I will not willfully and deliberately fly my

models in a careless, reckless and/or dangerous manner.

5) I will not fly my model unless it is identified with my name

and address or AMA number, on or in the model. Note:

This does not apply to models while being flown indoors.

7) I will not operate models with pyrotechnics (any device

that explodes, burns, or propels a projectile of any kind).

RADIO CONTROL

1) I will have completed a successful radio equipment ground

check before the first flight of a new or repaired model.

2) I will not fly my model aircraft in the presence of spectators

until I become a qualified flier, unless assisted by an

experienced helper.

3) At all flying sites a straight or curved line(s) must be

established in front of which all flying takes place with the

other side for spectators. Only personnel involved with

flying the aircraft are allowed at or in the front of the flight

line. Intentional flying behind the flight line is prohibited.

4) I will operate my model using only radio control

frequencies currently allowed by the Federal

Communications Commission.

5) I will not knowingly operate my model within three miles

of any pre-existing flying site except in accordance with

the frequency sharing agreement listed [in the complete

AMA Safety Code].

9) Under no circumstances may a pilot or other person

touch a powered model in flight; nor should any part of

the model other than the landing gear, intentionally touch

the ground, except while landing.

AMA SAFETY CODE (EXCERPTS

)

PREFLIGHT

34

Page 35

35

Please try to find a local club (check www.modelaircraft.orgfor

listings) or find an experienced modeler for help before starting

to fly. There are a lot of mistakes that can be made during the

assembly of helicopters that an experienced modeler can catch.

They will help you get the model setup properly and verify that

the model is trimmed out and ready for your first flight.

The web sites listed below are discussion forums for R/C

Helicopters and Planes.There is a lot of information available

on the forums.

www.rcgroups.com

www.rcuniverse.com

www.runryder.com

Computer flight simulators are excellent practice bef ore risking

your model.Great Planes RealFlight®G3.5 (GPMZ4405) is the

most realistic simulator available and is highly recommended.

CONTROLS

Shown below are the controls available on the Heli-Max

Kinetic .50 and how they operate during flight.

Forward Cyclic

Moving the right (cyclic) stick forward causes the helicopter

to lean forward and start moving forward.

Aft Cyclic

Moving the right (cyclic) stick backward causes the helicopter

to lean backward and start moving backward.

Left Cyclic

Moving the right (cyclic) stick to the left causes the helicopter

to lean left and start moving in that direction.

Right Cyclic

Moving the right (cyclic) stick to the right causes the helicopter

to lean right and start moving in that direction.

Ascend Collective

When the left (collective) stick is mov ed f orward, the helicopter

will ascend.

FLYING

Page 36

Descend Collective

When the left (collective) stick is moved downward, the

helicopter will descend.

Left T ail Rotor

When the left (tail rotor) stick is moved to the left, the

nose of the helicopter will move left and the helicopter will

rotate counterclockwise.

Right T ail Rotor

When the left (tail rotor) stick is moved to the right, the

nose of the helicopter will move right and the helicopter will

rotate clockwise.

TRAINING GEAR

If you have ne v er flown a helicopter bef ore, consider purchasing

training gear.It not only helps prevent crashes and tip-ov ers, b ut

prevents damage b y softening not-so-perfect landings.The HeliMax Training Gear (HMXE2025) is highly recommended.

FLYING CONDITIONS

During your first flight, it is very helpful to fly in light winds and

have a helper to keep an e y e on things around you.If you are

flying off grass, make sure it is cut low. This will allow the

helicopter to slide around without catching. Finally, make

sure there are no obstacles or distractions in your flying area.

BEFORE EACH FLIGHT

Please inspect the model for loose or damaged parts.

Inspect the main rotor blades and ball links. Make sure you

have selected the proper model in the transmitter and all of

the controls operate in the correct direction.

ST ARTING THE MODEL

Set the engine’s needle valve to the recommended factory

setting. Please review the manufacturer’s operating

instructions for the engine.

If you are flying at a club, be sure y ou use their frequency control

system.T urn on the radio first and select the correct model.Turn

on the helicopter next. Allow the gyro to initialize for at least 5

seconds before moving the model or using the transmitter.

Fill the fuel tank. Make sure the idle up switch on the

transmitter is set to normal mode and the throttle is at idle.

Check the throttle arm on the engine to verify it is at idle.

Attach the glow igniter to the glow plug. You must have a

solid hold on the blade grip in case the model starts at a

throttle position other than idle. Use the starter to turn the

engine over. If the engine does not want to start, check the

glow plug by removing it and attaching the glow igniter.

Verify that the needle settings are correct. It is possible the

engine could be flooded. If no problems can be found,

assume the engine is flooded.Remov e the fuel line from the

carburetor and try starting the engine again.

Once the model has been started and has warmed up,

remove the glow igniter. Carr y the model out to the location

where you plan on flying. Place the model on the ground and

walk back at least 30' [or 10m].

36

Page 37

37

ADJUST BLADE TRACKING

If you feel uncomfortable adjusting blade tracking by yourself,

please have a helper do the sighting f or you and simply fly the

model. Slowly bring the main rotor up to speed but do not lift

off the ground. Please wear safety glasses when performing

the next step. Observe whether the rotational planes of the

blades are the same. If they are not, adjust one of the short

double linkages to bring the blades into the same plane.

TAKEOFF

Slowly add power and observe the model. If you feel it

needs trimming at any time, simply lower the collective stick

all the way down to land and adjust the trim on the

transmitter.For now, simply bring the collective stick up until

the helicopter is “light on the skids”. As you become more

comfortable with the helicopter, you can lift higher off the

ground. Stay low until you become comfortable.

If you should get into trouble, simply bring the collective stick

down slowly and the helicopter will settle and land. This is

when the training gear serves its purpose, since it helps to

level the helicopter automatically before landing.The tr aining

gear will also allow the model to slide on most surfaces.

You will notice the cyclic controls lag behind your control

inputs.This is perfectly normal and something you get the feel

for with time.It’s normal to drift around in a hover until you are

used to flying the model.The cyclic controls on the Kinetic .50

are fairly sensitive so only small movements are necessary.

HOVERING

Once the helicopter is hovering, concentrate on holding the

helicopter in one spot. This can take some practice.Wind has

a big effect on the stability of the helicopter .Be patient and take

your time.Trying to rush the learning process can be costly.

LANDING

Level the helicopter into a ho ver and slowly decrease power

until the helicopter settles onto the ground.

BASIC MANEUVERS