Engine & Turbine Management

Am Haselbach 1

D-79677 Schönau

Germany

Phone +49 7673 8208-0

Fax +49 7673 8208-188

E-mail info@heinzmann.com

www.heinzmann.com

V.A.T. No.: DE145551926

Heinzmann GmbH & Co. KG

HEINZMANN®

Digital Speed Governors

Digital Basic System

PANDAROS - III

DG 16.6 - 01 up to - 05

DG 30.6 - 01 up to – 05

DG 40.6 - 01 up to - 05

This publication may not be reproduced by any means whatsoever or passed on to any third parties.

6685 Manual DG 01 010-e / 01-14

Copyright 2014 by Heinzmann GmbH & Co. KG. All rights reserved.

The appropriate manuals must be thoroughly studied before

installation, initial start-up and maintenance.

All instructions pertaining to the system and safety must be followed in

full. Non-observance of the instructions may lead to injury to persons

and/or material damage.

HEINZMANN shall not be held liable for any damage caused through

non-observance of instructions.

Independent tests and inspections are of particular importance for all

applications in which a malfunction could result in injury to persons or

material damage.

All examples and data, as well as all other information in this manual

are there solely for the purpose of instruction and they may not be used

for special application without the operator running independent tests

and inspections beforehand.

HEINZMANN does not guarantee, neither expressly nor tacitly, that

the examples, data or other information in this manual is free from

error, complies with industrial standards or fulfils the requirements of

any special application.

To avoid any injury to persons and damage to systems, the

following monitoring and protective systems must be provided:

Overspeed protection independent of the rpm controller

HEINZMANN shall not be held liable for any damage caused through

missing or insufficiently rated overspeed protection.

thermal overload protection

The following must also be provided for alternator systems:

Overcurrent protection

Protection against faulty synchronisation for excessively-large frequency, voltage or

phase difference

Directional contactor

The reasons for overspeeding may be:

Failure of positioning device, control unit or its auxiliary devices

Linkage sluggishness and jamming

The following must be observed before an installation:

Always disconnect the electrical mains supply before any interventions to the system.

Only use cable screening and mains supply connections that correspond with the

European Union EMC Directive

Check the function of all installed protection and monitoring systems

Please observe the following for electronically controlled injection

(MVC):

For common rail systems each injector line must be equipped with a separate

mechanical flow-rate limiter

For unit pump (PLD) and pump-injector unit (PDE) systems, the fuel enable is

first made possible by the solenoid valve’s control plunger motion. This means that

in the event of the control plunger sticking, the fuel supply to the injection valve is

stopped.

As soon as the positioning device receives power, it can actuate the

controller output shaft automatically at any given time. The range of the

controller shaft or control linkage must therefore be secured against

unauthorised access.

HEINZMANN expressly rejects any implied guarantee pertaining to

any marketability or suitability for a special purpose, including in the

event that HEINZMANN was notified of such a special purpose or the

manual contains a reference to such a special purpose.

HEINZMANN shall not be held liable for any indirect and direct

damage nor for any incidental and consequential damage that results

from application of any of the examples, data or miscellaneous

information as given in this manual.

HEINZMANN shall not provide any guarantee for the design and planning

of the overall technical system. This is a matter of the operator its planners

and its specialist engineers. They are also responsible for checking whether

the performances of our devices match the intended purpose. The operator is

also responsible for a correct initial start-up of the overall system.

Contents

Contents

Page

1 Safety instructions and related symbols .............................................................................. 1

1.1 Basic safety measures for normal operation ............................................................... 2

1.2 Basic safety measures for servicing and maintenance ................................................ 2

1.3 Before putting an installation into service after naintenance and repair works ......... 2

2 General ................................................................................................................................... 3

3 Functions ................................................................................................................................ 5

3.1 General functions ............................................................................................................. 5

3.2 Variation specific additional functions ............................................................................ 6

3.2.1 Variation DC 6-01 (standard generator) .................................................................... 6

3.2.2 Variation DC 6-02 (standard general) ....................................................................... 6

3.2.3 Variation DC 6-03 (extended generator 1) ................................................................ 7

3.2.4 Variation DC 6-04 (extended generator 2) ................................................................ 7

3.2.5 Variation DC 6-05 (extended general, especially vehicle) ........................................ 7

4 Further information .............................................................................................................. 9

5 Block diagram ...................................................................................................................... 11

6 Sensors .................................................................................................................................. 13

6.1 Overview ....................................................................................................................... 13

6.2 Magnetic pick-up IA ... .................................................................................................. 14

6.2.1 Technical data.......................................................................................................... 14

6.2.2 Installation ............................................................................................................... 14

6.2.3 Tooth profile ............................................................................................................ 15

6.2.4 Clearance of magnetic pick-up ................................................................................ 15

6.2.5 Dimensions .............................................................................................................. 16

6.3 Cooling medium temperature sensor TS 01 - 28 - PT 1000 (EDV- No.: 600 00 053 00) ....... 17

6.4 Pressure sensors ............................................................................................................. 18

6.4.1 Oil pressure sensor .................................................................................................. 18

6.4.2 Boost pressure sensors............................................................................................. 19

6.4.2.1 Boost pressure sensor with plug ....................................................................... 19

6.4.2.2 Boost Pressure Sensor with Housing and Terminal Strip ................................ 20

Digital Governor Basic System PANDAROS III

Contents

7 Setpoint adjusters ................................................................................................................ 21

7.1 Setpoint potentiometer SW 01 - 1 - b (1 turn) (EDV- No.: 600 00 041 01) .................. 21

7.2 Setpoint potentiometer SW 02 - 10 - b (10- turn) (EDV- No.: 600 00 042 01) ............ 21

7.3 Setpoint value adjustment by current signal .................................................................. 22

7.4 Digital presetting of setpoint values .............................................................................. 22

7.5 Setpoint value adjustment by pedal ............................................................................... 22

7.6 Pneumatic setpoint adjuster ........................................................................................... 22

8 Control unit DC 6 – 01 ... 05 ............................................................................................... 23

8.1 Specification .................................................................................................................. 23

8.1.1 General .................................................................................................................... 23

8.1.2 Inputs and outputs ................................................................................................... 24

8.2 Dimensions .................................................................................................................... 25

8.3 Mounting ....................................................................................................................... 26

9 Actuators .............................................................................................................................. 27

9.1 Design and Mode of Operation...................................................................................... 27

9.2 Installation ..................................................................................................................... 28

9.3 Specification .................................................................................................................. 29

9.4 Dimensions .................................................................................................................... 30

10 Regulating linkage ............................................................................................................. 31

10.1 Length of lever arm ..................................................................................................... 31

10.2 Order specification for lever arm ................................................................................. 31

10.3 Connecting linkage ...................................................................................................... 31

10.3.1 Linkage adjustment for diesel engines .................................................................. 32

10.3.2 Linkage adjustment for carburettor engines .......................................................... 33

11 Electrical connection ......................................................................................................... 35

11.1 Connection for variation DG 6-01 (standard generator) .............................................. 35

11.2 Connection for variation DG 6-02 (standard general) ................................................. 36

11.3 Connection for variation DG 6-03 (extended generator 1) .......................................... 37

11.4 Connection for variation DG 6-04 (extended generator 2) .......................................... 38

11.5 Connection for variation DG 6-05 (extended general) ................................................ 39

11.6 Harness ........................................................................................................................ 40

12 Parametrization options .................................................................................................... 43

12.1 Parametrization at the factory ...................................................................................... 43

12.2 Parametrization with the Hand Held Programmer HP 03 ........................................... 43

12.3 Parametrization with the PC ........................................................................................ 43

Digital Governor Basic System PANDAROS III

Contents

12.4 Parametrization with user mask ................................................................................... 44

12.5 Transferring data sets ................................................................................................... 44

12.6 Assembly line end programming ................................................................................. 44

13 Starting the engine - brief instruction ............................................................................. 45

14 Download of manuals ........................................................................................................ 47

Digital Governor Basic System PANDAROS III

1 Safety instructions and related symbols

DANGER indicates a hazardous situation the consequence of which could

be fatal or severe injuries if it is not prevented.

