Printed in Germany

IMAGING-PAM

M-series

Chlorophyll Fluorometer

Instrument Description

and

Information for Users

2.152 / 07.06

5. revised Edition: March 2014

imag-m-series0e_3.doc

Heinz Walz GmbH, 2014

Heinz Walz GmbH Eichenring 6 91090 Effeltrich Germany

Phone +49-(0)9133/7765-0 Telefax +49-(0)9133/5395

E-mail info@walz.com Internet www.walz.com

CONTENTS

I

1 Safety instructions ........................................................................ 1

1.1 General safety instructions ....................................................... 1

1.2 Special safety instructions ........................................................ 2

2 Introduction .................................................................................. 3

3 Components of the IMAGING-PAM MAXI-version .................. 7

3.1 Control Unit IMAG-CG ........................................................... 9

3.2 LED-Array Illumination Unit IMAG-MAX/L and IMAG-

MAX/LR ................................................................................ 11

3.3 CCD Camera IMAG-K6 and objective K6-MAX .................. 15

3.4 CCD Camera IMAG-K7 and objectives K7-MAX/Z and K7-

MAX/S ................................................................................... 17

3.5 Mounting Stand with Eye Protection IMAG-MAX/GS ......... 19

3.6 Leaf Distance Holder IMAG-MAX/B ................................... 24

3.7 Notebook PC IMAG-PC ........................................................ 25

3.8 Adapter IMAG-MAX/GWK .................................................. 26

4 Components of the IMAGING-PAM MINI-version .................. 27

4.1 Multi Control Unit IMAG-CG ............................................... 27

4.2 MINI-Head LED-Array IMAG-MIN/B and IMAG-MIN/R .. 28

4.3 CCD Camera IMAG-K6 or IMAG-K7 .................................. 30

4.4 IMAG-MIN/GFP with IMAG-K6 .......................................... 32

4.5 Leaf Holder IMAG-MIN/BK with Grip Holder ..................... 38

4.6 Adapter for GFS-3000 (IMAG-MIN/GFS) ............................ 42

4.7 ImagingWin software versions for various types of MINI-

Version ................................................................................... 44

5 Components of the IMAGING-PAM MICROSCOPY-version . 46

5.1 Multi Control Unit IMAG-CG ............................................... 47

5.2 CCD Camera IMAG-K6 ........................................................ 47

5.3

Axio ScopeA.1 Epifluorescence Microscope ......................... 49

5.3.1 Reflector Modules .............................................................. 51

CONTENTS

II

5.3.2 Assembling of beam splitter and filters .............................. 52

5.3.3 Mounting of the reflector module ...................................... 54

5.4 LED Modules ......................................................................... 56

5.4.1 Adjustment of brightness by grey filters ............................ 56

5.4.2 Integration of LED modules into Axio Scope.A1 .............. 58

5.4.3 Connecting LED modules with IMAG-CG ....................... 60

5.4.4 Switching LED modules for measurements ....................... 60

5.4.5 IMAG-RGB ....................................................................... 60

6 How to get started ...................................................................... 63

6.1 Connecting the cables ............................................................ 63

6.2 Software installation ............................................................... 64

6.2.1 Installation and Starting of ImagingWin ............................ 64

6.2.2 Installation of camera driver .............................................. 66

6.3 First steps and examples of routine measurements ................ 66

7 ImagingWin ................................................................................ 81

8 IMAGINGWIN - System Operation .......................................... 83

8.1 Definition of New Record ...................................................... 83

8.1.1 Fo, Fm ................................................................................ 83

8.1.2 New Record ........................................................................ 84

8.1.3 Measure .............................................................................. 84

8.2 Functions applying to the View-mode ................................... 85

8.3 Light controls ......................................................................... 87

9 IMAGINGWIN - Register Cards ............................................... 90

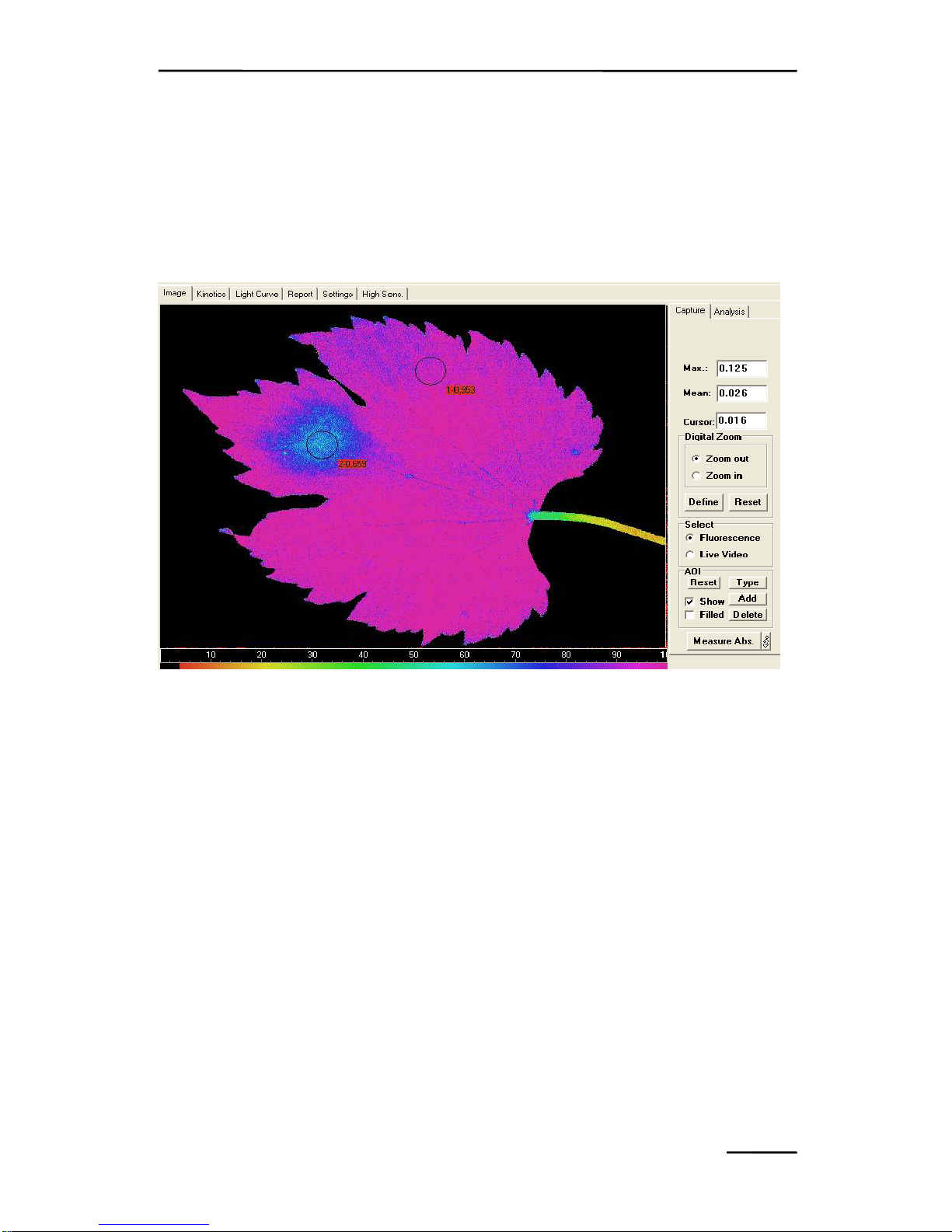

9.1 Image-window ........................................................................ 90

9.1.1 Different types of images ................................................... 90

9.1.1.1

Current fluorescence yield, Ft ........................................ 91

9.1.1.2 Dark fluorescence yield, Fo ........................................... 91

9.1.1.3 Fluorescence yield, F ..................................................... 92

CONTENTS

III

9.1.1.4 Maximal fluorescence yield, Fm .................................... 92

9.1.1.5 Maximum fluorescence yield, Fm' ................................. 93

9.1.1.6 Maximal PS II quantum yield, Fv/Fm ........................... 93

9.1.1.7 Effective PS II quantum yield, Y(II) .............................. 94

9.1.1.8 Quantum yield of regulated energy dissipation, Y(NPQ)95

9.1.1.9 Quantum yield of nonregulated energy dissipation,

Y(NO) ............................................................................ 96

9.1.1.10Absorptivity, Abs. .......................................................... 97

9.1.1.11Apparent rate of photosynthesis, PS/50 ......................... 99

9.1.1.12NIR light remission, NIR ............................................. 100

9.1.1.13Nonphotochemical quenching, NPQ/4 ........................ 101

9.1.1.14Red light remission, R .................................................. 102

9.1.1.15Coefficient of nonphotochemical quenching, qN ........ 103

9.1.1.16Coefficient of photochemical quenching, qP ............... 104

9.1.1.17Coefficient of photochemical quenching, qL ............... 105

9.1.1.18Inhibition, Inh. ............................................................. 106

9.1.2 Image capture and analysis .............................................. 107

9.1.2.1 Measure Abs. ............................................................... 107

9.1.2.2 Area of Interest, AOI ................................................... 108

9.1.2.3 Select: Fluorescence or Live Video ............................. 110

9.1.2.4 Zoom ............................................................................ 112

9.1.2.5 Cursor ........................................................................... 113

9.1.2.6 Analysis ....................................................................... 113

9.2 Kinetics window ................................................................... 116

9.3 Light Curve window ............................................................ 122

9.4 Report window ..................................................................... 128

9.5 Settings window ................................................................... 132

9.5.1 Light parameters .............................................................. 133

CONTENTS

IV

9.5.2 Gain and Damping ........................................................... 136

9.5.3 Absorptivity ..................................................................... 137

9.5.4 Slow Induction parameters ............................................... 138

9.5.5 Image Correction .............................................................. 138

9.5.6 Image Transformation ...................................................... 141

9.5.7 Battery .............................................................................. 141

9.5.8 Display parameters ........................................................... 142

9.5.9 Go Speed .......................................................................... 144

9.5.10 PS Limit ........................................................................... 144

9.5.11 Inh. Ref. AOI ................................................................... 145

9.5.12 Yield Filter ....................................................................... 145

9.5.13 Fm Factor ......................................................................... 146

9.5.14 F Factor ............................................................................ 149

9.5.15 Reset Default Settings, Open or Save User Settings ........ 152

9.6 High Sens. window .............................................................. 153

9.6.1 Special SP-Routine .......................................................... 154

9.6.2 Fo Averaging.................................................................... 156

9.6.3 Fv/Fm Contrast Enhancement by Background Suppression156

9.7 RGB-Fit window .................................................................. 157

9.7.1 RGB Gain ......................................................................... 160

9.7.2 Fit Correction ................................................................... 160

10 IMAGINGWIN - Menu Bar ..................................................... 163

10.1 File ....................................................................................... 163

10.1.1 Transfer FoFm .................................................................. 163

10.1.2 Using Skript files - Load Script/Run Script ..................... 163

10.1.3

Exit ................................................................................... 171