WARNING indicates a hazardous situation which could lead to fatal injury

or severe injuries if it is not prevented.

CAUTION indicates a hazardous situation which could lead to minor

injuries if it is not prevented.

NOTICE indicates possible material damage.

Safety instructions are not only denoted by a signal word but also by hazard

warning triangles. Hazard warning triangles can contain different symbols

to illustrate the danger. However, the symbol used is no substitute for the

actual text of the safety instructions. The text must therefore always be read

in full!

This symbol does not refer to any safety instructions but offers important

notes for better understanding the functions that are being discussed. They

should by all means be observed and practiced.

1 Safety instructions and related symbols

This publication offers wherever necessary practical safety instructions to indicate inevitable

residual risks when operating the engine. These residual risks imply dangers to

- Personnel

- Product and machine

- The environment

The primary aim of the safety instructions is to prevent personal injury!

The signal words used in this publication are specifically designed to direct your attention to possible

damage extent!

Digital Governor Basic System PANDAROS III 1

1 Safety instructions and related symbols

In this publication the Table of Contents is preceded by diverse instructions that among

other things serve to ensure safety of operation. It is absolutely imperative that these

hints be read and understood before commissioning or servicing the installation.

1.1 Basic safety measures for normal operation

The installation may be operated only by authorized persons who have been duly trained

and who are fully acquainted with the operating instructions so that they are capable of

working in accordance with them.

Before turning the installation on please verify and make sure that

- only authorized persons are present within the working range of the engine;

- nobody will be in danger of suffering injuries by starting the engine.

Before starting the engine always check the installation for visible damages and make

sure it is not put into operation unless it is in perfect condition. On detecting any faults

please inform your superior immediately!

Before starting the engine remove any unnecessary material and/or objects from the

working range of the installation/engine.

Before starting the engine check and make sure that all safety devices are working

properly!

1.2 Basic safety measures for servicing and maintenance

Before performing any maintenance or repair work make sure the working area of the

engine has been closed to unauthorized persons. Put on a sign warning that maintenance

or repair work is being done.

Before performing any maintenance or repair work switch off the master switch of the

power supply and secure it by a padlock! The key must be kept by the person

performing the maintenance and repair works.

Before performing any maintenance and repair work make sure that all parts of engine

to be touched have cooled down to ambient temperature and are dead!

Refasten loose connections!

Replace at once any damaged lines and/or cables!

Keep the cabinet always closed. Access should be permitted only to authorized persons

having a key or tools.

Never use a water hose to clean cabinets or other casings of electric equipment!

1.3 Before putting an installation into service after naintenance and

repair works

Check on all slackened screw connections to have been tightened again!

Make sure the control linkage has been reattached and all cables have been reconnected.

Make sure all safety devices of the installation are in perfect order and are working

properly!

2 Digital Governor Basic System PANDAROS III

2 General

2 General

The HEINZMANN Digital Governors of the PANDAROS series have been designed as

speed governors for diesel and gas engines with low and medium power. In addition to their

primary purpose of controlling speed, these governors are capable of performing some other

tasks and functions.

The control system consists of the control unit, the actuator, the setpoint adjusters, the sensors,

and the connection cables.

The control unit includes the control electronics. At the core of the control unit is a very fast

and powerful 16 bit microprocessor. The actual controller programme based on which the

processor operates is permanently stored in a FLASH-EPROM.

The current engine speed is sensed by a magnetic pick-up on the flywheel or a measuring wheel.

One temperature sensor can measure the engine temperature and can cause changings of

governor parameters or alarm messages.

The speed setpoint, additional sensor inputs and the inputs for the analogue accessory are

depending on variations. There are 5 standard variations available. More variations are

possible on customer request.

With the serial interface ISO 9141 resp. RS 232 is communication to other devices possible.

Digital Governor Basic System PANDAROS III 3

3 Functions

3 Functions

The HEINZMANN electronic governors of PANDAROS series are speed governors that

offer a small range of functions. Even so, in addition to speed regulation, there are depending

on the variation the following functions available:

3.1 General functions

a) Start quantity adjustment

For setting start quantity, minimum start quantity or maximum start quantity may

alternatively be selected. If necessary either can be configured in dependence of

temperature. Furthermore, variable start quantity can be provided, by which start

quantity is automatically increased during start-up.

b) Speed ramps

For applications where speed is not supposed to respond to changes of setpoint values as

fast as possible, a speed ramp is available. According to requirements, it may be

parametrized separately for increasing or decreasing speed. In addition, a separate speed

ramp is provided for start-up which will make the engine ramp slowly to operating

speed after starting.

c) All speed governing with adjustable droop

Some applications require speed governing with droop, e,g, generator parallel operation

without HEINZMANN load measuring unit. The droop can be adjusted as desired.

With droop adjusted to 0, the governor operates in isochronuous mode.

d) Setting the speed range

The minimum and maximum speed adjustable by the (external) setpoint, can be

parametrised.

e) Engine stop

When the switch input for engine shutdown is activated, the governor will cause the

actuator to fully pull to stop direction until the engine has stopped.

f) Overspeed protection

An overspeed point can be parametrised. If this point is overcome, the governor will

issue an alarm and the actuator will fully pull to stop direction.

g) Correction of PID parameters

To optimize the dynamics for every operating point, the PID parameters may be

corrected in dependence of speed, temperature and load by means of freely

programmable stability maps.

Digital Governor Basic System PANDAROS III 5

3 Functions

h) Speed dependent quantity limitation

It is possible to programme quantity limitation curves in dependence of speed so that for

all speeds there can be torque reduction as is admissible for the engine or desired by the

user.

i) Temperature dependent idling speed and quantity limitation

At low temperatures, the engine can be run at some higher idling speed. With the engine

warming up, idling speed is reduced to its normal value. It is possible to programme

quantity limitation curves in dependence of temperature so that for every temperature

there will be torque reduction available as is admissible for the engine or desired by the

user.

j) Operating hour meter

The operating hours when the engine is turning (speed is detected) will be added.

k) Failure diagnosis and display

If a sensor or the actuator is at fault, an alarm is issued and there will be a change-over

to emergency operation if so provided or an engine shutdown. Internal errors get

detected also and they will be stored as all other failures. All failures can be read out

with an external handprogrammer or with a communication program on a PC or laptop

with communication cable.

l) Communication

Two serial interface ports are available: ISO 9141 and RS-232.

3.2 Variation specific additional functions

3.2.1 Variation DC 6-01 (standard generator)

(refer to connection diagram page 31)

The setpoint is realized with two push buttons: increase speed and decrease speed.

3.2.2 Variation DC 6-02 (standard general)

(refer to connection diagram page 32)

The setpoint is given by an analogue setpoint source (voltage source 0..5 V, current

4..20 mA or potentiometer 5 k ) and one switch input for fixed speed.

6 Digital Governor Basic System PANDAROS III

3 Functions

3.2.3 Variation DC 6-03 (extended generator 1)

(refer to connection diagram page 33)

The speed setpoint is realized with two switch inputs to increase speed and decrease

speed each.

The HEINZMANN load measuring unit is connected to an additional analogue input

for load governing in parallel operation.

An additional switch input it to select if the switch inputs for synchronization or the

analogue input from the load measuring unit is active.

3.2.4 Variation DC 6-04 (extended generator 2)

(refer to connection diagram page 34)

The setpoint is given by an analogue setpoint source (voltage source 0..5 V, current

4..20 mA or potentiometer 5k ).

Two additional analogue inputs are used for connecting the HEINZMANN load

measuring unit for load governing in parallel mode and for connecting the

HEINZMANN synchronizer.

A switch input is to select if the inputs of the HEINZMANN units or if the analogue

setpoint source is active.

3.2.5 Variation DC 6-05 (extended general, especially vehicle)

(refer to connection diagram page 35)

The setpoint is given by an analogue setpoint source (voltage source 0..5 V, current

4..20 mA or potentiometer 5k ) and a switch input for fixed speed.

For turbocharged engines, fuelling can be reduced to achieve smokeless operation

whenever there is no boost pressure (e.g., during start-up or on load changes). The

respective limit curves can be programmed accordingly.

For the purpose of oil pressure monitoring, speed/pressure dependent limit curves can

be provided. If oil pressure is low, an alarm is issued; if oil pressure continues to drop,

the engine is shut down.

The governor may also be adjusted as an idle/max speed governor.

Digital Governor Basic System PANDAROS III 7

4 Further information

4 Further information

This publication describes in detail the technical data and connections of the control

electronics, of the sensors, of the setpoint adjusters and of the actuators.

The functions of the different adjustment parameters and characteristics are described in detail

in the manual

Basic Information: DG 07 001-e 04-10-Control-device-for-conventional-injection.

The mode of operation of the communication programme DcDesk 2000 is described in detail

in the manual and in the programms help function.

Operation Instructions of Communication Program DcDesk 2000,

Manual-No. DG 00 003-e.

Digital Governor Basic System PANDAROS III 9

-

DC

24 V - Power Supply

Switch Inputs

Analogue Setpoint Adjuster

Interface RS 232

Pressure Sensors

Temperature Sensor

Micro Controler

Actuator

Drive

DC

EEPROM

ISO9141

Speed Sensor

Watch-

dog 1

Watch-

dog 2

Watch-

dog 3

DC 6 Board

5 V

Actuator Position

Sensing

M

Integrated Hand Programmer

Failure Lamp

Analogue

Synchronizer

Analogue

Load Measuring Unit

LCD-Display

WINDOW

FUNCTION

ESCAPE

ENTER

5 Block diagram

5 Block diagram

According to the different types, there are not all functions and inputs available!

Fig. 1: Block Diagram

Digital Governor Basic System PANDAROS III 11

Sensor

Speed

Coolant

Temperature

Oil Pressure

Boost Pressure

HZM Designation

IA ..

TS 01-28-PT1000

DSO 01-6

DSO 01-10

DSL/G 0..-2

DSL/G 0..-5

DSL/G 0..-10

Connection

SV 6-IA-2K

2 pole

SV 6-IA-2K

2 pole

DIN 43650 A

2 Line System

DIN 43650 A

2 Line System

Measuring Procedure

inductive, active

PT1000, passive

active

active

Measuring Range

50...9.000 Hz

-50...+150°C

0...6 bar

0...10 bar

0...2 bar

0...5 bar

0...10 bar

Supply Voltage

Range

passive

10...34 V DC

12...36 V DC

Output Signal Range

0...10 V AC

ca. 700...1500 Ohm

4...20 mA

4...20 mA

Operating

Temperature Range

-55...+120°C

-50...+150°C

-25...+125°C

-40...+100°C

6 Sensors

6.1 Overview

6 Sensors

In order to ensure maximum flexibility with regard to the sensors, the minimum/ maximum

current values and the measuring ranges of the pressure and temperature sensors have been

provided programmable.

Digital Governor Basic System PANDAROS III 13

6 Sensors

60

*min)/1( zn

60

160*1500

Mind that the speed can be measured by the pulse pick-up without any bias. For best

results the speed pick-up should take the engine speed signal from the crankshaft.

A suitable position for this is, e.g., the starter gear but not the injection pump wheel!

The pick-up gear must consist of magnetic material (e.g., steel, cast iron).

6.2 Magnetic pick-up IA ...

6.2.1 Technical data

Operating principle inductive sensor

Distance from sensing gear 0.5 .. 0.8 mm

Output 0 V .. 10 V AC

Signal form Sine (depending on tooth shape)

Resistance approx.. 52 Ohm

Temperature range -55°C up to +125°C

Protection grade IP 55

Vibration < 10g, 10 .. 100 Hz

Shock < 50g, 11 ms half sine wave

Corresponding plug SV 6 - IA - 2K (EDV- No.: 010-02-170-00)

6.2.2 Installation

The installation of the pick-up has to be arranged in such a way as to obtain a frequency

as high as possible. Normally, the HEINZMANN governors of the series Pandaros are

designed for a maximum frequency of 9000 Hz. Frequency (by Hz) is calculated

according to the formula

f

z = number of teeth on the pick-up wheel

Example:

n = 1.500

z = 160

f =

(Hz)

=

= 4.000 Hz

14 Digital Governor Basic System PANDAROS III

6 Sensors

6.2.3 Tooth profile

Any tooth profile is admissible. The top width of the tooth should be 2.5 mm minimum,

the gap and the depth of the gap at least 4 mm. For index plates the same dimensions are

valid.

Due to tolerances, a radial arrangement of the magnetic pick-up is preferable..

6.2.4 Clearance of magnetic pick-up

The distance between the magnetic pulse pick-up and the tooth top should range from

0.5 and 0.8 mm. (It is possible to screw in the magnetic pick-up till it touches the tooth

and then unscrew it for about half a turn.)

Fig. 2: Clerance of pick-up

Digital Governor Basic System PANDAROS III 15

6 Sensors

G

L

35

19

Measures

L G Remarks

Type

(mm)

01 - 38

38

M 16 x 1,5

02 - 76

76

M 16 x 1,5

appropriate

03 - 102

102

M 16 x 1,5

plug

11 - 38

38

5/8"-18UNF-2A

SV6-IA-2K

12 - 76

76

5/8"-18UNF-2A

13 - 102

102

5/8"-18UNF-2A

6.2.5 Dimensions

Fig. 3: Dimensions of pick-up

Ordering specification, e.g. IA 02-76

16 Digital Governor Basic System PANDAROS III

6 Sensors

B

A

seal ring DIN 7603-14x18 (Cu)

pin configuration:

B = -

19

SW

5/8"-24

M14x1,5

8

h7

16

28

17,5

56,5

A = +

6.3 Cooling medium tem perature sensor TS 01 - 28 - PT 1000

(EDV- No.: 600 00 053 00)

Measuring range -50°C up to +150°C

Precision 1.5°C

Resistance at 25 °C (R25) 1000 Ohm 0.5 %

Maximum operating voltage 5 V

Maximum operating current 3 mA

Recommended operating current approx 1mA

Time constant in fluids approx. 13 seconds

Admissible temperature range

connector socket -40°C up to +105°C

Protection grade IP 65

Vibration < 20 g, 10 - 300 Hz

Shock < 50 g, 11 ms half-sine wave

Tightening torque 50 Nm 15 %

Connector SV 6 - IA - 2K (EDV- No.: 010 02 170 00)

Fig. 4: Temperature sensor TS 01 - 28 - PT 1000

Digital Governor Basic System PANDAROS III 17

6 Sensors

12

22

48,8 26

Ø 19

27

G1/4"

M5

SW 19

Pressure Sensor

EDV- No.