10.2 Options ................................................................................. 172

10.2.1 Ruler ................................................................................. 172

CONTENTS

V

10.2.2 Scale ................................................................................. 172

10.2.3 Info Icons ......................................................................... 173

10.2.4 Mean over AOI ................................................................ 173

10.2.5 Define AOI-array geometry ............................................. 175

10.2.6 Create AOI array: ............................................................. 176

10.3 Al-List .................................................................................. 178

10.3.1 LED currents / PAR values .............................................. 178

10.3.2 Light Calibration .............................................................. 180

10.4 Recalc ................................................................................... 181

10.5 Transect ................................................................................ 182

11 List of key commands .............................................................. 185

12 Technical specifications ........................................................... 186

12.1 Components used in all Versions ......................................... 186

12.1.1 Control Unit IMAG-CG ................................................... 186

12.1.2 IMAG-K7 ......................................................................... 187

12.1.3 IMAG-K6 ......................................................................... 187

12.1.4 Windows Software ImagingWin ...................................... 187

12.1.5 Battery Charger 2120-N ................................................... 188

12.2 Components specifically relating to Maxi-version .............. 189

12.2.1 LED-Array Illumination Unit IMAG-MAX/L ................. 189

12.2.2 LED-Array Illumination Unit IMAG-MAX/LR .............. 190

12.2.3 Optional filter plate IMAG-MAX/F (only for IMAG-

MAX/L!) .......................................................................... 191

12.2.4 External 300 W Power Supply ......................................... 191

12.2.5 K7-MAX/Z ....................................................................... 191

12.2.6 K7-MAX/S ....................................................................... 192

12.2.7 K6-MAX .......................................................................... 192

12.2.8 K6-MAX/M and K7-MAX/M .......................................... 193

CONTENTS

VI

12.2.9 Mounting Stand with Eye Protection IMAG-MAX/GS ... 193

12.2.10 IMAG-MAX/B.............................................................. 194

12.2.11 ST-101........................................................................... 194

12.2.12 Transport Box IMAG-MAX/T ...................................... 194

12.2.13 IMAG-MAX/GWK1 ..................................................... 195

12.3 Components specifically relating to MINI-version .............. 195

12.3.1 IMAG-MIN/B .................................................................. 195

12.3.2 IMAG-MIN/R .................................................................. 196

12.3.3 IMAG-MIN/GFP ............................................................. 196

12.3.4 K7-MIN ............................................................................ 197

12.3.5 K6-MIN ............................................................................ 197

12.3.6 K6-MIN/FS ...................................................................... 197

12.3.7 K7-MIN/M and K6-MIN/M ............................................. 198

12.3.8 IMAG-S ........................................................................... 198

12.3.9 IMAG-MIN/ST ................................................................ 198

12.3.10 ST-1010......................................................................... 199

12.3.11 IMAG-MIN/BK ............................................................ 199

12.3.12 IMAG-MIN/GFS .......................................................... 199

12.4 Components specifically relating to MICROSCOPY-versions199

12.4.1 IMAG-AXIOSCOPE ....................................................... 199

12.4.2 IMAG-L470M .................................................................. 200

12.4.3 IMAG-L625M .................................................................. 200

12.4.4 IMAG-RGB ..................................................................... 200

12.4.5 IMAG-AX-REF ............................................................... 201

13 Warranty ................................................................................... 202

13.1

Conditions ............................................................................ 202

13.2 Instructions to obtain Warranty Service, .............................. 203

CHAPTER 1 SAFETY INSTRUCTIONS

1

1 Safety instructions

1.1 General safety instructions

1. Read the safety instructions and the operating instructions first.

2. Pay attention to all the safety warnings.

3. Keep the device away from water or high moisture areas.

4. Keep the device away from dust, sand and dirt.

5. Always ensure there is sufficient ventilation.

6. Do not put the device anywhere near sources of heat.

7. Connect the device only to the power source indicated in the

operating instructions or on the device.

8. Clean the device only according to the manufacturer’s

recommendations.

9. If the device is not in use, remove the mains plug from the

socket.

10. Ensure that no liquids or other foreign bodies can find their way

inside the device.

11. The device should only be repaired by qualified personnel.

CHAPTER 1 SAFETY INSTRUCTIONS

2

1.2 Special safety instructions

The IMAGING-PAM is a highly sensitive research instrument

which should be used only for research purposes, as specified in this

manual. Please follow the instructions of this manual in order to

avoid potential harm to the user and damage to the instrument.

Never use the Multi Control Unit IMAG-CG with more than one

Measuring Head plugged in at the same time.

The IMAGING-PAM employs strong blue light for excitation of

chlorophyll fluorescence, for driving photosynthetic electron

transport and for transient saturation of photosynthetic energy

conversion (Saturation Pulse method). In order to avoid harm to your

eyes, please avoid looking directly into this light, particularly during

Saturation Pulses.

CHAPTER 2 INTRODUCTION

3

2 Introduction

The IMAGING-PAM Chloroph

yll Fluorometer is specialized for the

study of two-dimensional heterogeneities of photosynthetic activity.

The Imaging-PAM M-series covers a wide range of applications.

Large scale samples with areas exceeding multiwell plate format can

be imaged as well as microscopically small samples at the level of

single cells. MAXI-, MINI- and MICROSCOPY-versions have been

issued that are operated with the same Multi Control Unit IMAG-

CG. Like all PAM fluorometers, the Imaging-PAM applies pulse-

amplitude-modulated measuring light for assessment of chlorophyll

fluorescence yield. The same LEDs not only serve for generation of

the pulse-modulated measuring light, but also for actinic illumination

driving photosynthesis and for Saturation Pulses transiently

saturating energy conversion at Photosystem II (PS II) reaction

centers. The Saturation Pulse method provides a non-destructive

means of analyzing the photosynthetic performance of plants. It

allows to assess the quantum yield of energy conversion at PS II

reaction centers, which is affected by numerous intrinsic and

environmental parameters, like the physiological health, light

conditions and various stress factors. Since the introduction of PAM

fluorometry in 1985, a large amount of literature has been published

on the practical use of this method in many fields of plant science. In

principle, with all IMAGING-PAM Fluorometers the same kind of

measurements are possible as with Standard-PAM Fluorometers (e.g.

Dual-PAM, PAM-2500 or MINI-PAMII), most users already may be

accustomed to. Hence, also with all versions of the IMAGING-PAM

M-series the characteristic fluorescence levels Fo, Fm and Fm' can

be assessed and quenching coefficients derived. Also the PS II

quantum yield Fv/Fm (or F/Fm') can be determined and Induction

Curves as well as Light Saturation Curves with quenching analysis

can be measured.

CHAPTER 2 INTRODUCTION

4

The most essen

tial new information provided by chlorophyll

fluorescence imaging relates to the detection of lateral

heterogeneities of fluorescence parameters which reflect

physiological heterogeneities. It has been known for some time, that

even physiologically healthy leaves are "patchy" with respect to

stomatal opening. Furthermore, stress induced limitations, which

eventually will lead to damage, are not evenly distributed over the

whole leaf area. Fluorescence imaging may serve as a convenient

tool for early detection of such stress induced damage. Hence,

favorite fields of application of fluorescence imaging are plant stress

physiology and plant pathology. An outstanding feature of the

Imaging-PAM distinguishing it from standard PAM fluorometers is

the possibility of parallel assessment of several samples under

identical conditions. For this applications the MAXI-version is

particularly well suited, e.g. for the screening of mutants in plant

molecular biology and for the assessment of samples in multi-well

plates, e.g. 96-well plates in ecotoxicological studies. The MINIversion is particularly compact and easy to handle and therefore best

suited for field applications. MINI- and MAXI-versions can also be

readily adapted for simultaneous measurements with the GFS-3000

Gas Exchange Measuring System. The MICROSCOPY-versions

provide the opportunity of imaging heterogeneities at the level of

single cells (e.g. guard-cells or algae cells). Using the RGB-Head it

is even possible to differentiate between different pigment types, like

diatoms, chlorophytes and cyanobacteria.

The MAXI- and MINI-versions not only measure fluorescence,

but also provides an estimate of incident light absorptivity. This

aspect is particularly important when dealing with lateral

heterogeneities of chlorophyll content often accompanying stress- or

pathogen-induced damage. For assessment of absorptivity of the

incident photosynthetically active radiation (PAR), the same sample

is irradiated with diffuse near-infrared (NIR) and red light, the

CHAPTER 2 INTRODUCTION

5

remitted parts of which are imaged with the same CCD-camera

which serves for fluorescence imaging.

As the different versions of the Imaging-PAM M-series are

optimized for largely different sample sizes, they apply quite

different LED sources. While the same methodology applies for all

versions, there are very different power requirements for appropriate

intensities of measuring, actinic and saturation pulse light. The

MAXI-IMAGING-PAM is equipped with an extremely powerful

array of 44 high power (3 W) Luxeon LEDs, each of which is driven

with currents up to 1.6 A. The same type of LEDs is also used in the

MINI-IMAGING-PAM (featuring 12 LEDs illuminating 24 x 32 mm

area) and various versions of the MICROSCOPY-IMAGING-PAM

(with a single LED coupled in various ways to the excitation port of

various types of Epifluorescence Microscopes). Therefore, the same

Power-and-Control Unit (IMAG-CG) can be used for these different

measuring heads.. The new IMAG-CG also features an output for

controlling a special RGB-LED-Lamp that is equipped with its own

LED drivers.

As the various versions of the Imaging-PAM M-series put

different demands on the sensitivity, different CCD-cameras are

employed. Two different CCD-cameras are available for the MAXIand MINI-version. For high sensitivity applications (e.g.

phytotoxicity bioassay using multiwell plate with algae suspensions)

a 2/3" CCD camera (1392x1040 pixel with 4-pixel-binning) is

recommended, which is also generally used with the

MICROSCOPY-versions. For standard applications an economical

1/2" CCD camera (640x480 pixel) is available, which is particularly

useful in conjunction with a powerful zoom objective.

This manual provides some essential information on the

components of the different versions of the Imaging-PAM M-series

CHAPTER 2 INTRODUCTION

6

and on the ImagingWin software. While the latter in principle applies

to all versions, it also offers some special features that can be used

with particular versions only (e.g. RGB-Fit images using the

MICROSCOPY/RGB-version). As it is most frequently used and

also featuring the widest range of applications/configurations, there

is some emphasis on the MAXI-version in this manual.

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

7

3 Components of the IMAGING-PAM MAXI-

version

In the following chapters the three different versions: th

e MAXI-,

MINI- and Microscopy-version of the Imaging-PAM M-series are

described. As the MAXI-version is most frequently used, those

components that are common to all versions are dealt with in this

chapter on the MAXI-version.

The basic measuring system of the MAXI-IMAGING-PAM consists

of:

1) Control Unit IMAG-CG with Battery Charger 2120-N and

External 300 W Power Supply

2) LED-Array Illumination Units IMAG-MAX/L (blue) or IMAGMAX/LR (red). A useful accessory for measurements with IMAGMAX/L investigating mirroring samples (like multiwell plates filled

with algae suspensions) is the Filter Plate IMAG-MAX/F, which

absorbs the small fraction of red light contained in the blue LED

light.

3) CCD Cameras IMAG-K7 or IMAG-K6 with accessories and

mounting sets

4) Mounting Stand with Eye Protection IMAG-MAX/GS,

laboratory stand ST-101 or Leaf Distance Holder IMAG-MAX/B

5) PC with ImagingWin-software

Combining imaging and gas exchange measurements, the adapter

IMAG-MAX/GWK for gas exchange chamber GWK1 is available.

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

8

Fig. 1: Transport Box IMAG MAX/T provided with each of the basic

Imaging systems offers enough space for all essential components

(except PC)

For transport of components 1 - 4, as well as of all essential

cables, the Transport Box IMAG-MAX/T is provided.

Note:

In the LED-Array Illumination Unit an

Adapter Ring may be inserted (not

screwed). To avoid damag

e to the

instrument, please do not take it out of the

box by using this hole as a handle.

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

9

3.1 Control Unit IMAG-CG

The Control Unit IMAG-CG contains a rechargeable Li-ion

battery (14.4 V/6 Ah). The main printed circuit board of the IMAGCG contains a RISC processor microcontroller, the power supply for

the CCD camera and the LED drivers for the Maxi-LED-Arrays. The

same LED drivers also serve for the alternative MINI- or

MICROSCOPY-Heads (MINI- and RGB-sockets at the backside of

the instrument). The Control Unit provides the power for driving the

LED-Arrays of all members of the M-Series systems except the

MAXI-IMAGING-PAM, which is driven by an external 300 W

Power Supply.