Max. Operating

Pressure (bar)

DSO 01 - 6

600-00-058-00

6

DSO 01 - 10

600-00-058-01

10

6.4 Pressure sensors

6.4.1 Oil pressure sensor

Measuring range 0 - 6 bar or 0 - 10 bar

Over pressure 15 bar resp. 20 bar

Supply voltage 10 - 34 V DC

Output signal 4 - 20 mA

Storage temperature -25°C up to +85°C

Ambient temperature -25°C up to +85°C

Oil temperature -25°C up to +125°C

Protection grade IP 65

Vibration < 20 g, 10 - 300 Hz

Shock < 50 g, 11 ms half-sine wave

Tightening torque max. 25 Nm

Connection DIN 43650-A, 2-line system

18 Digital Governor Basic System PANDAROS III

Fig. 5: Oil pressure sensor

6 Sensors

89

12

2

G3/8"

Ø 30

124,7

30,5

Ø 19

PG9

SW 24

33,5

53

Boost Pressure

EDV- No.

Max. Operating

Pressure (bar rel.)

DSL 01 - 2

600-00-057-00

2

DSL 01 - 5

600-00-057-01

5

DSL 01 - 10

600-00-057-02

10

6.4.2 Boost pressure sensors

The boost pressure sensors are also available in an additional housing with terminal

strip.

Measuring range 0 - 2 bar, 0 - 5 bar or 0 - 10 bar

Over pressure 4 bar resp. 10 bar resp. 16 bar

Supply voltage 12 - 36 V DC

Output signal 4 - 20 mA

Storage temperature -55°C up to +100°C

Ambient temperature -40°C up to +100°C

Protection grade IP 65

Vibration < 2 g, 5 - 500 Hz

Shock < 50 g, 11 ms half-sine wave

Connection DIN 43650-A or terminal strip, 2-line system

6.4.2.1 Boost pressure sensor with plug

Fig. 6: Boost pressure sensor with plug

Digital Governor Basic System PANDAROS III 19

6 Sensors

Am Haselbach 1

D-79677 SchÎnau/Schw.

Germany

Phone: (07673) 8208-0

Telefax: (07673) 8208-88

GmbH + Co.

HEINZMANN

R

10

4,5

52

57

27,5

14

80

113

125

6

91

29,5

SW 24

G3/8"

G1/4"

15

30

30

Pressure Sensor

EDV- No.

Max. Operating

Pressure (bar rel.)

DSG 04 - 2

600-00-056-00

2

DSG 04 - 5

600-00-056-01

5

DSG 04 - 10

600-00-056-02

10

6.4.2.2 Boost Pressure Sensor with Housing and Terminal Strip

Fig. 7: Boost pressure sensor with housing

20 Digital Governor Basic System PANDAROS III

7 Setpoint adjusters

9,5

3/8" - 32 NEF - 2A

Ø 27

23

26

8,8

3/8" - 32 NEF - 2A

Ø 23

17

32

7 Setpoint adjusters

With regard to the variety of applications, various setpoint adjusters are available for the

HEINZMANN digital speed governors of series Pandaros.

7.1 Setpoint potentiometer SW 01 - 1 - b (1 turn)

(EDV- No.: 600 00 041 01)

Displacement angle approx. 312°

Resistance 5 kOhm

Temperature range -55°C to + 120°C

Protection grade IP 00

7.2 Setpoint potentiometer SW 02 - 10 - b (10- turn)

(EDV- No.: 600 00 042 01)

Displacement angle 10 turns

Resistance 5 kOhm

Temperature range -55°C to + 120°C

Protection grade IP 00

Fig. 8: Potentiometer SW 01 - 1 - b

Digital Governor Basic System PANDAROS III 21

Fig. 9: Potentiometer SW 02 - 10 - b

7 Setpoint adjusters

On request, the potentiometers, as specified under 6.1. and 6.2. can be supplied with

analogue adjustment knob with lock in place of the standard rotating knob. In this case,

ordering specification is SW..-..-m.

Likewise, a clamping fixture can be installed instead of the knob. The ordering

specification will then be SW ..-..-k.

7.3 Setpoint value adjustment by current signal

For the speed setpoint value a current signal of 4 – 20 mA can be directly connected to the

control unit. If the signal fails, the governor will adjust minimum speed according to the

4 mA value or use a pre-programmed substitute value.

7.4 Digital presetting of setpoint values

On condition that the governor is configured correctly, a digital setpoint source is possible

directly with two switch inputs (increase/decrease speed), e.g. digital synchronizing

manually or with PLC.

7.5 Setpoint value adjustment by pedal

This unit is basically an angular position transducer that translates gas pedal positions into

a proportional current or voltage for 0 - 45° rotational displacement. The resulting output

can be used for speed setting. For more information refer to manual E 83 005 - e.

7.6 Pneumatic setpoint adjuster

If pneumatic setpoint adjustment is desired, the boost pressure sensors may be used to

supply the signals. For detailed specifications of these sensors refer to chapter 5.5.2.

22 Digital Governor Basic System PANDAROS III

8 Control unit DC 6 – 01 ... 05

8 Control unit DC 6 – 01 ... 05

8.1 Specification

8.1.1 General

Supply voltage 12 V DC or 24 V DC

min. voltage 9 V DC

max. voltage 33 V DC

max. ripple voltage max. 10 % bei 100 Hz

Current consumption max. 7 A, and

max. 11 A for max. 60 Seconds

Permissible voltage dip at

maximum current consumption max. 10 % in control unit

Fuse protection of governor 12 A

Storing temperature -40°C up to +85°C

Operating temperature -40°C up to +80°C

Operating temperature LCD -10°C up to +60°C

optional -20°C up to +70°C

Humidity up to 98% at 55°C

Dynamic strength max. 2 mm at 10 up to 20 Hz,

max. 0,24 m/s at 21 up to 63 Hz

max. 7 g at 64 up to 2000 Hz

Shock 50 g, 11 ms- half-sine wave

Protection grade IP 00

Insulation resistance > 1 MOhm at 48 V DC

Weight approx. 0.5 kg

EMC Directives 2004/108/EC

2004/104/EG

according to EMC Standards: ISO 11452-2

ISO 7637-2 / -3

DIN EN 61000-6

Digital Governor Basic System PANDAROS III 23

8 Control unit DC 6 – 01 ... 05

8.1.2 Inputs and outputs

All inputs and outputs are protected against reverse-voltage and short circuit to battery

plus and minus.

Speed input for inductive sensor, with

fi = 25 up to 9000 Hz, Ui = 0.5 up to 30 V AC

Temperature input for PT1000 / Ni1000 sensors

tolerance: < ±2°C at 0°C up to 130°C,

rest < ±4°C

Reference voltage setpoint adjuster U

= 5 V ±1 %, I

ref

< 30 mA

ref

Setpoint default analogue U = 0..5 V, Re = 100 k , fg = 15 Hz

or I = 4 .. 20 mA, Re = 200 , fg = 15 Hz

Setpoint default digital 1 U0 < 2 V, U1 > 6.5 V, Rpd = 100 k

Setpoint default digital 2 U0 < 2 V, U1 > 6.5 V, Rpd = 4.75 k ,

oder Rpu = 4.75 k oder Rpd = 150 k

Digital input engine stop U0 < 2 V, U1 > 6.0 V, Rpd = 4.75 k

or Rpu = 4.75 k or Rpd = 150 k

Actuator position sensing internal in actuator with reference feedback

analogue U

= 1.4 ..3.0 V, U

Reg.weg

= 8 V ±x %, I

ref

< 20 mA

ref

digital only with HEINZMANN-StG and Bosch EDC

Drive output I < 7 A, I < 11 A für T < 60 s, PWM

Digital output failure lamp I

< 0.3 A, U

sink

< 1.0 V, I

rest

< 0.1 mA

leck

Rpu = 4.75 k oder Rpu = , ground switched

Serial interface ISO 9141, RS 232 variable from 2.4 kbit/s up to 57.6 kbit/s

standard 9.6 kbit/s

Additional Inputs

only for DC 6 – 03… 05 Ue = 0..10 V, Re = 20 k , fg = 15 Hz

or Ue = 0..5 V, Re = 100 k , fg = 15 Hz

or Ie = 4 .. 20 mA, Re = 200 , fg = 15 Hz

or U0 < 2 V, U1 > 6.5 V, Rpd = 4.75 k

or Rpu = 4.75 k oder Rpd = 150 k

24 Digital Governor Basic System PANDAROS III

84,5

Am Haselbach 1

D-79677 Schönau/Germany

Phone: +49 (7673) 8208-0

Fax: +49 (7673) 8208-188

R

1918

T

17151413121110

9

8

7654H L 1 2 3 16 20 21

CANH

CANL P2 P1 0V

Tmp

0V

+5V SpA 0V SpD

Err Stp

0V

Pu

0V

FbC FbM FbR 0V +Act- -Batt+

FOR StG 6...10 ADD COIL UNIT!