Note: Never switch on the Control Unit IMAG-CG with more

than one Measuring Head connected at the same time.

The functional elements at the front side of the instrument are:

POWER Power on/off switch; when switched on, the green

status LED at the right hand side of the switch

lights up.

Fig. 2: Front and rear side views of the Control Unit IMAG-CG

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

10

CHARGE-LED Ch

arge LED lights up red while battery is charging

with the help of the Battery Charger 2120-N. When

the battery is fully charged, the LED lights up

green.

CHARGE Socket for connecting Battery Charger 2120-N. An

external 12 V battery cannot recharge the internal

14.4 V Li-ion battery.

Note: Please avoid charging the internal Li-ion battery while the

IMAGING-PAM is switched on.

MAXI-HEAD Socket for connecting LED-Array Illumination Unit

IMAG-MAX/L (MAXI-Head).

CAMERA Socket for camera cable via which trigger signals

and power is transferred to the CCD-camera of the

MAXI-Head or MICROSCOPY-IMAGING-PAM.

At the rear side of the housing, the Control Unit features three

sockets, which apply for use of alternative Measuring-Heads:

MINI-HEAD Socket for connecting MINI- Heads as well as the

IMAG-L470M or IMAG-L625M LED lamps of

the MICROSCOPY-version

RGB-HEAD Socket for connecting the optional Red/Green/

Blue-Head of the MICROS-COPY-version

Ext. out Socket for connecting an optional external light

source

When using MINI-Head, the camera can directly be mounted on

the top of the Control Unit housing. For this purpose a wing-screw is

provided.

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

11

3.2 LED-Array Illumination Unit IMAG-MAX/L and IMAGMAX/LR

Fig. 3: Front view of IMAG MAX/L with objective lens of CCD-camera

protruding through central opening

The LED-Array Illumination Unit IMAG-MAX/L features 44

high-power royal-blue (450 nm) LED-lamps equipped with

collimating optics, which are arranged for maximal intensity and

homogeneity at 17 - 20 cm distance to the object plane. These LEDlamps provide the pulse-modulated blue excitation light and at the

same time serve for actinic illumination and Saturation Pulses. In

addition, there are 4 groups of 8 LEDs providing the pulse

modulated light for assessment of PAR-Absorptivity (see 9.1.1.10).

These LEDs are arranged in pairs, with each pair featuring a red

(660 nm) and a near-infrared (780 nm) LED. The lenses of these

LEDs are removed in order to obtain homogenous illumination of the

sample. While only a relatively small amount of this light is remitted

from the sample to the CCD-camera, this is sufficient to give good

signals, as both wavelengths can pass the red long-pass filter in front

of the CCD-chip, in contrast to the blue excitation light.

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

12

A useful accessory for measurements with mirroring samples

(like multiwell plates filled with algae suspensions) is the Filter Plate

IMAG-MAX/F that absorbs the small fraction of red light contained

in the blue LED light. This plate can be mounted with 4 screws at the

front side of the Illumination Unit. Unavoidably, the effective PARvalues are lowered by about 15% by the filtering.

Fig.

4: Mounting of IMAG-MAX/F. Four screws are provided with the

filter plate

The LED-Array Illumination Unit IMAG-MAX/LR has a

similar organization as IMAG-MAX/L but features 44 red (650 nm)

high-power LED-lamps and the four groups of red (660 nm) and a

near-infrared (780 nm) LEDs. The IMAG-MAX/LR includes the

filterplate IMAG-MAX/FR .

Both Illumination Units feature two cables, which connect to the

MAXI-HEAD socket at the front side of the Control Unit IMAG-CG

and to the external 300 W power supply.

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

13

Fi

g. 5: IMAG MAX/L in conjunction with IMAG MAX/GS and mounted

CCD camera IMAG MAX/K6

On the top side of the Illumination Units a fan is located that

serves for cooling the aluminum plate on which the slugs of the highpower LEDs are mounted. The adapter, on which the CCD-camera is

mounted, at the rear side features an adapter hole for installation of a

15 mm metal bar, which may serve for mounting the Measuring

Head independently of the Mounting Stand with Eye Protection

(IMAG-MAX/GS) (see Fig. 6). This bar is fixed with a hex-nut

screw, for which a corresponding key is provided. Please note that

the nut should press against the flattened side of the bar.

Fi

g. 6: Measuring Head consisting of LED-Array Illumination Unit and

CCD-camera mounted via 15 mm Ø metal bar on optional st

and

(St

and with Base Plat

e ST 101)

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

14

Warning:

When used without Mounting Stand and Eye protection,

the user should avoid looking directly into the LED-Array

Illumination unit.

The user is urgently advised to ensure an alternative eye

protection, which is effective in applications where the

standard IMAG-MAX/GS cannot be applied.

When mounted independently from the Mounting Stand with Eye

Protection (IMAG-MAX/GS, see 3.5), the working distance of the

LED-Array can be adjusted between 14.5 and 22.5 cm, resulting in

imaged areas between 7.5 x 10 and 11 x 15 cm. Optimal light field

homogeneity is obtained at the standard distance of 18.5 cm (imaged

area 9 x 12 cm), with +/- 7% maximal deviation of intensity from the

mean value.

A fixed standard distance of 18.5 cm is provided when the

IMAG-MAX/L is mounted on the IMAG-MAX/GS (see 3.5). As the

LED-intensity is defined by the ImagingWin software, the photon

flux density (PAR) at this standard distance is well defined. Small

variations in the PAR-distribution as well as the unavoidable

vignetting effect of the camera objective lens can be measured and

corrected for by software (see Image Correction in section 9.5.5).

Three different Image Corrections are supported by the ImagingWin

software for three different distances: Type 1, Type 2 and MAXI

(chapter 9.5.5).

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

15

Note:

In the LED-Array Illumination Unit

an Adapter Ring may be inserted,

(not screwed). To avoid damage to

the

instrument, please do not pull

the Imag-MAX/L out of the box

by using this hole as a handle.

3.3 CCD Camera IMAG-K6 and objective K6-MAX

Fig. 7: CCD Camera IMAG-K6

The CCD Camera IMAG-K6 (Allied Vision Technologies)

features a 2

/3" chip with 1392 x 1040 pixels. The data are

digitized within the camera and transferred via ethernet

interface (GigE-Vision®) to the PC. The sockets for connecting

the GigE-cable as well as the camera-control-cable (roundshaped connector) are located at the rear side of the camera.

As the CCD-chip features 1392 x 1040 pixels in contrast to the

resulting 640 x 480 pixels of the ImagingWin fluorescence

images, the signals of 4 pixels are combined (2x2 pixel binning)

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

16

thus p

roviding outstanding sensitivity. This feature is particularly

useful for reliable assessment of the "dark fluorescence" parameters

Fo, Fm and Fv/Fm.

Note:

The aperture of the IMAG-K6 standard lens can be closed. This

increases the depth of focus, but decreases the signal intensity. For

plane objects, the setting of the aperture should always completely

open.

The camera is equipped with a metal angle bar (black anodized),

which serves for mounting it on the corresponding adapter on the

IMAG-MAX/L Illumination Unit. Mounting the IMAG-K6 camera

for use in conjunction with MINI- or MICROSCOPY- Version are

described in the corresponding chapters. If the camera is shared

between different M-series instruments and setups, it might be

necessary to adapt camera objective and the distance ring between

objective and the CCD chip.

A Cosmicar-Pentax objective with 12.5 mm focal length (F=1.4)

is used in conjunction with the LED-Array Illumination Unit IMAGMAX/L or IMAG-MAX/LR (Fig. 8). A 3 mm RG 665 (Schott)

color glass filter serves as long-pass filter for protecting the CCDchip from blue excitation light, while passing the red fluorescence as

well as the 660 and 780 nm measuring beams for PAR-Absorptivity

(see 9.1.1.10 - 9.1.1.14). A short-pass filter ( < 790 nm), mounted in

a threaded metal ring, protects the CCD-detector against excess nearinfrared radiation contained in ambient daylight. For the optical

properties of the camera it is essential that this filter as well as the

RG 665 are placed between CCD-chip and objective lens (increase of

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

17

effective focal length by plane-parallel glass plates). For other Mseries instruments like the MICROSCOPY-Version and the GFP

MINI-Version this filter has to be removed before mounting the

camera.

3.4 CCD Camera IMAG-K7 and objectives K7-MAX/Z and K7-

MAX/S

Also the CCD Camera IMAG-K7

(Allied Vision Technologies) can be

used, which features a 1/2" chip with

640 x 480 pixel resolution. The data are

digitized within the camera and

transferred via ethernet interface (GigEVision

®

) to the PC. Analog to the IMAG-

K6 camera the sockets for connecting the

ethernet cable and the camera-power-supply cable (round-shaped

connector) are located at the rear side of the camera.

The camera can be equipped either with a standard objective

lens featuring 12 mm focal length (F=1.2 / f=12mm - K7-MAX/S) or

Fig. 8: Cosmicar-Pentax objective 12.5 mm focal length, short pass filter and

mounting device (left), distance ring (middle)

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

18

a Zoom objective lens with 8 – 48 mm focal length (F=1.0 -

K7-MAX/Z Fig. 10). Different mounting angles The adapter ring in

the LED-Array Illumination Unit (IMAG-MAX/L) has to be

detached for using the Zoom objective.

Fig. 9: Adapter Ring of the LED-Array Illumination Unit

A

3 mm RG 645 (Schott) color glass filter serves as long-pass filter

for protecting the CCD-chip from blue excitation light, while passing

the red fluorescence as well as the 660 and 780 nm measuring beams

for PAR-Absorptivity (see 9.1.1.10). A short-pass filter ( < 770 nm),

mounted in a threaded metal ring, protects the CCD-detector against

excess near-infrared radiation contained in ambient daylight. For the

optical properties of the camera it is essential that this filter as well as

the RG 645 is placed between CCD-chip and objective lens (increase

of effective focal length by plane-parallel glass plates).

Using the IMAG-K7 camera fluorescence image intensity is

about 50 % of that obtained with the IMAG-K6 camera. While on

one hand it does not allow 4-pixel binning, on the other hand the

applied objective lenses display a higher aperture. Please note that

with the Zoom objective the aperture and consequently image

intensity drop at focal lengths exceeding 30 mm. When properly

adjusted (by provided distance ring and close-up lens) the image

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

19

remains focused when changing focal length (magnification). Minor

adjustment by the focusing ring may be required.

Fig. 10: CCD Camera with Zoom objective

3.5 Mounting Stand with Eye Protection IMAG-MAX/GS

The Mounting Stand IMAG-MAX/GS provides the standard

means for mounting the powerful LED-Array Illumination Unit at

defined distance to the object, assuring full eye protection of the user.

It features a red perspex hood that absorbs the strong blue light

emitted from the LED-array and at the same time allows to view the

red chlorophyll fluorescence of the sample with bare eyes. The

Measuring Head, consisting of the LED-Array Illumination Unit and

the CCD-camera, is mounted with the help of two clamps on the top

of the Mounting Stand IMAG-MAX/GS.

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

20

Fi

g. 11 IMAG-MAX/GS with mounted LED-Array Illumination Unit

IMAG-MAX/L and CCD-Camera

Using this Mounting Stand, the Illumination Unit and the CCDcamera are coupled with each other at a fixed working distance of

18.5 cm between LED-Array and object plane, resulting in

homogenous illumination of an imaged area of 10 x 13 cm. A defined

working distance is important for proper Image Correction (see

9.5.5), which corrects for unavoidable inhomogeneities in measuring

light intensity and camera sensitivity over the imaged area. In

principal, it is also possible to vary the working distance, when the

LED-Array Illumination Unit is mounted independently from the

IMAG-MAX/GS (see Fig. 6). In this case, however, the homogeneity

of the light field may be suboptimal and the user has to take care

about protecting the eyes against excessive light, particularly during

saturation pulses.

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

21

Fi

g. 12: IMAG MAX/GS with lifted red-perspex hood showing leaf sample

resting on x-y stage

In standard applications, the sample is resting on an x-y stage

covered with non-fluorescent and non-reflecting black foam-rubber.

The sample compartment becomes accessible after sliding the red

perspex hood upwards, using two flat hands gently pressing against

the two sides. In its fully lifted position the hood is held by two

magnets.

The x-y stage allows to move the sample by maximally 25 and

19 mm in x- and y-directions, respectively. The force stabilizing its

position on the bottom of the Mounting Stand is increased by

magnets mounted at its reverse side.

Note: During transportation or shipping the x-y stage plate has

to be removed from the sample compartment of the

IMAG-MAX/GS and packed separately within the

Transport Box IMAG-MAX/T to avoid damages.

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

22

Fig. 13: Bottom part of IMAG MAX/GS with black 96-well microtiter plate

in defined centered sample position

After removing the x-y stage plate, alternatively a multiwell plate

can be placed into the sample plane. A correctly centered position is

defined by two positioning elements (horizontal perspex bar and

metal screw defining right limit). It is recommended to use black

non-fluorescent multiwell plates (e.g. Sigma-Aldrich article no.

M9685). At high sensitivity measurements (high ML intensity, high

Gain), in this application a mirror image of the LED-lamps may be

superimposed on the fluorescence image of the samples contained in

the wells. This phenomenon is due to the fact the blue LEDs emit

some red light, which can be mirrored from the multiwell plate

and/or the water surface of suspension samples via the camera

objective lens onto the CCD chip. If this causes a problem, the red

emission can be removed with the help of the optional Filter Plate

IMAG-MAX/F, which can be mounted in front of the LED-Array

Illumination Unit. Now also clear multiwell plates can be used.

Fluorescence imaging of algae suspensions in 96-well plates can

serve as a powerful tool in ecotoxicology and plant molecular

biology (e.g. screening for mutants).

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

23

Fi

g. 14: IMAG MAX/GS, with bottom part being removed, resting on two

spacers to give room for potted plant

Alternatively, it is also possible to remove the bottom part of the

IMAG-MAX/GS for fluorescence imaging of larger samples, like

potted plants. The Mounting Stand can be readily jacked up with the

help of four profile-metal legs with mounting-angles, which can be

screwed to the bottom corners of the Mounting Stand (see Fig. 14).

For this purpose, with the Mounting Stand being turned upside

down, the four nuts first have to be put into the grooves at the bottom

corners. Standard legs with 20 cm length (including mounting screws

and nuts) are delivered with the instrument. With the thus increased

distance to the bottom, the use of a Screw Jack is advantageous,

which allows to move a sample (e.g. potted plant) up/down for

focusing the image at the standard working distance of 18.5 cm. In

this case, the focus of the objective lens should be set for 18.5 cm

working distance (between front of LED-Array and sample) and then

remain unchanged.

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

24

3.6 Leaf Distance Holder IMAG-MAX/B

Fig. 15: Leaf Distance Holder IMAG-MAX/B with IMAG-MAX/L and

IMAG-K6

Using the Leaf Distance Holder IMAG-MAX/B the illumination unit

with CCD-camera are mounted at standard working distance of 18.5,

resulting in homogenous illumination of an imaged area of

10 x 13 cm of the x-y stage plate.

The assembly of this light weight device is simple. The four black

legs are screwed to the provided screw holes in the bottom corner of

the LED array as well as to the base containing the x-y stage plate.

For convenient sample preparation the x-y stage plate can be taken

off the base by unscrewing the knurled head screws.

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

25

Warning:

IMAG-MAX/B does not provide eye protection! The user

should avoid looking directly into the LED-Array

Illumination unit.

3.7 Notebook PC IMAG-PC

Operation of the IMAGING-PAM requires a PC with the

following minimum requirements:

• Processor: 1

.7 GHz

• RAM: 4 GB

• built-in USB interface

• built-in ethernet interface for GigE-Vision

®

• built-in DVD/CD-RW drive

• operating system: Vista, Windows 7 32- or 64-Bit, Windows 8

As operation in conjun

ction with the IMAGINGPAM requires significant CPU usage, an effective ventilating

system is required for cooling the CPU.

The Notebook PC IMAG-PC is delivered with fully installed

software. Depending on the market situation, best value brand-name

devices are chosen which have proven well suited for use in

conjunction with the IMAGING-PAM.

If the instrument has been purchased without PC, the user first

has to install the software (see chapter 6.2)

CHAPTER 3 COMPONENTS OF THE MAXI-VERSION

26

3.8 Adapter IMAG-MAX/GWK

The combined application of IMAGING-PAM and gas exchange

measurements by GFS-3000 provides comprehensive analysis

options. For examples physiological heterongeneities or differences

in genotypes can be visualized in fluorescence images under

changing CO

2

, O2 or temperature conditions applied by the gas

exchange system. The adapter IMAG-MAX/GWK positions the

MAXI-IMAGING PAM on top of the GWK1 providing eye

protection during the merge of imaging and gas exchange analysis

over a measuring area of 10 x 13 cm.

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

27

4 Components of the IMAGING-PAM MINI-

version

The MINI-version of the IMAGING-PAM consists of:

1)

Control Unit IMAG-CG with Battery Char

ger 2120-N

2) MINI-Head (blue) IMAG-MIN/B or

MINI-Head (red) IMAG-MIN/R or

MINI-Head (GFP) IMAG-MIN/GFP

3)

CCD Cameras IMAG-K7 or IMAG-K6 with cam

era objectives

K7- or K6-MIN and mounting sets K7- or K6-MIN/M and K6MIN/FS for use with IMAG-MIN/GFP

4)

PC with ImagingW

in-software

A

useful accessory for leaf measurements is the Leaf Holder IMAGMIN/BK. For simultaneous measurements of gas exchange with the

GFS-3000 the Adapter IMAG-MIN/GFS is available. Also available

for convenient use is a laboratory stands as well as a tripod and a fine

drive tripod adapter for outdoor applications.

4.1 Multi Control Unit IMAG-CG

The same Multi Control Unit IMAG-CG is used for all versions of

the IMAGING-PAM M-series. It was already described in section

3.1.1. in conjunction with the MAXI-version. The LED-Array of the

MINI-Head is plugged into to the MINI-Head connector on the rear

side of the IMAG-CG unit. The Camera cable connector is located

on the front side of IMAG-CG.

The MINI-Head with mounted camera can directly be attached on

top of the Control Unit housing IMAG-CG. For this purpose a wing-

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

28

screw is provided. Alternatively it can be also mounted on a tripod or

be held by hand using a special grip (see 4.5).

4.2 MINI-Head LED-Array IMAG-MIN/B and IMAG-MIN/R

Fig. 4.1 Top view of MINI-Head IMAG-MIN/B LED-array without

alumin

ium rods holding the sample-platform

The blue and red versions of the MINI-Head (IMAG-MIN/B and

IMAG-MIN/R) are identical except for the color of the LEDs and the

LED-filters. As blue and red LEDs display different intensity-current

relationships, different PAR-lists apply, that are incorporated in two

different versions of the ImagingWin program (see chapter 10).

The LED-array of the MINI-Head features 12 high-power LED-

lamps each equipped with collimating optics, which are arranged in 4

groups of 3 LEDs. Each group is equipped with a short-pass filter

eliminating red light that otherwise would pass the long-pass filter in

front of the CCD-camera and overlap with chlorophyll fluorescence.

In the blue version (IMAG-MIN/B emission peak 460 nm) a bluegreen glass filter (Schott BG39) is used. In the red version (IMAG-

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

29

MIN/R emission peak 620 nm) a special short-pass interference filter

(< 645 nm) is used. The LEDs are mounted at an angle that is

optimized for obtaining a homogenous light field at the given

working distance. These LEDs provide the pulse-modulated

excitation light and at the same time serve for actinic illumination

and Saturation Pulses. In addition, there are four groups of LEDs

(2x6 and 2x4) providing the pulse modulated light for assessment of

PAR-Absorptivity (see 5.4.1.10 - 9.1.1.14). These LEDs are arranged

in pairs, with each pair featuring a red (660 nm) and a near-infrared

(780 nm) LED. The lenses of these LEDs are removed in order to

obtain homogenous illumination of the sample. While only a

relatively small amount of this light is remitted from the sample to

the CCD-camera, this is sufficient to give good signals, as both

wavelengths can pass the red long-pass filter in front of the CCDchip, in contrast to the filtered excitation light.

The LED-array cable connects to the MINI-HEAD socket at the

rear side of the IMAG-CG Control Unit.

Warning: Please avoid looking directly into the LED-

Array Illumination unit to prevent

Eye-damage!

The MINI-Head is designed for a fixed working distance

between camera and sample (7 cm), which is defined by

four aluminium rods with a sample-platform on top of the LEDArray. At the standard working distance, using the 16 mm lens, a

24 x 32 mm area is imaged.

All MINI-Head LED-Arrays can be extended with a Leaf Clip

and a Grip Holder (see chapter 4.5).

The MINI-Head LED-Array IMAG-MIN/GFP is described in

chapter 4.4.

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

30

4.

3 CCD Camera IMAG-K6 or IMAG-K7

The CCD Cameras IMAG-K6 or IMAG-K7 are described in

chapter 3.4 for the imaging MAXI-version. Both can also be used in

the imaging MINI-version in combination with IMAG-MIN/B and

IMAG-MIN/R. In combination with IMAG-MIN/GFP only IMAGK6 can be used (see chapter 4.4)

For usage in the Imaging MINI-version these CCD cameras need to

be equipped with the objective K6-MIN for IMAG-K6 (F1.4/f = 25

mm) and an 7.2 mm distance ring or K7-MIN for IMAG-K7 (F1.4/f

= 16 mm) with an 4.2 mm distance ring. For both configurations a

3 mm RG 645 (Schott) color glass filter serves as long-pass filter for

protecting the CCD-chip from blue excitation light, while passing the

red fluorescence as well as the 660 and 780 nm measuring beams for

PAR-Absorptivity (see 9.1.1.10). A short-pass filter (λ < 770 nm),

mounted in a threaded metal ring, protects the CCD-detector against

excess near-infrared radiation contained in ambient daylight. For the

optical properties of the camera it is essential that this filter as well as

the RG 645 is placed between CCD-chip and objective lens (increase

of effective focal length by plane-parallel glass plates).

Please adjust the objective aperture! Closing the aperture

increases focal depth and decreases light delivery to the

camera (to avoid signal saturation).

The cameras are mounted to the metal holder preinstalled on top

of the MINI-Head LED-Array. The camera side with four screw

holes and the label points to the same direction as the label of the

LED-Array, the camera side with seven screw holes points to the

same direction as the backside of the LED-Array, where the cables

are located and the metal angle bar of the mounting set is mounted.

Fig. 17 displays the mounting positions and required screws for

mounting the camera and the metal angle bar.

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

31

Fig. 16: Camera side with 4 screw holes and label (left) - facing the labelled

LED-Array side, camera side with 7 screw holes (right) facing the

LED-Array backside and the metal angle bar (Fig. 17 A)

Fig. 17: Screw indication and camera mounting positions, metal angle bar

i

ncluding grip of Leaf Holder IMAG-MIN/BK, screw annotation

The metal angle bar of the mounting set K6 and K7-MIN/M (Fig.