GND

GND

GND

REF

GND

GND

Multi Funct. Port Setpoint / MFP

DRIVE-

DRIVE+

FB-REF

FB-MEA

FB-COM

Actuator

STOP/DI

+

-

GND

CANH

CANL

12A

Serial No.

Type-No.

V

22 23

24

25

to Actuator

DRIVEDRIVE+

COIL UNIT FOR StG 6...10

DRIVEDRIVE+

CU-01

to DC6

282726

25

22212019171615141312111098761 2 3 4 5 18 23 24

DC 6

PANDAROS

6

ca. 35

31,5

5

5

240

250

5

101,5

111,5

5

The terminals 1 to 3 are not available with standard versions DC 6-01 and DC 6-02

8.2 Dimensions

8 Control unit DC 6 – 01 ... 05

Fig. 10: Housing of control unit DC 6-01..05

Digital Governor Basic System PANDAROS III 25

8 Control unit DC 6 – 01 ... 05

8.3 Mounting

When selecting the location, care should be taken for easy access in order to facilitate readout of the failure indication and replacement of the device under field conditions. Any

mounting position is admissible. When fitting the device directly on the engine, it should

be mounted using vibration absorbers.

26 Digital Governor Basic System PANDAROS III

9 Actuators

feedback probe

feedback cam

governor output shaft

gearbox

dc disk armature

motor

9 Actuators

9.1 Design and Mode of Operation

The actuator torque is generated by a DC disk armature motor and transmitted to the

governor output shaft by way of a gearbox.

The use of special materials and long-time lubricants assures maintenance-free operation

and long working life of the actuators.

A feedback cam is mounted on the governor output shaft which is scanned contactlessly by

a probe, thus transmitting the precise position of the output shaft to the control unit.

If the actuator strikes against a stop, as may occur, e.g., under parallel mains operation or

may be caused by engine overload or cylinder failure, the current limitation will take effect

after approx. 20 seconds; by this the current to the actuator is reduced to a value that cannot

harm the motor.

Fig. 11: Sectional drawing of actuator

Digital Governor Basic System PANDAROS III 27

9 Actuators

Altogether, this type of actuator provides the following advantages:

- High regulation power working in both directions.

- Extremely low current consumption during steady state and relatively low current

consumption on change of load.

- Indifference to slow voltage changes of the supply; abrupt voltage changes cause governor

disturbances.

9.2 Installation

The actuator must be mounted firmly on the engine by means of reinforced brackets.

Unstable arrangements, as caused by weak bracket material or missing stiffenings, have to

be avoided by all means; they are bound to intensify vibrations, which will lead to

premature wear of the actuator and the connecting linkage!

Generally any mounting position is possible; however, the actuators should not be mounted

with the plug connection pointing straight upward.

28 Digital Governor Basic System PANDAROS III

StG 16 - 01

StG 30- 01

StG 40 - 01

Effective rotation at

output shaft

42°

Max. torque at governor

output shaft

approx. 15 Nm

approx. 28 Nm

approx. 44 Nm

Torque in steady state

condition

approx. 5 Nm

approx. 9 Nm

approx. 14.5 Nm

Response time 0-100 %

without load

approx. 120 ms

approx. 170 ms

approx. 190 ms

Current consumption of

whole governor

maximum current

safe current in

steady state condition

approx. 5 A

approx. 1.7 A

Storage temperature

-55°C up to +110°C

Ambiente emperature in

operation

-25°C up to +90°C

Ambiente temperature

special version

-40°C up to +90°C

Humidity

up to 98 %

Protection grade

IP 55

Weight without base

Weight of base

approx. 12.3 kg

approx. 1.3 kg

9.3 Specification

9 Actuators

Digital Governor Basic System PANDAROS III 29

9 Actuators

Patents pending

Range Voltage

for BasicSystem E

Serial No.

R

GmbH + Co.

HEINZMANN

Am Haselbach 1

D-79677 SchÎnau

Germany

Telefon: (07673) 8208-0

Telefax: (07673) 8208-88

Patents pending

Range Voltage

for BasicSystem E

Serial No.

R

GmbH + Co.

HEINZMANN

Am Haselbach 1

D-79677 SchÎnau

Germany

Telefon: (07673) 8208-0

Telefax: (07673) 8208-88

Diese Schraube darf nicht verstellt werden!

Never turn this screw!

Ne pas toucher a cette vis!

216

30

SAE Serration 1/2" - 36

238

M8

66

18

2

11 70

79,5

151,5

Füllung Fuel Combustible

100

50

0

42°

12

72

74

289

38

81

180

A B

134

146

125,4

112,7

actuator without base

section A-B

72

Diese Schraube darf nicht verstellt werden!

Never turn this screw!

Ne pas toucher a cette vis!

Füllung Fuel Combustible

100

50

0

42°

166

217

38

81

180

9.4 Dimensions

Fig. 12: Actuators StG 16 – 01, StG 30 – 01 and StG 40 - 01

30 Digital Governor Basic System PANDAROS III

10 Regulating linkage

10 Regulating linkage

10.1 Length of lever arm

The length of the lever arm is determined in such a way that approx. 90 % of the governor

output shaft adjustment angle can be used. Based on this, the rack length L of governors

with 36° adjustment angle is calculated as L = 1.8 a, "a" being the travel distance of the

injection pump or the carburettor.

10.2 Order specification for lever arm

Please order RH 16 - 01 (EDV- No.: 504 170 02 00)

10.3 Connecting linkage

The connecting linkage from the governor to the injection pump or the carburettor should

be length-adjustable and have a (pressure or tension) elastic link. If possible, joint rod

heads in accordance with DIN 648 should be used as connecting links. The linkage must

operate easily and without clearance.

In case of friction or backlash in the linkage connecting actuator and injection pump resp.

throttle valve no optimal control is possible.

Digital Governor Basic System PANDAROS III 31

10 Regulating linkage

Patents pending

Range Voltage

for BasicSystem E

Serial No.

R

GmbH + Co.

HEINZMANN

Am Haselbach 1

D-79677 SchÎnau

Germany

Telefon: (07673) 8208-0

Telefax: (07673) 8208-88

Diese Schraube darf nicht verstellt werden!

Never turn this screw!

Ne pas toucher a cette vis!

Füllung Fuel Combustible

100

50

0

pressure elastic member

stop

stop

displacement

angle

injection pump

actuator

0 - 2 fuel mark

full load position

10.3.1 Linkage adjustment for diesel engines

The length of the connecting linkage is adjusted in such a way that with the governor in

stop position the injection pump is set to 0 - 2 fuel marks. (Travel of the injection pump

control rack is limited by the governor.)