17 A) serves for mounting the MINI-Head with camera onto the

IMAG-CG Control Unit, to the grip of the Leaf Holder IMAGMIN/BK or to a tripod. Furthermore the mounting set K6 and K7-

IMAG-K7 with K7-MIN

1 2 3 4 5

1+3

1+2+A

5

5

4+A

IMAG-K6 with K6-MIN

IMAG-K6 GFP/PS II

5

4+A

A

IMAG-K7 with K7-MIN

1 2 3 4 5

1+3

1+2+A

5

5

4+A

IMAG-K6 with K6-MIN

IMAG-K6 GFP/PS II

5

4+A

AA

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

32

MIN/M contains a perspex device to unplug the GigE cable from a

mounted CCD camera (see Fig. 18)

Fig. 18: Perspex device to unplug GigE cable from a mounted camera

4.4 IMAG-MIN/GFP with IMAG-K6

For GFP measurements using the MINI-version the IMAGMIN/GFP LED array is needed in combination with the filter slide

IMAG-K6/FS, the 2/3" CCD camera IMAG-K6, the K6-MIN

objective and the K6-MIN/M montage set.

As the LED-array of the other MINI-Heads IMAG-MIN/GFP

features 12 high-power LEDs (emission peak 470 nm) arranged in 4

groups of 3 LEDs and equipped with a short-pass filter (< 500 nm).

These LEDs provide the pulse-modulated GFP excitation light and at

the same time serve for actinic illumination and Saturation Pulses. In

addition, there are four groups of LEDs featuring red (660 nm) and a

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

33

near-infrared (780 nm) LED pairs providing the pulse modulated

light for assessment of PAR-Absorptivity (see 5.4.1.10 - 9.1.1.14).

The LED-array cable connects to the MINI-HEAD socket at the

rear side of the IMAG-CG Control Unit.

The detector filter slide K6-MIN/FS is mounted in front of the 25

mm camera objective K6-MIN as shown in Fig. 19 .

Fig. 19: Standard lens for IMAG-MIN/GFP (focus ring = f, aperture = a),

filter slider in GFP position

Before mounting the objective with filter slide to the IMAG-K6 CCD

camera a 5 mm distance ring needs to be mounted and if IMAG-K6

has been used in another IMAGING-PAM configuration additional

short pass filters (e.g. Fig. 8 left) between camera and objective as

well as other distance rings need to be removed. Afterwards the

IMAG-K6 CCD camera with distance ring, objective and filter slide

is attached to the IMAG-MIN/GFP head using the topmost position

of the metal holder (see Fig. 17).

For special applications it is also possible to use a lens with a wider

angle (16 mm). In this case the camera has to be mounted in one of

the two lower positions (not shown) with the filter slider mounted on

the camera lens subsequently.

With the help of this filter slider the detection filter in front of the

25 mm lens can be exchanged from PSII measurement to GFP

measurement and vice versa.

f

a

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

34

Fig. 20: switching of the filter slider between two positions (A – PSII, C-

GFP position)

The view into the GFP Mini-Head from the sample side (Fig. 20)

explains the two positions of the filter slider.

The filter slider carries two detection filters. The dark red one

(RG665) enables the camera to detect PSII-fluorescence and a

special interference filter for the detection of wavelengths between

500 and 600 nm is used for GFP detection.

A B C

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

35

The filter slider can be pushed from left to right (Fig. 20 A to C), to

change the detection filter from PSII-fluorescence to GFP. For

lowering background effects, the GFP Head is shipped with a sample

of a low fluorescent black adhesive film which can be used as a

background layer.

A

B

Fig. 21: possible color modes for the GFP images

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

36

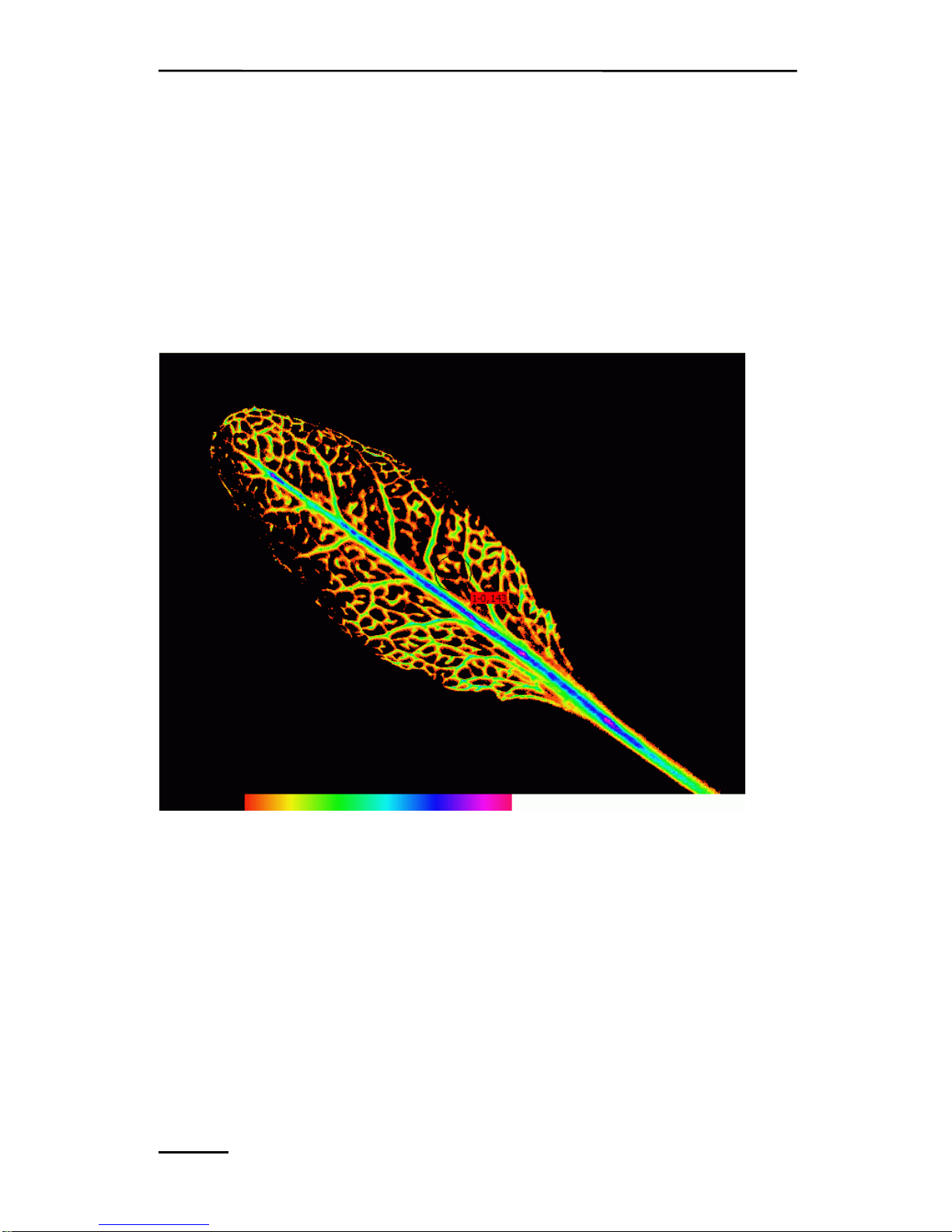

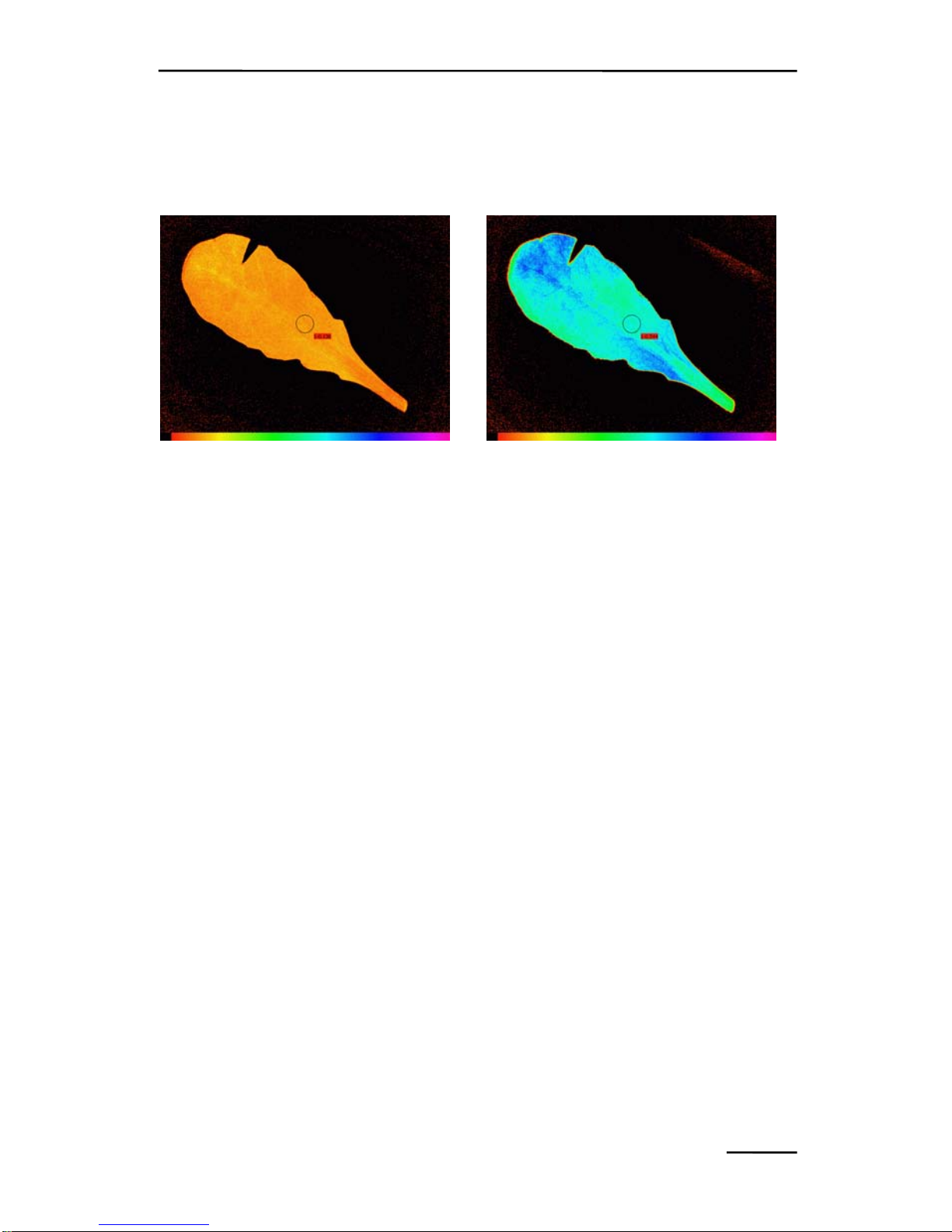

There are different color modes reasonable for the GFP

measurements. Fig. 21 A shows an image in the false color scale

mode of the “Analysis” function (see also chapter 9.1.2.6). Another

option is the black and white mode as in Fig. 21 B. The Description

of the Display Parameters can be found under chapter 9.5.8 (display

parameters) of the manual. Pictures can be exported via the export

function described in chapter 8.2.

Fig. 22: Expanded Color for enhancing GFP images

This example picture (Arabidopsis thaliana with promSUC2 GFP)

has been measured with the following settings:

-

Filter slider in the GFP position

- MF 8, ML

max, Damp

ing 4, Gain on 8

In contrast to the PSII fluorescence, for GFP

measurement some

settings must be very high. For this reason long exposure to these

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

37

settings may lead to the bleaching of the sample. Using the

„Analysis“ sliders, the inevitable background can be suppressed.

Since the camera used for the combined GFP-Head is highly sensitive, settings have to be changed between GFP and PSII measurement:

- PSII fluorescence – ML=1, Gain=2, Damp

=1

The basic im

age fluorescence now should have a value of nearly

0.15, to prevent overflow during the saturating flash. If still overflow

appears, please also use the aperture of the camera lens to lower the

fluorescence signal. (The benefit of doing this is that the depth of

focus is increased which may help to get also bent leaves in focus

without cutting.)

For Absorptivity measurements in the PSII mode no starting values

for red and NIR can be given because these values depend on the

aperture of the used lens. For details read more under chapter 5.8.3

and 5.4.2.1 of this manual.

As for the other MINI-head LED arrays the metal angle bar of

the mounting set K6-MIN/M serves for mounting the MINI-Head

with camera onto the IMAG-CG Control Unit, to the Leaf Holder

IMAG-MIN/BK or to a tripod and can be extended with a Leaf Clip

and a Grip Holder.

A

B

Fig. 23: Fo image in the PSII mode (A) vs. Fm image (B)

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

38

4.5 Leaf Holder IMAG-MIN/BK with Grip Holder

Fig. 24:

MINI-Head with CCD camera and grip holder

When the Leaf Holder is delivered together with the MINIversion of the Imaging-PAM, it is already mounted on the MINIHead. A grip holder is provided, which can be fixed to the metal

angle on the camera. Using this grip the MINI-Head can be carried

with one hand and the lever of the leaf clip can be moved up with the

same hand (see Fig. 25).

Fig. 25: Mini-Head with grip holder used in field

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

39

This is particularly useful in field applications. The MINI-Head

may either be carried separately or together with the IMAG-CG, on

which it may be mounted with the help of a wing screw.

Alternatively the Mini-Head may also be mounted on a tripod using

the same metal angle to which the carrying grip can be connected

(see Fig. 26).

Fig. 26: Mini-Head with Leaf Holder mounted on a tripod

When the Leaf Holder is ordered separately from the MINIHead, it has to be assembled by the user. Fig. 27 shows the

components of the Leaf Holder. The following figures (Fig. 28 - Fig.

30) m

ay help to put the various parts together

.

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

40

Fig. 27: Components of the Leaf Holder

First the frame (1) is mounted with two screws (2) on the sample

platform of the MINI-Head. Then the clip (3) is fixed with two

screws (4) to the sample platform. While Fig. 28 shows the mounted

clip from the bottom (camera) side, Fig. 29 shows it from the top

side. On the perspex top side of clip the nylon screw (5) is fixed

which holds the two O-rings (6) which function as a spring forcing

together the two parts of the clip (see Fig. 28 and Fig. 29). The Orings may age and then have to be replaced. For this purpose the

spare O-rings (7) are provided. The grip (8) is fixed with the two

screws (9) via a metal angle to the camera, as shown inFig. 30.

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

41

Fig. 28: Leaf clip mounted on sample platform of MINI-Head viewed from

camera side

Fig. 29: Leaf clip mounted on sample platform of MINI-Head viewed from

top side

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

42

Fig. 30: Leaf clip and grip holder mounted on MINI-Head

4.6 Adapter for GFS-3000 (IMAG-MIN/GFS)

The MINI-version of the IMAGING-PAM M-series can be

applied for simultaneous measurements of CO

2

gas exchange and

chlorophyll fluorescence. For this purpose the adapter IMAGMIN/GFS is available which replaces the sample-platform of the

standard version. The adapter features a frame with two ball-pins that

allow to click the MINI-Head onto the Measuring Head of the GFS-

3000. The distance rods carrying this frame are 11 mm shorter than

in the standard version in order to assure identical working distance

from the camera to the leaf sample within the gas exchange cuvette.

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

43

Fig. 31: MINI-Head mounted on Standard Measuring Head of the GFS-

3000 Gas Exchange Fluorescence System

When the MINI-Head is used in combination with the gas exchange

measuring system, it is controlled by the combined ImagingWin and

GFSWin programs running synchronously on the same PC. The

synchronous operation allows an accurate time assignment of gas

exchange and fluorescence data in a common Report file. While the

actinic illumination for driving photosynthetic electron transport is

provided by the LED-array of the MINI-Head, the switching on/off

of actinic light is controlled via the GFSWin software. Further

peculiarities that are important for the combined operation of MINIHead and GFS-3000 under GFWin and ImagingWin are described in

a separate brochure.

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

44

4.7 ImagingWin software versions for various types of MINI-

Version

Upon start of the ImagingWin program the user may choose between

different software versions for the various types of MINI-Heads.

While these versions are practically identical, they feature different

PAR-Lists (found under „Options“ in the software or chapter 10 in

the manual).

Particular Image Corrections (found under „Settings“ or 9.5.5)

apply to different MINI-Heads.

Note:

When the program is started for the first time after installation of the

software, it comes up with a warning that the file for Image

Correction is not found. It is recommended that the user determines

the Image Correction for his particular MINI-Head before starting

serious measurements (see chapter 9.5.5).

With every Measuring Head of the three different correction images

can be stored: Type 1, Type 2 and Maxi or Mini or IMAG L450

and RGB.

For measuring Image Correction please proceed as follows:

• set the optical conditions under which the actual measurements

are going to be done (working distance, focusing position, see above)

• select Type 1, Type 2 or Maxi/Mini/Micro/IMAG L450/RGB

(under Settings/Image Correction)

• in the case of MAXI- and MINI- versions place at least two

layers of white paper (e.g. folded DIN-A4) into sample plane; in the

case of the MICROSCOPY-version the plastic fluorescence standard

• put the image somewhat out of focus to avoid imaging fine

structures of the white paper tissue or dust etc. on the surface of the

fluorescence standard

• press the measure button (under Settings/Image Correction)

CHAPTER 4 COMPONENTS OF THE MINI-VERSION

45

The measured correction image will be saved until it is

overwritten by a new measurement. The correction images will

remain valid as long as the same optical parameters apply (LED

Illumination Unit, working distance, focusing position, camera

objective lens, microscope objective lens).

CHAPTER 5 COMPONENTS OF THE MICROSCOPY-VERSION

46

5 Components of the IMAGING-PAM

MICROSCOPY-version

The MICROSCOPY-version of the IMAGING-PAM consists of:

1)

Control Unit IMAG-CG with Battery Char

ger 2120-N

2)

CCD Came

ra IMAG-K6 (2/3")

3)

Modified Zeiss

Axio ScopeA.1

4) LED Modules as:

Microscopy LED Lamp

(blue) IMAG-L470M or

Microscopy LED Lamp

(red-orange) IMAG-L625M or

Microscopy LED Lamp (UV-

A) IMAG-L365M or

Red-Green-Blue Microscopy LED Lamp

IMAG-RGB

5)

PC with ImagingW

in-software

Operation of the MICROSCOPY-IMAGING-PA

M requires an

epifluorescence m

icroscope. For this purpose relatively simple

microscopes with short excitation pathways are suited. Most

essential components for optimal image qualities are high aperture

objectives and a suitable video adapter. While the IMAG-K6 camera

features a 2/3" CCD chip, it is recommended to use a 0.5x video

adapter for 1/2" chips, in order to obtain a more intense fluorescence

image.

The Zeiss Axio Scope.A1 microscope may be particularly

recommended for use in conjunction with the MICROSCOPYversion.

The features of these components will be described briefly in the

following subsections.

CHAPTER 5 COMPONENTS OF THE MICROSCOPY-VERSION

47

5.1 Multi Control Unit IMAG-CG

The same Multi Control Unit IMAG-CG is used for all versions

of the IMAGING-PAM M-series. It was already described in section

3.1 in conjunction with the MAXI-version. The cable of the

MICROSCOPY LED Lamps IMAG-L470M or IMAG-L625M is

connected to the MINI-Head socket at the rear side of the control

unit. The cable of the Red-Green-Blue Microscopy LED Lamp

IMAG-RGB is connected to the RGB-Head socket at the rear side of

the control unit. The rear side also features a CAMERA-socket to

which the Camera cable has to be connected. This cable is used to for

trigger signal and to power the IMAG-K6 camera.

5.2 CCD Camera IMAG-K6

The CCD Camera IMAG-K6 as described in chapter 3.3 features

a 2/3" chip with 1392 x 1040 pixels and 4-pixel-binning, resulting in

fourfold image intensity for the 640 x 480 pixel displayed on the

monitor screen.

If the IMAG-K6 has been used in another IMAGING-M

application. Please take off the objective, filters and the distance

ring. The IMAG-K6 camera can now be connected on top of the

phototube of the Axio Scope.A1 via video adapter. 0.5x adapter for

1/2" CCD cameras (Zeiss; 416112-0000-000, Fig. 32).

CHAPTER 5 COMPONENTS OF THE MICROSCOPY-VERSION

48

Fig. 33: Zeiss camera adapter mounted on Axio Scope.A1

The camera IMAG-K6 (not shown) can be screwed onto the Cmount adapter shown in Fig. 33. Afterwards the camera needs to be

connected to the camera port of the IMAG-CG multi control unit as

well as to the computer via Gigabit Ethernet.

Fig. 32: Camera adapter for connecting Axio Scope.A1 with IMAG K6

CHAPTER 5 COMPONENTS OF THE MICROSCOPY-VERSION

49

The user should get familiar with the

switch which allows switching between

binocular or phototube / photomultiplier pathways (see Fig. 34).

Furthermore the halogen transmitted

light lamp should be switched off

during epifluorescence measurements to

avoid actinic illumination of the sample.

5.3 Axio ScopeA.1 Epifluorescence Microscope

Fig. 35: MICROSCOPY-IMAGING-PAM based on Zeiss ScopeA.1

Epifluorescence Microscope

Fig. 34: Pathway switch

CHAPTER 5 COMPONENTS OF THE MICROSCOPY-VERSION

50

The MICROSCOPY-IMAGING-PAM is readily adapted to the

Zeiss Axio ScopeA.1 microscope giving excellent fluorescence

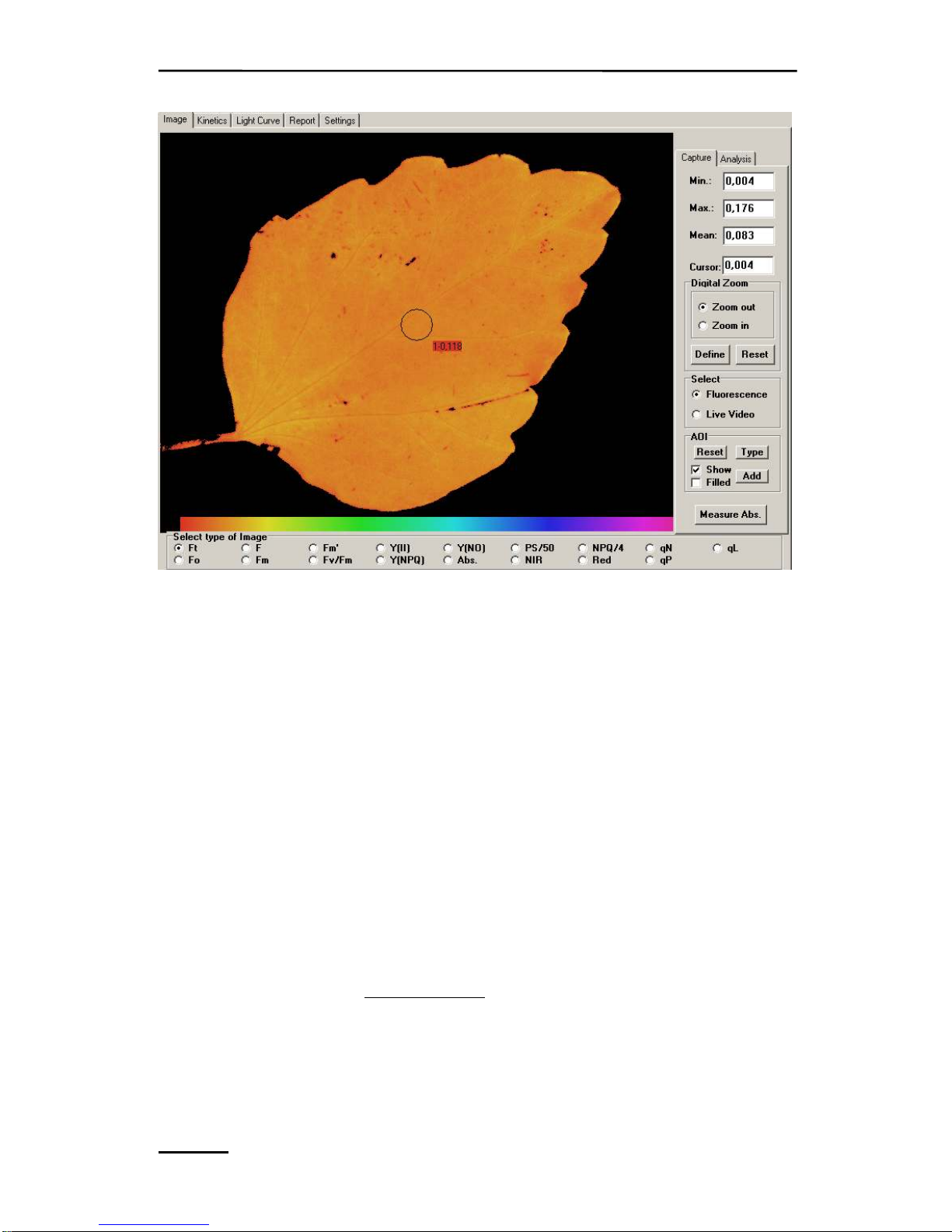

images. If a complete IMAGING-PAM MICROSCOPY Version has

been purchased, some parts are already mounted to make the first

setup a bit easier. For safe shipping purposes some components had

to be detached.