Fig. 13: Linkage for diesel engines

The resistance of the pressure elastic link is overcome when the control rack has reached

the full load stop and the speed continues to decrease (overload). Furthermore, the elastic

link is overcome when stopping via the emergency switch.

32 Digital Governor Basic System PANDAROS III

10 Regulating linkage

Patents pending

Range Voltage

for BasicSystem E

Serial No.

R

GmbH + Co.

HEINZMANN

Am Haselbach 1

D-79677 SchÎnau

Germany

Telefon: (07673) 8208-0

Telefax: (07673) 8208-88

Diese Schraube darf nicht verstellt werden!

Never turn this screw!

Ne pas toucher a cette vis!

Füllung Fuel Combustible

100

50

0

actuator

tension elastic member

displacement

angle

full load position

no load position

throttle valve

opened completely

If carburettor or injektion pump are to the left of the governor as opposed to their

position on the drawings, then the direction of motion of the elastic link must also be

reversed

10.3.2 Linkage adjustment for carburettor engines

For carburettor or gas engines, the length of the connecting linkage is adjusted in such a

way that with the governor in full load position the throttle valve is completely open. In

idling speed position, the elastic link must be slightly overcome. This allows adjustment of

the idle screw without changing the governor adjustment.

Fig. 14: Linkage for carburettor and gas engines

Digital Governor Basic System PANDAROS III 33

11 Electrical connection

4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

24V

C

B

D

A

E

A

B

M

DC .. 6-01

StG 6 .. 10 - 01

Actuator

Magnetic Pickup IA ..

Battery

Fuse

12 A

Governor

on

Control Unit

Temperature Sensor

Common Alarm

Run (open Engine Stop)

Increase Speed

Decrease Speed

22 23 24 25

CU-01

StG 16, 30, 40

11 Electrical connection

The electrical connection possibilities are depending on the variation of the control unit.

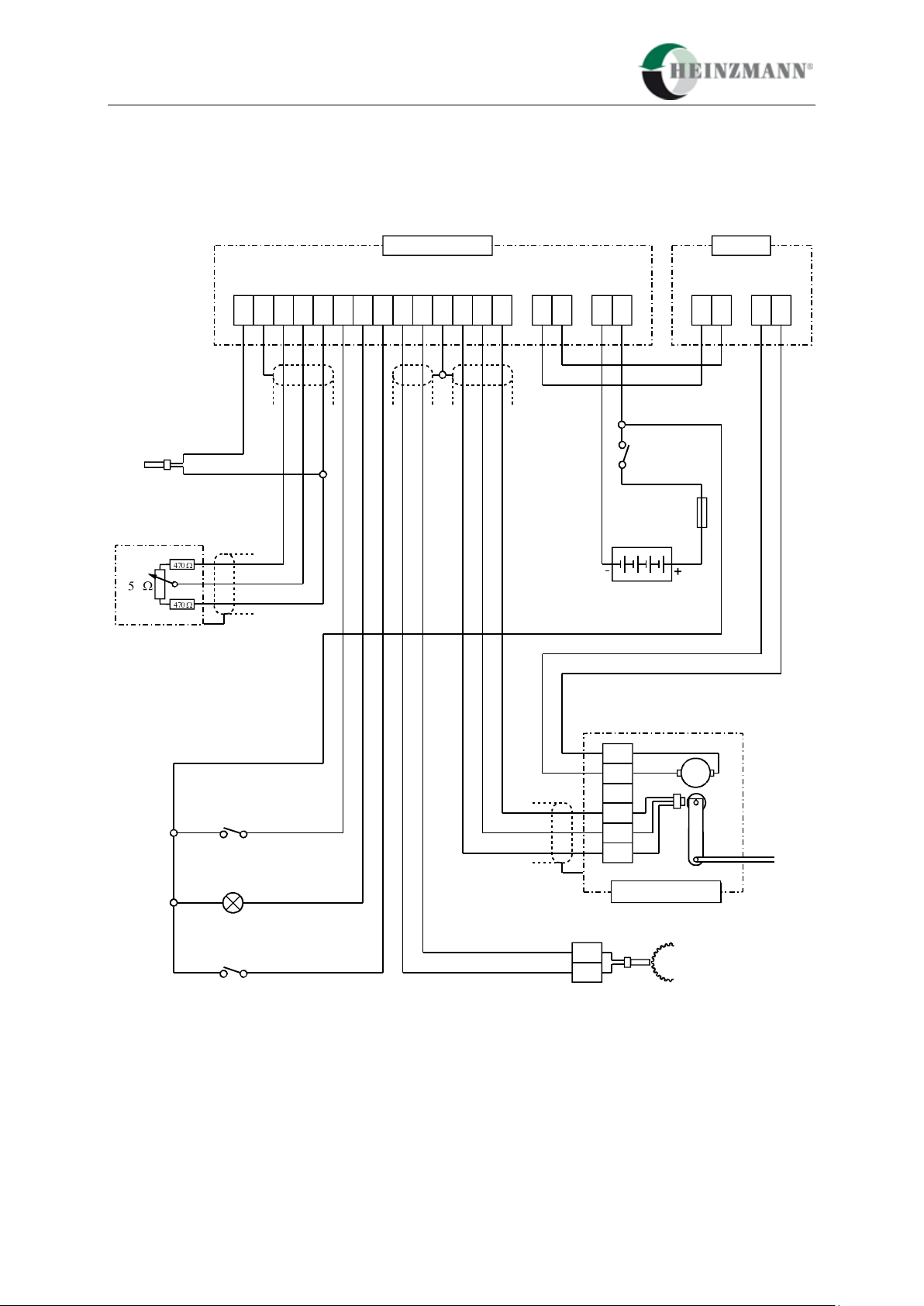

11.1 Connection for variation DG 6-01 (standard generator)

Digital Governor Basic System PANDAROS III 35

Fig. 15: Connection diagram for variation DG 6-01

11 Electrical connection

4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

24V

C

B

D

A

E

A

B

M

DC .. 6-02

StG 6 .. 10 - 01

Actuator

Magnetic Pickup IA ..

Battery

Fuse

12 A

Governor

on

Control Unit

Common Alarm

Run (open Engine Stop)

Fixed Speed

22 23 24 25

CU-01

k

max.

min.

Temperature Sensor

Setpoint Potentiometer

cw

ccw

out

StG 16, 30, 40

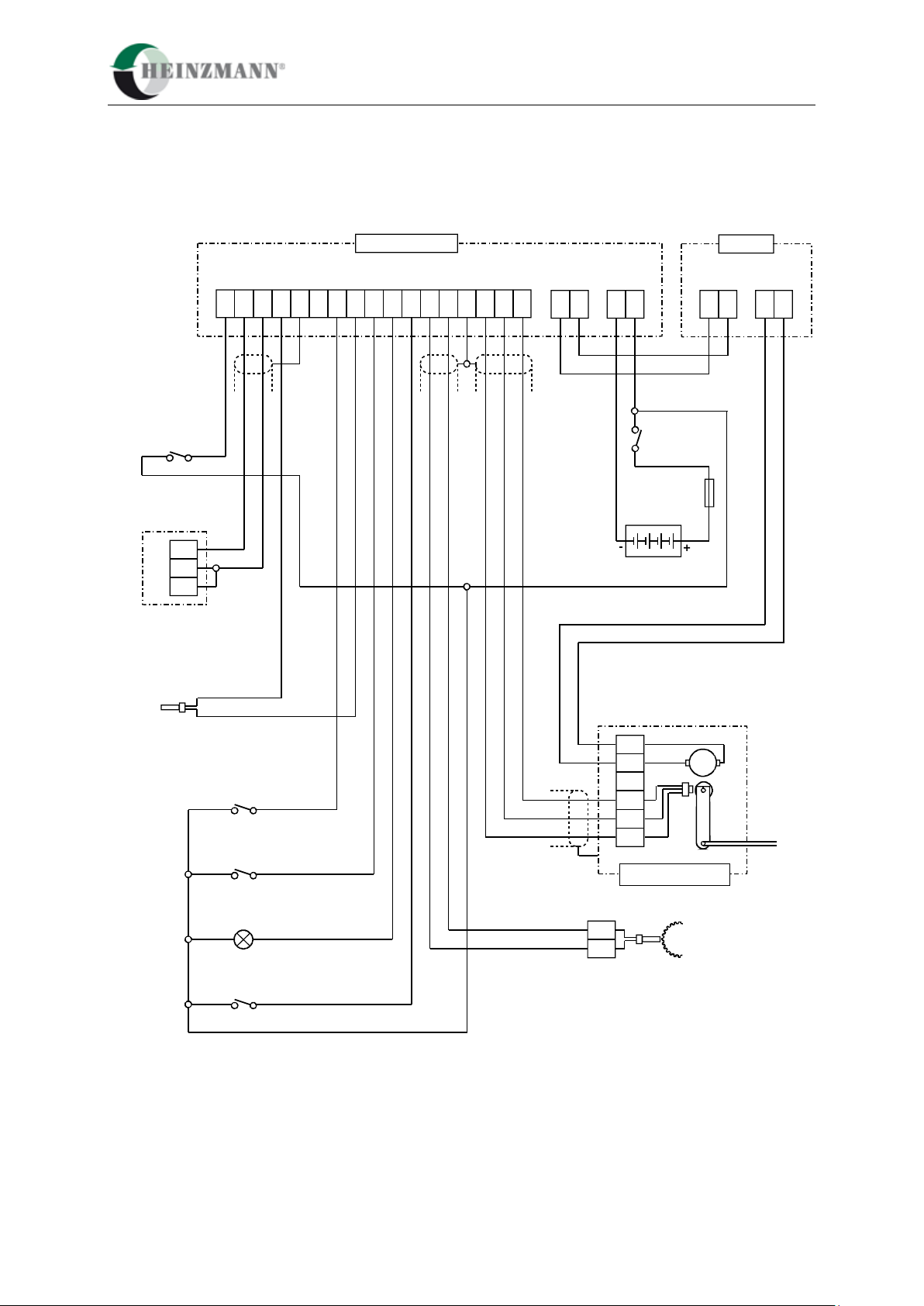

11.2 Connection for variation DG 6-02 (standard general)

36 Digital Governor Basic System PANDAROS III

Fig. 16: Connection Diagram for Variation DG 6-02

11 Electrical connection

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

C

B

D

A

E

A

B

M

DC .. 6-03

StG 6 .. 10 - 01

Actuator

Magnetic Pickup IA ..

Control Unit

Temperature Sensor

Common Alarm

Run (open Engine Stop)

16

15

14

Load Measuring Unit

LMG 03-S2

Auxiliary Contact

Generator Breaker

Increase Speed

Decrease Speed

18 19 20 21

24V

Battery

Fuse

12 A

Governor

on

22 23 24 25

CU-01

StG 16, 30, 40

11.3 Connection for variation DG 6-03 (extended generator 1)

Digital Governor Basic System PANDAROS III 37

Fig. 17: Connection diagram for variation DG 6-03

11 Electrical connection

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

k

max.

min.

DC .. 6-04

Control Unit

Temperature Sensor

Setpoint Potentiometer

Selector Switch

Analogue Accessory Units/

Setpoint Potentiometer

Common Alarm

Run (open Engine Stop)

16

15

17

16 A

14

Synchronizer

SyG 02

Load Measuring Unit

LMG 03-S2

C

B

D

A

E

A

B

M

StG 6 .. 10 - 01

Actuator

Magnetic Pickup IA ..

24V

Battery

Fuse

12 A

Governor

on

22 23 24 25

CU-01

cw

ccw

out

StG 16, 30, 40

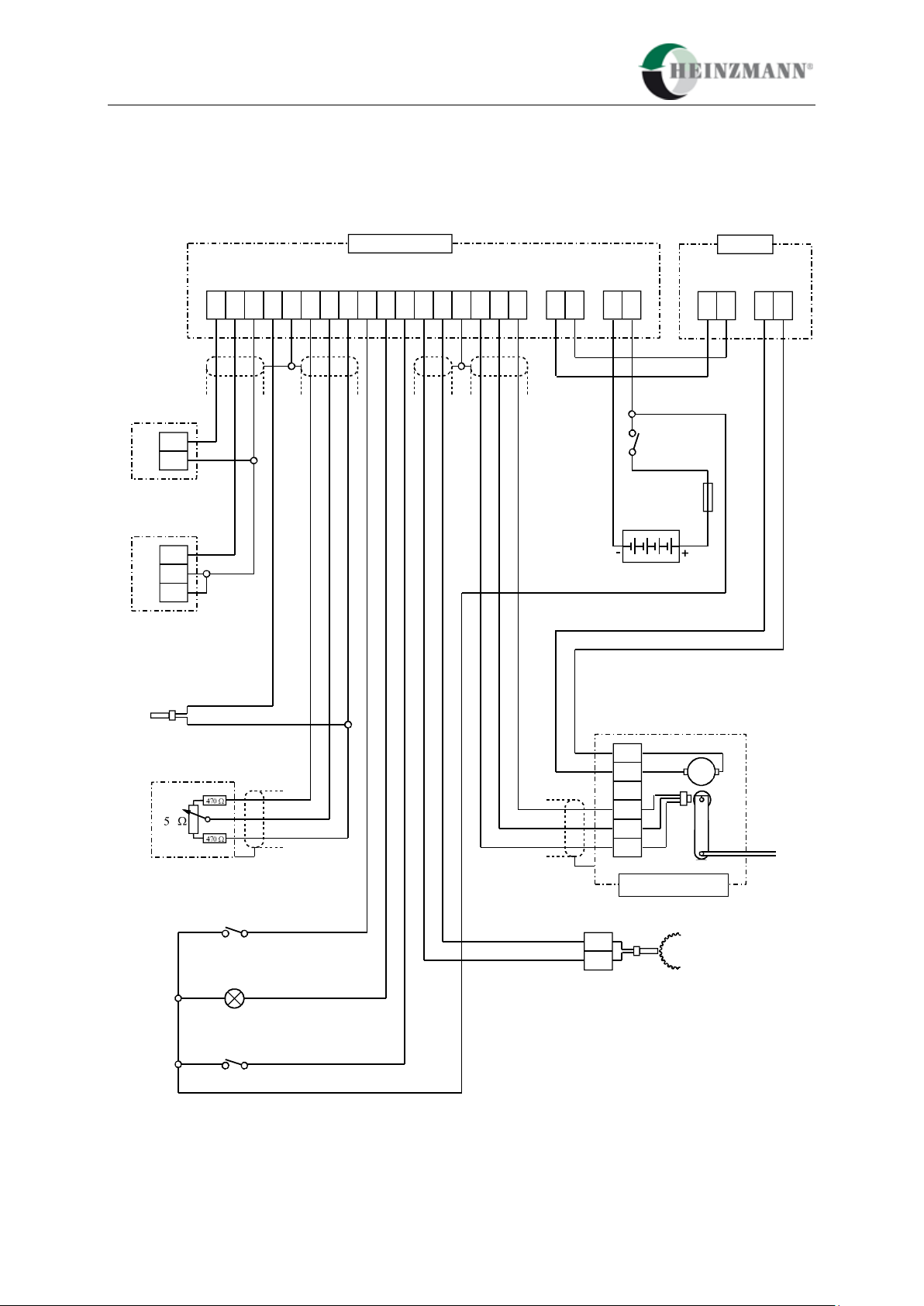

11.4 Connection for variation DG 6-04 (extended generator 2)

38 Digital Governor Basic System PANDAROS III

Fig. 18: Connection Diagram for Variation DG 6-04

11 Electrical connection

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 2021

k

max.

min.