Existing Zeiss Axio ScopeA.1 microscopes can be adjusted to the

MICROSCOPY-IMAGING-PAM on request.

Please note that openings in the microscope parts are sealed by

stickers or caps that have to be removed before mounting the parts

The Axio Scope.A1 has a special port that can carry up to four

LED modules which are available in ten different wavelengths

starting with 380 nm up to 625 nm. For the standard PAM

application we are recommending the 625 nm red LED module or the

470 nm blue light version (not suitable for the measurement of

cyanobacteria). More Information on the Zeiss LED modules can be

found in chapter 3.4.9 of the Axio Scope.A1 manual or in the internet

on www.Zeiss.de. The LED modules offer very homogeneous

illumination of the measured area and are modified for PAM

applications with additional filters by Walz.

When other wavelengths, than the recommended ones, shall be

applied for special measurements, please contact Walz for

recommendations on appropriate filter combinations.

Important parts required for optimal performance are the microscope

objective lenses. High aperture lenses like the Zeiss Fluar 10x/0.5,

Fluar 20x/0.75 and Fluar 40x/1.30 Oil are recommended. In this

context, it has to be considered that a high aperture enhances image

CHAPTER 5 COMPONENTS OF THE MICROSCOPY-VERSION

51

intensity two-fold by increasing excitation intensity as well as

fluorescence collection. The image intensity with a Zeiss Fluar

20x/0.75, for example, is 6.6 times higher than with a Zeiss Apoplan

20x/0.45. In view of the fact that image intensity is the limiting

factor in MICROSCOPY-PAM applications, an investment in high

aperture lenses should have high priority.

5.3.1 Reflector Modules

In complete IMAGING-PAM MICROSCOPY instruments

necessary filters of the reflector modules are already mounted.

In case the reflector module is purchased as a separate part, please

follow the instructions below. The correct orientation of the beam

splitter filter is essential for the correct functioning of the

IMAGING-PAM system.

It is required to mount the reflector modules into the turret of the

Zeiss Axio Scope.A1 as described in chapter 5.3.3. When using more

than one LED module, please note that each LED module needs its

own reflector module (chapter 3.1.6 Fig 3-9 and 3.4.6 Zeiss manual).

CHAPTER 5 COMPONENTS OF THE MICROSCOPY-VERSION

52

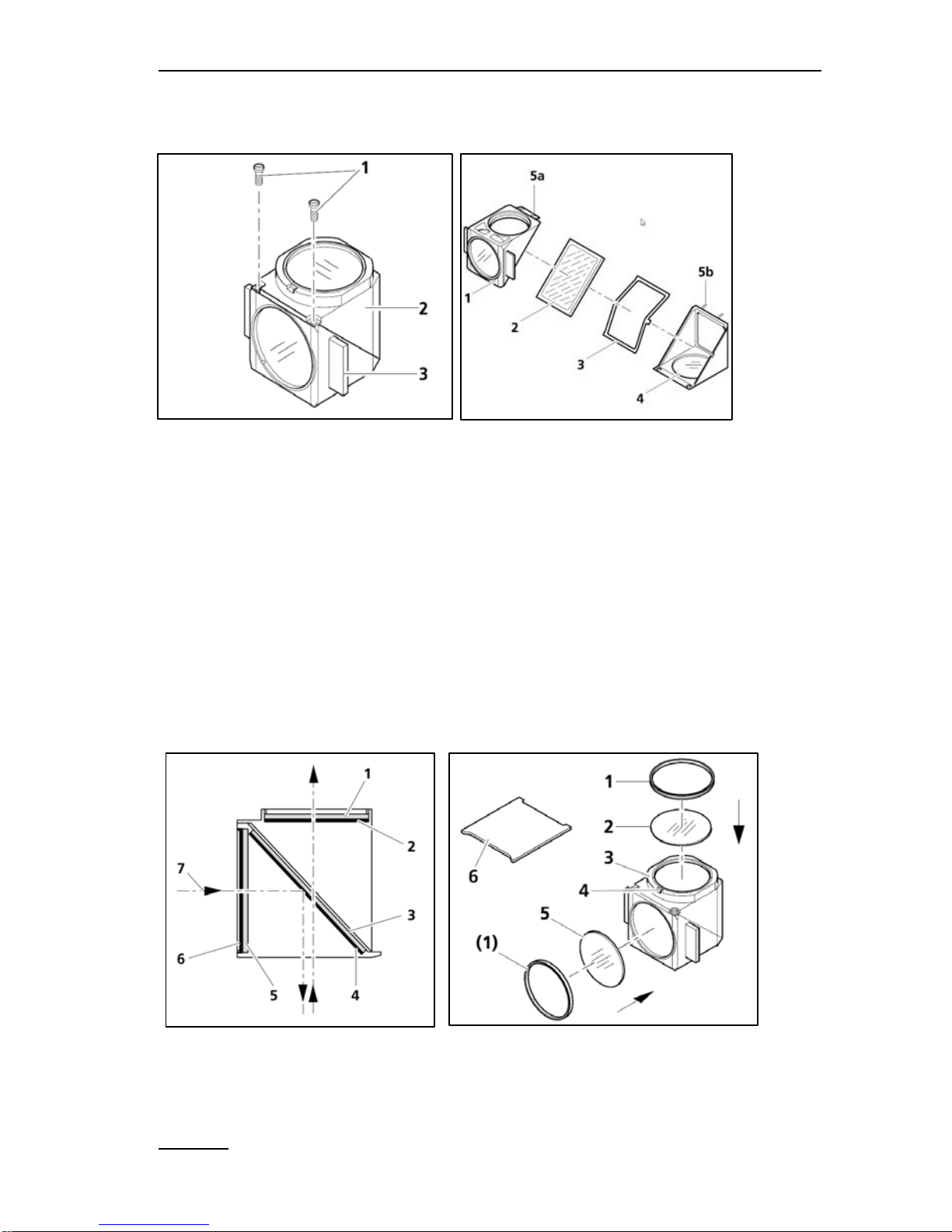

5.3.2 Assembling of beam splitter and filters

B

Zeiss Zeiss

Fig. 36: The reflector module – mounting the beam splitter

A) For opening the reflector module, loosen two screws (A/1). The

em

ission part (A/2) can now be detached from

the excitation part

(A/3) by

a turn around the lower angle. B) Tilt the excitation part

on

top

and lift the emission part out of the holding fixtures. A

spring box

(B/3)

holds the beam splitter filter. Take care that the mi

rrored side of

the beam splitter is pointing upwards.

B

LED Zeiss Zeiss

Fig. 37: Reflector module with filter configuration

CHAPTER 5 COMPONENTS OF THE MICROSCOPY-VERSION

53

A) The arrows in Fig. 37/A1 mark the path of the illumination beam

or the imaging beam seen from the side. B) lists the different

filters

and

parts that may be needed.

The detector filter B /2 (RG665), a

filter for the excitation light source (B /5

- normally not needed).

B

/6 is the m

ounting tool for the adapter rings (B /1). The beam

splitter

filter (A /3) is already mounted in this figure (see Fig. 37/B).

Fig. 38: Labeling the color splitter

When purchasing the filters separately, independently of the

original Zeiss reflector module frame (424931-0000-000), they have

to be mounted into the reflector module FL according to the

description in this chapter. The red filter RG665 (25 mm in diameter)

is inserted on top of the reflector module and held by the adapter ring

1 (Fig. 37/B), so that the filter will show towards the camera of the

IMAGING version.

The rectangular beam splitter filter is mounted in a 45° angle (Fig.

37/A3). The mirrored side has to show towards the LED light source.

The coating faces outward (in relation to the reflector module) in the

direction of the excitation filter (Fig. 37/B5 – not used in the

standard setup).

Note:

the reflecting (coated)

side of the color splitter

has a tapered edge or

corner.

Zeiss

CHAPTER 5 COMPONENTS OF THE MICROSCOPY-VERSION

54

5.3.3 Mounting of the reflector module

The mounting of the reflector module into the Zeiss Axio Scope.A1

is described in Fig. 39.

Fig. 39: Changing the reflector module in the upper stand FL-LED

In the front of the microscope a grey plastic cover, behind which the

turret for the reflector modules can be found, can be pulled off in

forward direction for mounting the reflector modules in the reflector

turret. It is just held in place by magnets.

Remove the cover cap (indicated with 1 in Fig. 39) in front of the

filter turret to get access to the reflector module ports.

Zeiss

CHAPTER 5 COMPONENTS OF THE MICROSCOPY-VERSION

55

Fig. 40: Mounting the reflector module

The reflector module is inserted after turning it by 180° around its

vertical axis (the reflector module is mounted with its excitation filter

side Fig. 37/A7 facing to the front). It shall be inserted carefully into

the upper spring elements. Then engage it firmly by gently pressing

it down into the turret.

When switching to another LED light source, also the reflector

module is switched. Please make sure that the numbers of the LED

module positions correspond with the numbers of the reflector

modules in the turret of the Axio Scope.A1.

A grey circle (a) in Fig. 40 marks the switch that normally regulates

the LED modules. Since the LED modules for PAM use will be

connected via the top cover of the microscope with the central

control unit of the imaging system (IMAG-CG), this switch is not

active anymore (see chapter 5.4.3).

CHAPTER 5 COMPONENTS OF THE MICROSCOPY-VERSION

56

5.4 LED Modules

There is a wide choice of wavelengths available for the Zeiss LED

modules so that experienced users can easily modify their

epifluorescence system by additional light sources with various

wavelengths. LED modules might need to be adapted as described in

this chapter. Also the filters used in the reflector module might be

necessary to adapt (see chapter 5.3.3)

5.4.1 Adjustment of brightness by grey filters

Since the original LED modules from Zeiss are far too bright for

PAM purposes (especially for the measuring light) neutral grey filters

have to be used.

A set of these filters are provided with each LED module purchased

from Walz (Y = 6,6; 13,7; 23,5 and 51,2). The darkest ones are

already used for dimming the LED. Two more neutral grey filters are

provided for fine adjustment

when other magnifications like

the standard 20 x Fluar lens

(Zeiss) are used. The higher the

magnification used, the smaller

the illuminated spot of the

imaged field, which means that

there is a good chance to increase

measuring light intensity on the

sample plane too much. In this case it might be necessary to change

the filter composition in front of the LED module by using the

provided tool shown in Fig. 41. The side pointing upwards is used

for mounting the filters of the LED modules.