DC .. 6-05

Control Unit

Oil Pressure Sensor

Boost Pressure Sensor

Temperature Sensor

Setpoint Potentiometer

Fixed Speed

Run (Engine Stop)

Common Alarm

C

B

D

A

E

A

B

M

StG 6 .. 10 - 01

Actuator

Magnetic Pickup IA ..

24V

Battery

Fuse

12 A

Governor

on

22 23 2425

CU-01

cw

ccw

out

StG 16, 30, 40

11.5 Connection for variation DG 6-05 (extended general)

Fig. 19: Connection Diagram for Variation DG 6-05

Digital Governor Basic System PANDAROS III 39

11 Electrical connection

It is not possible to use all offered signals at the same time, because some

inputs have to be assigned differently depending on the variation.

L1

Battery

Control Unit DC 6-01..05

Actuator

Setpoint Adjuster

Magnetic Pickup

Sensors

Switch Inputs

Error Messages

Communication

L2

L3

L4

L5

L6

L7

L10

+

-

Füllung Fuel Combustible

0

50

100

10

20

30

40

50

60

70

80

90

100

0

Generator-

management

DGM 02

CAN communication

L13

11.6 Harness

40 Digital Governor Basic System PANDAROS III

Fig. 20: Cable Designation

11 Electrical connection

The allowed length and necessary cross-sections of the cables to connect are as follows:

L 1 Power supply max. 15 m 2 x 2.50 mm²

L 2.1 Actuator feedback 3 x 0.75 mm², shielded

L 2.2 Actuator drive up to 10 m 2 x 2.50 mm²

over 10 - 20 m 2 x 4.00 mm²

L 3.1 Setpoint potentiometer 3 x 0.75 mm², shielded

L 3.2 4 - 20 mA input 2 x 0.75 mm²

L 3.3 0 - 5 V 2 x 0.75 mm², shielded

L 3.4 Synchronizer 2 x 0.75 mm², shielded

L 3.5 Load measuring unit 2 x 0.75 mm², shielded

L 4 Magnetic pick-up 2 x 0.75 mm², shielded

L 5.1 Temperature sensor 2 x 0.75 mm²

L 5.2 Boost sensor 2 x 0,75 mm²

L 5.3 Oil pressure sensor 2 x 0.75 mm²

L 6.1 Engine stop 1 x 0.75 mm²

L 6.2 Increase speed 1 x 0.75 mm²

L 6.3 Decrease speed 1 x 0.75 mm²

L 6.4 other switch functions 1 x 0.75 mm²

(the switches have to be supplied with battery plus)

L7 Error message 1 x 0.75 mm²

(the error lamp has to be supplied with battery plus, ground is switched)

L 13 CAN communication with DGM 02 2 x 0,14 mm², shielded

Digital Governor Basic System PANDAROS III 41

11 Electrical connection

42 Digital Governor Basic System PANDAROS III

12 Parametrization options

12 Parametrization options

The software for the HEINZMANN series Pandaros has been designed in a way that will

allow programming both at the HEINZMANN factory and by the engine manufacturer.

Since erroneous programming can cause considerable damages, full use should be made of the

level structure and the user masks.

As a principle, first programming should always be conducted by experienced personnel and

must be checked before first commissioning the engine. If possible, a HEINZMANN

specialist should be consulted when first programming is performed.

The following sections describe the possibilities of parametrizing the control unit:

12.1 Parametrization at the factory

During final inspection at the factory, the functionability of the unit is checked by a test

programme. If the operational data for the control unit is available, the test programme is

carried out using this data. It is then only the dynamics data and if need be the fuel

limitations and sensors that will have to be calibrated on the engine.

12.2 Parametrization with the Hand Held Programmer HP 03

All parametrization can also be done by means of the hand held programmer

‘Programmer 3’. This handy device is particularly suited for development and series

calibration as well as for servicing.

12.3 Parametrization with the PC

Parametrization can also be conducted using a PC and the comfortable HEINZMANN

software DcDesk 2000. As compared with the hand held programmer, it offers the great

advantage of having various curves graphically represented on the screen and being at the

same time able to introduce changes as well as of having time diagrams displayed without

an oscilloscope when commissioning the control unit on the engine. Furthermore, the PC

offers a better overview as the PC programme has a menu structure and allows to have

several parameters continuously displayed.

Besides, the PC programme permits to save and download the operational data to and from

diskettes.

Digital Governor Basic System PANDAROS III 43

12 Parametrization options

12.4 Parametrization with user mask

Principally, parametrization may be performed with the help of user masks that have been

provided by HEINZMANN or may conveniently be created by the user himself. Within a

user mask, only those parameters are accessible that are actually needed.

12.5 Transferring data sets

Once parametrizing a particular engine model and its application has been completed, the

data set can be saved (in the hand held programmer or on a floppy disk). For other

applications of the same kind the data set can then be downloaded into the respective

control units.

12.6 Assembly line end programming

This type parametrizing is used by the engine manufacturer during the test bench run when

the control unit is programmed in accordance with the engine requirements as laid down in

the order.

44 Digital Governor Basic System PANDAROS III

13 Starting the engine - brief instruction

Additional overspeed protection independent of the speed

controller is compulsory!

13 Starting the engine - brief instruction

13.1 Adjust clearance of magnetic pulse pick-up.

13.2 Check program with respect to relevant parameters: number of teeth, speed, etc.

13.3 Calibrate sensors and setpoint adjusters, if necessary.

13.4 Make autoadjustment of actuator.

13.5 Set point potentiometer in mid-position:

P - Gain to 50

I - Stability to 0

D- Derivative to 0

If the dynamic values have already been determined for an installation, they can be

programmed directly at this point.

13.6 Start engine and run it up to nominal speed using the set point potentiometer.

13.7 Increase gain (P-fraction) up to instability and reduce until stability is attained.

Increase stability (I-fraction) up to instability and reduce until stability is attained.

Increse derivative (D-fraction) up to instability and reduce until stability is attained.

With these values set, engine speed is to be disturbed briefly (e.g., by shortly

pressing the stop switch), and the transient oscillations are to be observed.

13.8 Check over the entire speed range.

If for maximum and minimum speed other values than the programmed ones should

result, this will be due to tolerances of the set point potentiometer. If the speed

derivation is not acceptable, it will be necessary to measure the setpoint source.

13.9 Gain-correction (P-correction) for gas engines resp. for variable speed governors

with larger speed ranges; adjust map if necessary.

13.10 Checking the remaining program items, e.g., starting fuel injection, ramp time, etc.

Digital Governor Basic System PANDAROS III 45

14 Download of manuals

14 Download of manuals

Technical manuals can be downloaded in pdf-format from our homepage:

www.heinzmann.com

If the desired manual should not be available there, send an e-mail to:

info@heinzmann.de

or write to:

HEINZMANN GmbH & Co. KG

Technische Redaktion

Am Haselbach 1

D-79677 Schönau/Germany

Please include the following information:

your name

name and address of your company

e-mail or address where you want the manuals to be sent to (if different from above)

item code (as on front page, bottom right) and title of the desired manual

or alternatively the technical data of your HEINZMANN equipment

We would be pleased to receive your comments about the contents and presentation of our

publications. Send your comments to the e-mail or address shown above please.

Digital Governor Basic System PANDAROS III 47

Loading...

Loading...