Zeiss LED modules are shipped together with a set of filters:

Fig. 41: LED-module filter tool

CHAPTER 5 COMPONENTS OF THE MICROSCOPY-VERSION

57

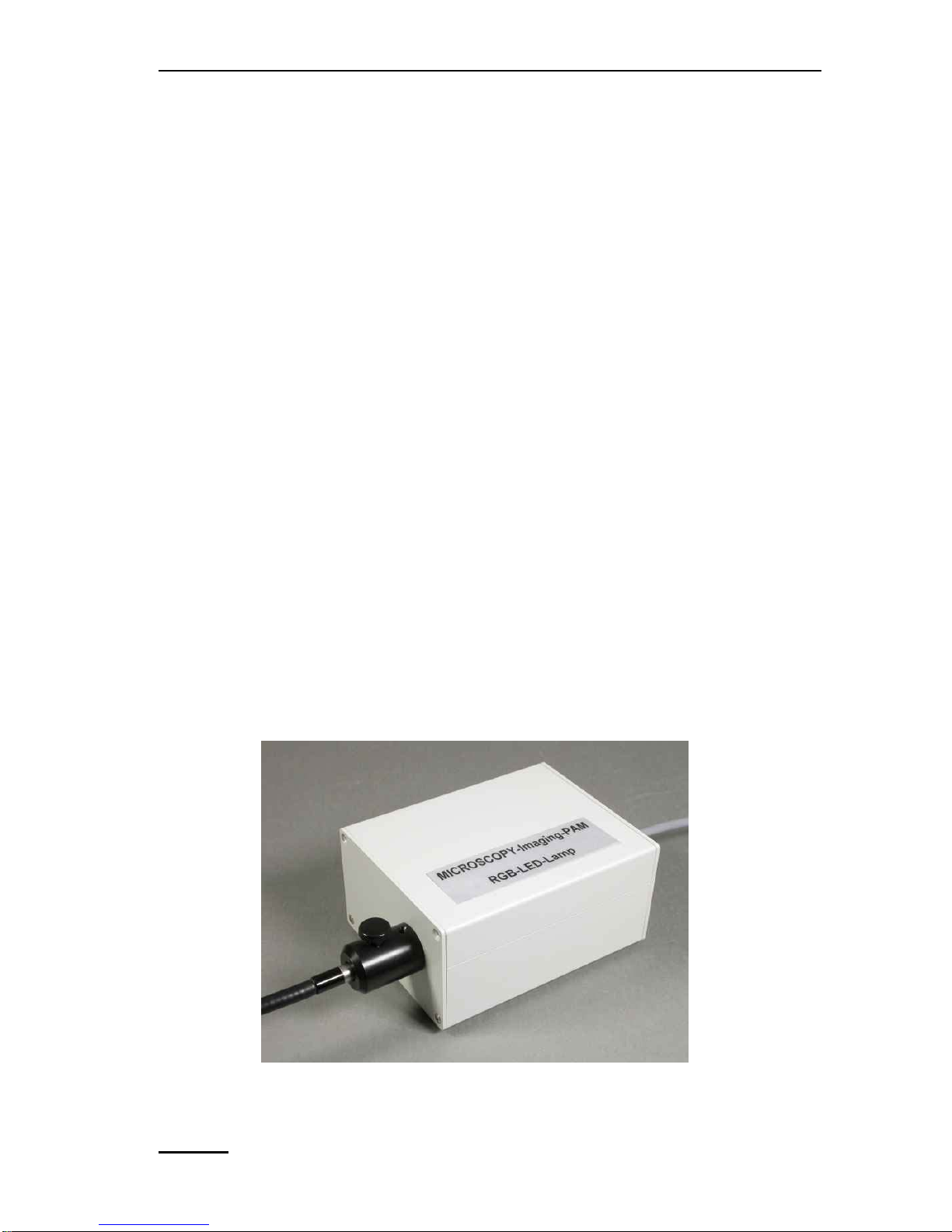

The red LED module IMAG-L625M

comes with a set of grey neutral

density filters that can be used to adapt

the emitted light to different

magnifications. The additional

KPF647,5 filter cuts off unwanted

wavelengths and shall be mounted as

last filter in front of the ND filters.

With the blue LED module

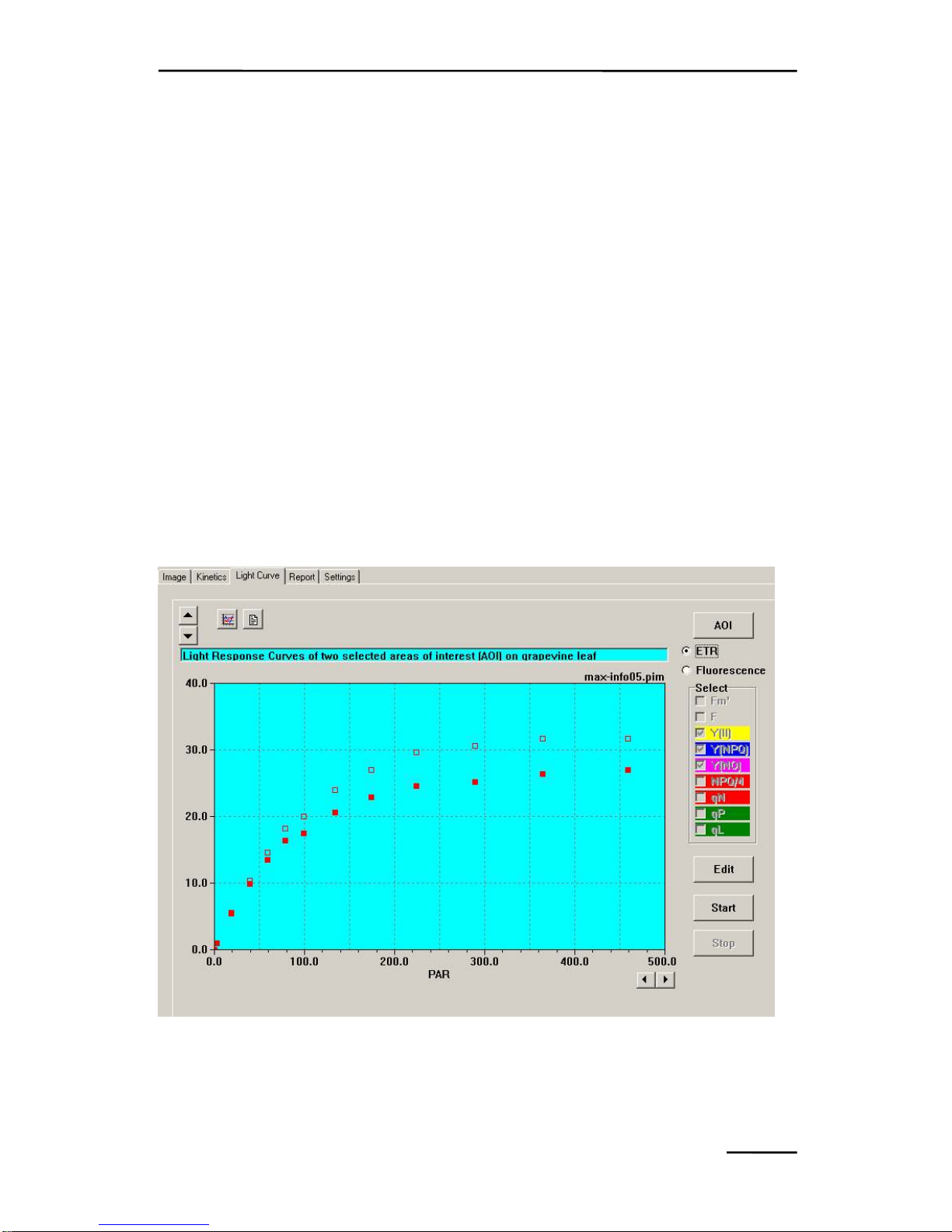

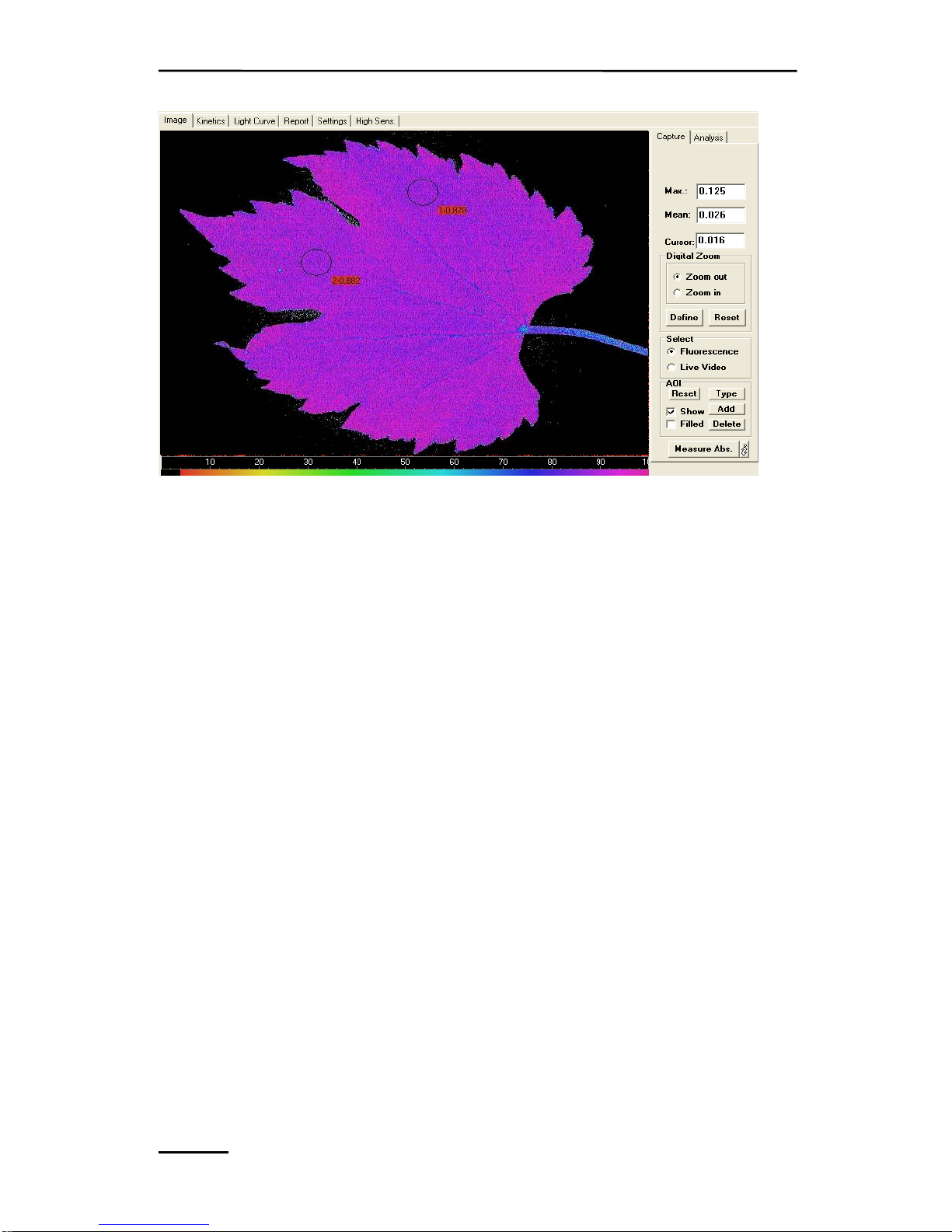

IMAG-L470M also four ND filters are